1. Introduction

The management concepts of a company and its processes have a significant impact on the consumption of resources (materials, raw materials, energy, people, machinery, equipment, time, space), which in turn has an impact on the costs of the production and logistics processes implemented, and consequently on the financial performance of these companies. The implementation of management concepts such as Lean Management, Agile and SixSgima has a significant impact on the efficiency of the core processes (production, services) and the processes supporting them.

In recent years, companies have had to deal with various challenges: the economic crisis of 2007, the Covid-19 pandemic, rising energy prices, inflation. In addition, there are phenomena that are long-term trends and have a social character (ageing population, generation Z, technological advances), which also have an impact on process efficiency.

Energy is one of the important resources in most production processes and value streams. Energy consumption costs account for a significant share of companies' total costs AND sales value. Energy wastage therefore increases the cost of doing business. The benefits of reducing energy consumption are not only lower costs for companies, but also a reduction in the negative impact on the environment.

Applied process management methods such as Lean Management help to reduce the consumption of material resources. However, this must be viewed holistically in the context of the energy efficiency discussed here. Indeed, the consumption of these resources also has an indirect impact on energy consumption. The costs of waste and the benefits of ‘process leaning’ may be greater than they appear.

Significant energy savings can also be achieved by eliminating production waste, unnecessary processing and transport. However, energy is also needed for basic processes, such as powering equipment, lighting and cooling, as well as for auxiliary processes, such as administrative processes.

The impact of specific solutions is not clear-cut. In general, solutions aimed at eliminating waste and using production resources more efficiently undoubtedly also have a positive impact on energy efficiency. However, some solutions may result in a higher demand for energy, for example. Companies using the Just-In-Time system in logistics (procurement) may benefit financially, but increasing the frequency of transports may increase energy consumption and have a negative impact on the environment (increased number of transports, worse utilisation of transport capacity and mileage).

By shortening the flow path of materials and components, the flow efficiency of production is increased, which undoubtedly promotes energy efficiency. However, the pandemic situation may have forced a move away from such solutions in this sphere as well, which may result in increased energy demand. Perhaps the best example of this is the “Cell Layout”, which was very popular in Lean organisations. The close location of the workers, however, created a risk during the pandemic period.

Moreover, crisis situations may lead to even more radical solutions and, for example, to a move away from Lean Management to Agile. Such solutions have been advocated for many years (even before the pandemic) by the authors of various studies.

3. Results

3.1. Analysis of the Literature

According to a survey of the U.S. hardwood industry, the average share of energy consumption costs in total costs is 7.90% (9.70% - primary producers, 7.10% secondary producers - 5.90% to 7.80%) [1,2]. Studies conducted in 11 European countries - including Austria, Belgium, Germany, Italy, Luxembourg, Spain, France, Croatia, Italy, Poland, Portugal and Slovakia - have shown that energy consumption accounts for a significant portion of many companies' costs, with significant differences between industries and between countries [3]. On average, energy consumption accounted for about 5% of the cost of goods, materials and consumables sold and about 12% of external supplies and services. Energy price levels began to rise in 2021. In 2022, as a result of the war in Ukraine, gas prices rose by 400% and electricity prices by up to 200%. An additional factor was the increase in consumption and production following the Covid-19 pandemic.

Rising energy prices are having an increasing impact on companies' financial performance, according to another study covering 1,342 companies in 22 European countries in 2022 [4]. Similar results were obtained in studies conducted in other parts of the world. An analysis of the financial performance of large manufacturing industries listed on the Pakistan Stock Exchange from 2007 to 2016 (textile sector, cement sector, sugar sector, auto assembly sector and pharmaceutical sector). It showed that energy prices have a significant and positive relationship with financial performance [5]. Also according to the study conducted in China industrial companies that achieved the energy savings target have an advantage in terms of profitability [6]. However, companies may show positive productivity growth in the medium term, especially in less energy-intensive sectors [7].

Bamiatzi et. al. [8] analyzed the 2008 economic crisis and concluded that a company's profitability is less influenced by industry characteristics and more influenced by how a company and its processes are managed.

"Lean manufacturing" is considered one of the most effective management methods, also the method of managing consumption of the energy, by identifying and eliminating wastes. According to the results of some studies in most of the cases where LGS tools have been applied (e.g. - TPM - Total Productive Maintenance, 6R), there was a positive impact on the economic bu t also on the environmental efficiency [9].

Numerous studies conducted in different industries and in different parts of the world confirm the benefits of Lean Management for energy and environmental efficiency [10]. Below are some illustrative examples of this.

The types of waste and associated energy consumption often identified in the literature (EPA) are presented in

Table 1.

The first example is a manufacturing company that, in the midst of an energy crisis, achieved greater energy efficiency by using Lean tools and a Kaizen approach [12]. Energy consumption was reduced by up to 7.5% on the production line, by 3.5% at the extruder stage and by up to 20% at the injection stage of the manufacturing process.

Using a process map (VSM) and process improvement at a company that produces valve regulators for liquefied petroleum gas (LPG) cylinders, a 25% reduction in energy consumption was achieved [13]. Reducing the WIP at this company from 21,300 to 6240 parts per day and reducing space utilization on the production floor reduced energy consumption by 15.6%. One of the solutions at this company was a work cell on the assembly line, the use of which reduced transportation between assembly, painting and inspection stations, which also translated into lower consumption of energy, water and carbon emissions.

Very similar results were achieved at a company in a completely different industry, namely from the food industry. In this company, thanks to the application of "Lean", it was possible to reduce waste, including changeover time and manual process. As a result SEC (The specific energy consumption) improved by 15.1% due to the reduction of wastage on the production line [14].

An electrical component company achieved even better results - the introduction of production cells, a pull system and increased fault tolerance resulted in a 72.37% reduction in energy consumption [15].

Also in one of the studies conducted in the building (construction) industry with the use of the life cycle assessment (LCA) methodology outlined in the ISO 14040, it was proved, that four lean techniques value stream mapping (VSM), just in time (JIT), continuous flow, and total productive maintenance (TPM), energy consumption was reduced by 9.2% and CO2 emissions by 4.4% [16].

Very similar results are also reported in other studies. For example Gonce and Somers [17] conducted studies in various manufacturing companies. The conclusion of these studies is that streamlining processes in even without capital expenditure would reduce energy consumption by 15 per cent. Especially in companies that have implemented Lean, there is a basis for increasing energy efficiency through process integration and improvements in quality, productivity, flexibility. Many Lean Management techniques allow energy efficiency as a side effect - reducing waste in the form of, for example, overproduction, unnecessary transport and quality errors results in a decrease in energy consumption.

Although there are many Lean tools identified in the literature, there are six that can be used to significantly reduce energy consumption : Standard Work, Visual Workplace, Error Proofing, TPM, Quick Changeover, and Right-Sized Equipment [18].

Phong and Minh [19] identified "classic" tools and solutions that can be used to significantly reduce energy consumption:

5S and Visual Workplace, which provide visual indicators that make it easy to identify energy use targets, which can help employees and managers to be aware of energy consumption and opportunities for reduction;

Standardized work: workplace procedures that take into account the best practices for reducing energy consumption in training materials, standard operation and maintenance of equipment, 5S checklists

Poka-yoke - not making mistakes also reduces energy consumption

Total Productive Maintenance (TPM): By systematically maintaining equipment, plants can reduce defects in the production process and reduce energy costs by over 20%.

Train employees to identify energy losses and increase equipment efficiency through maintenance and operation.

Kaizen - to increase equipment performance.

SMED - reducing set-up and changeover times.

VSM: helps to understand how energy is used throughout the process.

Selecting equipment with the right (optimal) parameters (performance, speed): e.g. an outdated machine has a much higher performance than required.

The effectiveness of these solutions, the authors cited here, demonstrated using the example of Case, one of the largest wooden furniture manufacturers in northern Vietnam (known as WL). WL. The company faced pressure to reduce costs in the context of Covid-19 and a customer-enforced requirement to reduce energy consumption for export products. Using the methods mentioned above, unit energy consumption (SEC = Energy used /Product s amount) dropped by as much as 67.88% in 2021 (from 46.83 to 31.75 kWh/m3).

Table 2 shows the solutions used by this company and the energy savings they have brought about.

The conclusion that emerges from these cases is that the energy crisis has not discouraged these companies from applying Lean Management. On the contrary, it has further mobilized them to seek savings. However, the authors of other studies caution against drawing too hasty conclusions - which solutions should be applied to design a resilient system.

In addition to lean management other factors such as a smart environment relying on digitization and the Industry 4.0 tools and technologies can support the evolution of a company towards a higher levels of operational and lean-green performance [20,21]. Similar initiatives are also underway in companies that have implemented concepts that “compete” with Lean Management, such as Six Sigma or Agile. For example the U.S.-based Dow Company has improved energy intensity (energy consumption per pound of product) by 22% through Six Sigma and employee engagement [22].

The goal of “Agile Project Management (APM)” [23] is to foster innovation and energy-efficient solutions in the heating, ventilation and air conditioning (HVAC) industry, which is at the forefront of addressing environmental challenges with innovative technologies. The main tenets of the project are iterative development, adaptive planning, collaboration with customers, flexibility and responsiveness to change. HVAC enables rapid adaptation to changing customer needs and technological advances.

Agile can be used to streamline processes (and consequently increase energy efficiency) not only in the manufacturing area, but also in transportation. “Agile approach” to process optimization in urban logistics [24].

Even greater benefits can be achieved by combining these concepts and using hybrid solutions [25]. The search for solutions combining different competing concepts is necessary if high efficiency in terms of disruptions, crises and energy consumption is to be achieved [26]. Companies can be LARG - Lean, Agile, Resilient and Green [27]. Integration of Lean and Six Sigma in different areas of manufacturing and services is required to increase the resilience of systems [28] and enables to increase process efficiency, and improve overall economic, energy and environmental performance [29–34].

Research at a major multinational aerospace and defense company has shown that Lean practices foster anticipation, adaptation, increase flexibility and resilience [20]. However, the authors state that if standardization is too high, "Lean" practices can also undermine organizational resilience. Besides although lean manufacturing is regarded as energy efficient management concept new tools and methods are needed to analyze and reduce this consumption.

Baysan et. al. [15] developed a holistic methodology, which integrates Energy Value Stream Mapping, experimental design and simulation, with the aim of analyzing and reducing the energy consumption by reducing unevenness (mura) and overburden (muri), as root causes of energy consumption - waste (muda). The proposed methodology applied to a cable ladder manufacturing system yielded approximately 72.37% reduction in energy consumption.

A novel Lean method, which takes into account also the environment concern, is the Energy Cost Deployment (ECD), whose objective are to classify, analyse, and eliminate energy losses within the factory [35]. The effectiveness of the ECD method was illustrated using an industrial case study concerning a tissue-paper mill.

The Leanergy method developed by the Okavango-energy consulting firm [36] represents a structured Lean manufacturing approach that extends savings to processes and operations. The rationale for this new concept is that not all Lean tools are tools that simultaneously help reduce energy consumption [37].

The goal of the Lean Energy Management concept [38] is to optimize the energy efficiency of enterprises by continuously reducing energy costs, which in turn is achieved by reducing energy consumption on the one hand and reducing energy procurement costs on the other. As the authors state, many of the classic tools of Lean Manufacturing methods are used to achieve this goal, but they also stress that transparent processes in particular are involved. However, to achieve high energy efficiency to a greater extent, they propose a specialized “energy flow map” (EVM) method that shows how specific the problem is. The classic VSM method is therefore insufficient, and there is a need to develop new tools. The usefulness of this method was demonstrated in a case study of die casting [39]. Total energy demand in the process chain was reduced by 6.17%.

This raises another question, is process improvement alone without investment and technological development enough? The energy efficiency of manufacturing processes is heavily influenced by the technologies of Industry 4.0. Four groups of technologies (artificial vision and artificial intelligence, incremental manufacturing and robotics, big data and advanced analytics, and the Internet of Things) are helping to improve the energy efficiency of these processes by an average of 15-25% [40]. Integration of Green Lean Six Sigma (GLSS) and Industry 4.0 (I4.0) helped to improved hospital care through better safety, hygiene and real-time diagnostics [41]. Lean Manufacturing can be supported by Quick Response Manufacturing especially in environments with high variation and small volumes [42]. Other authors are also developing similar models. For example Costa et. al. [43] developed a model that integrates 4.0 and LM practices and facilitates companies' transition towards environmental sustainability. The model was validated through interview with a sample company. Studies conducted in 30 Chinese provinces between 2006 and 2019 have shown that smart technology, productivity effects, economies of scale and resource allocation effects of smart manufacturing can significantly improve energy efficiency [44]. A study also conducted in China by Chu et. al [45] among A-listed companies in Shanghai and Shenzhen between 2011 and 2021 found that AI can drive corporate energy transformation and artificial intelligence can help corporations achieve energy transformation. Similar studies are being conducted by other authors - Song et. al. [46], for example, showed in their study that the digital economy can promote better energy use efficiency

For supply chains as well, the use of modern technologies is advocated to support these concepts: digitization through mobile apps, artificial intelligence systems and Big Data and machine learning, as well as new concepts such as Lean omnichannel [47]. The Lean omnichannel approach is an effective practice to maintain production costs, SC visibility, SC inventory availability and sales. Companies can achieve high levels of sustainability through resilience if they are committed to a sustainable return on investment. Integrating supply chain resilience with quality management leads to more sustainable and better organizational performance. This integration provides synergistic benefits, contributing to increased operational efficiency [48]. A conceptual lean supply chain reference model (LSCP 4.0) has been developed that combines Industry 4.0 (I4.0) digital technologies with Lean Manufacturing tools to reduce waste and minimize costs [49]. The model has been applied and verified in the case of a large shoe company.

A manifestation of the recognition of the relevance of the problem of energy consumption and its peculiarities is the Department of Energy Reduction established at Toyota SA in April 2010 [50]. Its task is to focus on the implementation of an energy management system in line with the company's goals and based on Toyota's philosophy of continuous improvement (see also: [51]). The establishment of such a department in a company that is a symbol of "Lean Management" shows that achieving energy efficiency goals requires deeper changes in companies, that apply this concept.

The issue of integrating energy aspects into Lean Management has been the subject of research by McKinsey and related experts. Below are the results of one of the studies [52].

According to the authors, over the years manufacturers have made tremendous gains in increasing labor and capital productivity by implementing Lean Manufacturing principles. To a lesser extent, however, there have been efforts to increase energy efficiency. As the authors of the report cited here state:

“The waste of energy and resources is typically overlooked or excluded from lean problem solving on the grounds that it is too complex for the front line to address, cuts across too many functions, or both”.

Meanwhile, energy consumption can account for a significant portion of production costs. The authors give the example of a manufacturer of LCD TVs, where energy consumption costs accounted for 45% of production costs. Considering the share of production costs in the value of sales and the profitability of large manufacturers, this is indeed a significant share. The share of energy consumption costs in the production costs of steel or chemical products can be 15% or more (e.g., 30%). The authors estimate that these costs can be reduced by up to 30 percent, in part by applying Lean principles. The savings achieved by the surveyed companies amount to millions of euros in savings per year (as much as €50 million in savings per year in one of the surveyed companies). It was necessary to map the value stream of raw materials and move away from the traditional assumption that benefits could be achieved without expense only by eliminating wastes and streamlining processes.

3.2. Analysis and Comparison of Companies' Financial Performance

In order to determine the impact of an increase in the cost of energy consumption on financial performance, the authors analysed the financial results from recent years of Polish companies, multinationals and companies that apply Lean Management, Agile and Six Sigma strategies.

The authors took the data for the calculations from the financial reports of the companies:

Those applying Lean Management

Japanese companies (Toyota Motor Corporation, Honda, Nissan, Suzuki, Mitsubishi Motors Corporation)

American companies (General Motors Company, Parker Hannifin, Illinois Tool Works, Kimberley-Clark Corporation, Textron, General Electric, 3M)

Those applying Six Sigma (Textron, Motorola, BAE Systems, Denso Corporation, Eastman Kodak Company, Xerox, Boeing)

Those using Agile (Sony, Lego, Siemens, Koninklijke Philips)

Combining these concepts:

LeanSixSigma (John Deere, Ford Motor Company, Caterpillar Inc.)

LeanAgile (Intel Corp., Nike, Inc.)

Global corporations - the world's largest manufacturing companies

Polish companies - manufacturing companies

For all these companies, average values were calculated for changes in net profits and the share of the cost of goods sold (COGS) in revenues. The aim of these analyses was to find out whether the economic efficiency of these companies had been affected by developments in recent years. In particular, the authors wanted to see how the increase in energy prices affected economic and financial efficiency.

This topic has been tackled by the authors of this article before, and the results of research into the impact of energy costs on the efficiency of Polish manufacturing companies are included in an earlier publication [53].

Table 3,

Table 4,

Table 5 and

Table 6 - show the evolution of net profits and TCN's share of revenue over two 4-year periods: 2016 - 2019 and 2020 - 2023), i.e. before Pandemic I during the Covid-19 pandemic and the ‘energy crisis’, which was partly related to the war in Ukraine.

In the period before the pandemic, the companies surveyed increased their profits. Among multinationals, the most in companies using Agile (287.63%), followed by those using SixSigma (71.52%) and combining different concepts: Lean with Agile (64.53%) and LeanSigma (54.47%). Gains also increased in US Lean companies (37.56%) and global corporations (31.38%). Perhaps surprisingly, the smallest increases in profits were in the home of Lean Management in Japan (14.53%). But what may be even more surprising is that Polish manufacturing companies did even better (up 134.14%).

How to interpret this data? Is Lean not such an economically efficient concept after all? Or, conversely, is it confirming the principle that companies that have already achieved a high level of efficiency find it more difficult to increase it? The answer to this question would require further research.

Polish companies did even better in the following period (profit growth of 143.27%). The pandemic crisis and the increase in energy costs did not harm the profits of Lean Management leaders, on the contrary, profits increased to a greater extent in both the USA (71.64%) and Japan (55.56%).

In contrast, profit increases were smaller in companies using Six Sigma (22.13% - which is less than in the previous period) and LeanSigma (24.80%). Agile companies were not immune to the crises during this period (-75.71% decrease in profits) as well as those that combined Lean with Agile (only 3.88% increase). International corporations recorded relatively lower growth, but still only slightly less than in the previous period.

As the increase in energy prices has an impact on costs, it is precisely the costs that should be analysed, above all the manufacturing costs, especially as they account for a very large proportion of total costs in manufacturing companies. Lean Management and SixSigma are intended to help improve the efficiency of these processes.

The data shows that the share of COGS in the value of sales has remained relatively stable. This raises the question of whether management concepts such as Lean, Agile and SixSigma are helping process efficiency and cost reduction. Most surprisingly, there was an increase in the share of these costs in Japanese Lean companies between 2016 and 2019 (by 8.92%), as well as in companies that combined Lean and Agile (7.23%). This group of companies saw a further increase of 18.06% in the next period (2019 - 2023). In contrast, it is again fair to say that Lean Leaders, however, have done well during the crises of recent years - in Japan, the share of COGS declined (-2.10%), in the US it remained at a similar level to the previous period. The least resilient in this respect proved to be the combination of Lean and Agile (increase in COGS share by as much as 18.06%). International corporations (-3.99%) and Polish companies (-0.22%) managed to reduce costs during this difficult period. These results are comparable to those of Lean, Six Sigma or Agile leaders.

However, hasty conclusions can be drawn from such averaged data. Firstly, it is necessary to analyse not only the average data of individual groups but of individual companies. Such data are presented in

Table 2,

Table 3 and

Table 4.

It turns out that there are very large differences between the individual companies, which shows that it is not only the management concept itself or its processes that are important, but also how the concept is implemented and perhaps factors beyond the control of the company.

The company we most associate with Lean Management i.e. Toyota experienced a -18.59% drop in profits in the pre-pandemic period. However, Toyota's financial performance together with Nissan (-57.13%) understates the statistics in this group, as the other Japanese forms increased their profits in both 4-year periods, with Mitsubishi Motors Corporation increasing profits by as much as 120.54% in recent years.

US Lean companies fared much better - with the exception of two cases (Illinois Tool Works and Kimberley-Clark Corporation), these companies posted profit increases in both periods, and more than Japanese companies. Textron's profits between 2020 and 2023 increased by as much as 198.06% (more than Mitsubishi - 120.54%).

In both countries, however, there is wide variation in the effects across companies.

There are even greater differences between companies using SixSigma, Agile and combinations of these strategies. Moreover (as in Lean), it is not possible to conclude that a company that increased its profits in the years before the pandemic was also in a good financial position in the following period, or vice versa.

The largest increase in profits took place at Eastman Kodak Company (540.00%), while the following year also saw the largest increase in this group, but a decrease in profits (-109.98%). In some of the companies in this group, financial performance improved in the latter period (Denso Corporation 271.29%, Textron 198.38%, Motorola 79.85%). However, it is difficult to conclude from this that SixSigma organisations have proved more resilient to crises.

In contrast, the financial situation was worse at Agile organisations - two had smaller profit increases: Sony - 29.48% and at Siemens - 244.73%. These increases in the previous period were 572.05% 708.09% respectively. The other two had declines in profits - at Lego -99.38% and Koninklijke Philips -30.22%. In the following years these declines were even greater - respectively: -439.87%, -137.17%.

The situation was better for companies using combinations of these strategies, with 3 out of 5 companies seeing profits increase before 2020 and even more in the following years (John Deere - 113% - 270%, Caterpillar Inc. - 148% - 245%, Nike, Inc. - 49.2%, 99.7%). The proportion of such companies is higher than in organisations using Lean Management and those using SixSigma. This seems to support the thesis that the views presented in the literature (see 2. Materials and Methods) on the benefits of combining these concepts are valid.

However, when it comes to the share of COGS in the value of sales, the changes in this value are much smaller than the changes in profits. Meanwhile, one would expect to see an increase in process efficiency in companies that apply these process management concepts. A decrease in the share of these costs between 2016 and 2019 occurred in 55 per cent of companies but in most cases the savings were a few per cent. The largest ‘leaning’ occurred in one Lean organisation - Suzuki (-14.43%), a SixSigma organisation - BAE Systems (-12.71%), one Agil organisation - Sony (-6.75%) and one that combines Lean and SixSigma - Caterpillar Inc. (-8%). As it turns out, however, these ‘productivity leaders’ proved little immune to the crises of the following years, in which TKW shares either remained at similar levels or even increased. Manufacturing costs, on the other hand, declined during the ‘energy crisis’ for companies that had experienced increases in the previous period (Honda - -14.31%, Parker Hannifin -11.76%, Boeing -17.89%, John Deere -23%). Again, it would be difficult to demonstrate that any management strategy is more efficient. The effectiveness apparently depends on the decisions made within a given company. It is possible to hypothesise that the crises forced the companies that experienced them to introduce more radical solutions than just ‘small step’ improvements.

The data presented above are aggregated. In order to have a better picture, it would be necessary to carry out such an analysis on an annual basis. The results of such an analysis are presented in Fig. 1 -. 5.

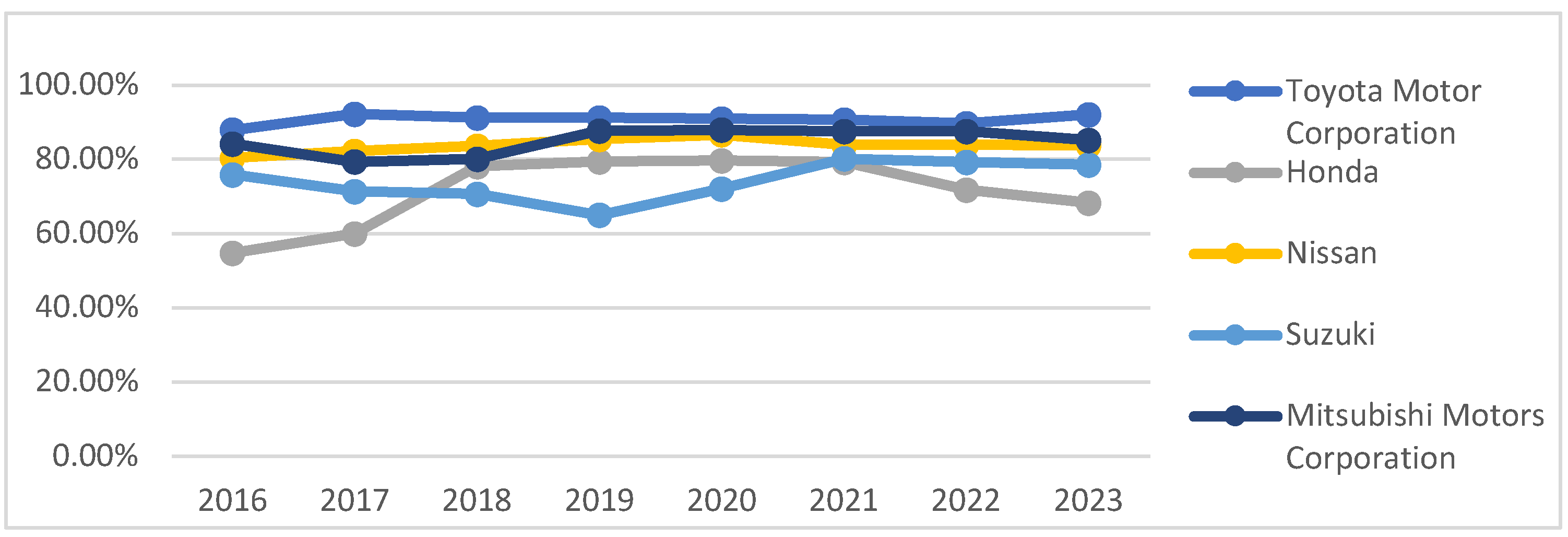

In the Japanese Lean companies (Fig. 1), with the exception of Honda, it is difficult to identify any year in which any of these companies experienced a decrease or increase in manufacturing costs. Apparently, the application of JIT did not result in an increase in these costs.

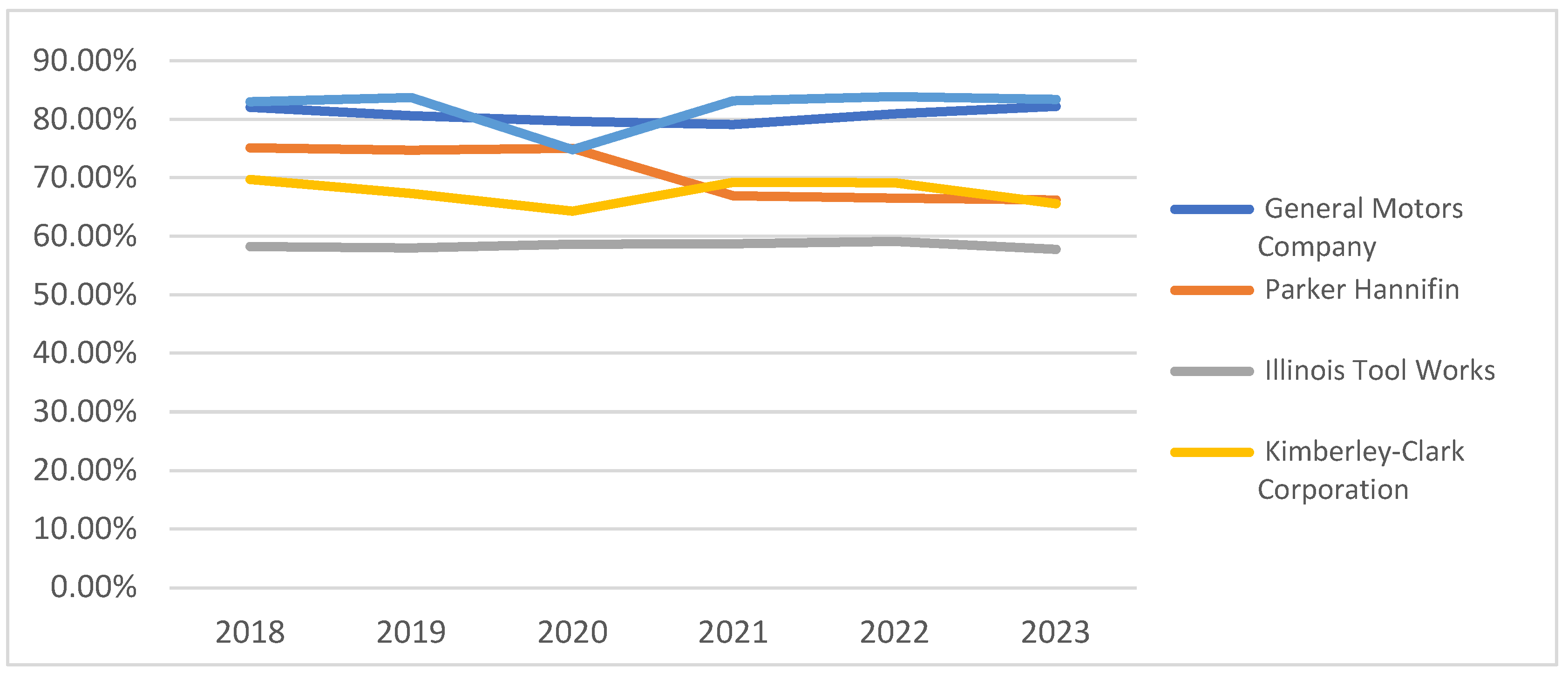

The share of these costs has also remained stable in ‘lean’ US companies (Fig. 2). At ‘Parker Hannifin’, there was even a decrease in their share in 2020.

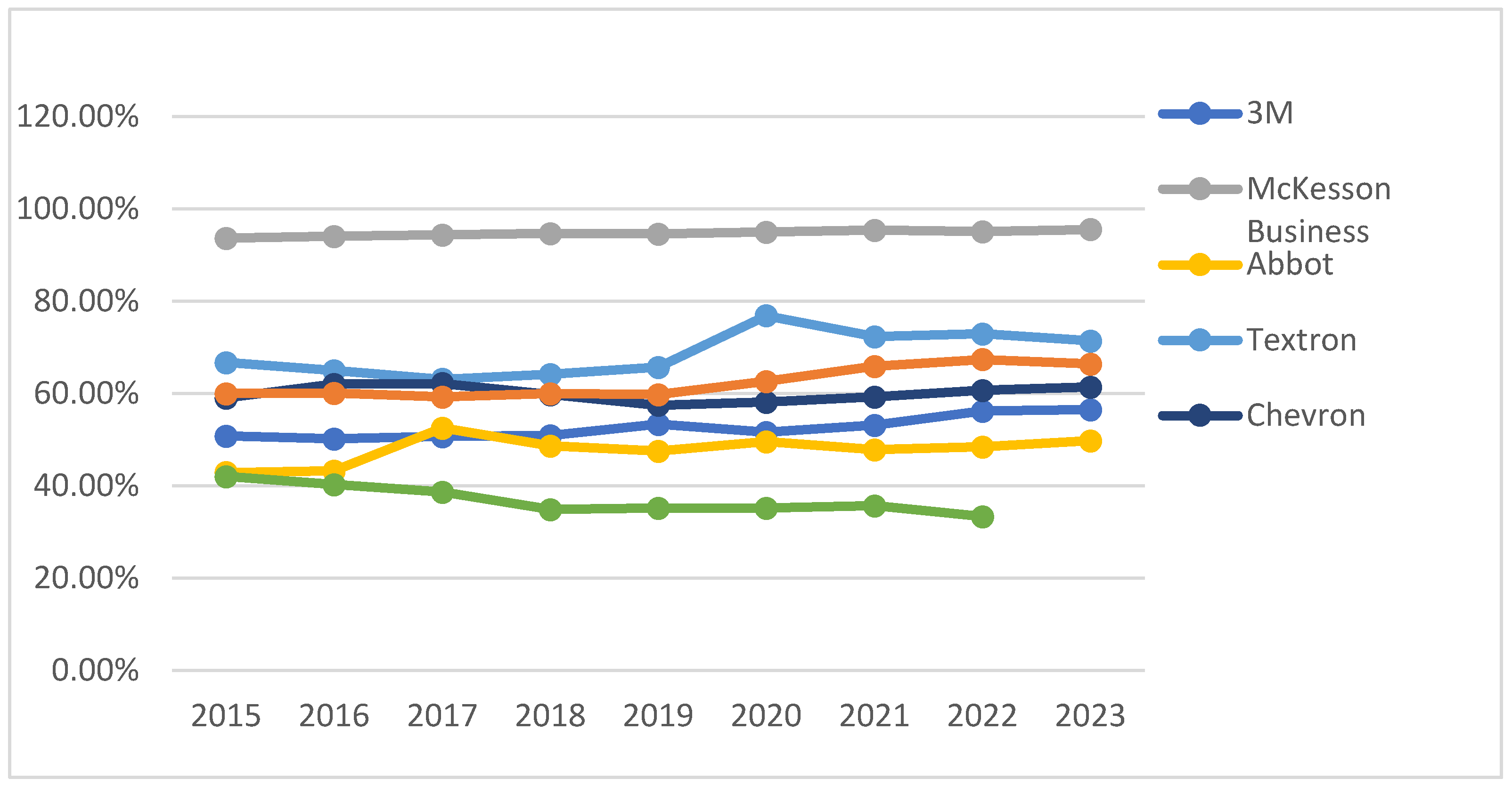

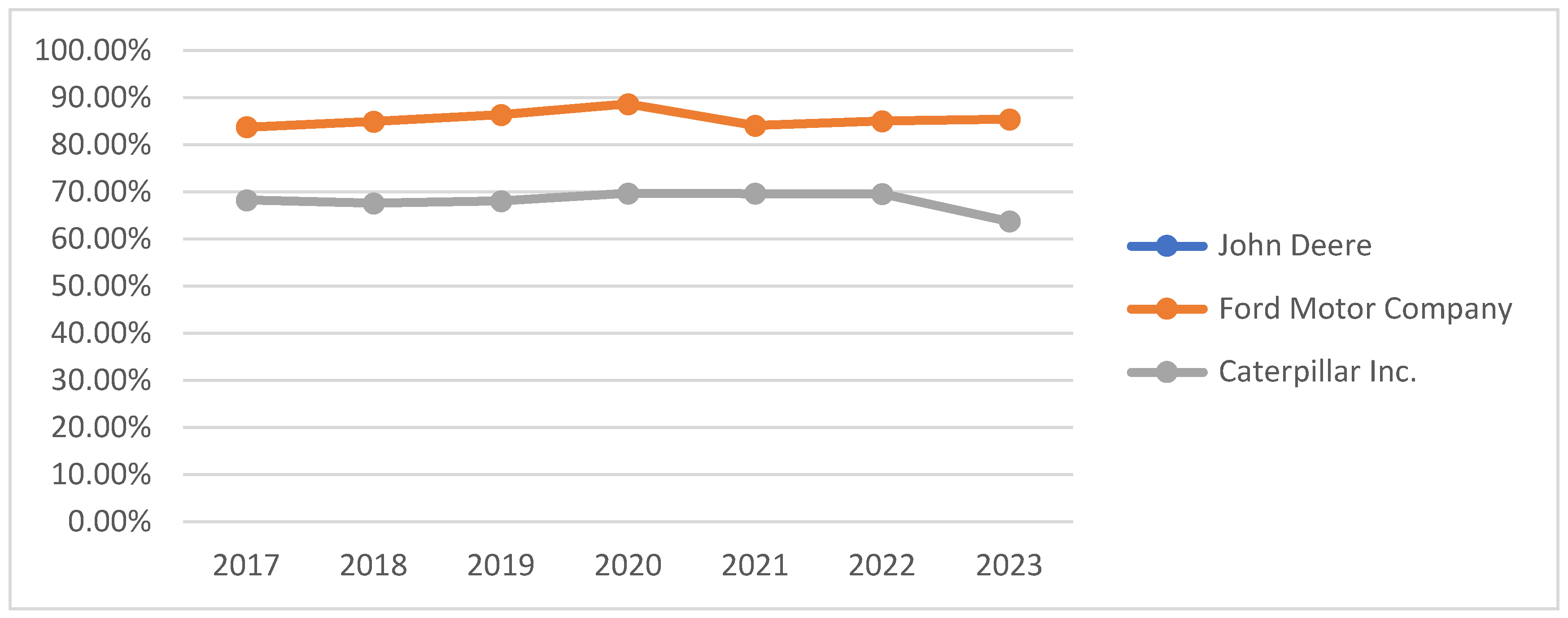

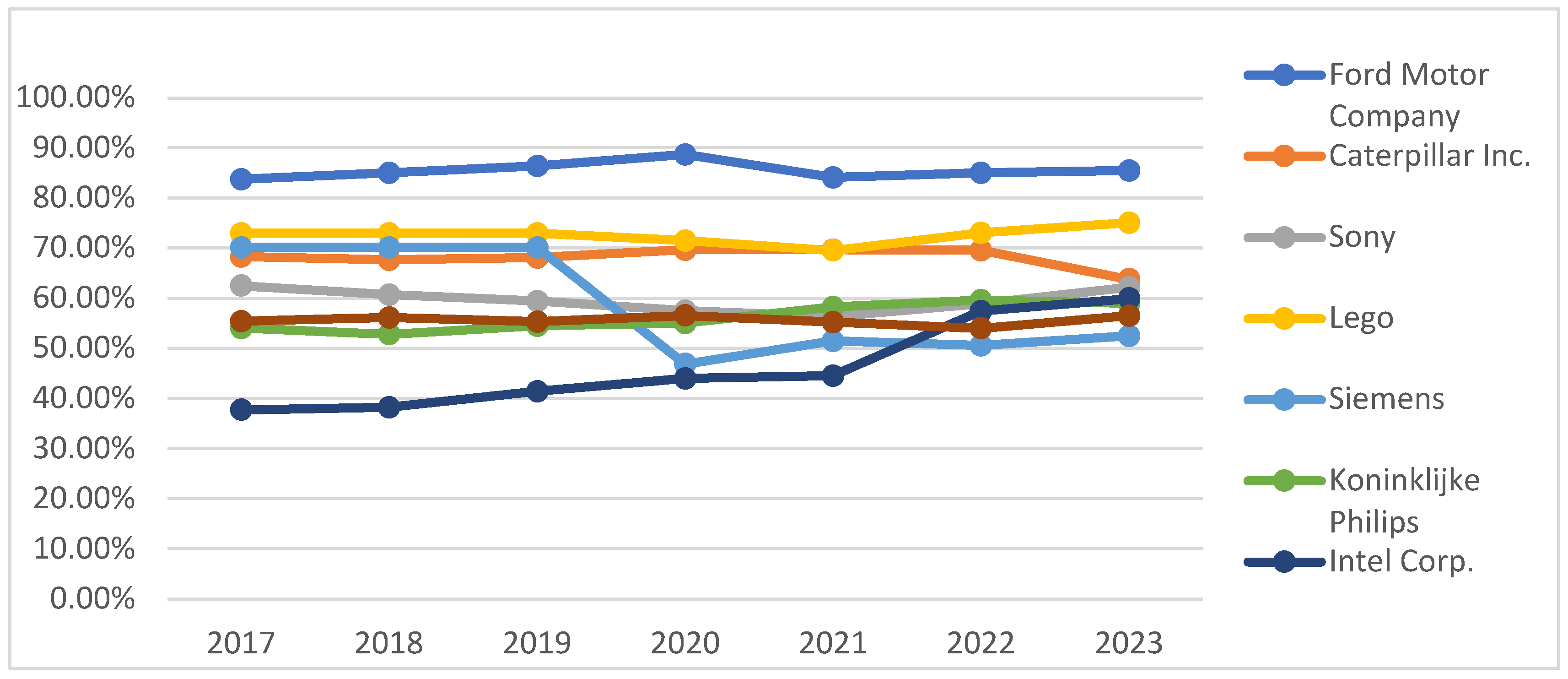

The share of these costs remains even more stable in companies applying SixSigma. (Fig. 3) and those combining Lean and Six Sigma (Fig. 4).

The same was also true in companies applying Agile and Lean (Fig. 4). In only one company in this group did the share of these costs decrease in a significant way in 2020. (46.88% from 70.15% before 2020). However, it remained at a similar level in the following years. Intel Corp. In contrast, these costs have steadily increased their share over the years - 37.75%, in 2017, 43.99% in 2020, 59.96% in 2023.

Thus, it is not apparent in any of these groups or individual companies that the application of management concepts is helping to increase the efficiency of production (and perhaps logistics) processes. On the other hand, it is also not apparent that, in this respect, phenomena in their environment, such as increases in energy prices, have had an impact on their efficiency. Perhaps, however, it is precisely this stability that demonstrates their great resilience - i.e. that they are able to keep costs under control despite crises or that they introduce innovative solutions that allow them to avoid the negative effects of these crises. However, in order to find an answer to this question, it would be necessary to carry out thorough research in these companies.

Figure 1.

Share of COGS in Revenue - Japanese companies applying Lean Management (2016 - 2023).

Figure 1.

Share of COGS in Revenue - Japanese companies applying Lean Management (2016 - 2023).

Figure 2.

Share of COGS in Revenue - US companies applying Lean Management (2016 - 2023).

Figure 2.

Share of COGS in Revenue - US companies applying Lean Management (2016 - 2023).

Figure 3.

Share of COGS in Revenue - US companies applying Six Sigmaement (2016 - 2023)..

Figure 3.

Share of COGS in Revenue - US companies applying Six Sigmaement (2016 - 2023)..

Figure 4.

Share of COGS in Revenue - US companies applying LeanSixSigma(2016 - 2023)..

Figure 4.

Share of COGS in Revenue - US companies applying LeanSixSigma(2016 - 2023)..

Figure 5.

Share of COGS in Revenue - US companies applying Lean and Agile (2016 - 2023).

Figure 5.

Share of COGS in Revenue - US companies applying Lean and Agile (2016 - 2023).

3.3. Interviews

The authors of this article conducted interviews in June and July 2024 with employees of companies operating in Poland that apply Lean Management, consultants serving such companies, and academics working on Lean Management issues.

The responses concerned a dozen companies from the following industries: food, metal (steel processing), furniture, aeronautics, automotive, engine production, plastic production, feed production, agricultural equipment production, yacht production,

The questions asked related to recent years:

Have costs increased or the economic situation worsened at a time of economic disruption and instability caused by the Covid-19 pandemic, the war in Ukraine and fluctuating energy prices?

Has the company had to make changes to its process organisation?

Has the increase in energy prices resulted in a shift away from the logistics strategies previously used (Just-In-Time), or have stocks increased as a result?

Is Lean crisis-proof?

The surveyed organizations operate in very different industries. Of the companies surveyed, the automotive industry has been most affected by the crisis of recent years, reducing sales and employment. It is the very industry from which Lean Management originated and is at the forefront of the concept. This raises the question of whether Lean is therefore crisises-proof. Opinions on this are divided, but several respondents believe it is not immune. However, one might ask, if these companies had not implemented Lean Management, wouldn't the crises have affected them even more?

Respondents from this industry are reporting improvements. For example, one manufacturer produced 300 engines in January 2023, 500 units in March and 700 units in July.

Due to the disruption, costs have increased and the economic situation has worsened at some companies. However, this was largely influenced by increased customer demands, resulting in higher costs. Companies using Lean are often companies working in integrated supply chains, so the economic situation depends largely on the partners in the chain, which is also influenced by the JIT strategy.

Here are some key reasons why production costs have increased:

Rising costs of raw materials and energy (the war in Ukraine)

Supply chain problems (caused by the Covid-19 pandemic)

Increase in labour costs (increase of the minimum wage)

Lean organizations has faced a serious challenge - safety standards on the one hand, and the need to maintain process time standards on the other.

Some companies had to make changes in the management of both processes and employees. Training and upskilling of employees was necessary. The pandemic situation - separation of employees from each other, hygiene - had a big impact here. However, according to respondents, the pandemic did not have as much impact on the organization of work and forms of production organization (production cells).

Companies that used Just-In-Time are still using it. The flow in the supply chain is still "Pull". On the other hand, solutions like those of Japanese companies can rarely be found in Polish companies. In the companies surveyed, deliveries are not made in directly to the production lines. Components supplied from suppliers are delivered close to the production machines, but often in quantities equivalent to, for example, several production days. In addition, the JIT system does not cover all components, but only some of them (e.g. 20%), and these are the ones with the highest value. There is also wide variation in the size of delivery batches, e.g., from 1 unit to 2,000 units.

The increase in transportation costs as a result of rising fuel prices therefore had little impact on the solutions used. Companies did not increase delivery volumes. Instead, inventories increased, but this was more due to an increase in safety stock levels. Changes in the supply of components or parts for production were more influenced than the increase in transportation costs by the uncertainty in the companies' environment resulting, for example, from the political situation (war in Ukraine) and the associated increase in delivery times and greater uncertainty about their timeliness. However, companies are trying not to increase inventory levels too much - they are trying to optimize them. Thus, the JIT system does not necessarily mean the complete elimination of inventories, because this is not its essence. In some companies, JIT is a solution used not in cooperation with the supplier, but in the internal chain if the company itself produces production parts. In some cases, JIT is imposed by the customer.

Not every company that claims to use Lean also uses Just-In-Time delivery. For example, a producer of food for animals, due to fluctuating raw material costs, buys raw materials in large quantities to stockpile at times when raw material prices are favorable. As a result, it achieved record profits during the crisis. This has also saved it from having to reduce its workforce and raise the prices of its products.

One of the people interviewed - dr. Czerska had similar (but only to a certain extent) comments :

« Lean is not immune to crises, and companies should adapt to phenomena in the modern world, which is facilitated by companies' use of lean thinking and lean management. As far as JIT is concerned, even if a company experiences an increase in transportation costs (as a result of rising energy prices), this does not mean that it is necessary to increase delivery volumes and inventories, because the distance between the manufacturer and its supplier can be shortened. »

To summarize it can be said that while there are differences of opinion, the more common view is that while Lean organizations are not entirely immune to crises, Lean allows them to get through them more easily. If they didn't use Lean, their situation would be even worse. For example companies like Mercedes are recovering from crises by winning new orders.

Prof. P. Walentynowicz gave an example of a company in the agricultural industry that did not apply Lean and is doing well, but he believes that if it had applied Lean, it would have done even better. However, Lean alone in its classic form is not enough - it needs to be combined with other concepts: Agile, Six Sigma, Industry 4.0. Agile strategy can be more effective in adapting to change, especially changes in the company's environment. Lean is immune to internal crises (poor management, organization). The Just-In-Time system may need to be modified - for example, to Just-In-Case. Lean can greatly enhance an organization's ability to survive and adapt in crises by focusing on efficiency, flexibility and continuous improvement. However, full resilience to crises requires more than just implementing Lean - companies should take appropriate steps to increase this resilience.

Mr. Paweł Dobek, a production optimizer in ZMM Maxpol believes that in this day and age, in the modern labor market, there is no choice but to invest in technological solutions (problems with employees, employee absenteeism - such as the lack of an experienced worker). In this company, the increase in productivity and labor efficiency in the long term has been achieved through the use of traditional tools (e.g. Poka-Yoke) to streamline processes with the support of modern technology (3D printing technology, robots and cobots). But it is important to maintain a balance between automation and human labor. In this company AI solutions are implemented gradually and with great care.

The company has been using Lean Management for more than five years (that is, before the pandemic) and has succeeded in reducing waste, simplifying processes and increasing productivity. The pandemic has not caused the company's economic situation to deteriorate; on the contrary, the company has increased its profits. In the period of 5 before the implementation of Lean, i.e. 2014-2018, the company recorded a 5.02% increase in the annual average The Overall Equipment Effectiveness (OEE) indicator.

Costs at this company have increased due to inflation, the market situation and supply chain disruptions caused by the pandemic. However, the use of Lean Management helped it get through difficult times and adapt faster to changes in the market. These changes did not mean fundamental changes in the organization, but process improvements that allowed for increased productivity. The company did not move away from JIT, but tried to apply solutions to reduce energy costs (renewable energy sources, installation of photovoltaic panels, energy recovery in various ways).

However, in Mr. Dobek's opinion, Lean is not immune to crises, but a Lean organization is more likely to survive in difficult times.

4. Discussion and Conclusions

The authors conducted research based on a literature review, an analysis of financial results of companies applying Lean Management, Agile and Six Sigma concepts (as well as their combinations), which are well known and appreciated by theoreticians and practitioners, and interviews with representatives of companies applying (or declaring to apply) Lean Management, including Just-In-Time.

Based on the literature review, the authors conclude that:

Lean management generally has a positive impact on energy efficiency through the elimination of waste.

‘Lean manufacturing’ is considered one of the most effective methods of managing also energy, especially the use of tools such as 5S, Visual Workplace, standardised work, poka-yoke, Total Productive Maintenance (TPM, SMED, value stream mapping).

In companies that have implemented concepts such as Six Sigma or Agile, there are also initiatives aimed at reducing energy consumption, e.g. Agile can be used to streamline processes (and as a result increase energy efficiency) in both production and transport.

Even greater benefits can be achieved by combining Lean and Agile or Lean and Six Sigma concepts and using hybrid solutions. Benefits can also be achieved by combining the digital technologies of Industry 4.0 with the tools of Lean Manufacturing.

One method aimed at analysing energy consumption and its reduction is the Leanergy method, which extends source savings to processes and operations.

To achieve high energy efficiency, it is necessary to analyse energy and resource consumption in detail, rather than simply hoping to avoid wasting them by streamlining processes.

Based on an analysis of the financial results of Polish companies, multinationals and companies that apply Lean Management, Agile and Six Sigma strategies, the authors conclude that:

In determining the impact of an increase in the cost of energy consumption on financial performance, the average values of the change in net profits and the share of COGS in revenue were calculated for all these companies. It turned out that there were very large differences between the individual companies in each group, which shows that it is not only the management concept itself or its processes that are important, but how the concept is implemented and perhaps also other factors.

In general, the situation was better in companies using combinations of strategies (Lean and Agile or Lean and Six Sigma), confirming that the views presented in the literature.

It is not apparent that any of the management concepts used are helping to increase the efficiency of production processes, but on the other hand it is also not apparent that the increase in energy prices is impairing their efficiency, which may indicate that despite crises these companies are able to keep costs under control or that they are introducing innovative solutions that allow them to avoid the negative effects of these crises.

Based on the interviews conducted in Polish companies, which implemented "Lean Management", the authors conclude that:

The rise in fuel and energy prices has not affected the move away from the just-in-time concept. Companies that have used Just-In-Time and continue to use it. However, there are opinions that the Just-In-Time system may need to be modified, e.g. to Just-In-Case.

The majority of respondents believe that although Lean organisations are not immune to crises, Lean allows them to get through these crises more easily. If they did not use "Lean" their situation would be worse.

Some point out that Lean in its classic form alone is not enough - it needs to be combined with other concepts: Agile, Six Sigma, Industry 4.0 in order to adapt to changes taking place in a company's environment.

Lean can significantly enhance an organisation's ability to survive and adapt in crises thanks to its focus on efficiency, flexibility and continuous improvement. However, full resilience to crises requires taking take appropriating and may be new steps.

The surveyed companies are aiming to reduce energy consumption, using renewable energy sources.

Although "Lean" organizations are not immune to crises, they get through them more easily. However, greater benefits can be achieved by using hybrid solutions, such as combining Lean and Agile or Lean and Six Sigma concepts. Lean management generally has a positive impact on energy efficiency by eliminating waste, but in order to achieve high energy efficiency, it is necessary to analyze energy consumption in detail and proactively implement solutions to reduce energy consumption.

However, in addition to the problem of the resilience of these concepts to crises in their environment, there is another issue on which requires further research. Namely, whether we are facing significant transformations in both companies and their economic, social and technical environment. This is particularly true of the concept of Lean Management, which contains interesting and surprising contradictions. One very distinctive one is the combination of innovation and creativity with a conservative approach to certain problems. This has manifested itself in the approach to technical solutions. Proponents of Lean Management have always prided themselves on the fact that it is a concept that uses the potential contained in people and their creativity, rather than technical solutions. It seem however, that in the current times, when we have problems in the labor market on the one hand, and rapid technological advances (e.g. artificial intelligence) on the other, these conservative views, preached for decades should be revised.

There is a need to continue research on the energy efficiency of business management concepts and their processes and verify the already conducted. For example, according to the results of studies already cited in this article, there is a positive impact of Lean Management tools on the environmental efficiency (Teixeira et. al., 2021). However there were also a small number of cases where it was found that an increased consumption of energy and water lean tools was induced by implementing SMED (Single Minute Exchange of Dies). It is suprising because the effect of such tools should be not only reductions of time of setups and changovers but also costs and also costs of energy.

This raises questions about whether the surveyed companies are actually using Lean Management tools and whether the employees of these companies understand the meaning of the terms used in the literature ?

The general conclusion that emerges from the research is that the effectiveness of the management systems, systems and tools used does not mean that they are the answer to all problems. It refers especially to the problem of energy consumption - even if given tools, e.g. “Lean Management” indirectly promote energy efficiency, specialized tools are needed. Lean Management is not a concept that provides immunity to instability in the environment, and its assumptions should be revised and long-term trends of a social nature (aging population) should be taken into account, and the opportunities offered by modern technologies should be used.

The financial results, especially the continuing similar (high) share of costs (COGS) in the value of sales, seem to confirm the need to revise the management methods used so far.