Submitted:

31 October 2025

Posted:

03 November 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Sample and Study Area Description

2.2. Experimental Design and Control Conditions

2.3. Measurement Methods and Quality Assurance

2.4. Data Processing and Model Equations

3. Results and Discussion

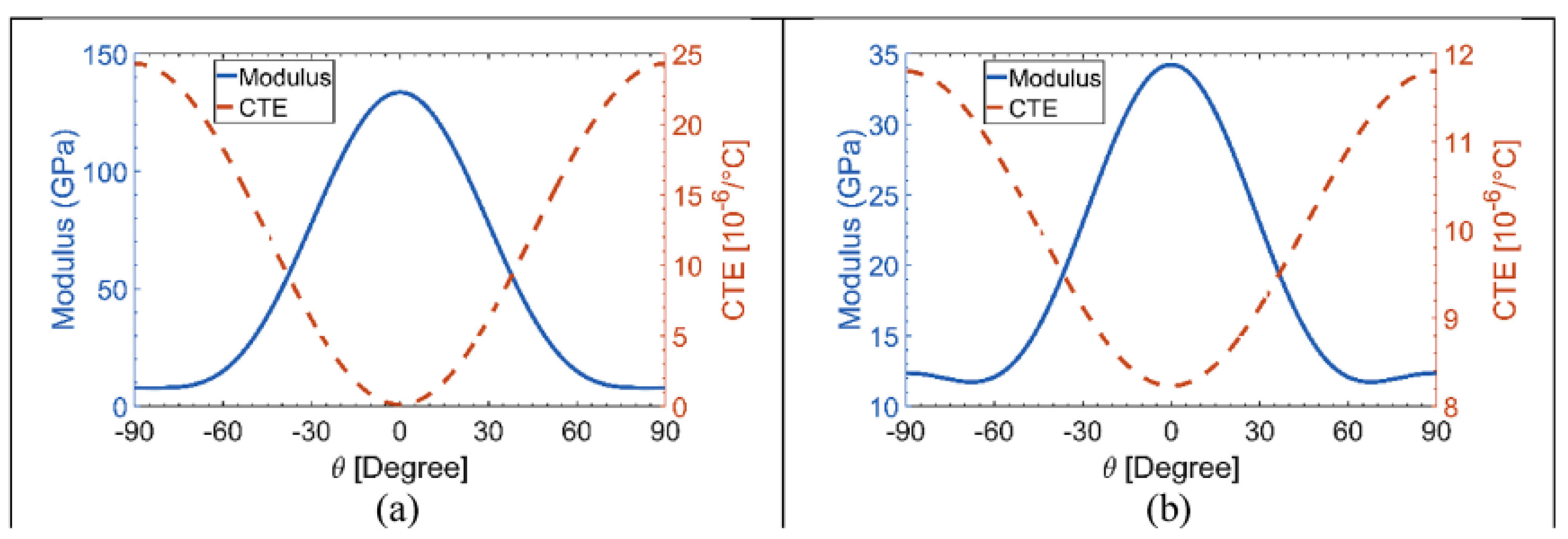

3.1. Shape-Programming Accuracy in Composite Laminates

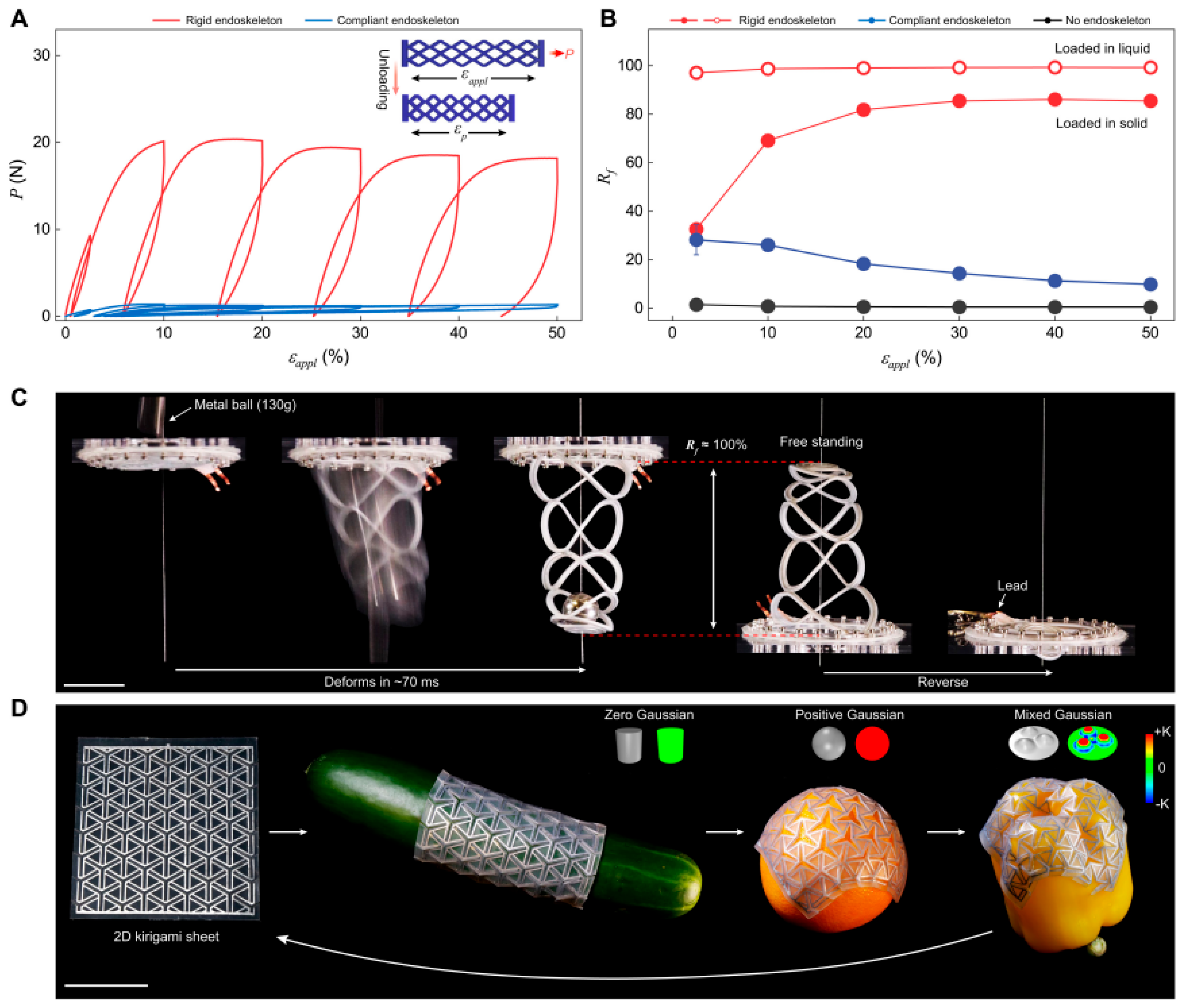

3.2. Chromatic Texture Uniformity During Morphing

3.3. Actuation Durability and Cyclic Performance

3.4. Comparative Evaluation and Application Perspective

4. Conclusion

References

- Jeon, S. J., Hauser, A. W., & Hayward, R. C. (2017). Shape-morphing materials from stimuli-responsive hydrogel hybrids. Accounts of chemical research, 50(2), 161-169. [CrossRef]

- Wu, C., Chen, H., Zhu, J., & Yao, Y. (2025). Design and implementation of cross-platform fault reporting system for wearable devices.

- Chen, Q., Kalpoe, T., & Jovanova, J. (2024). Design of mechanically intelligent structures: Review of modelling stimuli-responsive materials for adaptive structures. Heliyon, 10(14). [CrossRef] [PubMed]

- Waidi, Y. O. (2025). Recent Advances in 4D-Printed Shape Memory Actuators. Macromolecular Rapid Communications, 46(10), 2401141. [CrossRef] [PubMed]

- Mintchev, S., & Floreano, D. (2016). Adaptive morphology: A design principle for multimodal and multifunctional robots. IEEE Robotics & Automation Magazine, 23(3), 42-54. [CrossRef]

- Gharavi, L., Zareinejad, M., & Ohadi, A. (2022). Dynamic finite-element analysis of a soft bending actuator. Mechatronics, 81, 102690. [CrossRef]

- Nsilani Kouediatouka, A., Ma, Q., Liu, Q., Mawignon, F. J., Rafique, F., & Dong, G. (2022). Design methodology and application of surface texture: A review. Coatings, 12(7), 1015. [CrossRef]

- Li, J., & Zhou, Y. (2025). BIDeepLab: An Improved Lightweight Multi-scale Feature Fusion Deeplab Algorithm for Facial Recognition on Mobile Devices. Computer Simulation in Application, 3(1), 57-65. [CrossRef]

- Bock, F. E., Aydin, R. C., Cyron, C. J., Huber, N., Kalidindi, S. R., & Klusemann, B. (2019). A review of the application of machine learning and data mining approaches in continuum materials mechanics. Frontiers in Materials, 6, 110. [CrossRef]

- Karande, P., Gallagher, B., & Han, T. Y. J. (2022). A strategic approach to machine learning for material science: how to tackle real-world challenges and avoid pitfalls. Chemistry of Materials, 34(17), 7650-7665. [CrossRef]

- Xu, S., Yang, R., Yang, Y., & Zhang, Y. (2025). Shape-morphing bioelectronic devices. Materials Horizons. [CrossRef] [PubMed]

- Chivate, A., & Zhou, C. (2024). Additive manufacturing of micropatterned functional surfaces: a review. International Journal of Extreme Manufacturing, 6(4), 042004. [CrossRef]

- Qin, F., Cheng, H. Y., Sneeringer, R., Vlachostergiou, M., Acharya, S., Liu, H., ... & Yao, L. (2021, May). ExoForm: Shape memory and self-fusing semi-rigid wearables. In Extended Abstracts of the 2021 CHI Conference on Human Factors in Computing Systems (pp. 1-8).

- Rodriguez, J. N., Zhu, C., Duoss, E. B., Wilson, T. S., Spadaccini, C. M., & Lewicki, J. P. (2016). Shape-morphing composites with designed micro-architectures. Scientific reports, 6(1), 27933. [CrossRef] [PubMed]

- Chen, F., Li, S., Liang, H., Xu, P., & Yue, L. (2025). Optimization Study of Thermal Management of Domestic SiC Power Semiconductor Based on Improved Genetic Algorithm.

- Stuart-Smith, R., Studebaker, R., Yuan, M., Houser, N., & Liao, J. (2022). Viscera/L: Speculations on an Embodied, Additive and Subtractive Manufactured Architecture. Traits of Postdigital Neobaroque: Pre-Proceedings (PDNB), edited by Marjan Colletti and Laura Winterberg. Innsbruck: Universitat Innsbruck.

- Hu, W. (2025, September). Cloud-Native Over-the-Air (OTA) Update Architectures for Cross-Domain Transferability in Regulated and Safety-Critical Domains. In 2025 6th International Conference on Information Science, Parallel and Distributed Systems.

- Lee, J., Park, D., Lee, M., Lee, H., Park, K., Lee, I., & Ryu, S. (2023). Machine learning-based inverse design methods considering data characteristics and design space size in materials design and manufacturing: a review. Materials horizons, 10(12), 5436-5456. [CrossRef] [PubMed]

- Wu, Q., Shao, Y., Wang, J., & Sun, X. (2025). Learning Optimal Multimodal Information Bottleneck Representations. arXiv preprint . arXiv:2505.19996.

- Sun, X., Wei, D., Liu, C., & Wang, T. (2025). Multifunctional Model for Traffic Flow Prediction Congestion Control in Highway Systems. Authorea Preprints.

- Patel, D. K., Zhong, K., Xu, H., Islam, M. F., & Yao, L. (2023). Sustainable morphing matter: design and engineering practices. Advanced Materials Technologies, 8(23), 2300678. [CrossRef]

- Zhu, W., & Yang, J. (2025). Causal Assessment of Cross-Border Project Risk Governance and Financial Compliance: A Hierarchical Panel and Survival Analysis Approach Based on H Company's Overseas Projects.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).