1. Introduction

Industrial robots are a key component of modern manufacturing systems, where high precision, robustness, and reliability are required in the presence of varying loads, mechanical interactions, and dynamic uncertainty [1,2,3]. The accuracy and robustness of industrial manipulators become critically important in the context of increasing automation, short production cycles, and the strict cyber-resilience requirements imposed by contemporary regulatory frameworks.

The dynamics of robotic manipulators depend on configuration, inertial parameters, and friction, which makes control highly sensitive to changes in the operating environment. These dependencies complicate the achievement of guaranteed stability and performance using classical control laws based on traditional linear methods [4]. In addition, the presence of noisy measurements and model uncertainty necessitates optimal and robust estimation of states and parameters [5]. The challenges become even more pronounced in industrial architectures based on PLC controllers, where scan-cycle frequency, communication delay, and network jitter directly affect control performance [6,7].

Quantitative feedback theory offers a systematic approach to robust control by formulating design requirements through frequency-domain bounds and plant templates that cover the admissible parameter variations [8,9,10]. The methodology is suitable for multi-axis robots whose dynamics vary with configuration. However, full dynamic decoupling through inverse dynamics requires accurate parameterization and significant computational resources, making it difficult to implement in real time in PLC-based systems [2,11]. This motivates the use of a partially decoupled approach in which the dominant nonlinearities are compensated, while the remaining cross-couplings are treated as structured uncertainty - an idea rooted in the classical works of Luh, Spong, and Vidyasagar [2,11] and later adapted to QFT by Boje [13]. A consolidated classification of digital twin approaches and trends in their development is presented in [14].

In parallel with advances in robust control methods, the digital twin has emerged as a key tool for virtual verification, simulation of extreme operating regimes, and risk analysis in industrial environments [15,16,17]. Platforms such as ROBOGUIDE enable detailed modelling of the kinematics and dynamics of industrial robots and support communication with real PLC controllers. Such PLC-in-the-loop digital architectures make it possible to evaluate real effects of communication delays, disturbances, and worst-case dynamic models without risk to physical equipment [18].

A further need for an integrated robust and cyber-resilient architecture arises from the NIS2 Directive, which imposes requirements on industrial operators for command traceability, access control, observability, and resilience during cyber incidents [19,20]. This transforms the PLC from a mere execution controller into a security gateway and necessitates architecture that simultaneously maintains high control accuracy and enhanced cyber-resilience.

1.1. Motivation

Despite the significant progress in robust control, Digital Twin technologies, and industrial automation, there is still a lack of an integrated framework that simultaneously applies QFT for controlling a multi-axis industrial robot with parametric uncertainty, validates the behavior through a realistic PLC-in-the-loop twin architecture, incorporates the NIS2 principles of observability, traceability, and resilience, and operates under real industrial communication and PLC cycle constraints.

Existing implementations of QFT in robotics often rely on highly simplified models and do not consider real network effects or PLC limitations [8,9,10]. Conversely, Digital Twin systems typically depend on standard PID or vendor-specific controllers and are rarely used for formal verification of robust control strategies [15,16,17]. Finally, most architectures oriented towards cyber-resilience and NIS2 focus on network security but do not include an analysis of the control algorithms themselves [19,20].

These gaps motivate the development of a Digital Twin with QFT & NIS2 Security framework that combines robust control, realistic virtual execution, and cyber-resilience aligned with industrial standards.

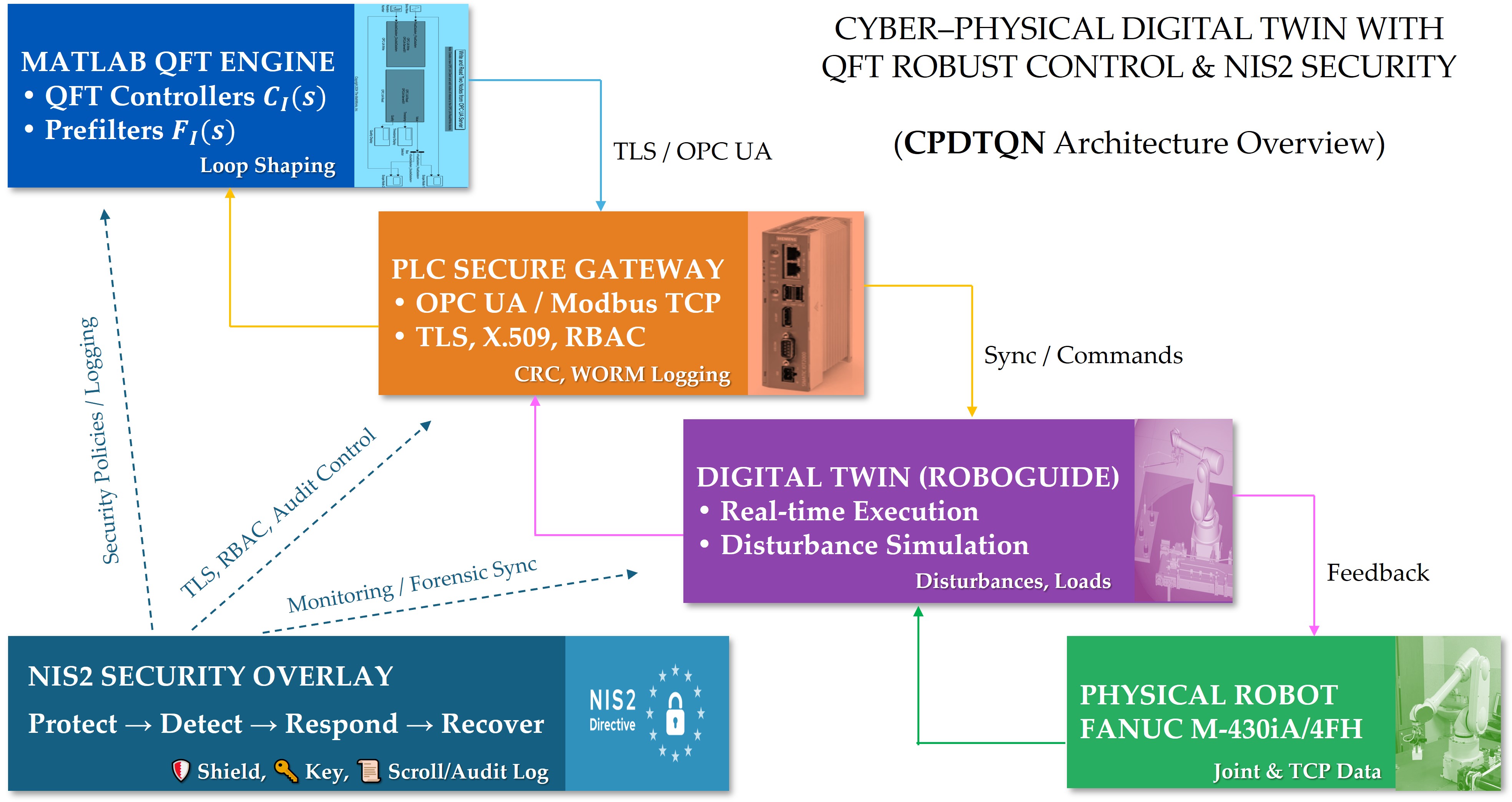

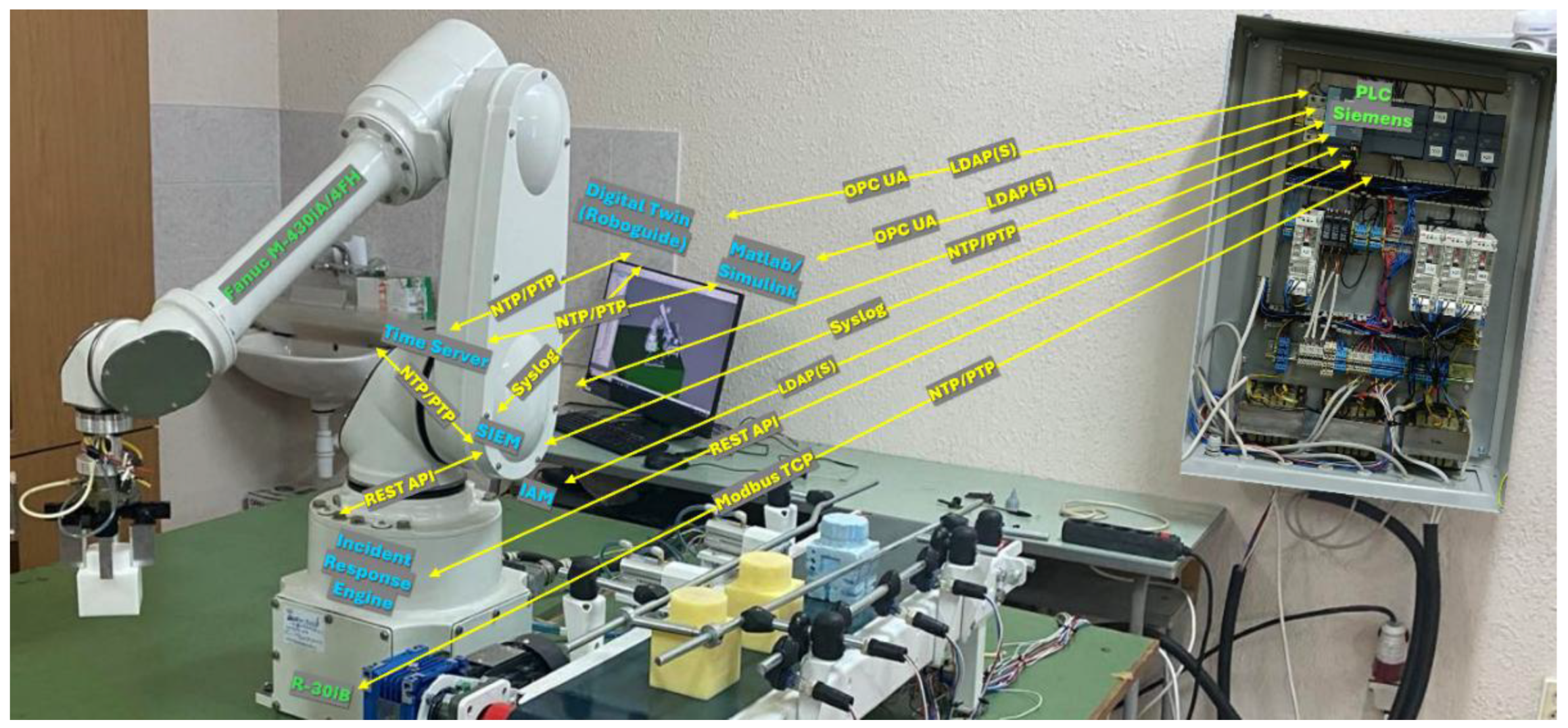

In this work, these requirements are addressed through an experimental platform - the Cyber-Physical Digital Twin with QFT & NIS2 Security CPDTQN, shown in

Figure 1 - which integrates an industrial robot, a Siemens PLC, and a digital twin in the ROBOGUIDE environment, interconnected through standard industrial protocols.

In

Figure 1, the green labels denote the physical devices (industrial robot, Siemens PLC, sensors and actuators), the blue labels denote the virtual services deployed on the industrial server (digital twin, MATLAB/Simulink, SIEM, incident response engine), and the yellow labels represent the communication protocols between components (Modbus TCP, OPC UA, NTP/PTP, REST API, Syslog, LDAP).

1.2. Main Contributions

The main contributions of the present work are as follows:

- (1)

Robust QFT control of a five-axis industrial manipulator. A control-oriented model of the servo axes of the FANUC M-430iA/4FH is developed, on which QFT controllers and prefilters are synthesized, ensuring robust tracking under parametric uncertainty, external disturbances, and varying loads. This extends existing QFT applications, which typically consider only simulation environments.

- (2)

Partially decoupled multi-axis QFT formulation. A methodology is presented in which the dominant nonlinearities are compensated, while the residual interactions are treated as structured uncertainty, enabling synthesis via standard QFT bounds without requiring full dynamic inversion - a rarely applied approach in the literature.

- (3)

Twin-based validation through CPDTQN architecture. An integrated MATLAB-PLC-ROBOGUIDE system with Modbus TCP, OPC UA, and PTP synchronization is implemented, enabling evaluation of the controller under conditions close to real industrial environments, including communication delays, PLC cycle timing, and worst-case dynamic models. This combination of QFT control, PLC-in-the-loop execution, and a synchronized digital twin is practically absent from prior research.

- (4)

NIS2-oriented cyber-resilient architecture. The PLC is treated not merely as an execution device but as a protected zero-trust gateway with TLS protection, X.509 authentication, CRC verification, WORM-based logging, and forensic analysis capabilities. This augments the digital twin architecture with mechanisms for traceability, observability, and security in line with NIS2.

- (5)

Quantitative twin-based evaluation via RMS, maximum, and 3D TCP error. Unified metrics are introduced for comparing MATLAB/QFT behavior with twin-based execution, including nominal, worst-case, and disturbed scenarios. The results demonstrate close alignment between simulation and twin execution, as well as absence of negative impact from the security mechanisms-representing a novel contribution to the cyber-resilience analysis of robotic systems.

1.3. Structure of the Paper

The paper is organized as follows.

Section 2 presents a review of related work in robust control, digital twin technologies, and cyber-resilience of industrial systems.

Section 3 describes the proposed CPDTQN architecture and the communication mechanisms employed.

Section 4 introduces the kinematic and dynamic models of the robot, as well as the parameter uncertainties used in the QFT analysis.

Section 5 formulates the NIS2-oriented aspects, including security, traceability, and their integration into the CPDTQN architecture.

Section 6 presents simulation results, dynamic analysis, and twin-based validation.

Section 7 provides a discussion and interpretation of the results.

Section 8 summarizes the main conclusions and outlines directions for future work.

2. Related Work

2.1. Robust Control, Digital Twins, and Industrial Communication

Modern industrial robotic systems are evolving toward deep integration between the physical installation, digital models, and secured communication layers - a trend characteristic of Industry 4.0 and Industry 5.0 environments [21,22,23,24].

However, the transition to real-time cyber-physical architecture remains only partially realized. Digital Twin (DT) technologies have become an essential tool for diagnostics and simulation, yet many existing developments remain predominantly offline- or simulation-oriented rather than integrated into real closed-loop robotic systems [25,26,27,28].

In robotics, DT models enable trajectory validation and anomaly analysis, but most solutions lack real-time coupling with industrial controllers, which limits their applicability under dynamic disturbances and uncertainty [29,30].

From a control perspective, robust methods-including QFT-provide a well-established mechanism for handling parametric uncertainty [8,9,10,11,31]. Despite this strong theoretical foundation, few studies examine the application of QFT control in industrial settings with real communication constraints such as PLC scan cycles, latency, or jitter. Even works addressing dynamic or uncertain manipulators [10,13,32] rarely establish an explicit connection between robust control and digital twins, which significantly restricts the validation of control strategies in realistic scenarios.

Some studies combine robust control with DT-based verification, but these developments are fragmented and do not consider key industrial factors such as network load, communication protocols, and synchronization [27,33].

2.2. Research Gaps and Positioning of the Present Work

Despite the substantial body of literature on robust control, Digital Twin technologies, and industrial cybersecurity, the analysis reveals several significant, systematic, and consistently overlooked gaps.

First, there is an almost complete absence of studies that combine QFT control, PLC-based closed-loop execution, and DT synchronization under realistic communication conditions such as latency, jitter, and packet loss [27,33,37]. Existing developments typically consider only isolated components - QFT control without a DT, DT without PLC-in-the-loop capability, or PLC implementations without robust control strategies - making the results unsuitable for deployment in industrial environments.

Second, cybersecurity in the context of robotic systems is treated in a fragmented manner. The literature on NIS2 provides a mature framework for risk management [19,20,46,47,48], but it is not integrated with control algorithms, and even less so with real PLC architectures. There is a lack of publications examining the impact of cryptography, RBAC, X.509 authentication, WORM logging, and SIEM correlation on the timing dynamics of the control process.

Third, there is no quantitative link between robust control strategies and regulatory requirements for resilience, accountability, and traceability. Although QFT is well studied for handling uncertainty [8,9,10,11,12], its behavior within a cyber-resilient, regulation - aligned architecture remains insufficiently explored.

The present work addresses these gaps by proposing an integrated CPDTQN architecture that:

incorporates multiple uncertainty models [10,13,31,32],

treats the PLC as a deterministic security gateway [34,35,36,37,38,39],

integrates a bidirectional DT for real-time diagnostics [25,26,27,28,29,30],

applies regulatory NIS2-compliant mechanisms [19,20,46,47,48].

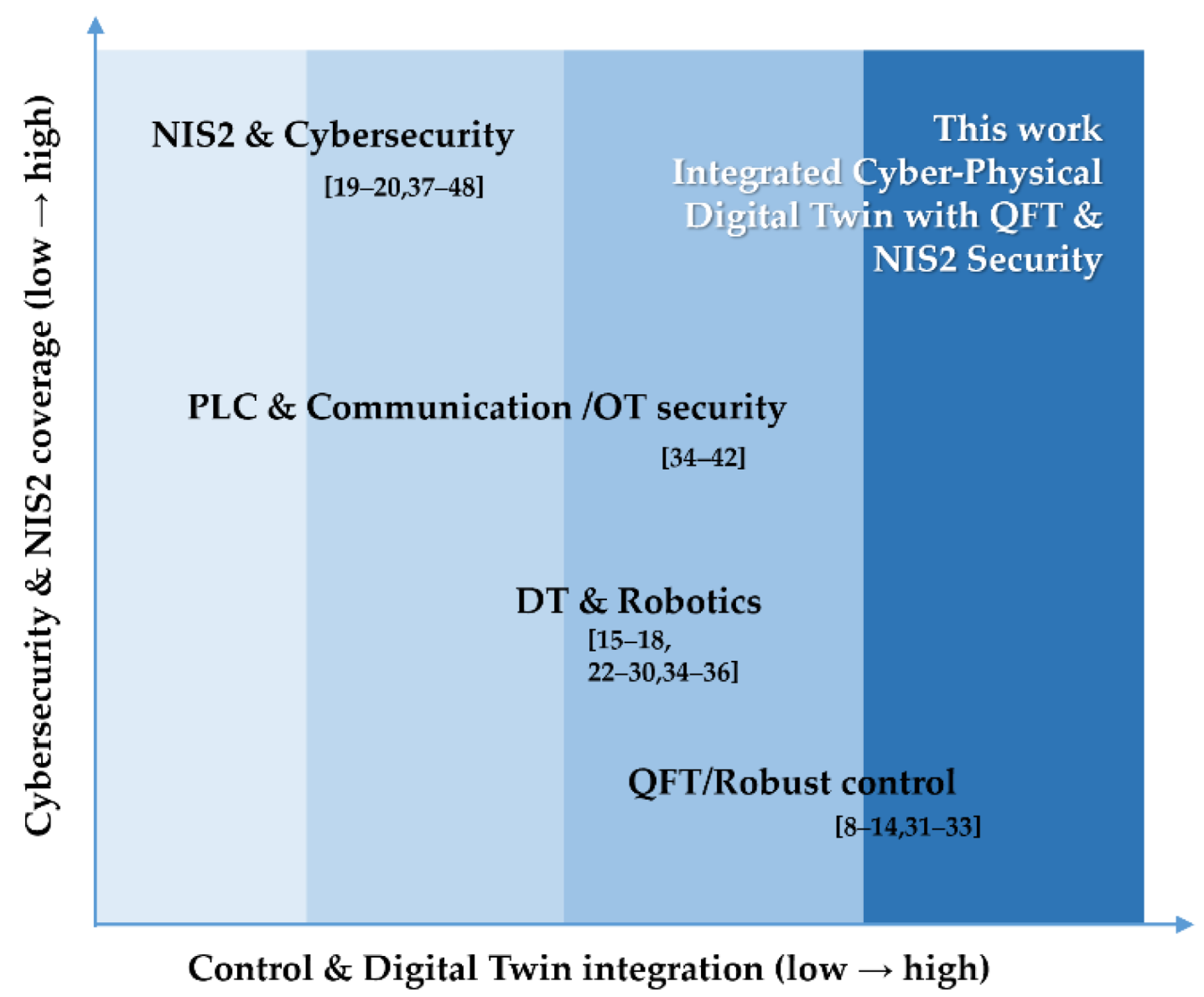

Table 1 summarizes these gaps and clearly illustrates the lack of overlap between the existing research domains.

Figure 2 additionally visualizes the missing links between the four key components QFT, PLC, Digital Twin, and NIS2 security—highlighting the need for an entirely new integrated framework.

Thus, the present study positions itself at the unique intersection of robust control, industrial cyber-physical integration, and regulatory cyber-resilience, addressing a consistently overlooked gap in contemporary literature.

3. CPDTQN Architecture for the FANUC M-430iA/4FH Robot

This section presents the CPDTQN architecture, which integrates the digital twin [34] of the industrial robot FANUC M-430iA/4FH, a Siemens PLC controller, and MATLAB/Simulink-based QFT regulators. The CPDTQN architecture combines the physical work cell, the virtual model in ROBOGUIDE, and the algorithmic control layer, maintaining synchronized bidirectional data exchange, real-time execution, and NIS2-compliant mechanisms for monitoring and traceability [45]. This organizational structure provides the environment required for validating the kinematic and dynamic models introduced in

Section 4, as well as for conducting the twin-based experimental analyses presented in

Section 6.

The digital twin and its associated services (MATLAB/Simulink, SIEM, IAM, and the incident-response module) are executed on a dedicated industrial server that is logically segmented from the corporate IT infrastructure. The physical devices, the robot, the PLC, and the peripheral mechanisms, are placed in an isolated OT zone. This multilayer segmentation meets the NIS2 requirements for minimizing the exposed attack surface, ensuring traceability, and separating critical assets [45].

Communication between components is implemented through industrial Ethernet-based protocols. Modbus TCP/IP serves as the primary channel for transmitting joint reference values and telemetry between the PLC and the robot. Structured data, diagnostic information, and synchronization events are exchanged through PLC-based mechanisms, including OPC UA secure channels, NTP/PTP time alignment, and protected logging. MATLAB/Simulink executes the QFT-based controller with a fixed sampling period of and sends control values to the PLC, which validates, routes, and forwards the data to both the robot and the digital twin [39].

In this way, the CPDTQN architecture maintains real-virtual coherence, enables evaluation of latency, jitter, and disturbances, and provides NIS2-compliant traceability of all control actions, log entries, and system events, as elaborated in

Section 5.

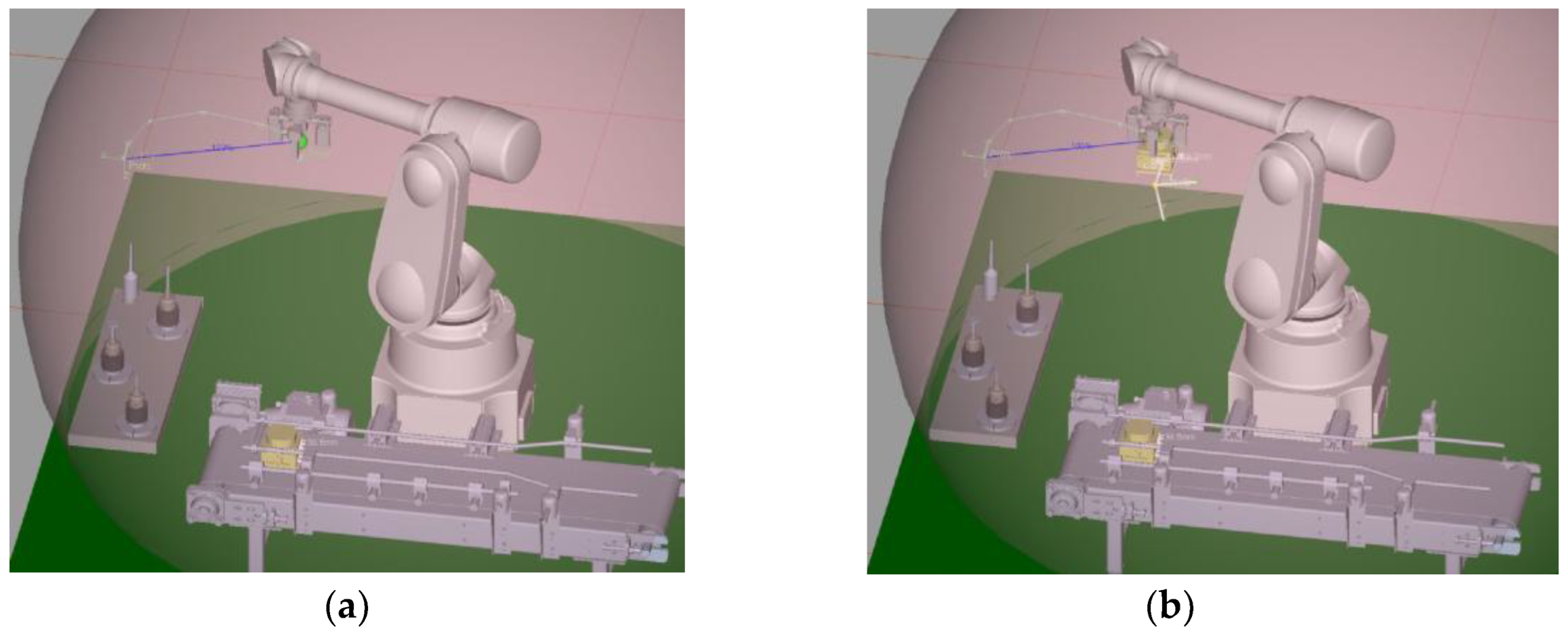

3.1. Digital Twin Concept and Objectives

The digital twin of the FANUC M-430iA/4FH represents a dynamic and synchronized virtual replica of the physical manipulator [34,36,43], maintaining bidirectional data exchange with the Siemens PLC and MATLAB. The requirements for kinematic and dynamic modelling presented in

Section 4 are followed, providing an environment for verification of QFT-based control. The main objectives of the digital twin are:

Accurate virtual modelling. The twin uses a 3D model with hierarchical links, a defined TCP, and coordinate frames. Alignment with the physical robot is ensured through transformation matrices between ROBOGUIDE, the PLC, and MATLAB, analogous to the approaches described in

Section 4.

Real-time synchronization. The data exchange includes joint angles, statuses, and diagnostic registers at frequencies of 20-50 Hz for motion - critical signals and 50-200 Hz for telemetry. These values are consistent with the PLC scan cycle and the communication constraints of the industrial infrastructure.

Support for QFT-based control. The digital twin receives trajectories, inverse kinematics (IK) is computed in MATLAB, movement is visualized, and measurements are returned, enabling comparison between nominal and worst-case models. This supports robustness analysis under disturbances.

Reduction of risk and setup time. ROBOGUIDE enables validation of trajectories, collision scenarios, end-effector positioning, and control strategies without interrupting the production process.

NIS2-compliant observability. The digital twin maintains NTP/PTP synchronization, centralized logging, and IAM integration, ensuring traceability and access control.

3.2. Communication Architecture between the Robot and the Digital Twin

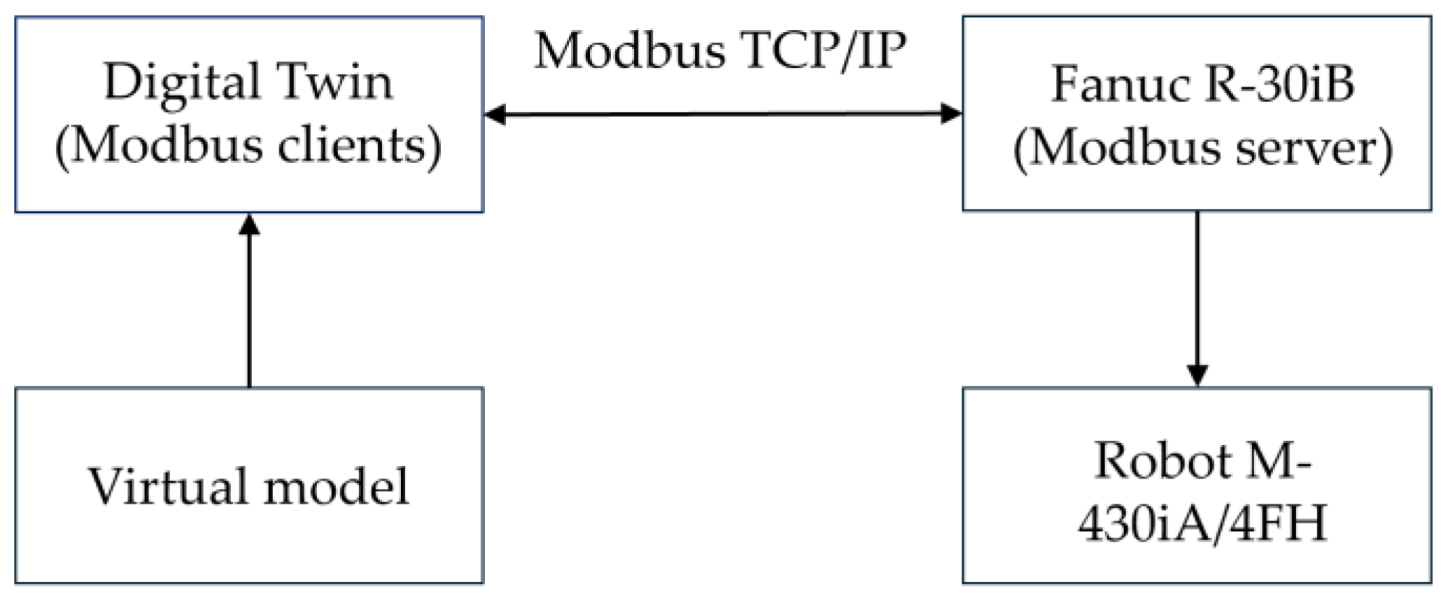

Communication between the industrial robot FANUC M-430iA/4FH and its digital twin is implemented through industrial Ethernet-based protocols that enable bidirectional real-time data exchange. This functionality is available in ROBOGUIDE version 8.0 and above, which supports external communication between the virtual and physical R-30iB robot controllers. The overall communication scheme is illustrated in

Figure 3, showing the connection between the M-430iA/4FH robot and its digital twin, as well as the primary Modbus TCP/IP channels.

The digital twin, executed in ROBOGUIDE, interacts with the robot controller via Modbus TCP/IP. This communication protocol is used for the exchange of control commands, telemetry, and status information. The data exchange uses Modbus TCP/IP (IEC 61158), with the FANUC R-30iB controller operating as a Modbus Server and the digital twin functioning as a Modbus Client. The characteristics of the Modbus TCP communication channel are summarized in

Table 1.

The Modbus exchange includes coils, discrete inputs, holding registers, and input registers, through which joint positions, logical states, diagnostic parameters, alarms, and trajectory information are transmitted. The overall communication flow between MATLAB, the PLC, the robot, and the digital twin encompasses stages of initialization, state synchronization, and the command phase (IK and QFT control, execution and visualization in ROBOGUIDE, diagnostics, and safety). A representative register mapping for robot feedback and command exchange is shown in

Table 2.

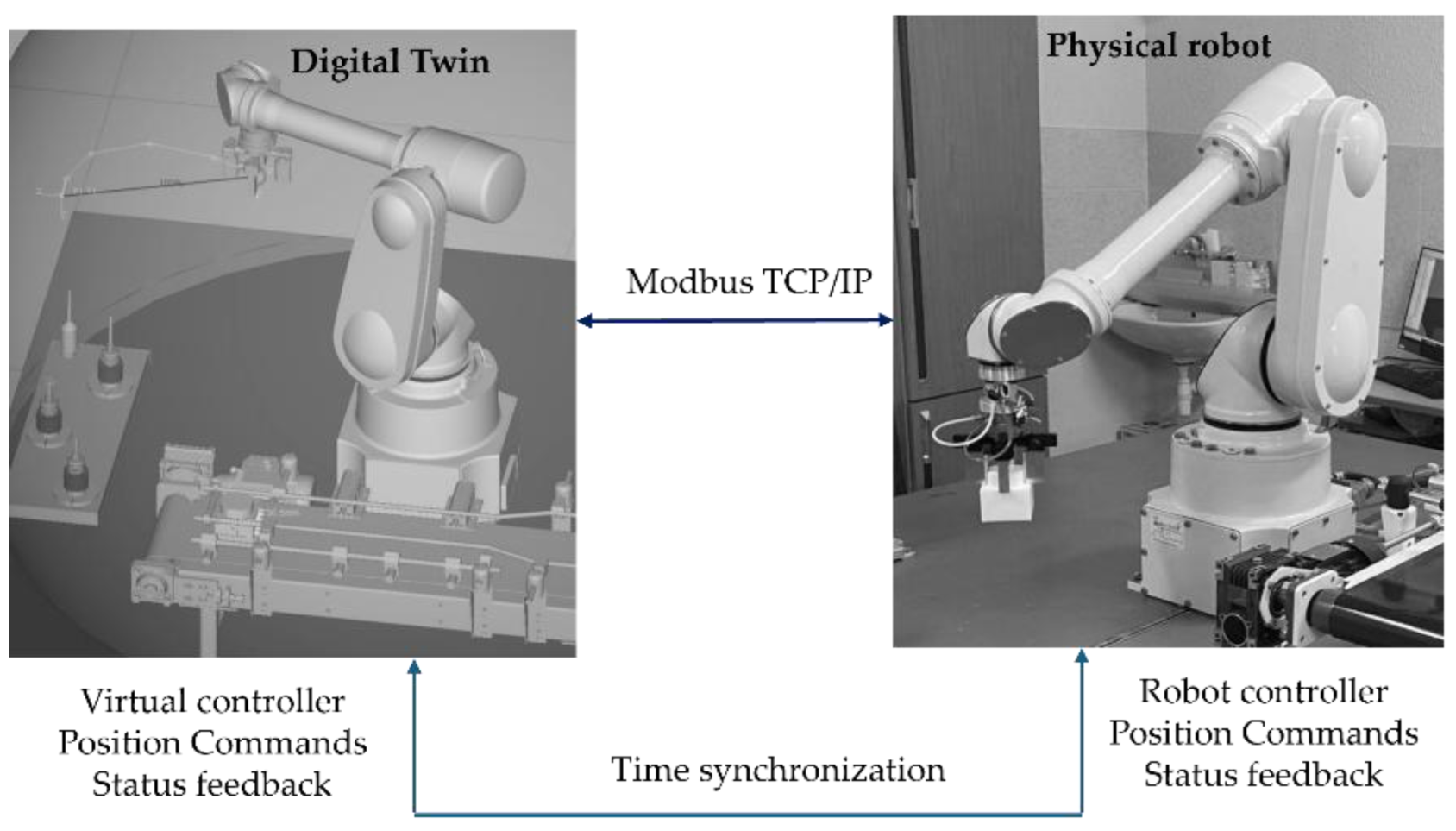

Synchronization of the execution time between the PLC, MATLAB, and ROBOGUIDE is critical for comparing real-virtual trajectories. NTP and PTP are used, and the overall scheme is shown in

Figure 4. This synchronization enables correction of communication delays

when evaluating trajectory-tracking errors.

Due to the differences between the coordinate systems of ROBOGUIDE and the physical controller, transformation matrices are used to align the TCP, zeroing positions, and kinematic frames, ensuring compatibility with the joint dynamic models derived in

Section 4. The communication link between the digital twin and the real robot provides reduced setup time, detection of latency, jitter, and disturbances, as well as the capability for integration into Industry 4.0 environments. The limitations of this communication include sensitivity to inaccurate model parameter identification, the inherent latency of Modbus TCP, and the need for periodic updates of the DT model.

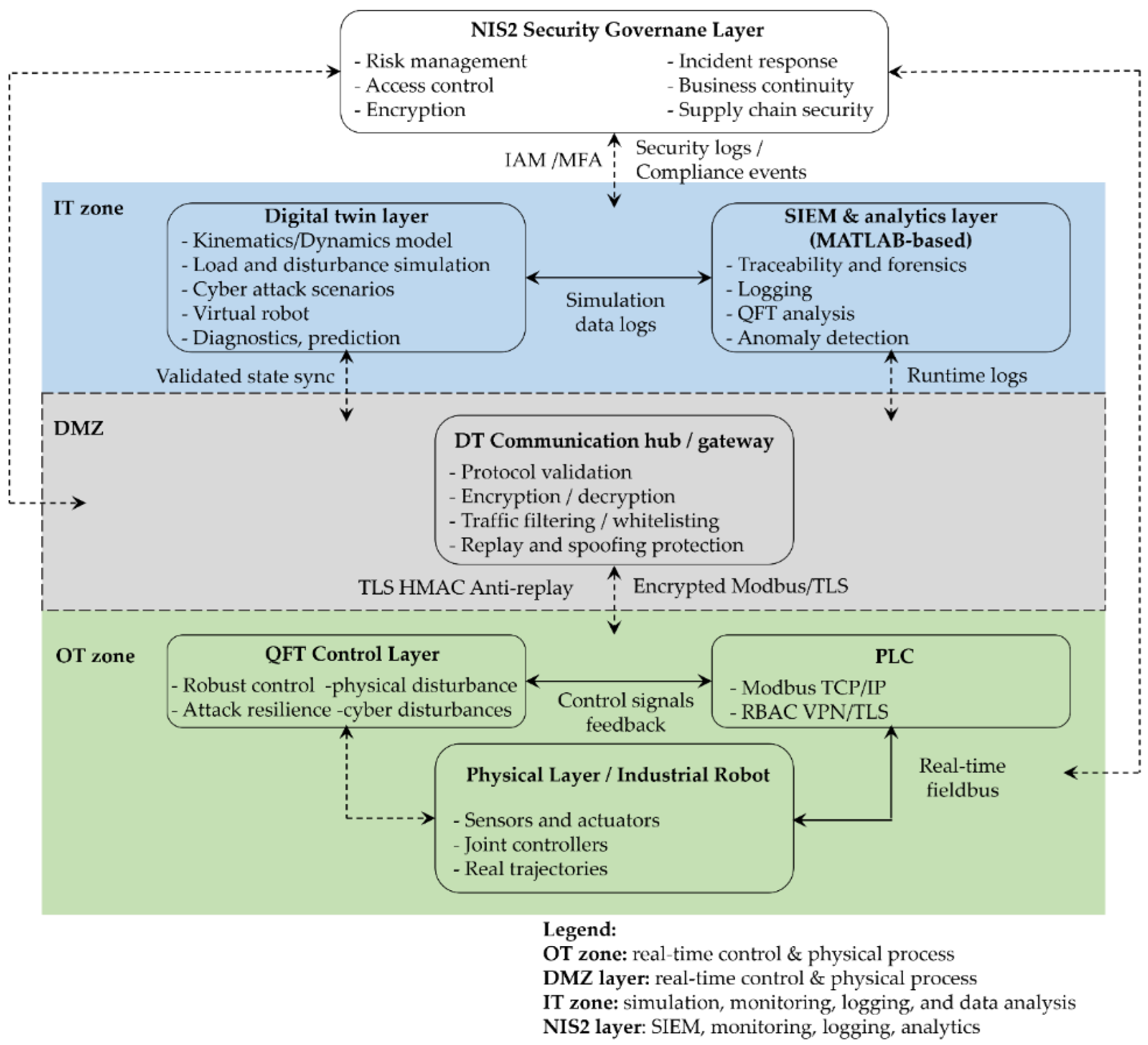

3.3. Integrated CPDTQN Architecture with Security Extensions

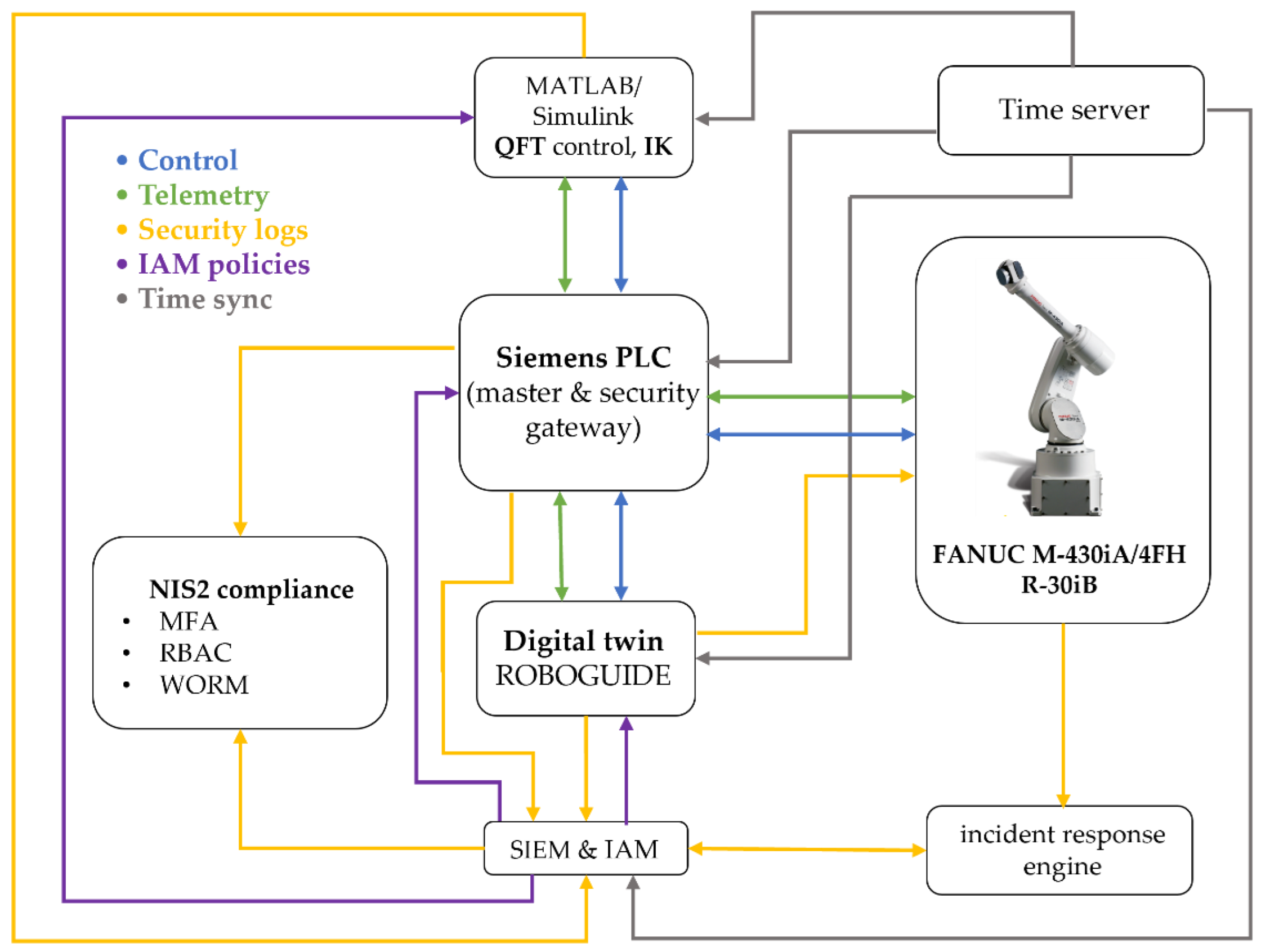

The integrated CPDTQN architecture unifies control, simulation, and observability of the FANUC M-430iA/4FH industrial robot within a single cyber-physical framework [36,37,41]. The overall architectural layout is shown in

Figure 5, which extends both the basic Digital Twin concept presented in

Figure 4 and the conceptual model illustrated in

Figure 1.

The CPDTQN architecture shown in

Figure 5 illustrates the various communication flows and functions, which are color-coded. The first flow is the

Control flow, shown in blue. Here, control commands are exchanged between the MATLAB/QFT controller, the Siemens PLC, and the digital twin in ROBOGUIDE. The PLC receives control inputs from MATLAB over OPC UA (TLS 1.3, X.509) [39], validates them, and forwards them to the robot via Modbus TCP [38,40], while the digital twin uses these commands to simulate the motion and validate the trajectories.

The second flow is Telemetry, shown in green. It represents the stream of telemetry data from the real FANUC M-430iA/4FH robot and the R-30iB controller to the PLC and the digital twin. This includes joint positions, status signals, alarms, and diagnostic data, which enable real-time synchronization and monitoring.

The third flow is Security logs, shown in yellow. It carries log events to the SIEM for analysis and correlation, including monitoring of command operations, CRC checks, alarms, and system states.

Identity and role management via LDAP/Kerberos/OAuth2, the application of RBAC policies, and access control to the PLC, the digital twin, and the MATLAB/QFT controller are implemented through the

IAM policies communication flow, shown in purple in

Figure 5.

Time synchronization via NTP/PTP across all components - providing consistent timestamps for traceability, latency and jitter correction, and digital forensic analysis implemented through the Time sync flows, shown in grey.

Functionally, the CPDTQN architecture in

Figure 5 consists of three layers:

Physical Layer contains the real FANUC M-430iA/4FH robot, the R-30iB controller, and the peripheral infrastructure. The robot operates in Modbus Server mode and transmits telemetry to the PLC, which in turn sends reference setpoints and diagnostic data to MATLAB and ROBOGUIDE.

Virtual Layer, executed in ROBOGUIDE and MATLAB/Simulink, includes the digital twin, the QFT controller [35], and the additional NIS2-related services (SIEM, IAM, Incident response engine). It is logically isolated from the office IT environment in accordance with the segmentation requirements outlined in

Section 5.

Coordination Layer (PLC Gateway) synchronizes all communication channels and acts as both the master controller and a security gateway. The PLC receives QFT-based control values from MATLAB, validates them, and forwards them to the robot via Modbus TCP/IP, while telemetry from the robot is returned to the PLC and routed to the digital twin. In this way, a closed-loop system is maintained that accounts for latency, jitters, and external disturbances.

In

Table 3, the communication links between the PLC, the robot, MATLAB/Simulink, the digital twin, and the NIS2-compliant services are summarized, showing the role of each protocol in coordinating the physical and virtual systems. The matrix demonstrates how the PLC functions simultaneously as a master controller and a security gateway, integrating control commands, telemetry, logs, and synchronization channels into a unified communication infrastructure.

Through time synchronization, centralized command validation, and real-virtual consistency, the CPDTQN architecture turns the digital twin into an active component of the control loop. This enables verification of the QFT controllers under realistic communication conditions, latency, and disturbances, and provides a platform for cyber-resilient control aligned with the requirements of NIS2.

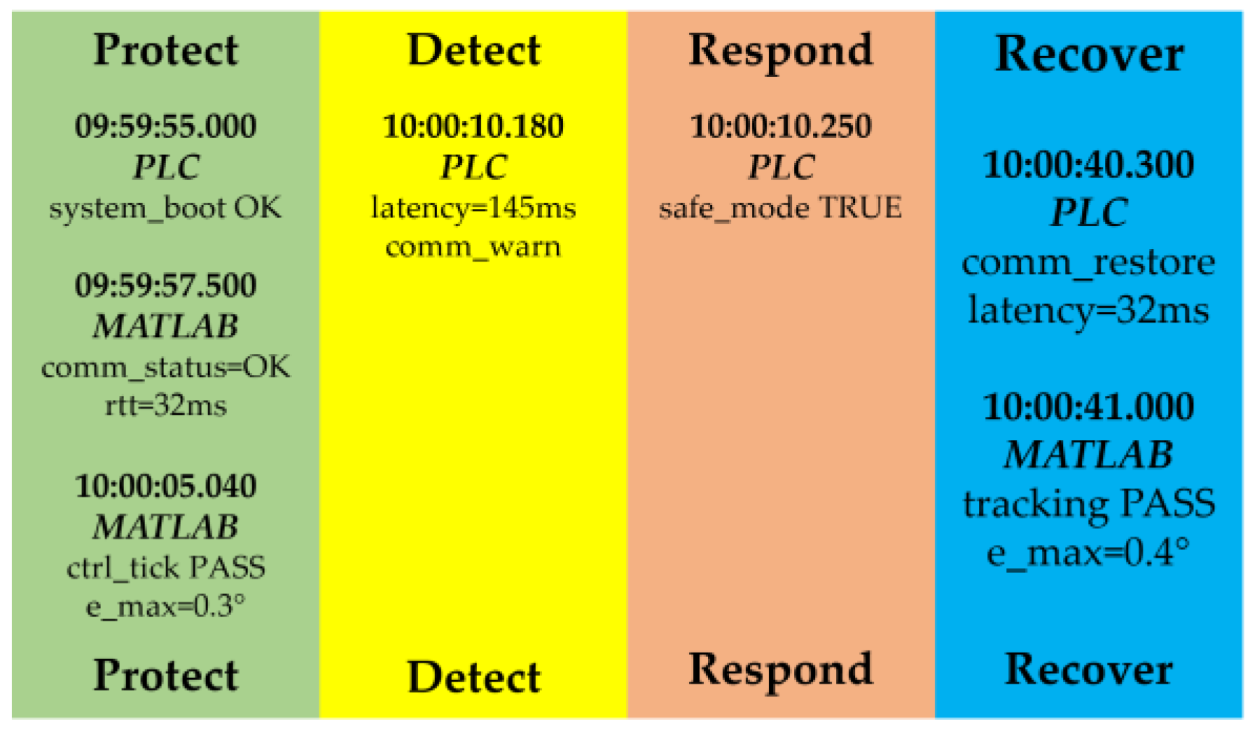

3.4. NIS2-Compliant Security, Logging and Traceability

In accordance with the requirements of Directive (EU) 2022/2555 (NIS2), the digital twin architecture is augmented with mechanisms for authentication, access control, cryptographic protection, centralized logging, and event traceability. These functions ensure that the operation of the FANUC M-430iA/4FH industrial robot complies with regulatory standards for the protection of critical cyber-physical systems.

Access to the PLC, the digital twin, and the MATLAB/QFT controller is governed by a multilayer authentication scheme that includes multi-factor authentication (MFA), X.509 certificates for establishing TLS 1.3 sessions, and role-based access control (RBAC), under which operators, engineers, and automated services receive strictly defined permissions. Identity management is performed centrally through IAM services (LDAP/Kerberos/OAuth2), and all successful and failed access attempts are recorded in an immutable database, ensuring full audit traceability in the spirit of NIS2.

To secure communication between the physical and virtual parts of the system, a range of cryptographic and network mechanisms are applied: TLS 1.3 encryption for OPC UA channels, IPsec tunneling for Modbus TCP/IP traffic, network segmentation via VLANs to separate control, telemetry, and administrative services, as well as deep packet inspection (DPI) within the PLC to detect malicious or malformed packets. These measures mitigate the risk of unauthorized commands, data manipulation, and man-in-the-middle attacks.

The centralized logging system aggregates logs from the PLC, ROBOGUIDE, and MATLAB via Syslog over TLS. Logged events include control commands, Modbus operations, alarms, diagnostic parameters, TCP and joint deviations, and IAM events (login/logout, role changes). All records are stored in WORM (Write Once, Read Many) format, ensuring an immutable audit trail and fulfilling NIS2 requirements for transparency and accountability.

Precise temporal correlation between the physical robot, PLC, and digital twin is achieved through the Network Time Protocol (NTP) and the Precision Time Protocol (PTP). A unified time base enables correction of latency, jitter, and RTT when analyzing tracking errors and facilitates forensic investigation in which SIEM events are correlated using a universal timestamp.

Integration with the SIEM enables automated incident monitoring. The system detects invalid CRC values, unauthorized access attempts, motion anomalies (e.g., deviations in the TCP trajectory), excessive temperatures, or inconsistencies in speed and position. Upon detecting an anomaly, the SIEM generates an alert to the incident response engine, which may block a command, temporarily isolate a device via PLC rules, or trigger a safety mode (freeze motion). All actions are recorded for forensic analysis.

The proposed architecture supports complete traceability through synchronized timestamps, cryptographically signed WORM logs, and automatic correlation between real and virtual states. Each command pathway (MATLAB → PLC → FANUC M-430iA/4FH → PLC → digital twin → SIEM) can be reconstructed with high precision, enabling detailed digital forensic analysis. These mechanisms satisfy all key NIS2 requirements for protection, observability, accountability, and resilience of critical cyber-physical systems, making the CPDTQN architecture a reliable platform for industrial validation under real cyber-risk conditions.

3.5. Functional Roles of System Components

The integrated CPDTQN architecture comprises several interconnected components [36] that collectively realize control, synchronization, monitoring, and traceability of the FANUC M-430iA/4FH industrial robot. As shown in

Figure 5 and

Figure 1, communication between these elements is accomplished through a multichannel industrial infrastructure centrally coordinated by Siemens PLC. The system maintains a closed loop of control - feedback - virtual verification, and the primary links between components and protocols are summarized in

Table 3.

Siemens PLC acts as the central coordination module, functioning simultaneously as the master controller and security gateway. As a controller, it exchanges control values and telemetry with the robot via Modbus TCP/IP (details in

Table 1 and

Table 2), supports polling cycles of 20-50 ms for motion-critical signals, and distributes information to MATLAB/Simulink and ROBOGUIDE. As a security gateway, it enforces authentication via X.509 certificates, encrypts OPC UA sessions, filters traffic via DPI, and applies RBAC/IAM policies in accordance with NIS2. Its central role in communication flow is clearly depicted in

Figure 1.

MATLAB/Simulink implements the algorithmic layer of control, performing inverse kinematics (IK), the QFT controllers for all five axes, and robustness analysis under nominal and worst-case models (as detailed in

Section 4). Data exchange with the PLC is conducted through a secure OPC UA channel using the standard Simulink OPC UA Read/Write blocks. Telemetry registers from the PLC are updated every control cycle directly into the Simulink model, while the computed control values are written back into the PLC’s OPC UA address space—never bypassing the PLC gateway. This ensures that the QFT controller operates synchronously with the PLC polling cycle and maintains the NIS2-compliant system structure. Simulink also performs continuous tracking-error evaluation, RMS metrics, and disturbance sensitivity assessment, forwarding these data to the SIEM for observability and traceability. The combination of IK, QFT control, and OPC UA synchronization enables MATLAB to function as the central algorithmic node that maintains coherent real-virtual behavior between the physical robot and the digital twin.

The digital twin, implemented in ROBOGUIDE, is a high-fidelity virtual replica of the robot [34], reproducing its kinematics and dynamics in real time. It visualizes the trajectories generated by MATLAB and the PLC and enables real-virtual comparison through the synchronization concept shown in

Figure 4. The digital twin performs simulation-based diagnostics, detects collisions, workspace limitations, and TCP anomalies, and exchanges structured data with the PLC via OPC UA (

Table 3). It serves as a reference model that provides NIS2-aligned traceability and allows verification of commands prior to physical execution.

The physical robot FANUC M-430iA/4FH and the R-30iB controller execute the control commands generated by the algorithmic layer and transmit telemetry to the PLC, including joint positions, alarms, logical states, and diagnostic parameters (see

Table 2). The robot operates as a Modbus TCP server and uses NTP/PTP synchronization to maintain a unified time base with the virtual model, supporting accurate real-virtual motion analysis as shown in

Figure 4.

The SIEM system aggregates Syslog/TLS events from the PLC, MATLAB, ROBOGUIDE, and IAM, correlates them using synchronized timestamps, and analyzes deviations such as malformed command frames, CRC errors, nonstandard Modbus packets, or motion anomalies. This fulfills NIS2 requirements for monitoring, accountability, and incident-data retention and is a key element in the communication scheme shown in

Figure 1.

The incident response engine uses SIEM alerts to trigger automated actions such as terminating active sessions, restricting control commands, isolating communication channels, or activating safety modes (freeze motion or safe stop). It records all actions in a WORM log, supporting forensic analysis and ensuring operational resilience under disturbances or cyber events.

The time server provides a unified time base for the PLC, MATLAB, ROBOGUIDE, SIEM, and the incident response engine via NTP for system time and PTP for precision synchronization. This minimizes phase offsets in real-virtual comparisons, ensures consistent timestamping (critical for NIS2 traceability), and enables correction of communication delays during the tracking analyses in

Section 6.

The functional integration of all components from

Figure 5,

Figure 1, and

Table 3 creates a resilient and traceable cyber-physical system that supports real-time QFT control of an industrial robot, ensures reliable synchronization between the physical and virtual models, guarantees encrypted and segmented communication, and maintains a complete audit trail consistent with NIS2. This architecture provides a reliable platform for validating control strategies under realistic network conditions, latency, and disturbances, forming a comprehensive model for cyber-resilient robotic systems.

4. Control of the Multi-Axis Manipulator

4.1. Motivation for the QFT Approach

In the control of industrial robots, a fundamental challenge is the presence of parametric uncertainty and nonlinear interactions between mechanical links. In real manufacturing environments, the dynamic characteristics of the manipulator vary depending on load, friction, geometric configuration, and changes in the center of mass associated with different end-effectors. These factors lead to deviations between the nominal mathematical model and the real system, which may compromise control stability if the controller is designed using conventional control law.

Quantitative Feedback Theory, introduced by Horowitz [8], provides an alternative that enables explicit quantitative handling of uncertainty. Unlike or -synthesis, which require accurate matrix models, QFT uses a graphical design procedure in the Nichols plane, where the influence of parameter variations on stability and performance can be visualized. This allows the engineer to synthesize a controller that guarantees both robustness and the desired dynamic behavior for all admissible parameter variations of the system.

QFT is particularly suitable for robotic systems with multiple independent axes, where partial dynamic decoupling enables each loop to be treated as a SISO system. Each regulator can therefore be designed independently, without requiring full MIMO optimization. This approach is effective when cross-axis couplings are relatively weak and can be treated as part of the structured uncertainty of the plant, represented through templates.

An additional advantage of QFT is the ability to directly define performance bounds on stability, tracking, and disturbance rejection. This is especially valuable in industrial contexts, where not only accuracy but also reliability under process variations must be ensured.

Consequently, QFT provides a clear and quantitative framework for synthesizing controllers that can be verified both in MATLAB and through the digital twin in the ROBOGUIDE environment. This makes QFT particularly suitable for integration into the proposed CPDTQN architecture (

Figure 5), in which robustness and cybersecurity are treated as interconnected aspects of the control problem.

4.2. Hierarchical Architecture, Forward and Inverse Kinematics [3]

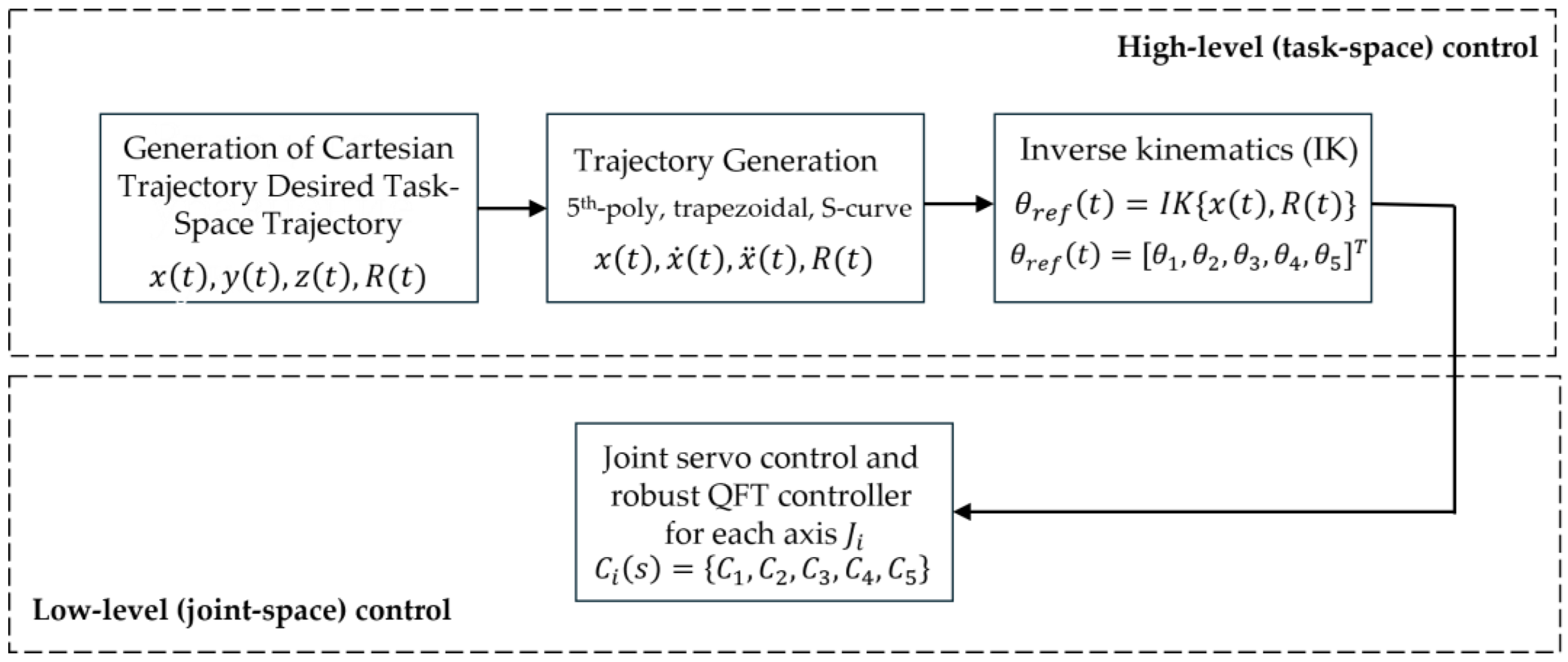

The control structure of the industrial manipulator follows the classical two-layer hierarchy established in robotics [2], in which the high level operates in Cartesian space and generates the desired TCP trajectories, while the low level performs local joint control through feedback. DH-parameter formalism, forward and inverse kinematics, as well as the differential relationships defined by the Jacobian, are strictly based on the standard approaches described in [1,3].

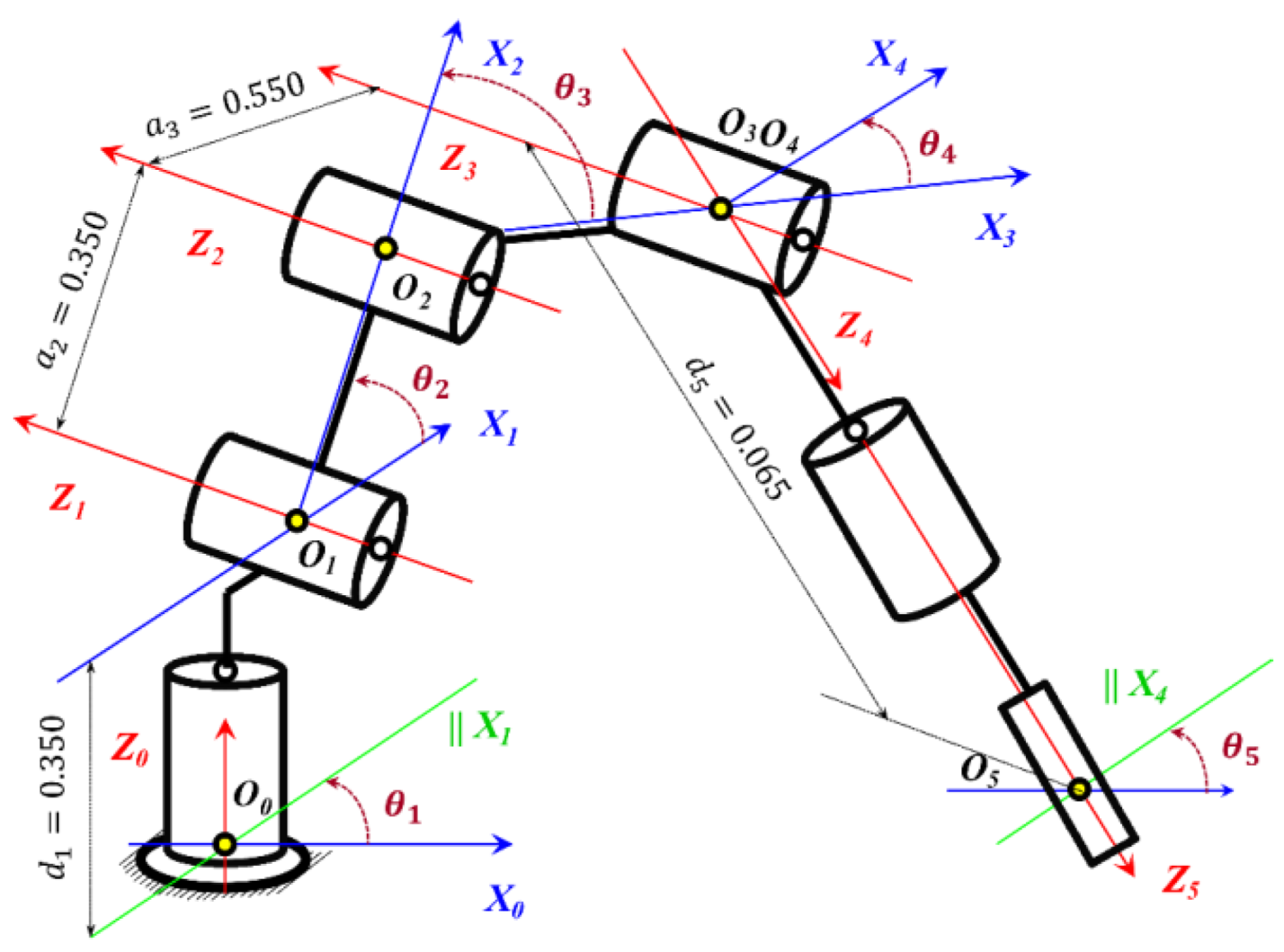

This functional decomposition allows the complex nonlinear dynamic effects to be handled at the low level, whereas the high level operates on an idealized kinematic representation. The kinematic chain of the 5-DOF anthropomorphic manipulator used in this study is shown in

Figure 6, with a joint configuration of type R-R-R-R-R.

At the high level, the robot receives the desired end-effector trajectory in terms of position and orientation as given in (1):

where

specifies the Cartesian position, and

is the orientation matrix with respect to the base coordinate frame.

The objective of the high-level layer is to convert the information in (1) into reference joint coordinates through the inverse kinematics (IK) given in (2):

Direct kinematics is obtained through the successive multiplication of the homogeneous transformations between the links (3):

where each transformation

(4) is defined by the DH parameters shown in

Figure 6:

The position and orientation of the end-effector (Tool Center Point, TCP) are obtained from (5):

The differential relationship between joint velocities and TCP velocity is expressed through the Jacobian matrix (6):

For revolute joints, the Jacobian columns are computed using (7):

These relationships are used to numerically refine the analytical inverse kinematics. The IK of the anthropomorphic 5-DOF manipulator is solved through the standard decomposition into two subproblems: position (axes ) and orientation (axes ). Here, J₁ corresponds to the base axis, J₂ to the shoulder, to the elbow, to the wrist pitch, and J₅ to the wrist roll.

The rotation angle

of joint

is obtained from the horizontal projection (8):

The vertical and horizontal components used in (8) are given by (9):

The intermediate distance required for the elbow joint

is computed as (10):

From (10), the elbow joint angle

follows as (11):

The shoulder joint angle

is computed using (12):

Once the first three joints are obtained, the orientation of link 3 is determined from the rotation matrix

, and the desired wrist motion is described by (13):

The wrist-joint angles

and

are then obtained from (14) and (15):

The analytical expressions obtained in (8–15) provide a closed-form solution to the IK. However, in the practical implementation a hybrid approach is used combining the analytical solution with iterative Jacobian-based corrections to improve numerical robustness during fast robot trajectories or when operating near kinematic singularities.

At the low level, each of the five joints

implements an independent local feedback loop (16):

where

are the QFT controllers are synthesized with respect to nominal and uncertain dynamic models of the actuators.

The actual dynamics of the manipulator are described by the Lagrangian model (17):

where the matrix

is dense and captures the mutual dynamic couplings among the joints

;

is the matrix of centrifugal and Coriolis forces arising from the motion of the links

; and

is the vector of gravitational forces acting on each joint

depending on the configuration.

These nonlinear interactions and external disturbances are compensated by the robust QFT controllers at a low level, enabling the high-level layer to operate on an idealized kinematic model, while the low-level control ensures the actual, robust, and accurate execution of the reference joint trajectories .

4.3. Trajectory Generation in the Task Space [1,11]

Trajectory generation is a fundamental element of the high-level control layer, as it defines the desired motion of the tool center point (TCP) in the task space in a manner that is smooth, physically realizable, and consistent with the kinematic and mechanical constraints of the FANUC manipulator. Let the desired Cartesian trajectory be specified by a position vector and an orientation matrix as in (1). The resulting time functions must be mathematically smooth up to the second derivative to avoid abrupt changes in TCP velocity and acceleration, which could disrupt the stability of the low-level control loops.

In the present work, these requirements are satisfied through time parameterization using an optimized 7-phase S-curve profile, which ensures bounded jerk, acceleration

, and velocity

of the desired motion trajectory

of the end-effector. Let

denote the normalized S-curve parameter of the reference path, defined through integration of the velocity and acceleration according to (18):

The acceleration follows the standard 7-phase structure (acceleration increase – constant acceleration – acceleration decrease – zero-acceleration segment - symmetric deceleration profile). The normalized position parameter serves as a universal time index, through which every point of the desired TCP spatial trajectory is reached with dynamically compatible velocity.

The desired Cartesian TCP trajectory is defined through a set of control points

] between which a smooth B-spline/PCHIP interpolation is constructed. Accordingly, the final TCP position of the end-effector is obtained from (19):

This approach ensures

-class smoothness of the commanded TCP trajectory, the absence of sharp curvature transitions, and dynamic feasibility even during high-speed robot motion. The resulting trajectory

is then supplied to the analytical inverse kinematics from

Section 4.2, which generates the reference joint coordinates given by (20):

The reference joint velocities

(21) and accelerations

(22) are determined using the manipulator Jacobian

, as is standard for anthropomorphic robotic architectures.

The computed expressions for the joint position

, joint velocity

, and joint acceleration

of the joints

constitute the complete set of reference joint trajectories that are supplied to the low-level controller. The schematic structure of the high-level control layer is shown in

Figure 7.

The high-level layer generates a trajectory in the Cartesian TCP coordinate space, which is transformed into joint reference coordinates

through IK. The low-level layer employs QFT controllers to ensure robust tracking of

despite parameter variations, load changes, friction, and external disturbances. In this way, the high-level layer operates on an idealized kinematic model, while the low-level layer compensates for the actual nonlinear dynamics of the manipulator and guarantees stable and accurate execution of the motion, as illustrated in

Figure 7.

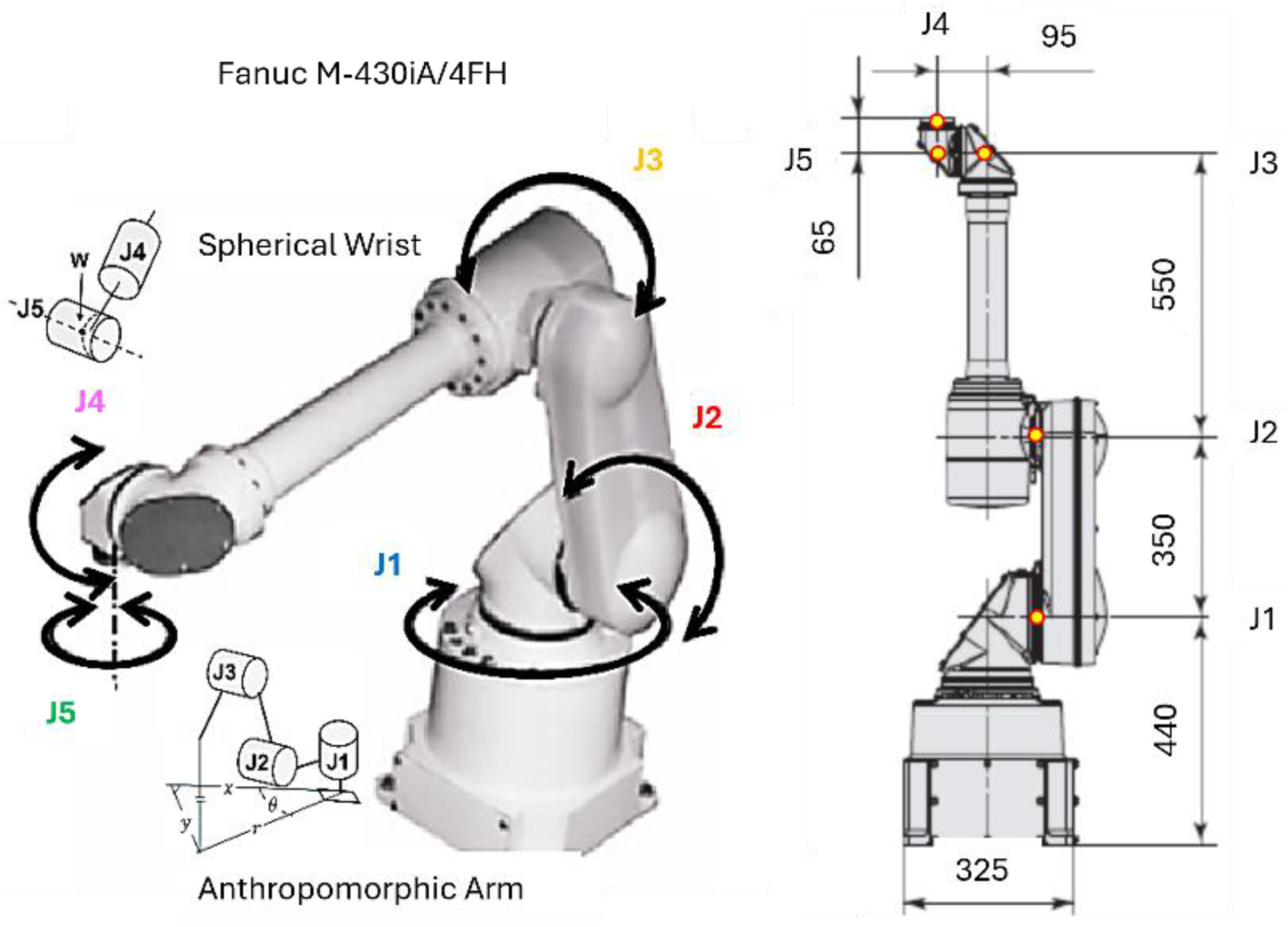

The robot used in this study is an anthropomorphic five-axis manipulator with revolute joints

, consisting of a shoulder, elbow, and spherical wrist, as shown in

Figure 8. The position control of each joint

is performed through an electric actuator, where the primary measured coordinates are the joint angular positions

. Each drive motor is modelled as a first-order element with an integrator, describing the relationship between the control input voltage

and the angular displacement

.

In the complete dynamic model of the manipulator, cross-couplings exist between the joints , arising from inertial, centrifugal, and gravitational interactions. For example, the motion of the shoulder joint with angle alters the inertia affecting the elbow joint and its angle , while rotation of the base joint by angle can induce dynamic deviations in the wrist coordinates of joint with angle .

These mutual interactions render the system a multi-input–multi-output (MIMO) structure, which typically requires complex matrix-based controller synthesis.

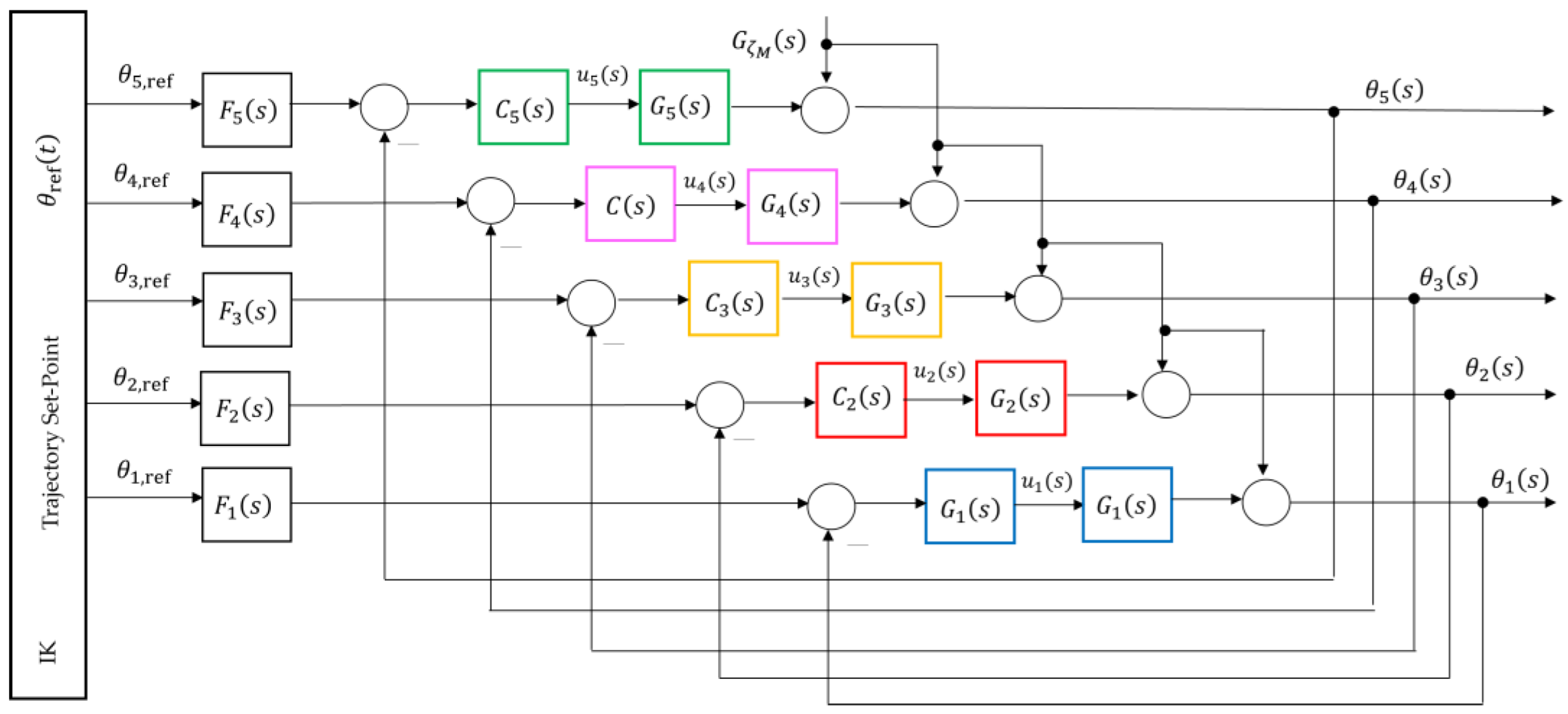

For the purposes of the present study, a decoupling strategy is adopted in which each joint

is treated as an independent single-input-single-output (SISO) loop with its own controller

and plant

, as expressed in (23) and illustrated in

Figure 9.

where:

is the control voltage or current applied to the servo amplifier;

is the angular position of the corresponding joint

;

is the static gain determining the relationship between the control input and the steady-state angular displacement

;

is the electromechanical time constant associated with the dynamics of the servo amplifier and the effective mass moment of inertia.

Decoupling of the Multi-Axis Dynamics

For designing the QFT controllers, a partial decoupling approach is applied [1,2,14], which allows each joint

to be treated as an independent SISO subsystem. To this end, equation (17) is rewritten in the form (24):

If the off-diagonal elements of the matrices

and

are assumed to be significantly smaller than the corresponding diagonal elements, the dynamics of each joint

can be approximated as a nearly decoupled SISO subsystem. Under this approximation, equation (17) is reduced to the following scalar form (25):

where

represents the aggregated effect of all cross-axis dynamic couplings (26):

In the context of QFT,

is treated as a multiplicative uncertainty (27) on the nominal plant (23):

where

is the nominal dynamics of joint

, and

describes the relative deviation between the real and nominal dynamics (typically

).

Thus, each joint

is controlled through the input

independently, following the structure in

Figure 9 and equation (28):

The interactions between the axes are accounted for in the QFT templates through an expanded range of the gains and time constants of the plant (23). These parameter ranges incorporate the effects of inertial, centrifugal, Coriolis, and gravitational cross-couplings between the joints, modeled as generalized uncertainty in each SISO subsystem.

The chosen partially decoupled approach is justified because structural independence is naturally present, each servo motor has its own actuator and encoder, enabling direct position control of . Moreover, the electrical drives have a bandwidth significantly higher than the mechanical couplings, meaning the internal motor dynamics dominate. This is also advantageous for PLC-based synchronization, since the controller can enforce timing alignment and eliminate accumulated errors between control channels.

Consequently, the full MIMO model is reduced to five SISO loops, each with a transfer function of the form (23). These transfer functions are used in the following section to construct QFT templates and derive robust bounds. The conceptually decoupled five-axis model is shown in

Figure 21, where each loop is assigned to its own QFT controller. The cross-axis interactions are not modeled as explicit dynamic couplings; instead, they are treated as multiplicative uncertainty in the transfer function of each joint

as in (27). Thus, the influence of other joint motions on

is encapsulated within the extended ranges of the gains

and time constants

, reflected directly in the QFT templates.

Within the current architecture (MATLAB - PLC - FANUC M-430iA/4FH),

Figure 5, a closed-loop position control of each joint

is realized: the QFT controller in MATLAB computes the control input

required to maintain the desired joint position

. The PLC acts as an industrial middleware layer that forwards the command to the servo drive and ensures synchronization and safety. The robot responds by adjusting the joint angle

, which is measured by the encoders and returned as feedback. Accordingly, the QFT controller governs the joint rotation

, generating torque commands that compensate for friction, load variations, and cross-coupling effects. As a result, the joint position

of each axis remains stable and tracks the desired TCP-derived profile even under parametric variations and external disturbances, while the PLC ensures coordination between the virtual (twin) and physical system.

4.5. Modeling of the Individual Axes

4.5.1. Modeling Assumptions and Axis Dynamics

After decoupling the dynamic model of the robot, each joint

can be treated as an independent SISO plant whose dynamics are dominated by the drive motor and the mechanical inertia of the corresponding link, as shown in

Figure 9. For practical control purposes, the plant is approximated by the dynamic model given in (23).

The model (23) is valid within the operating workspace of the manipulator, where nonlinear effects such as friction, backlash, and gravity are treated as external disturbances (27), while the cross-axis interactions are captured through the parametric variations of and .

Under this formulation, the regulators

for each of the joints

ensure accurate tracking of the reference angle

. The goal is to drive the tracking error (29) to zero through the control input

applied to the plant, such that the actual joint motion

follows the desired trajectory

.

The values in

Table 4 represent the nominal parameters of the individual axes

and their corresponding variations, which are used for generating the QFT templates and for analyzing the worst-case dynamics.

The parameters

and

in

Table 4 describe the control-oriented dynamic characteristics of the five actuated axes

of the anthropomorphic manipulator FANUC M-430iA/4FH, represented as a dynamic plant with transfer function (23). Specifically, the parameters

characterize the base rotation (axis

), where the overall structural inertia dominates. The parameters

correspond to the shoulder motion (axis

), which is the most inertial and slowest axis due to the large gravitational moment. The parameters

describe the elbow joint (axis

), exhibiting medium dynamics and moderate parameter variations. The parameters

and

characterize the two wrist axes (axes

and

), which are defined by low inertia and the highest response speed.

The parameter ranges

in

Table 4 are selected to cover the expected variations arising from different robot configurations, payload changes, and dynamic couplings between the axes. These ranges are used to construct the QFT templates and to identify the most adverse parameter combinations (worst-case dynamics), which define the boundary conditions for synthesizing the controllers

.

4.5.2. Modeling of Disturbance Influence

In addition to the nominal dynamics of each axis

, the real robotic system is affected by various internal and external disturbances that influence the joint position

. The primary disturbance sources typically include variable payload forces exerted by the manipulated object or tool, friction in the joints and gear reducers, mechanical backlash, and dynamic couplings between adjacent axes. To account for their influence on the controlled coordinate

, the system is augmented with an additional disturbance channel that represents the path of the disturbance

to the output

, as illustrated in

Figure 9.

Empirically, this disturbance channel is modeled as a linear transfer function corresponding to an external torque- or force-induced disturbance, given by (30):

The denominator represents the inertial and damping characteristics of the mechanical structure, while the numerator includes the dynamic zero term , associated with the elastic coupling between the tool and the manipulator. The negative sign reflects the fact that an increase in the external disturbance force produces a deviation in the direction opposite to the commanded trajectory.

The transfer function describing the external-disturbance dynamics in (30) was identified through simulation experiments in ROBOGUIDE, where a moment disturbance was applied to the digital twin and the corresponding response in the joint coordinate was analyzed in MATLAB.The resulting third-order transfer function (30) was selected as a compromise between model adequacy and structural simplicity. In the context of QFT analysis, this channel is treated as an output disturbance acting on each plant (23) and is used to evaluate the disturbance sensitivity, from which the disturbance-rejection bounds are derived. The overall objective of the QFT controller is to minimize the influence of on the output at low frequencies while maintaining stability and satisfactory dynamic performance within the operational bandwidth.

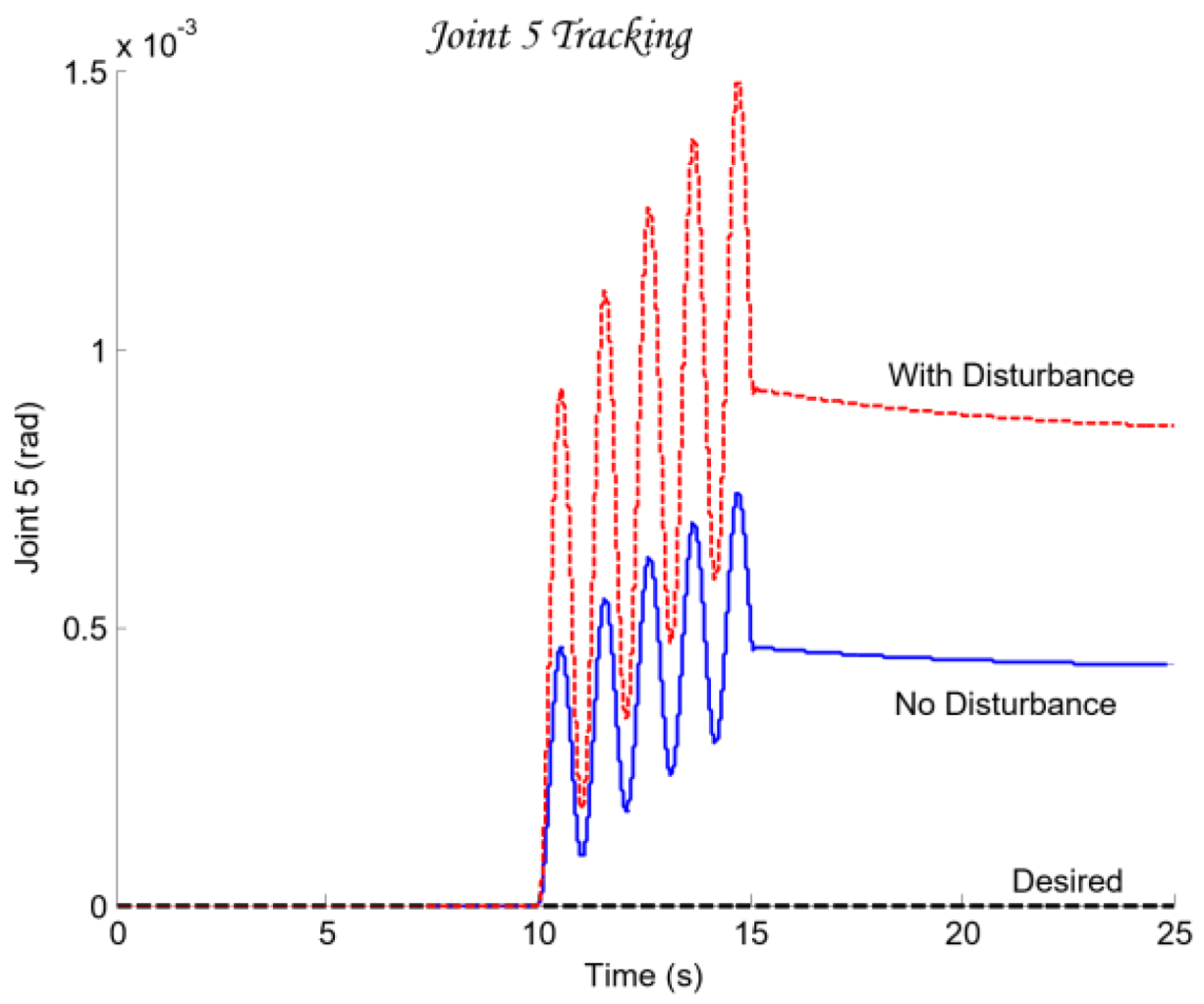

In Section 4.6.2, model (30) is used in forming the QFT bounds for all five controllers

, since the moment disturbance propagates through the entire kinematic chain. The strongest effect is observed at the terminal axis

due to the cumulative structural dynamics along the manipulator arm, as illustrated in

Figure 9.

4.5.3. Modeling of Parametric Variations and Worst-Case Dynamics

In a real robotic system, the dynamics of each joint

vary as a function of the joint position

, the applied load, and the interactions between the links. To account for this uncertainty, the plant parameters

and

are varied within the ranges presented in

Table 4. The nominal model of each axis is described by the transfer function (31):

which serves as the reference point for QFT controller design in the Nichols chart.

The actual dynamics under different parameter combinations are represented by the model (32):

For controller synthesis, the worst-case dynamics are determined, that is, the parameter combination corresponding to the largest values of

and

, given by (33):

Within the QFT methodology, the templates define the regions of uncertainty in which the controllers must ensure stability and performance for all admissible values of the parameters and . In this way, accurate tracking of the joint positions of the five axes , represented by the angular coordinates , is guaranteed across the entire operating envelope.

4.6. QFT Algorithm Overview [8,9,10]

The synthesis procedure of a QFT controller for each joint consists of several fundamental steps:

Plant modeling. The nominal (31) and perturbed (32) models from

Table 4 are selected. These models are used to construct the QFT plant templates in the Nichols plane.

Template construction. For selected frequencies, referred to as essential frequencies , the magnitude–phase characteristics of all admissible variants of the plant dynamics are computed. The resulting envelopes form the plant templates, which represent parametric uncertainty.

Bounds specification. Robust performance bounds are defined: tracking bounds , ensuring low sensitivity at low frequencies; disturbance-rejection bounds , derived from the disturbance model ; a universal high-frequency bound (the U-contour), which specifies a region that the frequency response of the designed open-loop system must not enter. Together these constraints define the optimal bounds , which the QFT controller must satisfy.

Loop shaping. In the Nichols plane, the frequency response of the optimal open-loop system is shaped so that it satisfies all templates and bounds based on the nominal plant model and the optimal limits .

Prefilter design. The prefilter is used to refine the transient response and limit its aggressiveness. Its purpose is to shape the closed-loop frequency response so that the resulting time-domain behaviors specifically the joint trajectories and their settling characteristics meets the required performance criteria.

Verification. Closed-loop stability and performance are verified for all admissible plant variations and under the influence of the disturbance channel .

The dynamics of each of the five axes of the anthropomorphic manipulator are represented by the reduced first-order model with an integrating term (23). For every joint, a parametric uncertainty region is defined as (34), where the nominal and extreme (worst-case) combinations of the parameters

are obtained according to

Table 4.

The parametric uncertainty for each axis can be expressed through the nominal and worst-case plant models. The five joints exhibit distinct electromechanical characteristics:

|

- Base rotation: |

|

|

|

- Shoulder motion: |

|

|

|

- Elbow joint: |

|

|

|

- Wrist rotation (yaw): |

|

|

|

- Wrist rotation (pitch/roll): |

|

|

Thus, the parametric uncertainty for each axis can be represented as a compact set

(35):

where the transfer function (31) represents the nominal point of the set

, corresponding to the combination of the minimum parameter values

and

. The QFT plant templates are constructed for a vector of essential frequencies

(36), which best capture the dynamics of the corresponding axis

; that is, these frequencies span approximately two decades around the break frequency

of the nominal plant (31).

Accordingly, the following vectors

of essential frequencies are obtained for the axes

through

, as given in (37).

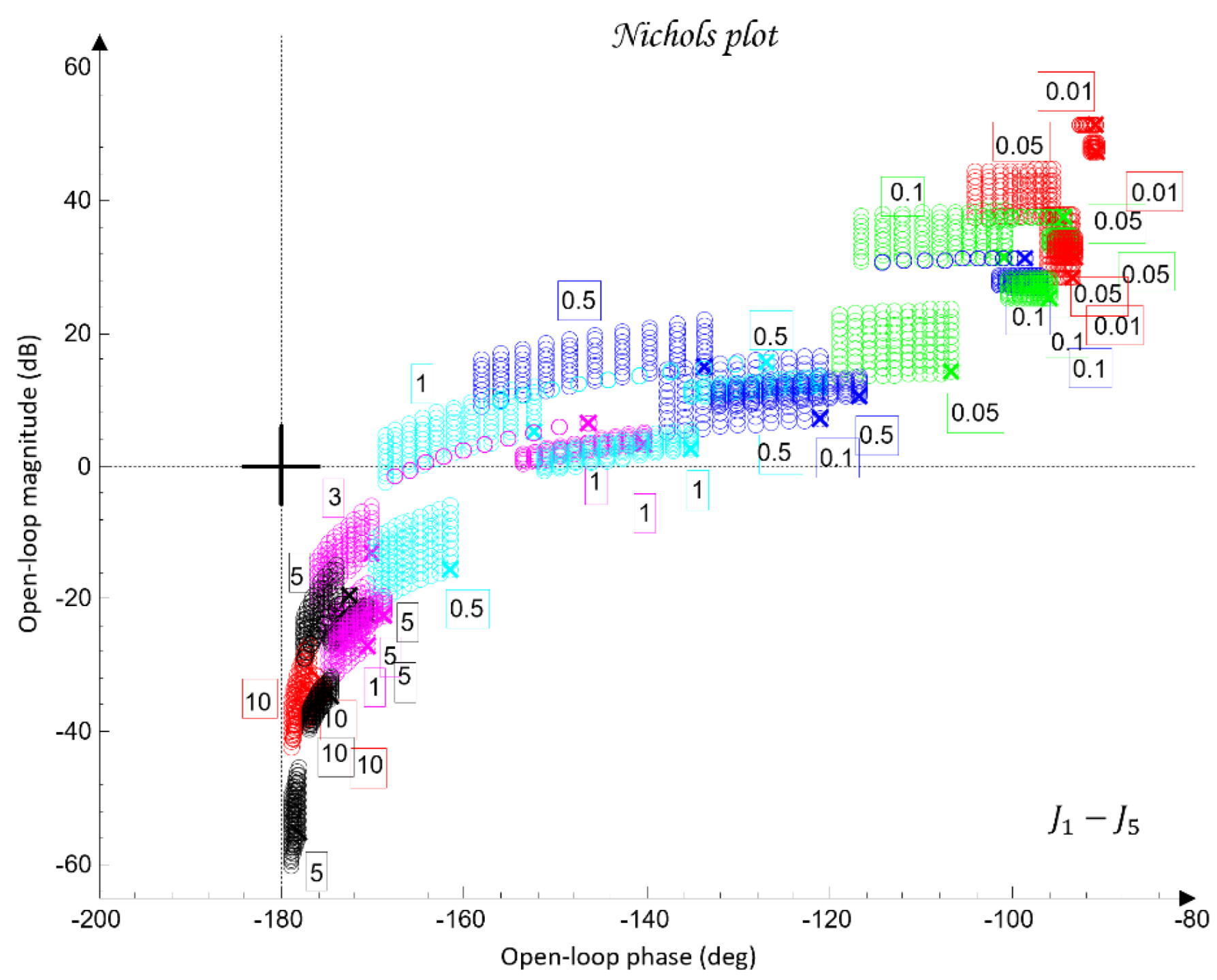

Figure 10 shows the QFT plant templates of the dynamic models of the robot axes in the frequency domain on the Nichols plane.

The uncertainty regions obtained in

Figure 10 clearly illustrate the pronounced variations in the dynamics of the joints

, caused by load changes, friction effects, and cross-axis interactions. The wide spread of the plant templates confirms the presence of significant uncertainty in the model (23), making the use of robust QFT synthesis essential for ensuring stable and high-quality tracking of the joint coordinates

under all admissible operating conditions.

Before constructing the robust bounds, it is necessary to specify the admissible performance criteria

(38) and (39) for each joint

, consistent with the physical constraints of the robot and its DH parameters. These criteria are formulated as prototype models of the desired closed-loop behavior and define lower and upper limits on the output variable

, in accordance with the QFT methodology.

Trajectory (spline): The reference 3D trajectory is defined through five control points, as given in (19).

where the smooth desired trajectory is generated using a cubic spline over the normalized parameter

.

The performance criterion for QFT takes the form (39):

where

is the desired B-spline trajectory and

is the resulting end-effector position. It should be noted that the criterion in (39) reflects the industrial requirement applied to the real FANUC controller, which employs gravity compensation, feedforward structures, and LookAhead planning. These mechanisms allow the real system to achieve sub-millimetre accuracy in the TCP space.

In the simulation model, which uses the simplified first-order SISO dynamics (23) without nonlinear compensation and without the internal high-frequency FANUC algorithms, larger deviations from the geometric spline trajectory are expected. Therefore, for the purpose of model-based analysis, it is appropriate to introduce an additional operational criterion based on the maximum 3D error observed under nominal and worst-case dynamic models (40):

which reflects the dynamic limitations of the simplified model without contradicting the stricter industrial requirement given by (39).

Thus, the two criteria serve different purposes: (39) corresponds to the real engineering specification for the physical robot, whereas the operational criterion (40) provides the basis for evaluating robustness in the simulation environment. Criterion (40) ensures that the end effector follows the prescribed spline within an admissible error bound suitable for both simulation and industrial applicability.

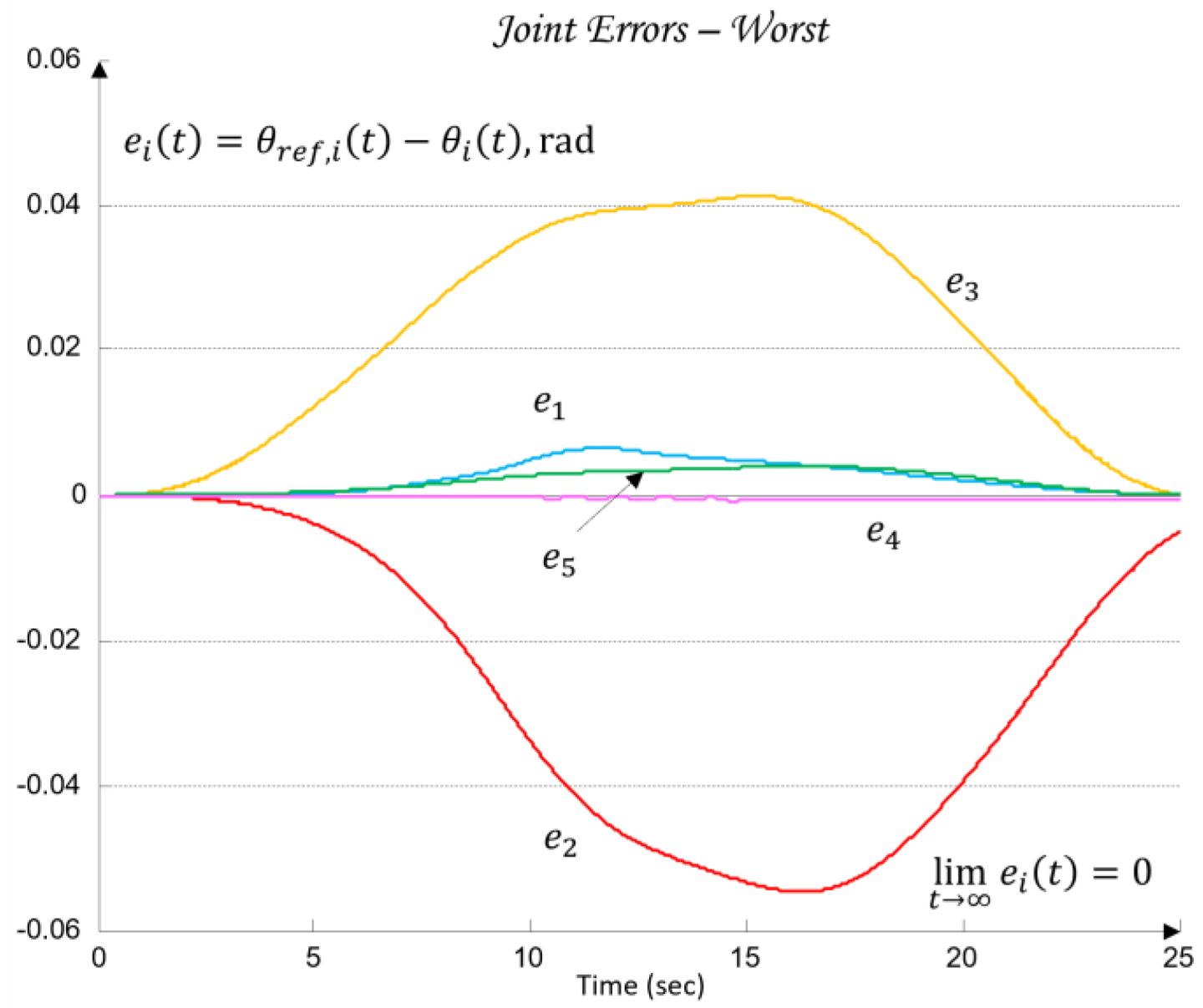

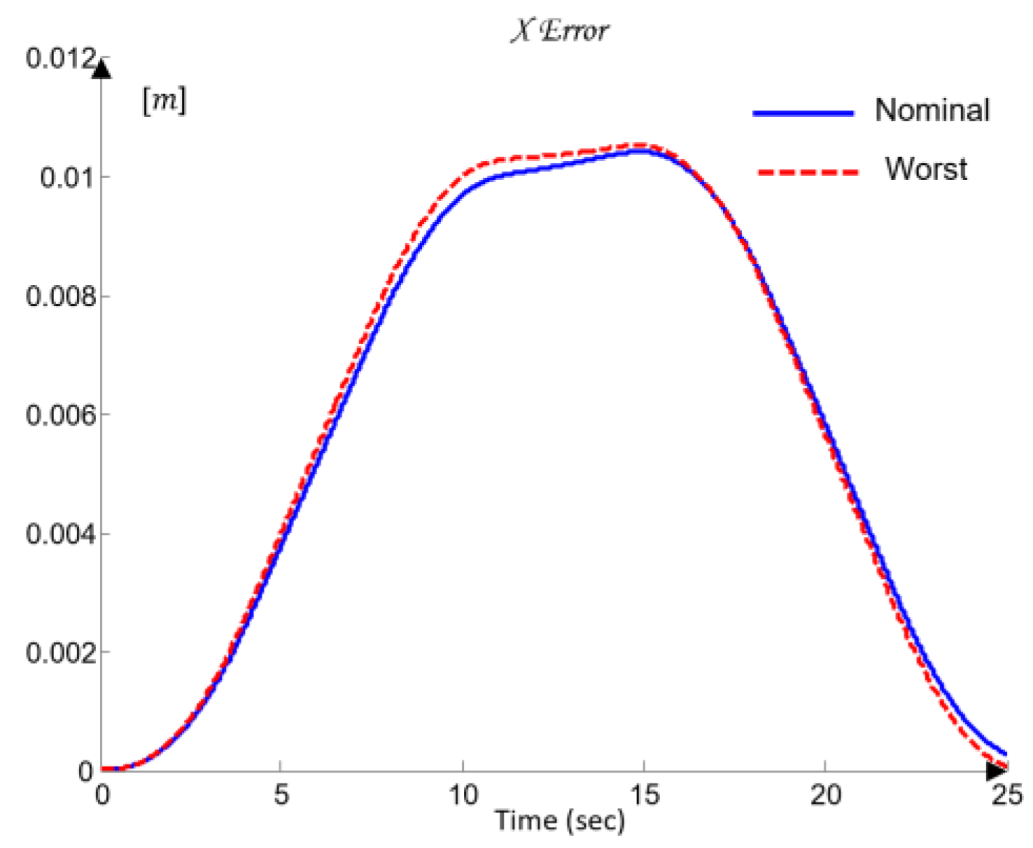

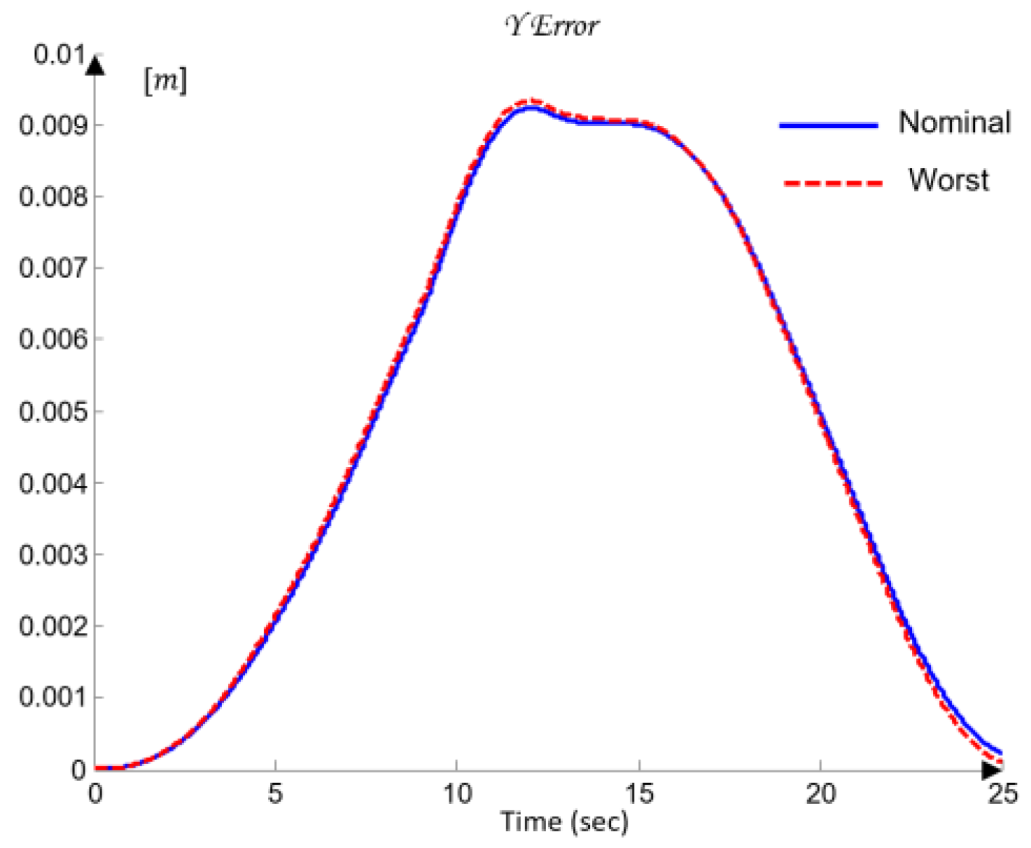

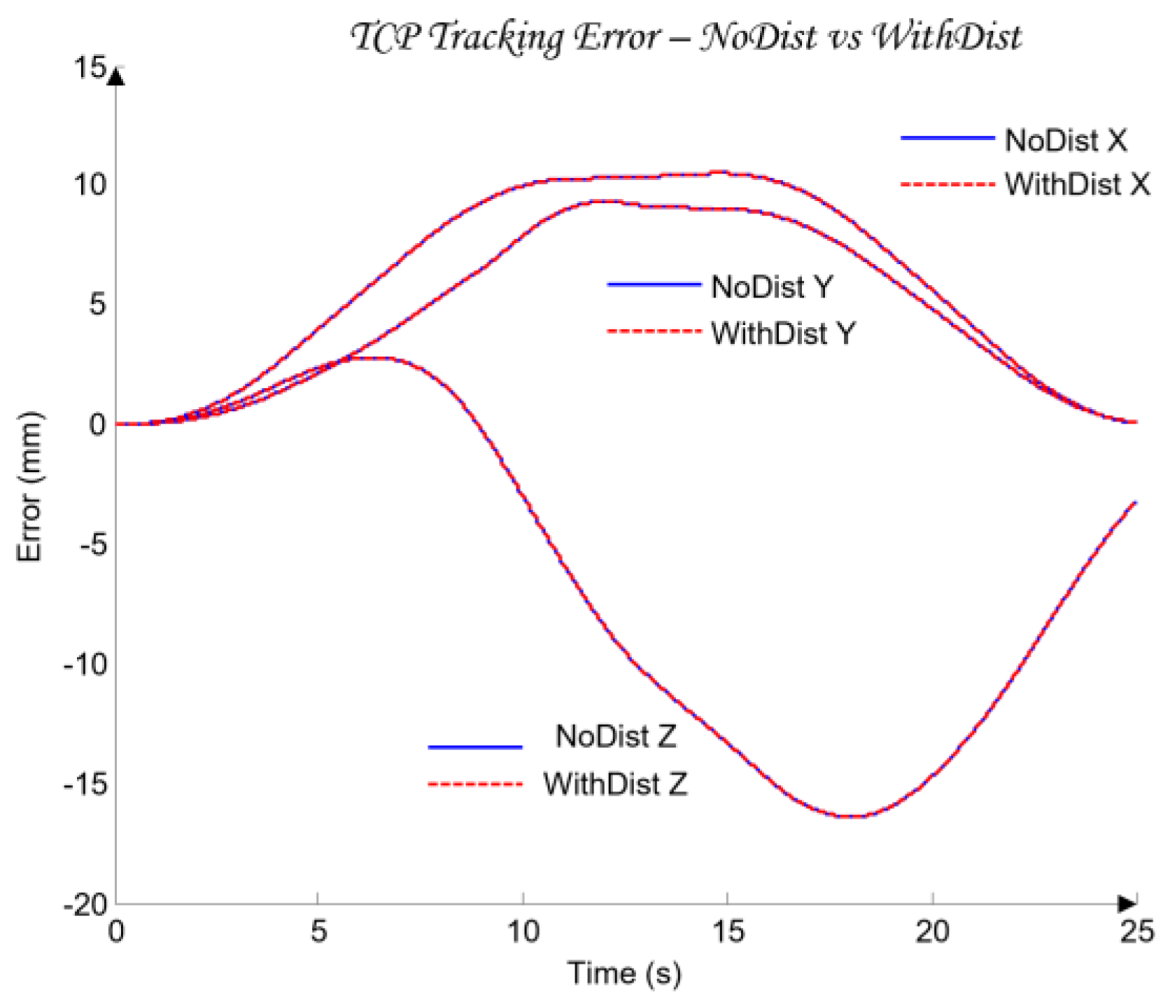

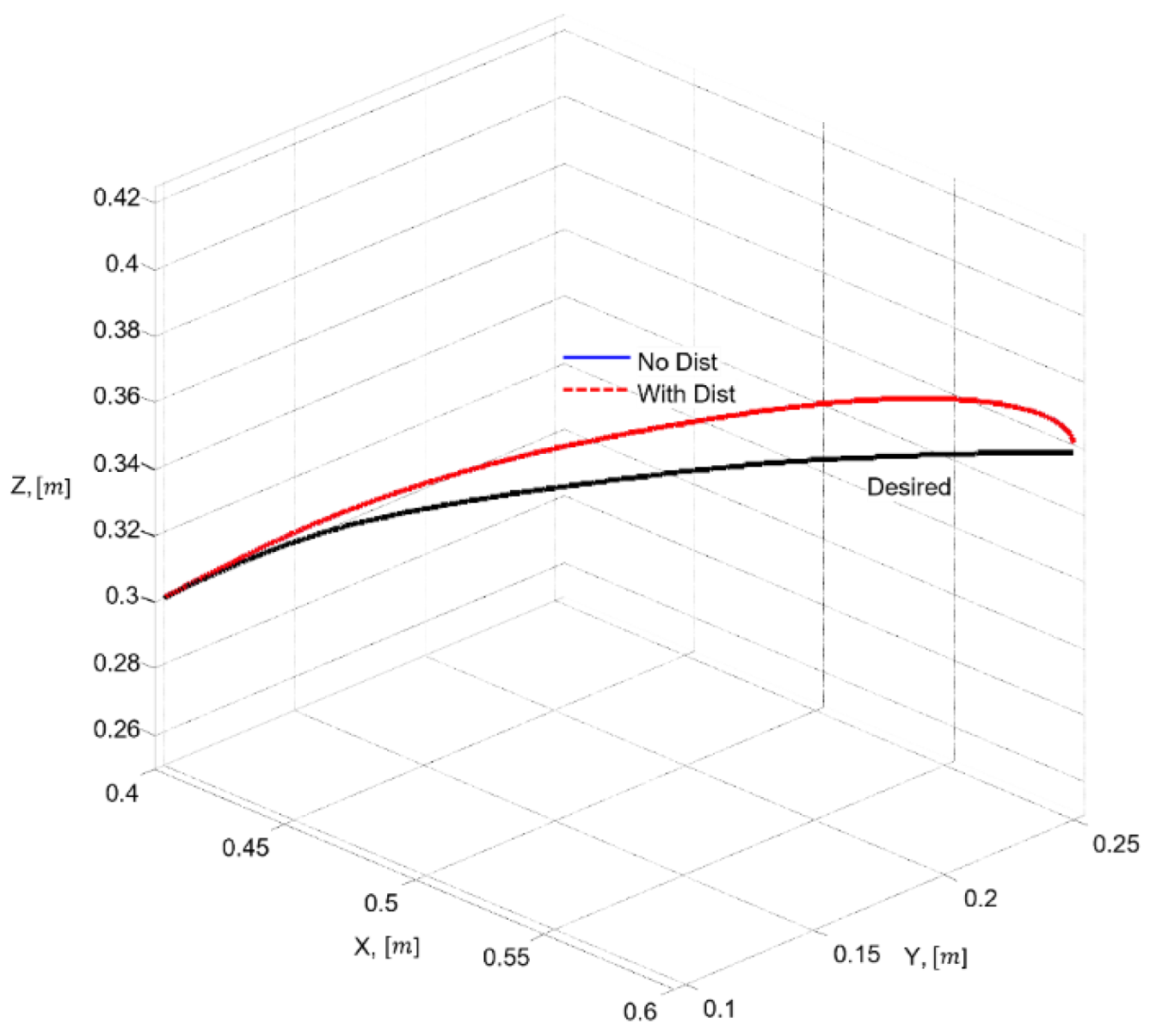

Additionally, for the purposes of simulation-based robustness assessment, quantitative error metrics are introduced in both the joint space and the TCP space, defined through the maximum error and the root-mean-square (RMS) value. Let the total 3D error between the desired and the realized TCP trajectory be denoted by (41):

where the maximum and RMS errors are defined as (42)

These metrics are later used in

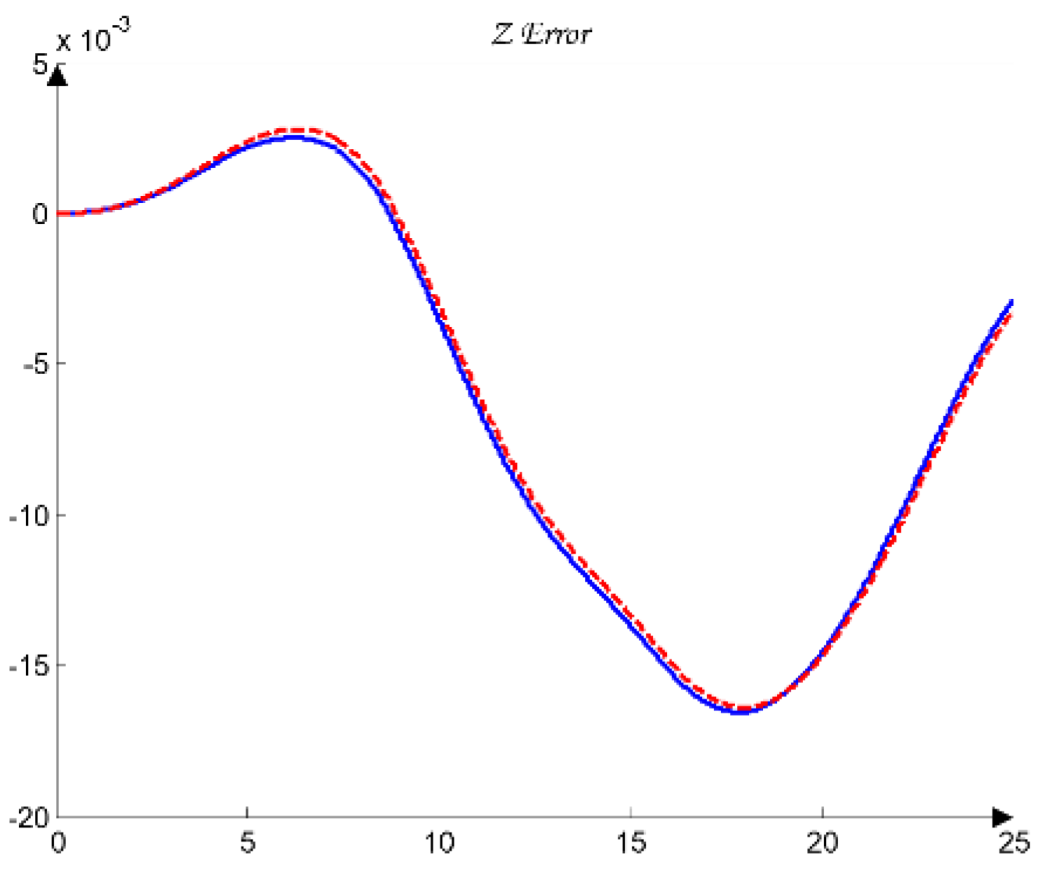

Section 6 to validate the control performance and to compare the nominal and worst-case joint models.

The following pairs of desired closed-loop systems (43) are defined, specifying the target joint-space dynamics for the robot joints

, whose dynamic parameters satisfy the constraints in (38).

During the design of (43), it is taken into account that the difference in the magnitudes

between the closed-loop systems

and

in the frequency domain must continuously increase in order to cover, during the QFT controller synthesis, the high-frequency uncertainty (44).

Next, three robust bounds are constructed: the tracking bounds

, defined by (38); the output-disturbance bound

, derived from (30); and the formation of the U-contour, which specifies a forbidden region for the open-loop frequency response in the Nichols plane around the critical point

. The magnitude of the U-contour is determined by the weighting factor

which ensures that the transient responses of the joint coordinates

exhibit no overshoot. All robust bounds are plotted in the frequency domain for the vectors of essential frequencies (37) for each of the five joints

, using the uncertainty regions of the five plants

(35) and comparing their position relative to the iso-magnitude curves in the Nichols plane and the difference

, following the standard QFT procedure.

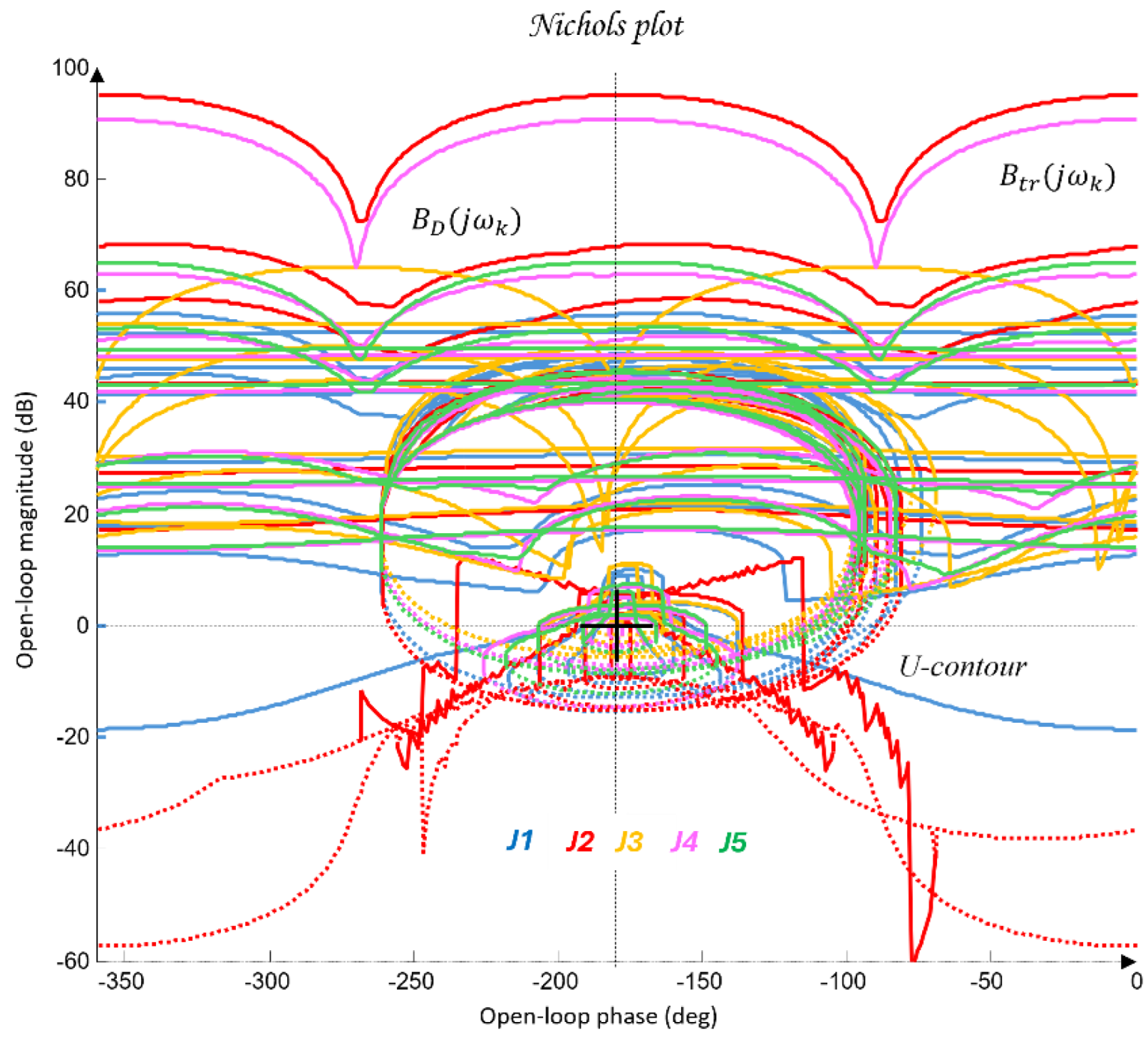

Figure 11 shows the robust bounds for each joint of the robot:

in blue,

in red,

in yellow/orange,

in purple, and

in green, corresponding to the vector of essential frequencies

(37).

The final step before designing the joint QFT controllers

consists of optimizing the bounds from the network shown in

Figure 11. This is performed by comparing, at each essential frequency, the tracking bounds

, the disturbance-rejection bounds

, and the U-contour. For every frequency point, the uppermost bound is selected. In this way, the optimal bounds

are constructed, ensuring that the controllers are synthesized for the worst-case combination of the plant parameters of the dynamic models (23), as illustrated in

Figure 12.

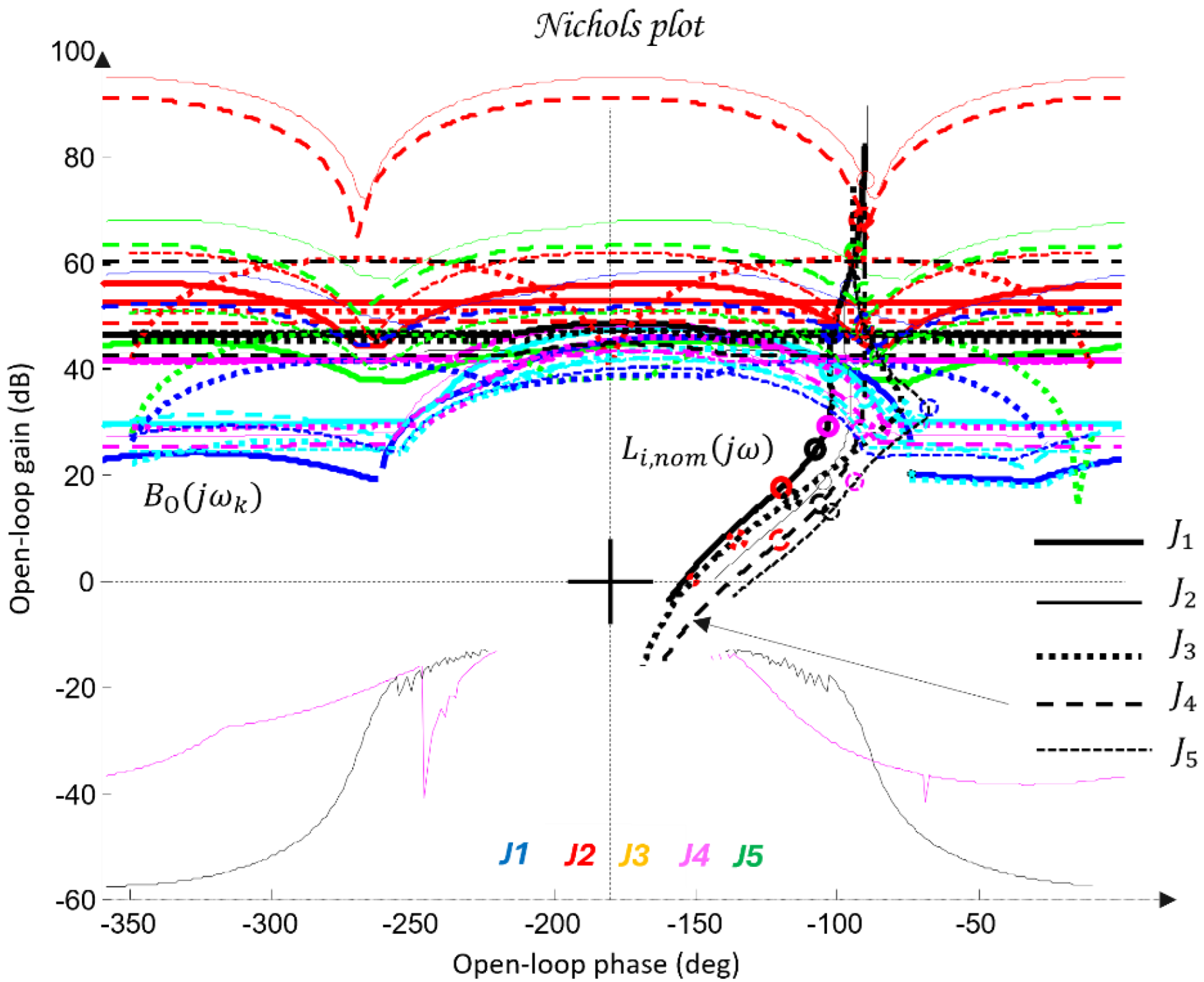

Controller Synthesis and Validation

Loop shaping is carried out by designing a QFT controller that ensures low closed-loop sensitivity and a sufficiently large closed-loop bandwidth. The resulting transfer function of the QFT controller , obtained following the QFT methodology, is of low order, since the regulator design is based on the nominal joint models of the robot (35) and on the optimal bounds .

The outcome of this design step is the set of optimal open-loop frequency responses

, which lie on or above the corresponding robust optimal bounds

for all essential frequencies

(37), as illustrated in

Figure 12.

For the selection of the controllers

, loop shaping is performed by augmenting the complex transfer function of the nominal open-loop system (45) with poles and zeros until an optimal solution is obtained (46):

The transfer functions of the QFT controllers

for the individual joints

are given by (47):

Figure 12 presents the optimal open-loop frequency responses of the five systems with the designed QFT controllers (47) and the nominal plant (35). The frequency characteristics in

Figure 12 show that the closed-loop bandwidths of the joint controllers

are wide, since the added lead dynamics of the controllers

shift the open-loop response (46) to the right.

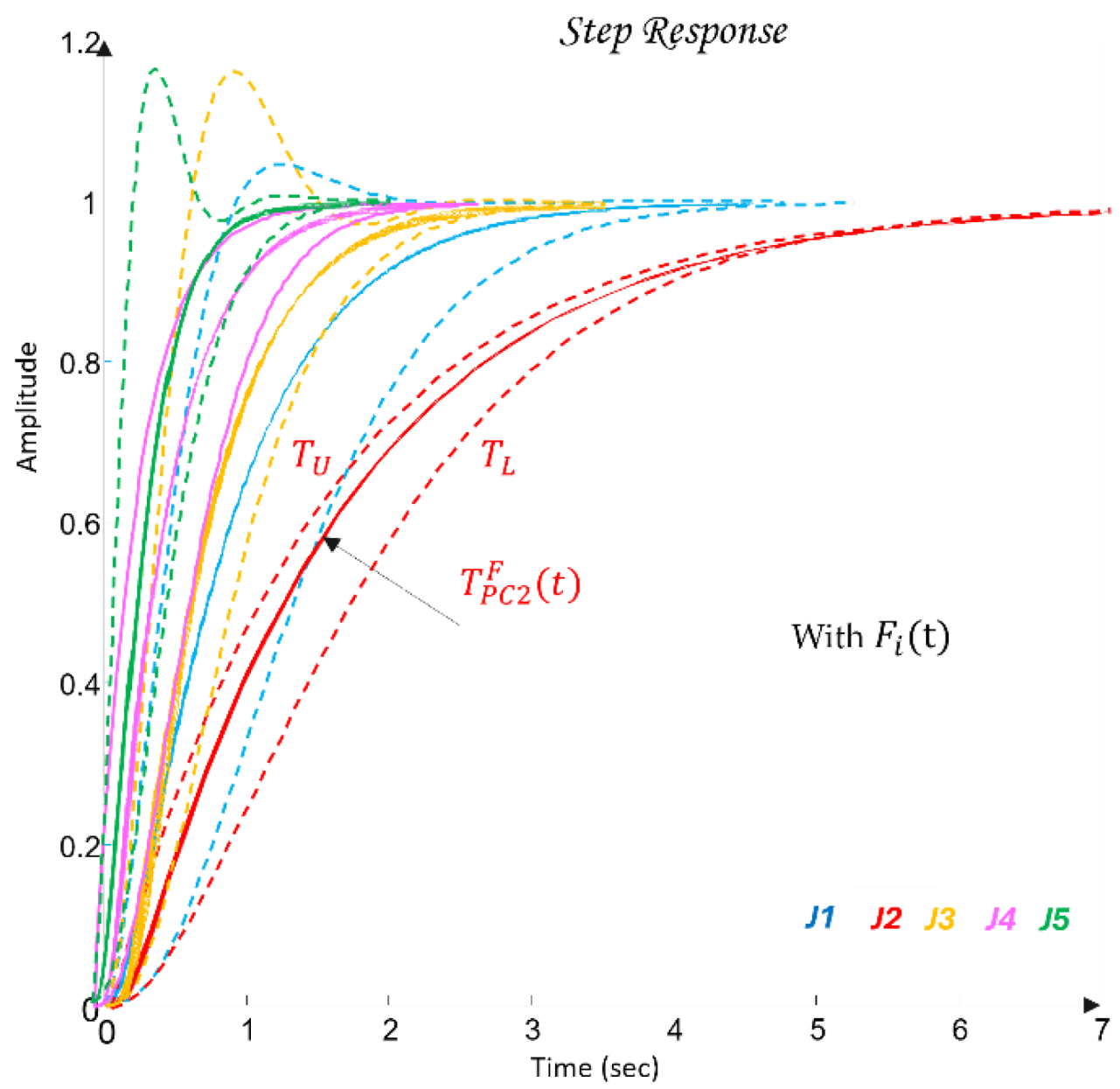

Figure 13 shows the time-domain transient responses of the closed-loop systems

for the individual joints

, plotted in different colors.

The closed-loop responses

shown in

Figure 13 are obtained in a simulation environment under a unit step input. It is evident that the responses are very fast and do not guarantee compliance with the performance requirements (38), defined by the desired envelopes

and

. This discrepancy highlights the role of the designed QFT controllers

(47).

The final step of the QFT methodology consists of designing an additional dynamic element applied at the input of the joint-level control system of each axis

. Its purpose is to ensure the desired control performance of the joints through proper shaping of the reference position

. This task is accomplished by synthesizing a prefilter

(48), whose dynamics slow down and shape the response of the existing QFT-controlled system, thereby ensuring robustness and the required performance of the closed-loop system

, as illustrated in

Figure 9.

The synthesis of the prefilter

is performed in the frequency domain for each of the five joints

. In the present case, two poles are added to shift the magnitude of the closed-loop frequency response of the QFT-controlled system by approximately

dB, followed by fine tuning of the pole locations, as shown in

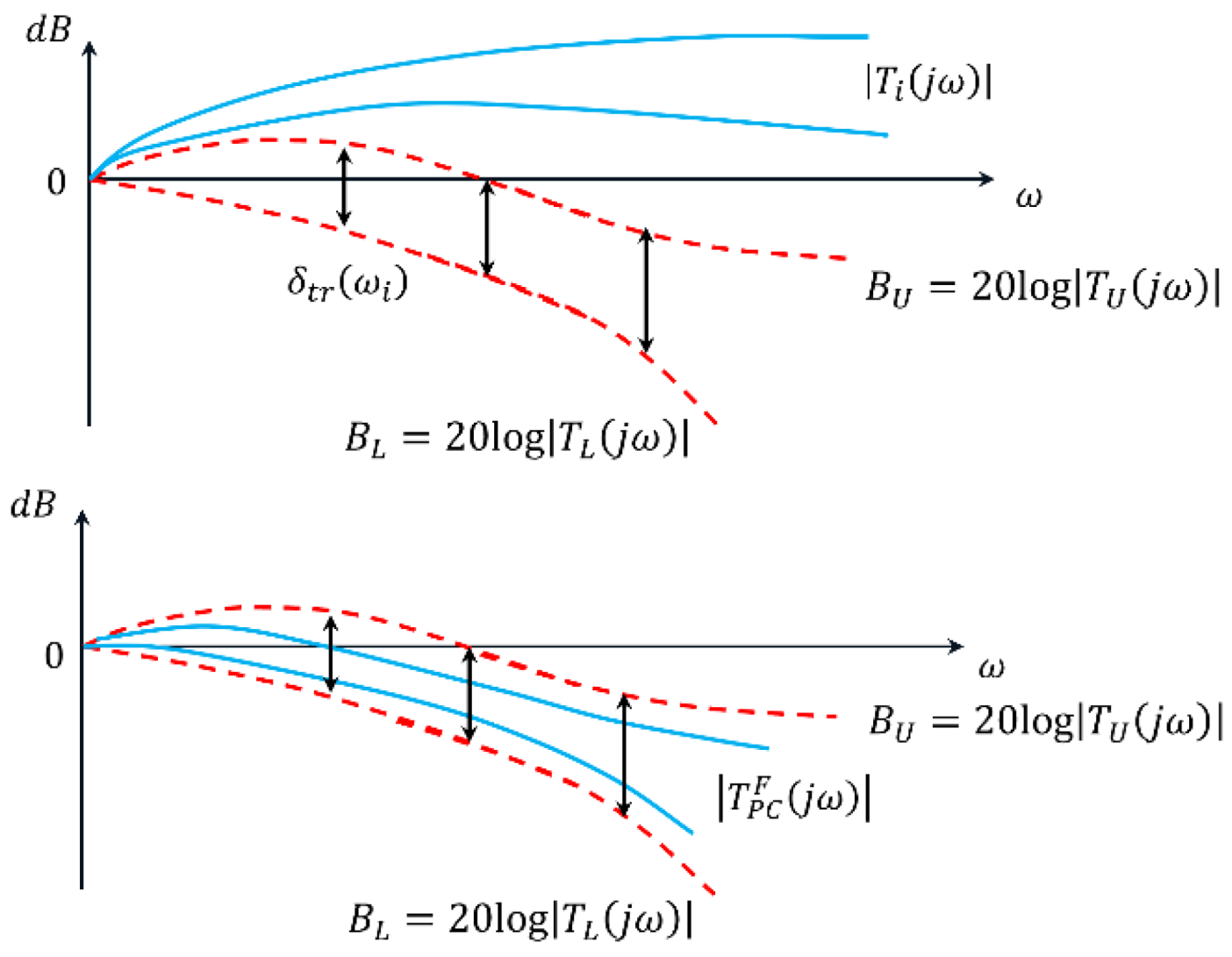

Figure 14.

The following prefilter transfer functions

have been designed as part of the joint-level control system for the axes

(49):

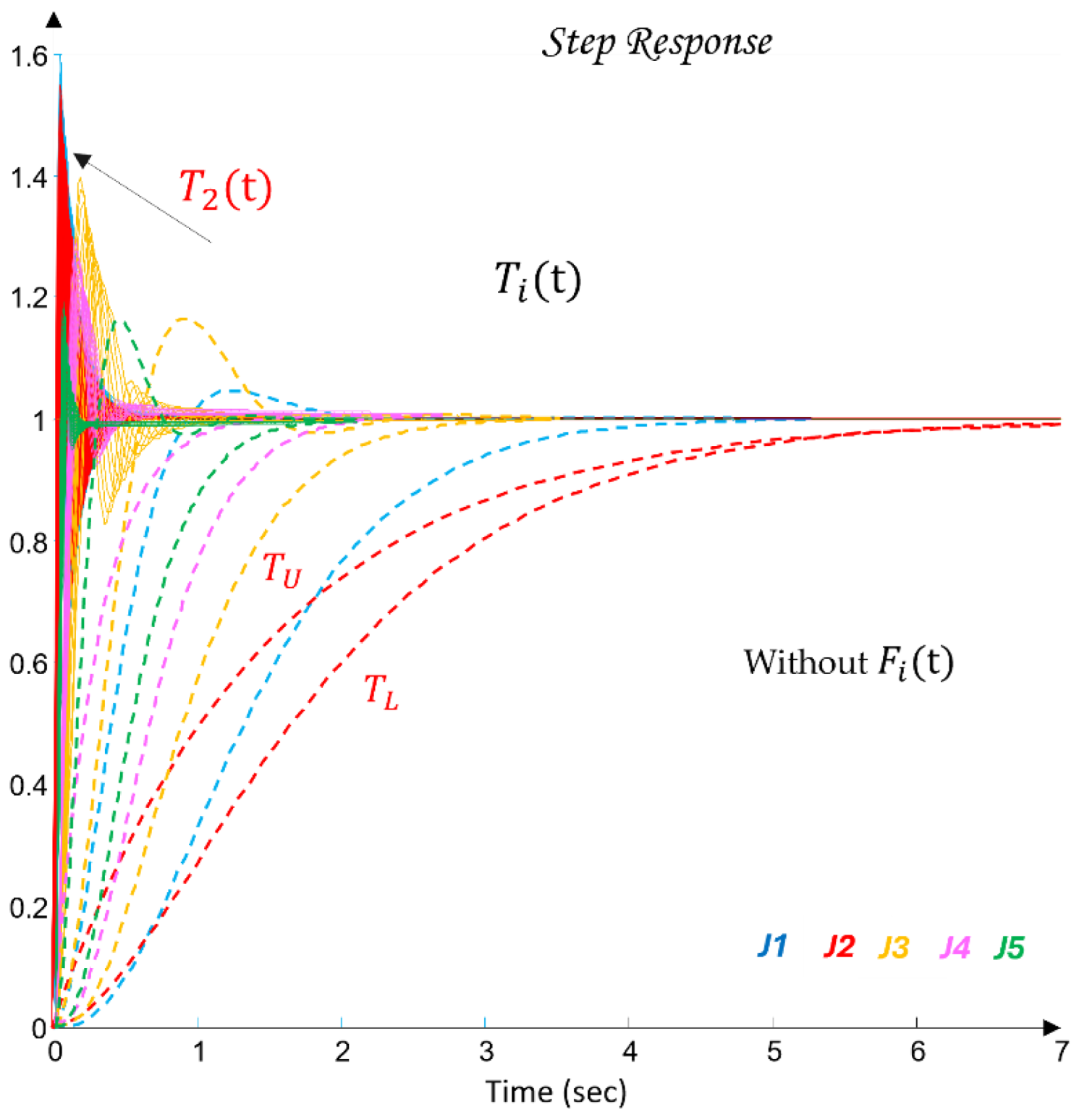

Figure 15 shows the transient responses of the closed-loop control systems

for the robot joints

.

It is evident that the dynamics of the prefilters

ensure the desired control quality specified in (38), as well as robustness of the closed-loop system, since the model uncertainty in the joint dynamics

(

Figure 10) is practically eliminated. In other words, the entire set of plant models between

and

, whose behavior is regulated by

and

, results in a family of transient responses that visually collapse into a single trajectory.

4.7. Discrete-Time Realization of the QFT Controllers and Prefilters

Although the synthesis of the QFT controllers

and the prefilters

in this work is performed in the continuous-time domain, their actual implementation within the PLC-MATLAB-Digital Twin control loop is carried out in discrete time. The discretization is aligned with the architecture presented in

Section 3, where the control cycle operates with a fixed sampling period of

corresponding to a sampling frequency of 50 Hz. This frequency is approximately 15–20 times higher than the crossover frequency of the optimal open-loop systems obtained during the QFT loop-shaping procedure in

Section 4.6. As a result, the discrete-time realization of the five joint subsystems preserves the essential phase characteristics and does not violate the robustness constraints imposed by the templates and the bounds

,

, and

. The chosen discretization approach follows the conclusions of earlier studies in [49] on frequency-oriented QFT synthesis, where the Tustin method (bilinear transformation) consistently demonstrated the best compatibility between analog and digital closed-loop behavior in the presence of parametric uncertainty. The Tustin method preserves the local shape of the frequency response around the crossover region and minimizes the uncertainty introduced by discretization—an essential requirement for maintaining the correct behavior of the U-contour. In contrast, Zero-Order Hold (ZOH) discretization introduces significant phase distortion around the Nichols-plot crossing region, which may lead to violations of robustness constraints and changes in relative stability. For this reason, ZOH is not suitable in a QFT context. The 20 ms sampling period is also consistent with the PLC layer, which supports an event-driven control tick of 20 ms, independent of its internal scan cycle. This ensures conflict-free integration between the continuous-time model, the digital realization in MATLAB, and the actual execution within the PLC–ROBOGUIDE environment, without introducing additional latency or undesirable phase shifts. Consequently, the discretized transfer functions of the controllers

(50) and the prefilters

(51) operate correctly and in real time within the MATLAB–PLC–ROBOGUIDE loop, where the PLC provides deterministic communication through OPC UA and Modbus TCP, in accordance with the architecture described in

Section 3.

The resulting discrete-time transfer functions (50)-(51) are used directly in real time within the MATLAB-PLC-ROBOGUIDE control loop (

Section 6), where they are validated against both nominal and worst-case models. In this way, the discretization ensures correct digital execution of the QFT control law, preserves stability and accuracy under worst-case dynamics and external disturbances, and guarantees full compatibility with the communication constraints of the CPDTQN architecture, as demonstrated in the results presented in

Section 6.3-6.4.

5. Digital Twin Integration and NIS2 Security Compliance

In the context of the expanding digitalization associated with Industry 4.0 and Industry 5.0, industrial robotic systems have evolved from isolated mechanical devices into fully integrated cyber–physical environments in which PLC controllers, robotic manipulators, cloud services, digital twins, and intelligent control algorithms exchange data in real time [43,44,45]. This integration significantly increases the adaptability and efficiency of manufacturing processes, while simultaneously expanding the system’s attack surface [44]. Communication protocols, telemetry streams, digital-twin models, and configuration resources become critical points exposed to risks such as unauthorized access, data manipulation, software compromise, or injection of malicious behavioral models [19,20,48].

Against this background, Directive (EU) 2022/2555 (NIS2) introduced an expanded pan-European regulatory framework with requirements for risk management, cyber-resilience, incident reporting, supply-chain protection, and continuity of critical services [19,20,46]. Although industrial robots are not defined as independent sectors, they fall within regulated categories related to the production of critical goods, digital infrastructure, and ICS/SCADA environments [19,46]. Consequently, the integration of digital twins and robust control must be assessed not only from a technical perspective but also in terms of regulatory requirements for security, traceability, and accountability.

Within the CPDTQN architecture (

Figure 5), the digital twin operates as a synchronized model of the physical robot, maintaining continuous bidirectional exchange of states, parameters, and control variables [43,44]. This enables virtual diagnostics, simulation-based validation, monitoring, and disturbance response, while simultaneously requiring secure data exchange among the MATLAB/QFT controller, the PLC, and the twin environment. Quantitative Feedback Theory (QFT) provides the formal framework needed for synthesizing robust control laws under parametric uncertainty and external disturbances [44,48], and in this work it is combined with NIS2-oriented mechanisms for access control, cryptographic protection, logging, and risk management. The resulting multilayer configuration ensures resilience at three levels: technical resilience through the robust controller, operational resilience through monitoring and simulation in the digital twin, and regulatory resilience through compliance with the NIS2 requirements. The specific alignment between the architecture and the regulatory framework is summarized in

Table A1, where the implemented measures are mapped to the corresponding articles of the directive.

5.1. PLC Communication with the Digital Twin (Modbus TCP/IP)

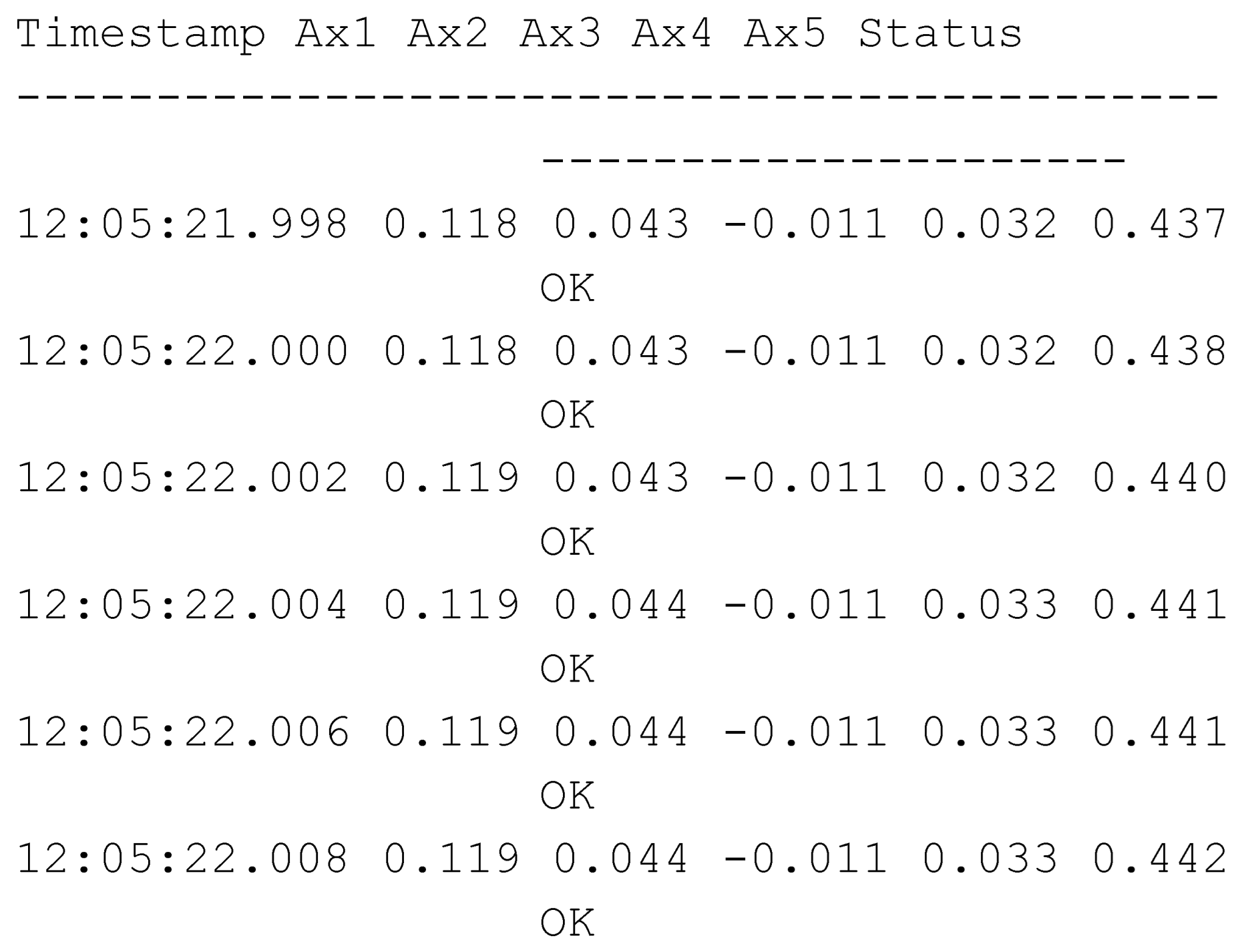

The communication between the PLC and the digital twin is implemented via Modbus TCP/IP with additional TLS encryption, where the PLC operates as the master device and the Digital Twin as the slave device [44]. This channel is used to transmit the control inputs , the measurements for the five axes, as well as accompanying telemetry - positions, velocities, currents, and input/output module states. The same mechanism is also used for transmitting alarms, diagnostic states, and synchronization data between the physical system and the virtual model, ensuring real-time bidirectional exchange [44].

Records for positions, loads, variable friction, velocity profiles, and diagnostic flags are logged and synchronized using UTC timestamps, which enables continuous monitoring and full event recoverability. This approach provides traceability and accountability, required for ensuring compliance with NIS2 obligations related to access control, logging, and risk management.

The Modbus TCP/IP protocol, although widely adopted in industrial practice, does not inherently include mechanisms for encryption, authentication, or integrity verification [44]. As a result, it is susceptible to eavesdropping, command tampering, MITM attacks, replay scenarios, falsified measurements, noise injection, and firmware compromise in the absence of secure update mechanisms. In the context of NIS2, these risks are particularly significant for robotic systems classified as critical manufacturing components [19,20]. In the present implementation, cryptographic protection is provided through TLS encapsulation (VPN tunneling or protocol wrapping), which adds confidentiality, integrity, and authenticity to Modbus TCP/IP communications, even though the protocol itself does not provide such mechanisms by design.

The implemented CPDTQN architecture mitigates these vulnerabilities through role-based access control and authentication executed at the PLC level, which acts as a secure gateway between the control algorithm and the actuation mechanisms [19,20]. Additional protection is provided through Modbus TCP with TLS or via OPC UA with enabled Security Policies [44]. All critical events and command sequences are logged in parallel within both the PLC and MATLAB, enabling reconstruction of the complete interaction timeline and facilitating compliance verification and forensic analysis [9].

The Digital Twin environment functions both as a state redundancy layer and as a simulation-based recovery and risk assessment tool, allowing test scenarios involving parameter variations, communication delays, or controlled cyber incidents [43,44,48].

In this form, the communication scheme extends the classical closed-loop structure by adding a layer of observability, reliability, and cyber-resilience, with the implemented mechanisms following the Protect–Detect–Respond–Recover principles embedded in the NIS2 directive.

5.2. Simulated Disturbances and Loads in the Digital Twin

The Digital Twin environment enables controlled reproduction of a wide spectrum of dynamic scenarios through which the behavior of the QFT controller is validated under parametric uncertainty, disturbances, and cyber incidents. The virtual environment supports the application of physical effects such as variations in inertial parameters, changes in friction, external forces, impacts, and asymmetric loading of the manipulator. In addition to these physical influences, sensor-related anomalies are also modeled, including noise, drift, intermittent faults, or partial loss of measurement signals. A third category of scenarios includes communication disturbances manifested through delays, packet loss, spoofing, replay attacks, or MITM interference, all of which may degrade the control margin. Furthermore, software-oriented attacks are considered, such as manipulation of digital-twin parameters, firmware compromise, or execution of unsigned updates.

QFT control is inherently designed to provide robustness under structured uncertainty and worst-case variations. The Digital Twin environment enables systematic generation of such worst-case and stochastic scenarios, in which stability, tracking performance, overshoot, and response speed are measured, along with the system’s reaction under disrupted communication or simulated cyber incidents. The resulting data defines the compatibility threshold between the model and physical reality and serves as a foundation for establishing resilience and recovery policies in accordance with NIS2 principles.

All simulations are documented, logged, and archived as part of the audit and accountability requirements. These records constitute evidential material for subsequent validation of security measures and for forensic investigation of incidents, thereby positioning the Digital Twin environment as a tool with an importance comparable to that of operational monitoring systems in real installation.

5.3. Cybersecure Communication in Compliance with NIS2

The security of communication between the MATLAB/QFT controller, the PLC, and the digital twin is ensured through a set of mechanisms aligned with the requirements of NIS2. Access control is implemented through role-based access control (RBAC) and centralized identity management, which includes authentication of users and devices via X.509 certificates. Clear segmentation between the IT and OT domains, together with the use of a DMZ zone for the Digital Twin Hub, limits the attack surface and prevents unauthorized access to critical interfaces. In this configuration, the PLC functions as a trusted gateway that isolates the execution layer from external software modules, including MATLAB.

Traffic protection is achieved through TLS encryption or VPN tunneling, preventing eavesdropping, command-packet manipulation, and man-in-the-middle (MITM) attacks. For critical command messages, HMAC mechanisms are used to ensure integrity verification. Device authentication is enforced through secure boot, TPM, and periodic firmware integrity checks. Replay attacks are mitigated using nonces, sequence numbers, and time stamps. Cryptographic keys are managed through a centralized Key Management System (KMS), supporting rotation, revocation, and controlled deprovisioning.

A key component of NIS2 compliance is the logging of events and anomalies. All interactions between MATLAB, the PLC, and the Digital Twin are aggregated into a centralized SIEM, which enables event correlation, early deviation detection, automated triggering of incident-response procedures, and maintenance of a complete audit trail. In this way, the communication layer complies with the NIS2 requirements for risk management, detection, and reporting, as defined in Articles 21-23 of the directive [19].

5.4. MATLAB-Based Logging and Monitoring for Traceability

MATLAB/Simulink is used as a central tool for logging, monitoring, and forensic analysis, ensuring traceability throughout the entire control cycle from generating control signals to their execution in the PLC and the response of the digital twin. In simulation mode, MATLAB records inputs, outputs, parametric configurations, and any detected anomalies, storing all data in standardized formats suitable for post-processing. In real-time operation, the system monitors states, deviations, and incidents through its connection to the Digital Twin Hub, maintaining synchronization between the virtual and physical components. The logs include extended metadata such as software versions, configuration parameters, device identifiers, and time stamps, enabling full reconstruction of the event history in case of an incident. Integrating these logs with SIEM systems allows centralized correlation, deviation detection, and preservation of evidentiary data. Reconstruction of the sequence of events serves as the basis for forensic analysis and supports compliance verification with NIS2, which emphasizes accountability, reporting, and auditability. In this way, MATLAB functions as a key component for ensuring traceability and accountability, complementing the protective mechanisms implemented in the PLC and the digital twin and establishing the architecture as fully documented and verifiable according to NIS2 criteria.

5.5. CPDTQN Architecture with NIS2 Security Layers

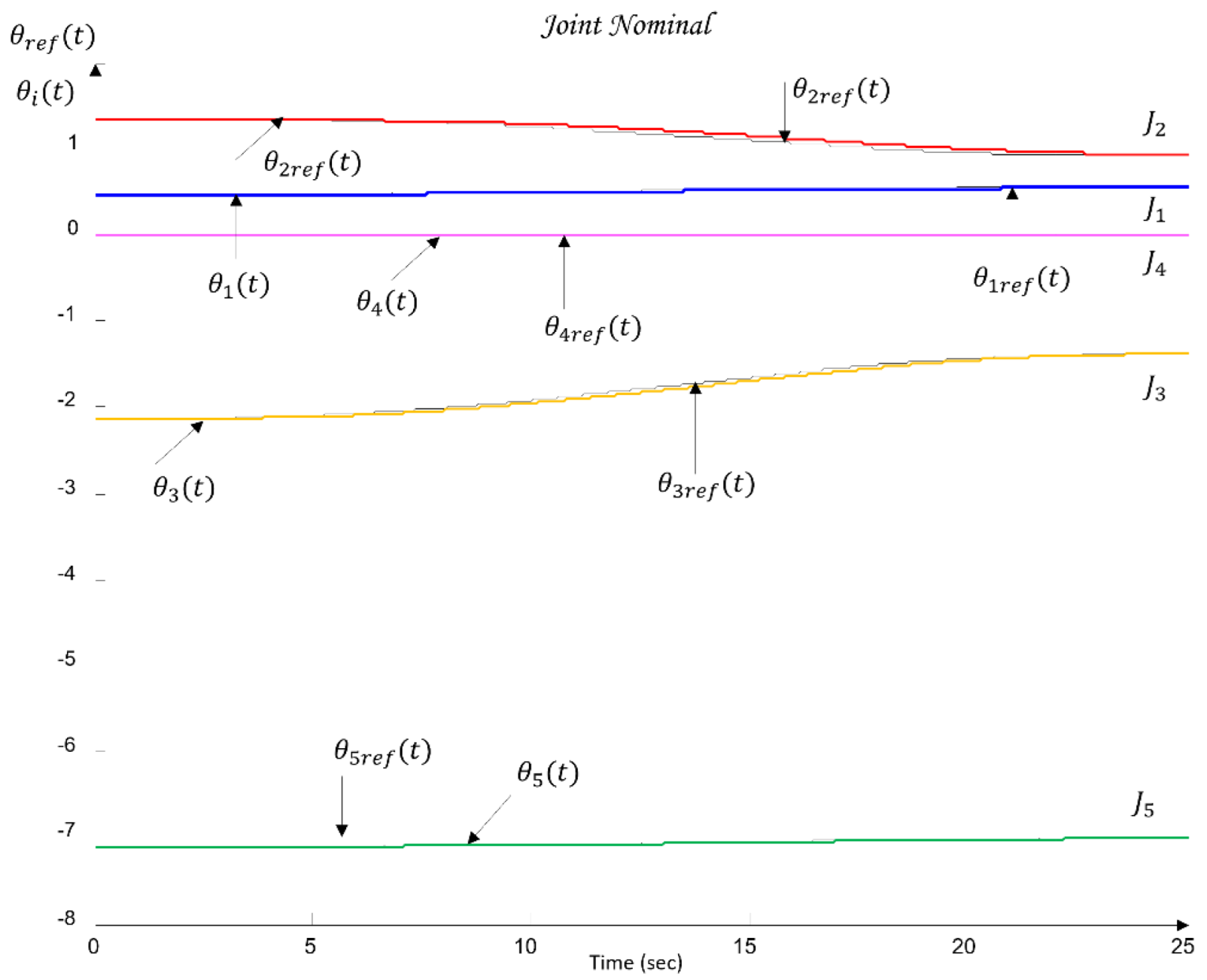

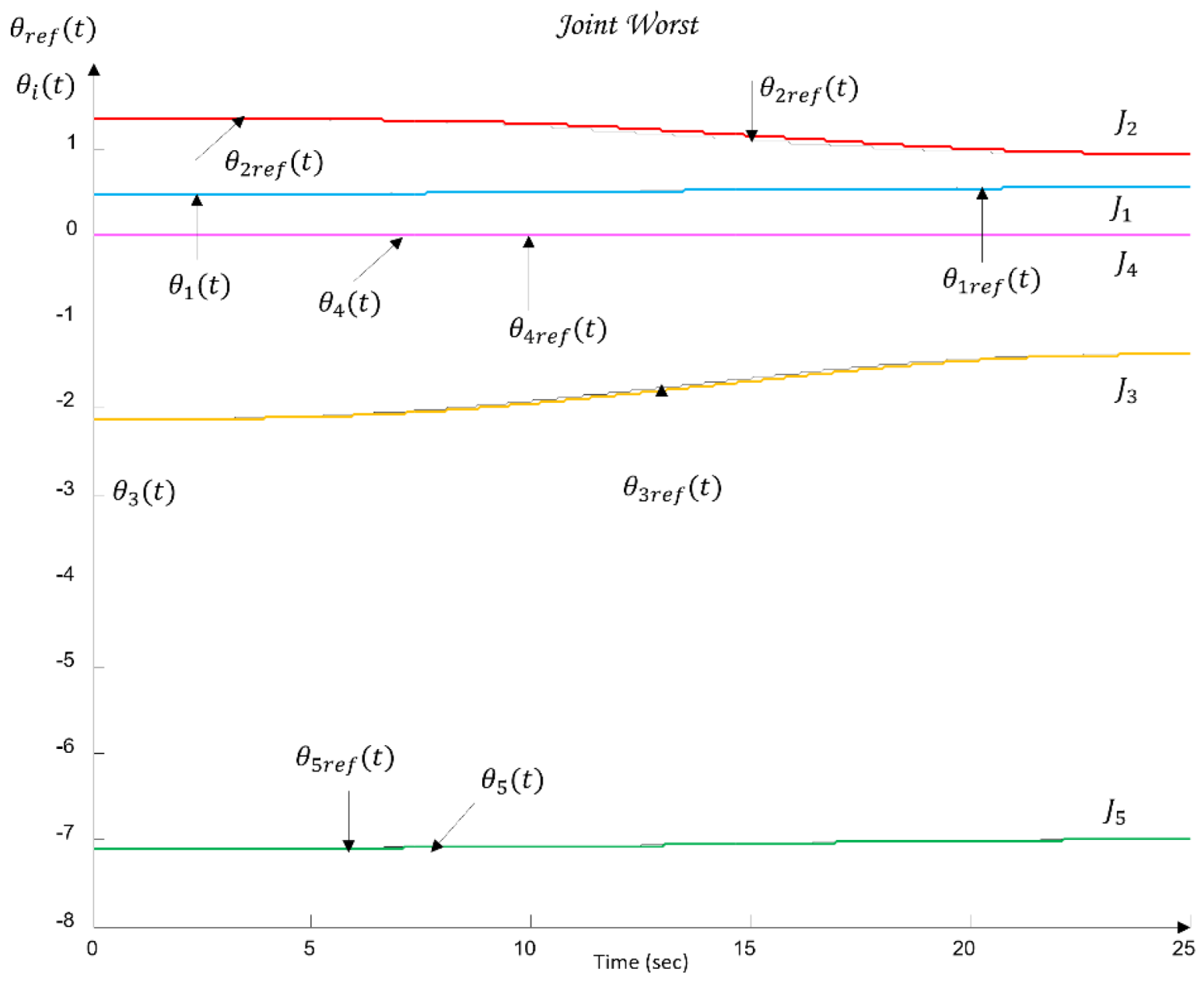

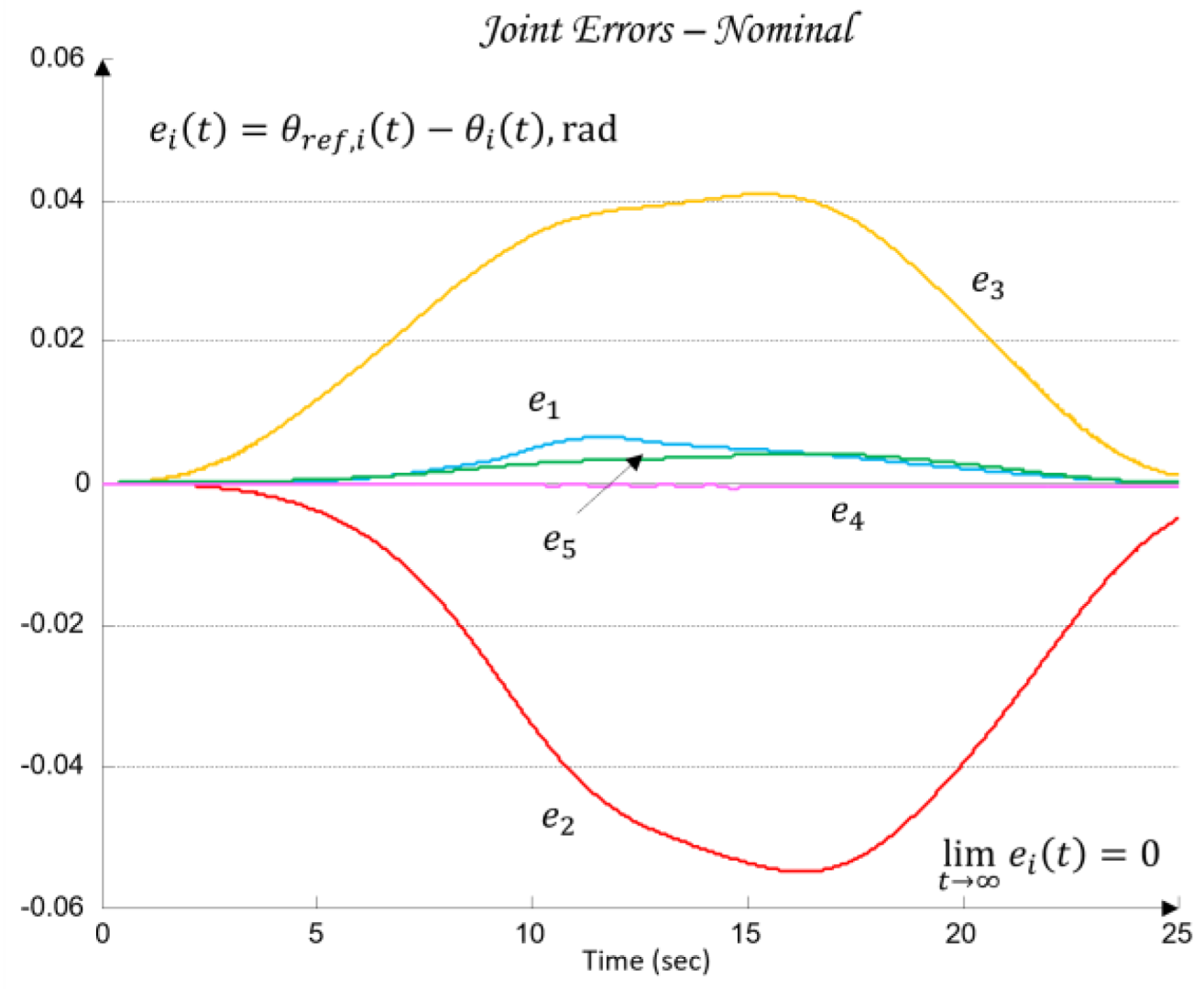

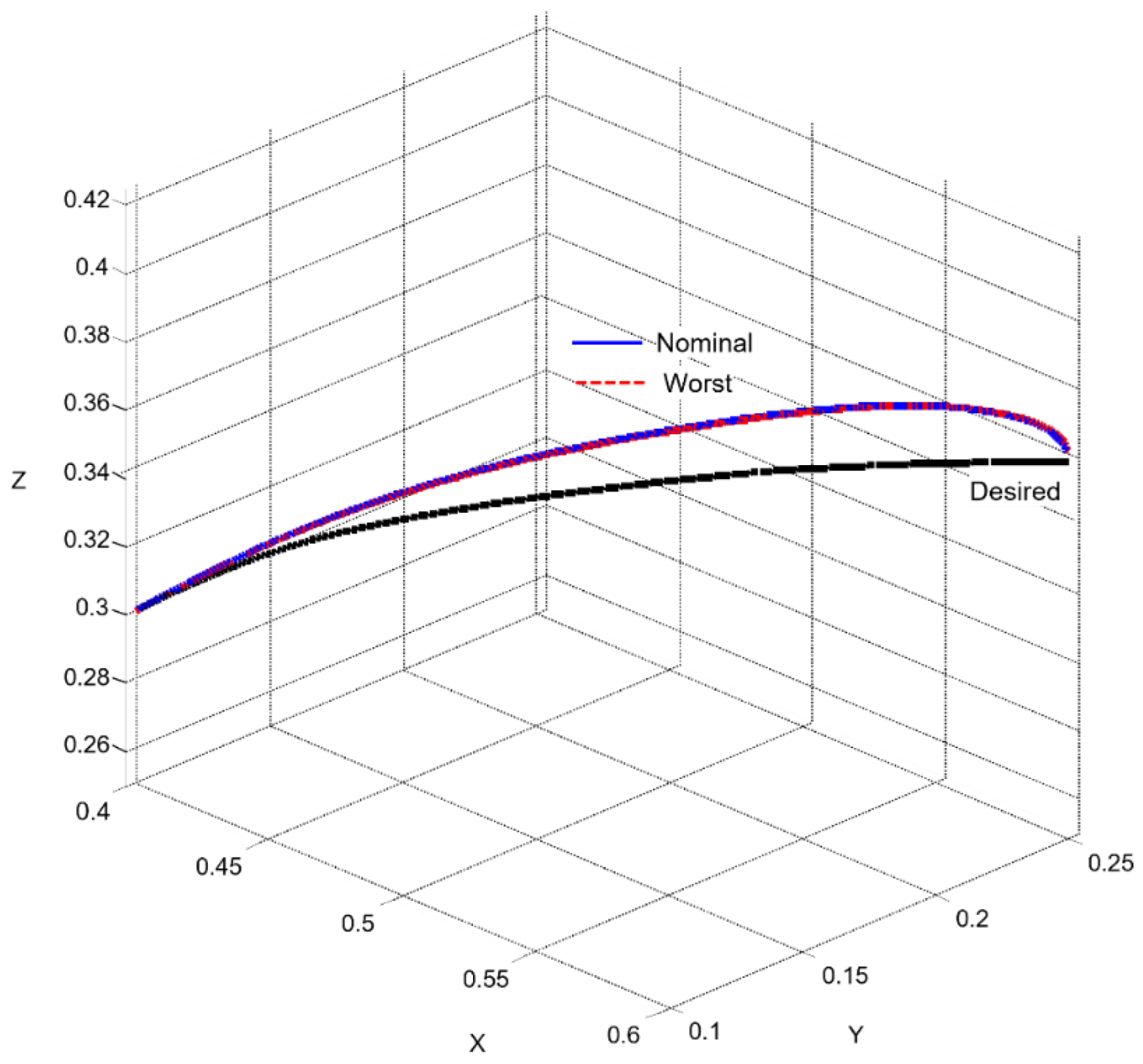

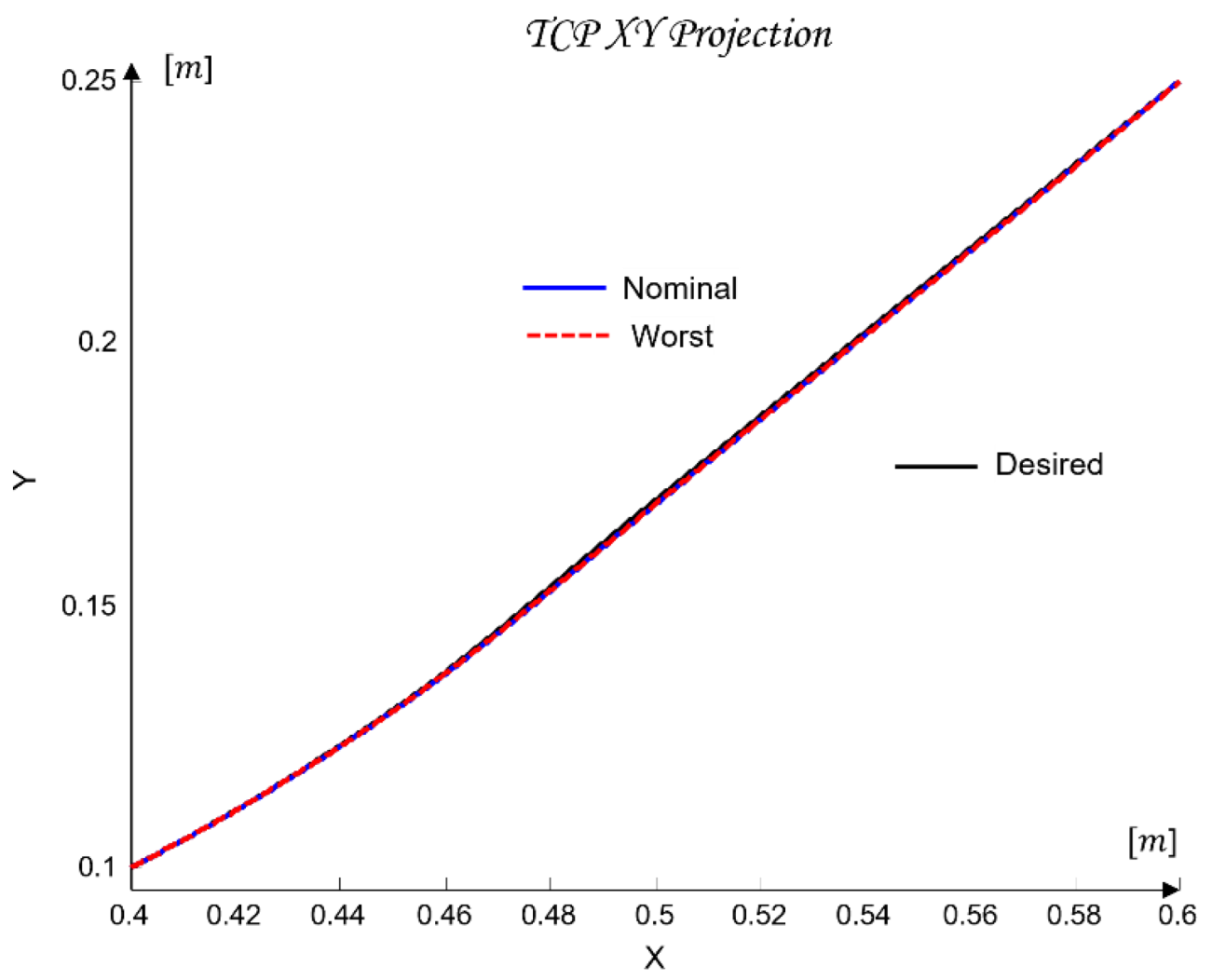

The proposed CPDTQN architecture enables a controlled integration between the real-time OT control layer and the IT layers responsible for monitoring, analytics, and security, using the Digital Twin environment for verification, diagnostics, and traceability. The structure shown in