1. Introduction

Injera, a traditional Ethiopian flatbread made from fermented teff flour, holds central cultural, nutritional, and economic significance in Ethiopia and Eritrea[

1,

2]. Traditionally baked on a large circular griddle known as a

mitad, the process demands a substantial and sustained thermal energy supply[

1]. In rural households, the predominant energy source has historically been biomass, particularly firewood, crop residues, and animal dung[

3]. This reliance has contributed to deforestation, indoor air pollution, and labor burdens, particularly on women and children. Despite the growing urban shift toward electric stoves, rural communities continue to face energy poverty and infrastructure limitations[

4].

Biogas, produced from anaerobic digestion of organic waste such as animal manure, emerges as a renewable, locally available, and environmentally sustainable cooking fuel[

5,

6]. Its application in domestic and institutional cooking, especially in injera baking, offers a potential pathway toward clean cooking goals aligned with Ethiopia’s Climate Resilient Green Economy [CRGE] strategy and Sustainable Development Goal 7 [access to affordable, reliable, sustainable, and modern energy][

7].

This review article critically examines the technological evolution, performance evaluations, and design innovations of biogas-fueled injera baking stoves. It highlights thermal efficiency, burner geometry, manifold configurations, and heat distribution strategies. Special attention is given to how these engineering solutions interact with sociocultural factors such as injera quality, user acceptability, and scalability. In doing so, it identifies research gaps and provides future directions to improve adoption and performance.

The Ethiopian government has undertaken multiple initiatives to disseminate domestic biogas systems through programs such as the National Biogas Programme of Ethiopia [NBPE], supported by agencies like SNV Netherlands Development Organization[

8]. While biogas has found moderate success in heating and lighting applications, its use for injera baking remains at an early stage due to technical and cultural challenges. The high thermal demand, large griddle size, and need for even heating make injera baking a particularly demanding application compared to boiling or frying[

9].

Initial biogas stove designs were adopted from general-purpose cooking burners, leading to suboptimal outcomes. Issues such as uneven heat flux, poor injera texture, and long warm-up times limited household acceptance[

10,

11]. Moreover, biogas pressure from small-scale digesters is typically low, below 50mbar, which complicates its direct use in high-flame applications like injera baking[

8,

12,

13]. These early limitations highlighted the need for specialized design tailored to the thermodynamic and combustion requirements of injera.

Recent efforts have focused on adapting burner geometries, insulating materials, and griddle configurations to improve thermal efficiency and user satisfaction. Focus on insulation performance, while computational fluid dynamics [CFD] approaches provide insights into burner optimization was studied[

14]. Nonetheless, a gap persists in transitioning from simulation to field-validated, community-scale designs.

This review synthesizes technical findings across three decades, connecting design evolution with practical deployment outcomes. It emphasizes the critical importance of integrating engineering design with end-user requirements, particularly in rural Ethiopian contexts where injera baking is not merely culinary but also a daily ritual embedded in social life.

2. Historical Development of Biogas Injera Baking Stoves

The technological evolution of biogas injera baking stoves in Ethiopia reflects over three decades of iterative experimentation and engineering adaptation, driven by the urgent need to replace inefficient biomass-based cooking practices[

15]. Traditional clay-based stoves, such as the widely used Mirt stove, offer low thermal efficiency—often below 20%—and are heavily dependent on fuelwood, contributing to severe deforestation and domestic air pollution[

16]. In response, researchers have sought to develop biogas-fueled alternatives that meet the thermal, spatial, and cultural demands of injera baking. This chapter traces the major research milestones in biogas stove design for injera preparation, highlighting innovations in combustion geometry, insulation, modeling, and field implementation.

The first notable attempt to design a biogas injera stove dates back to 1996, when Dereje introduced a steel-pipe burner composed of three concentric rings [

Figure 1]. Operating at a gas flow rate of 41 liters per minute [approximately 2.5 m³/h], the stove delivered a thermal output of 11 kW and achieved a thermal efficiency of 16%. Despite improved flame coverage relative to single-point burners, the system suffered from high heat losses and poor insulation. Each injera consumed approximately 193 liters of biogas, reflecting the inefficiency of early biogas combustion systems. Dereje's work underscored the need for enhanced combustion control, optimized flame distribution, and insulation mechanisms to retain thermal energy.

Nearly two decades later, Dejene Kebede and Alemayehu Kiflu [2014] shifted the research focus toward thermal retention and insulation [

Figure 2]. Their analytical study employed Fourier’s law of heat conduction to examine the impact of insulation materials—such as vermiculite, ceramic fiber, and locally sourced clay—on heat loss through the stove’s walls and base[

14]. While no baking experiments were conducted, simulations revealed that a 30 mm clay-insulated wall could reduce heat loss by 28% compared to an uninsulated setup. This study introduced the importance of material properties in stove design, particularly thermal conductivity and insulation thickness, laying the groundwork for future systems that integrated both burner optimization and heat containment[

14,

18,

19].

The integration of computational modeling into stove design was first realized by Bezuayehu Mulugeta, Shewangizaw W. Demissie, and Derese T. Nega in 2017[

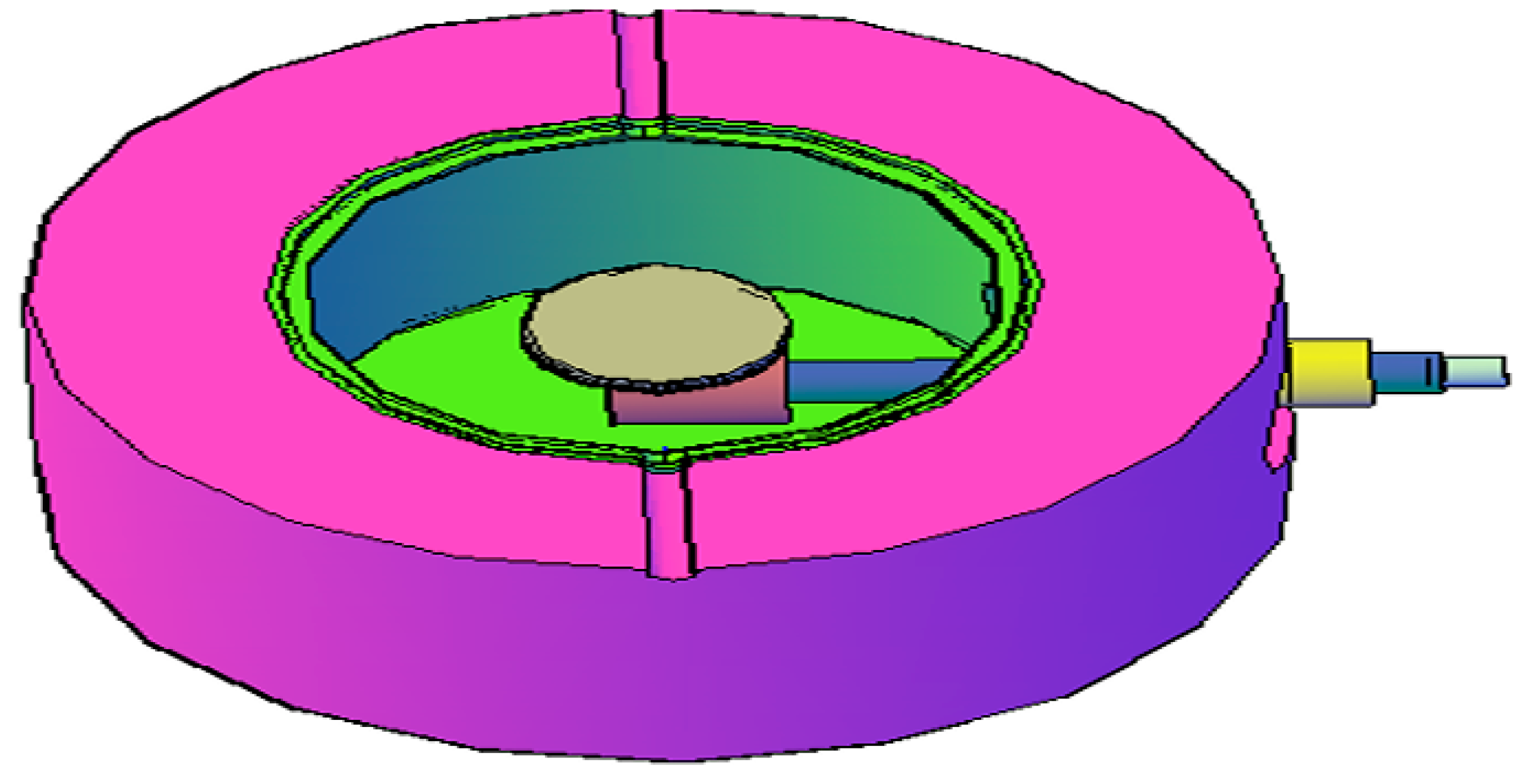

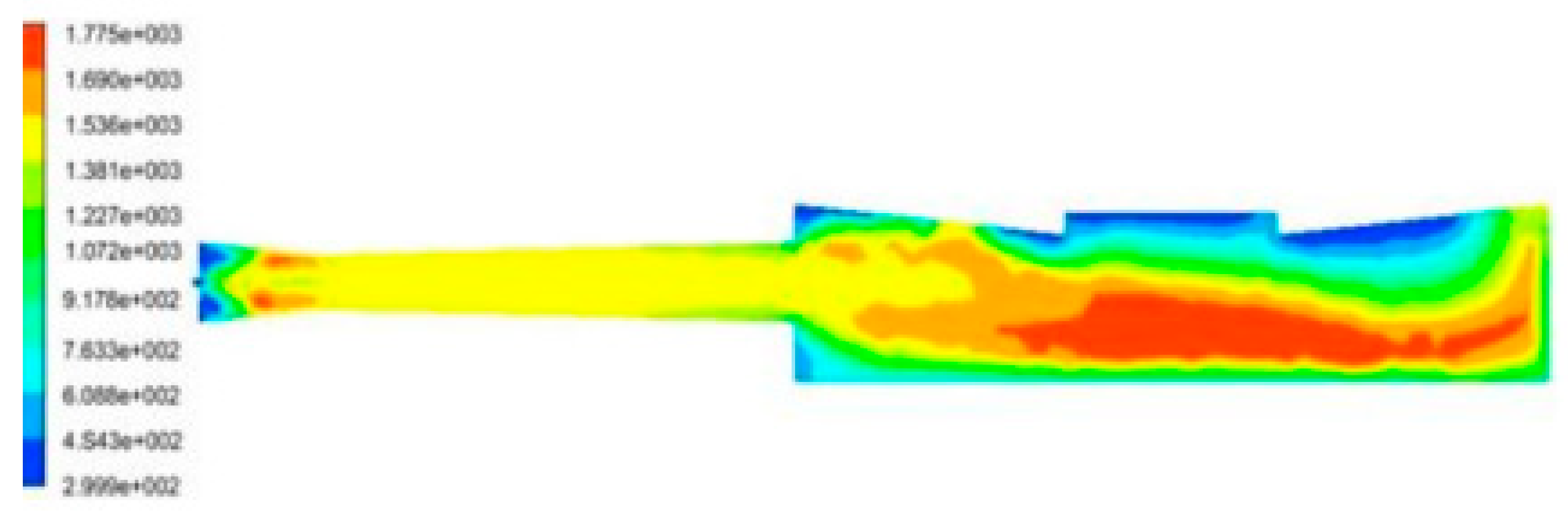

20]. Using ANSYS Fluent for computational fluid dynamics [CFD] simulations, the team analyzed the effects of burner port diameter, number of ports, and manifold geometry on temperature distribution and flow patterns across the mitad surface [

Figure 3]. Their simulations identified a 26 cm manifold as optimal for achieving uniform thermal distribution, especially when paired with a dense radial pattern of small flame ports. However, this advanced modeling effort lacked experimental validation, and the absence of real-world performance metrics left open questions about the applicability of CFD outcomes in dynamic baking environments.

A turning point in the field came with the work of Derese T. Nega and colleagues in 2021, who implemented a full-scale system integrating a CFD-informed burner design with a custom-fabricated clay mitad[

20]. The design featured a 260 mm steel manifold drilled with flame ports tailored to a 540 mm diameter baking surface, closely aligning with hotel-scale injera production. Field trials conducted at Jimma Degitu Hotel confirmed improved baking outcomes, including better browning uniformity and reduced biogas consumption. While thermal efficiency metrics were not fully quantified, the successful field deployment demonstrated the feasibility of CFD-optimized designs under real cooking conditions[

Figure 4].

In a parallel development, Getu Alemayehu [2012] explored the scalability of biogas injera stoves for communal use [

Figure 5]. His prototype featured a reinforced clay mitad [530 mm in diameter] paired with three concentric burner rings, operating at 0.93 m³/h of biogas. Deployed across five rural households in the Amhara region, the stove exhibited social acceptability and continuous baking capability. However, technical challenges emerged, including uneven heat distribution and insufficient flame intensity at the griddle’s edges. These findings emphasized the importance of aligning burner geometry with the mitad’s surface area to avoid cold zones and ensure uniform injera quality.

Building on these advances, an adjustable conical burner design was introduced that emphasized heat focus and fuel efficiency[

8]. By reducing the mitad diameter to 400 mm and incorporating an internal flame-guiding cone, the design achieved a significant improvement in combustion efficiency, with a measured thermal efficiency of 25%. The system operated at 605 L/h of biogas, achieving a rapid warm-up time of just three minutes and an average baking time of four minutes per injera. The conical geometry enhanced flame velocity and centralized heat delivery, although scalability for larger households or institutional settings remained a concern [

Figure 6].

Collectively, these research efforts represent a trajectory of progressive refinement, moving from rudimentary steel-ring designs to analytically informed, field-validated prototypes. The integration of modeling, thermal insulation, geometric adaptation, and user-centered field trials has shaped the current understanding of how biogas injera stoves can achieve both thermal and operational efficiency. However, the need for standardized performance testing, environmental adaptability, and cost-effective scalability remains critical to widespread adoption.

3. Recent Innovations and Performance Enhancements in Biogas-Fueled Injera Baking Stoves

In response to the growing demand for cleaner cooking technologies in Ethiopia, research into biogas-fueled injera baking stoves has undergone significant development, transitioning from basic experimental models to more advanced, performance-optimized systems. Several key innovations integrate empirical testing, material enhancements, and improvements in burner design, aiming to balance both energy efficiency and culinary quality.

One notable advancement in stove design work and development of a full-scale biogas injera stove incorporating an optimized burner manifold and a thermally efficient clay mitad was conducted [

21]. The system was designed with a 260 mm manifold, equipped with evenly distributed flame ports, which were modeled using computational fluid dynamics [CFD] simulations from previous studies[

21]. The aim of this design was to provide uniform heat distribution across a 540 mm mitad, aligning with the standard size used in commercial kitchens and cooperative centers. A field implementation of the system at Jimma Degitu Hotel utilized biogas sourced from an 8.5 m³ household digester, which had a retention time of 45 days, offering sufficient gas for continuous stove operation. Although the study primarily focused on qualitative performance indicators, such as heat distribution, user satisfaction, and operational stability, it demonstrated several practical benefits. These included faster warm-up times of approximately 4 minutes, lower gas consumption per injera, and uniform browning with consistent texture. Despite these promising outcomes, quantitative metrics such as thermal efficiency and gas utilization rates were not explicitly measured, which limits the ability to make broader comparisons to other stove models. Nonetheless, this research provided important insights into integrating both structural and thermodynamic design elements in a field-tested biogas stove. While many designs for biogas injera stoves have concentrated on household use, Getu Alemayehu [2012] focused on scalability, developing a stove suitable for community-level implementation. Alemayehu’s design featured a circular triple-ring flame port configuration and a 530 mm mitad, operating at a flow rate of 0.93 m³/h. The stove was piloted across five households under semi-controlled conditions. A key aspect of this design was its attention to social compatibility, which is essential for successful adoption in rural areas. Alemayehu’s findings highlighted several strengths, such as the stove's ability to support sequential baking for family-sized needs and the manageable maintenance requirements, which could be handled with basic training. However, technical evaluations revealed some shortcomings, including low flame temperature near the stove’s periphery, which resulted in uneven injera edges, and long preheating times compared to traditional wood or electric mitad. Additionally, inconsistent gas pressure regulation led to suboptimal combustion. These challenges underscored the gap between design intent and actual thermal performance, signaling the need for further refinements in burner control and manifold adjustments to enhance the stove’s functionality for community-scale adoption.

Another significant development was introduced a conical burner design aimed at improving flame directionality and focus[

22]. Unlike traditional flat or ring-shaped burners, this innovation featured an inner conical insert that compressed and directed the flame toward the center of the mitad. This design improved flame intensity and velocity in the central region, allowing for faster preheating times—reduced to just 3 minutes—and average baking times of approximately 4 minutes per injera. The stove, designed for smaller households, operated at 605 L/h of biogas and achieved a thermal efficiency of 25%, among the highest recorded in biogas stove literature. However, the conical structure posed fabrication challenges, requiring precision-cut sheet metal and a fixed mounting system to prevent warping under high heat. Despite these fabrication issues, the design significantly improved the quality of the baked injera, particularly in terms of uniformity of texture and visual appearance.

In addition to these design innovations, recent research has also focused on refining the geometry and layout of the burner ports. Studies have shown that smaller port diameters [approximately 1.5–2.0 mm] can increase gas velocity while reducing backpressure. Uniform spacing of the flame ports ensures symmetrical heat distribution, while slightly raised ports [2–4 mm] help reduce soot accumulation. Research by Mulugeta et al. [2017] and Nega et al. [2021] demonstrated that uneven or clustered port distribution can lead to thermal hotspots, which negatively impact the quality of the injera and reduce overall fuel efficiency. Consequently, modern designs are increasingly incorporating laser-cut or CNC-drilled burners to achieve precise and standardized port geometries, thus optimizing thermal performance.

Material innovation has also contributed significantly to performance improvements. Traditional mitad griddles were often uninsulated or made from low-thermal-mass clay, which led to rapid heat loss during cooking. Recent stove designs have incorporated multi-layered composites to address this issue. These composites typically consist of a high-density clay inner layer with alumina additives for thermal mass, a middle layer of perlite or rice husk ash for insulation, and an outer structural clay layer reinforced with wire mesh. This multi-layer design has been shown to reduce heat loss by up to 35%, according to comparative field trials [

20]. Furthermore, the inclusion of materials such as expandable vermiculite or kaolin has improved the durability of the stoves by enhancing crack resistance under cyclic thermal loading—an essential feature for stoves used in rural environments where durability is a major concern.

The last decade of research has thus seen substantial advancements in biogas injera stove design. While earlier efforts primarily focused on flame containment and matching combustion pressure to fuel input, more recent innovations integrate both structural and material improvements to enhance performance on multiple fronts. These advancements have led to notable outcomes, including efficiency gains from less than 20% to approximately 25%, reductions in baking time from 7–10 minutes to around 4 minutes, and improved injera quality in terms of consistent browning and edge cooking[

8] .Moreover, there is an increasing emphasis on ensuring that designs are scalable for community-level adoption, taking into account both technical feasibility and social acceptability. However, the absence of standardized test procedures and universally accepted performance metrics remains a barrier to the widespread adoption of these improved stoves, and continued efforts are needed to address these challenges. Despite these limitations, the ongoing development of biogas-fueled injera stoves represents a promising step toward more sustainable cooking technologies that can reduce fuel consumption, enhance cooking efficiency, and support environmental conservation in Ethiopia

.

4. Performance Metrics and Design Considerations

Evaluating the performance of biogas injera baking stoves necessitates a comprehensive approach that integrates thermal, structural, and user-centered metrics [

Table 1]. Various studies have attempted to characterize stove performance using differing methodologies, flow rates, and validation techniques, often making cross-comparison difficult due to the absence of standardized protocols. For instance, Dereje [1996] experimentally reported a thermal efficiency of only 16% using a three-ring manifold and a flow rate of 41 L/min, whereas Chala [2019], employing an adjustable conical burner and a mitad size of 400 mm with a biogas flow rate of 605 L/h, achieved a higher efficiency of 25% under experimental conditions. Mulugeta et al. [2017] used computational fluid dynamics [CFD] to simulate burner performance with a 26 cm manifold diameter, though without field validation, while Nega et al. [2021] conducted a field test with a 540 mm mitad and a stove supplied by an 8.5 m³ biogas plant, albeit without reporting efficiency values. Alemayehu [2012] tested a circular ring burner stove with a 530 mm mitad across five households using a flow rate of 0.93 m³/h, but similarly did not quantify efficiency.

Thermal efficiency remains the most commonly cited performance indicator; however, reproducibility is limited due to non-uniform testing conditions and lack of consensus on evaluation criteria. Additionally, critical performance parameters such as baking time, preheat duration, and injera quality—particularly texture consistency, doneness, and edge completeness—are often reported subjectively or anecdotally, rather than through systematic or quantitative measurement.

Several design elements critically affect stove performance. Burner geometry directly influences flame shape, heat flux distribution, and combustion efficiency, while manifold pressure and flow control mechanisms determine the stability and consistency of flame jets. The thermal conductivity and structural integrity of the mitad, particularly the choice of insulation materials, significantly impact heat retention, baking uniformity, and fuel consumption. User-centric features, including the ergonomic design of the stove interface, ease of ignition, and maintenance accessibility, also play a pivotal role in long-term adoption, safety, and usability—especially in rural settings where technical support is limited. Despite these multifactorial considerations, the lack of a universal testing standard, such as ISO/IWA Tier indicators used for other types of cookstoves, continues to hinder comparative evaluations and technological advancement. Developing harmonized, context-specific evaluation frameworks for biogas injera stoves would greatly enhance the reliability of performance assessments, support evidence-based design improvements, and enable effective policy formulation and certification schemes.

Performance analysis of biogas injera baking stoves requires multidimensional metrics that capture thermal, structural, and user-centered criteria. This section compares key designs using quantitative and qualitative indicators.

5. Technical Challenges and Research Gaps

The development of biogas-powered injera stoves has shown significant promise in improving cooking efficiency and sustainability, but several technical challenges and research gaps remain. These challenges hinder the widespread adoption and optimal performance of biogas stoves, necessitating further investigation and innovative solutions. This chapter highlights key technical issues and identifies areas where research is needed to advance biogas stove technology.

One of the most significant challenges faced by biogas injera stoves is the mismatch between the biogas pressure provided by rural digesters [typically below 50mbar] and the energy demands of large-diameter mitads, often 50mbar or larger. Insufficient biogas pressure results in weak flame jets that cause uneven heat distribution, leading to cold spots and longer baking times. While pressure regulators and compensating valves can help alleviate this issue, few stove designs are fully adaptive to the local pressure fluctuations of biogas systems. Emphasize on the need for pressure-stabilized burner manifolds tailored to the characteristics of local biogas production capabilities[

21,

22]. A more thorough investigation into burner designs that can accommodate variable pressure is crucial for optimizing the performance of these stoves.

Achieving uniform heat distribution across the mitad surface remains another persistent challenge. Central overheating and peripheral underheating result from poor flame geometry, inadequate port distribution, and lack of reflective insulation[

21,

23,

24]. Although computational fluid dynamics [CFD]-based studies have simulated more uniform heat profiles, these models have not been extensively validated in real-world field conditions[

20]. The discrepancy between simulation and real-world performance calls for more experimental validation to ensure that design solutions can achieve their intended outcomes.

Thermal efficiency and fuel consumption are additional areas of concern. Many biogas injera stoves operate at thermal efficiencies below 30%, with high specific gas consumption [greater than 150 L per injera][

22,

25]. This inefficiency is significantly higher than that of electric stoves or advanced biomass cookstoves. Several factors contribute to this inefficiency, including heat loss to the environment due to inadequate insulation, excess air entrainment leading to incomplete combustion, and suboptimal burner-to-mitad spacing[

18,

26,

27]. These issues collectively reduce the cost-effectiveness of biogas utilization and limit the environmental benefits of the technology. Further research into optimizing stove efficiency through improved insulation, combustion control, and burner design is essential for reducing both fuel consumption and environmental impact.

In addition to thermal inefficiency, the limited experimental validation of simulation-based designs remains a critical gap. While computational tools such as CFD and finite element analysis have been increasingly used to design efficient burners and manifolds [

20], many promising designs have not undergone thorough lab or field validation. This lack of empirical testing leaves theoretical designs unproven, with uncertainties surrounding their scalability and real-world performance. Bridging this gap requires cross-disciplinary collaboration between design engineers, combustion scientists, and field practitioners to ensure that simulation-based solutions are tested and optimized in practical, real-world environments.

Another critical challenge is the lack of standardized insulation materials for biogas stoves. Traditional clay mitads often have high thermal conductivity and poor resistance to cracking under cyclic heating, leading to heat loss and reduced stove longevity. Recent efforts to incorporate alternative materials such as rice husk ash, vermiculite, and ceramic fibers [

21] have shown some promise, but a standardized, universally effective insulation solution has yet to be developed. Furthermore, few studies have examined how different insulation materials impact the quality of the baked injera, particularly in terms of texture, thickness, and moisture content. These factors are essential for consumer acceptance and should be prioritized in future material studies.

Environmental variability, particularly Ethiopia's diverse altitudes and climates, also poses a significant challenge. The performance of biogas stoves can vary greatly depending on local conditions such as altitude, humidity, and temperature. Current stove designs are often not adapted to these environmental variations, which can affect flame behavior, combustion rates, and insulation performance. There is a need for more research into altitude-sensitive burner configurations and humidity-tolerant insulation materials to ensure that biogas stoves can perform optimally across Ethiopia's diverse regions[

11].

The absence of standardized testing protocols for biogas injera stoves is another significant barrier to progress. Most studies rely on inconsistent or bespoke performance metrics, which makes cross-study comparisons unreliable. There is currently no ISO-compliant framework for evaluating biogas cookstoves, making it difficult to establish a benchmark for performance[

19]. Incorporating internationally recognized standards, such as ISO/IWA Tier indicators for cookstoves [thermal efficiency, indoor emissions, durability], would provide a reliable framework for evaluating and certifying stoves, facilitating their adoption and scaling as shown in

Table 2 below.

Finally, non-technical factors such as user training and stove usability also play a significant role in the success or failure of biogas stove adoption[

28]. Improper use, lack of maintenance knowledge, and low perceived benefits often lead to stove abandonment. Few studies have incorporated user-centered design approaches, behavior studies, or ergonomic assessments to ensure that stove designs are aligned with cultural practices and are easy to operate and maintain. A techno-social approach that integrates both technical and social considerations is essential for the successful adoption of biogas stoves, particularly in rural communities where these stoves are most needed[

7,

29].

In conclusion, while significant progress has been made in the development of biogas-powered injera stoves, several technical challenges and research gaps remain. These challenges include the mismatch between biogas pressure and stove size, inconsistent heat distribution, low thermal efficiency, limited experimental validation, and the absence of standardized insulation materials. Furthermore, environmental variability and the lack of standardized testing protocols hinder the ability to scale these technologies effectively. Addressing these issues will require a concerted effort from researchers, engineers, and practitioners, with a focus on integrating computational analysis, field validation, material innovation, and socio-cultural considerations into stove design.

6. Future Research Directions

Addressing the challenges identified in the previous chapter requires a multi-faceted research approach that integrates thermodynamic modeling, material science, user-centered design, and policy alignment. The following high-priority research directions are essential for advancing the development of biogas injera stoves and overcoming the existing barriers.

Development of Pressure-Adaptive Burner Designs

One of the primary obstacles in biogas stove performance is the mismatch between the low and fluctuating pressures of rural biogas digesters and the energy requirements of larger stoves. Future research should focus on designing stoves that can accommodate these variable pressures. Key areas of investigation include modeling the flame characteristics of low-pressure jets, integrating dynamic flow regulators to maintain stable combustion, and testing nozzle geometries that enhance mixing and flame stability. Variable-orifice burner designs, which adjust to changes in gas pressure, could offer an adaptive solution to inconsistent biogas production.

Optimization of Heat Transfer and Mitad Compatibility

Achieving uniform heat distribution across the surface of the mitad is critical for improving cooking efficiency and injera quality[

20,

24,

26]. Experimental studies should investigate how to better match burner output with the thermal properties of the mitad material and size. Techniques such as infrared thermography and finite difference modeling could be employed to identify cold zones and optimize flame port layouts. Hybrid heat transfer enhancement methods, such as concentric ring burners combined with radiant reflectors, offer potential solutions for improving heat uniformity across the cooking surface.

Exploration of Advanced Insulation Materials Insulation plays a crucial role in enhancing stove efficiency by reducing heat loss. Further research into lightweight, low conductivity materials that can withstand thermal cycling without compromising injera quality is necessary. Aerated ceramics, geopolymer composites, and nanomaterial-based coatings are promising alternatives[

30].

The performance of these materials should be evaluated in terms of heat retention, cost-effectiveness, and food safety, ensuring that they meet the needs of both efficiency and quality.

Validation of CFD-Based Designs Through Field Trials

While computational fluid dynamics [CFD] studies have shown great potential in optimizing burner designs, physical prototyping and field trials are essential to validate these designs under real-world conditions. Future research should integrate CFD with Design of Experiments [DoE] methods to streamline the optimization of parameters such as flame shape, burner geometry, and fuel-to-air ratio. Field trials should focus on evaluating stove performance in terms of efficiency, flame shape, user feedback, and the texture, doneness, and palatability of the injera.

Development of Hybrid Energy Systems

Biogas supply can be unreliable, particularly in rural areas with fluctuating gas yields. Exploring hybrid energy systems, such as combining biogas with solar thermal concentrators, could help mitigate gas shortages and enhance stove performance during low gas yield periods. Additionally, solar-assisted preheating or electric ignition systems may improve user convenience and increase the energy resilience of the stove, making it more versatile and reliable for everyday use. Adaptation for Diverse Environmental Conditions. Ethiopia’s diverse geographic conditions, ranging from highland to lowland areas, significantly influence biogas stove performance[

31,

32]. Burner designs need to be adaptable to these environmental variations, particularly the sensitivity of the air-fuel mixture to altitude and humidity. Researchers should conduct controlled lab simulations to understand how different temperature and pressure conditions affect combustion rates and flame behavior. This will inform the development of stove variants tailored to specific regions and environmental conditions. User-Centered Design and Socio Technical Integration. To increase adoption and ensure the long-term success of biogas stoves, it is crucial to understand user behavior, cultural preferences, and local practices. Research in user-centered design, particularly participatory design frameworks, can help improve stove ergonomics, safety, and cooking outcomes. Furthermore, integrating training modules and visual manuals tailored for low-literacy users will ensure that stoves are used efficiently and properly maintained. These studies should also consider gender roles and the division of labor in cooking tasks to ensure the technology is culturally acceptable and beneficial.

Standardization and Certification Protocols.

There is a significant need for standardized testing protocols for biogas stoves in Ethiopia, aligned with international standards such as ISO/IWA Tier indicators for cookstoves. Collaborative efforts between academic institutions, governmental bodies [e.g., the Ministry of Water and Energy], and NGOs could facilitate the establishment of testing and certification pathways, ensuring that biogas stoves meet established benchmarks for thermal efficiency, emissions, and durability. Standardization would also enable better cross-study comparisons and support the scaling up of successful stove models[

13,

16].

Life-Cycle Assessment and Economic Feasibility Analysis

To assess the long-term viability of biogas injera stoves, comprehensive life-cycle assessments [LCA] and techno-economic evaluations are essential. These assessments should consider factors such as feedstock availability, stove lifespan, maintenance costs, and the potential for carbon offsetting[

33]. Furthermore, economic feasibility analysis should incorporate subsidy models and micro-finance solutions to make these stoves affordable and accessible to low-income households. Understanding the cost-benefit ratio and environmental impact of biogas stoves will support decision-making for policy development and large-scale implementation[

29].

Author Contribution

Taha Abdella [PhD Candidate]: Developed article organization and Writing

Data Availability

authors declare that the data supporting the findings of this study are available within the paper.

Competing interest

The authors declare no competing interest in carrying out this study

References

- Amtataw, M.; Kassahun, E.; Tibebu, S.; Andargie, T.; Ayanaw, T.; Agazie, A.; et al. Nutritional and anti-nutritional evaluation of injera made from Sorghum, Rice, Teff, and Flaxseed flours using D-optimal mixture design. Sci Rep. 2025, 15, 3959. [Google Scholar] [CrossRef] [PubMed]

- Awulachew, M.T.; Kuffi, K.D. Improving the Quality of Injera by Optimizing the Mixing Proportion of Fenugreek, Sorghum and Teff Flour. 2024. [Google Scholar]

- Beyene, A.D.; Koch, S.F. Clean fuel-saving technology adoption in urban Ethiopia. Energy Economics 2013, 36, 605–613. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0140988312002770. [CrossRef]

- Manaye, A.; Amaha, S.; Gufi, Y.; Tesfamariam, B.; Worku, A.; Abrha, H. Fuelwood use and carbon emission reduction of improved biomass cookstoves: evidence from kitchen performance tests in Tigray, Ethiopia. Energ Sustain Soc. 2022, 12, 28. [Google Scholar] [CrossRef]

- Desta, G.A.; Melka, Y.; Sime, G.; Yirga, F.; Marie, M.; Haile, M. Biogas technology in fuelwood saving and carbon emission reduction in southern Ethiopia. Heliyon. 2020, 6, e04791. [Google Scholar] [CrossRef]

- Fagerström, A. The role of anaerobic digestion and biogas in the circular economy. Murphy JD, editor. Dublin: IEA Bioenergy; 2018.

- Addis Alemayehu, Y. Status and Benefits of Renewable Energy Technologies in the Rural Areas of Ethiopia: A Case Study on Improved Cooking Stoves and Biogas Technologies. Int J Renew Energy Dev. 2015, 4, 103–111. [Google Scholar] [CrossRef]

- Bilhate Leta Chala. National Survey on Current Status of Institutional Biogas Systems Installed in Ethiopia. Unpublished; 2009 [cited 2025 Mar 25]. [CrossRef]

- Abdella, T. Experimental Investigation of Biogas Injera Baking Stove Using Circular Ring Pipe Burner. In Review; 2023. Available online: https://www.researchsquare.com/article/rs-3558204/v1 (accessed on 22 April 2025).

- Ashagrie, Z. Improvement of injera shelf life through the use of chemical preservatives. AJFAND. 2012, 12, 6409–6423. [Google Scholar] [CrossRef]

- Bikila, G.M.; Tola, Y.B.; Kuyu, C.G. Standardization of teff [ Eragrostis teff ] injera making process conditions for better physicochemical and sensory quality. Food Science & Nutrition. 2024, 12, 3417–3432. [Google Scholar]

- Lutfi, U.M.; Hendriani, R.; Nefri, J. Applicative Biogas Plant For Processing Cow Dung In The Small Scale Livestock Farming. 2021. [Google Scholar]

- Berhe, M.; Hoag, D.; Tesfay, G.; Keske, C. Factors influencing the adoption of biogas digesters in rural Ethiopia. Energ Sustain Soc. 2017, 7, 10. [Google Scholar] [CrossRef]

- Kebede, D.; Kiflu, A. Design of Biogas Stove for Injera Baking Application. 2014. [Google Scholar]

- Abdella, T. Experimental Investigation of Biogas Injera Baking Stove Using Circular Ring Pipe Burner. In Review; 2023 [cited 2025 Mar 25]. Available online: https://www.researchsquare.com/article/rs-3558204/v1 (accessed on 25 March 2025).

- Tesfay, A.H.; Tsegay, K.; Kahsay, M.B.; Hailu, M.H.; Adaramola, M.S. Performance comparison of three prototype biomass stoves with traditional and Mirt stoves for baking Injera. Energ Sustain Soc. 2024, 14, 11. [Google Scholar] [CrossRef]

- Tadesse, M. The Developmental Patterns of Injera Baking Stoves: Review on the Efficiency, and Energy Consumption in Ethiopia. SSRG-IJME. 2020, 7, 7–16. [Google Scholar] [CrossRef]

- Chandra, A.; Tiwari, G.N.; Srivastava, V.K.; Yadav, Y.P. Performance evaluation of biogas burners. Energy Conversion and Management. 1991, 32, 353–358. [Google Scholar] [CrossRef]

- K.C.Khandelwal & Vibha k. Popular Summary of the Test Report on Biogas Stoves and Lamps. SNV; 2009 p. 48.

- Nega, D.T.; Mulugeta, B.; Demissie, S.W. Design, Optimization and CFD Simulation of Improved Biogas Burner for “Injera” Baking in Ethiopia. International Journal of Engineering Research 6.

- Nega, D.T.; Mulugeta Yirgu, B.; Demissie, S.W. Improved biogas ‘Injera’ bakery stove design, assemble and its baking pan floor temperature distribution test. Energy for Sustainable Development 2021, 61, 65–73. Available online: https://linkinghub.elsevier.com/retrieve/pii/S097308262100003X. [CrossRef]

- Bilhate Leta Chala. Energy efficient injera baking with biogas in Ethiopia. German: HOHENHEIM; 2019.

- Sisay, A.K.; Shiferaw Kebede, M.; Chanie, A.M. Development of an enhanced electrical injera baking pan [Ethiopian Traditional mitad] using steel powder additives and gypsum insulation. Heliyon. 2024, 10, e38952. [Google Scholar] [CrossRef]

- Banooni, S.; Hosseinalipour, S.M.; Mujumdar, A.S.; Taheran, E.; Bahiraei, M.; Taherkhani, P. Baking of Flat Bread in an Impingement Oven: An Experimental Study of Heat Transfer and Quality Aspects. Drying Technology. 2008, 26, 902–909. [Google Scholar] [CrossRef]

- Tucho, G.; Moll, H.; Schoot Uiterkamp, A.; Nonhebel, S. Problems with Biogas Implementation in Developing Countries from the Perspective of Labor Requirements. Energies. 2016, 9, 750. [Google Scholar] [CrossRef]

- Rismaya, R.; Syamsir, E.; Nurtama, B.; Tohyeng, N. The effects of water addition and baking time on process optimization of pumpkin muffins: a pilot plant scale study. Canrea 2022, 183–207. Available online: http://agritech.unhas.ac.id/ojs/index.php/canrea/article/view/711. [CrossRef]

- Chaouki Ghenai Isam Janajreh Combustion of Renewable Biogas Fuels, J.E.P.E. 2015, 9[10]. Available online: http://www.davidpublisher.org/index.php/Home/Article/index?id=19269.html.

- Berhe, M.; Hoag, D.; Tesfay, G.; Keske, C. Factors influencing the adoption of biogas digesters in rural Ethiopia. Energ Sustain Soc. 2017, 7, 10. [Google Scholar] [CrossRef]

- Novak Pintarič, Z.; Kravanja, Z. The Importance of using Discounted Cash Flow Methodology in Techno-economic Analyses of Energy and Chemical Production Plants. J sustain dev energy water environ syst. 2017, 5, 163–176. [Google Scholar] [CrossRef]

- Wondimagegn, G.H.; Ahmed, K.; Edao, S.A. Developing and Performance Evaluation of Metal Sand Pan stove for Baking. IIJSR. 2023, 07, 53–63. [Google Scholar] [CrossRef]

- Tucho, G.; Moll, H.; Schoot Uiterkamp, A.; Nonhebel, S. Problems with Biogas Implementation in Developing Countries from the Perspective of Labor Requirements. Energies. 2016, 9, 750. [Google Scholar] [CrossRef]

- Getaneh, A.; Eba, K.; Tucho, G.T. Assessment of Biomass Energy Potential for Biogas Technology Adoption and Its Determinant Factors in Rural District of Limmu Kossa, Jimma, Ethiopia. Energies. 2024, 17, 2176. [Google Scholar] [CrossRef]

- Geddafa, T.; Melka, Y.; Sime, G. Cost-benefit Analysis and Financial Viability of Household Biogas Plant Investment in South Ethiopia. Sustainable Energy res. 2023, 10, 20. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).