Submitted:

07 January 2025

Posted:

08 January 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

- Overdue/delayed contractor payments: clients should not begin any project without sufficient cash, plan projects based on existing financial resources, and factor in contingency provisions when developing project budgets.

- Incomplete design at the time of tender: Clients should retain a professional and qualified consultant to develop tender and contract documentation, including a preliminary design rather than a concept design.

- Design errors: When choosing a consultant, clients should re-examine selection criteria, form a separate panel of design specialists, and include technology such as BIM into the project.

- Cost underestimation: Contractors can improve their cost estimating procedures by using worldwide standard norms when creating BOQs, such as NRM.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- African Development Bank. Study on Road Infrastructure Costs: Analysis of Unit Cost and Cost Overruns of Road Infrastructure Projects in Africa; AFDB: Abidjan, 2014. [Google Scholar]

- Ahmada, Z., Anigbogub, N. and Molwusb, J. Conceptual Framework for Minimizing Road Projects’ Cost Overruns. Journal of Applied Sciences & Environmental Sustainability 2019, 11(5), 49–62. [Google Scholar]

- Akinsiku, O. and Ajay, O. The Effects of Delayed Payment of Contractors on Construction Project Delivery in Nigeria. ‘The Construction, Building and Real Estate Research Conference of the Royal Institution of Chartered Surveyors’, Toronto, 20- 22 September 2016; RICS: London, 22 September 2016. [Google Scholar]

- Belachew, A., Mengesha, W. and Mohammed, M. Causes of Cost Overrun in Federal Road Projects of Ethiopia in Case of Southern District. American Journal of Civil Engineering (AJCE) 2017, 5(1), 27–40. [Google Scholar] [CrossRef]

- Al Amri, T. and Marey-Pérez, M. Impact of Covid-19 On Oman’s Construction Industry. Technium Social Sciences Journal 2020, 9, 661–670. [Google Scholar] [CrossRef]

- Safinia, S., Al-Hinai, Z., Yahia, H. A.,; Abushammala, M. F. Sustainable construction in sultanate of Oman: Factors effecting materials utilization. Procedia engineering 2017, 196, 980–987. [Google Scholar] [CrossRef]

- Shahi, K. Evaluation of Current Construction Permitting Process in City of Toronto and Future of Permitting in the Global Construction Industry. Unpublished dissertation, University of Toronto, Toronto, 2018. [Google Scholar]

- Cotton, M. and Mahroos-Alsaiari, A. Key Actor Perspectives on Stakeholder Engagement in Omani Environmental Impact Assessment: An Application Of Q- Methodology. Journal of Environmental Planning and Management 2014, 58(1), 91–112. [Google Scholar]

- AlHosani, I. and Venkatachalam, S. Identification of Factors Affecting Cost Overruns in UAE’s Road Projects. UAE Graduate Students Research Conference (GSRC), UAE University, 27-28 April 2016; UAEU: Al Ain, 28 April 2016. [Google Scholar]

- Aljohani, A., Ahiaga-Dagbui, D. and Moore, D. Construction Projects Cost Overrun: What Does the Literature Tell Us? International Journal of Innovation, Management and Technology 2017, 8(2), 137–143. [Google Scholar]

- Alzebdeh, K., Bashirb, H. and Al Siyabic, S. Applying Interpretive Structural Modeling to Cost Overruns in Construction Projects in The Sultanate of Oman. The Journal of Engineering Research 2015, 12(1), 53–68. [Google Scholar]

- Ahady, S., Gupta, S. and Malik, K. A Critical Review of Causes of Cost Overrun in Construction Industries in Developing Countries. International Research Journal of Engineering and Technology 2017, 4(3), 2550–2558. [Google Scholar]

- Ahmad, Z., Anigbogu, N. and Molwus, J. Peculiarities of Road Projects’ Cost Overruns. International Journal of Scientific & Engineering Research 2018, 9(6), 121–124. [Google Scholar]

- Amoa-Abban, K. and Allotey, S. Cost Overruns in Building Construction Projects: A Case Study of a Government of Ghana Project in Accra. Journal of Developing Country Studies 2014, 4(24), 54–64. [Google Scholar]

- Barnham, C. Quantitative and Qualitative Research: Perceptual Foundations. International Journal of Market Research 2015, 57(6), 837–854. [Google Scholar] [CrossRef]

- Berger, R. Now I See It, Now I Don’t: Researcher’s Position and Reflexivity in Qualitative Research. Qualitative Research 2015, 15(2), 219–234. [Google Scholar] [CrossRef]

- Al-Yousfi, W. M., Yahia, H. A.,; Kishore, R. Instigating Smart City Infrastructure in Oman: Considering Social Benefits and Economic Values. Journal of Student Research 2019. [Google Scholar]

- Sohu, S., Abdullah, A., Nagapan, S., Rind, T. and Jhatial, A. Controlling Measures for Causes of Cost Overrun in Highway Projects of Sindh Province. Engineering, Technology & Applied Science Research 2019, 9(3), 4276–4280. [Google Scholar]

- Akinsiku, O. and Ajay, O. The Effects of Delayed Payment of Contractors on Construction Project Delivery in Nigeria. The Construction, Building and Real Estate Research Conference of the Royal Institution of Chartered Surveyors, Toronto, 20- 22 September 2016; RICS: London, 2016. [Google Scholar]

- Pinto, J. Lies, damned lies, and project plans: Recurring human errors that can ruin the project planning process. Business Horizon 2013, 56(5), 643–65. [Google Scholar] [CrossRef]

- Chan, A. and Oppong, G. Managing the Expectations of External Stakeholders in Construction Projects. Engineering, Construction and Architectural Management 2017, 24(5), 736–756. [Google Scholar] [CrossRef]

- Abusafiya, H. and Suliman, S. Causes and Effects of Cost Overrun on Construction Project in Bahrain: Part I (Ranking of Cost Overrun Factors and Risk Mapping). Modern Applied Science 2017, 11(7), 20–27. [Google Scholar] [CrossRef]

- Adugna, N. A Study of Causes of Delay and Cost Overrun in Office Construction Projects in the eThekwini Municipal Area, South Africa. Unpublished Master thesis, Durban University of Technology, Durban, 2015. [Google Scholar]

- Albalushi, I., Usman, F. and Alnuaimi, A. Construction Cost Overrun and Variations: Investigation on Its Causes and Consequences. Australian Journal of Basic and Applied Sciences 2013, 7(14), 311–323. [Google Scholar]

- Dattalo, P. Determining Sample Size: Balancing Power, Precision, and Practicality; Oxford University Press, Inc: New York, 2008. [Google Scholar]

- Goyal, A. An Analysis of Cost Overrun in the Construction Industry. Unpublished dissertation, Arizona State, Arizona, 2017. [Google Scholar]

- Haddadi, A., Hosseini, A., Johansen, A. and Olsson, N. Pursuing Value Creation in Construction by Research -A Study of Applied Research Methodologies. Procedia Computer Science 2017, 121, 1080–1087. [Google Scholar] [CrossRef]

- Hampson, A. and Perera, S. Contractual Procedures in The Construction Industry, 7th ed; Routledge: New York, 2018. [Google Scholar]

- Hartley, J. Concurrent Engineering: Shortening Lead Times, Raising Quality, and Lowering Costs; Routledge: New York, 2017. [Google Scholar]

- Kitchenham, B. and Pfleeger, S. Principles of Survey Research Part 5: Populations and Samples. Software Engineering Notes 2002, 27(5), 17–20. [Google Scholar] [CrossRef]

- Yahia, H. A., Al-Shukaili, A. M., Manchiryal, R. K., Eissa, T.,; Mohammed, A. A. Strategic Planning for the Development of Smart Cities in Oman. In The Emerald Handbook of Smart Cities in the Gulf Region: Innovation, Development, Transformation, and Prosperity for Vision 2040; Emerald Publishing Limited., 2024; pp. 289–304. [Google Scholar]

- Kothari, C. Research Methodology Methods and Techniques, 2nd ed; New Age International Pvt Ltd: New Delhi, 2004. [Google Scholar]

- Krejcie, R. and Morgan, D. Determining Sample Size for Research Activities. Educational and Psychological Measurement 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Banerjee, P.,; Yahia, H. A. Evaluation of Project Cost Management and Cost Trend Analysis. Engineering Research Transcripts 2023, 4, 59–66. [Google Scholar]

- Lee, J. Cost Overrun and Cause in Korean Social Overhead Capital Projects: Roads, Rails, Airports, And Ports. Journal of Urban Planning and Development 2008, 134(2), 59–62. [Google Scholar] [CrossRef]

- Lende, P. and Rathod, A. Study of Factors Affecting Cost Overrun in Road Construction Project. International Journal of Research in Engineering, Science and Management 2018, 1(8), 115–119. [Google Scholar]

- Levy, S. Project Management in Construction, Middle East Handbook 2019. Unpublished handbook. Dubai: Linesight, 7th ed; McGraw Hill Professional Linesight: Dubai, 2017. [Google Scholar]

- Lohr, S. Sampling: Design and Analysis, 2nd ed; Cengage Learning, Inc: Boston, 2009. [Google Scholar]

- Meduri, S. and Annamalai, T. Unit Costs of Public and PPP Road Projects: Evidence from India. Journal of Construction Engineering and Management 2013, 139(1), 35–43. [Google Scholar] [CrossRef]

- Petticrew, M. and Roberts, H. Systematic Reviews in the Social Sciences: A Practical Guide; Blackwell Publishing Ltd: Oxford, 2006. [Google Scholar]

- Al Sulaimani, S. H. K.,; Yahia, H. Evaluating the impact of change orders on construction projects in Oman. Journal of Student Research 2021. [Google Scholar]

- Ke, Y., Ling, F. and Ning, Y. Public Construction Project Delivery Process in Singapore, Beijing, Hong Kong and Sydney. Journal of Financial Management of Property and Construction 2013, 18(1), 6–25. [Google Scholar] [CrossRef]

- Al-Harthi, F. M., Al Manwari, D. A.,; Yahia, H. A. Identification and assessment of risk factors affecting construction project in Oman. Journal of Student Research 2021. [Google Scholar]

- Al Adawi, O. S., Al Hina, S. S., Yahia, H. A.,; Manchiryal, R. K. Governmental Stakeholders Impact on Construction Projects in Oman. Journal of Student Research 2019. [Google Scholar]

- Sekaran, U. Research Methods for Business: A Skill Building Approach, 3rd ed; John Wiley & Sons Ltd: New York, 2000. [Google Scholar]

| Ages (% of Total) |

Total |

|||||

|---|---|---|---|---|---|---|

| Age and Gender | Under 25 years old | 25-35 years old |

36-46 years old |

47-57 years old |

Above 57 years old | |

| Male | 0.0% | 40.0% | 22.4% | 11.8% | 9.4% | 83.5% |

|

Female |

1.2% | 14.1% | 1.2% | 0.0% | 0.0% | 16.5% |

| Total | 1.2% | 54.1% | 23.5% | 11.8% | 9.4% | 100.0% |

| Ages (% of Total) |

Total |

|||||

|---|---|---|---|---|---|---|

| Age and Gender | Under 25 years old | 25-35 years old |

36-46 years old |

47-57 years old |

Above 57 years old | |

| Male | 0.0% | 40.0% | 22.4% | 11.8% | 9.4% | 83.5% |

|

Female |

1.2% | 14.1% | 1.2% | 0.0% | 0.0% | 16.5% |

| Total | 1.2% | 54.1% | 23.5% | 11.8% | 9.4% | 100.0% |

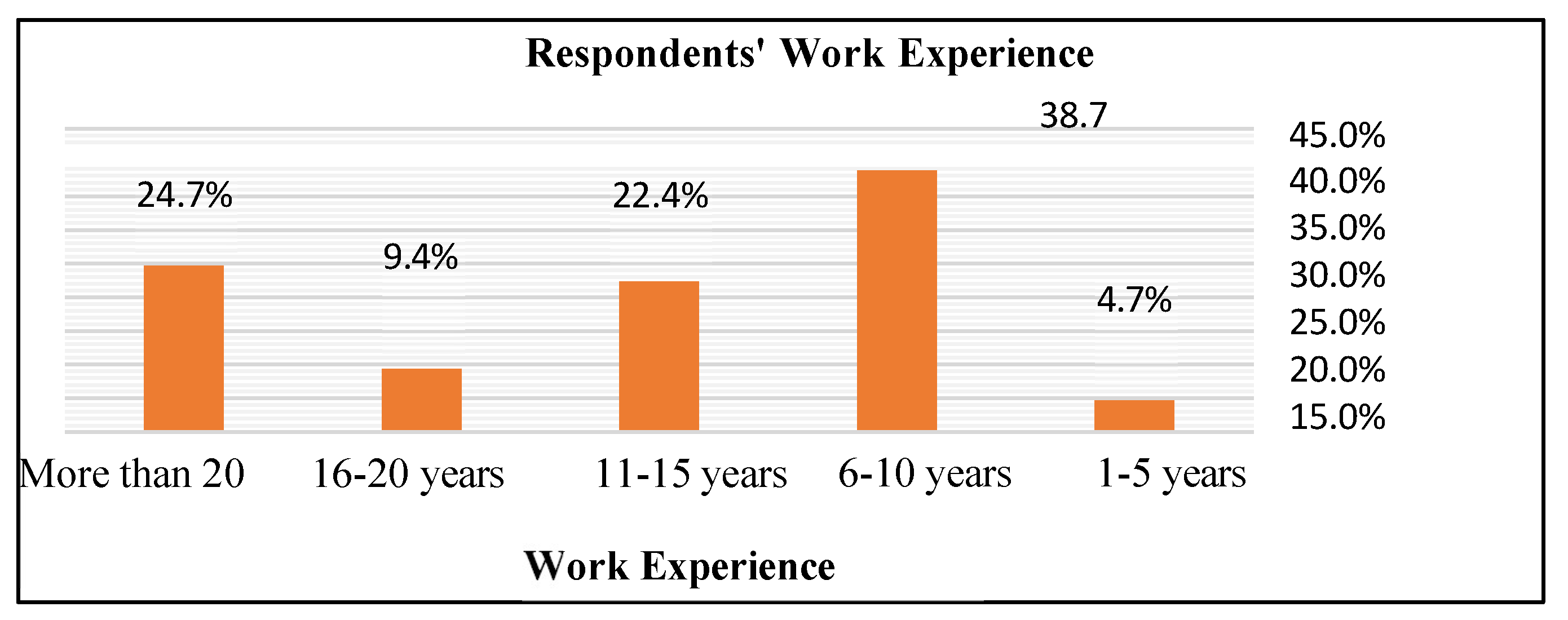

| Work Experience (% of Total) |

Total |

|||||

|---|---|---|---|---|---|---|

| Education | 1-5 years |

6-10 years |

11-15 years |

16-20 years |

> 20 years |

|

| PhD | 0.0% | 0.0% | 0.0% | 0.0% | 2.4% | 2.4% |

| Master | 0.0% | 5.9% | 8.2% | 2.4% | 8.2% | 24.7% |

| Bachelor | 4.7% | 29.4% | 12.9% | 7.1% | 12.9% | 67.1% |

| Diploma | 0.0% | 3.5% | 1.2% | 0.0% | 1.2% | 5.9% |

| Total | 4.7% | 38.8% | 22.4% | 9.4% | 24.7% | 100.0% |

| Group | Cost Overrun Causes | RII | Central Tendency | Rank | ||

|---|---|---|---|---|---|---|

| Mean | Median | Mode | ||||

| Client- Related | Contractors are not paid on time (overdue/delay payments) |

0.816 |

2.45 |

3.00 |

3.00 |

1 (1) |

| Design- Related |

Incomplete design at the time of tender |

0.780 | 2.34 | 3.00 | 3.00 | 2 (2) |

| Design- Related | Design errors | 0.780 | 2.34 | 2.00 | 3.00 | 2 (3) |

| Contractor- Related |

Cost underestimation | 0.776 | 2.33 | 3.00 | 3.00 | 3 (4) |

| Client- Related |

Funding difficulties | 0.769 | 2.31 | 2.00 | 3.00 | 4 (5) |

| Client- Related | Slow decision-making | 0.761 | 2.28 | 2.00 | 2.00 | 5 (6) |

| Contractor- Related |

Time underestimation | 0.761 | 2.28 | 2.00 | 3.00 | 5 (7) |

| Design- Related | Design changes due to faulty design during construction |

0.757 |

2.27 |

2.00 |

3.00 |

6 (8) |

| External Related |

Corona Virus COVID-19 | 0.757 | 2.27 | 3.00 | 3.00 | 6 (9) |

| Client- Related | Improper project planning | 0.753 | 2.26 | 2.00 | 2.00 | 7 (10) |

| Design- Related |

Uncontrolled design changes |

0.753 | 2.26 | 2.00 | 2.00 | 7 (11) |

| Client- Related | Time underestimation for completing the project | 0.749 | 2.25 | 2.00 | 2.00 | 8 (12) |

| Other Stakeholders- Related |

Slow decision-making by various project’s stakeholders |

0.741 |

2.22 |

2.00 |

2.00 |

9 (13) |

| External Related | Unforeseen soil and physical terrain conditions | 0.733 | 2.20 | 2.00 | 2.00 | 10 (14) |

| Design- Related |

Inadequate ground investigations |

0.729 | 2.19 | 2.00 | 2.00 | 11 (15) |

| Contractor- Related | Funding difficulties faced by contractors | 0.722 | 2.16 | 2.00 | 3.00 | 12 (16) |

| Client- Related |

Right of Way and land acquisition issues |

0.710 | 2.13 | 2.00 | 2.00 | 13 (17) |

| Other Stakeholders- Related | Late requests by various project’s stakeholders such as utilities and other concerned authorities |

0.710 |

2.13 |

2.00 |

2.00 |

13 (18) |

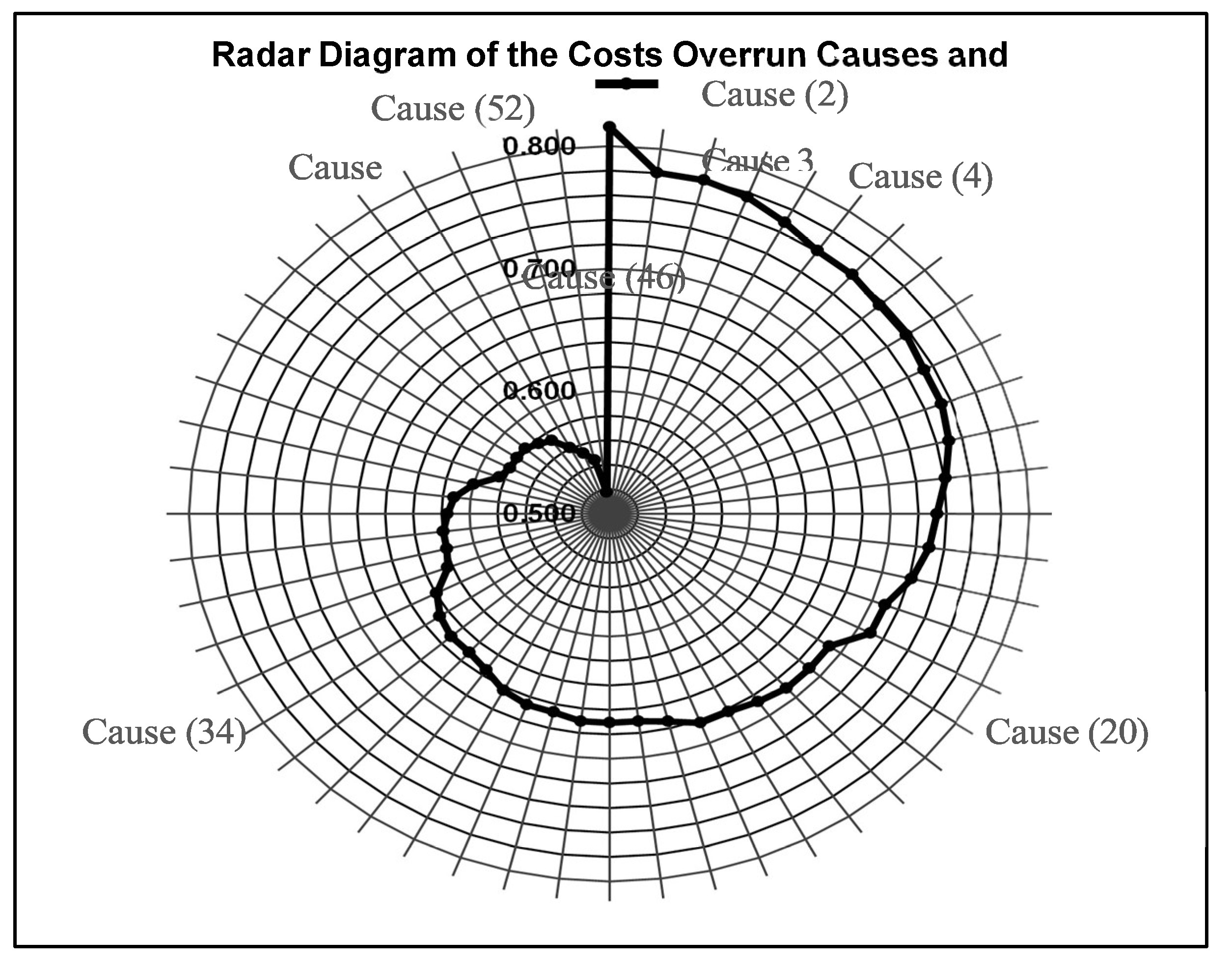

| RII Range | Impact Level | Causes within the Range | No. of Causes |

|---|---|---|---|

| >0.700 | Very High Impact (MostCritical) | Cause (1) to Cause (18) | 18 |

| 0.600-0.700 | Average to High Impact | Cause (19) to Cause (42) | 24 |

| <0.700 | Very Low to Low Impact | Cause (43) to Cause (52) | 10 |

| Group | Cost Overrun Causes | MV | Rank |

|---|---|---|---|

| Client-Related | Contractors are not paid on time (overdue/delay payments) | 2.447 | 1 (1) |

| Design-Related | Incomplete design at the time of tender | 2.341 | 2 (2) |

| Design-Related | Design errors | 2.341 | 2 (3) |

| Contractor-Related | Cost underestimation | 2.329 | 3 (4) |

| Client-Related | Funding difficulties | 2.306 | 4 (5) |

| Client-Related | Slow decision-making | 2.282 | 5 (6) |

| Contractor-Related | Time underestimation | 2.282 | 5 (7) |

| Design-Related | Design changes due to faulty design during construction | 2.271 | 6 (8) |

| External Related | Corona Virus COVID-19 | 2.271 | 6 (9) |

| Client-Related | Improper project planning | 2.259 | 7 (10) |

| Design-Related | Uncontrolled design changes | 2.259 | 7 (11) |

| Client-Related | Time underestimation for completing the project | 2.247 | 8 (12) |

| Other Stakeholders- Related |

Slow decision-making by various project’s stakeholders |

2.224 | 9 (13) |

| External Related | Unforeseen soil and physical terrain conditions | 2.200 | 10 (14) |

| Design-Related | Inadequate ground investigations | 2.188 | 11 (15) |

| Contractor-Related | Funding difficulties faced by contractors | 2.165 | 12 (16) |

| Client-Related | Right of Way and land acquisition issues | 2.129 | 13 (17) |

| Other Stakeholders- Related |

Late requests by various project’s stakeholders such as utilities and other concerned authorities |

2.129 | 13 (18) |

| Most Critical Causes of Costs Overrun in Roads’ Project of Oman | UAE | KSA | Jordan | Ethiopia | India | Pakistan | Nigeria | |

| Contractors are not paid on time (overdue/delay payments) | × | × | × | |||||

| Incomplete design at the time of tender |

||||||||

| Design errors | × | × | × | × | ||||

| Cost underestimation | × | × | ||||||

| Funding difficulties | × | |||||||

| Slow decision-making | × | × | ||||||

| Time underestimation | ||||||||

| Design changes due to faulty design during construction |

× | |||||||

| Corona Virus COVID-19 | ||||||||

| Improper project planning | × | |||||||

| Uncontrolled design changes |

× | × | ||||||

| Time underestimation for completing the project | × | × | × | |||||

| Slow decision-making by project’s stakeholders |

× | |||||||

| Unforeseen terrain conditions | × | |||||||

| Inadequate ground investigations |

||||||||

| Funding difficulties faced by contractors |

||||||||

| Right of Way and land acquisition issues | × | |||||||

| Late requests by project’s stakeholders | × | |||||||

| No. | Variables | Description and Equations | Ref. | Result |

|---|---|---|---|---|

| 1 | W | 12S m2 (n3 − n) |

Eq. (6) | NA |

|

2 |

S |

N Σ(Ri − R¯)2 i=1

|

Eq. (7) |

78941.9230 |

| 3 | n | Number of costs overrun causes | NA | 52 |

| 4 | m | Number of ranking parties | NA | 3 |

| 5 | Numerator | 12S | NA | 947303.076 |

| 6 | Denominator | m2(n3-n) | NA | 1265004 |

| 7 | ∴ W | Dividing row 5 and 6 to find (W) | NA | 0.74885381 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).