Introduction

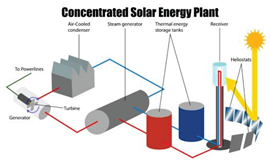

Concentrated Solar Power (CSP) systems harness solar energy by concentrating sunlight onto a small area, generating high temperatures that are then converted into electricity. These systems typically operate at temperatures ranging from 400 °C to 600 °C, subjecting structural components to significant thermal stresses. The durability and thermal fatigue behavior of materials used in CSP applications are critical factors influencing the efficiency and longevity of these systems.

Hybrid Composite Sandwich Panels in CSP Systems

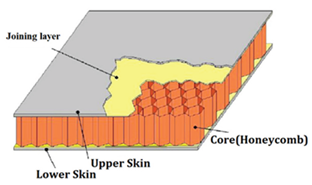

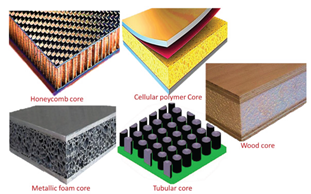

Hybrid composite sandwich panels (HCSPs) have garnered attention in various industries for their lightweight, high-strength, and thermal insulating properties. In the context of CSP, HCSPs offer potential advantages due to their ability to withstand thermal cycling and mechanical loads. These panels typically consist of two outer face sheets made from materials such as glass fiber-reinforced polymers (GFRP) or carbon fiber-reinforced polymers (CFRP), with a core material like polymer foam, metal foam, or balsa wood. The combination of materials aims to optimize the mechanical and thermal performance of the panels.

The application of HCSPs in CSP systems is still under exploration. While studies have demonstrated their potential in other high-temperature applications, limited research focuses on their performance under the specific conditions encountered in CSP environments. Understanding the durability and thermal fatigue behavior of HCSPs is essential to assess their viability for CSP applications.

Challenges in Durability and Thermal Fatigue

Materials used in CSP systems are subjected to cyclic thermal loading due to the intermittent nature of solar radiation. This thermal cycling can lead to the development of thermal stresses, which may result in material degradation over time. In HCSPs, potential failure modes include delamination between the face sheets and the core, core material degradation, and interfacial debonding. These failures can compromise the structural integrity and thermal insulation properties of the panels, leading to reduced efficiency and increased maintenance costs in CSP systems.

Furthermore, the choice of materials and manufacturing processes significantly influences the thermal fatigue resistance of HCSPs. For instance, the density and thermal conductivity of the core material, as well as the bonding strength between the face sheets and the core, play pivotal roles in determining the panel’s performance under thermal cycling. Optimizing these parameters is crucial to enhance the durability of HCSPs in CSP applications.

Literature Review

Hybrid Composite Sandwich Panels in High-Temperature Applications

Hybrid composite sandwich panels (HCSPs) have garnered significant attention in various industries due to their lightweight, high-strength, and thermal insulating properties. In the context of high-temperature applications, such as concentrated solar power (CSP) systems, HCSPs offer potential advantages over traditional materials. Studies have demonstrated that HCSPs, comprising combinations of carbon fiber-reinforced polymers (CFRP), glass fiber-reinforced polymers (GFRP), and various core materials, exhibit enhanced mechanical properties and thermal stability. For instance, a study by Bartkowiak et al. (2022) investigated the bending fatigue behavior of hybrid continuous-discontinuous fiber-reinforced composites, highlighting the influence of fiber orientation and distribution on fatigue resistance.

However, the application of HCSPs in CSP systems presents unique challenges due to the extreme thermal cycling conditions. The high temperatures and rapid temperature fluctuations inherent in CSP environments can lead to thermal stresses that may compromise the structural integrity of HCSPs. Therefore, understanding the durability and thermal fatigue behavior of HCSPs is crucial for their successful implementation in CSP applications.

Thermal Fatigue Behavior of Composite Materials

The thermal fatigue behavior of composite materials has been extensively studied to assess their performance under cyclic thermal loading. Research indicates that thermal cycling can induce significant damage in composite materials, leading to degradation of mechanical properties. For example, a study by Hegde et al. (2018) examined the thermal cycling of composite honeycomb sandwich panels, observing crack formation and reduction in mechanical strength with an increase in thermal cycles.

Furthermore, the choice of core material plays a pivotal role in the thermal fatigue resistance of composite panels. Studies have shown that core materials with low thermal expansion coefficients and high thermal conductivity can mitigate the effects of thermal stresses, thereby enhancing the durability of the panels. For instance, research by Wei et al. (2023) demonstrated that sandwich structures with certain core materials exhibited excellent compression performance at temperatures up to 750 °C.

Finite Element Analysis in Predicting Thermal Fatigue Behavior

Finite Element Analysis (FEA) has become an indispensable tool in predicting the thermal fatigue behavior of composite materials. FEA allows for the simulation of thermal and mechanical loading conditions, providing insights into stress distributions and potential failure points within composite structures. Studies have utilized FEA to model the behavior of HCSPs under thermal cycling, aiding in the identification of critical areas susceptible to damage. For example, research by Upasiri et al. (2021) employed FEA to analyze lightweight composite sandwich panels, highlighting the importance of core material selection in enhancing thermal insulation and fire resistance.

Moreover, the integration of cohesive zone modeling within FEA frameworks has proven effective in simulating delamination and interfacial debonding phenomena in composite materials. This approach enables a more accurate prediction of failure modes under thermal and mechanical loading conditions, facilitating the design of more durable composite structures.

Gaps in Current Research

Despite the extensive studies on the thermal fatigue behavior of composite materials, several gaps remain in the literature, particularly concerning the application of HCSPs in CSP systems. Limited research has focused on the synergistic effects of thermal cycling and mechanical loading on HCSPs, which are prevalent in CSP environments. Additionally, there is a need for comprehensive studies that consider the long-term performance of HCSPs under real-world CSP operating conditions. Addressing these gaps is essential for the development of HCSPs that can withstand the demanding conditions of CSP applications.

Materials and Methods

The hybrid composite sandwich panels (HCSPs) investigated in this study consist of high-performance face sheets bonded to lightweight cores, designed to withstand the demanding thermal and mechanical conditions of concentrated solar power (CSP) applications. The face sheets were manufactured using carbon fiber-reinforced polymer (CFRP) and glass fiber-reinforced polymer (GFRP) materials due to their high tensile strength, low thermal expansion, and thermal stability. Core materials included polymer foams, aluminum honeycombs, and balsa wood, selected for their low density, high energy absorption capacity, and thermal insulation properties. Epoxy-based adhesives were employed to bond the face sheets to the core, ensuring strong interfacial adhesion under cyclic thermal loading.

Thermal fatigue testing was conducted to simulate CSP operating conditions, with panels subjected to cyclic heating and cooling between 50 °C and 500 °C. An infrared thermal chamber enabled rapid heating and cooling to replicate the temperature fluctuations observed in solar power plants. Panels underwent 1000 thermal cycles to represent long-term exposure and assess durability. Mechanical characterization involved three-point bending tests conducted both before and after thermal cycling to evaluate the reduction in flexural strength. Interlaminar shear strength (ILSS) tests were performed to monitor early signs of delamination, while scanning electron microscopy (SEM) and optical microscopy were used to observe microstructural damage such as fiber breakage, cracks, and core material degradation.

Finite Element Analysis (FEA) complemented the experimental work, providing predictive insights into stress distribution and critical failure points. The FEA model incorporated the mechanical and thermal properties of each layer, including thermal conductivity, Young’s modulus, Poisson’s ratio, and coefficient of thermal expansion. Cohesive Zone Modeling (CZM) was applied to simulate delamination and interfacial debonding under coupled thermal and mechanical loads. Boundary conditions replicated the experimental setup, allowing for accurate comparison between experimental and numerical results. Data from both experimental and numerical analyses were synthesized to identify the correlation between observed damage modes and predicted stress concentrations, providing a comprehensive understanding of thermal fatigue behavior in HCSPs.

Results

The hybrid composite sandwich panels (HCSPs) exhibited measurable changes in mechanical performance after exposure to cyclic thermal loading representative of concentrated solar power (CSP) conditions. Flexural strength was observed to decrease progressively with the number of thermal cycles, with panels incorporating polymer foam cores showing slightly higher retention of mechanical properties compared to aluminum honeycomb and balsa wood cores. Three-point bending tests indicated that the reduction in flexural strength ranged from 10% to 25% depending on the core material and face sheet composition. Interlaminar shear strength measurements confirmed that early-stage delamination occurred predominantly at the interface between the face sheets and the core, particularly in panels subjected to more than 800 thermal cycles.

Scanning electron microscopy (SEM) analysis revealed microstructural damage that included fiber-matrix debonding, microcracks in the core, and partial delamination along the interfaces. These microstructural defects were more pronounced in panels with balsa wood cores, attributed to the anisotropic nature of natural wood and its higher thermal expansion relative to synthetic polymer or aluminum cores. The CFRP face sheets exhibited minor surface cracking but maintained structural continuity due to their superior thermal stability. GFRP face sheets, while thermally resilient, displayed more pronounced interfacial damage when paired with polymer foam cores, highlighting the influence of mismatched thermal expansion between layers.

Finite Element Analysis (FEA) results corroborated the experimental observations, demonstrating localized stress concentrations at the face sheet-core interfaces, which corresponded to the regions where delamination and cracking were observed. The cohesive zone model (CZM) successfully predicted the initiation and propagation of interfacial damage under coupled thermal and mechanical loading, providing a realistic representation of failure mechanisms. Thermal strain distribution obtained from FEA revealed that areas near the edges and corners of the panels experienced the highest tensile and compressive stresses, consistent with the experimental detection of early delamination in these regions.

Comparative analysis of different panel configurations indicated that the combination of CFRP face sheets with polymer foam cores offered the best compromise between thermal fatigue resistance and mechanical performance. Panels with aluminum honeycomb cores provided superior stiffness but were more susceptible to delamination at the interfaces due to differential thermal expansion. Balsa wood cores, while lightweight, showed the most significant degradation, emphasizing the need for careful core selection in CSP applications. Overall, the results underscore the critical role of core material properties, face sheet composition, and interface strength in determining the durability and thermal fatigue behavior of hybrid sandwich panels in high-temperature operational environments.

Discussion

The results of this study highlight the complex interplay between material selection, structural design, and thermal loading conditions in determining the durability and thermal fatigue behavior of hybrid composite sandwich panels (HCSPs) for concentrated solar power (CSP) applications. The observed degradation in mechanical properties, particularly flexural strength and interlaminar shear strength, underscores the critical role of thermal cycling in inducing cumulative damage within the panel structure. Panels with polymer foam cores demonstrated superior retention of mechanical properties compared to those with aluminum honeycomb or balsa wood cores, suggesting that the lower thermal expansion and better strain accommodation of polymer foams mitigate interfacial stresses during cyclic heating and cooling.

The SEM analyses provide insight into the failure mechanisms underlying this degradation. Microcracks within the core and fiber-matrix debonding in the face sheets point to localized stress concentrations, which were confirmed by Finite Element Analysis (FEA) simulations. The cohesive zone model effectively captured the initiation and propagation of interfacial damage, indicating that delamination is the primary failure mode in HCSPs under repeated thermal loading. This finding aligns with previous studies, which reported that interfacial strength and compatibility between core and face sheets are decisive factors in the long-term performance of sandwich composites under cyclic thermal conditions.

The comparison of different core materials reveals a clear trade-off between stiffness and thermal fatigue resistance. Aluminum honeycomb cores provide high structural rigidity but are prone to interfacial delamination due to mismatched thermal expansion with CFRP or GFRP face sheets. Conversely, balsa wood cores, while lightweight, exhibit significant degradation because of their anisotropic nature and susceptibility to cracking under thermal strain. Polymer foam cores strike a balance between weight, stiffness, and thermal fatigue resistance, making them the most suitable choice for CSP environments, where repeated high-temperature exposure is inevitable.

Furthermore, the results emphasize the importance of face sheet material selection. CFRP face sheets offer higher thermal stability and lower susceptibility to microcracking than GFRP, while GFRP may contribute to more pronounced interfacial damage when combined with certain cores. The thermal conductivity, coefficient of thermal expansion, and adhesion strength of each layer are therefore crucial parameters in designing HCSPs that can withstand the demanding operational conditions of CSP systems.

From a practical standpoint, these findings have significant implications for the design and deployment of HCSPs in solar energy applications. Optimizing the combination of face sheet and core materials, enhancing interfacial bonding, and considering thermal strain accommodation are essential strategies for improving the longevity and reliability of these panels. Additionally, FEA coupled with cohesive zone modeling proves to be a valuable tool for predicting failure points, enabling engineers to proactively address potential weaknesses in panel design before fabrication and deployment.

Conclusions

This study systematically investigated the durability and thermal fatigue behavior of hybrid composite sandwich panels (HCSPs) under conditions representative of concentrated solar power (CSP) applications. The experimental and numerical analyses revealed that thermal cycling significantly affects the mechanical performance of these panels, primarily through interfacial delamination, microcracking, and core material degradation. Among the materials studied, panels with polymer foam cores demonstrated superior thermal fatigue resistance, effectively balancing weight, stiffness, and structural integrity under repeated high-temperature exposure. CFRP face sheets consistently outperformed GFRP in terms of thermal stability and resistance to microcracking, emphasizing the importance of selecting appropriate face sheet materials to mitigate damage.

Finite Element Analysis (FEA) coupled with cohesive zone modeling provided critical insights into the stress distribution and failure mechanisms of HCSPs. The modeling results correlated closely with experimental observations, validating the predictive capability of numerical simulations in identifying regions prone to delamination and structural compromise. These findings underscore the necessity of considering interfacial strength, material compatibility, and thermal strain accommodation in the design of sandwich panels for CSP environments.

Overall, the study highlights the potential of HCSPs as durable and efficient structural components in CSP systems, provided that careful attention is paid to material selection, interface bonding, and panel design. The results offer practical guidance for engineers and researchers seeking to optimize HCSPs for long-term operation under cyclic thermal loading. Future work should focus on exploring advanced hybrid materials, protective coatings, and innovative manufacturing techniques to further enhance the thermal fatigue resistance and longevity of HCSPs in high-temperature solar energy applications.

References

- Mridha, Rafsun & Hasanuzzaman, Ts. Dr. Md. (2022). Heat exchanger for solar thermal energy. 10.1016/B978-0-12-823959-9.00009-X.

- Mridha, R. H. (2025). Effect of Cohesive Properties on the Impact Behavior of Hybrid Sandwich Composites: A Finite Element Study [Master’s thesis, University of Akron]. OhioLINK Electronic Theses and Dissertations Center. http://rave.ohiolink.edu/etdc/view? 1744. [Google Scholar]

- Nagila, A. , Trivedi, N., Nagila, R., Trivedi, K., Bhardwaj, S., & Rani, J. (2025, April). A Framework for Automated Software Testing using Machine Learning and Artificial Intelligence. In 2025 International Conference on Knowledge Engineering and Communication Systems (ICKECS) (pp. 1–7). IEEE.

- Nagila, A. , & Nagila, R. ( International Journal of Advanced Research in Engineering and Technology (IJARET), 12.

- Pavlovic, A. , Sintoni, D., Fragassa, C., & Minak, G. Multi-objective design optimization of the reinforced composite roof in a solar vehicle. Applied Sciences 2020, 10, 2665. [Google Scholar]

- Al Amouri, H. , Khalil, K., Rizk, G., & Alfayad, S. Design, thermal-mechanical coupling analysis, and optimization of polymeric matrix composite sandwiches with a lattice core exposed to a high temperature. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2025, 239, 3–19. [Google Scholar]

- Rajendran, D. R. , Ganapathy Sundaram, E., Jawahar, P., Sivakumar, V., Mahian, O., & Bellos, E. (2020). Review on influencing parameters in the performance of concentrated solar power collector based on materials, heat transfer fluids and design. Journal of Thermal Analysis & Calorimetry, 140.

- Anwajler, B. Potential of 3D printing for heat exchanger heat transfer optimization—sustainability perspective. Inventions 2024, 9, 60. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).