Submitted:

23 October 2025

Posted:

24 October 2025

You are already at the latest version

Abstract

This study evaluated the effects of different sintering protocols on the mechanical and microstructural properties of two multilayered zirconia materials: strength-gradient zirconia (KATANA YML) and color-gradient zirconia (KATANA UTML). Bar-shaped specimens were fabricated from both zirconia types. Three sintering protocols were applied: manufacturer recommended conventional (7 h at 1550 °C), high-speed (54 min at 1600 °C), and a modified high-speed protocol (51 min at 1600 °C). Eighty-four specimens underwent three-point flexural strength testing. SEM and XRD analyses were used to assess microstructure and phase composition. No significant differences in flexural strength were found among sintering protocols (p > 0.05), but YML consistently showed higher strength than UTML (p < 0.05). The highest strength in YML was observed after high-speed sintering, followed by the shortened and conventional protocols. In UTML, the modified protocol yielded the highest strength, followed by the high-speed and then conventional protocol. SEM revealed finer, more homogeneous grains with shorter sintering times. XRD confirmed stable phase composition across all protocols. High-speed and modified high-speed sintering protocols can reduce processing time without compromising zirconia’s mechanical performance. Material type had a greater effect on flexural strength than sintering time, though microstructure was protocol dependent. Proper selection of zirconia type and sintering strategy is essential for optimal outcomes.

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Specimen Preparation

- ▪

- YML-7 h (YML sintered for 7 hours)

- ▪

- YML-54 min (YML sintered for 54 minutes)

- ▪

- YML-51 min (YML sintered for 51 minutes)

- ▪

- UTML-7 h (UTML sintered for 7 hours)

- ▪

- UTML-54 min (UTML sintered for 54 minutes)

- ▪

- UTML-51 min (UTML sintered for 51 minutes)

2.3. Sintering Protocols

- Heating from room temperature to 1550 °C at 10 °C/min

- Holding at 1550 °C for 2 hours

- Cooling to room temperature at −10 °C/min

- Heating from room temperature to 1450 °C at a rate of 120 °C/min

- Then to 1600 °C at 10 °C/min

- Holding at 1600 °C for 20 minutes

- Cooling to 800 °C at −120 °C/min

- Heating from room temperature to 1400 °C at 50 °C/min

- Then to 1500 °C at 24 °C/min

- Then to 1560 °C at 24 °C/min

- No holding time

- Cooling according to automatic program schedule (manufacturer default)

2.4. Flexural Strength Testing

2.5. SEM and Grain Size Analysis

2.6. EDS Analysis

2.7. XRD Analysis

2.8. Statistical Analysis

3. Results

3.1. Flexural Strength Results

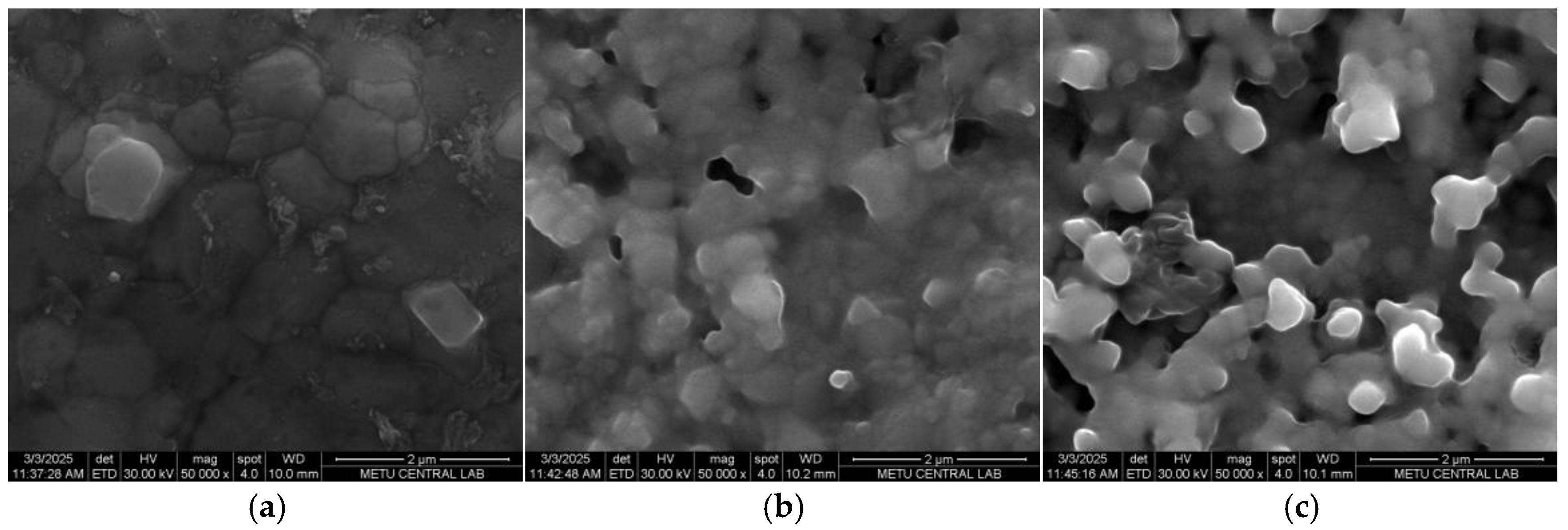

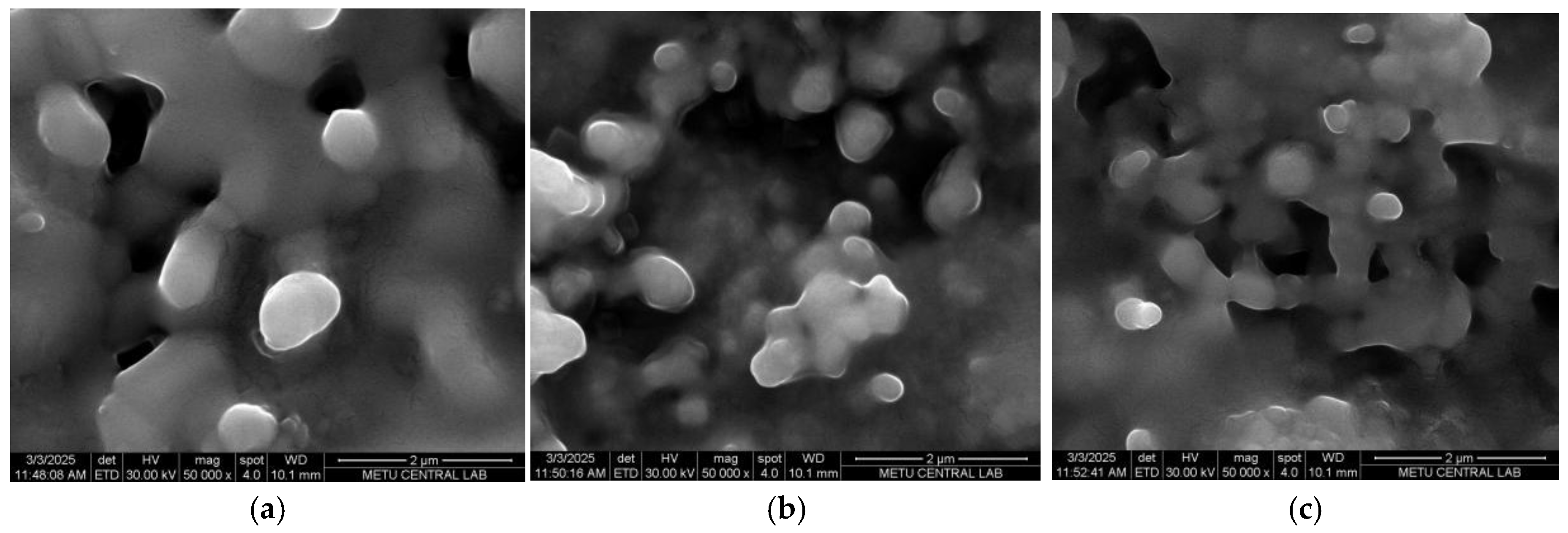

3.2. SEM and Grain Size Results

3.3. EDS Results

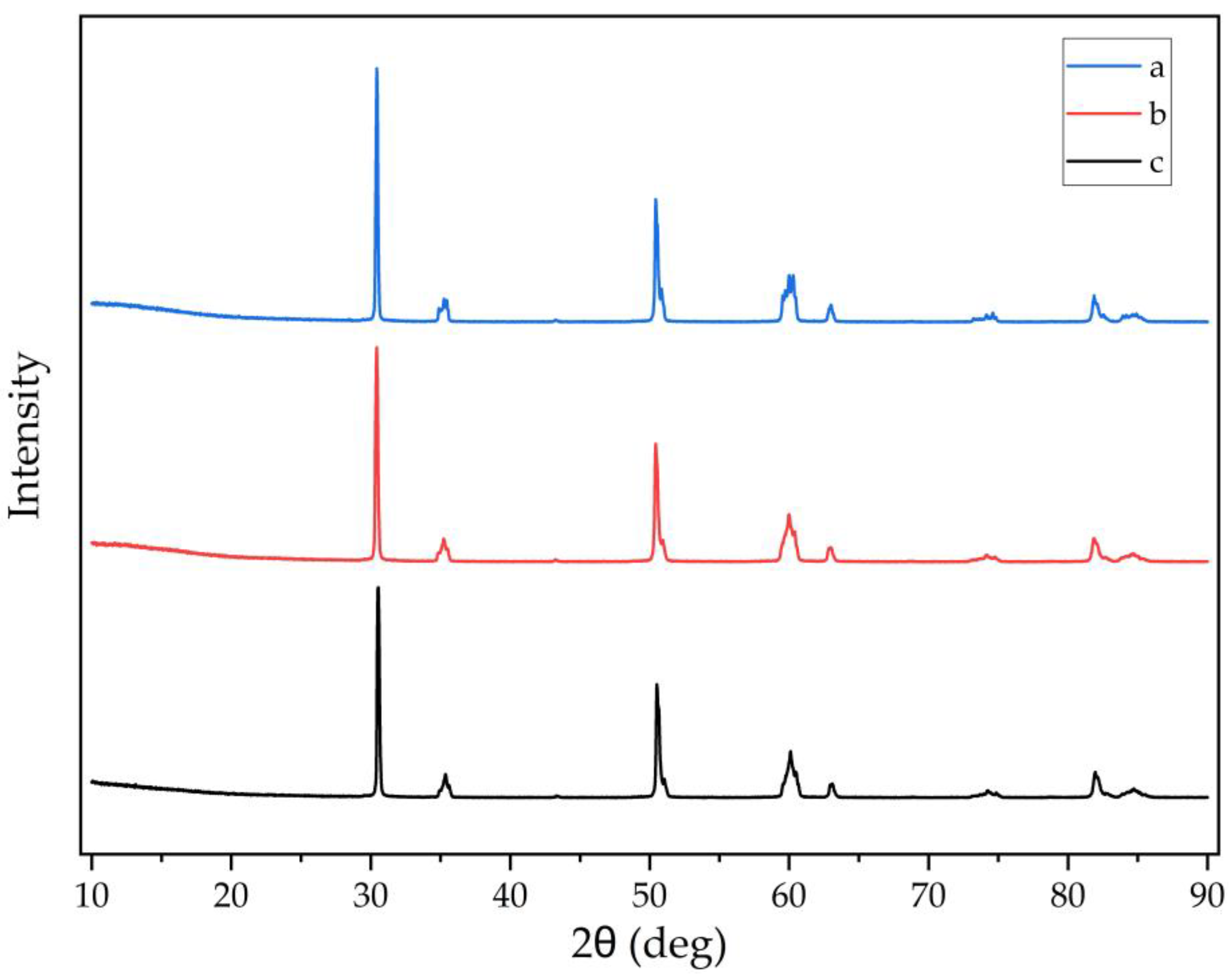

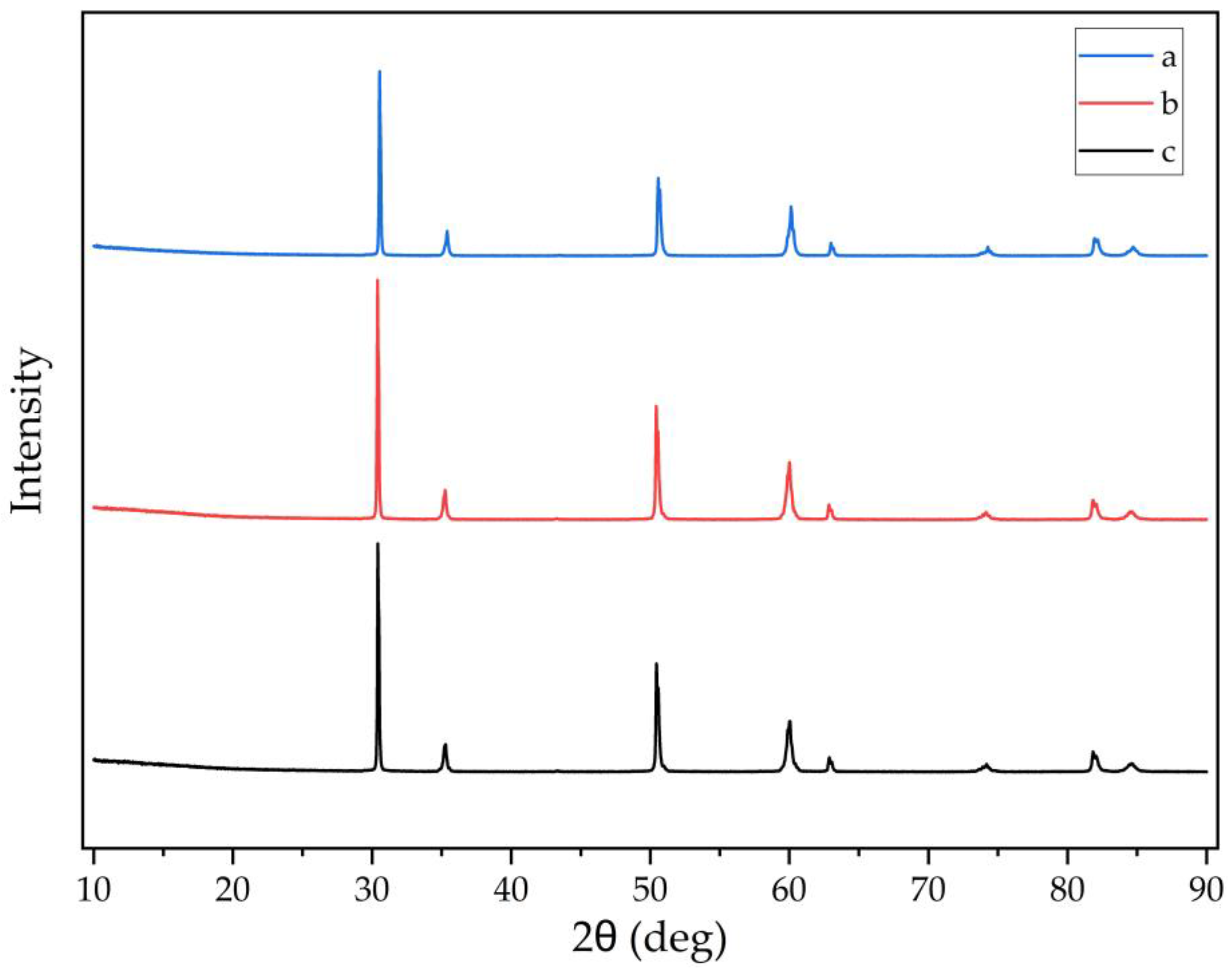

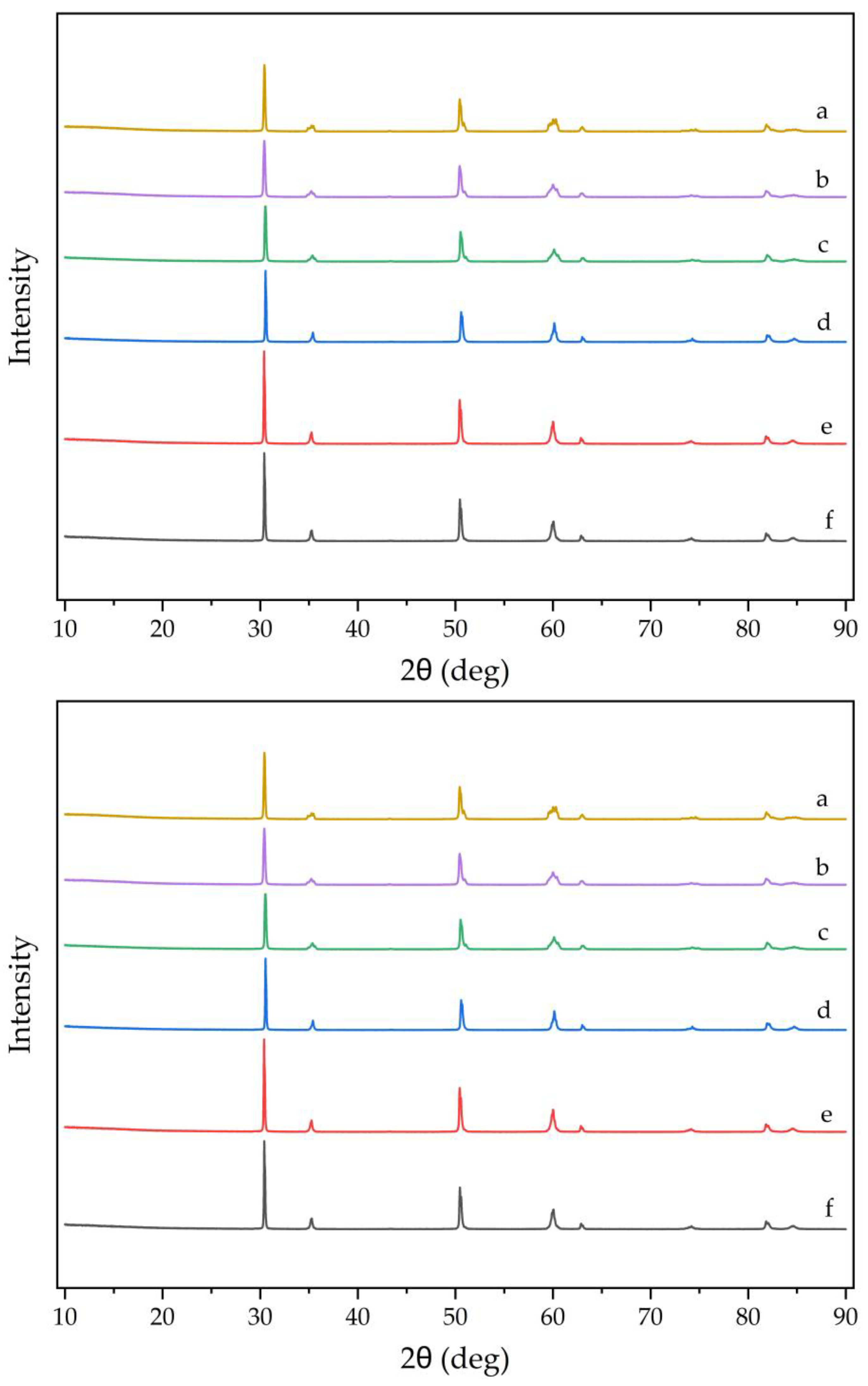

3.4. XRD Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spitznagel FA, Boldt J, Gierthmuehlen PC. CAD/CAM Ceramic Restorative Materials for Natural Teeth. J Dent Res 2018;97:1082–91. [CrossRef]

- Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res 2016;60:72–84. [CrossRef]

- Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: An overview. Dental Materials 2008;24:289–98. [CrossRef]

- Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials 1999;20:1–25. [CrossRef]

- Leib EW, Vainio U, Pasquarelli RM, Kus J, Czaschke C, Walter N, et al. Synthesis and thermal stability of zirconia and yttria-stabilized zirconia microspheres. J Colloid Interface Sci 2015;448:582–92. [CrossRef]

- Kongkiatkamon S, Rokaya D, Kengtanyakich S, Peampring C. Current classification of zirconia in dentistry: an updated review. PeerJ 2023;11:e15669. [CrossRef]

- Hannink RHJ, Kelly PM, Muddle BC. Transformation toughening in zirconia-containing ceramics. Journal of the American Ceramic Society 2000;83:461–87. [CrossRef]

- Lim CH, Vardhaman S, Reddy N, Zhang Y. Composition, processing, and properties of biphasic zirconia bioceramics: Relationship to competing strength and optical properties. Ceram Int 2022;48:17095–103. [CrossRef]

- Sulaiman TA, Suliman AA, Abdulmajeed AA, Zhang Y. Zirconia restoration types, properties, tooth preparation design, and bonding. A narrative review. Journal of Esthetic and Restorative Dentistry 2024;36:78–84. [CrossRef]

- Öztürk C, Can G. Effect of Sintering Parameters on the Mechanical Properties of Monolithic Zirconia. J Dent Res Dent Clin Dent Prospects 2019;13:247–52. [CrossRef]

- Cokic SM, Vleugels J, Van Meerbeek B, Camargo B, Willems E, Li M, et al. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent Mater 2020;36:959–72. [CrossRef]

- Ersoy NM, Aydoğdu HM, Değirmenci BÜ, Çökük N, Sevimay M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater Odontol Scand 2015;1:43–50. [CrossRef]

- Kaizer MR, Gierthmuehlen PC, dos Santos MB, Cava SS, Zhang Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram Int 2017;43:10999–1005. [CrossRef]

- Juntavee N, Attashu S. Effect of different sintering process on flexural strength of translucency monolithic zirconia. J Clin Exp Dent 2018;10:e821–30. [CrossRef]

- Stawarczyk B, Özcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CHF. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig 2013;17:269–74. [CrossRef]

- Attia MA, Radwan M, Blunt L, Bills P, Tawfik A, Arafa AM. Effect of different sintering protocols on the fracture strength of 3-unit monolithic gradient zirconia fixed partial dentures: An in vitro study. Journal of Prosthetic Dentistry 2023;130:908.e1-908.e8. [CrossRef]

- Gómez SY, Da Silva AL, Gouvêa D, Castro RHR, Hotza D. Nanocrystalline yttria-doped zirconia sintered by fast firing. Mater Lett 2016;166:196–200. [CrossRef]

- Strasser T, Wertz M, Koenig A, Koetzsch T, Rosentritt M. Microstructure, composition, and flexural strength of different layers within zirconia materials with strength gradient. Dental Materials 2023;39:463–8. [CrossRef]

- ISO 6872:2015 - Dentistry — Ceramic materials n.d. Available online: https://www.iso.org/standard/59936.html (accessed on 23 February 2025).

- Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dental Materials 2014;30:e419–24. [CrossRef]

- Zimmermann M, Ender A, Mehl A. Influence of CAD/CAM Fabrication and Sintering Procedures on the Fracture Load of Full-Contour Monolithic Zirconia Crowns as a Function of Material Thickness. Oper Dent 2020;45:219–26. [CrossRef]

- Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont 2013;5:161. [CrossRef]

- Liu H, Inokoshi M, Nozaki K, Shimizubata M, Nakai H, Cho Too T Di, et al. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dental Materials 2022;38:451–68. [CrossRef]

- Attachoo S, Juntavee N. Role of sintered temperature and sintering time on spectral translucence of nano-crystal monolithic zirconia. J Clin Exp Dent 2019;11:e146–53. [CrossRef]

- Mayinger F, Pfefferle R, Reichert A, Stawarczyk B. Impact of High-Speed Sintering of Three-Unit 3Y-TZP and 4Y-TZP Fixed Dental Prostheses on Fracture Load With and Without Artificial Aging. Int J Prosthodont 2021;34:47–53. [CrossRef]

- Bravo-Leon A, Morikawa Y, Kawahara M, Mayo MJ. Fracture toughness of nanocrystalline tetragonal zirconia with low yttria content. Acta Mater 2002;50:4555–62. [CrossRef]

- Inokoshi M, Zhang F, De Munck J, Minakuchi S, Naert I, Vleugels J, et al. Influence of sintering conditions on low-temperature degradation of dental zirconia. Dent Mater 2014;30:669–78. [CrossRef]

- Ahmed WM, Troczynski T, McCullagh AP, Wyatt CCL, Carvalho RM. The influence of altering sintering protocols on the optical and mechanical properties of zirconia: A review. J Esthet Restor Dent 2019;31:423–30. [CrossRef]

- Jansen JU, Lümkemann N, Letz I, Pfefferle R, Sener B, Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. Journal of Prosthetic Dentistry 2019;122:396–403. [CrossRef]

- Elisa Kauling A, Güth JF, Erdelt K, Edelhoff D, Keul C. Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J Prosthet Dent 2020;124:380–6. [CrossRef]

- Michailova M, Elsayed A, Fabel G, Edelhoff D, Zylla IM, Stawarczyk B. Comparison between novel strength-gradient and color-gradient multilayered zirconia using conventional and high-speed sintering. J Mech Behav Biomed Mater 2020;111. [CrossRef]

- Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LVJ. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand 2008;66:262–7. [CrossRef]

- Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. Journal of Advanced Prosthodontics 2013;5:161–6. [CrossRef]

- Oyar P, Durkan R, Deste G. Effects of sintering time and hydrothermal aging on the mechanical properties of monolithic zirconia ceramic systems. Journal of Prosthetic Dentistry 2021;126:688–91. [CrossRef]

- Rosentritt M, Preis V, Schmid A, Strasser T. Multilayer zirconia: Influence of positioning within blank and sintering conditions on the in vitro performance of 3-unit fixed partial dentures. J Prosthet Dent 2022;127:141–5. [CrossRef]

- Attia A, Kern M. Influence of cyclic loading and luting agents on the fracture load of two all-ceramic crown systems. J Prosthet Dent 2004;92:551–6. [CrossRef]

- Inokoshi M, Liu H, Yoshihara K, Yamamoto M, Tonprasong W, Benino Y, et al. Layer characteristics in strength-gradient multilayered yttria-stabilized zirconia. Dent Mater 2023;39:430–41. [CrossRef]

- Pekkan G, Pekkan K, Bayindir BÇ, Özcan M, Karasu B. Factors affecting the translucency of monolithic zirconia ceramics: A review from materials science perspective. Dent Mater J 2020;39:1–8. [CrossRef]

- Katada H, Inokoshi M, Kamijo S, Liu H, Xu K, Kawashita M, et al. Effects of multiple firings on the translucency, crystalline phase, and mechanical strength of highly translucent zirconia. Dent Mater J 2024;43:294–302. [CrossRef]

- Güntekin N, Kızılırmak B, Tunçdemir AR. Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering. Materials 2025;18. [CrossRef]

- Novitskaya E, Karandikar K, Cummings K, Mecartney M, Graeve OA. Hall–Petch effect in binary and ternary alumina / zirconia / spinel composites. Journal of Materials Research and Technology 2021;11:823–32. [CrossRef]

- Nonaka K, Teramae M, Pezzotti G. Effect of rapid cooling on residual stress and surface fracture toughness of dental zirconia. J Mech Behav Biomed Mater 2024;157:106656. [CrossRef]

- Kulyk V, Duriagina Z, Vasyliv B, Kovbasiuk T, Lyutyy P, Vira V, et al. ACTA PHYSICA POLONICA A Effect of Sintering Temperature on Crack Growth Resistance Characteristics of Yttria-Stabilized Zirconia 2022;141. [CrossRef]

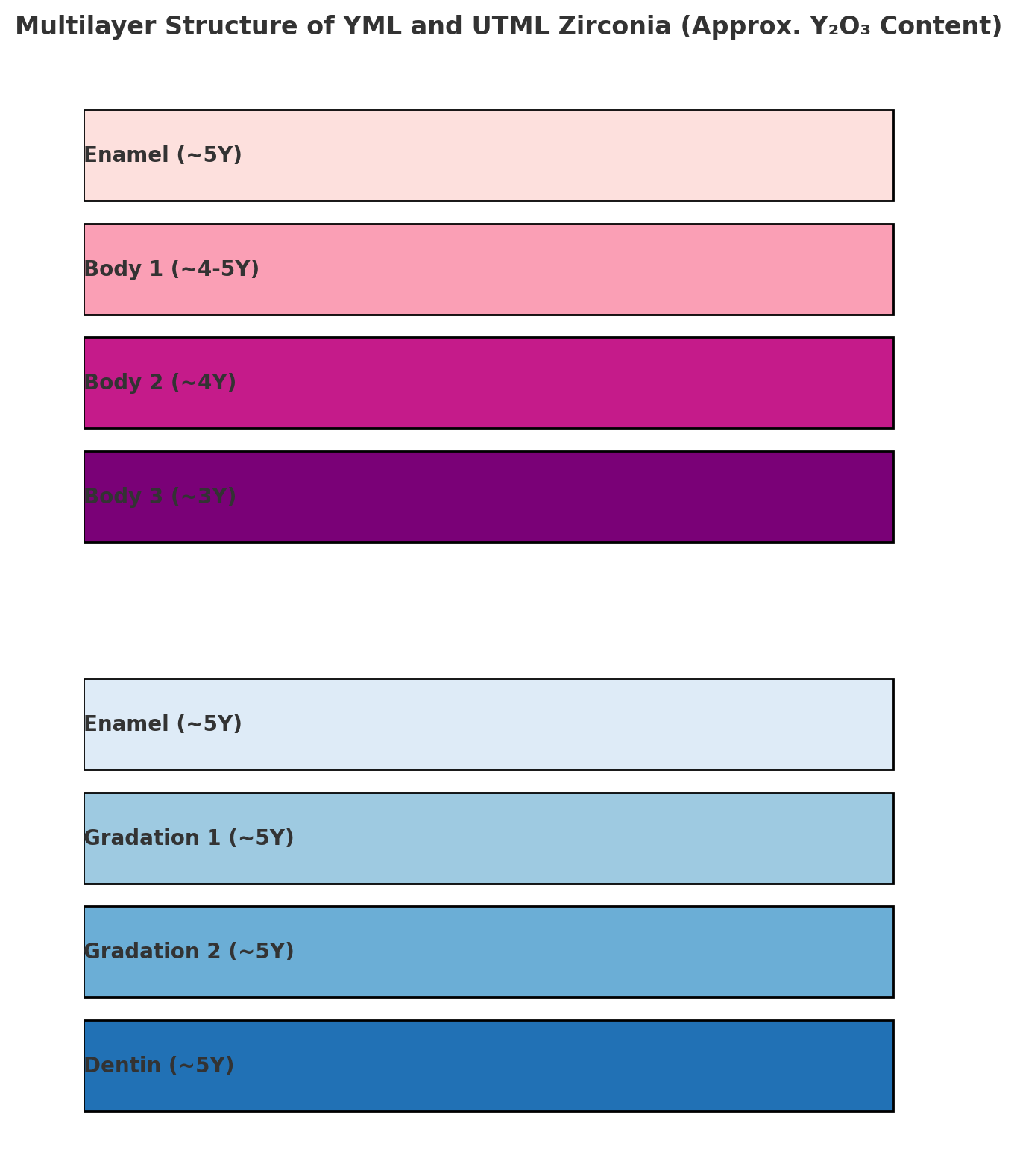

| Material | Trade Name | LOT No | Manufacturer | Y₂O₃ content (nominal) |

|---|---|---|---|---|

| Layered Monolithic Zirconia | KATANA™ YML (18 mm, NW) | EİTAY | Kuraray Noritake Dental Inc., Japan | Multilayer: dentin ≈ 3Y; transition ≈ 4Y; enamel ≈ 5Y |

| Layered Monolithic Zirconia | KATANA™ UTML (18 mm, ENW) | ENCJF | Kuraray Noritake Dental Inc., Japan | Uniform: ≈ 5Y |

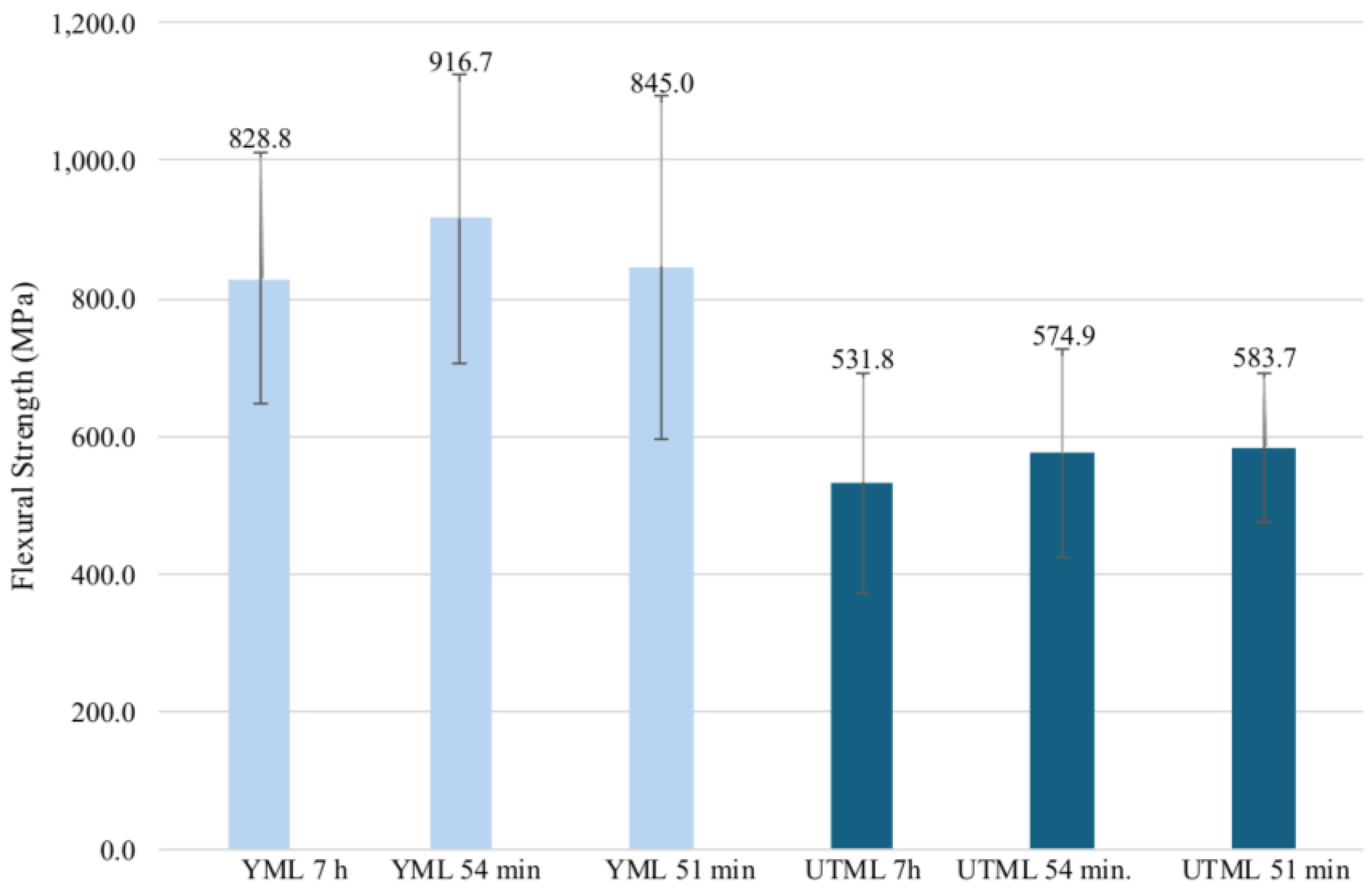

| Material | 7 h | 54 min | 51 min | Overall | Time- Based |

||||

|---|---|---|---|---|---|---|---|---|---|

| (n=28) | (n=28) | (n=28) | (n=86) | ||||||

| Mean | SS | Mean | SS | Mean | SS | Mean | SS | p** (F) | |

| YML (n=42) | 828,8 | 182,4 | 916,7 | 209,6 | 845,0 | 249,8 | 863,5 | 213,9 | 0,741 |

| (-0,30) | |||||||||

| UTML (n=42) | 531,8 | 160,3 | 574,9 | 150,7 | 583,7 | 108,9 | 563,5 | 140,1 | 0,435 |

| (-0,86) | |||||||||

| Overall (n=84) | 680,3 | 226,4 | 745,8 | 249,8 | 714,3 | 231,2 | 713,5 | 234,7 | 0,532 |

| (-0,64) | |||||||||

| Material | 0,00 | 0,00 | 0,00 | 0,00 | |||||

| based p* (t) | (-4,83) | (-4,32) | (-3,59) | (-7,45) | |||||

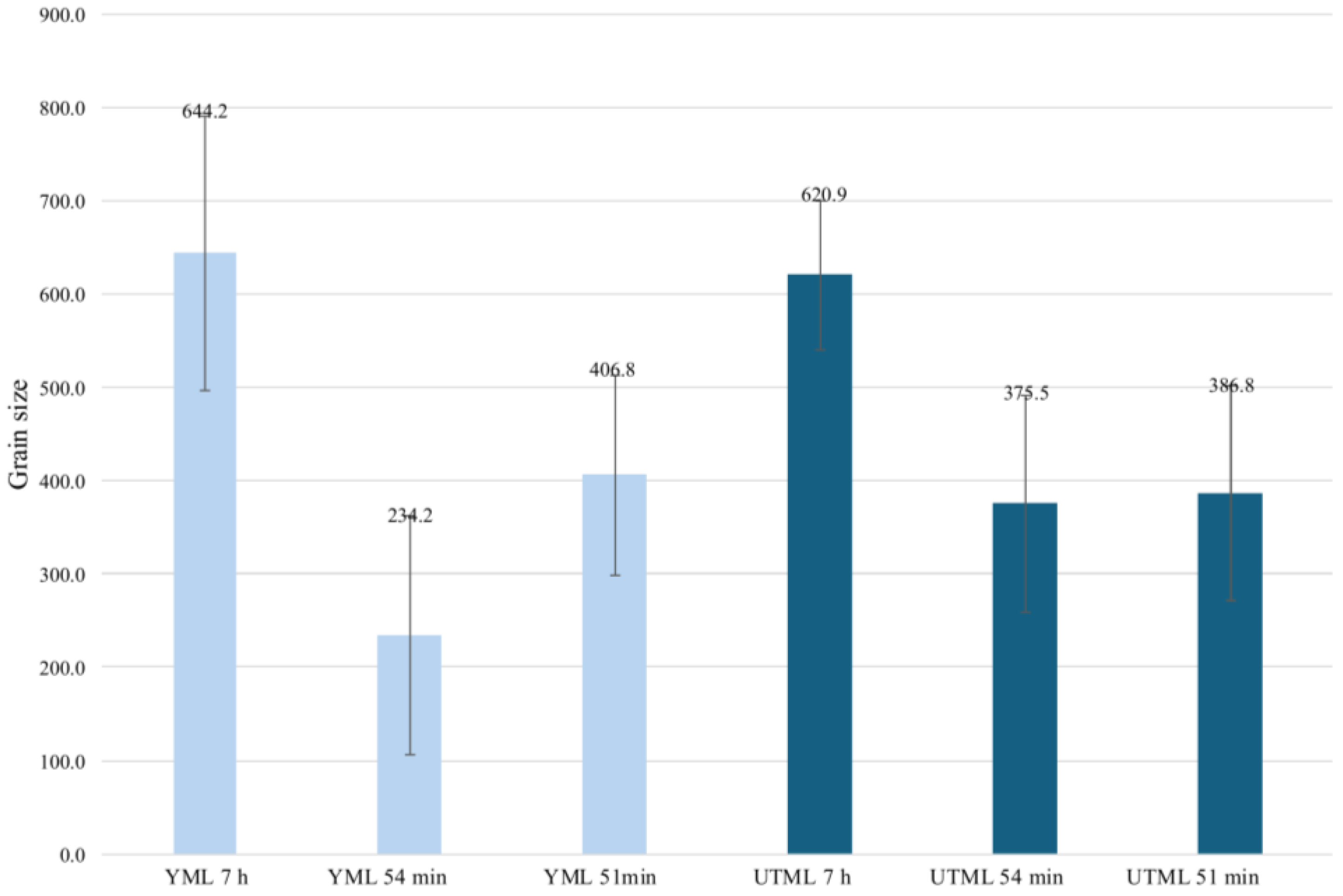

| Material | 7 h (n=20) |

54 min (n=20) |

51 min (n=12) |

Overall (n=60) |

Time- Based |

||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | SS | Mean | SS | Mean | SS | Mean | SS | p** (F) | |

| YML (n=30) | a644,2 | 146,5 | b234,2 | 128,4 | c406,8 | 107,0 | 428,4 | 211,1 |

0,000 (25,75) |

| UTML (n=30) | a620,9 | 80,1 | b375,5 | 116,6 | bc386,8 | 115,5 | 461,1 | 153,6 |

0,000 (17,21) |

| Overall (n=60) | a632,6 | 115,5 | b304,8 | 139,6 | bc396,8 | 108,8 | 444,7 | 183,8 |

0,001 (37,63) |

|

Material based p* (t) |

0,665 (0,441) |

0,019 (-2,578) |

0,692 (0,402) |

0,496 (-0,686) |

|||||

| Material | Sintering Duration | Zr (%) | Y (%) | O (%) |

|---|---|---|---|---|

| YML | 7 h | 79.06 | 7.21 | 13.73 |

| YML | 54 min | 76.51 | 9.56 | 13.93 |

| YML | 51 min | 76.56 | 9.07 | 14.37 |

| UTML | 7 h | 77.43 | 9.97 | 12.60 |

| UTML | 54 min | 75.43 | 10.32 | 14.25 |

| UTML | 51 min | 76.04 | 10.27 | 13.69 |

| Material | Sintering Duration | Tetragonal (%) | Cubic (%) |

|---|---|---|---|

| UTML | 7 h | 23 ± 2 | 77 ± 2 |

| UTML | 54 min | 35 ± 2 | 65 ± 2 |

| UTML | 51 min | 8 ± 2 | 92 ± 2 |

| YML | 7 h | 61.2 ± 0.9 | 38.8 ± 0.9 |

| YML | 54 min | 56.3 ± 1.1 | 43.7 ± 1.1 |

| YML | 51 min | 46 ± 1 | 54 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).