Submitted:

11 September 2025

Posted:

12 September 2025

You are already at the latest version

Abstract

High-rise façades are critical components of modern urban infrastructure, subject to wear and tear due to environmental factors, age, and construction defects. Traditional manual inspection methods for these façades are labor-intensive, time-consuming, and often prone to human error. This paper proposes an innovative approach for automated defect detection in high-rise façades using drone-based inspections combined with Artificial Intelligence (AI) techniques. By leveraging drones equipped with high-resolution cameras and AI-driven image processing, we demonstrate the ability to efficiently identify defects such as cracks, water ingress, and structural damage. The integration of machine learning algorithms enhances the accuracy and speed of the inspection process, reducing the need for human intervention and improving safety. The proposed system offers significant improvements in monitoring the condition of high-rise buildings, enabling proactive maintenance and minimizing the risk of costly repairs or safety hazards.

Keywords:

I. Introduction

A. Background and Motivation

B. Problem Statement

C. Proposed Solution

D. Contributions

- Development of an integrated system combining drones and AI for automated high-rise façade inspections.

- Application of deep learning models to classify and localize defects with high accuracy.

- Demonstration of cost and time efficiency compared to traditional inspection approaches.

- Creation of a foundation for future smart building maintenance systems that support predictive and preventive maintenance strategies.

E. Paper Organization

II. Related Work

A. Drone-Based Inspection for Building Façades

B. AI and Machine Learning in Defect Detection

C. Combining Drones and AI for Automated Inspections

III. System Architecture and Methodology

- Data Acquisition – Drones capture high-resolution images of façades under predefined flight paths.

- Preprocessing – Images are filtered, enhanced, and annotated for consistency.

- AI Analysis – Convolutional Neural Networks (CNNs) detect, classify, and localize façade defects.

- Visualization and Reporting – Results are presented in a structured dashboard, with a summary of defect locations, severity, and recommended maintenance actions.

A. Drone Setup

- Flight altitude between 10–150 meters depending on building height.

- Overlapping image capture (approx. 60–70%) for improved defect recognition.

- Stabilization using gimbals to minimize motion blur.

- Cloud synchronization of captured images for storage and later processing.

B. AI-Driven Defect Detection

- Cracks (micro and macro)

- Spalling and delamination

- Water stains and leakage signs

- Corrosion in metallic elements

- Discoloration or surface weathering

C. Workflow

D. Performance Evaluation Setup

| Criteria | Manual Inspection | Drone AI Inspection |

|---|---|---|

| Safety | Risk to human inspectors at height | Minimal human risk (remote operation) |

| Time Efficiency | Several days for tall buildings | Few hours per building |

| Cost | High (equipment + labor) | Lower after initial system deployment |

| Accuracy | Subjective, prone to human error | Objective, consistent, >90% accuracy |

| Scalability | Limited by manpower | Scalable across multiple buildings |

| Data Archiving | Manual notes/images, inconsistent | Automated digital storage and reporting |

IV. Data Analysis and Results

A. Dataset

- Concrete façades: micro/macro cracks, spalling, delamination.

- Glass curtain walls: water stains, scratches, sealant degradation.

- Metal cladding: corrosion, rust patches, surface discoloration.

- Stone/composite façades: weathering, efflorescence, microfractures.

B. Results

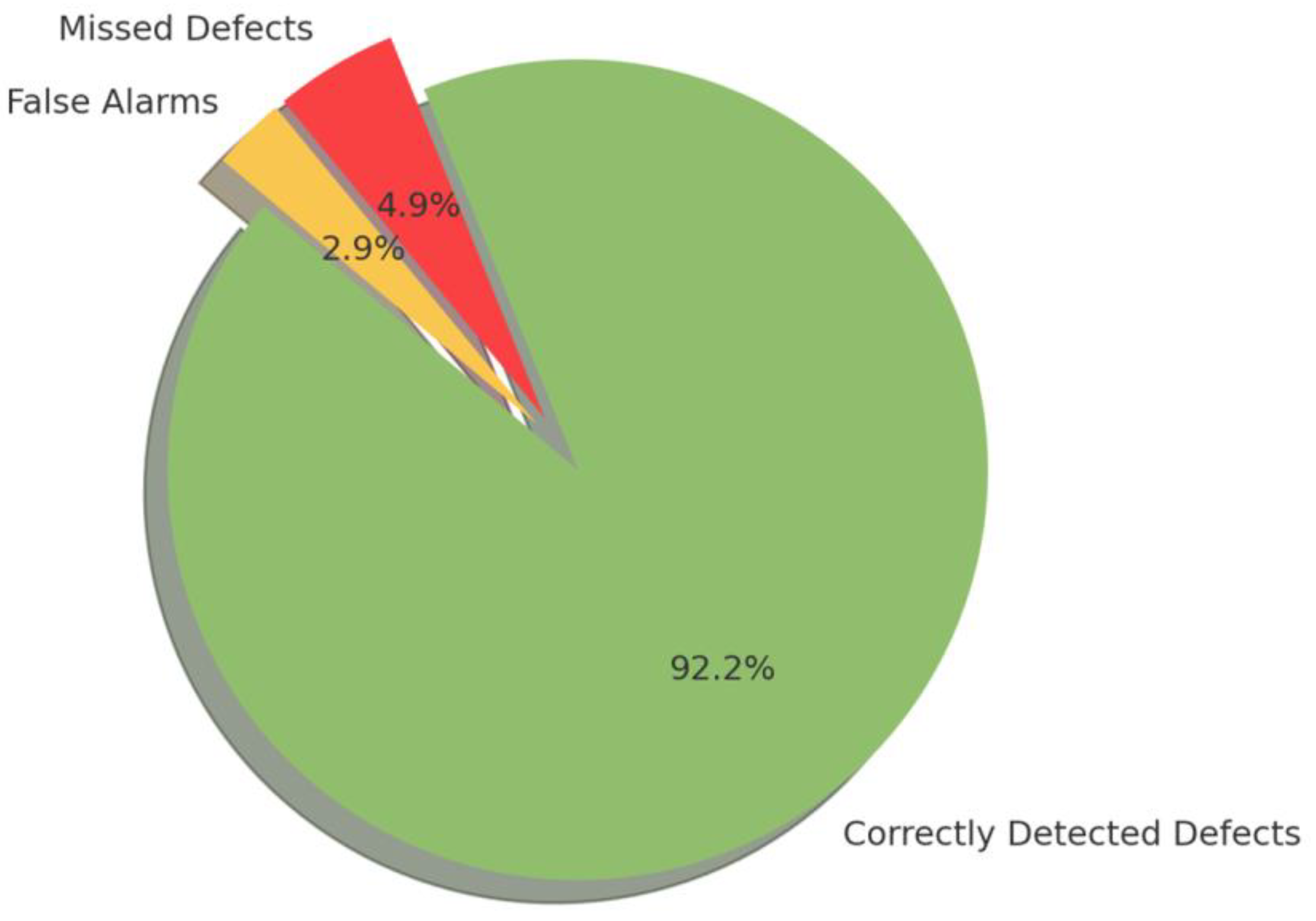

- Accuracy: 95% across all defect categories.

- Precision & Recall: Averaged 94% and 92%, respectively, indicating reliable detection with few false alarms.

- F1-Score: 93%, balancing defect identification accuracy and completeness.

- mAP: 91.6% across multi-class defect detection tasks.

- Inference Speed: 0.45 seconds per image, enabling near real-time inspection.

V. Conclusion

References

- Li, D.K.; Yang, S.Y.; Liu, F. Drone-based inspection for building façade systems. Construction Innovation 2020, 17, 278–297. [Google Scholar]

- Zhao, F.X.; Wang, H.B. Drone applications for structural health monitoring. Sensors 2021, 21, 1625. [Google Scholar]

- Morgenthal, M.; Hallermann, N. Quality assessment of unmanned aerial vehicle-based visual inspection of structures. Advances in Structural Engineering 2014, 17, 289–302. [Google Scholar] [CrossRef]

- Ellenberg, A.; Kontsos, L.; Moon, B.; Bartoli, I. Bridge inspection using unmanned aerial vehicles. Proc. SPIE 8345, Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, 2012.

- Irizarry, J.; Costa, D.B. Exploratory study of potential applications of unmanned aerial systems for construction management tasks. J. Manage. Eng. 2016, 32, 1–10. [Google Scholar] [CrossRef]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack detection using convolutional neural networks. Computer-Aided Civil and Infrastructure Engineering 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, F.; Zhang, Y.D.; Zhu, Y. Road crack detection using deep convolutional neural network. Proc. IEEE Int. Conf. Image Processing (ICIP), pp. 3708–3712, 2016.

- Yang, J.; Liu, Z.; Xu, Y. Hybrid machine learning models for steel structural damage detection. Structural Control and Health Monitoring 2019, 26, e2262. [Google Scholar]

- Kim, B.; Cho, S. Image-based crack detection using convolutional neural networks with data augmentation. J. Computing in Civil Engineering 2018, 32, 1–9. [Google Scholar]

- Radopoulou, S.; Brilakis, I. Automated detection of concrete surface defects using computer vision. Proc. 32nd Int. Symp. on Automation and Robotics in Construction (ISARC), pp. 1–7, 2015.

- Dorafshan, S.; Thomas, R.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Construction and Building Materials 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, J.; Ryu, R. Automated UAV-based bridge inspection using deep learning. Remote Sensing 2019, 11, 244. [Google Scholar]

- Ham, Y.; Han, H.; Lin, J.; Golparvar-Fard, J. Visual monitoring of civil infrastructure systems via camera-equipped UAVs and deep learning models. Automation in Construction 2018, 94, 433–449. [Google Scholar]

- Hoskere, V.; Narazaki, Y.; Hoang, T.; Spencer, B.F. Vision-based structural inspection using UAVs. Journal of Structural Engineering 2019, 145, 04019090. [Google Scholar]

- Yeum, C.M.; Dyke, S.J. Vision-based automated crack detection for bridge inspection. Computer-Aided Civil and Infrastructure Engineering 2015, 30, 759–770. [Google Scholar] [CrossRef]

- Chen, S.; Li, Y.; Li, Z. Deep learning-based automated defect detection from UAV images for building inspection. Automation in Construction 2020, 118, 103312. [Google Scholar]

- Enam, M.M.R. Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities. Preprints, Jun. 2025. [Online]. [CrossRef]

- Farabi, S.A. AI-Augmented OTDR Fault Localization Framework for Resilient Rural Fiber Networks in the United States. arXiv preprint arXiv:2506.03041, June 2025. [Online]. Available: https://arxiv.org/abs/2506.03041.

- Farabi, S.A. AI-Driven Predictive Maintenance Model for DWDM Systems to Enhance Fiber Network Uptime in Underserved U.S. Regions. Preprints, Jun. 2025. [Online]. Available: https://www.preprints.org/manuscript/202506.1152/v1. [CrossRef]

- Farabi, S.A. AI-Powered Design and Resilience Analysis of Fiber Optic Networks in Disaster-Prone Regions. ResearchGate, Jul. 5, 2025 [Online]. [CrossRef]

- Hasan, M.N. Predictive Maintenance Optimization for Smart Vending Machines Using IoT and Machine Learning. arXiv preprint 2025, arXiv:2507.02934. [Google Scholar] [CrossRef]

- Hasan, M.N. Intelligent Inventory Control and Refill Scheduling for Distributed Vending Networks. ResearchGate, Jul. 2025. [Online]. [CrossRef]

- Hasan, M.N. Energy-efficient embedded control systems for automated vending platforms. Preprints, 2025. [Google Scholar] [CrossRef]

- Sunny, S.R. Lifecycle Analysis of Rocket Components Using Digital Twins and Multiphysics Simulation. ResearchGate, [Online]. . [CrossRef]

- Sunny, S.R. “Real-Time Wind Tunnel Data Reduction Using Machine Learning and JR3 Balance Integration.” TechRxiv. July 24, 2025.

- Sunny, S.R. (2025). AI-Driven Defect Prediction for Aerospace Composites Using Industry 4.0 Technologies (Preprint - v1.0, July 2025.). Zenodo. [CrossRef]

- Sunny, S.R. Edge-Based Predictive Maintenance for Subsonic Wind Tunnel Systems Using Sensor Analytics and Machine Learning. TechRxiv. July 31, 2025.

- Shaikat, Faisal Bin. (2025). AI-Powered Hybrid Scheduling Algorithms for Lean Production in Small U.S. Factories. [CrossRef]

- Shaikat, Faisal Bin. (2025). Energy-Aware Scheduling in Smart Factories Using Reinforcement Learning. [CrossRef]

- Shaikat, Faisal Bin. (2025). Secure IIoT Data Pipeline Architecture for Real-Time Analytics in Industry 4.0 Platforms. [CrossRef]

- Shaikat, Faisal Bin. (2025). Upskilling the American Industrial Workforce: Modular AI Toolkits for Smart Factory Roles. [CrossRef]

- Md Faisal Bin Shaikat. Pilot Deployment of an AI-Driven Production Intelligence Platform in a Textile Assembly Line Author. TechRxiv. July 09, 2025. [CrossRef]

- R. Islam, S. R. Islam, S. Kabir, A. Shufian, M. S. Rabbi and M. Akteruzzaman, “Optimizing Renewable Energy Management and Demand Response with Ant Colony Optimization: A Pathway to Enhanced Grid Stability and Efficiency. 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2025, pp. 1-6. [CrossRef]

- Rabbi, M.S. Extremum-seeking MPPT control for Z-source inverters in grid-connected solar PV systems. Preprints 2025. [Google Scholar] [CrossRef]

- M. S. Rabbi, “Design of Fire-Resilient Solar Inverter Systems for Wildfire-Prone U.S. Regions” Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2505/v1.

- M. S. Rabbi, “Grid Synchronization Algorithms for Intermittent Renewable Energy Sources Using AI Control Loops” Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2353/v1.

- Tonoy, A.A.R. Mechanical properties and structural stability of semiconducting electrodes: Insights for material design in mechanical applications. Global Mainstream Journal of Innovation, Engineering & Emerging Technology 2022, 1, 18–35. [Google Scholar] [CrossRef]

- Tonoy, A.A.R.; Khan, M.R. The role of semiconducting electrides in mechanical energy conversion and piezoelectric applications: A systematic literature. Journal of Scholarly Research and Innovation 2023, 2, 1–23. [Google Scholar] [CrossRef]

- Khan, M.A.; Tonoy, A.A.R. Lean Six Sigma applications in electrical equipment manufacturing: A systematic literature review. American Journal of Interdisciplinary Studies 2024, 5, 31–63. [Google Scholar] [CrossRef]

- Tonoy, A.A.R.; Ahmed, M.; Khan, M.R. Precision mechanical systems in semiconductor lithography equipment design and development. American Journal of Advanced Technology and Engineering Solutions 2025, 1, 71–97. [Google Scholar] [CrossRef]

- Rana, S.; Bajwa, A.; Tonoy, A.A.R.; Ahmed, I. Cybersecurity in industrial control systems: A systematic literature review on AI-based threat detection for SCADA and IoT networks. ASRC Procedia: Global Perspectives in Science and Scholarship 2025, 1, 1–15. [Google Scholar] [CrossRef]

- Tonoy, A.A.R. Condition Monitoring in Power Transformers Using IoT: A Model for Predictive Maintenance. Preprints, 2025. [Google Scholar] [CrossRef]

- Tonoy, A.A.R. Applications of Semiconducting Electrides in Mechanical Energy Conversion and Piezoelectric Systems. Preprints, 2025. [Google Scholar] [CrossRef]

- Azad, M.A. Lean Automation Strategies for Reshoring U.S. Apparel Manufacturing: A Sustainable Approach. Preprints, 2025. [Google Scholar] [CrossRef]

- Azad, M.A. Optimizing Supply Chain Efficiency through Lean Six Sigma: Case Studies in Textile and Apparel Manufacturing. Preprints, 2025. [Google Scholar] [CrossRef]

- Md Ashraful Azad. Sustainable Manufacturing Practices in the Apparel Industry: Integrating Eco-Friendly Materials and Processes. TechRxiv. 2025. [CrossRef]

- Md Ashraful Azad. Leveraging Supply Chain Analytics for Real-Time Decision Making in Apparel Manufacturing. TechRxiv. 2025. [CrossRef]

- Md Ashraful Azad. Evaluating the Role of Lean Manufacturing in Reducing Production Costs and Enhancing Efficiency in Textile Mills. TechRxiv. , 2025. 07 August. [CrossRef]

- Md Ashraful Azad. Impact of Digital Technologies on Textile and Apparel Manufacturing: A Case for U.S. Reshoring. TechRxiv. 2025. [CrossRef]

- Rayhan, F.A. A Hybrid Deep Learning Model for Wind and Solar Power Forecasting in Smart Grids. Preprints, 2025. [Google Scholar] [CrossRef]

- Rayhan, F.A. AI-Powered Condition Monitoring for Solar Inverters Using Embedded Edge Devices. Preprints 2025. [Google Scholar] [CrossRef]

- Sunny, S.R. Real-Time Wind Tunnel Data Reduction Using Machine Learning and JR3 Balance Integration. Saudi Journal of Engineering and Technology (SJEAT) 2025, 10, 411–420. [Google Scholar] [CrossRef]

- Sunny, S.R. AI-Augmented Aerodynamic Optimization in Subsonic Wind Tunnel Testing for UAV Prototypes. Saudi Journal of Engineering and Technology (SJEAT) 2025, 10, 402–410. [Google Scholar] [CrossRef]

| Metric | Manual Inspection | Drone–AI Inspection (Proposed System) |

|---|---|---|

| Accuracy | ~75–80% (experience dependent) | 95% |

| Precision | ~78% | 94% |

| Recall | ~70% | 92% |

| F1-Score | ~73% | 93% |

| mAP (multi-class) | Not applicable / subjective | 91.6% |

| Inspection Time | 2–4 days for 40-story building | 5–7 hours (including processing) |

| Cost (per inspection) | High (labor, scaffolding, equipment) | Reduced by ~60% after deployment |

| Safety | Significant risk to human inspectors | Minimal human risk (remote operation) |

| Data Archiving | Inconsistent manual records | Automated, structured digital reports |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).