1. Introduction

Magnesium materials are being developed to optimize mechanical and corrosion properties for industrial and biomedical applications. In industry, magnesium offers a lightweight construction material, while in medicine, it is valued for biodegradable implants due to its biocompatibility. Both applications require high strength and reasonable ductility. For implants, corrosion resistance is critical to prevent excessive hydrogen release that could impede healing, whereas in aviation, improved ignition resistance is a major concern. Such properties can be enhanced through suitable alloying strategies [

1].

Rare earth elements are effective alloying additions, improving mechanical properties via solid solution strengthening and intermetallic phase formation [

2]. These intermetallic phases possess electrochemical potential similar to the magnesium matrix, minimizing corrosion risks. Yttrium, for example, forms stable, insoluble corrosion products (Y₂O₃, Y(OH)₃) that act as protective barriers and also enhance ignition resistance [3-5]. Moreover, rare earth additions weaken the basal texture after deformation, promoting a more favorable “rare-earth” texture with lower yield asymmetry. Even greater mechanical improvements are achieved by combining rare earths with elements like zinc, particularly in Mg-Y-Zn alloys, due to the formation of long-period stacking ordered (LPSO) phases [

6].

LPSO phases exhibit a long-range atomic periodicity along basal planes, providing exceptional strength and ductility [

7,

8]. Their formation is associated with reduced stacking fault energy via Y-Zn synergistic effects [

9,

10], Zn₆Y₈ cluster formation [11-13], and stabilization of face-centered cubic (fcc) regions within the hexagonal close-packed (hcp) matrix by basal glide with Shockley partial dislocations [

9,

14]. Several LPSO types (10H, 14H, 18R, 24R) have been reported, with 14H being the most stable [

15]. Besides Mg-Y-Zn, LPSO phases were also observed in Mg alloys containing rare earths combined with Al, Co, Ni, or Cu [

16].

A unique LPSO-derived microstructure, known as Mille-Feuille (MF) structure [

17,

18], can be formed by heat treatment. It consists of irregular LPSO layers within magnesium grains, built from cluster-arranged layers (CALs) of Zn₆Y₈ clusters. When multiple CALs are separated by thin Mg layers (up to 5 atomic layers), they form cluster-arranged nanoplates (CANaPs), and with thicker Mg spacings, the MF structure emerges [

18]. MF structures combine the hardness of LPSO phases with the ductility of the Mg matrix [

19]. During aging, CANaP dispersion peaks and their thickness increases; importantly, strength correlates strongly with CANaP dispersion but not their thickness. Jian et al. proposed a Hall-Petch-like relation between yield strength and stacking fault density [

20], highlighting the strengthening role of closely spaced stacking faults.

Despite these benefits, heat treatment alone yields limited mechanical improvements. Thermomechanical processing, particularly extrusion, is necessary to fully optimize properties through mechanisms such as solid solution strengthening, grain boundary strengthening (Hall-Petch), dispersion strengthening, and texture control [

21]. Extrusion promotes dynamic recrystallization (DRX) via particle-stimulated nucleation [

22], resulting in fine grains and enhanced strength. However, strong basal textures often form, leading to compressive-tensile yield asymmetry because twinning is favored in compression but suppressed in tension [

23,

24]. While DRX grains can still develop basal texture, twinning becomes harder with grain refinement. Moreover, some grains may remain non-recrystallized and have a strong basal texture. As a result, microstructure may contain bimodal structure of DRX and non-DRX regions.

The ultimate advantage of MF structure is the ability to form kinks, which suppresses twinning and reduces mechanical asymmetry [

21]. Kinks are formed during deformation or thermomechanical processing such as extrusion. Kinks can be observed in non-DRX grains. Contrary newly formed DRX grains may contain MF structure. Kinks also significantly strengthen the material, with kink dispersion positively affecting strength. Thus, by introducing numerous kinks the strength of the material could be significantly improved as described by Kawamura et al. [

18].

This work, therefore, focuses on the pre-deformation of heat-treated ingot with MF structure in order to gain kinks into the microstructure prior to extrusion. Subsequent extrusion should increase the number of kinks in the microstructure and provide improved mechanical properties.

2. Materials and Methods

Alloy with composition of Mg-3Y-1Zn (wt. %) was prepared by melting of pure elements in induction furnace at 750 °C under protective argon atmosphere. The melt was cast into steel mold with 20 mm in diameter. Subsequently cast ingots were heat treated at 540 °C for 72 hours finished with quenching in water. Then they were aged at 350 °C for 12 hours. One piece of ingot for extrusion was pre-deformed by 10% at 350 °C with strain rate of 0.001s-1. This ingot was extruded at the temperature of 350 °C with an extrusion ratio of 7.5 and ram speed of 2 mm·s-1.

For microstructure characterization the samples were ground on the SiC papers P80-P4000, afterward, they were polished on diamond pastes 3 µm and 1 µm. The final polishing was performed on the Eposil F suspension. Samples were etched in the solution of 4.2 g picric acid, 10 ml H2O, 10 ml acetic acid, 70 ml ethanol in order to investigate the grain size. Microstructure was studied by optical microscopy (OM) (Observer.D1m, Carl Zeiss AG, Jena, Germany).

Compressive and tensile properties were measured using INSTRON 1362 machine at room temperature at a strain rate of 0.001 s-1. Cylindrical samples with a diameter of 5 mm and 7.5 mm high were used for compressive tests. Compressive yield strength (CYS) and ultimate compressive strength (UCS) were determined from compressive curves. Tensile tests were performed on dog bone specimens with a gauge length of 25 mm and diameter equal to 3.5 mm. Tensile yield strength (TYS), ultimate tensile strength (UTS), and elongation to fracture (A) were determined from compressive curves. Three measurements were performed for each material.

3. Results and Discussion

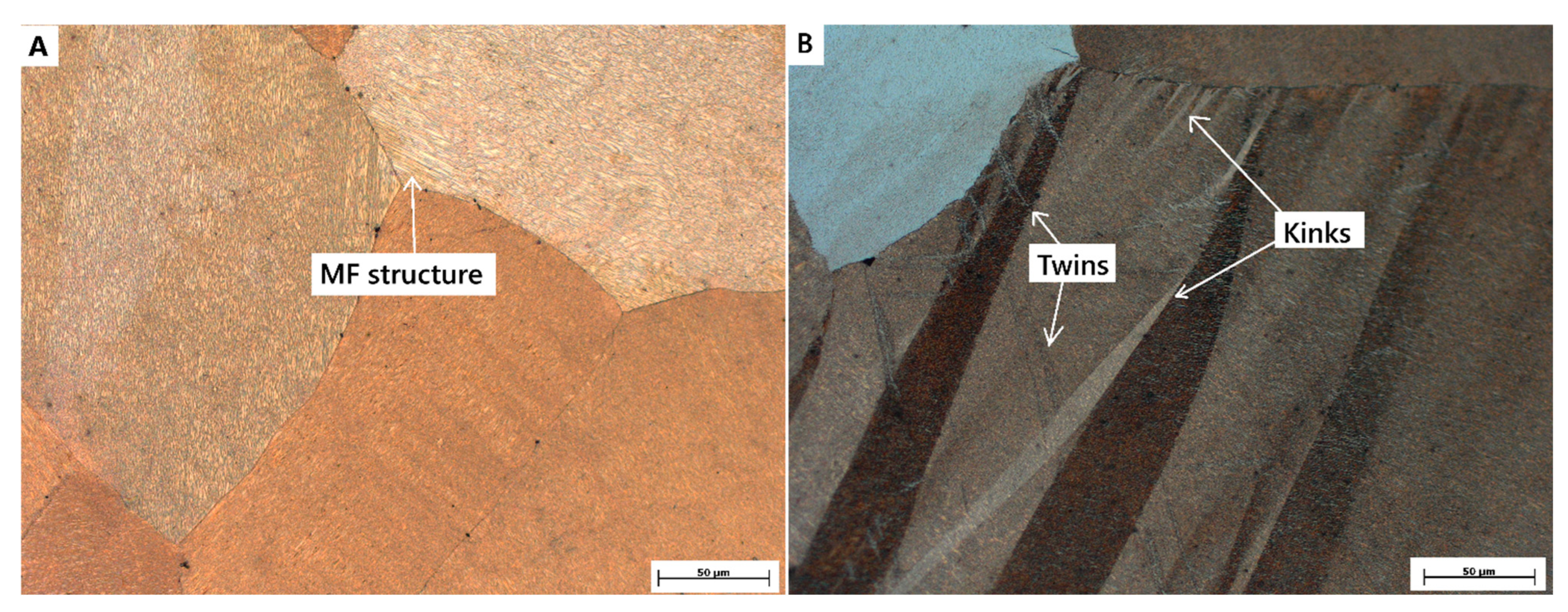

The effect of pre-deformation is illustrated in

Figure 1. The heat-treated ingot exhibits a clearly defined Mille-Feuille (MF) structure, along with few secondary phases identified as yttrium hydrides. Following 10% pre-deformation at 350 °C, the microstructure reveals the presence of kinks and deformation twins in the majority of grains (

Figure 2B). The creation of kinks and twins depends on the grain orientation towards the compressive force [

25]. No DRX was observed during pre-deformation which might be associated with slow deformation compared to the extrusion process. These pre-existing kinks, introduced prior to extrusion, are expected to influence the subsequent microstructural evolution during the extrusion process.

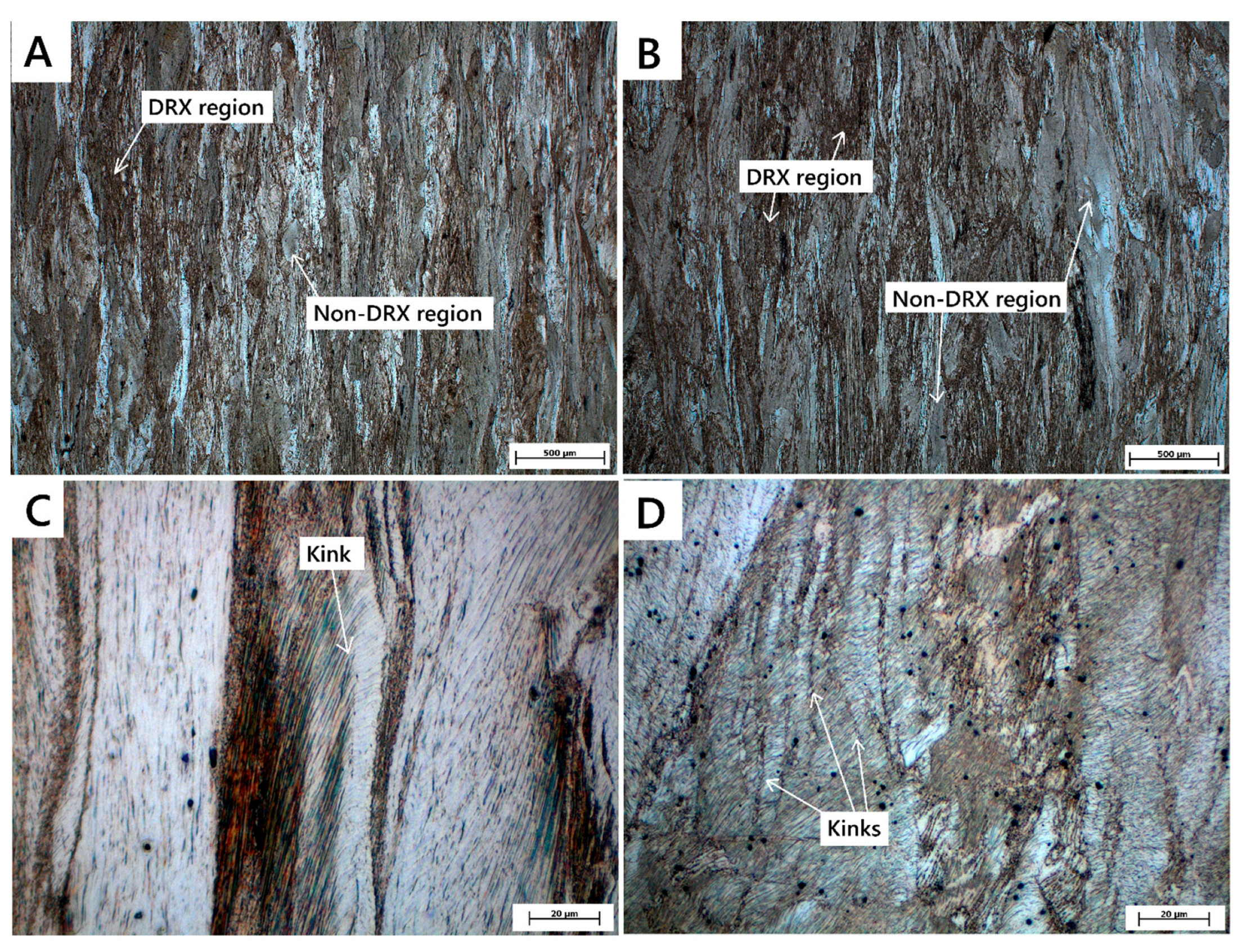

The microstructures of the extruded materials are shown in

Figure 2. All samples exhibit a bimodal structure consisting of DRX regions and large deformed (non-DRX) grains. The DRX occurred predominantly at the grain boundaries which is associated with the presence of the MF structure at those places [

25]. In magnesium alloys, non-DRX regions typically exhibit a strong basal texture [

23,

24]. While DRX regions often retain this basal orientation, the presence of rare earth elements has been shown to promote the development of a more randomized texture after recrystallization. Based on previous studies of this alloy system, it can be inferred that the DRX grains possess a weak basal texture, whereas the non-DRX grains maintain a strong basal texture [

25,

26]. Basal texture has strong consequences on mechanical properties. Materials with strong basal texture tend to reach high TYS, but low CYS due to the easy twinning in compression. Although the overall microstructural features and DRX fractions appear macroscopically similar across both samples, notable differences exist at the microscopic scale. Specifically, the pre-deformed sample contains a significantly higher density of fine kink bands within the non-DRX grains (

Figure 2D), in contrast to the extruded ingot without pre-deformation, where kink bands are formed only during extrusion (

Figure 2C). These observations suggest that kink structures introduced during pre-deformation are retained throughout the extrusion process in non-DRX grains.

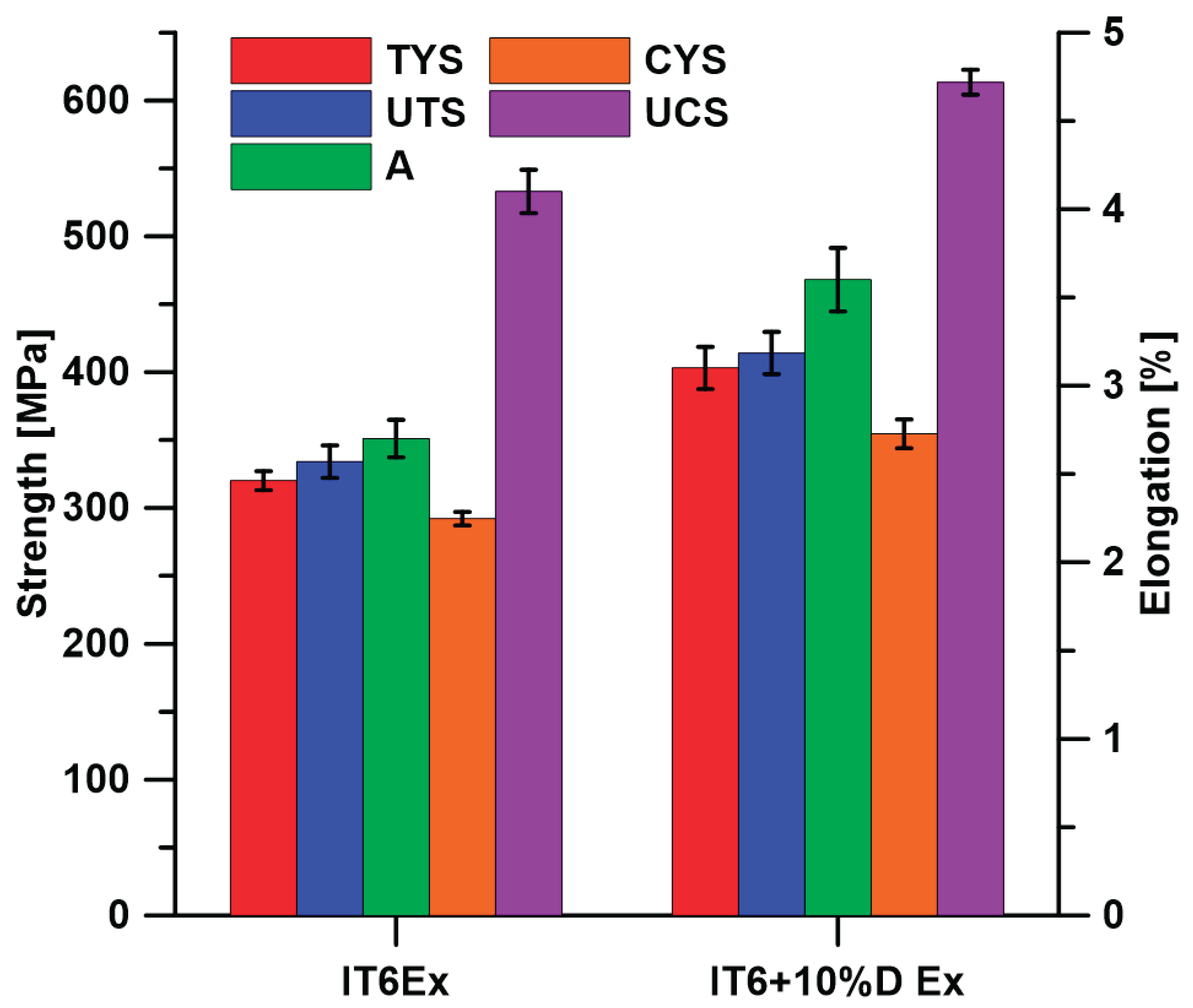

The tensile and compressive mechanical properties of the extruded materials are summarized in

Figure 3. The IT6 alloy without pre-deformation exhibits a TYS of approximately 320 MPa and an elongation of about 3%. This relatively high TYS is attributed to kink bands formed during the extrusion process. Despite the presence of a substantial fraction of non-DRX grains with strong basal texture typically associated with mechanical anisotropy the material demonstrates a low CYS/TYS ratio, with a CYS of approximately 292 MPa. This indicates a beneficial effect of kink structures in reducing anisotropy that is typical for materials with strong basal texture. Notably, pre-deformation of the ingot prior to extrusion significantly enhances the TYS to 403 MPa, CYS to 355 MPa, accompanied by a slight increase in elongation to 4%. This improvement is attributed to the higher density of kink bands, particularly within the non-DRX grains, introduced through the combined effects of pre-deformation and subsequent extrusion [

18]. Nevertheless, the simultaneous improvement of TYS by about 80 MPa, and elongation by about 1% shows the huge effectivity of this method. Therefore, introduction of kinks prior to extrusion that is performed at conditions supressing the DRX process is suitable method.

4. Conclusion

Extruded Mg-3Y-1Zn alloys were successfully prepared from both heat-treated and pre-deformed ingots. While extrusion of the heat-treated ingot yielded favorable mechanical properties, significantly higher strength was achieved through pre-deformation prior to extrusion. This enhancement is attributed to the introduction of kink bands during pre-deformation, which were further developed during the subsequent extrusion process. The accumulation of kink structures, particularly within non-recrystallized grains, contributed to the observed improvements in mechanical performance. This approach highlights the potential of utilizing kink strengthening in MF structured materials. Further optimization, such as employing multiple deformation steps followed by final extrusion, may offer even greater enhancements in mechanical properties.

Acknowledgement

This research was supported by Japan Society for the Promotion of Science (KAKENHI Grant-in-Aid for Scientific Research; 18H05475, 18H05476 and JP20H00312) and MRC International Collaborative Research Grant. The authors would like to thank the Czech Science Foundation (Project No. 22-22248S) and specific university research (A1_FCHT_2025_011) for financial support. The authors acknowledge the assistance provided by the Ferroic Multifunctionalities project, supported by the Ministry of Education, Youth, and Sports of the Czech Republic. Project No. CZ.02.01.01/00/22_008/0004591, co-funded by the European Union. CzechNanoLab project LM2023051 funded by MEYS CR is gratefully acknowledged for the financial support of the measurements/sample fabrication at LNSM Research Infrastructure. Miroslav Čavojský would like to thank Vega 1/0531/22 for financial support.

References

- Dvorsky, D.; Kubasek, J.; Vojtech, D.; Cavojsky, M. Structure and mechanical properties of WE43 prepared by powder metallurgy route. Manuf. Technol. 2016, 16, 896–902. [Google Scholar] [CrossRef]

- Dvorsky, D.; Kubasek, J.; Vojtěch, D.; Prusa, F.; Nova, K. Preparation of WE43 using powder metallurgy route. Manuf. Technol. 2016, 16, 680–687. [Google Scholar] [CrossRef]

- Kubasek, J.; Minarik, P.; Hosova, K.; Sasek, S.; Knapek, M.; Vesely, J.; Straska, J.; Dvorsky, D.; Cavojsky, M.; Vojtech, D. Novel magnesium alloy containing Y, Gd and Ca with enhanced ignition temperature and mechanical properties for aviation applications. J. Alloys Compd. 2021, 877, 10. [Google Scholar] [CrossRef]

- Inoue, S.-i.; Iwanaga, K.; Kawamura, Y. Oxidation behavior and improvement in nonflammability of LPSO-type Mg–Zn–Y–Sr alloy. J. Magnes. Alloy 2024. [Google Scholar] [CrossRef]

- Dvorsky, D.; Kubasek, J.; Vojtech, D. Corrosion protection of WE43 magnesium alloy by fluoride conversion coating. Manuf. Technol. 2017, 17, 440–446. [Google Scholar] [CrossRef]

- Yoshihito Kawamura, K.H. , Akihisa Inoue, Tsuyoshi Masumoto. Rapidly Solidified Powder Metallurgy Mg97Zn1Y2Alloys with Excellent Tensile Yield Strength above 600 MPa. Special Issue on Platform Science and Technology for Advanced Magnesium Alloys 2001, 42, 1172–1176. [Google Scholar]

- Kawamura, Y.; Yamasaki, M. Formation and Mechanical Properties of Mg97Zn1RE2Alloys with Long-Period Stacking Ordered Structure. Mater. Trans. 2007, 48, 2986–2992. [Google Scholar] [CrossRef]

- Yamasaki, M.; Hashimoto, K.; Hagihara, K.; Kawamura, Y. Effect of multimodal microstructure evolution on mechanical properties of Mg–Zn–Y extruded alloy. Acta Mater. 2011, 59, 3646–3658. [Google Scholar] [CrossRef]

- Kawano, S.; Iikubo, S.; Ohtani, H. Role of substituted atoms in stacking fault formation in long-period stacking ordered system. Computational Materials Science 2020, 171, 109210. [Google Scholar] [CrossRef]

- Datta, A.; Waghmare, U.V.; Ramamurty, U. Structure and stacking faults in layered Mg-Zn-Y alloys: A first-principles study. Acta Mater. 2008, 56, 2531–2539. [Google Scholar] [CrossRef]

- Hosokawa, S.; Maruyama, K.; Kobayashi, K.; Stellhorn, J.R.; Paulus, B.; Koura, A.; Shimojo, F.; Tsumuraya, T.; Yamasaki, M.; Kawamura, Y.; et al. Electronic structures and impurity cluster features in Mg-Zn-Y alloys with a synchronized long-period stacking ordered phase. J. Alloys Compd. 2018, 762, 797–805. [Google Scholar] [CrossRef]

- Yokobayashi, H.; Kishida, K.; Inui, H.; Yamasaki, M.; Kawamura, Y. Enrichment of Gd and Al atoms in the quadruple close packed planes and their in-plane long-range ordering in the long period stacking-ordered phase in the Mg–Al–Gd system. Acta Mater. 2011, 59, 7287–7299. [Google Scholar] [CrossRef]

- Egusa, D.; Abe, E. The structure of long period stacking/order Mg–Zn–RE phases with extended non-stoichiometry ranges. Acta Mater. 2012, 60, 166–178. [Google Scholar] [CrossRef]

- Kekule, T.; Smola, B.; Vlach, M.; Kudrnova, H.; Kodetova, V.; Stulikova, I. Thermal stability and microstructure development of cast and powder metallurgy produced Mg–Y–Zn alloy during heat treatment. J. Magnes. Alloy 2017, 5, 173–180. [Google Scholar] [CrossRef]

- Abe, E.; Ono, A.; Itoi, T.; Yamasaki, M.; Kawamura, Y. Polytypes of long-period stacking structures synchronized with chemical order in a dilute Mg–Zn–Y alloy. Philos. Mag. Lett. 2011, 91, 690–696. [Google Scholar] [CrossRef]

- Kawamura, Y. Material Characteristics and Future Perspective on LPSO-type Magnesium Alloys. Materia Japan 2015, 54, 44–49. [Google Scholar] [CrossRef]

- Hagihara, K.; Ueyama, R.; Yamasaki, M.; Kawamura, Y.; Nakano, T. Surprising increase in yield stress of Mg single crystal using long-period stacking ordered nanoplates. Acta Mater. 2021, 209, 116797. [Google Scholar] [CrossRef]

- Kawamura, Y.; Yamagata, H.; Inoue, S.-i.; Kiguchi, T.; Chattopadhyay, K. Kink bands and strengthening of millefeuille-structured magnesium alloys by cluster-arranged nanoplates (CANaPs): The case of Mg-0.4Zn-1.0Y alloy. J. Alloys Compd. 2023, 939, 168607. [Google Scholar] [CrossRef]

- Liu, H.; Briffod, F.; Shiraiwa, T.; Enoki, M.; Emura, S. Clustering Analysis of Acoustic Emission Signals during Compression Tests in Mille-Feuille Structure Materials. Mater. Trans. 2022, 63, 319–328. [Google Scholar] [CrossRef]

- Jian, W.W.; Cheng, G.M.; Xu, W.Z.; Koch, C.C.; Wang, Q.D.; Zhu, Y.T.; Mathaudhu, S.N. Physics and model of strengthening by parallel stacking faults. Appl. Phys. Lett. 2013, 103. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.; Zheng, M.; Wu, K.; Kamado, S. Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy. Scientific Reports 2017, 7, 40846. [Google Scholar] [CrossRef]

- Oñorbe, E.; Garcés, G.; Pérez, P.; Adeva, P. Effect of the LPSO volume fraction on the microstructure and mechanical properties of Mg–Y2X–Zn X alloys. J. Mater. Sci. 2012, 47, 1085–1093. [Google Scholar] [CrossRef]

- Hagihara, K.; Kinoshita, A.; Sugino, Y.; Yamasaki, M.; Kawamura, Y.; Yasuda, H.Y.; Umakoshi, Y. Plastic deformation behavior of Mg97Zn1Y2 extruded alloys. T. Nonferr. Metal. Soc. 2010, 20, 1259–1268. [Google Scholar] [CrossRef]

- Gong, W.; Aizawa, K.; Harjo, S.; Zheng, R.; Kawasaki, T.; Abe, J.; Kamiyama, T.; Tsuji, N. Deformation behavior of as-cast and as-extruded Mg97Zn1Y2 alloys during compression, as tracked by in situ neutron diffraction. Int. J. Plast. 2018, 111, 288–306. [Google Scholar] [CrossRef]

- Dvorský, D.; Kawamura, Y.; Inoue, S.-I.; Nishimoto, S.; Kubásek, J.; Boukalová, A.; Čavojský, M.; Heller, L.; Duchoň, J.; Vojtěch, D. Exploring kink strengthening in WZ21 magnesium alloy via slow solidification and extrusion. J. Magnes. Alloy 2025, 13, 2155–2173. [Google Scholar] [CrossRef]

- Dvorský, D.; Inoue, S.-I.; Yoshida, A.; Kubásek, J.; Duchoň, J.; de Prado, E.; Školáková, A.; Hosová, K.; Svora, P.; Kawamura, Y. Advantages of rapid solidification over casting of Mg-0.4Zn-1Y alloy. J. Magnes. Alloy 2024, 12, 2847–2862. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).