Submitted:

06 October 2025

Posted:

07 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

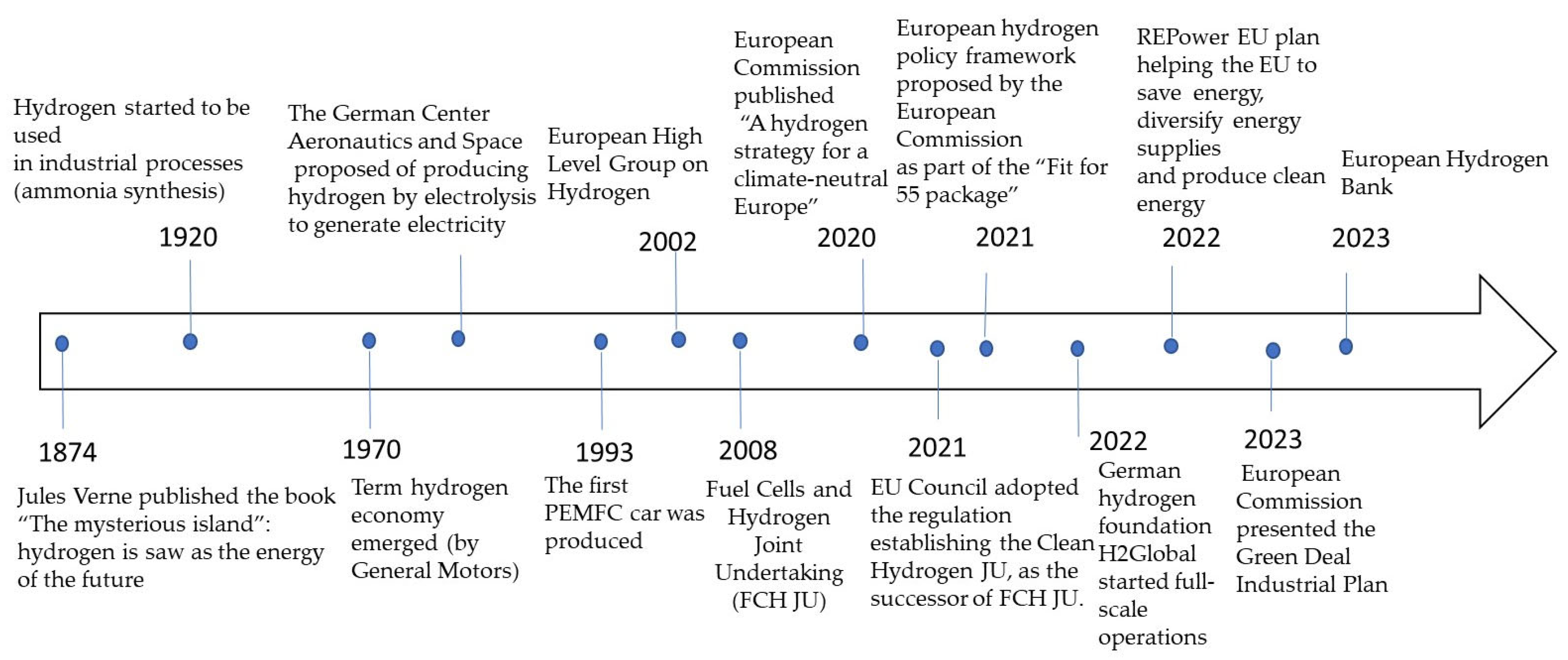

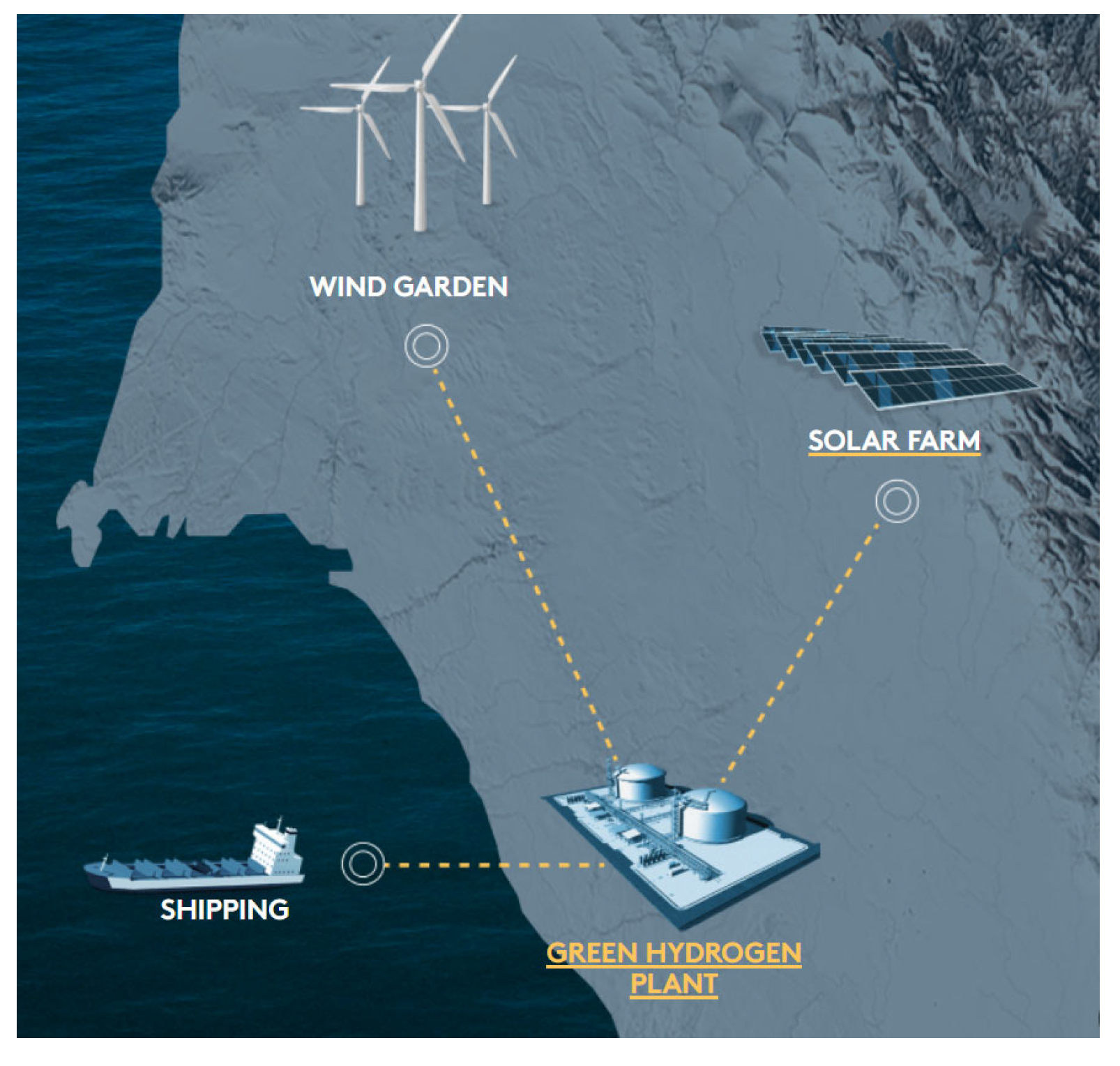

2. The Steps Toward a Green Hydrogen Economy in Europe

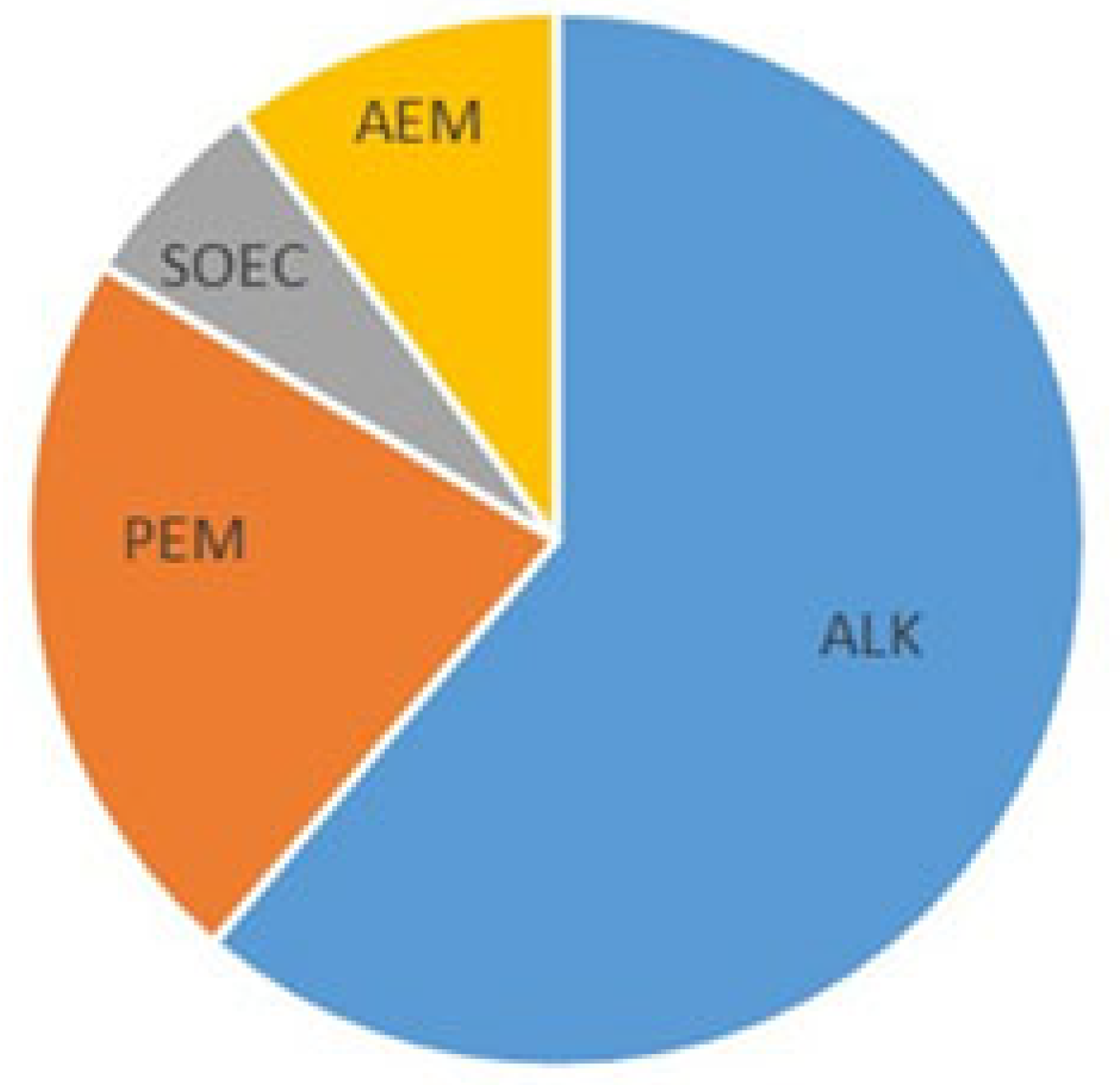

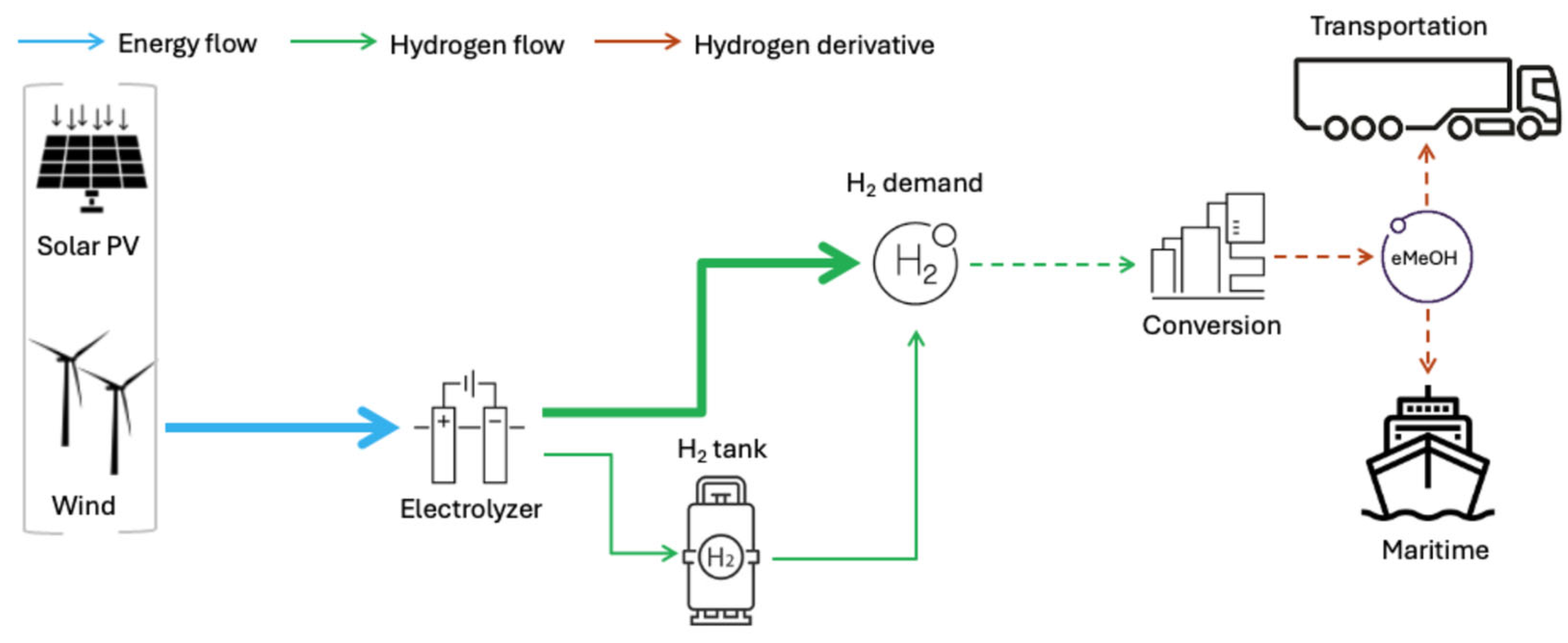

3. Types of Electrolyzers: Theoretical Background and Relevant Projects

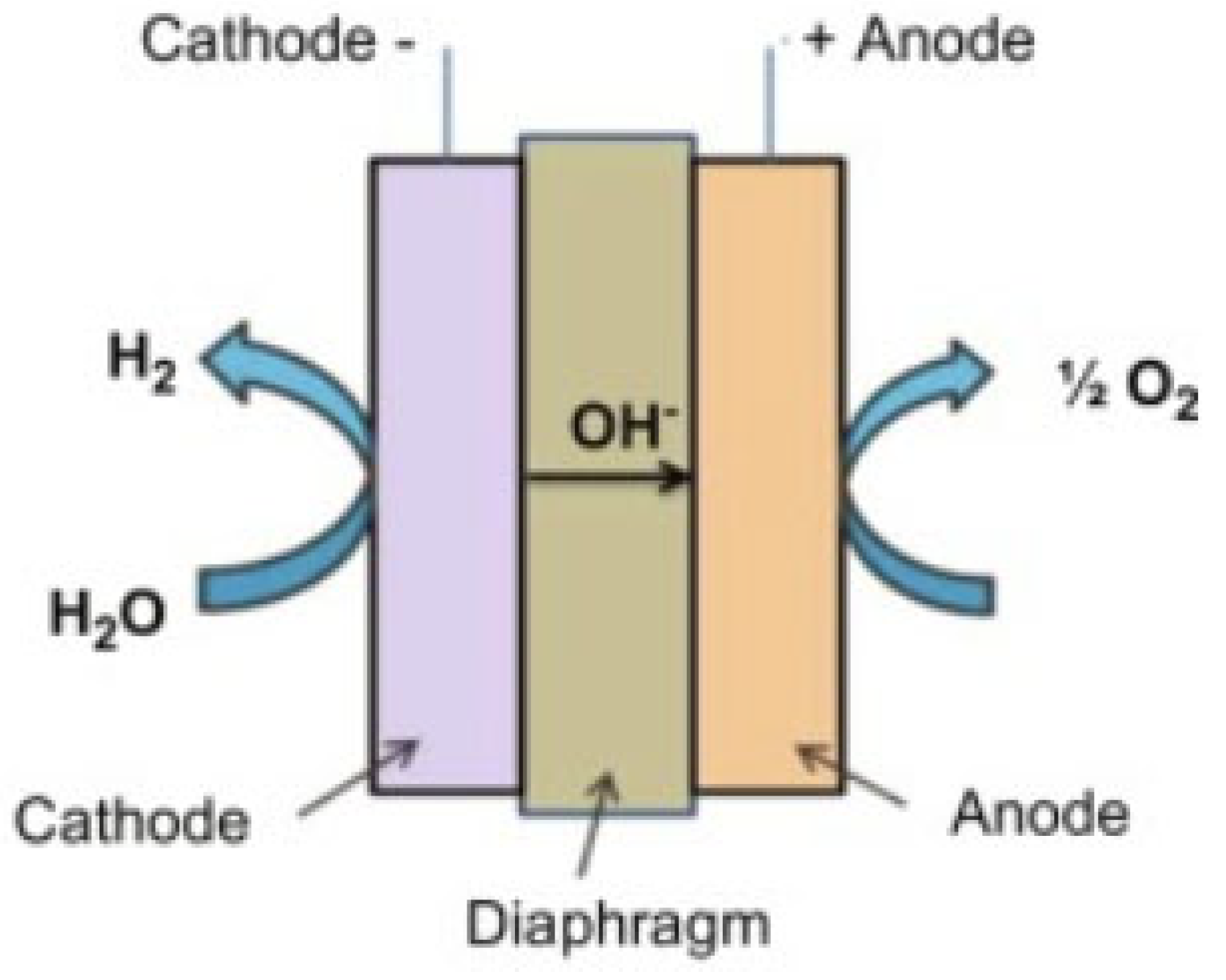

3.1. Alkaline Electrolysis

3.2. Proton Exchange Membrane

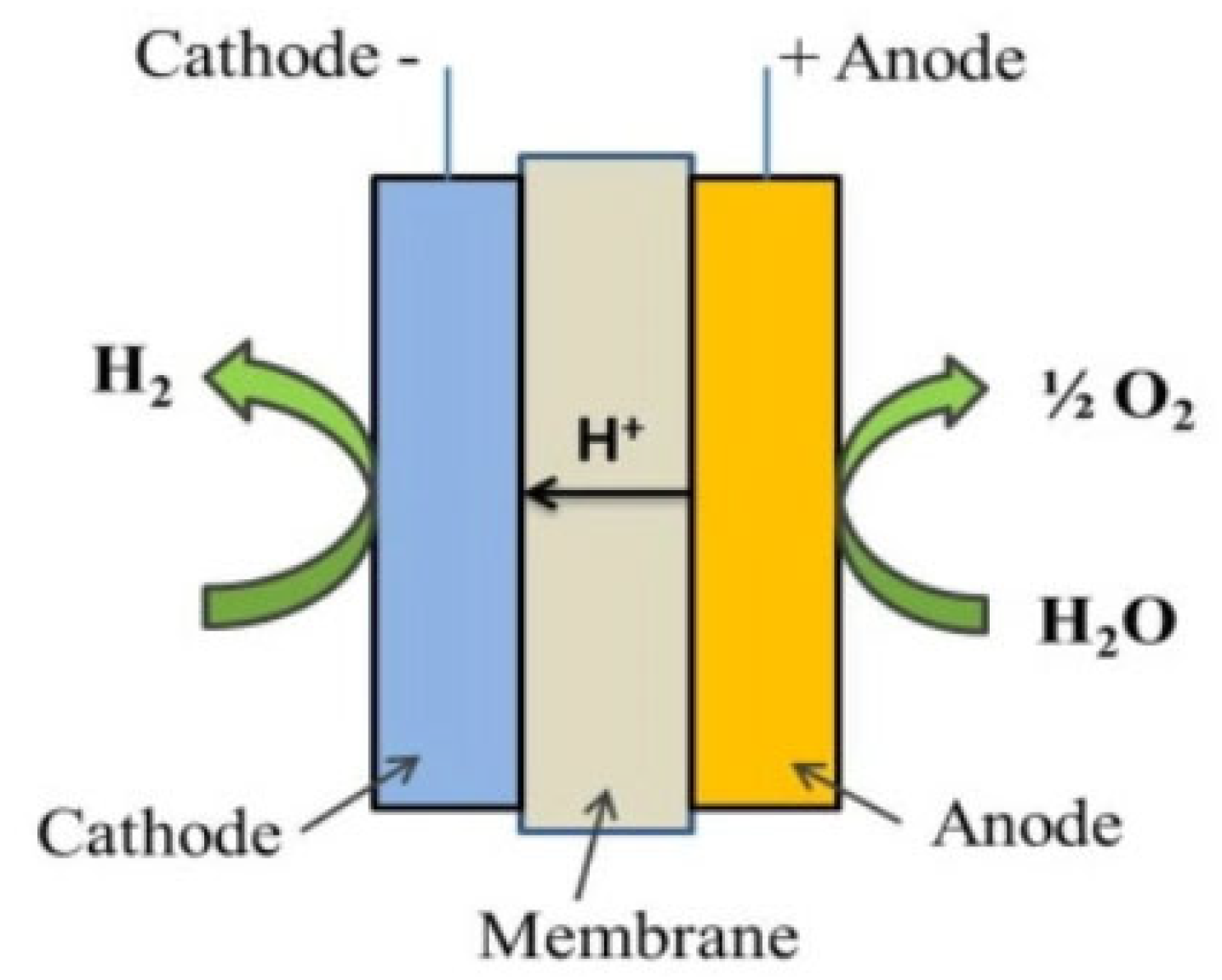

3.3. Solid Oxide Electrolysers

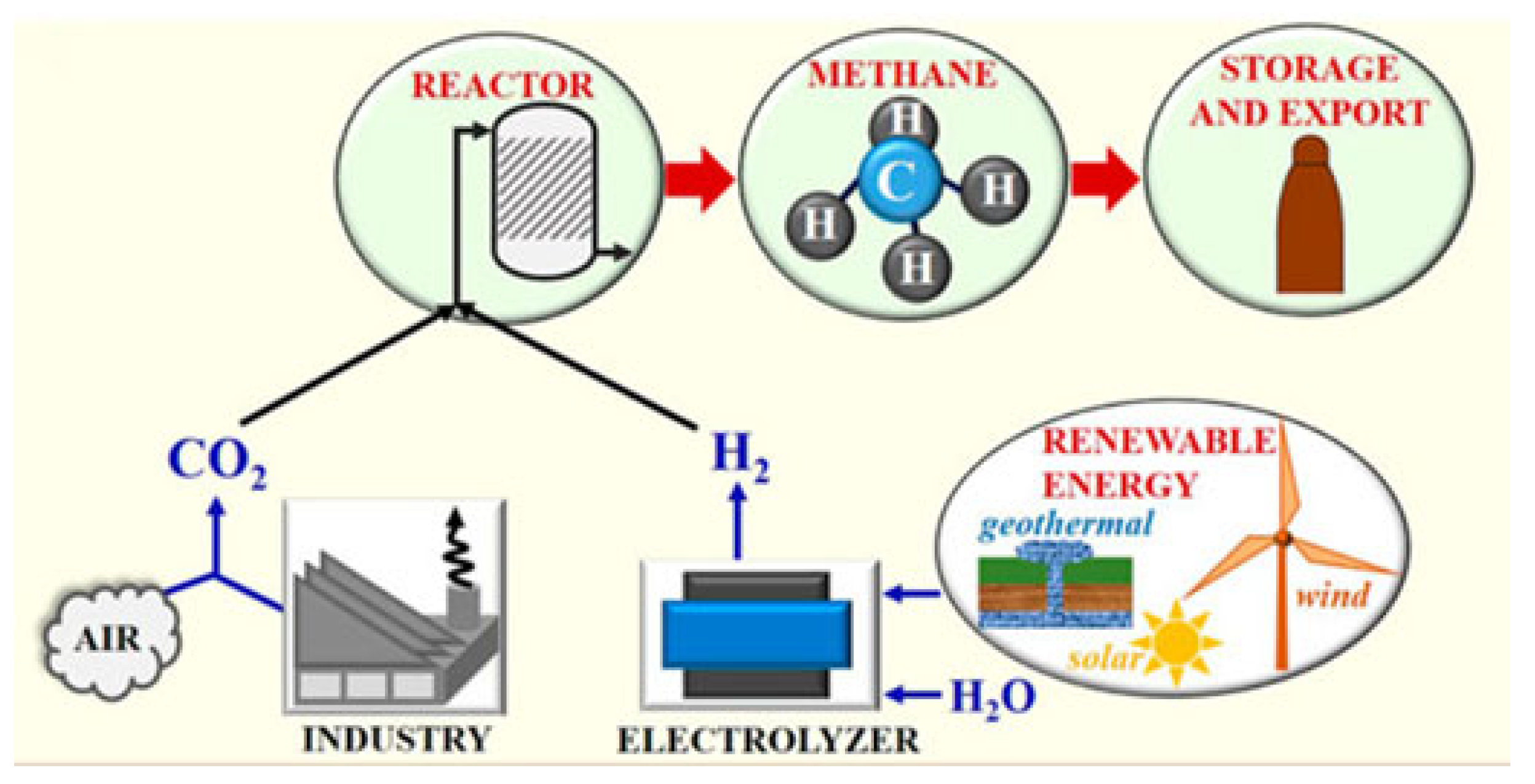

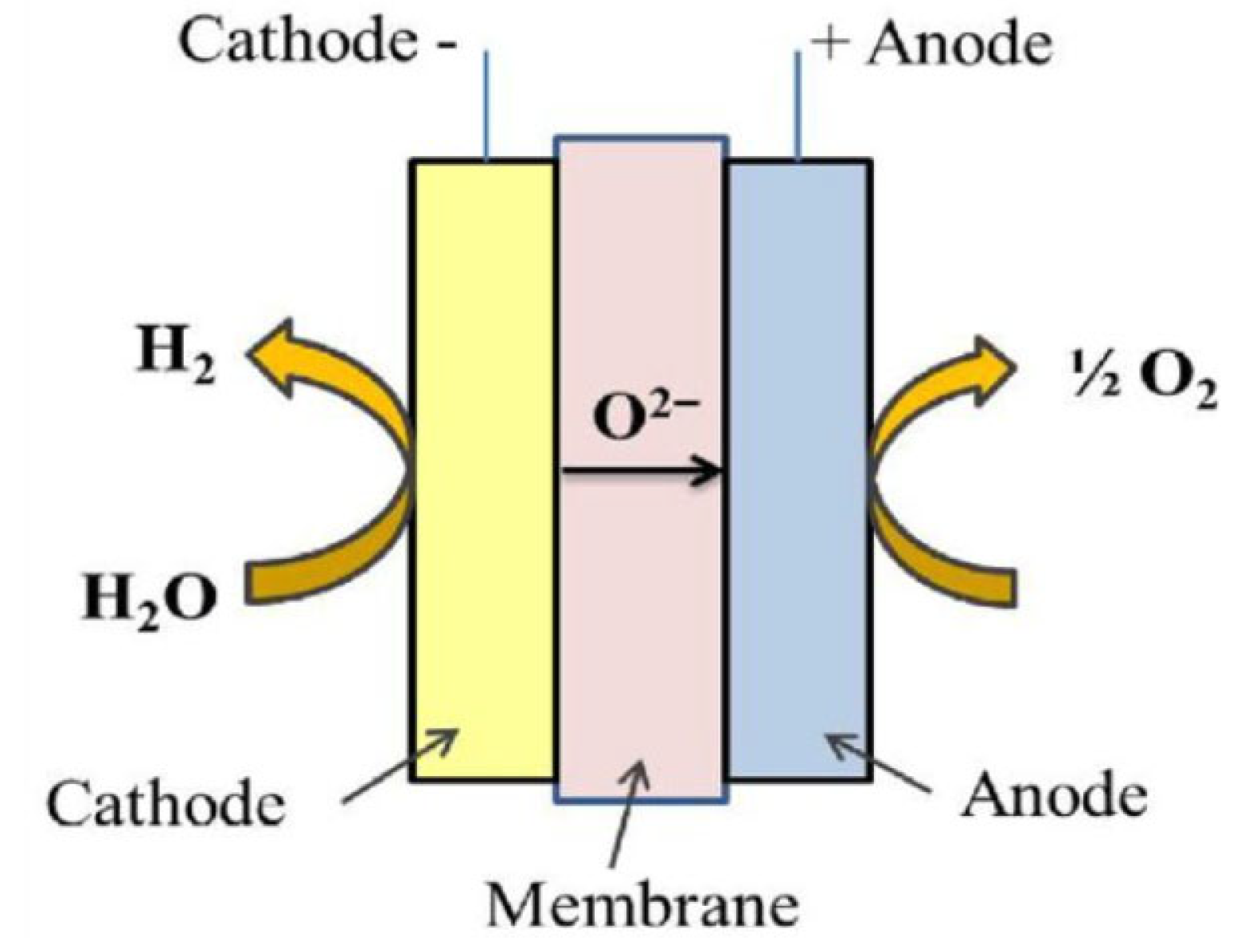

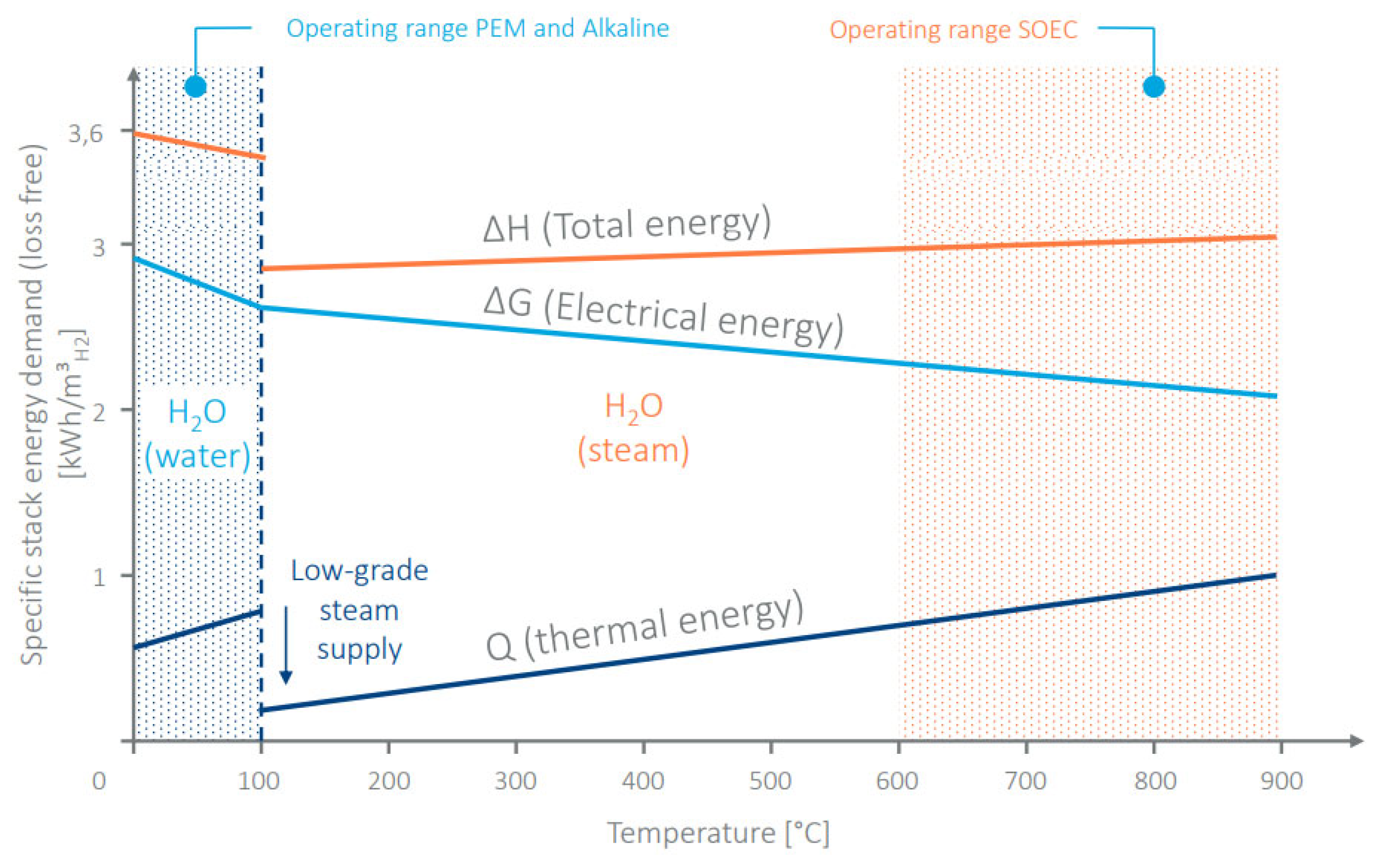

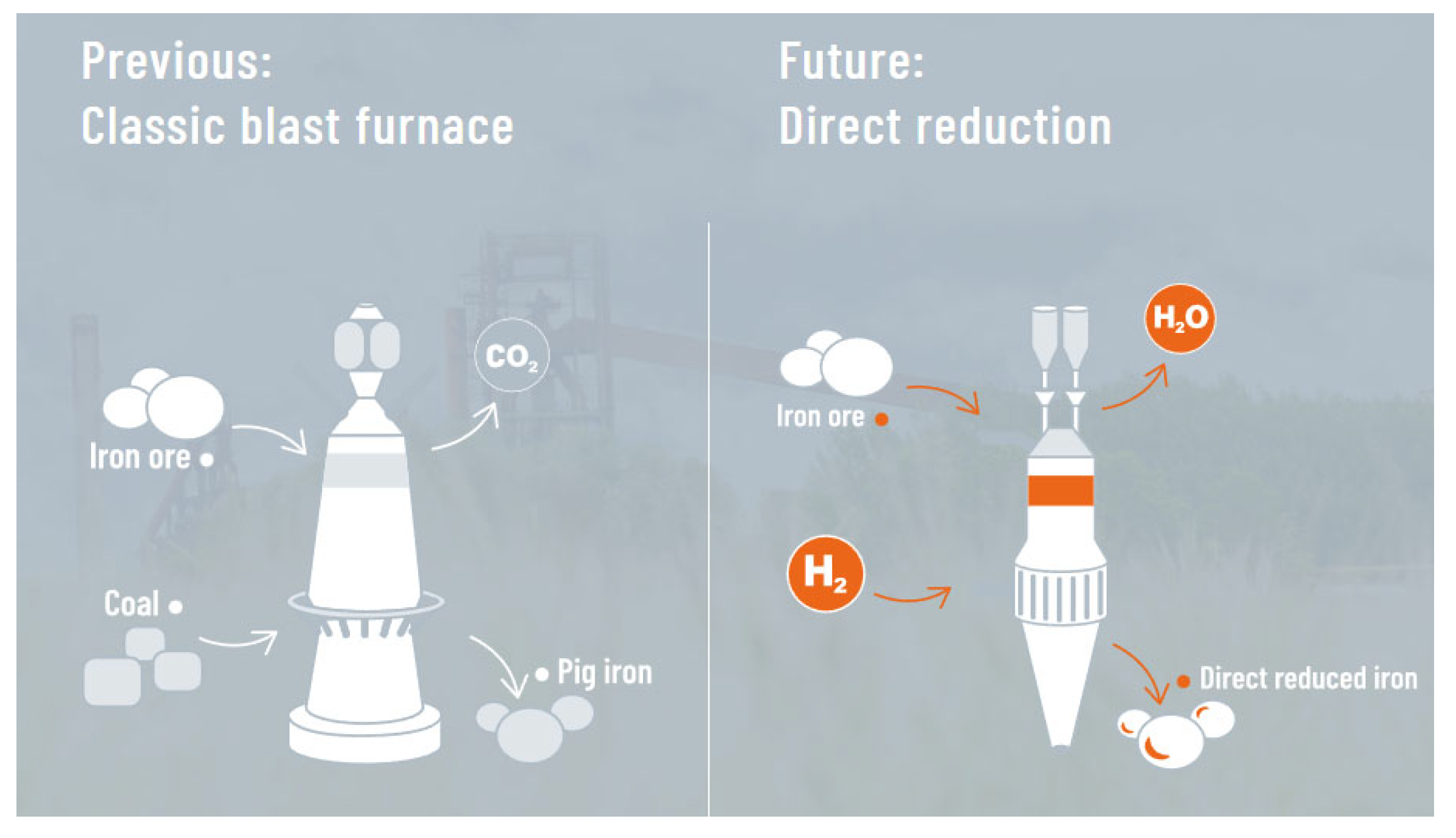

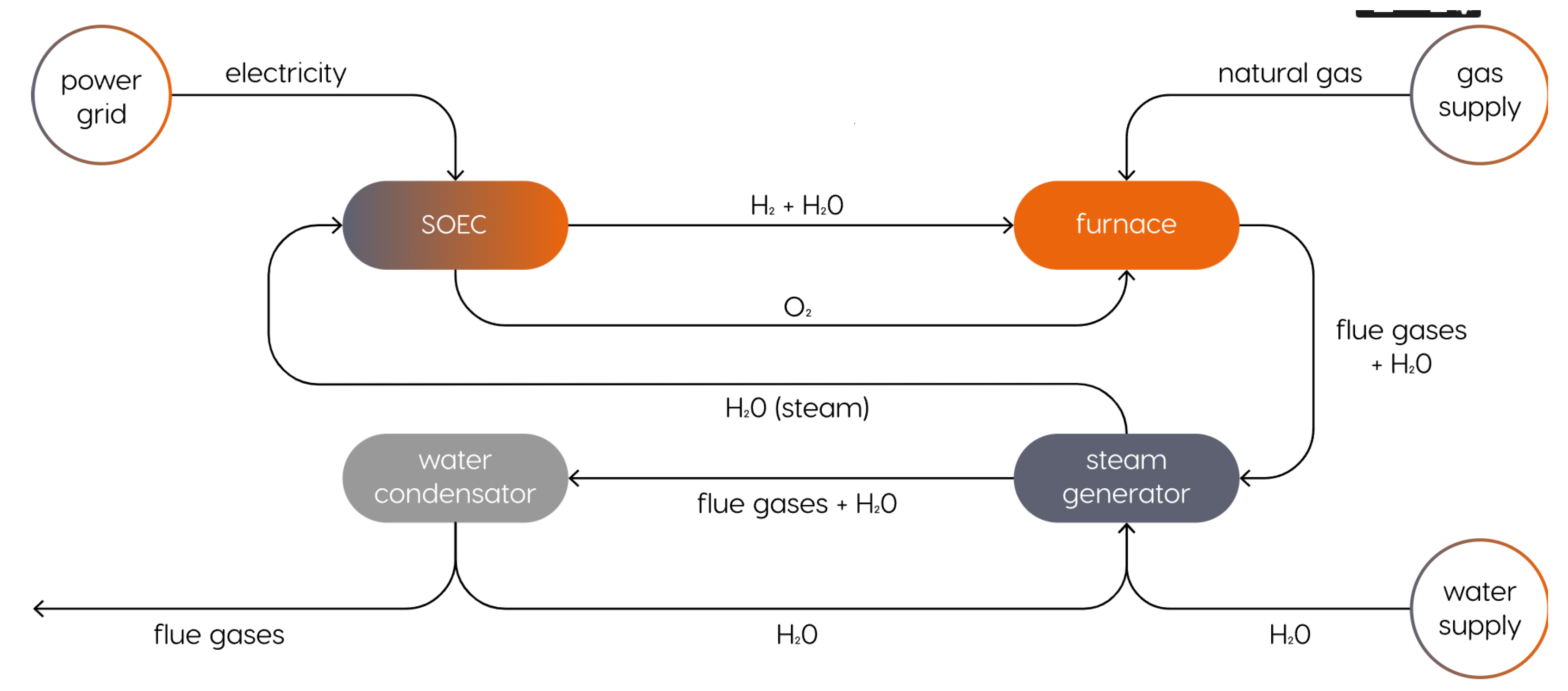

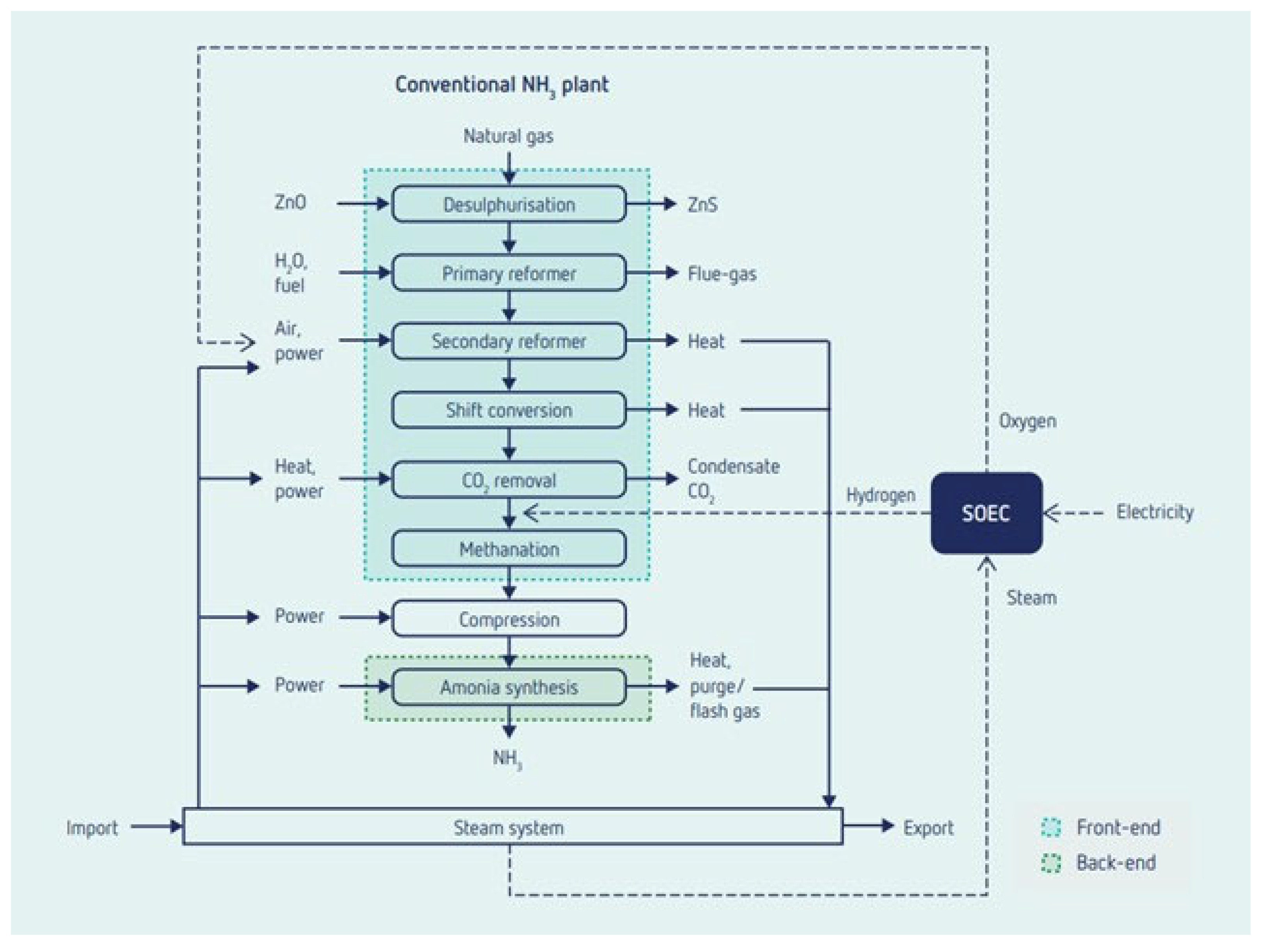

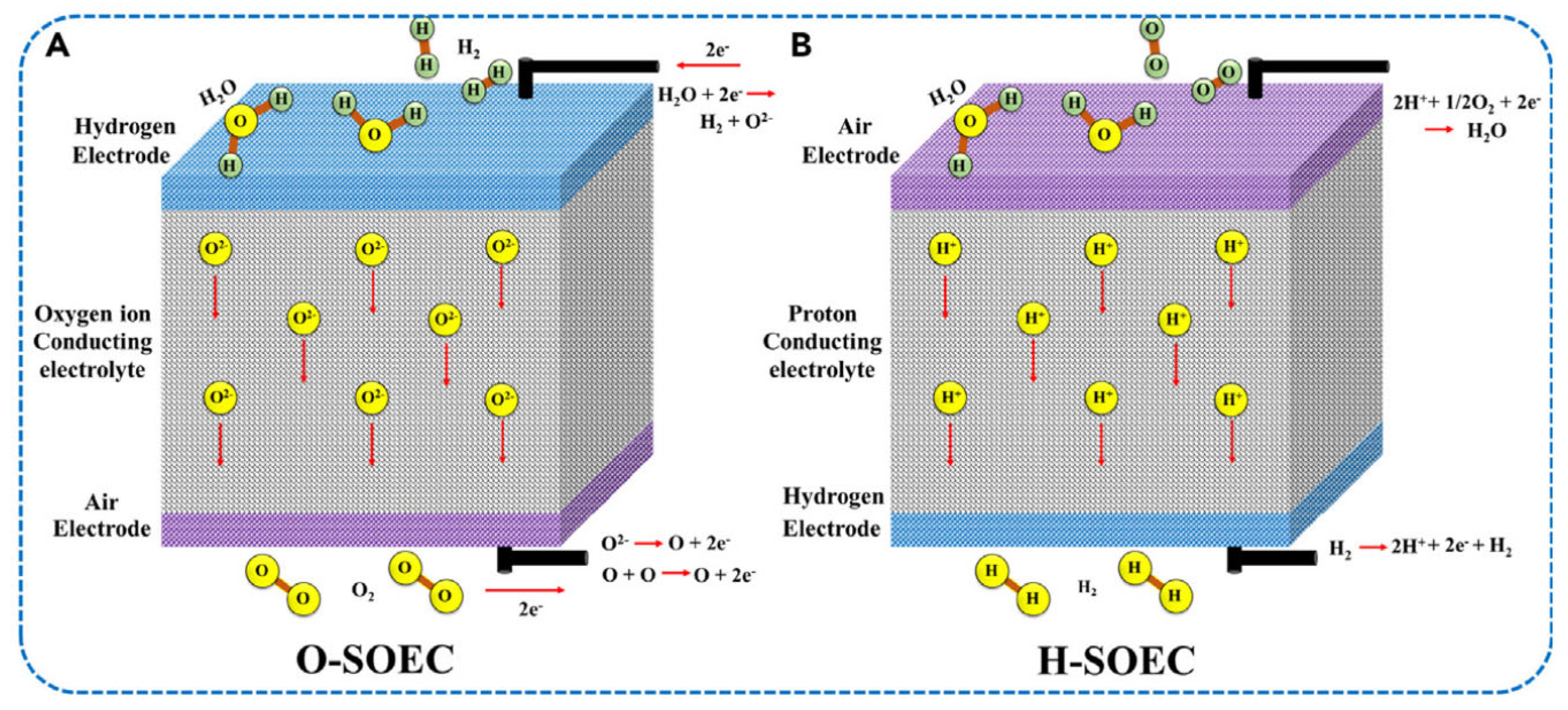

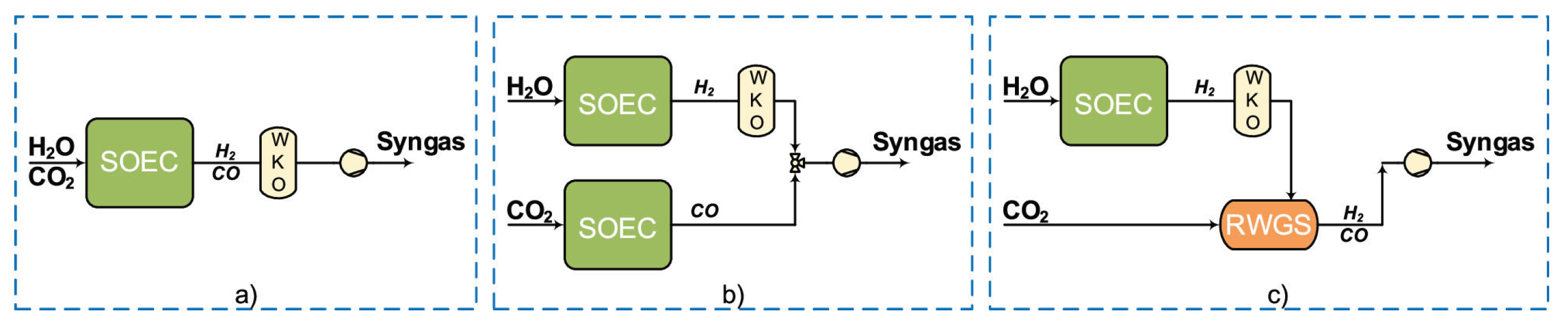

3.4. Anion Exchange Membrane

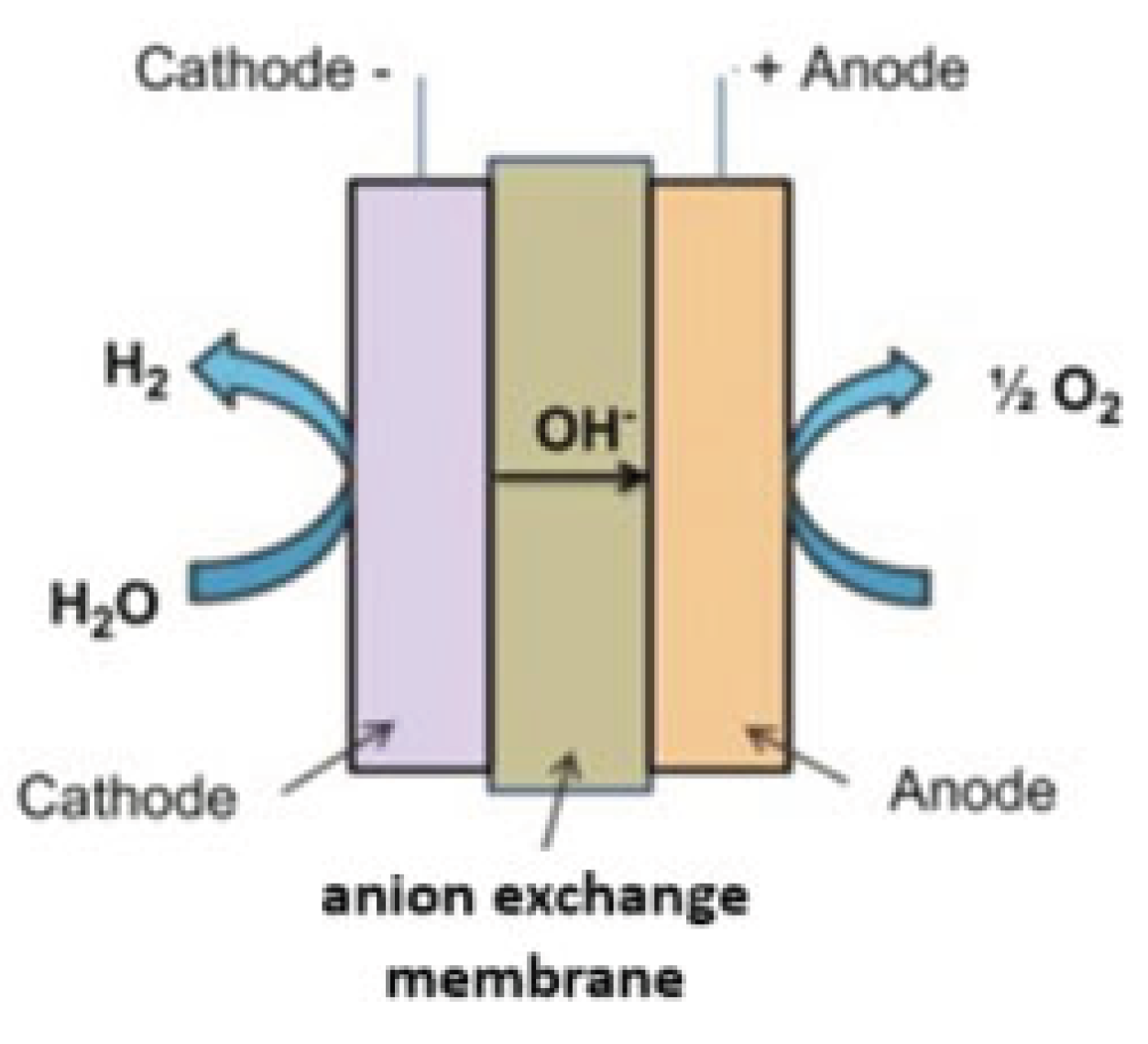

4. Socio-Political Challenges

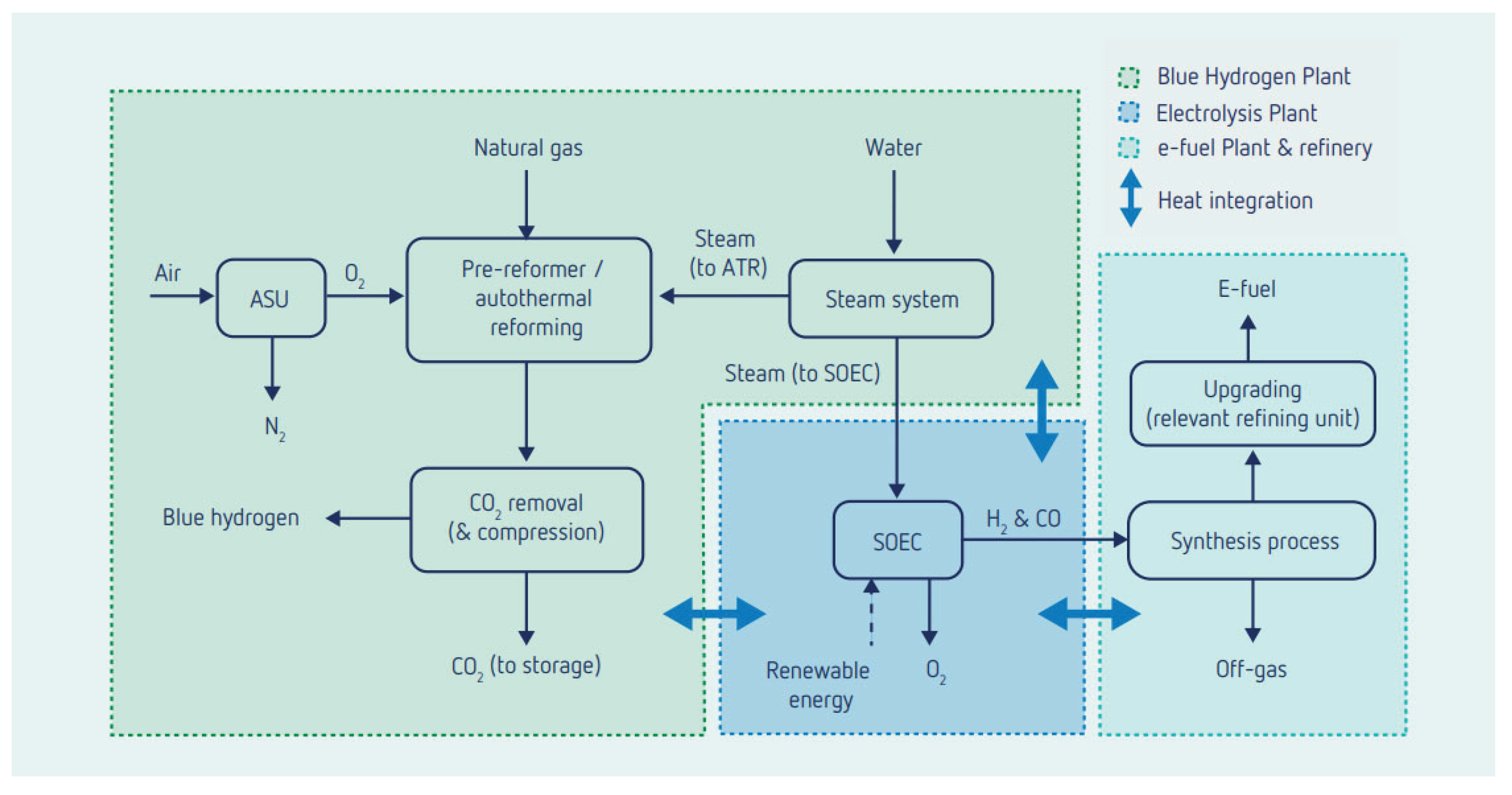

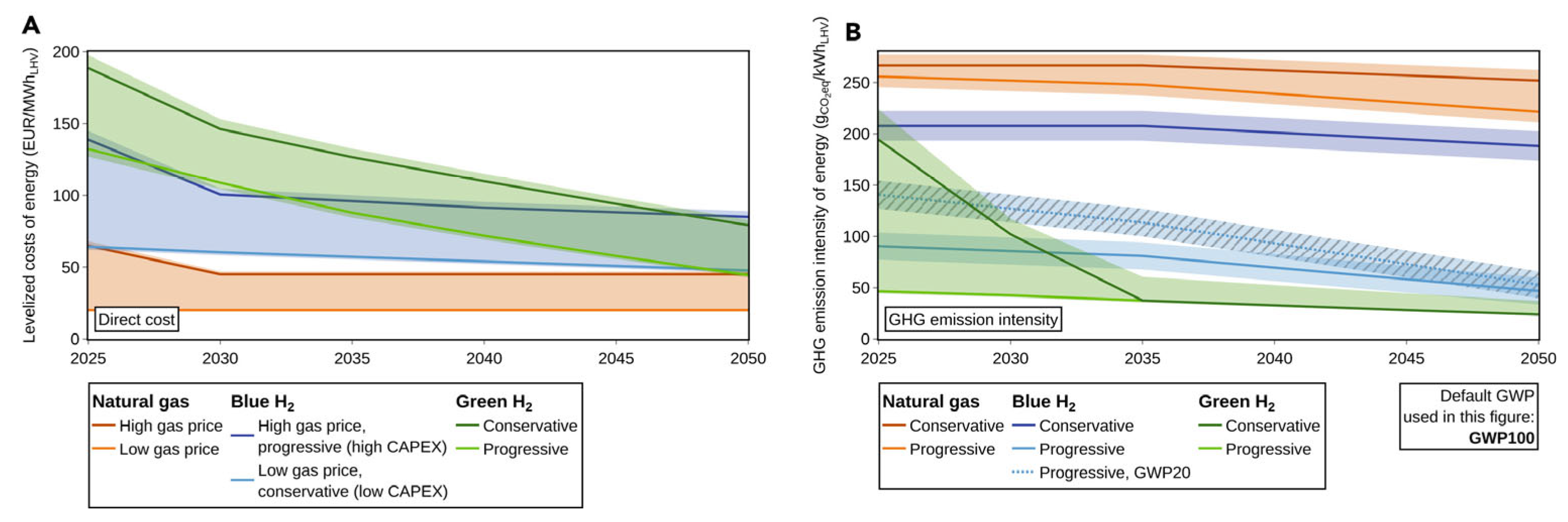

5. To What Extent Can Low Carbon Hydrogen Complement Green Hydrogen?

6. Conclusions and Outlook

References

- Ballentine, CJ; Karolytė, R. ; Cheng, A.; Lollar, B.S.; Gluyas, G.; Daly, M.C. Natural hydrogen resource accumulation in the continental crust. Nature Reviews Earth & Environment 2025, 6, 342–356. [Google Scholar]

- Klein, F.; Tarnas, J.D.; Bach, W. Abiotic sources of molecular hydrogen on Earth, Elements 2020, 16, 19–24.

- https://www.oxfordenergy.org/wpcms/wp-content/uploads/2024/09/ET38-Natural-geologic-hydrogen-and-its-potential-role-in-a-net-zero-carbon-future.pdf accessed on 13 September 2025.

- https://www.wired.com/story/gold-hydrogen/. (accessed on 13 September 2025).

- https://climate.mit.edu/ask-mit/how-clean-green-hydrogen. (accessed on 8 September 2025).

- Alabbadi, A.A.; AlZahrani, A.A. Nuclear hydrogen production using PEM electrolysis integrated with APR1400 power plant. Int J Hydrogen Energy 2024, 60, 241–260. [Google Scholar] [CrossRef]

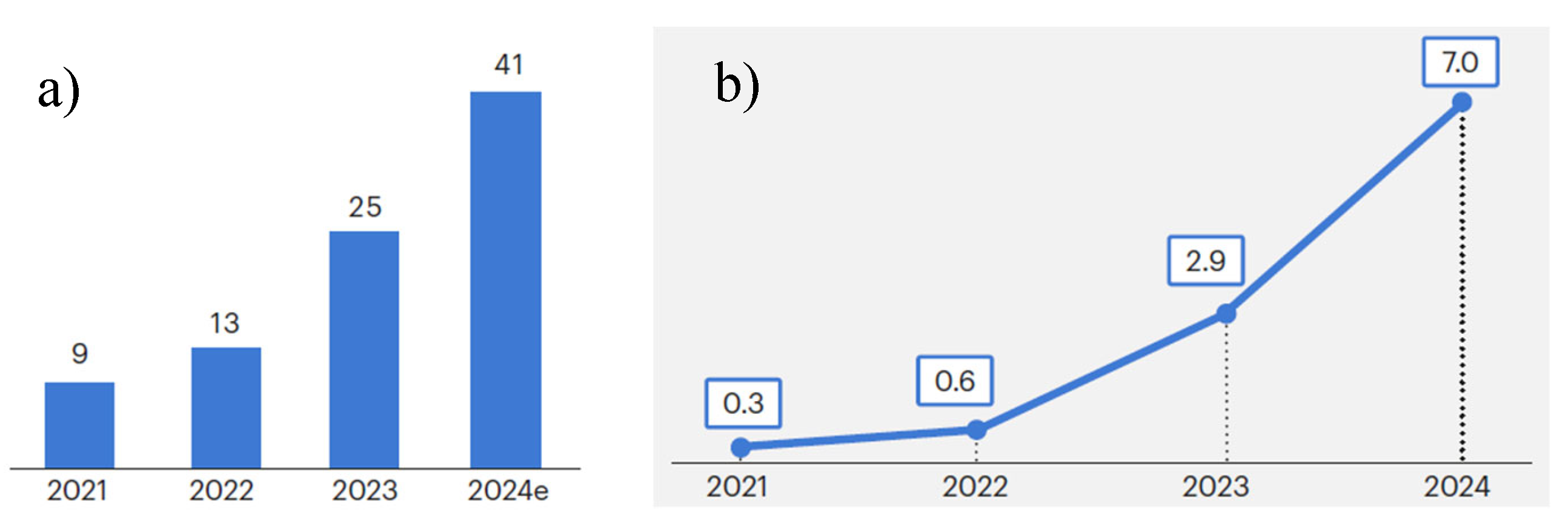

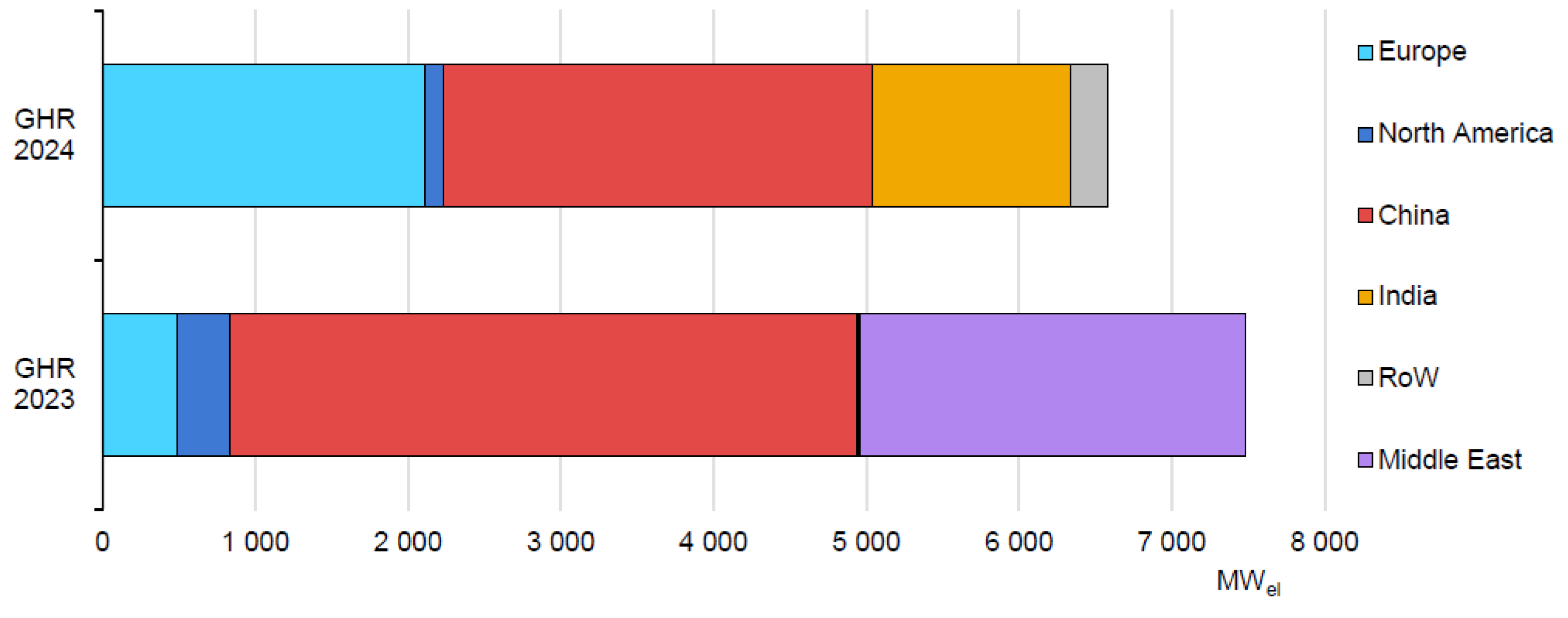

- Global Hydrogen review, 2024 available at: www.iea.org.

- The Clean Industrial Deal: A joint roadmap for competitiveness and decarbonization. Available online at https://commission.europa.eu/document/download/9db1c5c8-9e82-467b-ab6a-905feeb4b6b0_en. (accessed on 03 March 2025).

- A Clean Industrial Deal for competitiveness and decarbonisation in the EU. Available online at https://ec.europa.eu/commission/presscorner/detail/en/ip_25_550. (accessed on 03 March 2025).

- Bettenhausen, C. Green hydrogen is still making gains. Chemical & Engineering News, 8 May 2025.

- Ajanovic, A.; Sayer, M.; Haas, R. On the future relevance of green hydrogen in Europe. Applied Energy 2024, 358, 122586. [Google Scholar] [CrossRef]

- Groll, M. Can climate change be avoided? Vision of a hydrogen-electricity energy economy. Energy 2023, 264, 126029. [Google Scholar] [CrossRef]

- https://www.clean-hydrogen.europa.eu/about-us/our-story_en#:~:text=2002%20%2D%202004,on%20the%20clean%20energy%20map. (accessed on 09 September 2025).

- https://energy.ec.europa.eu/system/files/2020-07/hydrogen_strategy_0.pdf. (accessed on 09 September 2025).

- https://energy.ec.europa.eu/topics/eus-energy-system/hydrogen_en. (accessed on 09 September 2025).

- https://commission.europa.eu/topics/energy/repowereu_en. (accessed on 09 September 2025).

- [17] https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52023DC0156&qid=1682349760946. (accessed on 09 September 2025).

- Buonomenna, MG. Inorganic thin-film solar cells: Challenges at the terawatt-scale. Symmetry 2023, 159, 1718. [Google Scholar] [CrossRef]

- Danish Energy Agency, Energinet. Technology data for renewable fuels. Tech. rep., 2023, available online at http://www.ens.dk/teknologikatalog.

- Proost, J. State-of-the art CAPEX data for water electrolysers, and their impact on renewable hydrogen price settings. Int. J. Hydrog. Energy 2019, 44, 4406–4413. [Google Scholar] [CrossRef]

- Guillet, N. , Millet, P. Alkaline Water Electrolysis. In Hydrogen Production; Wiley-VCH 2015; pp 117−166, ISBN: 9783527333424.

- Tüysüz, H. Alkaline Water Electrolysis for Green Hydrogen Production Acc. Chem. Res. 2024, 57, 558–567.

- Santoro, C.; Lavacchi, A.; Mustarelli, P.; Di Noto, V.; Elbaz, L.; Dekel, D.R.; Jaouen, F. What is Next in Anion-Exchange Membrane Water Electrolyzers? Bottlenecks, Benefits, and Future. ChemSusChem 2022, 15, e202200027. [Google Scholar] [CrossRef]

- Hassan, A.; Abdel-Rahim, O.; Bajaj, M.; Zaitsev, I. Power electronics for green hydrogen generation with focus on methods, topologies, and comparative analysis. Scientific Reports 2024, 14, 24767. [Google Scholar] [CrossRef]

- [25] a) https://www.offshore-energy.biz/worlds-largest-green-hydrogen-plant-construction-reaches-80-completion/ accessed on 09 September 2025. b) https://nghc.com/.

- https://www.energiser.pt/en/forward/2023-10-04-Green-hydrogen-picks-up-pace-in-Portugal-28614f9a#:~:text=Galp%20has%20been%20increasingly%20involved,to%20commence%20operations%20in%202025 accessed on 09 September 2025.

- https://www.aman-alliance.org/Home/ContentDetail/87785. (accessed on 09 September 2025).

- https://www.portugal.gov.pt/en/gc23/communication/news-item?i=portuguese-green-energy-corridor-projects-have-a-european-seal-of-common-interest. (accessed on 09 September 2025).

- a) https://greenhyscale.eu/wp-content/uploads/2023/04/UK_Denmarks-first-large-scale-electrolyser-module-delivered.pdf.(accessed on 09 September 2025). b) Andreae, E.; Fan, Y.F.; Petersen, M.; You, S.; Bindner, H.W.; Jacobson. M. Z. Green hydrogen production pathways: Comparative insights from Denmark, the U.S., and China. Energy Conversion and Management 2025, 342, 120065.

- [30] Biswas, S.; Kulkarni, A.P.; Giddey, S.; Bhattacharya, S. A Review on Synthesis of Methane as a Pathway for Renewable Energy Storage With a Focus on Solid Oxide Electrolytic Cell-Based Processes. Frontiers in Energy Research 2020, 8, 570112. [Google Scholar] [CrossRef]

- https://fuelcellsworks.com/2025/01/23/fuel-cells/freija-unveils-plan-for-one-of-europe-s-largest-major-green-hydrogen-based-e-methane-facility-in-nokia-norway. (accessed on 09 September 2025).

- https://www.offshore-energy.biz/mol-group-opens-10-mw-green-hydrogen-plant-in-hungary/. (accessed on 09 September 2025).

- https://arcadiaefuels.com/arcadia-efuels-taps-plug-power-for-280-mw-electrolyzer-system/. (accessed on 09 September 2025).

- https://fuelcellsworks.com/news/galp-announces-launch-of-a-major-100-mw-electrolysis-plant-in-portugal. (accessed on 09 September 2025).

- https://www.spglobal.com/commodity-insights/en/news-research/latest-news/energy-transition/061024-yara-starts-up-europes-largest-green-hydrogen-plant-in-norway. (accessed on 09 September 2025).

- https://www.yara.com/corporate-releases/yara-opens-renewable-hydrogen-plant-a-major-milestone/. (accessed on 09 September 2025).

- https://www.shell.com/what-we-do/hydrogen/latest-news-from-shell-hydrogen/shell-to-build-100-megawatt-renewable-hydrogen-electrolyser-in-germany.html. (accessed on 9 September 2025).

- https://www.basf.com/global/en/media/news-releases/2025/03/p-25-046. (accessed on 9 September 2025).

- https://bebeez.eu/2025/03/20/nel-asa-receives-purchase-order-for-one-mc500-containerized-pem-electrolyser/. (accessed on 09 September 2025).

- https://nelhydrogen.com/wp-content/uploads/2020/03/Renewable-hydrogen-made-cost-competitive.pdf. (accessed on 9 September 2025).

- https://www.h2-view.com/story/hydrasun-selects-2-5mw-nel-electrolyser-for-aberdeen-hydrogen-hub/2123272.article/. (accessed on 9 September 2025).

- Buonomenna, MG. Proton-Conducting Ceramic Membranes for the Production of Hydrogen via Decarbonized Heat: Overview and Prospects. Hydrogen 2023, 4, 807–830. [Google Scholar] [CrossRef]

- a) https://multiplhy-project.eu/Documents/Workshop%20on%20Advanced%20PtG%20and%20PtL%20Technologies%20High-Temperature%20Electrolysis_Posdziech.pdf (accessed on 14 September 2025). b) Wu, C.; Zhu, Q.; Dou, B.; Fu, Z.; Wang, J.; Mao, S. Thermodynamic analysis of a solid oxide electrolysis cell system in thermoneutral mode integrated with industrial waste heat for hydrogen production. Energy 2024, 301, 131678.

- https://salcos.salzgitter-ag.com/en/index.html. (accessed on 09 September 2025).

- https://syrius-project.eu/project/. (accessed on 09 September 2025).

- Next level Solid Oxide electrolysis by Institute for Sustainable Process Technology available at https://ispt.eu/media/20230508-FINAL-SOE-public-report-ISPT.pdf. (accessed on 9 September 2025).

- https://www.topsoe.com/press-releases/topsoe-and-first-ammonia. (accessed on 09 September 2025).

- Hanif, M.B.; Rauf, S.; Abadeen,Z. ; Khan, K.; Tayyab, Z.; Qayyum,S.; Mosiałek, M.; Shao, Z.; Li, C.X.; Motola, M. Proton-conducting solid oxide electrolysis cells: Relationship of composition-structure-property,their challenges, and prospects. Matter 2023, 6, 1782–1830. [Google Scholar] [CrossRef]

- Choi, W.; Choi, Y.; Choi, E.; Yun, H.; Jung, W.; Lee, W.H.; Oh, H.-S.; Won, D.H.; Na, J.; Hwang, Y.J. ; Microenvironments of Cu catalysts in zero-gap membrane electrode assembly for efficient CO2 electrolysis to C2+ products. J. Mater. Chem. A 2022, 10, 10363–10372. [Google Scholar] [CrossRef]

- Cheon, H.; Kim, J.H.; Kim, J.S.; Park, J.-B. Valorization of single-carbon chemicals by using carboligases as key enzymes. Curr. Opin. Biotechnol. 2024, 85, 103047. [Google Scholar] [CrossRef] [PubMed]

- Berberich, M.E.; Beaulieu, J.J.; Hamilton, T.L.; Waldo, S.; Buffam, I. Spatial variability of sediment methane production and methanogen communities within a eutrophic reservoir: Importance of organic matter source and quantity. Limnol. Oceanogr. 2023, 65(6), 1–23. [Google Scholar] [CrossRef] [PubMed]

- Bube, S.; Sens, L.; Drawer, C.; Kaltschmitt, M. Power and biogas to methanol – A techno-economic analysis of carbon-maximized green methanol production via two reforming approaches. Energy Convers. Manag. 2024, 304, 118220. [Google Scholar] [CrossRef]

- Cheon, H.; Kim, J.H.; Kim, J.-S.; Park, J.-. BValorization of single-carbon chemicals by using carboligases as key enzymes. Curr. Opin. Biotechnol. 2024, 85, 103047. [Google Scholar] [CrossRef]

- Gupta, S.; Riegraf, M.; Costa, R.; Heddrich, M.P.; Friedrich, K.A. Solid Oxide Electrolysis Cell-Based Syngas Production and Tailoring: A Comparative Assessment of Coelectrolysis, Separate Steam, CO2 Electrolysis, and Steam Electrolysis. Ind. Eng. Chem. Res. 2024, 63, 8705–8712. [Google Scholar] [CrossRef]

- Strategic Research And Innovation Agenda 2021−2027, Clean Hydrogen Joint Undertaking; 2022 available at https://www.clean-hydrogen.europa.eu/system/files/2022-02/Clean%20Hydrogen%20JU%20SRIA%20-%20approved%20by%20GB%20-%20clean%20for%20publication%20%28ID%2013246486%29.pdf. (accessed on 09 September 2025).

- https://www.thyssenkrupp-nucera.com/thyssenkrupp-nucera-and-fraunhofer-ikts-open-first-soec-pilot-production-plant-for-stacks-for-the-production-of-green-hydrogen/. (accessed on 09 September 2025).

- Serov, A.; Kovnir, K.; Shatruk, M.; Kolen’ko, Y.V. Critical Review of Platinum Group Metal-Free Materials for Water Electrolysis: Transition from the Laboratory to the Market. Johnson Matthey Technol. Rev. 2021, 65, 207–226. [Google Scholar] [CrossRef]

- Jin, H.; Ruqia, B.; Park, Y.; Kim, H.J.; Oh, H.-S.; Choi, S.-I.; Lee, K. Nanocatalyst Design for Long-Term Operation of Proton/Anion Exchange Membrane Water Electrolysis. Adv. Energy Mater. 2021, 11, 2003188. [Google Scholar] [CrossRef]

- Ďurovič, M.; Hnat, J.; Bouzek, K. Electrocatalysts for the hydrogen evolution reaction in alkaline and neutral media. A comparative review. J. Power Sources 2021, 493, 229708. [Google Scholar] [CrossRef]

- Mahmood, N.; Yao, Y.; Zhang, J.-W.; Pan, L.; Zhang, X.; Zou, J.-J. Electrocatalysts for Hydrogen Evolution in Alkaline Electrolytes: Mechanisms, Challenges, and Prospective Solutions. Adv. Sci. 2018, 5, 1700464. [Google Scholar] [CrossRef]

- Baek, D.S.; Lee, J.; Lim, J.S.; Joo, S.H. Nanoscale electrocatalyst design for alkaline hydrogen evolution reaction through activity descriptor identification. Mater. Chem. Front. 2021, 5, 4042–4058. [Google Scholar] [CrossRef]

- https://cen.acs.org/environment/persistent-pollutants/say-goodbye-PFAS/97/i46. (accessed on 14 September 2025).

- Cousins, I.T.; Goldenman, G.; Herzke, D.; Lohmann, R.; Miller, M.; Ng, C.A.; Patton, S.; Scheringer, M.; Trier, X.; Vierke, L.; Wang, Z.; DeWittl, J.C. The concept of essential use for determining when uses of PFASs can be phased out. Environ. Sci. Process. Impacts 2019, 21, 1803–1815. [Google Scholar] [CrossRef]

- https://cordis.europa.eu/project/id/101112055/reporting#:~:text=The%20HYScale%20project%20is%20a,hydrogen%20technology%20innovation%20and%20deployment. (accessed on 14 September 2025).

- https://www.sintef.no/projectweb/channel-fch/aem-hub/#:~:text=The%20AEM%2DHUB%20is%20a%20cluster%20of%20three,water%20electrolysers%20(AEMEL)%20for%20green%20hydrogen%20production. (accessed on 14 September 2025).

- https://enapter.com/en/product/aem-nexus/. (accessed on 14 September 2025).

- https://fuelcellsworks.com/2025/03/13/electrolyzer/fallback-thursday-enapter-to-supply-aem-nexus-electrolysers-for-falconara-hydrogen-project-in-italy. (accessed on 14 September 2025).

- https://www.hydrogeninsight.com/innovation/italy-grants-317m-to-state-owned-company-to-build-aem-hydrogen-electrolysers/2-1-1784205. (accessed on 14 September 2025).

- European Commission. REPowerEU. Available from: https://commission.europa.eu/topics/energy/repowereu_en. (accessed on 14 September 2025).

- European Investment Bank. A pipeline to better lives Available from: https://www.eib.org/en/stories/morocco-water-scarcity. (accessed on 14 September 2025).

- Voice of America. Morocco expands freshwater efforts, but needs more energy. Available from: https://learningenglish.voanews.com/a/morocco-expands-freshwater-efforts-but-needs-more-energy/6844012.html. (accessed on 14 September 2025).

- Jenkins, K.; McCauley, D.; Heffron, R.; Stephan, H.; Rehner, R. Energy justice: A conceptual framework. Energy Res Soc Sci 2021, 75, 101–112. [Google Scholar]

- Muller, M.; et al. Hydrogen and justice: A framework for assessing the social impacts of hydrogen production. Energy Res Soc Sci 2023, 90, 102–115. [Google Scholar]

- Corporate Europe Observatory. Hydrogen from North Africa – a neo-colonial resource grab. Available from: https://corporateeurope.org/en/2022/05/hydrogen-north-africa-neocolonial-resource-grab (accessed on 14 September 202).

- Skládalová, D. Unmasking green colonialism in EU-Namibia hydrogen deal. Available from: https://www.ejiltalk.org/unmasking-green-colonialism-in-eu-namibia-hydrogen-deal/. (accessed on 14 September 2025).

- CIC energiGUNE. Electrolyzers: A manufacturing industry that everyone wants to lead [Online]. Available from: https://cicenergigune.com/en/blog/electrolyzers-manufacturing-industry-everyone-lead; (Accessed on 14 September 2025).

- Blackridge Research and Consulting. Global top 20 hydrogen electrolyzer manufacturers . Available from: https://www.blackridgeresearch.com/blog/list-of-global-top-hydrogen-electrolyzer-manufacturers-companies-makers-suppliers-in-the-world (Accessed on 14 September 2025).

- Dillman, K.J.; Heinonen, J. A ‘just’ hydrogen economy: a normative energy justice assessment of the hydrogen economy. Renew Sustain Energy Rev 2022, 167, 112648. [Google Scholar] [CrossRef]

- Dembi, V. Ensuring energy justice in transition to green hydrogen. Available from: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4015169 Accessed on 14 September 2025.

- Europe Hydrogen. Hydrogen production & water consumption [Online]. Available from: https://hydrogeneurope.eu/wp-content/uploads/2022/02/Hydrogen-production-water-consumption_fin.pdf (Accessed on 14 September 2025).

- International PtX Hub. A first look at water demand for green hydrogen and concerns and opportunities with desalination. Available from: https://ptx-hub.org/a-first-look-at-water-demand-for-green-hydrogen-and-concerns-and-opportunities-with-desalination/ (Accessed on 14 September 2025).

- Ourya, I.; Nabil, N.; Abderafi, S.; Boutammachte, N.; Rachidi, S. Assessment of green hydrogen production in Morocco, using hybrid renewable sources (PV and wind). Int J Hydrogen Energy 2023, 48, 37428–37442. [Google Scholar] [CrossRef]

- EU’s clean hydrogen plan raises dirty doubts Available from: https://www.politico.eu/article/eu-clean-hydrogen-plan-doubts/ (Accessed on 14 September 2025).

- Walker, G. Beyond distribution and proximity: Exploring the multiple spatialities of environmental justice. Antipode 2009, 41, 614–634. [Google Scholar] [CrossRef]

- Schlosberg, D. The justice of environmental justice: Reconciling equity, recognition, and participation in a political movement. In: Light A, De-Shalit A, editors. Moral and political reasoning in environmental practice. London, UK: MIT Press; 2003. p. 125–156.

- BBC. Hydrogen heating trial treats us like guinea pigs – residents. Available from: https://www.bbc.com/news/science-environment-64028510 (Accessed on 14 September 2025).

- ‘We’ve got no choice’: Locals fear life as lab rats in UK hydrogen heating pilot Available from: https://www.theguardian.com/environment/2022/nov/21/no-choice-hydrogen-heating-pilot-whitby-ellesmere-port-lab-rats (Accessed on 14 September 2025).

- Energy Institute. UK government rejects Whitby hydrogen village trial. Available from: https://knowledge.energyinst.org/new-energy-world/article?id=138075 (Accessed on 14 September 2025).

- Voice of America. Namibia’s Nama community rejects green-hydrogen port expansion. Available from: https://www.voanews.com/a/namibia-s-nama-community-rejects-green-hydrogen-port-expansion-/7574111.html (Accessed on 14 September 2025).

- Future Power Technology. La Guajira: The renewable centre tearing itself apart over wind. Available from: https://power.nridigital.com/future_power_technology_aug23/guajira-colombia-development-wayuu-enel-wind (Accessed on 14 September 2025).

- Latina Pensa. Colombian Government to solve vulnerabilities in La Guajira. Available from: https://www.plenglish.com/news/2023/06/24/colombian-government-to-solve-vulnerabilities-in-la-guajira/ (Accessed on 14 September 2025).

- Wind energy and Wayuu Indigenous communities: Challenges in La Guajira. Available from: https://www.sei.org/features/wind-energu-wayuu-la-guajira/ (Accessed on 14 September 2025).

- ReCharge. ‘This hurts us’. Enel suspends Colombia wind farm build as years of protests take toll. Available from: https://www.rechargenews.com/wind/this-hurts-us-enel-suspends-colombia-wind-farm-build-as-years-of-protests-take-toll/2-1-1456238 (Accessed on 14 September 2025).

- Bullard RD. Environmental justice in the 221st century. In: Dryzek J, Schlosburg D, editors. Debating the earth. Oxford, UK: Oxford University Press; 2005. p. 322–356.

- Davies, A. Environmental justice as subtext or omission: Examining discourses of anti-incineration campaigning in Ireland. Geoforum 2006, 37, 708–724. [Google Scholar] [CrossRef]

- McSheffrey, E. Northwest first nations join forces to pursue renewable energy in B.C. Available from: https://globalnews.ca/news/10076258/first-nations-renewable-energy-bc/ (Accessed on 09 September 2025).

- WSRW. Greenwashing occupation. Available from: https://vest-sahara.s3.amazonaws.com/wsrw/feature-images/File/405/616014d0c1f1d_Greenwashing-occupation_web.pdf (Accessed on 09 September 2025).

- Expensive ‘green’ hydrogen jeopardises German industrial energy transition Available from https://www.ft.com/content/bc4e49d6-ac89-4835-80dd-87663de0cfd1 (Accessed on 09 September 2025).

- https://energy.ec.europa.eu/topics/markets-and-consumers/hydrogen-and-decarbonised-gas-market_en (Accessed on 09 September 2025).

- https://ec.europa.eu/commission/presscorner/detail/en/ip_25_1743 (Accessed on 09 September 2025).

- George, J.F.; Muller, V.P.; Winkler, J.; Ragwitz, M. Is blue hydrogen a bridging technology? - the limits of a CO2 price and the role of state-induced price components for green hydrogen production in Germany. Energy Policy 2022, 167, 113072. [Google Scholar] [CrossRef]

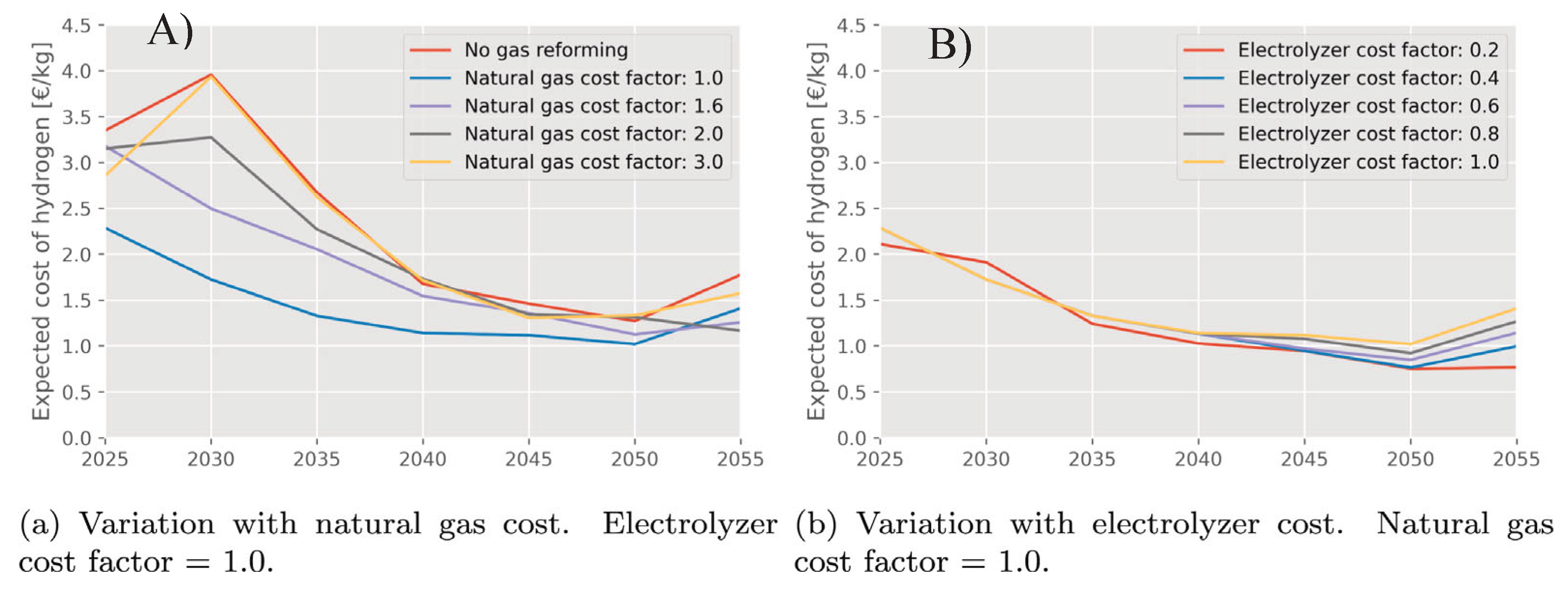

- Ueckerdt, F.; Verpoort, P.C.; Anantharaman, R.; Bauer, C.; Beck, F.; Longden, T.; Roussanaly, S. On the cost competitiveness of blue and green hydrogen. Joule 2024, 8, 104–128. [Google Scholar] [CrossRef]

- Bauer, C.; Treyer, K.; Antonini, C.; Bergerson, J.; Gazzani, M.; Gencer, E.; Gibbins, J.; Mazzotti, M.; McCoy, S.T.; McKenna, R.; et al. On the climate impacts of blue hydrogen production. Sustainable Energy Fuels 2021, 6, 66–75. [Google Scholar] [CrossRef]

- Oni, A.O.; Anaya, K.; Giwa, T.; Di Lullo, G.; Kumar, A. Comparative assessment of blue hydrogen from steam methane reforming, autothermal reforming, and natural gas decomposition technologies for natural gasproducing regions. Energy Convers. Manag. 2022, 254, 115245. [Google Scholar] [CrossRef]

- Antonini, C.; Treyer, K.; Streb, A.; van der Spek, M.; Bauer, C.; Mazzotti, M. Hydrogen production from natural gas and biomethane with carbon capture and storage—A techno-environmental analysis. Sustainable Energy Fuels 2020, 4, 2967–2986. [Google Scholar] [CrossRef]

- Global hydrogen review 2022. Available from https://www.iea.org/reports/global-hydrogen-review-2022 (Accessed on 09 September 2025).

- Durakovic, G.; Crespo del Granado, P.; Tomasgard, A. Are green and blue hydrogen competitive or complementary? Insights from a decarbonized European power system analysis. Energy 2023, 282, 128282. [Google Scholar] [CrossRef]

- https://energy.ec.europa.eu/news/important-step-towards-establishing-european-network-network-operators-hydrogen-2025-05-16_en (Accessed on 14 September 2025).

- https://ec.europa.eu/commission/presscorner/detail/en/ip_25_1743 (Accessed on 14 September 2025).

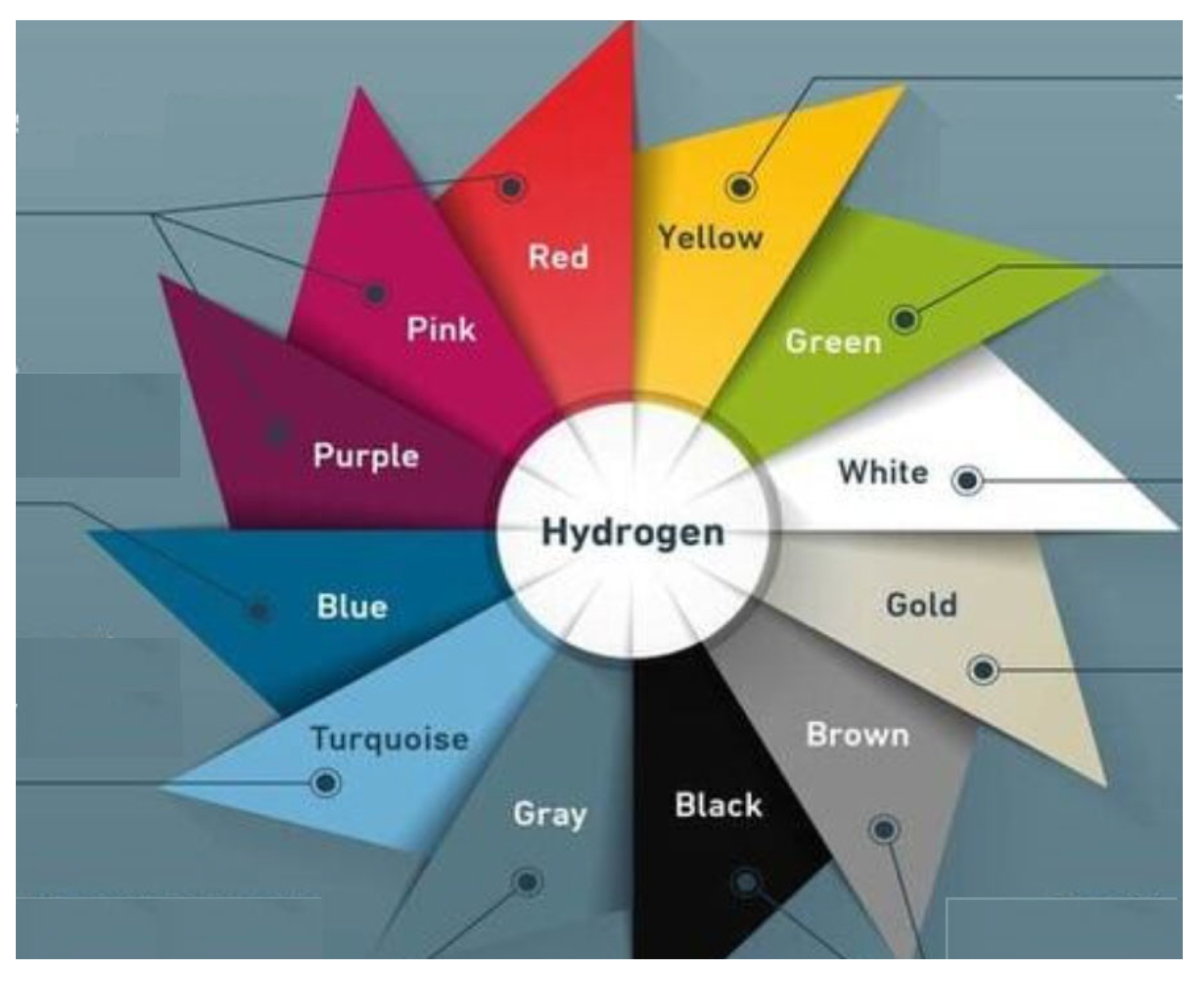

| Entry# | Hydrogen designation |

Carbon Footprint (Kg CO2 Kg-1 H2) |

Production Cost (US$ Kg-1 H2) |

| 1 |

Black/Grey | 10-25 | 1.0-2.7 |

| 2 |

Blue | 1-10 | 1.0-4.0 |

| 3 |

White | ≥0.4 | ≥1.0 |

| 4 | Green | 0.3 | 2.5-6.5 (by 2050 1.0-3.5) |

| Parameter | State of the art 2012 |

2017 |

FCH JU 2020 |

2024 |

2030 |

|

ALK single cell electricity consumption at nominal capacity [kWh kg-1] capital cost [EUR (kg d-1)- 1] ([EUR kW-1]) operation and maintanance cost [EUR (kg d-1)-1 yr-1] |

57 8000 (~3000) 160 |

51 1600 (750) 32 |

50 1250 (600) 26 |

49 1000 (480) 20 |

48 800 (400) 16 |

|

ALK stack degradation [% (1000 h)- 1] current density [A cm-2] use of CRMs as catalysts [mg W-1] |

- 0.3 8.9 |

0.13 0.5 7.3 |

0.12 0.7 3.4 |

0.11 0.7 2.1 |

0.1 0.8 0.7 |

| Manufacturer | Country | Model |

Flow rate (Nm3/h) |

Stack power consumption (kWh/Nm3) |

Delivery pressure (bar) |

Capacity factor (%) |

|

Green Hydrogen Systems |

Denmark |

A-series 90&180 | 90/180 | 75.73 | 30 | 0-100 |

| X-1200 |

1200 | 74.16 | 35 | 0-100 | ||

|

McPhy |

France/Italy/ Germany |

McLyzer 200 |

200 |

4.65 |

27-30 |

20-100 |

| McLyzer 200 | 400 | 4.65 | 27-30 | 20-100 | ||

| McLyzer 200 | 800 | 4.65 | 27-30 | 20-100 | ||

| McLyzer 200 |

3200 | 4.65 | 27-30 | 10-100 | ||

|

Sagim-NEL A-series |

France/US |

A150 | 50-150 | 3.8-4.4 | 1-200 | 15-100 |

| A300 | 150-300 | 3.8-4.4 | 1-200 | 15-100 | ||

| A485 | 300-485 | 3.8-4.4 | 1-200 | 15-100 | ||

| A1000 | 600-970 | 3.8-4.4 | 1-200 | 15-100 | ||

| A3880 | 2400-3880 | 3.8-4.4 | 1-200 | 15-100 | ||

| Sagim S.A. | France | M 1500 to 5000 |

1.5-5 | 5 | 7 | NR |

| AccaGen Sunfire |

Switzerland Germany |

Res2H2 Alkaline |

5 - |

4.5 - |

10-20 30 |

15-100 - |

| Parameter | State of the art 2012 |

2017 |

FCH JU 2020 |

2024 |

2030 |

|

PEM single cell electricity consumption at nominal capacity [kWh kg-1] capital cost [EUR (kg d-1)- 1] ([EUR kW-1]) operation and maintanance cost [EUR (kg d-1)-1 yr-1] |

60 8000 (~3000) 160 |

58 2900 (1200) 58 |

55 2000 (900) 41 |

52 1500 (700) 30 |

50 1000 (500) 21 |

|

PEM stack degradation [% (1000 h)- 1] current density [A cm-2] use of CRMs as PGM electro catalysts [mg W-1] |

0.375 1.7 - |

0.250 2.0 5.0 |

0.190 2.2 2.7 |

0.125 2.4 1.25 |

0.12 2.5 0.4 |

| use of CRMs as catalysts [mg W-1] |

- | 1.0 | 0.7 | 0.4 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).