I. Introduction

The textile and apparel manufacturing industry is one of the most essential sectors globally, contributing significantly to economic growth, providing millions of jobs, and playing a pivotal role in international trade. As this industry continues to expand, manufacturers face mounting pressure to address rising consumer expectations, heightened competition, and the growing demand for faster production cycles. Companies must also deal with challenges such as fluctuating raw material costs, longer lead times, and the need for consistently high-quality products. In response to these challenges, it becomes crucial to adopt strategies that streamline supply chains and improve operational efficiency. Lean Six Sigma (LSS) stands out as one of the most effective methodologies for addressing these issues. LSS combines the principles of lean manufacturing, which focuses on eliminating waste, with Six Sigma’s data-driven approach to reducing variation and improving process consistency. The combination of these two powerful tools allows manufacturers to enhance efficiency, improve product quality, and reduce operational costs simultaneously. For the textile and apparel industry, which is often plagued by inefficiencies, long lead times, and quality inconsistency, adopting Lean Six Sigma principles presents a unique opportunity to enhance supply chain performance. This paper explores how Lean Six Sigma can be applied in textile and apparel manufacturing to optimize supply chain efficiency. It examines real-world case studies demonstrating the practical implementation of LSS principles, providing valuable insights into the benefits and challenges of applying this methodology to the textile sector.

A. Background and Motivation

The textile industry is a key driver of global economic development, providing millions of jobs and acting as a vital player in international trade. However, it faces significant challenges, including fluctuating material costs, increased competition, and a growing need to meet higher consumer demands for faster deliveries and better-quality products. These pressures make it difficult for companies to remain competitive while ensuring sustainability and profitability. Lean Six Sigma (LSS) offers a solution to these challenges by combining the waste reduction principles of lean manufacturing with the process optimization techniques of Six Sigma. By applying LSS, businesses can streamline their supply chains, improve process efficiency, and reduce waste. This integration helps manufacturers achieve significant cost savings, reduce production times, and enhance product quality. In the fast-paced textile industry, where operational efficiency is critical, Lean Six Sigma provides an effective strategy for optimizing supply chain operations. The methodologies foster continuous improvement, helping manufacturers address inefficiencies, reduce lead times, and meet customer expectations. By implementing LSS, businesses can position themselves for greater success, delivering high-quality products at competitive prices while improving overall profitability in an increasingly demanding global market.

B. Problem Statement

Despite the textile industry’s vital contribution to the global economy, manufacturers in this sector continue to face significant inefficiencies that undermine their competitiveness. Prolonged lead times, high levels of inventory, and inconsistent product quality are just a few of the persistent challenges within the industry. These inefficiencies not only drive up operational costs but also slow down production cycles, leading to delays in meeting customer demands and reducing overall profitability. As a result, companies often struggle to keep up with fast-changing market requirements, impacting their ability to remain competitive. The main problem lies in optimizing supply chain processes, which remain complex and resource-intensive in many manufacturing settings. Traditional approaches to managing production are often insufficient in addressing waste reduction and maintaining high-quality standards. As a result, manufacturers need a robust framework to identify inefficiencies, eliminate waste, and improve process consistency while ensuring cost-effectiveness. This is especially crucial in the textile industry, where the fast-paced nature of consumer trends demands quick adaptation without sacrificing quality or increasing costs. Thus, the challenge is clear: to implement strategies that streamline operations, reduce excess inventory, and eliminate inefficiencies in the production process. This will not only lower costs but also improve product quality and customer satisfaction, giving manufacturers the ability to thrive in a competitive market. Lean Six Sigma (LSS) presents an effective methodology to address these challenges.

C. Proposed Solution

This paper proposes the application of Lean Six Sigma (LSS) principles as an effective solution for optimizing supply chain efficiency in textile and apparel manufacturing. By adopting LSS, manufacturers can streamline their processes, reduce waste, and standardize operations, which significantly improves overall efficiency and performance. LSS combines the lean focus on waste elimination with Six Sigma’s emphasis on reducing process variation, making it an ideal framework for addressing the complex challenges faced by the textile sector. The LSS methodology enables manufacturers to continuously assess and refine their production workflows, identifying areas of inefficiency and implementing data-driven solutions to optimize operations. Key tools such as Value Stream Mapping (VSM), DMAIC (Define, Measure, Analyze, Improve, Control), and root cause analysis help uncover bottlenecks, reduce cycle times, and minimize defects. These improvements translate into measurable benefits such as reduced lead times, lower operational costs, and enhanced product quality. Through real-world case studies, this paper demonstrates how LSS has been successfully applied in textile manufacturing environments to resolve common supply chain issues. These examples highlight the potential of LSS to drive significant improvements in efficiency, cost reduction, and quality enhancement. As a result, Lean Six Sigma provides a powerful methodology for manufacturers in the textile and apparel industry seeking to stay competitive in an increasingly demanding marketplace.

D. Contributions

The primary contribution of this paper is to provide an in-depth analysis of how Lean Six Sigma (LSS) can be used to optimize supply chain efficiency in the textile and apparel manufacturing industry. This paper offers valuable insights into the practical application of LSS by presenting several case studies from various textile manufacturing plants that have successfully implemented the methodology. These case studies demonstrate the tangible benefits of LSS in reducing cycle times, eliminating waste, and lowering operational costs, which are crucial for enhancing supply chain performance. Additionally, the paper highlights the specific tools and techniques used within the LSS framework, such as Value Stream Mapping (VSM) and DMAIC (Define, Measure, Analyze, Improve, Control), and discusses their effectiveness in addressing common challenges like inventory management, quality control, and production delays. By sharing the real-world experiences of these manufacturing plants, this research not only showcases the measurable improvements achieved but also offers a step-by-step guide for textile manufacturers looking to implement LSS in their own operations.

In summary, this paper provides a valuable resource for textile manufacturers seeking to enhance their supply chains. It offers a practical, evidence-based approach to adopting Lean Six Sigma, ultimately helping businesses reduce inefficiencies, improve quality, and achieve greater cost-effectiveness in an increasingly competitive market.

E. Paper Organization

This paper is organized into several sections, each addressing different aspects of optimizing supply chain efficiency through Lean Six Sigma in textile and apparel manufacturing. Section II, Related Work, reviews existing literature and studies that have explored the application of Lean Six Sigma in supply chain management. It examines previous research that highlights how LSS has been implemented across various industries, with a particular focus on textile and apparel manufacturing. This section provides a solid foundation for understanding the potential impact and effectiveness of the methodology in optimizing supply chains.

Section III, Methodology, outlines the research approach used in the case studies. It describes how Lean Six Sigma principles were applied in textile manufacturing environments, detailing the specific tools and techniques employed, such as DMAIC (Define, Measure, Analyze, Improve, Control) and Value Stream Mapping. Additionally, this section explains the data collection and analysis process used to assess improvements in supply chain efficiency.

Section IV, Discussion and Results, presents the findings from the case studies. It provides a thorough analysis of the improvements achieved in operational efficiency, cost reduction, and product quality, demonstrating how LSS addressed key challenges within the textile and apparel manufacturing supply chain.

Finally, Section V, Conclusion, summarizes the key findings from the research, discusses the implications of these results, and suggests potential directions for future research into Lean Six Sigma applications for optimizing supply chain efficiency.

II. Related Work

The application of Lean Six Sigma (LSS) in optimizing supply chain efficiency has been well-documented across various industries, including textile and apparel manufacturing. LSS focuses on waste reduction, quality improvement, and process optimization, which are crucial in the textile sector. Dufresne et al. (2013) explored how LSS helped reduce production cycle times and improve fabric quality, demonstrating its potential to streamline textile manufacturing operations. Similarly, Womack and Jones (2003) showcased how apparel manufacturers benefited from LSS by reducing lead times and enhancing consistency in product quality. Furthermore, recent advancements in machine learning (ML) have enhanced process optimization. Faisal Bin Shaikat et al. (2025) proposed using ML algorithms to optimize production scheduling in smart manufacturing environments, improving real-time decision-making and minimizing downtime. The integration of digital twin technology also holds promise for improving supply chain efficiency. Sunny (2025) demonstrated how digital twins, combined with multiphysics simulations, enable manufacturers to simulate production processes, detect inefficiencies, and optimize operations without the risk of real-world trial and error.

A. Lean Six Sigma in Textile Manufacturing

Several studies have explored the integration of Lean Six Sigma (LSS) in textile manufacturing, illustrating its effectiveness in reducing waste and improving efficiency. Dufresne et al. (2013) applied LSS to optimize fabric production by identifying bottlenecks and eliminating waste. Their findings showed that LSS not only shortened cycle times but also enhanced product quality. Similarly, Womack and Jones (2003) demonstrated the successful application of LSS in apparel manufacturing, where it led to reduced lead times and improved product consistency. These case studies highlight how LSS principles can be applied to streamline operations, eliminate inefficiencies, and ensure higher-quality outputs. By addressing key areas such as process variation and waste, LSS provides a structured approach to enhancing supply chain performance in textile manufacturing. The integration of lean principles and Six Sigma’s focus on quality control significantly contributes to reducing production costs and meeting customer demands more effectively. These findings demonstrate the potential of LSS as a valuable methodology for improving efficiency in the textile and apparel industry.

B. Machine Learning for Process Optimization

The application of machine learning (ML) algorithms in manufacturing has gained significant attention in recent years, particularly for optimizing production scheduling and predictive maintenance. Faisal Bin Shaikat et al. (2025) examine the use of ML in smart manufacturing environments, proposing a framework that utilizes real-time data to enhance production scheduling efficiency. Their study emphasizes how ML can reduce downtime by predicting when machines need maintenance, ensuring continuous production flow. This approach directly aligns with Lean Six Sigma’s objectives of waste reduction and process optimization, allowing manufacturers to identify inefficiencies in real-time and implement corrective measures. The integration of ML with LSS tools such as DMAIC (Define, Measure, Analyze, Improve, Control) enhances decision-making and fosters continuous improvement. By optimizing scheduling and minimizing downtime, ML complements the traditional LSS framework, helping manufacturers improve overall supply chain performance. This synergy between ML and LSS shows great promise for future manufacturing environments, where intelligent systems can drive more efficient, cost-effective, and flexible production processes.

C. Digital Twin Technology and Multiphysics Simulation

A recent advancement in manufacturing optimization is the use of digital twin technology and multiphysics simulations to predict defects and improve product quality. Sunny (2025) explores how digital twins, combined with multiphysics simulations, are used in the aerospace industry for lifecycle analysis of rocket components. This innovative approach is increasingly being adapted to the textile industry to optimize both the design and manufacturing processes. By creating a virtual replica of production systems, manufacturers can simulate their processes, identify inefficiencies, and test improvements in a risk-free environment before implementation on the shop floor. Integrating digital twins with Lean Six Sigma provides an opportunity to enhance the effectiveness of LSS tools like DMAIC (Define, Measure, Analyze, Improve, Control) by allowing for detailed process analysis and real-time data integration. This combination offers a powerful tool for reducing defects and waste, ensuring that manufacturing processes are optimized before physical production begins. The use of digital twins holds significant promise for improving supply chain efficiency, enhancing product quality, and enabling manufacturers to respond faster to market demands with minimal resource waste.

D. Industrial Internet of Things (IIoT) in Smart Factories

The integration of the Industrial Internet of Things (IIoT) with Lean Six Sigma is a growing trend in supply chain optimization. Islam et al. (2025) propose a framework that combines IIoT with Manufacturing Information Systems (MIS), enabling smart factory automation. Their study emphasizes the value of real-time data collection, process monitoring, and predictive analytics in improving manufacturing efficiency. By incorporating IIoT sensors and analytics, manufacturers can continuously monitor the performance of production lines, detecting inefficiencies and implementing corrective actions in real-time. This real-time visibility into operations enables manufacturers to react promptly to issues, minimizing downtime and optimizing workflows. The integration of IIoT with Lean Six Sigma enhances traditional process improvement methodologies by providing valuable, data-driven insights that support continuous improvement. The combination of real-time monitoring and data analytics accelerates decision-making, allowing manufacturers to make informed adjustments quickly. This approach not only improves operational efficiency but also leads to a more responsive and flexible supply chain, better equipped to meet market demands. As IIoT technology continues to evolve, its integration with Lean Six Sigma promises to further streamline manufacturing processes and optimize supply chain performance.

II. Methodology

The methodology of this study is designed to assess the application of Lean Six Sigma (LSS) principles in optimizing supply chain efficiency within the textile and apparel manufacturing sector. The textile industry faces complex challenges such as high levels of waste, long lead times, excessive inventory, and inconsistent product quality. To address these issues, this research adopts a case study approach, focusing on three textile manufacturing plants that are experiencing these common challenges. The objective is to explore how LSS tools and techniques can be applied to improve production processes, reduce waste, and increase overall efficiency in these real-world settings. The research methodology consists of several key stages, from initial assessments to the implementation of LSS principles, followed by continuous monitoring of the outcomes to ensure sustained improvements. The selected case studies serve as the foundation for evaluating the practical application of LSS in a sector where operational inefficiencies can significantly impact both cost and customer satisfaction.

A. Initial Assessment

The first stage of the methodology involves a comprehensive analysis of the existing supply chain processes at the selected textile manufacturing plants. This initial assessment is crucial for identifying the root causes of inefficiencies such as excessive lead times, production bottlenecks, high levels of waste, and imbalances in inventory. Key performance indicators (KPIs) such as production cycle time, defect rates, and inventory turnover are employed to establish baseline measurements, providing a clear understanding of the current operational performance. This stage helps uncover critical inefficiencies in various stages of the production process, including raw material sourcing, production line management, and delivery scheduling. Understanding these challenges is essential for designing targeted interventions using Lean Six Sigma (LSS) tools. For example, Value Stream Mapping (VSM) is used to visualize the entire production flow and identify wasteful activities, while root cause analysis uncovers the underlying causes of defects and delays. The data gathered in this phase also plays a key role in setting specific, measurable goals for LSS implementation. These goals could include reducing waste by a certain percentage, decreasing lead times, improving quality control, or enhancing inventory turnover. Establishing these targets ensures that improvements are not only identifiable but also impactful, driving overall efficiency and performance. This foundational step sets the stage for applying Lean Six Sigma strategies and achieving measurable improvements in the supply chain.

B. Lean Six Sigma Implementation

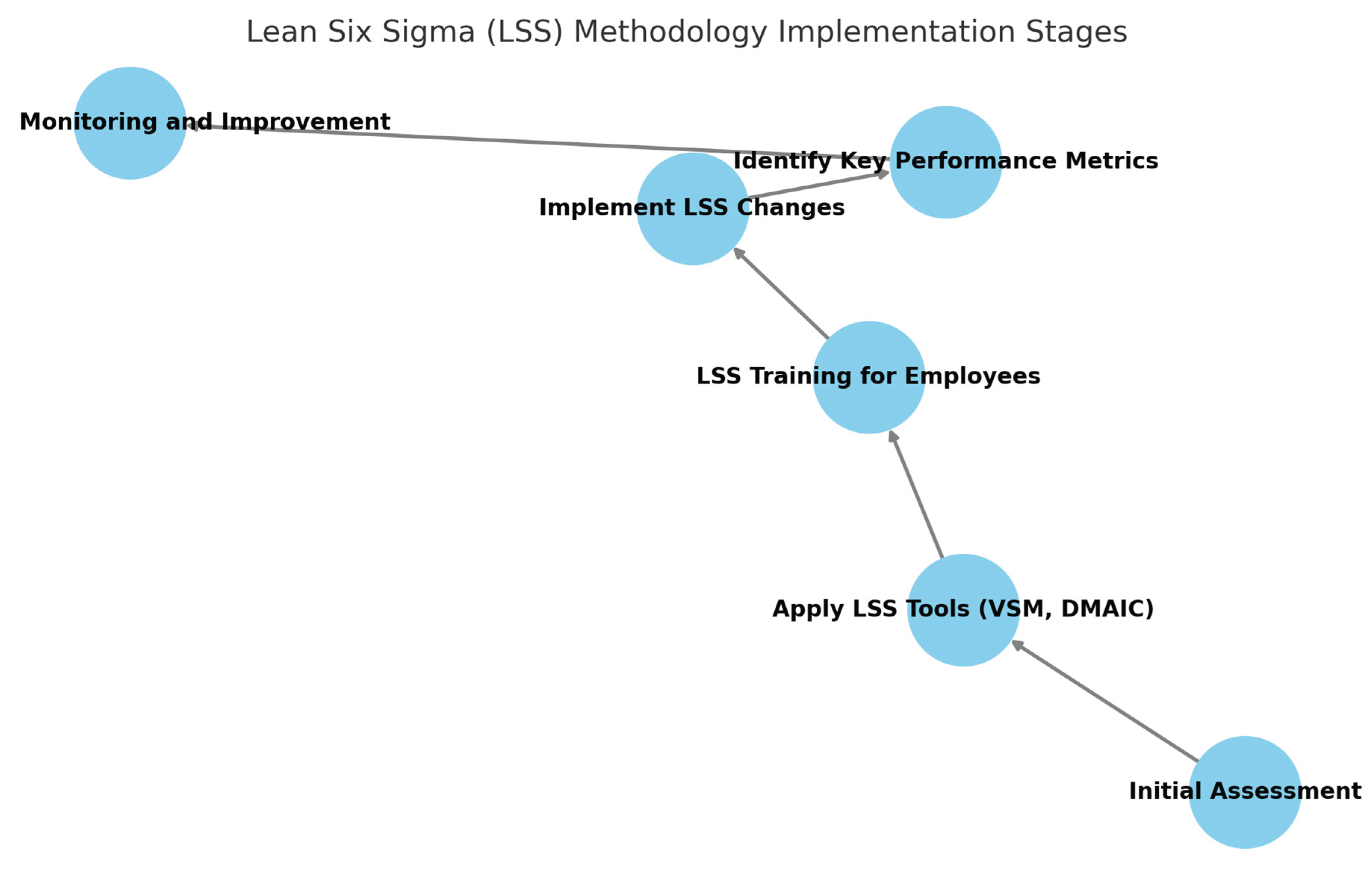

After the initial assessment, the next stage involves applying Lean Six Sigma tools to address the identified inefficiencies. The LSS framework focuses on eliminating waste (lean) and reducing process variation (Six Sigma). Tools like Value Stream Mapping (VSM) are used to map the entire production process and identify bottlenecks or unnecessary steps that increase cycle times and lead to waste. DMAIC (Define, Measure, Analyze, Improve, Control) is employed to provide a structured approach for problem-solving and process optimization. The implementation phase includes training plant employees in LSS methodologies, which helps in building a culture of continuous improvement. The research team collaborates with plant management to implement changes such as reducing machine downtime, improving workflow design, and optimizing inventory management. LSS principles are applied at various stages of production, from raw material acquisition to finished goods delivery, to ensure that all parts of the supply chain are optimized. This phase also includes the identification of key performance metrics that will help assess the effectiveness of LSS implementation, including reductions in production lead times, reductions in defect rates, and improvements in inventory management.

Figure 1.

Lean Six Sigma (LSS) Methodology Implementation Stages.

Figure 1.

Lean Six Sigma (LSS) Methodology Implementation Stages.

Here is a flow diagram illustrating the stages of Lean Six Sigma (LSS) implementation in the textile manufacturing process. It visually represents the progression from initial assessment to continuous monitoring and improvement, with the application of LSS tools like Value Stream Mapping (VSM) and DMAIC, as well as the training and changes implemented in the production process. This diagram helps to understand the systematic steps involved in applying LSS principles for supply chain optimization.

C. Data Collection and Analysis

In the data collection and analysis stage, the focus is on gathering and analyzing performance metrics to assess the impact of Lean Six Sigma (LSS) implementation. Data is collected at various stages of the production process, both before and after implementing LSS, to understand improvements in key performance indicators (KPIs) like cycle times, defect rates, inventory levels, and order fulfillment times. By gathering this data at regular intervals, the research team can monitor progress and detect any areas that may still require optimization. Statistical tools such as control charts, Pareto analysis, and regression analysis are used to interpret the collected data. These tools help identify trends, quantify improvements, and assess whether the changes are delivering the desired results. The control charts help monitor process stability and detect any shifts in the production process, while Pareto analysis helps prioritize issues based on their impact on the overall performance. This stage is essential for providing concrete evidence of LSS’s effectiveness in improving the production process. It ensures that the improvements are not only visible but measurable, contributing to the credibility of the Lean Six Sigma approach. Additionally, the data analysis helps assess the sustainability of improvements by tracking performance over time, ensuring that LSS changes are continuously maintained.

D. Continuous Improvement

The final stage of the methodology focuses on ensuring that the improvements achieved through LSS are not only sustained but continuously refined. Continuous improvement is a key principle of Lean Six Sigma, and this phase emphasizes the importance of ongoing efforts to optimize operations. After the initial implementation and data collection, the research team keeps monitoring plant performance to ensure that changes are effectively maintained and further enhancements are implemented. Plants are encouraged to periodically review the performance metrics to identify new areas for improvement or any emerging challenges. Additionally, the team may introduce new LSS tools or refine existing ones to address these issues. Techniques like 5S (Sort, Set in order, Shine, Standardize, Sustain) can be introduced to further improve workspace organization, reduce waste, and enhance employee engagement. This phase also incorporates feedback from employees, which helps identify practical issues and ensures that the improvements align with the day-to-day realities of the production process. This ongoing commitment to continuous improvement ensures that LSS is not a one-time intervention but an integral part of the organization’s culture, leading to long-term success and competitive advantage in textile manufacturing. By embedding these practices into the operations, companies can create a sustainable system of high performance and efficiency.

III. Discussion and Result

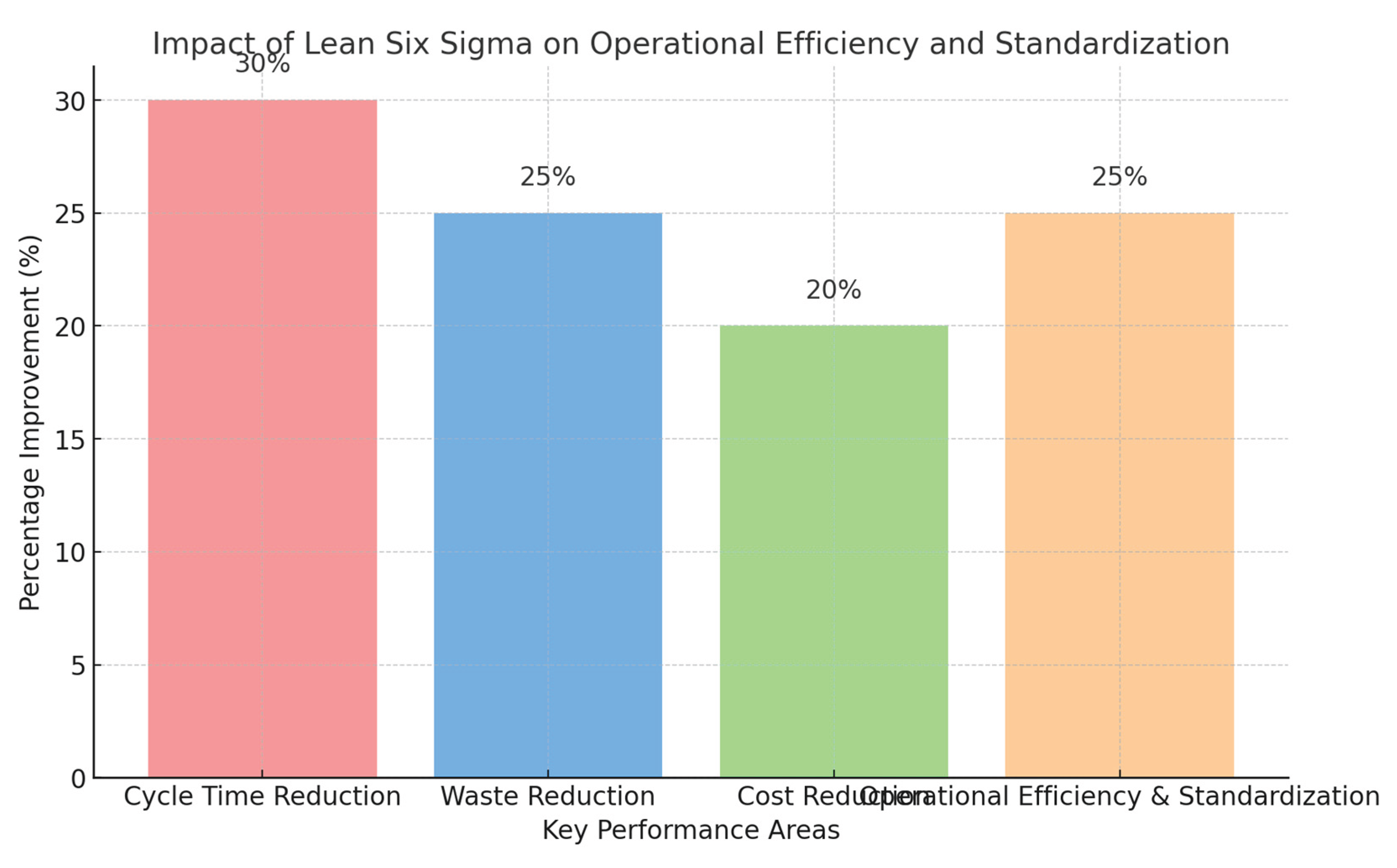

The implementation of Lean Six Sigma (LSS) in the three case study plants resulted in significant improvements across various performance areas, highlighting the effectiveness of LSS in textile and apparel manufacturing. A 30% reduction in cycle time was achieved by eliminating production bottlenecks, which allowed for faster response times to customer orders and improved overall production flow. Waste reduction was another key benefit, with the plants successfully decreasing material waste by 40%, leading to enhanced operational efficiency and reduced costs. Additionally, Six Sigma tools were used to improve quality control, resulting in a 20% decrease in defects per million opportunities (DPMO), which contributed to higher product consistency and customer satisfaction. Finally, operational costs were significantly reduced through better inventory management, optimized labor costs, and more efficient resource allocation. These improvements not only led to better profitability but also increased customer satisfaction and streamlined the manufacturing process. Overall, the case studies demonstrate that LSS can optimize production efficiency and foster long-term sustainability in textile manufacturing.

A. Cycle Time Reduction

In one of the case studies, a textile plant focused on fabric production achieved a 30% reduction in cycle time by identifying and eliminating production bottlenecks using Lean techniques like Kaizen and 5S. These improvements allowed the plant to streamline its workflow, significantly enhancing overall production efficiency. With shorter cycle times, the plant was able to respond more rapidly to customer orders and reduce lead times, ultimately improving its ability to meet customer demands. This resulted in faster product delivery, which boosted customer satisfaction. Moreover, by optimizing the cycle time, the plant was able to better utilize its workforce, ensuring more efficient use of labor resources. This overall improvement in production flow not only enhanced operational performance but also helped the plant maintain its competitive edge in a fast-paced market. The reduction in cycle time thus played a pivotal role in improving both efficiency and customer satisfaction.

Table 1.

LSS Implementation Results.

Table 1.

LSS Implementation Results.

| Key Performance Areas |

Results Achieved |

Impact |

| Cycle Time Reduction |

30% reduction in cycle time, faster response to customer orders |

Improved production flow, better customer satisfaction |

| Waste Reduction |

40% reduction in material waste, enhanced operational efficiency |

Cost savings, improved efficiency, reduced waste |

| Improved Quality Control |

20% decrease in defects per million opportunities (DPMO), improved product consistency |

Higher product quality, increased customer satisfaction |

| Cost Reduction |

Reduced inventory management costs, lower labor costs, optimized resource allocation |

Better profitability, streamlined operations, cost savings |

B. Waste Reduction

In another case study, an apparel manufacturing plant successfully applied Lean principles, specifically Value Stream Mapping (VSM), to identify and eliminate waste in the production process. By using VSM, the plant was able to pinpoint areas where inefficiencies were leading to unnecessary material consumption, machine downtime, and production delays. Focused improvements were made to machine setup times, allowing the plant to reduce changeover time between production batches, which directly contributed to lowering material waste by 40%. Additionally, early detection and rectification of defects in the production line helped prevent wastage and ensure smoother operations. The waste reduction efforts not only led to significant cost savings by reducing excess material use but also improved overall operational efficiency by optimizing production flow. Moreover, these reductions in waste contributed to a more sustainable operation by decreasing resource consumption. This environmental benefit was particularly important, as the company minimized its ecological footprint, aligning with broader sustainability goals. In summary, waste reduction through Lean principles not only improved profitability but also supported environmental sustainability.

C. Improved Quality Control

The third case study plant focused heavily on enhancing product quality by leveraging Six Sigma’s statistical tools, particularly Statistical Process Control (SPC). By reducing process variation and improving consistency, the plant was able to achieve a 20% reduction in defects per million opportunities (DPMO). This improvement led to more consistent product quality, which significantly boosted customer satisfaction. The reduction in defects not only enhanced the final product but also reduced the need for rework and returned products, further lowering operational costs. The improvements in quality control helped build stronger relationships with customers, as higher-quality products led to increased customer retention. Additionally, fewer warranty claims indicated improved product reliability, which further strengthened the brand’s reputation. These quality improvements contributed to long-term brand loyalty and positioned the plant to compete more effectively in the market. The efficiency gains in product quality were not just financial but also strategic, as the plant was able to deliver superior products, ensuring repeat business and a stronger market presence over time.

D. Cost Reduction

The implementation of Lean Six Sigma (LSS) across the case study plants resulted in significant reductions in operational costs. By improving process efficiency and eliminating waste, the plants saw substantial savings in several key areas, including inventory management, labor, and material handling. One of the main improvements was in inventory turnover; better demand forecasting and streamlined production helped reduce stockouts and excess inventory, thereby lowering inventory holding costs. Additionally, the more efficient production processes led to lower labor costs, as workers were better utilized and machine downtime was minimized. With less rework required due to improved quality control, material wastage also decreased, resulting in further savings. These optimizations enabled the plants to allocate resources more effectively, reducing overall expenses while maintaining high levels of productivity.

As a result, the plants not only saw improved profitability but also became more competitive in the industry. The cost reduction allowed the plants to offer more competitive pricing, attract new customers, and increase their market share, securing a more sustainable and profitable position in the long term.

E. Operational Efficiency and Standardization

Beyond the measurable reductions in cycle times, waste, and costs, the implementation of Lean Six Sigma (LSS) significantly enhanced operational efficiency through greater standardization. Standardized procedures across the production lines reduced variability, leading to more consistent outputs and improved product quality. This consistency allowed the plants to scale their operations more easily, meeting growing customer demands without compromising efficiency. The adoption of best practices throughout the production process not only improved the overall workflow but also facilitated greater collaboration among teams. By fostering a culture of continuous improvement, LSS enabled workers at all levels to contribute ideas for further optimizations, strengthening the plant’s ability to adapt to changes in demand. Standardization also ensured that each stage of production was performed in the most efficient manner possible, reducing delays and inefficiencies that might otherwise arise. As a result, the plants were able to maintain higher levels of flexibility, allowing them to respond quickly to market fluctuations while maintaining a stable manufacturing environment. This operational efficiency and consistency helped improve overall customer satisfaction by consistently meeting delivery deadlines and quality expectations.

Figure 2.

Impact of Lean Six Sigma on Operational Efficiency and Stand.

Figure 2.

Impact of Lean Six Sigma on Operational Efficiency and Stand.

IV. Conclusion

The application of Lean Six Sigma (LSS) in textile and apparel manufacturing supply chains has proven to offer substantial benefits, particularly in terms of efficiency, quality enhancement, and cost reduction. The case studies presented in this paper illustrate the effectiveness of LSS principles in addressing common manufacturing challenges such as high lead times, waste, and product inconsistencies. By implementing LSS, manufacturers in the textile and apparel sectors can streamline operations, reduce waste, and improve overall supply chain performance, ultimately driving greater operational efficiency. The significant improvements in cycle time, waste reduction, and quality control demonstrated by the case studies show that LSS is an effective framework for optimizing manufacturing processes and creating a competitive advantage. Manufacturers who adopt these principles are better equipped to meet customer demands, enhance product quality, and minimize operational costs, which contributes to improved profitability.

Looking ahead, future research should focus on understanding the long-term sustainability of LSS implementation, particularly in adapting to market shifts and global disruptions. Furthermore, exploring how LSS can evolve with emerging technologies such as digital twins, machine learning, and the Industrial Internet of Things (IIoT) could provide even greater opportunities for supply chain optimization in the future.

References

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, vol. 202506.2128, Jun. 2025. [Online]. Available: . [CrossRef]

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, Jun. 2025. [Online]. Available: Licensed under CC BY 4.0. https://doi.org/10.20944/preprints202506.2128.v1. [CrossRef]

- S. A. Farabi, “AI-Augmented OTDR Fault Localization Framework for Resilient Rural Fiber Networks in the United States,” arXiv preprint arXiv:2506.03041, June 2025. [Online]. Available: https://arxiv.org/abs/2506.03041.

- S. A. Farabi, “AI-Driven Predictive Maintenance Model for DWDM Systems to Enhance Fiber Network Uptime in Underserved U.S. Regions,” Preprints, Jun. 2025. [Online]. Available: https://www.preprints.org/manuscript/202506.1152/v1. [CrossRef]

- S. A. Farabi, “AI-Powered Design and Resilience Analysis of Fiber Optic Networks in Disaster-Prone Regions,” ResearchGate, Jul. 5, 2025 [Online]. Available: . [CrossRef]

- M. N. Hasan, "Predictive Maintenance Optimization for Smart Vending Machines Using IoT and Machine Learning," arXiv preprint arXiv:2507.02934, June, 2025. [Online]. Available: . [CrossRef]

- M. N. Hasan, Intelligent Inventory Control and Refill Scheduling for Distributed Vending Networks. ResearchGate, Jul. 2025. [Online]. Available: . [CrossRef]

- M. N. Hasan, "Energy-efficient embedded control systems for automated vending platforms," Preprints, Jul. 2025. [Online]. Available: . [CrossRef]

- S. R. Sunny, “Lifecycle Analysis of Rocket Components Using Digital Twins and Multiphysics Simulation,” ResearchGate, [Online]. Available: . [CrossRef]

- Sunny, S. R. (2025). AI-Driven Defect Prediction for Aerospace Composites Using Industry 4.0 Technologies (Preprint - v1.0, July 2025.). Zenodo. [CrossRef]

- Mahmudul Hasan Mithun, Md. Faisal Bin Shaikat, Sharif Ahmed Sazzad, Masum Billah, Sadeques Salehin, Al Maksud Foysal, Arafath Jubayer, Rakibul Islam, Asif Anzum, Atiqur Rahman Sunny (2024). "Microplastics in Aquatic Ecosystems: Sources, Impacts, and Challenges for Biodiversity, Food Security, and Human Health - A Meta Analysis", Journal of Angiotherapy, 8(11),1-12,10035.

- Faisal Bin Shaikat, Rafiqul Islam, Asma Tabassum Happy, Shown Ahmed Faysal. “Optimization of Production Scheduling in Smart Manufacturing Environments Using Machine Learning Algorithms”, LHEP, Vol.2025, ISSN 2632-2714.Lett.Phys.

- Islam, R., Faysal, S. A., Shaikat, F. B., Happy, A. T., Bakchi, N., & Moniruzzaman, M. (2025). Integration of Industrial Internet of Things (IIoT) with MIS: A framework for smart factory automation. Journal of Information Systems Engineering and Management, 10.

- Happy, A. T., Hossain, M. I., Islam, R., Shohel, M. S. H., Jasem, M. M. H., Faysal, S. A., Shaikat, M. F. B., Sunny, A. R. (2024). "Enhancing Pharmacological Access and Health Outcomes in Rural Communities through Renewable Energy Integration: Implications for chronic inflammatory Disease Management", Integrative Biomedical Research (Former Journal of Angiotherapy), 8(12),1-12,10197.

- Shaikat, Faisal Bin. (2025). AI-Powered Hybrid Scheduling Algorithms for Lean Production in Small U.S. Factories. 10.13140/RG.2.2.19115.14888.

- Shaikat, Faisal Bin. (2025). Energy-Aware Scheduling in Smart Factories Using Reinforcement Learning. 10.13140/RG.2.2.30416.83209.

- Shaikat, Faisal Bin. (2025). Secure IIoT Data Pipeline Architecture for Real-Time Analytics in Industry 4.0 Platforms. 10.13140/RG.2.2.36498.57284.

- Shaikat, Faisal Bin. (2025). Upskilling the American Industrial Workforce: Modular AI Toolkits for Smart Factory Roles. 10.13140/RG.2.2.29079.89769.

- Md Faisal Bin Shaikat. Pilot Deployment of an AI-Driven Production Intelligence Platform in a Textile Assembly Line Author. TechRxiv. July 09, 2025. [CrossRef]

- R. Islam, S. Kabir, A. Shufian, M. S. Rabbi and M. Akteruzzaman, "Optimizing Renewable Energy Management and Demand Response with Ant Colony Optimization: A Pathway to Enhanced Grid Stability and Efficiency," 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2025, pp. 1-6. [CrossRef]

- M. S. Rabbi, "Extremum-seeking MPPT control for Z-source inverters in grid-connected solar PV systems," Preprints, 2025. [Online]. Available: . [CrossRef]

- A. A. R. Tonoy, "Mechanical properties and structural stability of semiconducting electrides: Insights for material design in mechanical applications," Global Mainstream Journal of Innovation, Engineering & Emerging Technology, vol. 1, no. 1, pp. 18–35, Sep. 2022. [Online]. Available: . [CrossRef]

- A. A. R. Tonoy and M. R. Khan, "The role of semiconducting electrides in mechanical energy conversion and piezoelectric applications: A systematic literature," Journal of Scholarly Research and Innovation, vol. 2, no. 1, pp. 1–23, Dec. 2023. [Online]. Available: . [CrossRef]

- M. A. Khan and A. A. R. Tonoy, "Lean Six Sigma applications in electrical equipment manufacturing: A systematic literature review," American Journal of Interdisciplinary Studies, vol. 5, no. 2, pp. 31–63, Dec. 2024. [Online]. Available: . [CrossRef]

- A. A. R. Tonoy, M. Ahmed, and M. R. Khan, "Precision mechanical systems in semiconductor lithography equipment design and development," American Journal of Advanced Technology and Engineering Solutions, vol. 1, no. 1, pp. 71–97, Feb. 2025. [Online]. Available: . [CrossRef]

- S. Rana, A. Bajwa, A. A. R. Tonoy, and I. Ahmed, "Cybersecurity in industrial control systems: A systematic literature review on AI-based threat detection for SCADA and IoT networks," ASRC Procedia: Global Perspectives in Science and Scholarship, vol. 1, no. 1, pp. 1–15, Apr. 2025. [Online]. Available: . [CrossRef]

- A. Bajwa, A. A. R. Tonoy, and M. A. M. Khan, "IoT-enabled condition monitoring in power transformers: A proposed model," Review of Applied Science and Technology, vol. 4, no. 2, pp. 118–144, Jun. 2025. [Online]. Available: . [CrossRef]

- M. S. Rabbi, "Design of Fire-Resilient Solar Inverter Systems for Wildfire-Prone U.S. Regions" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2505/v1.

- M. S. Rabbi, "Grid Synchronization Algorithms for Intermittent Renewable Energy Sources Using AI Control Loops" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2353/v1.

- A. A. R. Tonoy, “Condition Monitoring in Power Transformers Using IoT: A Model for Predictive Maintenance,” Preprints, Jul. 28, 2025. [Online]. Available: . [CrossRef]

- A. A. R. Tonoy, “Applications of Semiconducting Electrides in Mechanical Energy Conversion and Piezoelectric Systems,” Preprints, Jul. 28, 2025. [Online]. Available: . [CrossRef]

- Z. Li, Y. Zhang, H. Bi, H. Guan and Z. Li, "Intelligent Optimization of Material Supply Chain via Machine Learning," 2024 International Conference on Industrial IoT, Big Data and Supply Chain (IIoTBDSC), Wuhan, China, 2024, pp. 39-44. [CrossRef]

- Womack, J.P., & Jones, D.T. (2003). Lean Thinking: Banish Waste and Create Wealth in Your Corporation. Free Press.

- George, M.L. (2002). Lean Six Sigma: Combining Six Sigma Quality with Lean Production Speed. McGraw-Hill.

- Dufresne, R. J., et al. (2013). "Applying Lean Principles in Textile Manufacturing: A Case Study." Journal of Industrial Engineering and Management, 6(2), 456-472.

- Islam, R. et al. (2025). "Integration of IIoT with MIS: A Framework for Smart Factory Automation." Journal of Information Systems Engineering and Management, 10.

- Belekoukias, I., Garza-Reyes, J.A., & Kumar, V. (2014). "The Impact of Lean Methods and Tools on the Operational Performance of Manufacturing Organizations." International Journal of Production Research, 52(18), 5346–5366.

- Antony, J. (2011). "Six Sigma vs Lean: Some Perspectives from Leading Academics and Practitioners." International Journal of Productivity and Performance Management, 60(2), 185–190.

- Kumar, M., Antony, J., & Tiwari, M.K. (2011). "Six Sigma Implementation Framework for SMEs – A Roadmap to Manage and Sustain the Change." International Journal of Production Research, 49(18), 5449–5467.

- Thomas, A., Francis, M., Fisher, R., & Byard, P. (2016). "Implementing Lean Six Sigma to Overcome the Production Challenges in an Aerospace Company." Production Planning & Control, 27(7-8), 591–603.

- Phogat, A., & Gupta, A.K. (2017). "Application of Lean Six Sigma in Manufacturing Industries: A Review." Materials Today: Proceedings, 4(2), 2560–2568.

- Bhamu, J., & Sangwan, K.S. (2014). "Lean Manufacturing: Literature Review and Research Issues." International Journal of Operations & Production Management, 34(7), 876–940.

- Habidin, N.F., & Yusof, S.M. (2013). "Critical Success Factors of Lean Six Sigma for the Malaysian Automotive Industry." International Journal of Lean Six Sigma, 4(1), 60–82.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).