1. Introduction

The oil and gas sector in Saudi Arabia is the backbone of the economy. It is the most significant source of exports, national revenues, and economic growth [

1]. Saudi Arabia possesses about 20% of the world's proven oil reserves [

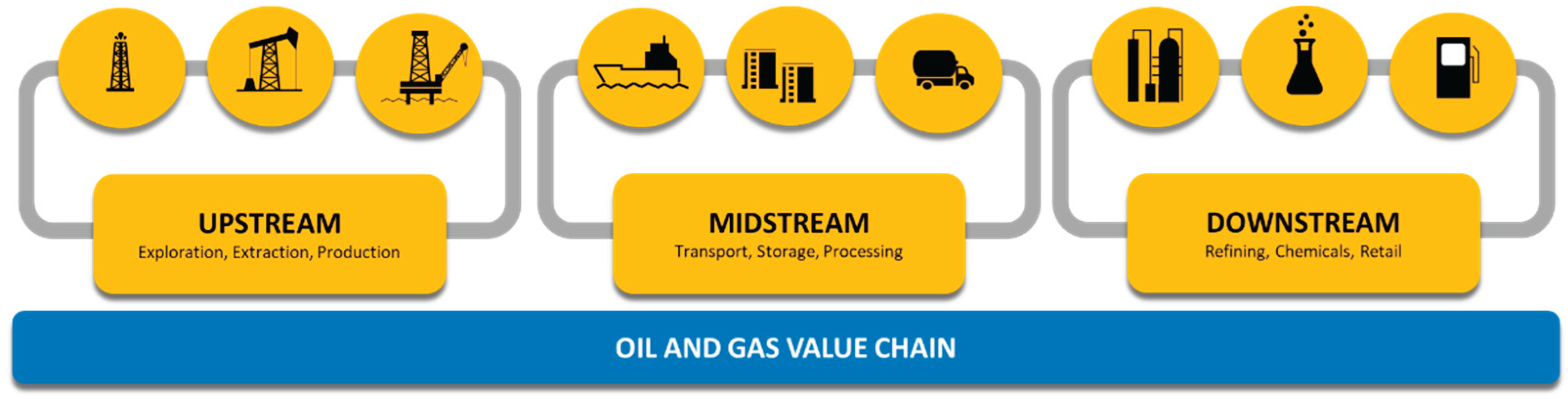

2]. Broadly speaking, the oil and gas industry value chain is divided into three main sectors: upstream, midstream, and downstream [

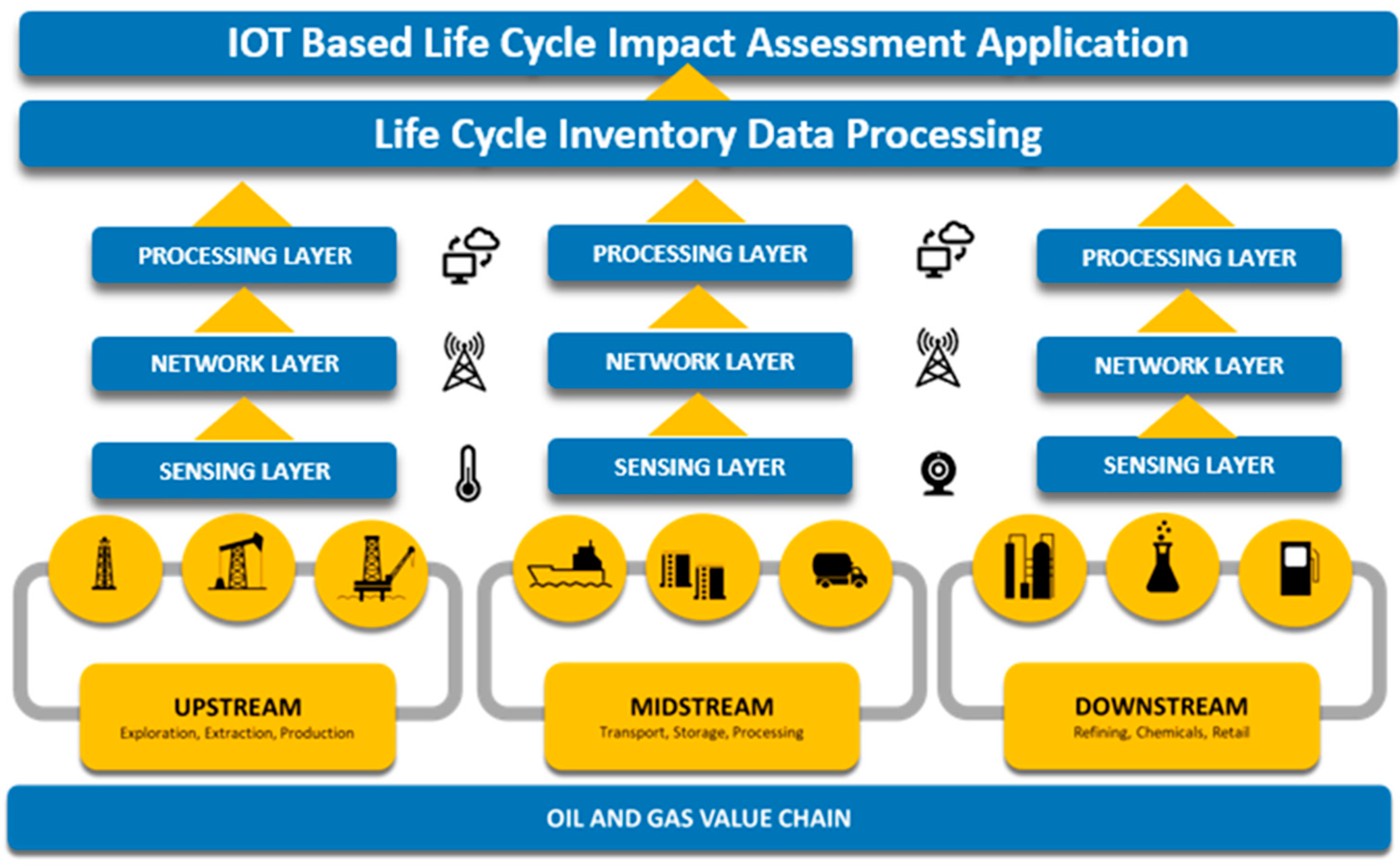

3]. As illustrated in

Figure 1, these segments represent various stages of oil and gas exploration, storage, transportation, and end-use. The upstream sector involves all the activities required for the search and extraction of crude oil. The midstream sector links the upstream and downstream sectors by providing facilities for the transportation, storage, and marketing of crude oil. Pipelines, tank farms, and transportation vehicles are part of the midstream infrastructure. Downstream activities are related to refining, chemicals, and retail. All of these activities are fundamental to the operation of oil and gas industry in Saudi Arabia.

Even though oil and gas industry in Saudi Arabia is the main driver of economic activity, it poses several environmental challenges that influence local ecosystems, public health, and climate change [

4]. These environmental impacts arise from all the activities from exploration to refining [

5]. One of the main concerns is the release of carbon dioxide through combustion of fossil fuels which still constitutes a major source of electricity in Saudi Arabia. Overall the carbon foot print of the country is much higher than the global average [

6]. Methane emissions that result from leaks during drilling, storage, and transportation also contribute toward global warming [

7]. Methane is much more potent than carbon dioxide in this regard. Another issue related to oil and gas industry is flaring of excess gas which contributes to air pollution and greenhouse gas emissions [

8]. Oil and gas exploration and refining also leads to land degradation and habitat destruction. Furthermore, harmful chemicals used in industry can seep into groundwater. Mitigating these impacts is essentially required in order to improve the sustainability of this sector. Adoption of both LCA and IoT practices can play a pivotal role in this regard.

LCA is one of the most commonly used methodologies to quantify environmental impacts of products, processes, and systems. It examines environmental inputs and outputs, including energy consumption, emissions to air, water, and land, and waste generation [

9,

10,

11]. For over the last thirty years, it has been extensively used in various industries to evaluate the sustainability of processes and systems and its use has been growing rapidly [

12,

13]. The method is regulated by the ISO 14000 series of standards [

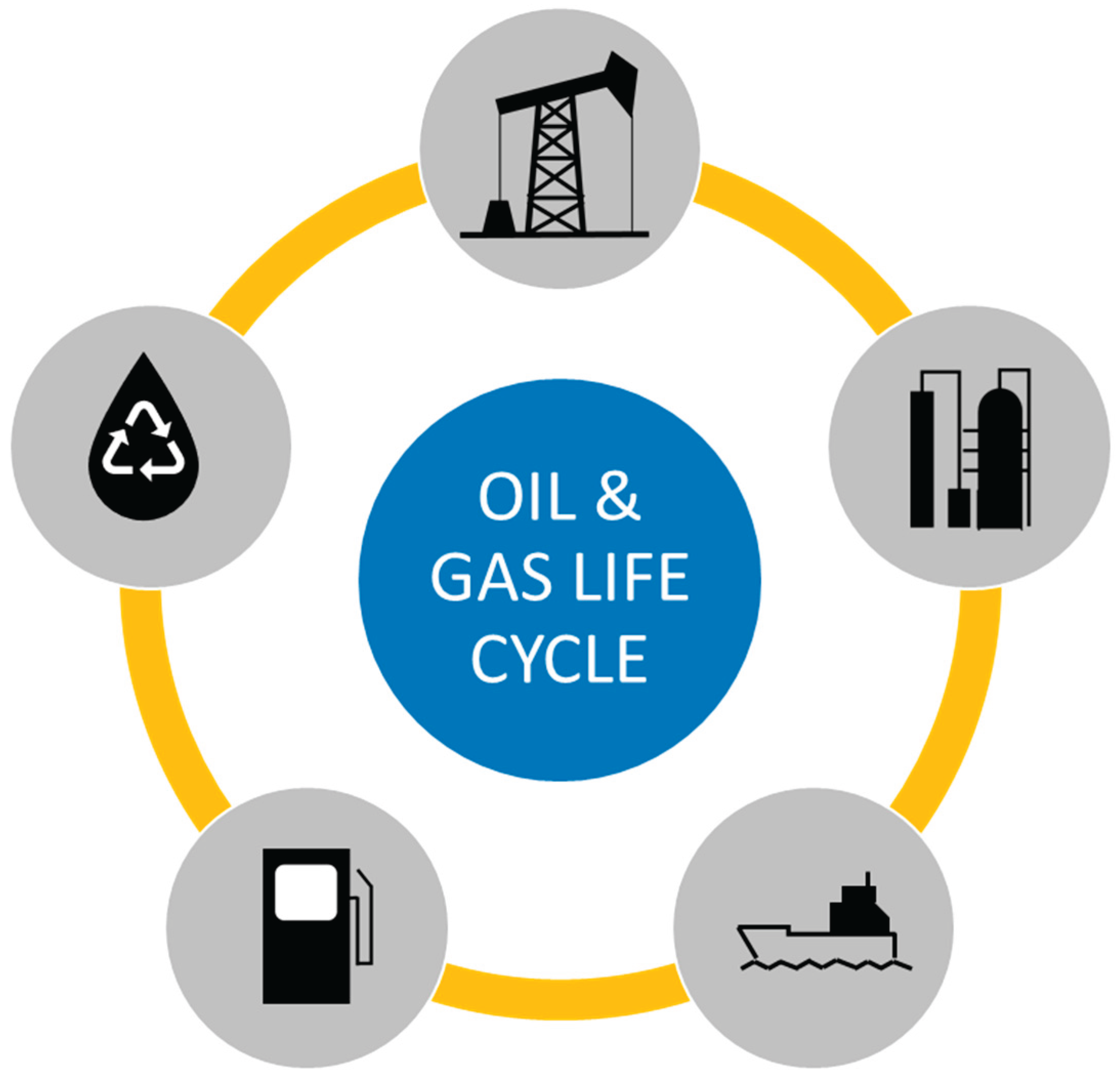

14]. LCA takes into account all stages of a product life cycle, including raw material extraction, transportation, processing, use, and recycling (

Figure 2). It then helps to identify environmental hot spots — the stages that create the most damage to the environment in the life cycle. Identifying these hot spots is important to implement targeted actions to reduce the overall environmental impacts.

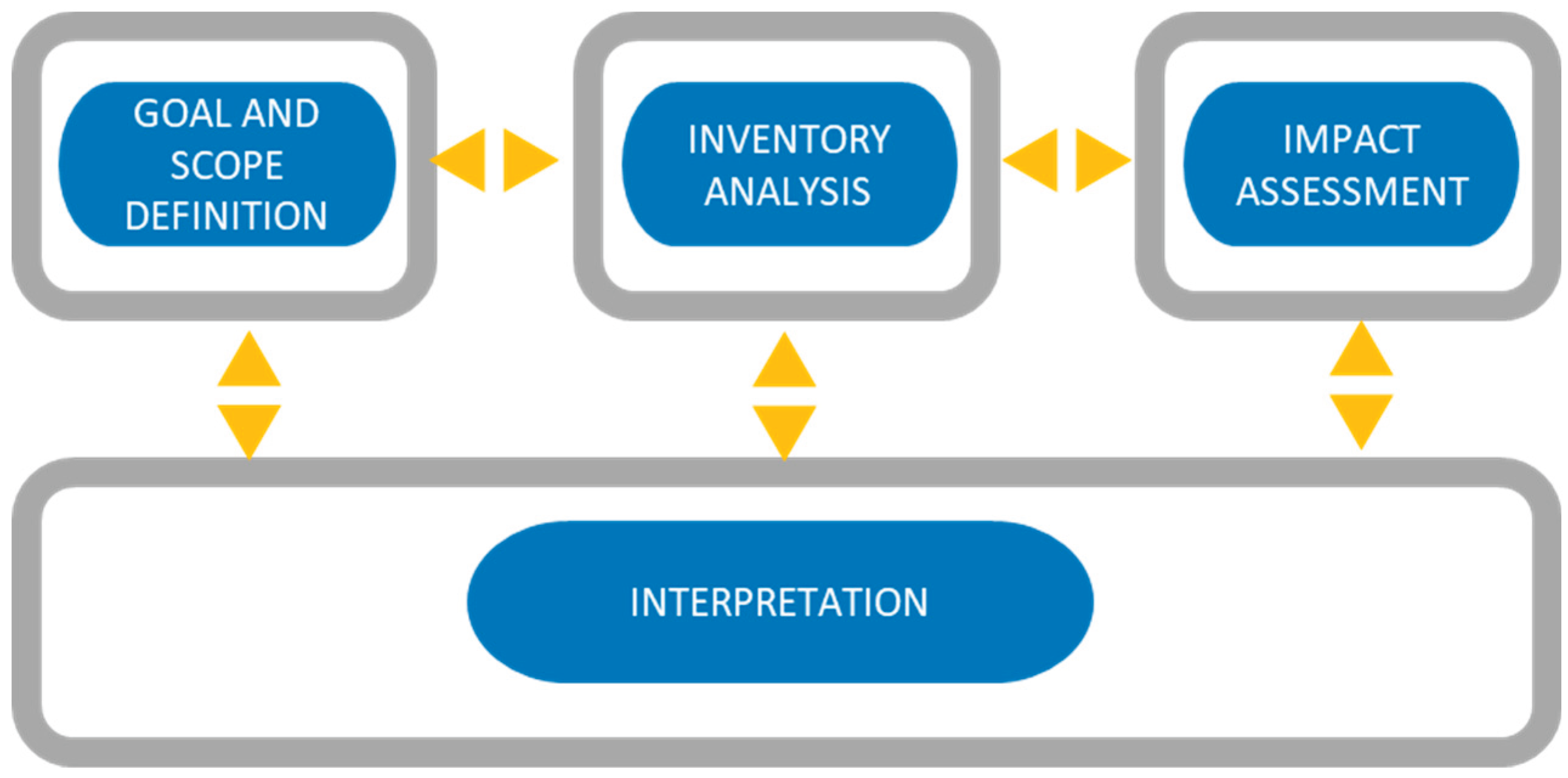

According to ISO standard [

14] there are four steps in any given LCA study (

Figure 3). Overall the process starts with developing the scope of a given study and the process ends with interpretation of results for improving sustainability. First of all, a clear goal and scope of the study is established and system boundaries are defined. These system boundaries are then used to collect inventory related to material, energy, and emissions for a given process. After that various environmental impacts like global warming potential, ozone depletion potential, etc. are calculated using life cycle impact assessment methods like Recepie. Finally, the results of the study are analyzed to propose recommendations for reducing the environmental burden of the process.

LCA offers many benefits related to sustainability goals in various industries. It can help in selecting environmentally friendly technologies, in optimizing water and energy use, and in reducing carbon emissions by redesigning processes. LCA provides a whole-system perspective for sustainability assessment, and by doing so, it prevents the burden-shifting problem where reducing the environmental impacts in one stage of the life cycle leads to increased impact in another stage. Replacing a metal component with a plastic alternative, for instance, can reduce emissions during transportation, but it can increase environmental damage during the disposal phase. LCA is very helpful in identifying such trade-offs. LCA also provides transparency across the whole value chain. It can also play a vital role in improving circularity by identifying waste management practices for industrial wastes and used equipment. Overall, LCA can enable oil and gas companies to make data-driven decisions to reduce carbon footprint and at the same time improve the efficiency of their operations. Despite its many advantages, LCA has several challenges, especially related to data collection and data quality [

15]. Collecting accurate and comprehensive data for the complete life cycle is often very time-consuming and expensive. Furthermore, the results of LCA studies are dependent on system boundaries and assumptions of the study. For this reason, making comparisons of various LCA studies is very difficult. Nevertheless, current research along with technological advancement in data collection is helping to tackle these shortcomings. LCA researchers have investigated combining various digital technologies into LCA studies [

16,

17,

18]. In this regard, Internet of Thing (IoT) can play a vital role as discussed next.

IoT is one of the technologies that is revolutionizing various sectors of the economy. It is defined as a collection of interconnected devices that collect, transmit, and analyze data [

19,

20,

21,

22]. It denotes an increasingly complex network of physical objects with embedded sensors that exchange data over various networks. IoT represents an ecosystem where physical objects can communicate, analyze information, and make decisions. IoT is transforming several sectors of economy and various industries [

23,

24,

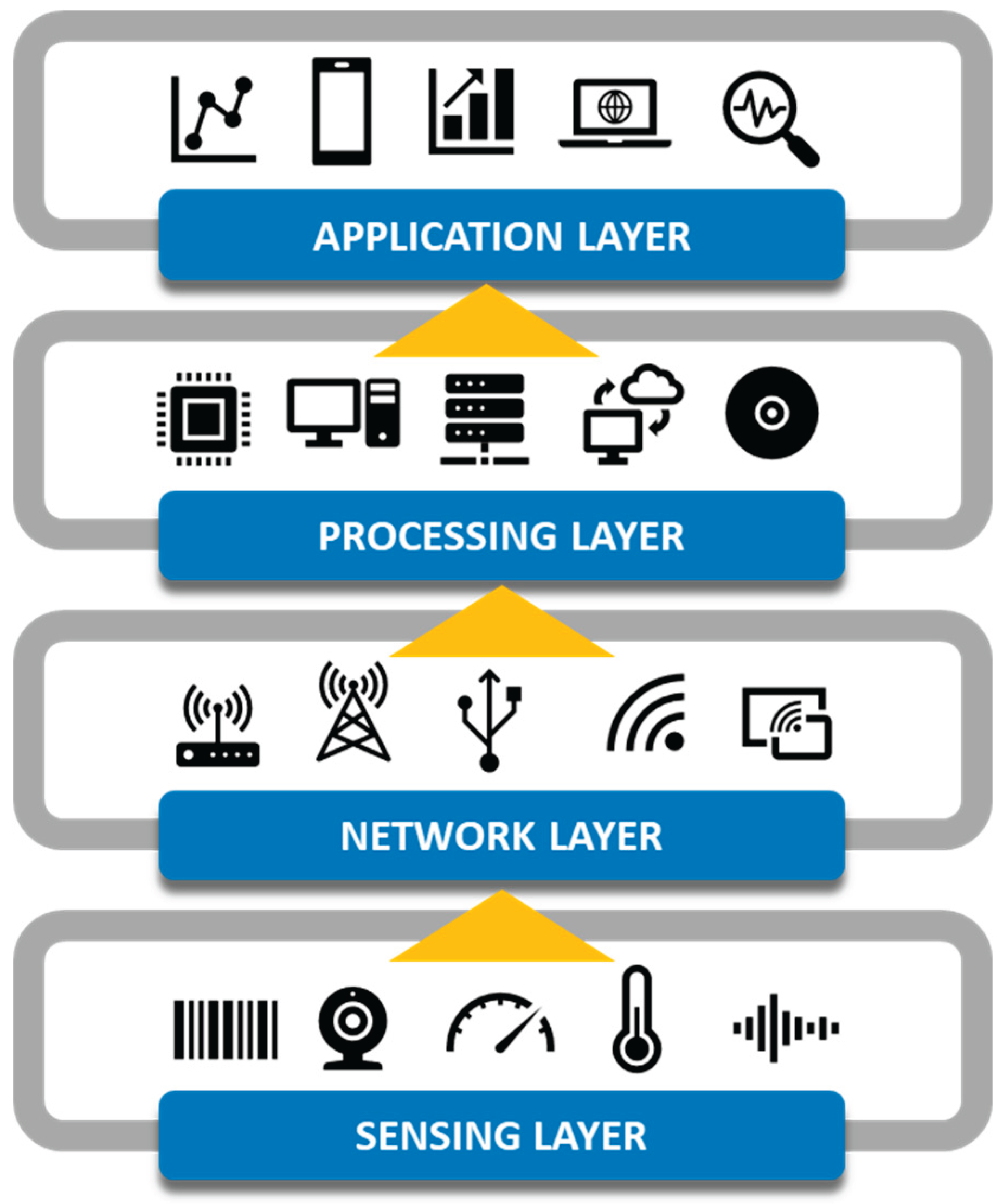

25] and plays a central role in Industry 4.0 and related digital transformation. An IoT architecture contains multiple layers and typically a four layered architecture (

Figure 4) consisting of perception, network, processing, and application layers is used to represent IoT applications in industry. Other IoT architectures can have more layers as required by the application. The perception layer is the physical layer where IoT devices and sensors collect data from the environment, such as temperature, pressure, humidity, etc. Devices usually included in the perception layer are cameras, sensors, RFID tags, and other embedded sensors. Data gathered from the perception layer is transferred over the network layer to cloud or edge servers for processing. Various types of communication technologies are used depending upon the IoT ecosystem. Wi-Fi, Bluetooth, and satellite communications are some of the technologies that IoT uses to transfer data to the processing layer. The processing layer, which consists of cloud computing platforms and edge computers, analyzes the large volumes of data collected by the perception layer. The application layer provides information to the end-users through mobile apps or specially designed dashboards. Together, all these layers form the backbone of IoT and provide a holistic system.

IoT has emerged as a very important tool to enhance the efficiency, sustainability, and safety in the oil and gas industry [

26]. IoT helps in several complex tasks like asset monitoring, preventive maintenance, and environmental safety. IoT sensors can monitor oil and gas operations in real time. For example, sensors on drilling rig and pipelines can collect real time data on pressure, temperature and other key parameters. This data is then transferred over the network layers to processing layer where advanced analytics help to reduce downtime and address maintenance issues proactively [

27]. IoT also plays a major role in enhance the safety of oil and gas operations. Wearable IoT devices can detect gas leaks and other health hazards and provide immediate alerts. IoT sensors also can monitor offshore oil rigs and oil pipelines and limits the need of manual inspection in hazardous locations. IoT sensors can also monitor pollutant levels for supporting environment compliance. As the oil and gas sector adopts digital transformation, IoT will play a critical role in improving efficiency, safety and sustainability.

Both IoT and LCA offer enormous benefits to enhance the operational efficiency and sustainability. For these reasons, researchers have started to explore integrating these concepts to enhance the studies exploring the integration of these concepts[

17,

28]. For instance, one study has explored the integration of LCA and IoT within the context of wind farms [

29]. This study has shown how LCA studies can benefit from real-time data collection from wind farm operations. Overall, integration of IoT and LCA offers a powerful way to enhance the sustainability of the oil and gas sector. However, their integration in the context of the Saudi Arabian oil and gas industry is still unexplored. This study tries to fill this gap by providing a conceptual framework that links IoT and LCA within the context of oil and gas industry. The rest of the paper is divided as follows. The next section describes the methodology adopted to develop the framework. After that, the framework is presented and its important concepts are explained. In the discussion section, advantages, limitations, and practical hurdles in adopting this framework are highlighted. There is a brief conclusion.

2. Materials and Methods

Both conceptual and theoretical frameworks are extensively used in research. Conceptual frameworks are often preliminary and exploratory in nature, and they help researchers to identify key constructs and their relationships to each other [

30]. Conceptual frameworks are qualitative in nature and require literature review and abstraction to find key relationships and constructs that define the framework [

31]. Theoretical frameworks, on the other hand, are more structured and grounded in established theories given in the literature [

30]. These frameworks are helpful in predicting the outcomes based upon prior knowledge. In general, conceptual frameworks are more flexible and adaptable as compared to theoretical frameworks. Conceptual frameworks provide several benefits in exploring research topics. They provide a systematic approach to integrate and develop relationships between key constructs and variables in a given study. This, in turn, helps to synthesize insights from various sources and disciplines and provide a comprehensive picture of complex interactions between key concepts [

32]. Conceptual frameworks are also very helpful in providing the visual tools to convey the interconnectedness of various elements of the research study. In addition to identifying relationships, these frameworks also help in pointing to future research.

In the Saudi Arabian oil and gas industry, LCA and IoT are relatively new ideas, and there exists no literature discussing the integration of these concepts. First, in order to understand the current status of LCA and IoT application in the Saudi Arabian oil and gas industry, an extensive literature review was conducted. Literature review is the most commonly used method to explore the present status and find the state of the art about a given topic [

33,

34]. Initially, the literature review was conducted using "LCA," "Saudi Arabia," "oil and gas industry," and "IoT" as keywords. Scopus was the main database used for this search, as the majority of relevant journals and conferences are indexed in Scopus. In addition to Scopus, a general search on the internet was also conducted using the same keywords to find industry reports and policy documents that are usually not listed in the Scopus database.

Results from this literature review were then used to identify the current application of LCA and IoT in the Saudi Arabian oil and gas industry and the future prospects of integrating them. A thorough reading and analysis of the selected papers was employed to extract themes, constructs, and linkages that helped in developing the framework presented in this paper. This analysis helped to highlight the gaps in integration of these technologies and led to develop a conceptual framework integrating LCA and IoT technologies to promote sustainability in Saudi Arbian oil and gas industry.

3. Conceptual Framework

This section begins by presenting the key findings from the literature review related to the use of LCA and IoT in the Saudi Arabian oil and gas industry. Following this, existing methodologies to integrate LCA and IoT are presented. Then, using thematic analysis and building on insights from the literature review, a novel framework designed for this study is presented. This framework can help to improve sustainability of the oil and gas industry by combining LCA and IoT in upstream, midstream, and downstream activities.

3.1. LCA in Saudi Arabian Oil and Gas Industry

Literature review related to the application of LCA in the Saudi Arabian oil and gas industry yielded only four research papers and one industry report. These studies compared the environmental impacts of various oil and gas industry products and processes. In one study[

35] authors compared the environmental impacts of three products: marine oil gas produced in Saudi Arabia, marine oil gas produced in the USA, and liquefied natural gas (LNG) produced in Qatar. The authors found that LNG produced in Qatar had the lowest environmental impacts; however, the authors pointed out that LNG losses during shipping and storage still pose a significant environmental burden. In a similar investigation [

36], various fuels including Saudi marine oil and green hydrogen were analyzed in the context of achieving International Maritime Organization's 2050 greenhouse gas emission reduction targets. The study concluded that use of green hydrogen for marine fuel can help to meet the targets. One more study compared the environmental impacts of various pipeline repair techniques used in the Saudi Arabian oil and gas industry [

37]. Considering the strategic importance of the oil and gas industry and its enormous carbon footprint, there is a significant opportunity to broaden the use of LCA in all the activities of the oil and gas industry.

3.2. IoT in Saudi Arabian Oil and Gas Industry

As mentioned earlier, IoT has become a leading technology for real-time monitoring, predictive maintenance, and asset management. Adopting IoT in Saudi Arabia's oil and gas sector can significantly enhance efficiency, safety, and environmental performance. The literature review related to the use of IoT in the Saudi Arabian oil and gas sector, however, resulted in very few published research studies. Most of these studies have primarily discussed the use of IoT for pipeline monitoring. For example, in one study IoT networks were reviewed for detecting leakages in pipelines [

38]. The paper compared various types of networks and challenges related to sensor power management, data accuracy, and operation in harsh environments.

Another study [

39] discussed the use of multi-criteria design analysis to evaluate various IoT solutions and recommended optimal choices. The study unified technical and economic considerations in selecting IoT applications. Alhomay and colleagues [

40] focused on the use of low-power, wide-area network technology for pipeline monitoring. Their study provided guidelines for designing sensor networks that optimize energy use and communication reliability. Overall, these papers provide valuable information for integrating IoT with oil and gas infrastructure. They emphasize a holistic approach by combining various layers of IoT infrastructure. Widespread use of IoT in the Saudi Arabian oil and gas industry can lead to significant benefits. However, barriers to its adoption remain, including compatibility with legacy systems, retrofitting current equipment, and investment costs. As IoT adoption gains momentum, integrating Life Cycle Assessment (LCA) and IoT presents another opportunity to make the oil and gas sector more environmentally responsible and resilient. With this in mind, the following framework is presented.

3.3. Conceptual Framework for Saudi Arabian Oil and Gas Industry

Figure 5 shows the propsoed framework to integrate LCA and IoT across the entire value chain of oil and gas sector. A four-layered IoT architecture is adopted and integrated with the five-stage life cycle assessment model to present the framework that can enhance sustainability and operational efficiency of the oil and gas value stream. An additional layer of LCA reporting is added to this framework that can combine static LCA inventories with dynamic data to provided real time enviromntal impacts. By integrating five stages of life cycle assessment with a four-layered IoT architecture comprising of perception, network, processing, and application layers, the oil and gas industry can achieve a real-time, data-driven environmental evaluation system that continuously monitors and analyzes every phase of the oil and gas life cycle.

In upstream operations of exploration and extraction phase, IoT sensors placed on drilling rigs and wellheads can collect valuable data such as methane emissions, water usage, and energy consumption. These inputs are then transmitted through the network layer via satellite or 5G networks. The data processing layer can analyze this data to detect inefficiencies or emissions spikes. This data is then fed to the application layer. Applications featuring dashboards can help visualize extraction-phase emissions per barrel, and at the same time, this information can be integrated with the LCA application layer to provide real-time environmental impact reports. The LCA layer will rely on existing inventories from standard databases such as EcoInvent [

41]and, at the same time, dynamic data provided by IoT. Data that cannot be collected via sensors, can be obtained through other enterpirse information systems. This real-time linking of the LCA database with IoT infrastructure can help reduce flaring, minimize land use, and enable proactive responses to environmental hazards.

In midstream operations of storage and transportation, the perception layer sensors include pressure sensors, flow meters, and gas detectors. These sensors can be placed on pipelines, tank farms, oil tankers, and shipping vessels. These sensors can monitor energy consumption, gas leakages, and transition efficiency in real time. Information from these sensors can then be transmitted across the network layers, even from remote and offshore locations. This data is processed in the data processing layer and then presented to the application layer. This data can then be used to produce real-time LCA inventories. Using advanced data processing tools, instant calculation of GWP of various transporting routes is possible. Interactive GIS-based dashboards can then be constructed to display emissions by location, transportation mechanism, and transport route. This information can provide insights to optimize routing and environmental impacts. This dynamic integration can help oil and gas firms to minimize the carbon footprint, improve transportation efficiency, and reduce operational risks like gas leaks or oil spills.

Integration of IoT and LCA can generate huge benefits in downstream operations. Refining, distribution, and end user consumption results in a large portion of emissions related to oil and gas industry. In refineries, the perception layer can capture real-time data on energy uses, flue gas composition, and hazardous emission. IoT sensors embedded in refining equipment can also provide real-time condition monitoring and early fault detection. This data then can be integrated with LCA inventories to generate environmental profile of refining operations and indicate environmental hot spots. Similarly data collected on fuel sales at distribution points can help in estimation of end used emissions. This data can help in reporting of Scope 3 emissions and regulatory disclosures.

The IoT and LCA framework can provide enhanced visibility in the end-of-life phases of recycling and decommissioning of oil and gas equipment. Extensive data gathering is required to estimate the environmental impacts of well decommissioning, dismantling offshore rigs, and recycling materials extracted from these activities. There is a huge opportunity to automate this data collection by providing a perception layer using RFID tags and sensors that can track the status and location of decommissioned equipment. Additionally, sensors can also detect land and water contamination near the abandoned sites. This data can be transmitted over network layers and processed to provide accurate estimates of material recovery and environmental burdens. LCA application tools can then present this information through lifecycle dashboards to show environmental impacts of various end-of-life scenarios for decommissioned equipment. This integration can enhance the sustainability of an often neglected aspect in the oil and gas sector.

In short, by integrating LCA and IoT, oil and gas companies can transform and revolutionize sustainability reporting across upstream, midstream, and downstream activities. Every phase of the oil and gas lifecycle can be monitored in real time and can be optimized to reduce environmental impacts by implementing this framework. Integration of four layers of IoT with LCA ensures the collection of real-time data, its secure transmission, processing of real-time insights, and intelligent decision support for monitoring environmental impacts and for regulatory compliance. By adopting this framework, LCA moves from a static and retrospective endeavor to a real-time and interactive activity. Adopting this framework will ensure long-term environmental stewardship and will assist in decarbonizing efforts of the oil and gas industry.

4. Discussion

This paper presented a novel framework integrating LCA and IoT technologies within the context of the Saudi Arabian oil and gas industry. The literature review for this paper revealed a very limited number of studies related to LCA and IoT in Saudi Arabia. Although some work is reported in relation to individual applications of LCA and IoT, their combined application still remains unexplored. This study was an attempt to fill this gap by providing a framework that linked the five stages of LCA—raw material extraction, processing, distribution, use, and disposal—to the four layers of IoT architecture—perception, transmission, processing, and reporting.

This framework enables the real-time collection and transmission of environmental data across the complete oil and gas supply chain. This data is then integrated with conventional LCI databases (like EcoInvent) to generate accurate and timely reports. This framework proposes an additional layer for LCA reporting that can integrate both static and dynamic data. This integration can help to identify environmental hotspots for a sector that has a very complex operational profile and a very significant carbon footprint. This integrated framework, if implemented, can help oil and gas companies to better manage environmental emissions, reduce carbon footprint, and meet challenging regulations and international climate commitments like net-zero targets.

One of the major strengths of this framework is to provide real-time continuous environmental emission reports across the entire value chain. Conventional LCA reports are usually static and historic in nature. They rely on the data that does not represent the fluctuations in the real-time operations of the company. This framework, on the other hand, leverages IoT sensors to gather real-time data from drilling rigs, pipelines, distribution channels, and refineries. This then allows for real-time monitoring of environmental impacts that can detect emission spikes as they happen. During the extraction phases, for instance, if excessive leaks of methane gas are detected their environmental impacts can be reported instantly and prompt actions can be taken to reduce the environmental harm.

Saudi Arabia's ambitious national development plan – Vision 2030 – places very strong emphasis on sustainability, and the country is committed to meet net-zero targets by 2060 [

42]. This framework helps to embed sustainability within IoT layers, thus enhancing sustainability and environmental responsibility of the oil and gas sector. Inclusion of end-of-life stages like decommissioning of rigs further strengthens the framework. This full life cycle visibility will help to meet the ESG requirements and will improve transparency of oil and gas operations.

When compared to existing practices of environmental reporting and management, this framework represents the next evolutionary step within the oil and gas sector. Both IoT and LCA are being used in several industries as separate domains, however combination of these two areas provide several benefits. This framework fills a critical gap in academic research and industrial practice by outlining a roadmap for a unified approach across the complete value chain. Furthermore, this framework provides finer resolution and instant access which is usually not present in conventional sustainability assessment tools like carbon foot-printing and environmental auditing. Traditional environmental reports and LCA studies can sometimes take considerable amount of time to prepare and generate meaningful action items. This framework on the hand can enable a live dashboard for environmental impact monitoring. It can lead to instant corrective actions resulting in financial and environmental benefits. Additionally, this framework also enhances the scope of conventional IoT applications in industry which are usually limited to efficiency and safety. Overall this framework can provide the roadmap to enhance existing ESG practices in the industry.

As with all scientific works, current work has limitations that need to be acknowledged. This framework, at the moment, is conceptual in nature and there are several steps required for practical implementation of this framework. There are significant challenges in linking conventional and static LCI databases like EcoInvent to real-time and dynamic data generated from IoT sensors. This will require designing new software platforms and advanced data analytics capabilities. Then there are issues of data ownership, confidentiality, and privacy among various stakeholders representing the complete oil and gas value chain. These issues can complicate collaboration and data sharing. Furthermore, this framework assumes a high level deployment of IoT infrastructure within the oil and gas sector. While digital transformation of Saudi oil and gas sector is underway, deployment of an IoT system that is fully integrated with LCA will require significant investment. Similar major efforts are required to retrofit existing infrastructure, integrating legacy software systems, and updating data collection mechanisms. Another limitation of the framework may arise from the use of non-region specific data in legacy LCI databases. At the moment, most of the LCI databases are based on European material flows, energy mixes, and operational characteristics. Integrating this data with real-time IoT data may lead to skewed or incomplete assessment. Without localization of LCI databases, results provided by this framework may be compromised.

There are several areas of future work that can enhance the utility of this framework. One of the most important steps will be to develop a pilot implementation of this framework within a selected facility of an oil and gas organization. These pilot runs will act as proof of concept for this framework and will provide important learning regarding cost implications, integration challenges, and organizational feedback. Lessons learned from pilot runs can be used to further develop and expand the framework across the complete value chain of oil and gas operations. Performance metrics like carbon footprints, energy consumption, and regulatory compliance can be tracked to validate the effectiveness of the framework. Another area of future research is to develop local LCI databases that can integrate IoT-generated data. This may require extensive collaboration between industry, academia, and regulatory organizations. A Saudi-specific LCI database will greatly enhance the benefits of this framework. Finally, other digital technologies like machine learning, digital twins, and AI should be explored for their integration into this framework. This will further enhance the integration of operational parameters with sustainability assessments.

5. Conclusions

This study proposed a conceptual framework to integrate the five stages of LCA with a four-layered IoT architecture within the context of the Saudi Arabian oil and gas industry. A literature review conducted for this study revealed that the application of both LCA and IoT in this sector is still in its nascent stages in Saudi oil and gas industry. Only a limited number of research articles and studies have explored the use of LCA and IoT and no study was found discussing the integration of integration of these concepts to promote sustainability in Saudi oil and gas industry. Globally, LCA is one of the most widely used sustainability assessment techniques, offering a structured approach to evaluating environmental impacts. Meanwhile, IoT enables real-time data collection throughout the oil and gas value chain. Integrating IoT-generated data with LCA can greatly enhance the accuracy and effectiveness of environmental impact assessments. By combining the four layers of IoT architecture with the five stages of LCA, substantial benefits can be gained in quantifying environmental impacts and devising actionable pathways to reduce them.

This framework offers valuable guidance for LCA practitioners and sustainability managers to align industrial operations with sustainability goals. Given the crucial role of the oil and gas industry in Saudi Arabia, it is important to promote tools and methodologies that not only enhance sustainability but also improve operational efficiency. The integration of LCA and IoT can help the oil and gas sector align with international sustainability commitments, including achieving net-zero emissions by 2060. In conclusion, this framework provides a foundation for future research and practical implementation, fostering operational efficiency and environmental responsibility in one of the most important sectors of the Saudi economy.

Funding

This research received no external funding.

Conflicts of Interest

Authors declares no conflicts of interest.

References

- S. Alabdulwahab, “The Linkage between Oil and Non-Oil GDP in Saudi Arabia,” Economies, vol. 9, no. 2021; 4. [CrossRef]

- OPEC, “OPEC Annual Statistical Bulletin 2018,” Organization of the Petroleum Exporting Countries, 2018.

- Y. T. Al-Janabi, “An overview of corrosion in oil and gas industry: Upstream, midstream, and downstream sectors,” in Corrosion Inhibitors in the Oil and Gas Industry, 2020. [CrossRef]

- T. Husain and A. A. Khalil, “Environment and Sustainable Development in the Kingdom of Saudi Arabia: Current Status and Future Strategy,” J Sustain Dev, vol. 6, no. 2013; 12. [CrossRef]

- Velastegui-Montoya, P. Escandón-Panchana, G. Peña-Villacreses, and G. Herrera-Franco, “Land use/land cover of petroleum activities in the framework of sustainable development,” 2023. [CrossRef]

- N. Alajlan and A. Alreshaidi, “The nexus of carbon dioxide emissions, economic growth, and urbanization in Saudi Arabia,” Environ Res Commun, vol. 4, no. 2022; 12. [CrossRef]

- Y. Charabi, “Digging deeper into cutting methane emissions from the oil and gas industry in the era of volatile prices,” Mitig Adapt Strateg Glob Chang, vol. 26, no. 2021; 2. [CrossRef]

- A. Alola, S. T. A. Alola, S. T. Onifade, C. Magazzino, and H. O. Obekpa, “The effects of gas flaring as moderated by government quality in leading natural gas flaring economies,” Sci Rep, vol. 13, no. 2023; 1. [Google Scholar] [CrossRef]

- H. Baumann and A.-M. Tillman, The Hitch Hiker’s Guide to LCA. 2004.

- M. Hauschild, H. M. Hauschild, H. Wenzel, and L. Alting, “Life cycle design - a route to the sustainable industrial culture?,” CIRP Ann Manuf Technol, vol. 48, no. 1999; 1. [Google Scholar] [CrossRef]

- D. W. Pennington et al., “Life cycle assessment Part 2: Current impact assessment practice,” 2004. [CrossRef]

- G. Unruh, “Strategic Sustainability Uses of Life- Cycle Analysis,” MITSloan Management Review, pp. 22–25, 2015.

- B. Moutik, J. B. Moutik, J. Summerscales, J. Graham-Jones, and R. Pemberton, “Life Cycle Assessment Research Trends and Implications: A Bibliometric Analysis,” 2023. [CrossRef]

- International Organization for Standardization, “ISO 14040 Environmental management--life cycle assessment--requirements and guidelines,” Geneva, 2006.

- M. A. Curran, “Strengths and Limitations of Life Cycle Assessment,” in Klöpffer, W. (eds) Background and Future Prospects in Life Cycle Assessment. LCA Compendium – The Complete World of Life Cycle Assessment., Dordrecht: Springer, 2014. [CrossRef]

- K. Safari and H. AzariJafari, “Challenges and opportunities for integrating BIM and LCA: Methodological choices and framework development,” 2021. [CrossRef]

- S. Su, X. S. Su, X. Li, Y. Zhu, and B. Lin, “Dynamic LCA framework for environmental impact assessment of buildings,” Energy Build, vol. 2017. [Google Scholar] [CrossRef]

- V. W. Tam, Y. V. W. Tam, Y. Zhou, C. Illankoon, and K. N. Le, “A critical review on BIM and LCA integration using the ISO 14040 framework,” 2022. [CrossRef]

- Al-Fuqaha, M. Guizani, M. Mohammadi, M. Aledhari, and M. Ayyash, “Internet of Things: A Survey on Enabling Technologies, Protocols, and Applications,” IEEE Communications Surveys and Tutorials, vol. 17, no. 2015; 4. [Google Scholar] [CrossRef]

- L. Atzori, A. L. Atzori, A. Iera, and G. Morabito, “The Internet of Things: A survey,” Computer Networks, vol. 54, no. 2010; 15. [Google Scholar] [CrossRef]

- Dorsemaine, J. P. Gaulier, J. P. Wary, N. Kheir, and P. Urien, “Internet of Things: A Definition and Taxonomy,” in Proceedings - NGMAST 2015: The 9th International Conference on Next Generation Mobile Applications, Services and Technologies, 2016. [CrossRef]

- S. Li, L. S. Li, L. Da Xu, and S. Zhao, “The internet of things: a survey,” Information Systems Frontiers, vol. 17, no. 2015; 2. [Google Scholar] [CrossRef]

- T. W. Chit, L. T. W. Chit, L. Ning, N. A. Paliath, Y. M. Long, H. Akhtar, and Y. Shanshan, “IIoT-enabled and Data-driven Sustainability Evaluation Framework for Textile Supply Chain,” in Proceedings of the 16th IEEE Conference on Industrial Electronics and Applications, ICIEA 2021, 2021. [CrossRef]

- Kaur, G. Singh, V. Kukreja, S. Sharma, S. Singh, and B. Yoon, “Adaptation of IoT with Blockchain in Food Supply Chain Management: An Analysis-Based Review in Development, Benefits and Potential Applications,” 2022. [CrossRef]

- P. Asopa, P. P. Asopa, P. Purohit, R. R. Nadikattu, and P. Whig, “Reducing carbon footprint for sustainable development of smart cities using IoT,” in Proceedings of the 3rd International Conference on Intelligent Communication Technologies and Virtual Mobile Networks, ICICV 2021, 2021. [CrossRef]

- T. R. Wanasinghe, R. G. T. R. Wanasinghe, R. G. Gosine, L. A. James, G. K. I. Mann, O. De Silva, and P. J. Warrian, “The Internet of Things in the Oil and Gas Industry: A Systematic Review,” IEEE Internet Things J, vol. 7, no. 2020; 9. [Google Scholar] [CrossRef]

- K. Yas and A. Al Qassab, “Oil and Gas pipelines monitoring using IoT platform,” Iraqi Journal of Information and Communication Technology, vol. 6, no. 2024; 1. [CrossRef]

- Ingrao, *!!! REPLACE !!!*; et al. , “The contribution of sensor-based equipment to life cycle assessment through improvement of data collection in the industry,” Environ Impact Assess Rev, vol. 2021; 88. [Google Scholar] [CrossRef]

- J. An, Z. J. An, Z. Zou, G. Chen, Y. Sun, R. Liu, and L. Zheng, “An IoT-based life cycle assessment platform of wind turbines,” Sensors (Switzerland), vol. 21, no. 2021; 4. [Google Scholar] [CrossRef]

- J. A. Luft, S. J. A. Luft, S. Jeong, R. Idsardi, and G. Gardner, “Literature Reviews, Theoretical Frameworks, and Conceptual Frameworks: An Introduction for New Biology Education Researchers,” CBE Life Sci Educ, vol. 21, no. 2022; 3. [Google Scholar] [CrossRef]

- Y. Jabareen, “Building a Conceptual Framework: Philosophy, Definitions, and Procedure,” International Journal of Qualitative Methods, vol. 8, no. 2009; 4. [CrossRef]

- M. Naeem, W. M. Naeem, W. Ozuem, K. Howell, and S. Ranfagni, “A Step-by-Step Process of Thematic Analysis to Develop a Conceptual Model in Qualitative Research,” Int J Qual Methods, vol. 2023; 22. [Google Scholar] [CrossRef]

- E. Ahn and H. Kang, “Introduction to systematic review and meta-analysis,” Korean J Anesthesiol, vol. 71, no. 2018; 2. [CrossRef]

- M. J. Grant and A. Booth, “A typology of reviews: An analysis of 14 review types and associated methodologies,” 2009. [CrossRef]

- S. Hwang, B. S. Hwang, B. Jeong, K. Jung, M. Kim, and P. Zhou, “Life cycle assessment of lng fueled vessel in domestic services,” J Mar Sci Eng, vol. 7, no. 2019; 10. [Google Scholar] [CrossRef]

- S. S. Hwang et al., “Life Cycle Assessment of Alternative Ship Fuels for Coastal Ferry Operating in Republic of Korea,” J Mar Sci Eng, vol. 8, no. 9, Sep. 2020. [CrossRef]

- M. M. Shaukat, F. M. M. Shaukat, F. Ashraf, M. Asif, S. Pashah, and M. Makawi, “Environmental Impact Analysis of Oil and Gas Pipe Repair Techniques Using Life Cycle Assessment (LCA),” Sustainability (Switzerland), vol. 14, no. 2022; 15. [Google Scholar] [CrossRef]

- S. S. Bakhder, G. S. S. Bakhder, G. Aldabbagh, N. Dimitriou, S. Alkhuraiji, M. Fadel, and H. Bakhsh, “IoT networks for monitoring and detection of leakage in pipelines,” International Journal of Sensor Networks, vol. 38, no. 4, pp. 2022. [Google Scholar] [CrossRef]

- B. Alojaiman, “A Multi-Criteria Decision-Making Process for the Selection of an Efficient and Reliable IoT Application,” Processes, vol. 11, no. 2023; 5. [CrossRef]

- H. Alhomyani, M. H. Alhomyani, M. Fadel, N. Dimitriou, H. Bakhsh, and G. Aldabbagh, “Modeling the Performance of a Multi-Hop LoRaWAN Linear Sensor Network for Energy-Efficient Pipeline Monitoring Systems,” Applied Sciences Switzerland, vol. 14, no. 2024; 20. [Google Scholar] [CrossRef]

- R. Frischknecht et al., “The ecoinvent database: Overview and methodological framework,” 2005. [CrossRef]

- F. Belaïd and C. Massié, “The viability of energy efficiency in facilitating Saudi Arabia’s journey toward net-zero emissions,” Energy Econ, vol. 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).