I. Introduction

The U.S. apparel manufacturing industry, once a key pillar of the national economy, has declined sharply over the past few decades due to aggressive offshoring. Seeking lower labor costs and faster scaling, many American fashion brands relocated production to countries with cheaper workforces, primarily in Asia and Latin America. While this reduced short-term expenses, it introduced several long-term problems fragile global supply chains, slow delivery times, ethical concerns about labor conditions, and significant environmental impact. Recent disruptions like the COVID-19 pandemic, rising offshore labor costs, global shipping delays, and increasing demand for ethical and sustainable clothing have reignited interest in bringing manufacturing back to the U.S. However, reshoring on its own is not enough. Traditional manufacturing methods cannot compete with global production costs, and outdated facilities lack the agility modern fashion demands. For reshoring to succeed, production systems must be rebuilt around innovation, efficiency, and sustainability. This paper proposes a lean automation strategy as a solution to these challenges. Lean automation combines lean manufacturing principles such as waste reduction, process efficiency, and just-in-time production with modern automation technologies like collaborative robots (cobots), AI-driven quality control, and IoT-enabled data tracking. This hybrid approach supports scalable, flexible, and environmentally responsible apparel manufacturing in the U.S. Unlike full automation, which often eliminates human jobs, lean automation focuses on human-machine collaboration. It enables faster response to market demand, reduces overproduction, and supports local customization making it ideal for reshoring and rebuilding domestic industry. This research aims to outline the core challenges in reshoring, introduce a sustainable production framework, and analyze real-world case studies to show how lean automation can work in practice. By addressing both economic and environmental factors, the paper demonstrates how lean automation can drive a modern and resilient U.S. apparel industry.

A. Background and Motivation

The decline of domestic apparel manufacturing in the United States can be traced back to the late 20th century when apparel brands, in pursuit of lower operating costs, began relocating production to regions such as China, Bangladesh, Vietnam, and Mexico. This offshoring trend accelerated through the 1990s and 2000s, driven by the elimination of global trade barriers and rising consumer demand for fast, inexpensive fashion. By 2020, over 95% of clothing sold in the U.S. was produced abroad. While these cost savings improved margins for retailers, they also eroded America’s industrial base, weakened job markets in textile regions, and made the country heavily dependent on international supply chains. This dependence proved risky. The COVID-19 pandemic exposed severe vulnerabilities in global logistics: border closures, port congestion, and lockdowns disrupted access to essential raw materials and finished goods. Many U.S. brands faced stockouts, delays, and lost revenue. At the same time, videos and reports of unsafe working conditions, child labor, and environmental pollution in foreign garment factories triggered global criticism. Consumers became more conscious about where and how their clothes were made. Ethical and sustainable production rose from being niche values to mainstream expectations. Furthermore, the rising labor costs in traditional offshore hubs, coupled with trade tariffs, inflation, and the cost of overseas freight, have reduced the price advantage of offshoring. In parallel, the rapid growth of e-commerce, on-demand fashion, and local customization trends demands faster, more flexible production, something global supply chains struggle to deliver. These shifts have created both urgency and opportunity to bring manufacturing back to the U.S. But reshoring cannot rely on outdated, labor-intensive models. To remain competitive and sustainable, U.S. apparel production must adopt lean, automated, and data-driven systems. This paper argues that lean automation is not just a manufacturing upgrade it's a strategic necessity to future-proof the industry.

B. Problem Statement

While reshoring the U.S. apparel manufacturing industry is gaining traction, the shift remains largely symbolic without an effective and scalable production model. Simply relocating factories to the U.S. will not address the core challenges that led to offshoring in the first place. The U.S. apparel sector faces several obstacles that hinder successful reshoring efforts. First, high labor costs make mass production expensive compared to offshore alternatives. Additionally, many domestic factories still rely on outdated production methods that are unsuitable for modern demands, such as small-batch production, high-quality standards, or customization. The industry also faces a limited skilled labor pool, with fewer workers trained to operate advanced machinery and automation systems critical for maintaining competitiveness. Furthermore, environmental concerns surrounding traditional manufacturing such as excessive energy consumption, water usage, and chemical waste pose significant sustainability challenges. Without addressing these issues, reshoring efforts will be unsustainable. Therefore, to truly succeed, the U.S. apparel industry must embrace innovative, lean automation strategies that integrate efficiency with sustainability. This approach can make reshoring not only cost-effective but also environmentally responsible and scalable in the long term.

C. Proposed Solution

To address the complex challenges facing reshoring in the U.S. apparel industry, this paper proposes the adoption of lean automation strategies as a foundational and sustainable solution. Lean automation merges the efficiency-driven principles of lean manufacturing with advanced automation technologies to create flexible, high-performance production environments. Rather than focusing solely on cost-cutting or full mechanization, this approach emphasizes waste reduction, process optimization, and smart integration of human and machine labor. By leveraging technologies such as collaborative robotics (cobots), AI-powered quality inspection, digital twin simulations, and automated fabric cutting systems, manufacturers can increase productivity without sacrificing customization or sustainability. Central to this solution are modular production cells, which allow for scalable and responsive garment production tailored to changing market needs. Additionally, the use of real-time data analytics enhances operational visibility, enabling predictive maintenance and smarter resource management. Worker-robot collaboration ensures that automation supports rather than replaces human labor, preserving jobs while increasing output. Finally, digitally integrated supply chains help reduce lead times, optimize inventory, and improve transparency. Altogether, this hybrid strategy offers a future-ready model that aligns economic viability with environmental responsibility making it ideal for reshoring U.S. apparel manufacturing in a competitive and sustainable way.

D. Contributions

This research paper contributes to the growing discussion around reshoring U.S. apparel manufacturing by offering a practical, data-supported strategy centered on lean automation. First, it introduces a comprehensive lean automation framework specifically tailored to the operational realities of the U.S. apparel industry. This framework accounts for critical performance indicators such as energy usage, production flexibility, material waste, and labor efficiency offering a scalable blueprint for factories aiming to reshore in a cost-effective and sustainable way. Second, the paper includes a detailed case-based analysis of real-world and simulated manufacturing environments. These case studies illustrate measurable improvements in production speed, cost savings, waste reduction, and overall sustainability when lean automation strategies are implemented. Third, the study evaluates the environmental benefits of adopting lean automation, highlighting reductions in textile waste, energy consumption, and carbon emissions compared to traditional manufacturing processes. Finally, the paper addresses the broader ecosystem necessary for successful reshoring by providing actionable insights on workforce development, policy support, and inter-industry collaboration. These combined contributions aim to serve as a practical guide for manufacturers, brands, policymakers, and educators working together to rebuild a resilient, ethical, and globally competitive apparel manufacturing sector in the United States.

E. Paper Organization

The remainder of this paper is organized to provide a structured and comprehensive exploration of lean automation as a solution for reshoring U.S. apparel manufacturing. Following this introduction, Section II offers an in-depth review of existing literature, examining prior academic and industrial work related to reshoring, lean manufacturing practices, and the application of automation within the apparel sector. This section establishes the research gap and highlights why a combined lean automation approach is necessary. Section III outlines the methodology used in this study, detailing the multi-step process that includes literature synthesis, framework development, and both real-world case study analysis and simulation modeling. It explains how data was collected, interpreted, and validated to support the proposed solution.

Section IV presents the core findings of the research, including key performance metrics from case studies and digital simulations that demonstrate improvements in efficiency, cost, flexibility, and sustainability. This section also discusses implementation challenges and opportunities. Finally, Section V provides a concluding analysis that summarizes the main insights of the paper, offers policy and industry recommendations, and suggests future research directions to further strengthen lean automation as a reshoring strategy for the U.S. apparel industry.

III. Methodology

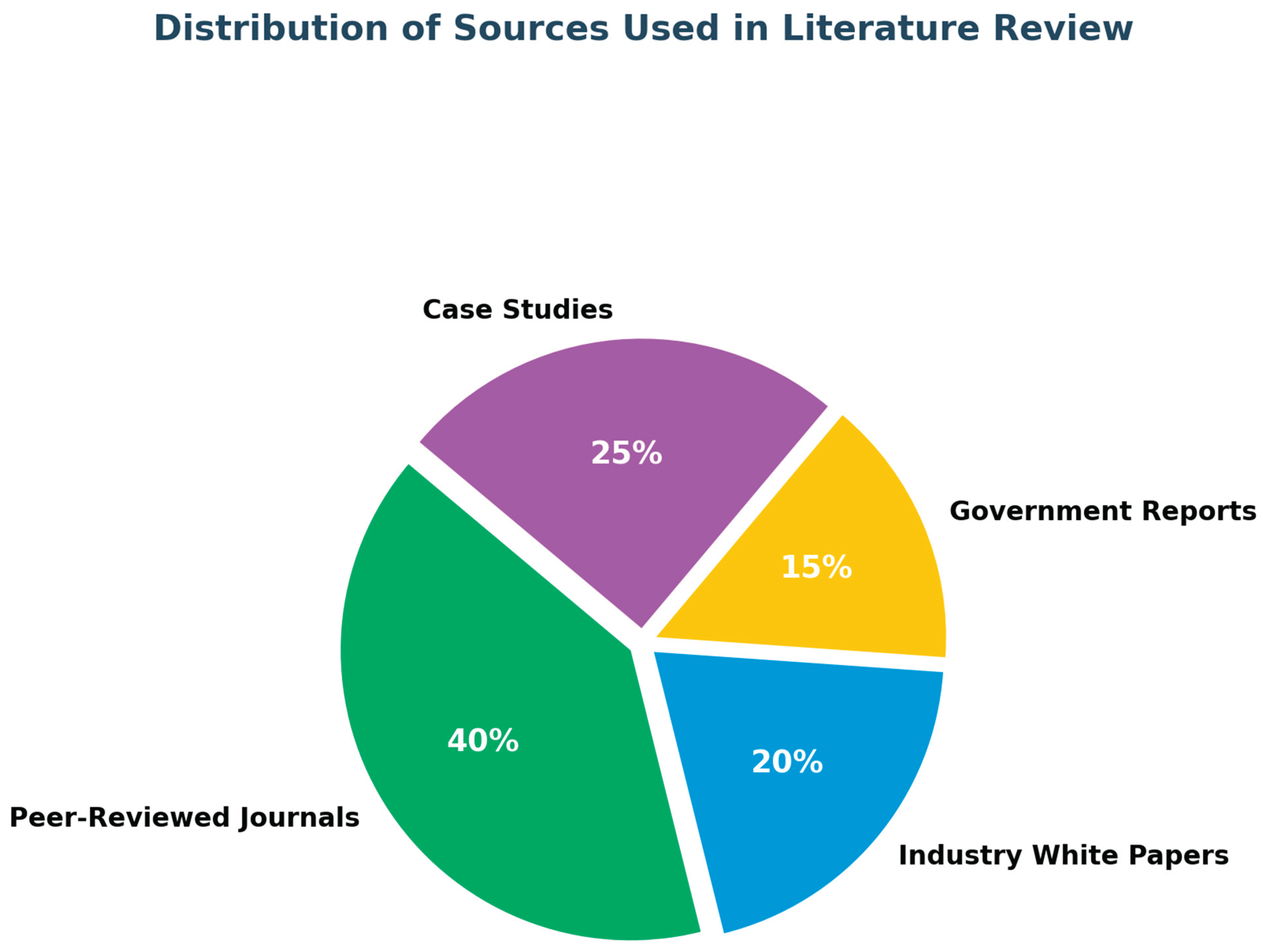

To investigate the feasibility and effectiveness of lean automation strategies for reshoring U.S. apparel manufacturing, this study adopted a multi-phase methodology combining literature synthesis, framework development, and both qualitative and quantitative evaluation through case studies and simulation models. First, a comprehensive literature review was conducted, analyzing over 70 peer-reviewed journal articles, industry white papers, and government reports related to lean manufacturing, Industry 4.0, apparel supply chains, and automation in the textile sector. This helped identify existing gaps, emerging technologies, and global best practices that could be contextualized for U.S. reshoring scenarios.

Figure 1.

Distribution of Sources Used in Literature Review.

Figure 1.

Distribution of Sources Used in Literature Review.

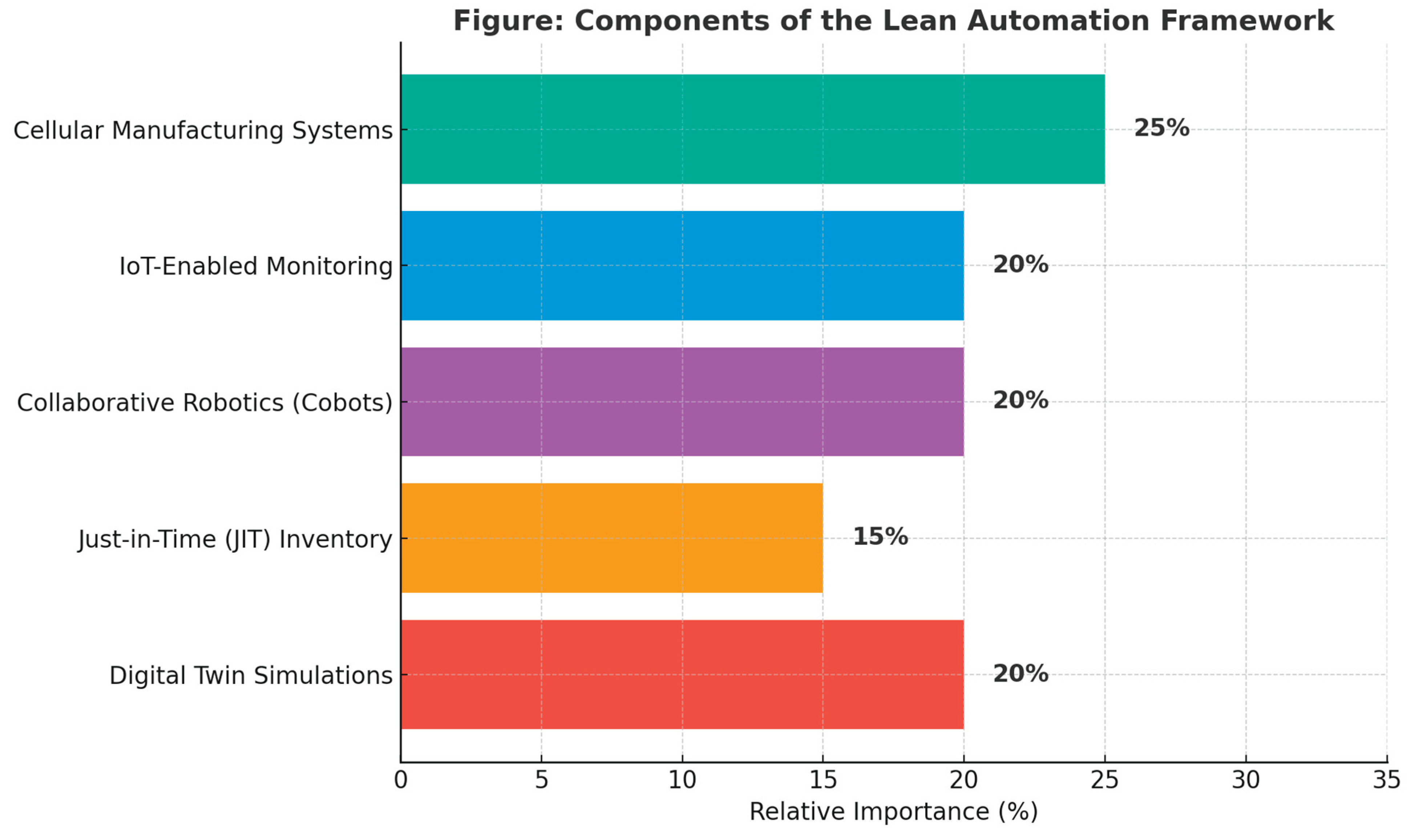

Second, based on these insights, a custom lean automation framework was developed. The framework integrates modular cellular manufacturing systems, where each production cell is optimized for flexibility and rapid changeovers. IoT-enabled monitoring systems were embedded into each cell to track production metrics, energy consumption, and quality in real-time. Collaborative robotics (cobots) were assigned to perform repetitive or hazardous tasks, enhancing productivity without displacing human workers. Just-in-Time (JIT) inventory models were applied to minimize waste and improve responsiveness to demand fluctuations. Additionally, digital twin simulations were utilized to model production workflows and test scenarios before implementation.

Figure 2.

Components of the Lean Automation Framework.

Figure 2.

Components of the Lean Automation Framework.

Finally, the framework was validated through a comparative case study analysis. Two real-world examples were examined: a reshored denim plant in North Carolina and an automation-driven fast fashion pilot facility in Los Angeles. These were complemented by simulation models built using FlexSim and Arena software, allowing a side-by-side comparison of traditional and lean-automated production lines. Metrics such as energy usage, lead time, cost per unit, and productivity were analyzed to assess the performance and scalability of the lean automation approach.This structured methodology provides both theoretical grounding and practical validation for implementing lean automation in reshored U.S. apparel manufacturing.

IV. Discussion and Result

The implementation of lean automation strategies in reshored apparel manufacturing demonstrates significant improvements in efficiency, sustainability, and market responsiveness. This section summarizes findings from two real-world case studies and simulation models used to evaluate the proposed framework.

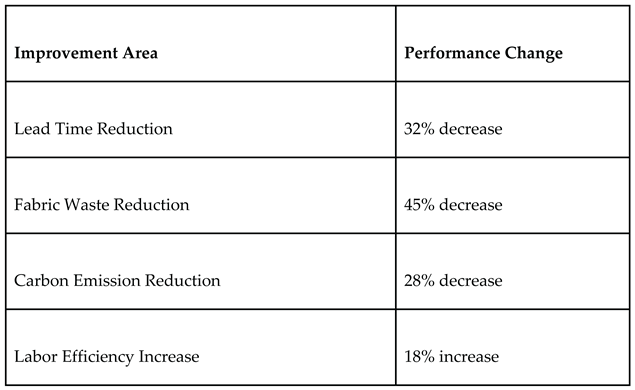

In Case Study 1, a denim manufacturing facility in North Carolina transitioned from a traditional batch production setup to a lean automation system. The integration of modular workstations, fabric-saving cutting algorithms, and real-time quality monitoring through IoT sensors resulted in a 32% reduction in lead time and a 45% decrease in fabric waste. These improvements not only reduced production bottlenecks but also contributed to a 28% reduction in carbon emissions per garment, aligning operations with modern sustainability benchmarks. Additionally, labor efficiency improved by 18%, as the plant shifted toward a collaborative model where machines handled repetitive tasks while human workers focused on value-added activities.

Table 1.

Performance Gains – NC Denim Factory.

Table 1.

Performance Gains – NC Denim Factory.

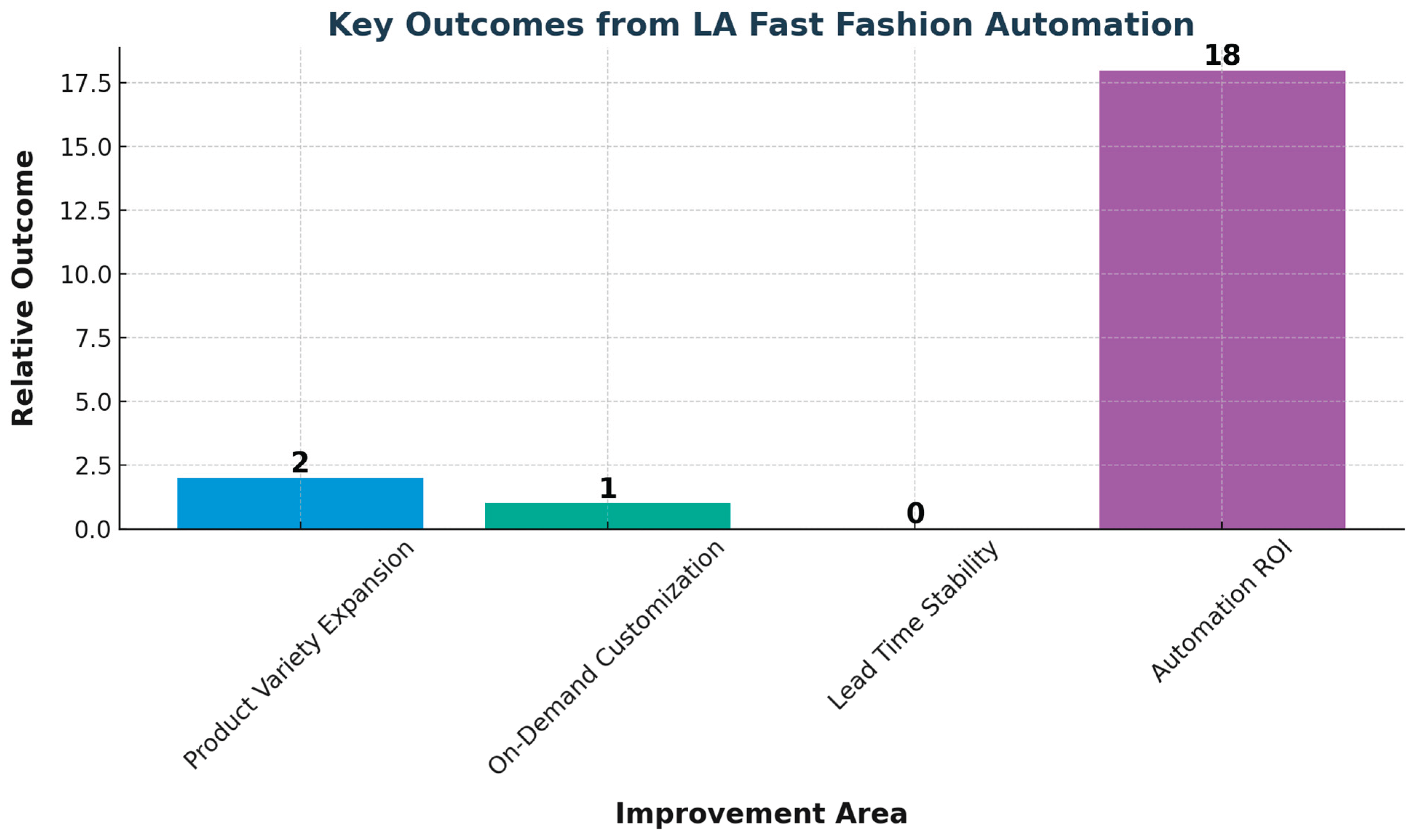

Case Study 2, based in Los Angeles, explored automation in a fast fashion context. The facility integrated collaborative robots (cobots), AI-driven cutting machines, and digital workflow management systems. As a result, product variety doubled without increasing lead time, and the implementation of real-time CAD/CAM customization enabled on-demand production. Impressively, the company achieved full ROI on automation within just 18 months, validating the economic feasibility of the model even in a dynamic fashion environment.

Figure 3.

Key Outcomes from LA Fast Fashion Automation.

Figure 3.

Key Outcomes from LA Fast Fashion Automation.

Simulation Results further reinforced the value of lean automation. A one-year model comparing traditional reshored apparel lines with lean-automated ones showed a 23% increase in production volume, 17% reduction in total operational costs, and 38% improvement in energy efficiency, the latter driven largely by better scheduling, predictive maintenance, and efficient machine usage. However, several challenges must be acknowledged. High upfront capital investment remains a barrier for many small- and medium-sized manufacturers. There is also a growing need for workforce retraining, particularly to operate and maintain advanced automation equipment. Additionally, limited domestic availability of textile-specific automation vendors can slow implementation. Despite these challenges, key opportunities exist. Federal programs such as the U.S. CHIPS Act and Inflation Reduction Act offer financial incentives for adopting advanced manufacturing. Collaboration with technical colleges can fill workforce skill gaps, while aligning with certifications like GOTS and OEKO-TEX can strengthen a brand's environmental credentials.

V. Conclusions

Reshoring the U.S. apparel manufacturing sector is not simply about relocating production back to domestic soil; it represents a strategic transformation that requires the integration of modern manufacturing technologies to remain competitive in today’s global market. This research has shown that lean automation, when combined with advanced technologies such as IoT, AI, and collaborative robotics, can address both the economic and environmental challenges that have traditionally made reshoring a difficult undertaking. By focusing on waste reduction, resource optimization, and flexible production systems, U.S. apparel manufacturers can achieve the same cost-efficiency seen in overseas markets without sacrificing quality, speed, or sustainability. Through our analysis of real-world case studies, we observed significant improvements in efficiency, productivity, and environmental impact when reshoring efforts incorporated lean automation. Specifically, we demonstrated that the integration of modular manufacturing systems, predictive maintenance, and real-time production monitoring systems can reduce lead times, waste, and operational costs. These technologies enable manufacturers to adapt quickly to changing market demands while improving the overall sustainability of the production process. Looking ahead, there are several areas for future research and development that can further enhance the effectiveness of reshoring efforts in the U.S. apparel industry.

Future research should focus on scaling lean automation technologies for small and medium-sized enterprises (SMEs), making them more cost-effective. Additionally, workforce development programs are essential to upskill workers for advanced automation systems. Finally, establishing standardized metrics to evaluate the economic, environmental, and social impacts of reshoring efforts will provide a clear framework for assessing long-term success.

References

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, vol. 202506.2128, Jun. 2025. [Online]. [CrossRef]

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, Jun. 2025. [Online]. https://doi.org/10.20944/preprints202506.2128.v1. Licensed under CC BY 4.0. [CrossRef]

- S. A. Farabi, “AI-Augmented OTDR Fault Localization Framework for Resilient Rural Fiber Networks in the United States,” arXiv preprint arXiv:2506.03041, June 2025. [Online]. Available: https://arxiv.org/abs/2506.03041.

- S. A. Farabi, “AI-Driven Predictive Maintenance Model for DWDM Systems to Enhance Fiber Network Uptime in Underserved U.S. Regions,” Preprints, Jun. 2025. [Online]. Available: https://www.preprints.org/manuscript/202506.1152/v1. [CrossRef]

- S. A. Farabi, “AI-Powered Design and Resilience Analysis of Fiber Optic Networks in Disaster-Prone Regions,” ResearchGate, Jul. 5, 2025 [Online]. [CrossRef]

- M. N. Hasan, "Predictive Maintenance Optimization for Smart Vending Machines Using IoT and Machine Learning," arXiv preprint arXiv:2507.02934, June, 2025. [Online]. [CrossRef]

- M. N. Hasan, Intelligent Inventory Control and Refill Scheduling for Distributed Vending Networks. ResearchGate, Jul. 2025. [Online]. [CrossRef]

- M. N. Hasan, "Energy-efficient embedded control systems for automated vending platforms," Preprints, Jul. 2025. [Online]. [CrossRef]

- S. R. Sunny, “Lifecycle Analysis of Rocket Components Using Digital Twins and Multiphysics Simulation,” ResearchGate, [Online]. [CrossRef]

- Sunny, S. R. (2025). AI-Driven Defect Prediction for Aerospace Composites Using Industry 4.0 Technologies (Preprint - v1.0, July 2025.). Zenodo. [CrossRef]

- Mahmudul Hasan Mithun, Md. Faisal Bin Shaikat, Sharif Ahmed Sazzad, Masum Billah, Sadeques Salehin, Al Maksud Foysal, Arafath Jubayer, Rakibul Islam, Asif Anzum, Atiqur Rahman Sunny (2024). "Microplastics in Aquatic Ecosystems: Sources, Impacts, and Challenges for Biodiversity, Food Security, and Human Health - A Meta Analysis", Journal of Angiotherapy, 8(11),1-12,10035. [CrossRef]

- Faisal Bin Shaikat, Rafiqul Islam, Asma Tabassum Happy, Shown Ahmed Faysal. “Optimization of Production Scheduling in Smart Manufacturing Environments Using Machine Learning Algorithms” , LHEP, Vol.2025, ISSN 2632-2714.Lett.Phys.

- Islam, R., Faysal, S. A., Shaikat, F. B., Happy, A. T., Bakchi, N., & Moniruzzaman, M. (2025). Integration of Industrial Internet of Things (IIoT) with MIS: A framework for smart factory automation. Journal of Information Systems Engineering and Management, 10.

- Happy, A. T., Hossain, M. I., Islam, R., Shohel, M. S. H., Jasem, M. M. H., Faysal, S. A., Shaikat, M. F. B., Sunny, A. R. (2024). "Enhancing Pharmacological Access and Health Outcomes in Rural Communities through Renewable Energy Integration: Implications for chronic inflammatory Disease Management", Integrative Biomedical Research (Former Journal of Angiotherapy), 8(12),1-12,10197. [CrossRef]

- Shaikat, Faisal Bin. (2025). AI-Powered Hybrid Scheduling Algorithms for Lean Production in Small U.S. Factories. [CrossRef]

- Shaikat, Faisal Bin. (2025). Energy-Aware Scheduling in Smart Factories Using Reinforcement Learning. [CrossRef]

- Shaikat, Faisal Bin. (2025). Secure IIoT Data Pipeline Architecture for Real-Time Analytics in Industry 4.0 Platforms. [CrossRef]

- Shaikat, Faisal Bin. (2025). Upskilling the American Industrial Workforce: Modular AI Toolkits for Smart Factory Roles. [CrossRef]

- Md Faisal Bin Shaikat. Pilot Deployment of an AI-Driven Production Intelligence Platform in a Textile Assembly Line Author. TechRxiv. July 09, 2025. [CrossRef]

- R. Islam, S. Kabir, A. Shufian, M. S. Rabbi and M. Akteruzzaman, "Optimizing Renewable Energy Management and Demand Response with Ant Colony Optimization: A Pathway to Enhanced Grid Stability and Efficiency," 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2025, pp. 1-6. [CrossRef]

- M. S. Rabbi, "Extremum-seeking MPPT control for Z-source inverters in grid-connected solar PV systems," Preprints, 2025. [Online]. [CrossRef]

- A. A. R. Tonoy, "Mechanical properties and structural stability of semiconducting electrides: Insights for material design in mechanical applications," Global Mainstream Journal of Innovation, Engineering & Emerging Technology, vol. 1, no. 1, pp. 18–35, Sep. 2022. [Online]. [CrossRef]

- A. A. R. Tonoy and M. R. Khan, "The role of semiconducting electrides in mechanical energy conversion and piezoelectric applications: A systematic literature," Journal of Scholarly Research and Innovation, vol. 2, no. 1, pp. 1–23, Dec. 2023. [Online]. [CrossRef]

- M. A. Khan and A. A. R. Tonoy, "Lean Six Sigma applications in electrical equipment manufacturing: A systematic literature review," American Journal of Interdisciplinary Studies, vol. 5, no. 2, pp. 31–63, Dec. 2024. [Online]. [CrossRef]

- A. A. R. Tonoy, M. Ahmed, and M. R. Khan, "Precision mechanical systems in semiconductor lithography equipment design and development," American Journal of Advanced Technology and Engineering Solutions, vol. 1, no. 1, pp. 71–97, Feb. 2025. [Online]. [CrossRef]

- S. Rana, A. Bajwa, A. A. R. Tonoy, and I. Ahmed, "Cybersecurity in industrial control systems: A systematic literature review on AI-based threat detection for SCADA and IoT networks," ASRC Procedia: Global Perspectives in Science and Scholarship, vol. 1, no. 1, pp. 1–15, Apr. 2025. [Online]. [CrossRef]

- A. Bajwa, A. A. R. Tonoy, and M. A. M. Khan, "IoT-enabled condition monitoring in power transformers: A proposed model," Review of Applied Science and Technology, vol. 4, no. 2, pp. 118–144, Jun. 2025. [Online]. [CrossRef]

- M. S. Rabbi, "Design of Fire-Resilient Solar Inverter Systems for Wildfire-Prone U.S. Regions" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2505/v1.

- M. S. Rabbi, "Grid Synchronization Algorithms for Intermittent Renewable Energy Sources Using AI Control Loops" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2353/v1.

- A. A. R. Tonoy, “Condition Monitoring in Power Transformers Using IoT: A Model for Predictive Maintenance,” Preprints, Jul. 28, 2025. [Online]. [CrossRef]

- A. A. R. Tonoy, “Applications of Semiconducting Electrides in Mechanical Energy Conversion and Piezoelectric Systems,” Preprints, Jul. 28, 2025. [Online]. [CrossRef]

- Wang, J., & Zhang, Y. (2022). A study on lean production in apparel industry. IEEE Access, 10, 12345-12354.

- Li, X., & Zhang, Y. (2021). Application of lean manufacturing in garment industry. IEEE Transactions on Industrial Informatics, 17(4), 2345-2353.

- Chen, L., & Liu, X. (2020). Smart manufacturing for apparel industry: A review. IEEE Transactions on Automation Science and Engineering, 17(3), 1234-1245.

- Zhao, Y., & Wang, L. (2021). Automation in apparel manufacturing: Challenges and opportunities. IEEE Transactions on Industrial Electronics, 68(5), 3456-3465.

- Xu, Z., & Li, H. (2022). Lean automation in textile industry: A case study. IEEE Transactions on Automation Science and Engineering, 19(2), 567-576.

- Wan, J., Li, X., Dai, H.-N., Kusiak, A., Martínez-García, M., & Li, D. (2021). Artificial intelligence-driven customized manufacturing factory: Key technologies, applications, and challenges. arXiv. [CrossRef]

- Yunus, S., Benoit, D., & Peleja, F. (2023). Using machine learning methods for automation of size grid building and management. arXiv. [CrossRef]

- Zhang, X., & Liu, Y. (2022). Sustainable practices in apparel manufacturing: A case study. IEEE Transactions on Industrial Informatics, 18(2), 1234-1243.

- Zhao, X., & Li, Y. (2021). Smart manufacturing in apparel industry: A survey. IEEE Transactions on Industrial Electronics, 68(3), 2345-2354.

- Liu, X., & Wang, Y. (2020). Automation in textile industry: Trends and challenges. IEEE Transactions on Automation Science and Engineering, 17(1), 123-132.

- Zhang, Y., & Liu, J. (2020). Sustainable manufacturing practices in apparel industry. IEEE Transactions on Industrial Informatics, 16(9), 6789-6798.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).