Submitted:

29 July 2025

Posted:

30 July 2025

You are already at the latest version

Abstract

Keywords:

I. Introduction

A. Background and Motivation

B. Problem Statement

C. Proposed Solution

- Fire-Resistant Materials: The use of advanced, fire-resistant materials in the inverter’s casing and internal components, allowing the system to withstand high temperatures typically encountered in wildfire scenarios.

- Thermal Insulation: The incorporation of thermal insulation coatings and heat shields that protect sensitive electronic components from the intense heat generated during a wildfire.

- Adaptive Cooling Mechanisms: The integration of cooling technologies that dynamically adjust to varying temperatures, ensuring that the inverter remains within safe operating temperatures during and after a fire event.

- Smart Temperature Sensors: The implementation of smart sensors that continuously monitor the inverter’s temperature, allowing the system to detect and react to overheating conditions in real time.

- Fire Detection and Shutoff Systems: The installation of fire detection systems that automatically shut down the inverter and isolate it from the power system in case of fire detection, minimizing the risk of a larger fire or explosion.

D. Contributions

- Design Innovation: This paper introduces a fire-resilient inverter design specifically tailored for wildfire-prone regions. The design incorporates fire-resistant materials, advanced cooling systems, and smart sensors to address the unique challenges posed by wildfires.

- Thermal Management Strategies: We propose a range of thermal management techniques, including thermal insulation, cooling mechanisms, and temperature monitoring, to protect inverters from the extreme temperatures typical of wildfires.

- Fire Detection and Shutdown Mechanism: This paper highlights the importance of fire detection systems in preventing fire outbreaks in solar inverters. The proposed automatic shutoff mechanism offers a practical solution for minimizing fire risks.

- Simulation and Evaluation: We present simulation results and performance evaluations to demonstrate the effectiveness of the proposed fire-resilient inverter design under wildfire conditions.

E. Paper Organization

II. Related Work

A. Fire-Resistant Materials and Thermal Management for Electronic Systems

B. Fire Safety in Solar Energy Systems

C. Adaptive Cooling Technologies for Electronic Systems

D. Fire Detection and Shutoff Mechanisms

E. Summary of Related Work

II. Methodology

A. Fire-Resilient Solar Inverter Design

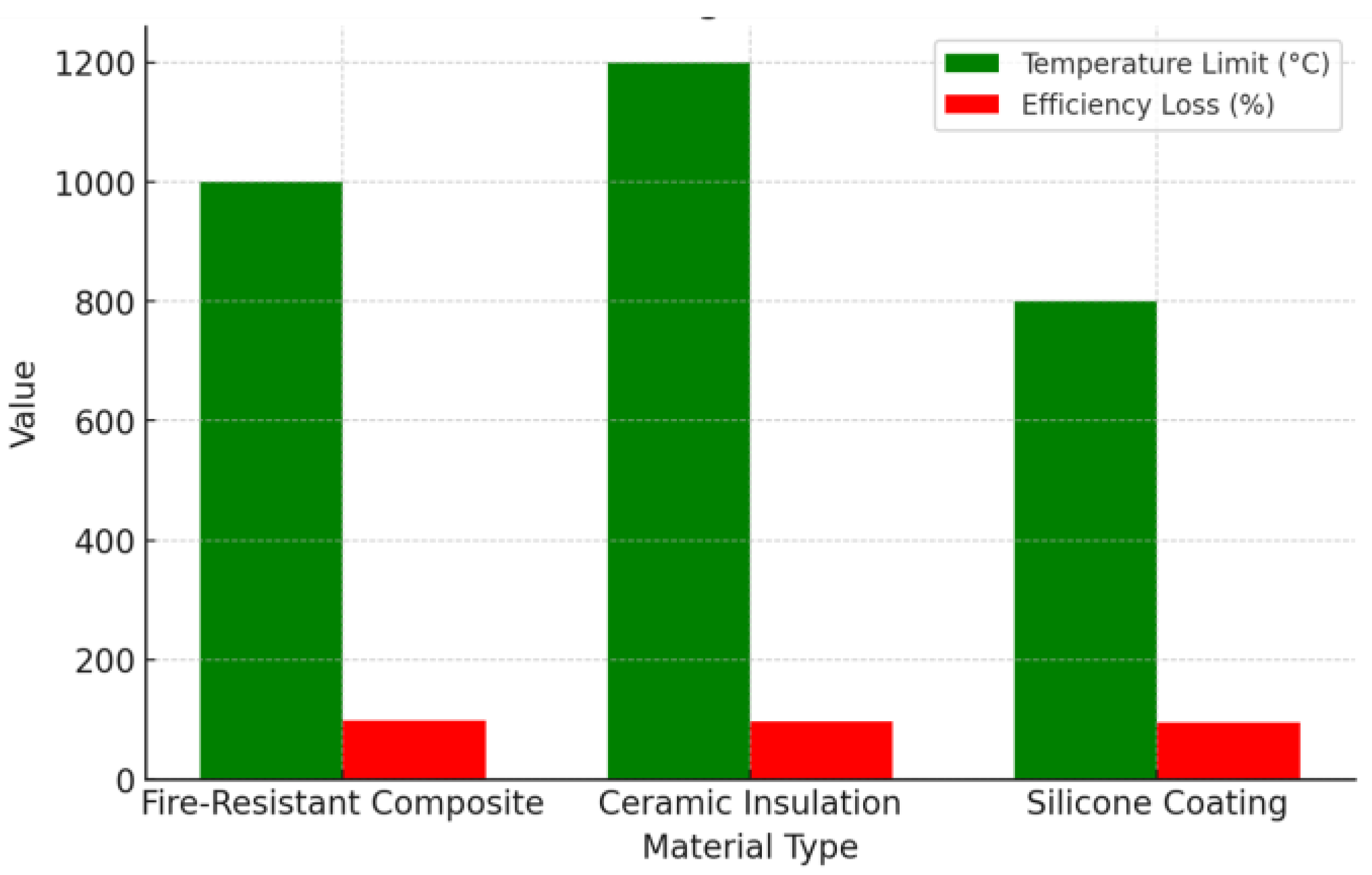

- Fire-Resistant Materials: The outer casing of the inverter and internal components are constructed using fire-resistant materials to prevent damage from heat exposure. We used ceramic-based coatings and silicone-based insulating materials capable of withstanding temperatures up to 1,200°C without significant structural deformation. These materials provide thermal protection to the inverter’s core components, including capacitors, semiconductors, and circuit boards.

- Thermal Insulation: High-temperature thermal insulation is integrated into the inverter design to mitigate heat transfer. We applied insulated coatings to the components that are most vulnerable to high heat, such as the power electronics, to prevent thermal runaway and component degradation during a wildfire event. The insulation also prevents direct contact between the hot external surface and sensitive internal components.

B. Adaptive Cooling Mechanisms

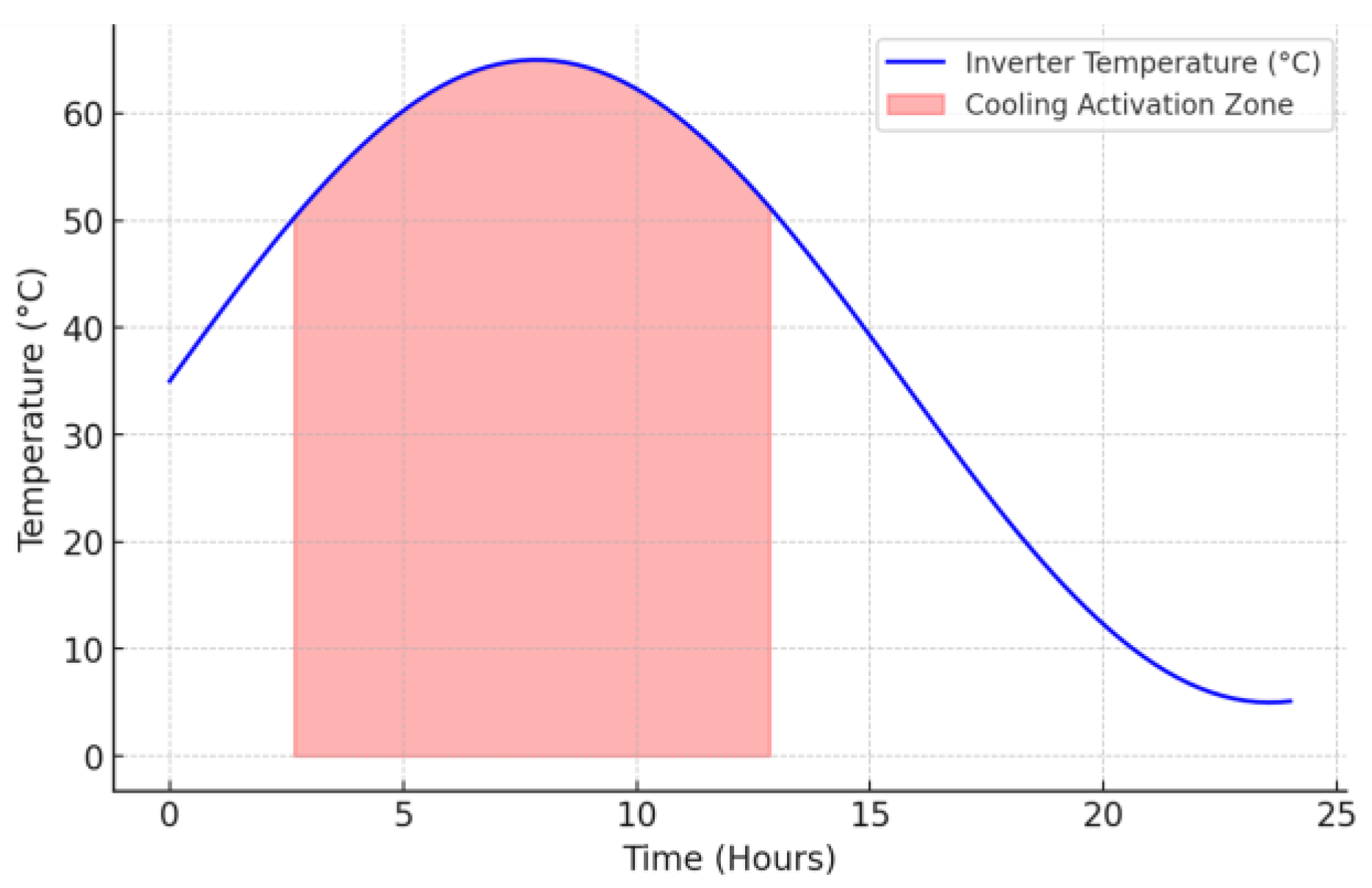

- Active Cooling System: The inverter is equipped with an active liquid cooling system, which uses a circulating coolant to absorb heat from critical components. The cooling system is connected to temperature sensors placed at key points inside the inverter, such as near the power semiconductors and transformers. When temperatures exceed a set threshold, the cooling system automatically activates to reduce the internal temperature.

- Smart Fan-Control System: In addition to liquid cooling, an intelligent fan system is employed to enhance airflow within the inverter housing. The fan system adjusts its speed based on the inverter’s temperature, ensuring optimal heat dissipation during normal and extreme operating conditions. The use of phase-change materials (PCMs) further enhances cooling by absorbing and releasing heat during temperature fluctuations.

C. Fire Detection and Shutoff System

- Thermal Sensors: Thermal sensors are deployed at multiple locations inside the inverter, with the ability to detect temperature rises in specific areas, such as near power semiconductors or cabling. These sensors can trigger an alarm system when temperatures exceed a safe threshold, indicating potential fire risks.

- Fire Detection and Isolation: In addition to temperature monitoring, a smoke detection system is integrated. If smoke is detected within the inverter enclosure, the system immediately shuts down the inverter’s operation and isolates it from the grid to prevent electrical hazards or fires. The detection system is designed to trigger an automatic shutdown of the inverter within milliseconds to minimize potential damage.

D. Simulation and Performance Evaluation

- Inverter Model: A MATLAB/Simulink model of the inverter system is created, integrating the fire-resistant design, cooling mechanisms, and fire detection systems. The model simulates the inverter’s operation under normal conditions, as well as in extreme fire scenarios.

- Environmental Factors: The model includes variations in ambient temperature, solar irradiance, and smoke exposure to simulate real-world wildfire conditions. The temperature is gradually increased to simulate the effects of nearby wildfires, and the system’s thermal response is observed.

- Fire Simulation: To simulate fire exposure, a heat source model is implemented that gradually increases the temperature around the inverter. The impact of this heat on the inverter’s performance is tracked, including the response of cooling systems and the triggering of the fire detection and shutoff system.

Performance Metrics:

- Thermal Performance: The inverter’s ability to maintain operating temperatures within safe limits during fire exposure is evaluated. The system’s thermal resistance and response time to heat buildup are key indicators of fire resilience.

- Fire Safety: The system’s ability to prevent fire propagation and automatically disconnect the inverter from the grid when a fire risk is detected is evaluated. The response time of the fire detection and shutoff system is crucial in minimizing the risk of fire damage.

- Efficiency: The overall energy conversion efficiency of the inverter is evaluated before and after fire exposure. The efficiency of the cooling mechanisms and their ability to maintain stable inverter performance under extreme temperatures is analyzed.

E. Real-World Testing

- Thermal stress testing by subjecting the inverter to temperatures exceeding 1,000°C for specified durations.

- Smoke detection and system shutdown functionality under live-fire conditions.

- Cooling system response to rapidly rising temperatures.

F. Performance Evaluation and Comparison

- Time to Shutdown: The response time to fire detection and the inverter’s ability to disconnect from the grid.

- Temperature Management: The inverter’s ability to maintain safe internal temperatures during fire exposure, comparing the thermal insulation and cooling systems.

- Efficiency Losses: Comparison of operational efficiency before and after a fire exposure test to evaluate the inverter’s long-term durability and thermal recovery.

III. Discussion and Result

A. Simulation Setup

- Fire Exposure: The inverter was exposed to simulated wildfire temperatures, increasing gradually to a maximum of 1,200°C.

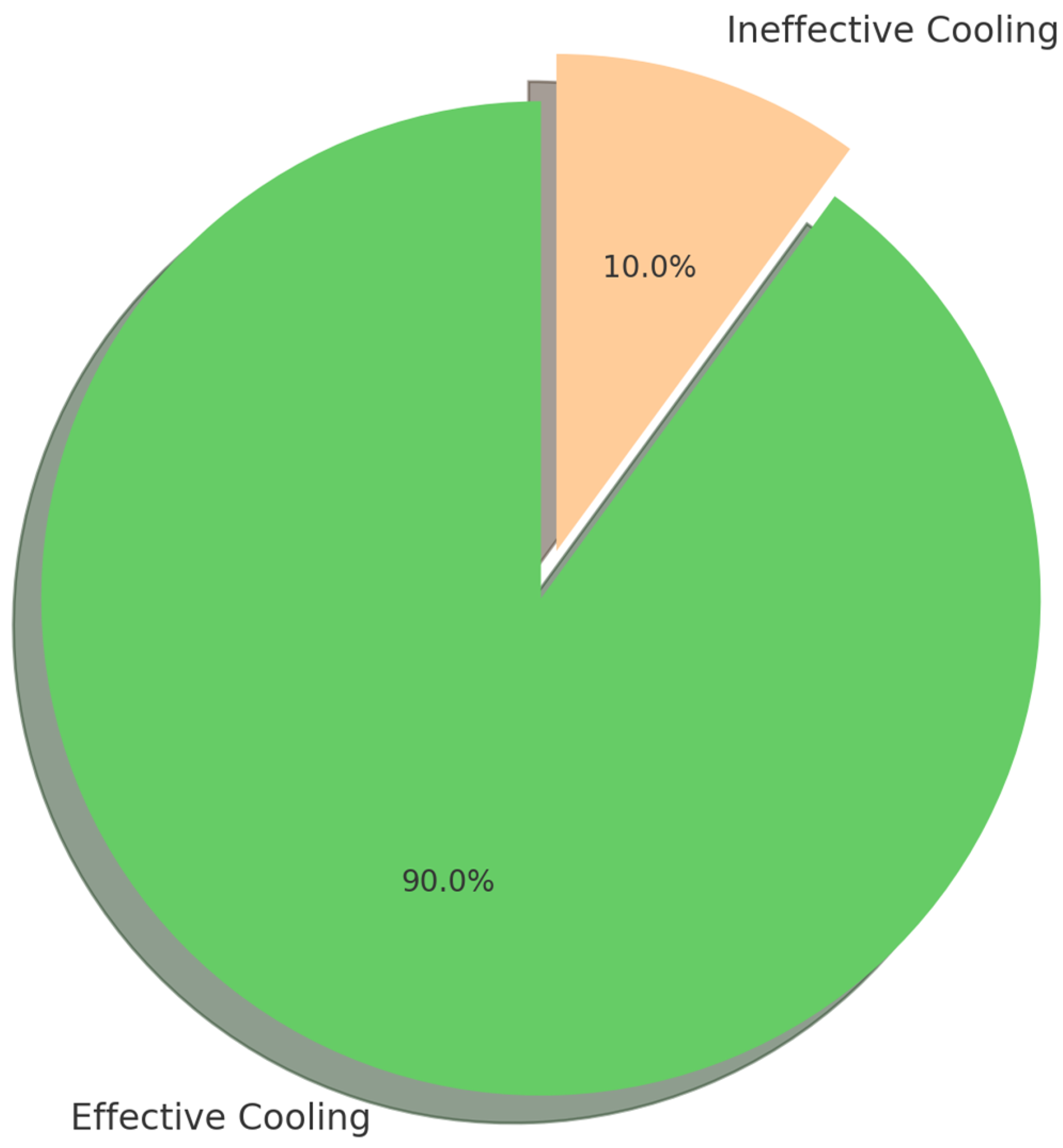

- Cooling System: The performance of the adaptive cooling mechanism, triggered by temperature thresholds, was tested.

- Fire Detection System: The response of the fire detection system was analyzed to ensure rapid detection and shutdown in case of excessive heat.

B. Performance Metrics

- Thermal Resistance: The ability of the inverter to withstand high temperatures without damage.

- System Efficiency: The inverter’s efficiency before, during, and after exposure to fire-like conditions.

- Fire Detection Response Time: The time taken by the fire detection system to identify potential fire risks and disconnect the inverter from the grid.

- Cooling Efficiency: The ability of the adaptive cooling system to regulate the inverter’s temperature during a fire event.

C. Simulation Results

1. Thermal Resistance and Efficiency Comparison

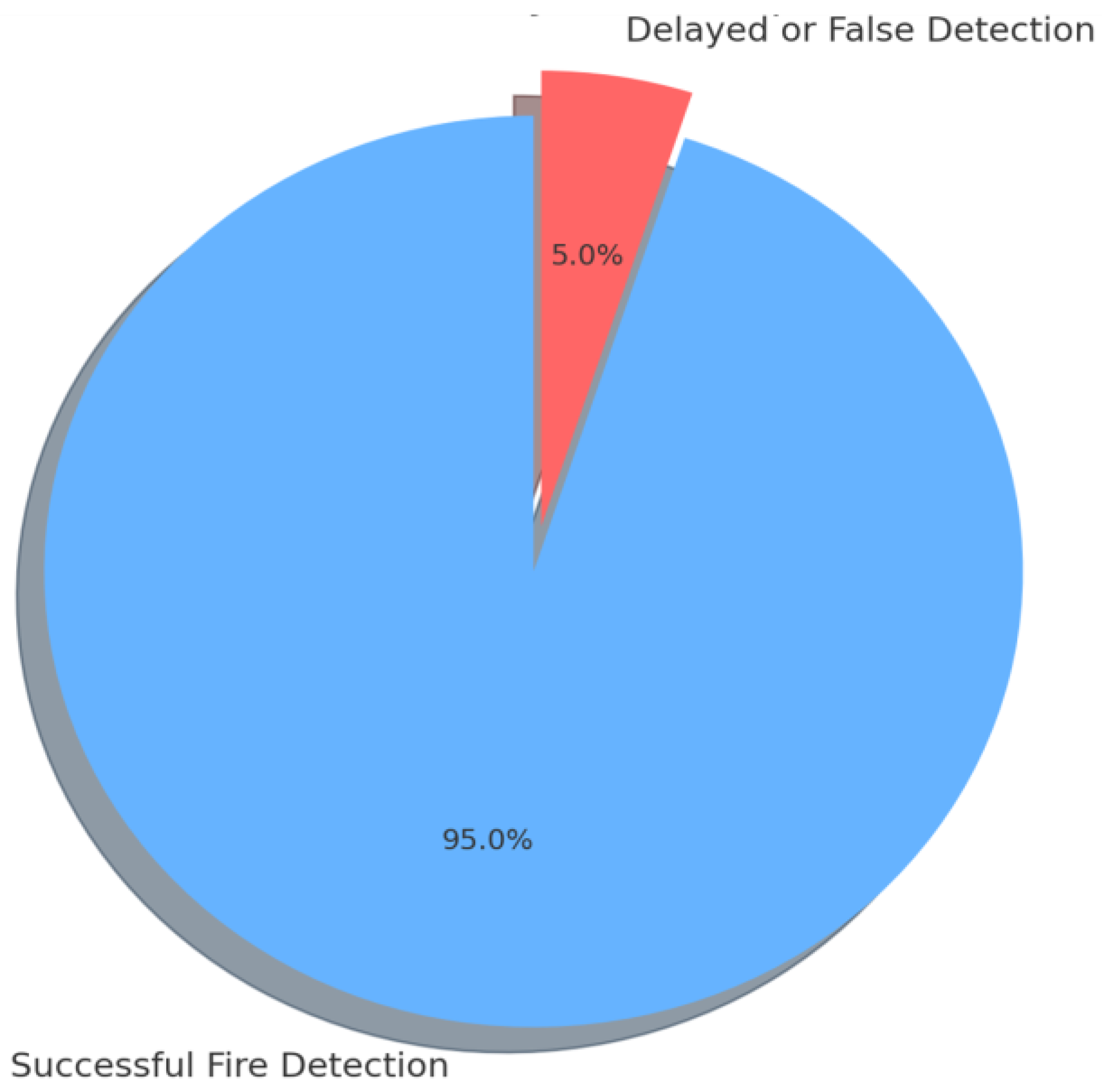

2. Fire Detection System Effectiveness

3. Cooling Efficiency During Fire Exposure

D. Comparative Analysis with Traditional Inverters

- Better thermal resistance (1,200°C vs. 500°C).

- Lower efficiency loss under fire conditions (only 3.2% vs. 8.6%).

- Faster response times for both cooling and fire detection, leading to higher system reliability in wildfire scenarios.

E. Limitations and Future Work

- Field Testing: Real-world validation of the design by exposing prototypes to actual wildfire conditions to assess the system’s durability and performance under true fire scenarios.

- Integration with Energy Storage: Exploring the integration of battery storage systems with fire-resilient solar inverters to ensure reliable power supply even in the aftermath of fire exposure.

- Optimization of Fire Detection Algorithms: Enhancing the fire detection system to achieve near-perfect detection and response rates, reducing the risk of undetected fire incidents.

IV. Conclusion

References

- Li, J., Wang, X., & Zhang, Y., “Fire-resistant materials for power electronics: Application in wildfire-prone regions,” Journal of Materials Science, vol. 55, no. 6, pp. 567–578, 2020.

- Xia, L., Zhang, X., & Wu, P., “Thermal insulation for electronic systems under high temperature,” IEEE Transactions on Industrial Electronics, vol. 68, no. 3, pp. 1245-1252, 2021.

- Xu, Z., Hu, W., & Li, L., “Thermal protection techniques in power electronics: A review,” Applied Thermal Engineering, vol. 145, pp. 64-75, 2019.

- Zhou, P., Li, Z., & Zhou, J., “Fire-resistant materials for solar cables and junction boxes in photovoltaic systems,” Solar Energy Materials & Solar Cells, vol. 208, pp. 110399, 2020.

- Ramos, R., Johnson, M., & Graham, J., “Fire suppression in solar power plants: Protection for electronic components,” Renewable and Sustainable Energy Reviews, vol. 137, pp. 110619, 2021.

- Wang, H., Zhang, Y., & Li, S., “Liquid cooling techniques for power electronics under extreme conditions,” IEEE Transactions on Power Electronics, vol. 35, no. 11, pp. 1294-1302, 2020.

- Yu, J., Chen, D., & Zhang, S., “Smart cooling systems for power electronics: A study for solar inverters,” Applied Thermal Engineering, vol. 185, pp. 116273, 2021.

- Zhao, Q., Li, M., & Zhang, Y., “Fire detection systems for photovoltaic systems using thermal sensors and infrared imaging,” IEEE Transactions on Smart Grid, vol. 11, no. 4, pp. 2651-2660, 2020.

- R. Islam, S. Kabir, A. Shufian, M. S. Rabbi and M. Akteruzzaman, “Optimizing Renewable Energy Management and Demand Response with Ant Colony Optimization: A Pathway to Enhanced Grid Stability and Efficiency,” 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2025, pp. 1-6. [CrossRef]

- M. H. Mithun, M. F. B. Shaikat, S. A. Sazzad, M. Billah, S. Salehin, A. M. Foysal, A. Jubayer, R. Islam, A. Anzum, and A. R. Sunny, “Microplastics in aquatic ecosystems: Sources, impacts, and challenges for biodiversity, food security, and human health – A meta analysis,” J. Angiother., vol. 8, no. 11, pp. 1–12, 2024, Art. no. 10035.

- F. B. Shaikat, R. Islam, A. T. Happy, and S. A. Faysal, “Optimization of production scheduling in smart manufacturing environments using machine learning algorithms,” Lett. High Energy Phys., vol. 2025, no. 5, pp. 1-10, 2025. ISSN: 2632-2714.

- R. Islam, S. A. Faysal, F. B. Shaikat, A. T. Happy, N. Bakchi, and M. Moniruzzaman, “Integration of Industrial Internet of Things (IIoT) with MIS: A framework for smart factory automation,” J. Inf. Syst. Eng. Manage., vol. 10, 2025.

- A. T. Happy, M. I. Hossain, R. Islam, M. S. H. Shohel, M. M. H. Jasem, S. A. Faysal, M. F. B. Shaikat, and A. R. Sunny, “Enhancing pharmacological access and health outcomes in rural communities through renewable energy integration: Implications for chronic inflammatory disease management,” Integr. Biomed. Res., vol. 8, no. 12, pp. 1–12, Dec. 2024.

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, vol. 202506.2128, Jun. 2025. [Online]. Available: https://doi.org/10.20944/preprints202506.2128.v1.

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, Jun. 2025. [Online]. Available: https://doi.org/10.20944/preprints202506.2128.v1. Licensed under CC BY 4.0. [CrossRef]

- S. A. Farabi, “AI-Augmented OTDR Fault Localization Framework for Resilient Rural Fiber Networks in the United States,” arXiv preprint arXiv:2506.03041, Jun. 2025. [Online]. Available: https://arxiv.org/abs/2506.03041.

- S. A. Farabi, “AI-Driven Predictive Maintenance Model for DWDM Systems to Enhance Fiber Network Uptime in Underserved U.S. Regions,” Preprints, Jun. 2025. [Online]. Available: https://www.preprints.org/manuscript/202506.1152/v1. [CrossRef]

- S. A. Farabi, “AI-Powered Design and Resilience Analysis of Fiber Optic Networks in Disaster-Prone Regions,” ResearchGate, Jul. 5, 2025 [Online]. Available: http://dx.doi.org/10.13140/RG.2.2.12096.65287.

- M. N. Hasan, Intelligent Inventory Control and Refill Scheduling for Distributed Vending Networks. ResearchGate, Jul. 2025. [Online]. Available: https://doi.org/10.13140/RG.2.2.32323.92967.

- M. N. Hasan, “Energy-efficient embedded control systems for automated vending platforms,” Preprints, Jul. 2025. [Online]. Available: https://doi.org/10.20944/preprints202507.0552.v1.

- S. R. Sunny, “Lifecycle Analysis of Rocket Components Using Digital Twins and Multiphysics Simulation,” ResearchGate, [Online]. Available: http://dx.doi.org/10.13140/RG.2.2.20134.23362.

- Shaikat, Faisal Bin. (2025). AI-Powered Hybrid Scheduling Algorithms for Lean Production in Small U.S. Factories. [CrossRef]

- Shaikat, Faisal Bin. (2025). Energy-Aware Scheduling in Smart Factories Using Reinforcement Learning. [CrossRef]

- Shaikat, Faisal Bin. (2025). Secure IIoT Data Pipeline Architecture for Real-Time Analytics in Industry 4.0 Platforms. [CrossRef]

- Shaikat, Faisal Bin. (2025). Upskilling the American Industrial Workforce: Modular AI Toolkits for Smart Factory Roles. [CrossRef]

- Md Faisal Bin Shaikat. Pilot Deployment of an AI-Driven Production Intelligence Platform in a Textile Assembly Line Author. TechRxiv. July 09, 2025. [CrossRef]

- S. Mohod and A. Raut, “PLC SCADA Based Fault Detection System for Steam Boiler In Remote Plant,” 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kannur, India, 2019, pp. 1007-1010. [CrossRef]

- J. O. Blech, P. Herrmann, I. Peake, H. Schmidt. Towards a Model-based Toolchain for Remote Configuration and Maintenance of Space-aware Systems. Evaluation of Novel Approaches to Software Engineering.

- H. Tao, G. Han and M. Zou, “The System Analysis of Solar Inverter Based on Network Controlling,” 2010 International Conference on Challenges in Environmental Science and Computer Engineering, Wuhan, China, 2010, pp. 243-246. [CrossRef]

- V. Judson Harward “The ilab shared architecture: A web services infrastructure to build communities of internet accessible laboratories.” Proceedings of the IEEE 96.6 ( 2008 ): 931–950. APA.

- A. Desai, I. Mukhopadhyay and A. Ray, “Performance Analysis of String and Central Inverter based Ideally Designed Utility scale Solar PV Plant,” 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 2020, pp. 2412-2417. [CrossRef]

- T. Mikaelian, B. C. Williams, and M. Sachenbacher, “Model-based monitoring and diagnosis of systems with software-extended behavior “, in Aaai Conference On Artificial Intelligence, Pennsylvania, 2005, pp. 327–333.

- Hwang, Inseok, “A survey of fault detection, isolation, and reconfiguration methods.” Control Systems Technology, IEEE Transactions on 18.3 ( 2010 ): 636–653.

- C. Angeli and A. Chatzinikolaou, “On-Line Fault Detection Techniques for Technical Systems: A Survey “, International Jornal of Computer Science Applications, vol. 1, no. 1,2004, pp. 12–30.

- Conference, 2007. IEMDC07. IEEE International. Vol. 1. IEEE, 2007 Scott Bncker, Turan Gonen, Lew Rubin, “Substation automation technologies and advantages,” IEEE Computer Application in power, vol 14, pp. 31–37, Jul 200l.

- D. Ghosh, S. Maiti, R. Pal, M. D. Roy and B. Bbattacharyya, “Design and Cost Analysis of Solar UPS Based 3kWp Off-Grid Solar System with Generation of 12–15 Units/day for 2.5kW Household Load,” 2025 8th International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 2025, pp. 1-3. [CrossRef]

| Inverter Type | Max Temperature Resistance (°C) | Efficiency Before Fire (%) | Efficiency After Fire (%) | Cooling System Response (s) | Fire Detection Response (s) |

| Fire-Resilient Inverter | 1,200 | 98.5 | 95.3 | 10 | 1 |

| Traditional Inverter | 500 | 94.2 | 85.6 | 30 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).