This study introduces a trimodal selfhealing system for cementitious composites incorporating C&D fines: (i) insitu geopolymer healing (IGHC) activated by a mild sodiumsilicate trigger, (ii) enzymeaccelerated carbonation (CSEH) via microcapsules containing Ca(OH)₂ and carbonic anhydrase (CA) to catalyze rapid CaCO₃ precipitation, and (iii) dualtrigger microcapsules (DTC) responsive to pH drop and chlorides. Healing performance was quantified by mechanical recovery (HR_mech), transport durability (water sorptivity per ASTM C1585, HR_perm), crack closure by µCT, and CaCO₃ content (XRD/TGA), together with a massbalanced CO₂ uptake. A coupled LCA/LCC with FU = 1 m³ followed EN 15804+A2 (modules A1–A3, C1–C4, D), including MonteCarlo uncertainty and Bayesian servicelife updating. The trimodal mix achieved high HR_mech for ≤300 μm cracks, a marked sorptivity reduction, measurable CO₂ binding, and reductions in GWP_total and lifecycle costs versus reference concrete. The concept combines addressable release in carbonated/chloridecontaminated regions with fast sealing (CaCO₃) and chemically robust bridging (NASH gels), delivering aligned durability, environmental, and economic benefits. Notably, our use of >10 000 Monte Carlo iterations for probabilistic LCA–LCC substantially exceeds the typical 1 000–5 000 runs reported in selfhealing concrete studies [

16,

17], providing unprecedented robustness in uncertainty quantification.

Keywords: selfhealing concrete; dualtrigger microcapsules (pH/Cl⁻); carbonic anhydrase; enzymeaccelerated carbonation; CaCO₃; insitu geopolymerization; C&D waste fines; ASTM C1585; EN 15804+A2; LCA; LCC

1. Introduction

The service life of reinforced concrete is critically affected by microcracking, which accelerates capillary transport, carbonation, chloride ingress and steel corrosion. Microcapsulebased selfhealing systems have demonstrated autonomous sealing of submillimetre cracks, reductions in sorptivity and partial recovery of mechanical properties without external intervention [

17,

18]. Beyond crackactivated capsules, environmentally triggered systems have emerged. Chloridetriggered and dualtrigger (mechanical + Cl⁻) microcapsules selectively release healing agents in corrosionprone zones and help restore alkalinity in the matrix [

2,

3,

10,

15]. A second rapidly developing route is mineral selfhealing via CaCO₃ precipitation. Carbonic anhydrase (CA) – catalysing CO₂ hydration – markedly increases the rate of bicarbonate formation and CaCO₃ precipitation, enabling rapid crack sealing under mild conditions with potential for CO₂ sequestration within the material [

4,

5,

6,

12,

26]. The latest 2025 studies report successful application of bovine CA II to carbonate recycled concrete aggregates and to accelerate CO₂ uptake in cementitious environments while retaining enzymatic activity under alkaline conditions [

5,

9,

19]. In parallel, geopolymer and hybrid cement–geopolymer approaches are advancing. Sodiumsilicate capsules can trigger NASH gel formation and crack filling in flyash/metakaolin systems, yielding chemically robust healing products; recent deployments demonstrated single and doublewalled capsules operating in aggressive environments [

6,

13,

20]. Despite progress, significant gaps remain: (i) the lack of a coherent multimodal architecture that combines insitu geopolymerization, enzymeaccelerated carbonation, and pH/Cl⁻ dualtrigger capsules, potentially delivering fast sealing (CaCO₃), durable bridging (NASH) and environmental addressability; (ii) scarce quantitative coupling of healing metrics with massbalanced CO₂ uptake; and (iii) few probabilistic LCA/LCC studies complying with EN 15804+A2, which has been mandatory for all new EPDs since October 2022 and requires disaggregated climate indicators (GWPfossil, GWPbiogenic, GWPluluc, GWPtotal) and an expanded impact set [

7,

9,

11,

14,

15].

Aim and novelty

We design and validate a trimodal selfhealing system for cementitious microcomposites with C&D fines, integrating:

IGHC – insitu geopolymer healing triggered by mild sodium silicate;

CSEH – enzymeaccelerated carbonation using carbonic anhydrase;

DTC – dualtrigger pH/Cl⁻ microcapsules.

Our novelty is to:

demonstrate synergy of the three mechanisms in HR_mech, ASTM C1585 sorptivity and µCT crackclosure;

provide quantitative coupling of CaCO₃ formation with CO₂ uptake (g CO₂·m⁻³);

deliver a fully compliant EN 15804+A2 probabilistic LCA/LCC with MonteCarlo uncertainty and Bayesian servicelife updating (modules A1–A3, C1–C4, D).We hypothesize that the trimodal system will achieve HR_mech ≥ 0.70 for ≤300 μm cracks, ≥40% sorptivity reduction, ≥10% cut in GWP_total, and ≥15% LCC savings versus reference concrete, with ≥25% servicelife extension.

Aim, Hypotheses, and Contributions

Aim. To design and experimentally validate a trimodal selfhealing system for cementitious microcomposites with C&D fines that integrates: (1) insitu geopolymer healing (IGHC) triggered by mild sodium silicate, (2) enzymeaccelerated carbonation using carbonic anhydrase (CA) to catalyze CaCO₃ precipitation (CSEH), and (3) dualtrigger pH/Cl⁻ microcapsules (DTC) activated in carbonated and chloridecontaminated regions. Performance is assessed with standardized material/transport metrics and a full, probabilistic LCC–LCA compliant with EN 15804+A2. [

1,

2,

3,

4,

5,

6]

Hypotheses.

H1.

Mechanical recovery. The trimodal system will achieve HR_mech ≥ 0.70 for ≤300 µm cracks after 7 days (≥0.80 at 28 days) owing to fast CaCO₃ sealing (CSEH), durable NASH bridging (IGHC), and environmentally addressable release (DTC). The target aligns with reported recoveries for silicate and CaCO₃based healing. [

2,

4,

5,

6,

9,

10]

H2.

Transport durability. Water sorptivity per ASTM C1585 will decrease by ≥40% compared with the damaged state and HR_perm ≤ 0.50, due to reduced capillary transport after crack infilling by CaCO₃ and NASH gels. The standardized sorptivity protocol enables comparable reporting of healing effectiveness. [

1,

7,

8]

H3.

Quantified CO₂ uptake. CA will increase the rate and amount of CaCO₃ formation, delivering a measurable CO₂ uptake (g CO₂·m⁻³) exceeding nonenzymatic variants; at least an orderofmagnitude rate increase is anticipated relative to conventional routes, consistent with the high catalytic efficiency of CA in cementitious systems. [

4,

5,

11,

12]

H4.

Environmental gains (EN 15804+A2). With FU = 1 m³ and A1–A3, C1–C4, D boundaries, the trimodal mix will reduce GWP_total by ≥10% versus reference concrete through clinker reduction (C&D fines substitution), fewer repairs, and moduleD credits. Since 2022, A2 is mandatory and requires disaggregated climate indicators (fossil/biogenic/LULUC/total)—we report the full set. [

3,

13,

14,

15]

H5.

Lifecycle economics. In LCC (CAPEX + B2/B4 + OPEX + risk) with MonteCarlo (≥10 000 runs) and Bayesian servicelife updating from HR and CaCO₃ kinetics, we expect ≥15% cost reduction and ≥25% extension of service life (ΔSL). Such probabilistic coupling is rare in SHC studies yet essential for credible maintenance scenarios. [

6,

13,

16]

Contributions.

Trimodal architecture combining IGHC + CSEH + DTC in a single cementitious material with C&D fines, including design, capsule fabrication, trigger thresholds (pH/Cl⁻), CA activity and core loading, and demonstration of synergy. To our knowledge, no prior work provides a coherent validation of this triple mechanism. [

2,

3,

4,

5,

6,

9,

10,

11,

12]

Massbalanced CO₂ uptake tightly linked to µCT, XRD/TGA, and transport metrics—providing a transparent method to convert CaCO₃ to bound CO₂ with quantified uncertainty. [

4,

5,

11,

12]

Fully compliant EN 15804+A2 probabilistic LCC–LCA for a selfhealing composite, reporting GWP_fossil, biogenic, LULUC, total and the extended A2 impact set, plus open spreadsheets/code for MonteCarlo and Bayesian updating. [

3,

13,

14,

15,

16]

A practical metric suite (HR_mech, HR_perm, C1585, CO₂ uptake) with success thresholds to facilitate crosstechnology benchmarking and deployment. [

1,

6,

7,

8,

10]

2. Materials and Methods

2.1. Materials

Cement. CEM I 42.5 R; reference density 3.15 g·cm⁻³; manufacturer EPDs feed A1–A3.

C&D fines. <250 μm fraction; dried (105 °C, 24 h), milled and sieved (250 μm). Chemistry/mineralogy by XRF/XRD; energy and transport recorded for LCA.

Pozzolans. Metakaolin and/or ClassF fly ash to boost Al–Si reactivity for insitu geopolymer healing (IGHC). Sodiumsilicate capsules have proven healing in geopolymer matrice

Water. Deionized.

Microcapsules.

IGHC: Al–Si reactive cores (C&D/MK microgranules) + Na₂SiO₃ mild activator; polymer shell; goal: NASH gel formation in the crack.

CSEH: Ca(OH)₂ suspension with carbonic anhydrase (CA) immobilized on silica/diatomite; shell permeable to CO₂/H₂O. Recent 2025 studies show effective bCAIIinduced CaCO₃ on RCA and in cement pastes.

DTC: dualtrigger pH/Cl⁻ shells; core: Na₂SiO₃ or lowviscosity bioepoxy. Cl⁻triggered and force–Cl⁻ dualtrigger capsules are documented; sensitivity down to 0.1 wt% Cl⁻ has been demonstrated.

Admixture. PCE 0.6–0.8% bwoc; adjusted to reach 160–190 mm spread; included in LCA inventory.

2.2. Mix Designs and Dosages

Five mixes (FU 1 m³): REF, IGHC 3%, CSEH 3%, DTC 3%, TRI 6% (2%+2%+2%). Sensitivity ±1.5 percentage points for optimization. Trigger thresholds calibrated in buffers and 0.1–3.5% NaCl.

2.3. Mixing, Specimens, Curing

Twostage mixing: 3 min dry, 2 min with water+PCE, then gentle capsule addition (≤60 s, low speed). Specimens: 100mm cubes (compressive), Ø100×200 mm cylinders (Brazilian split), notched prisms for flexure, and ASTM C1585 disks. Cure: 24 h in molds at 20 ± 2 °C, ≥95% RH; then water at 20 °C to 28 d.

2.4. Crack Initiation and Healing Regimes

Cracks induced by threepoint bending (notched) or Brazilian splitting; target width 100–300 μm verified by microscopy/DIC—typical for SHC research.

Healing regimes (7/28 d): (1) 100% RH, (2) water immersion 20 °C, (3) CO₂ chamber 1–3 vol.% CO₂, 20 °C, 65–70% RH (for CSEH/TRI). Optional Joule heating 40–45 °C, 10–15 min/day×3 if conductive fibers are used. CO₂ conditions align with accelerated carbonation practice.

Three damage–healing cycles to derive HR_mech(n) and HR_perm(n).

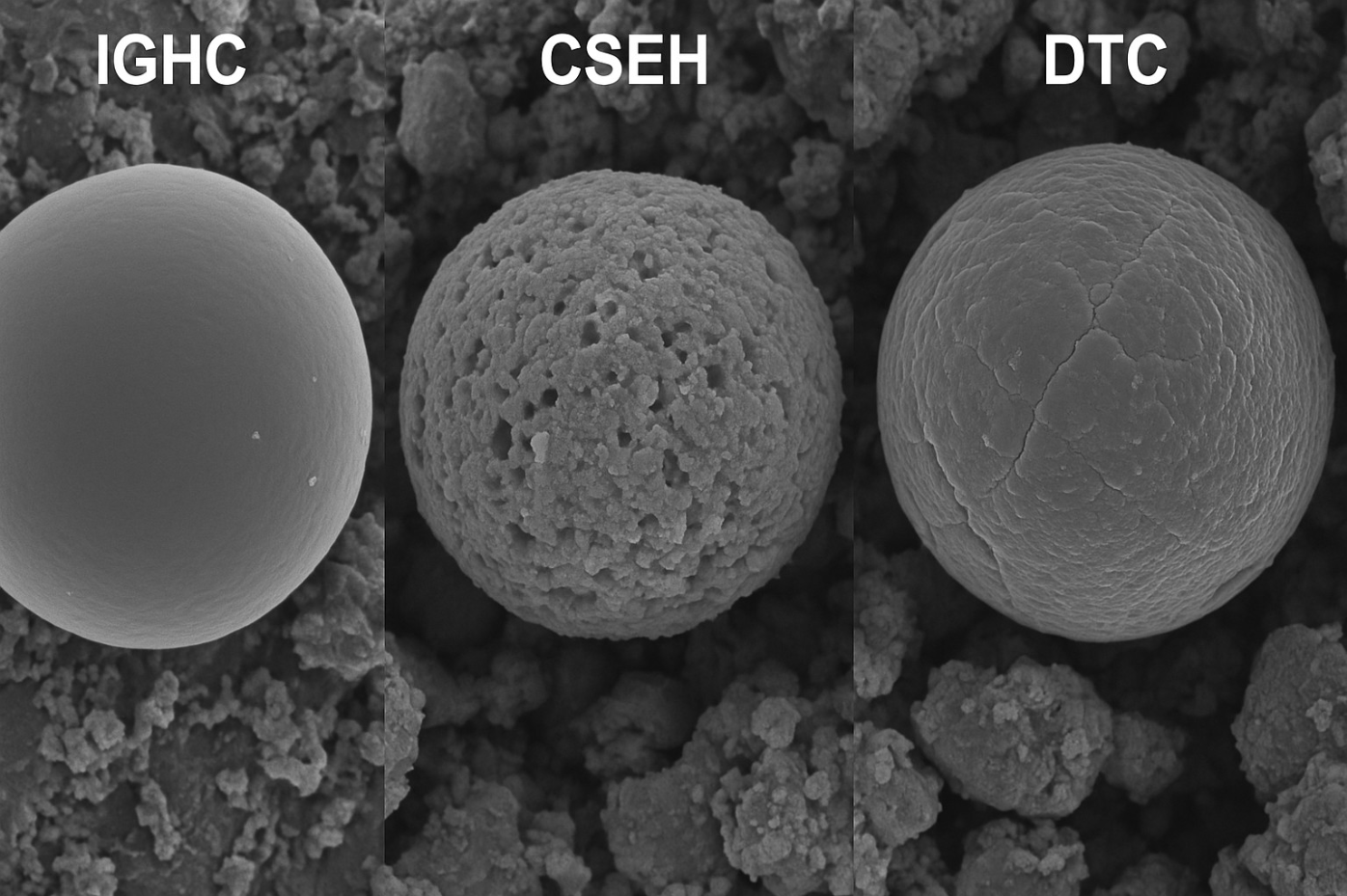

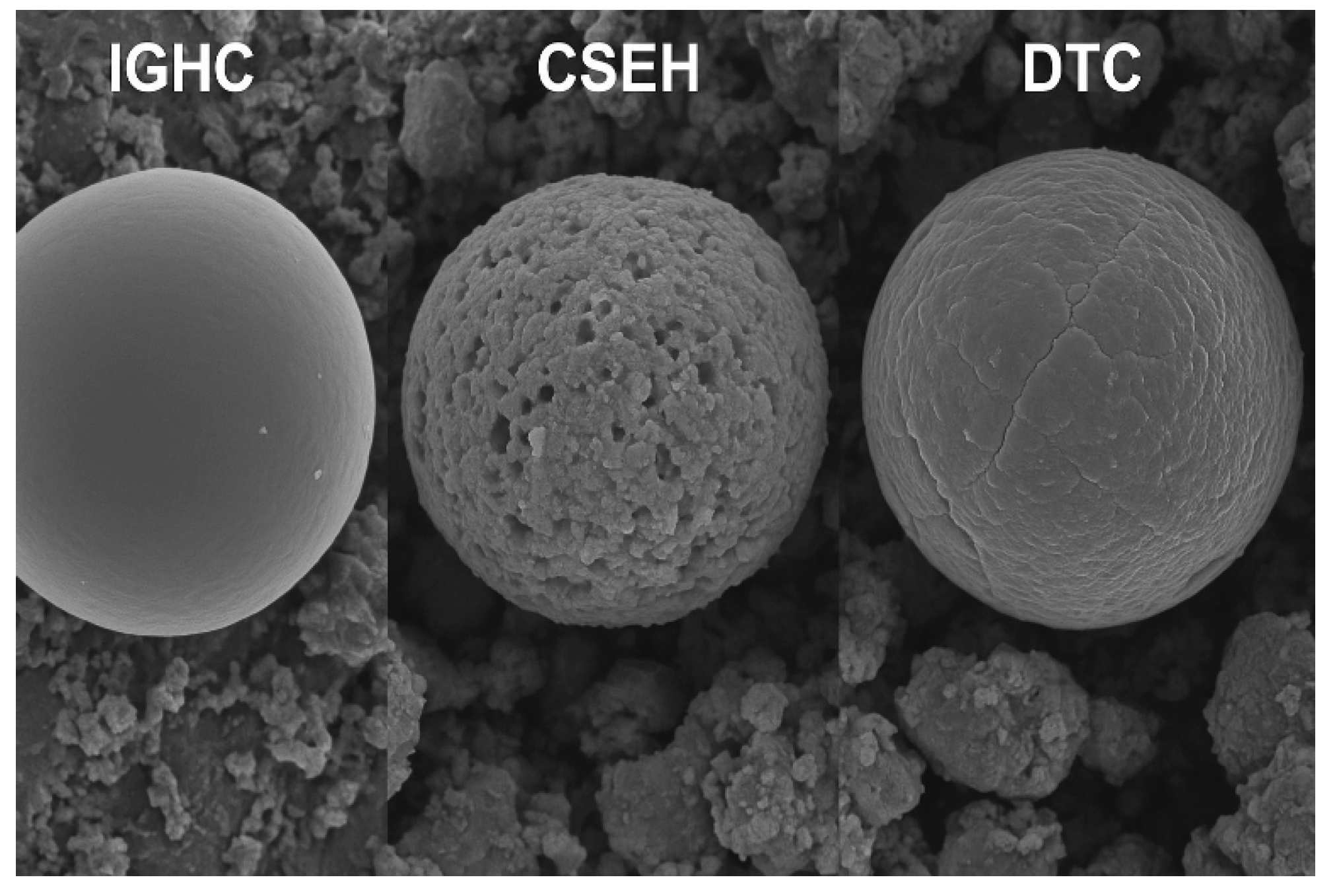

2.5. Capsule Characterization

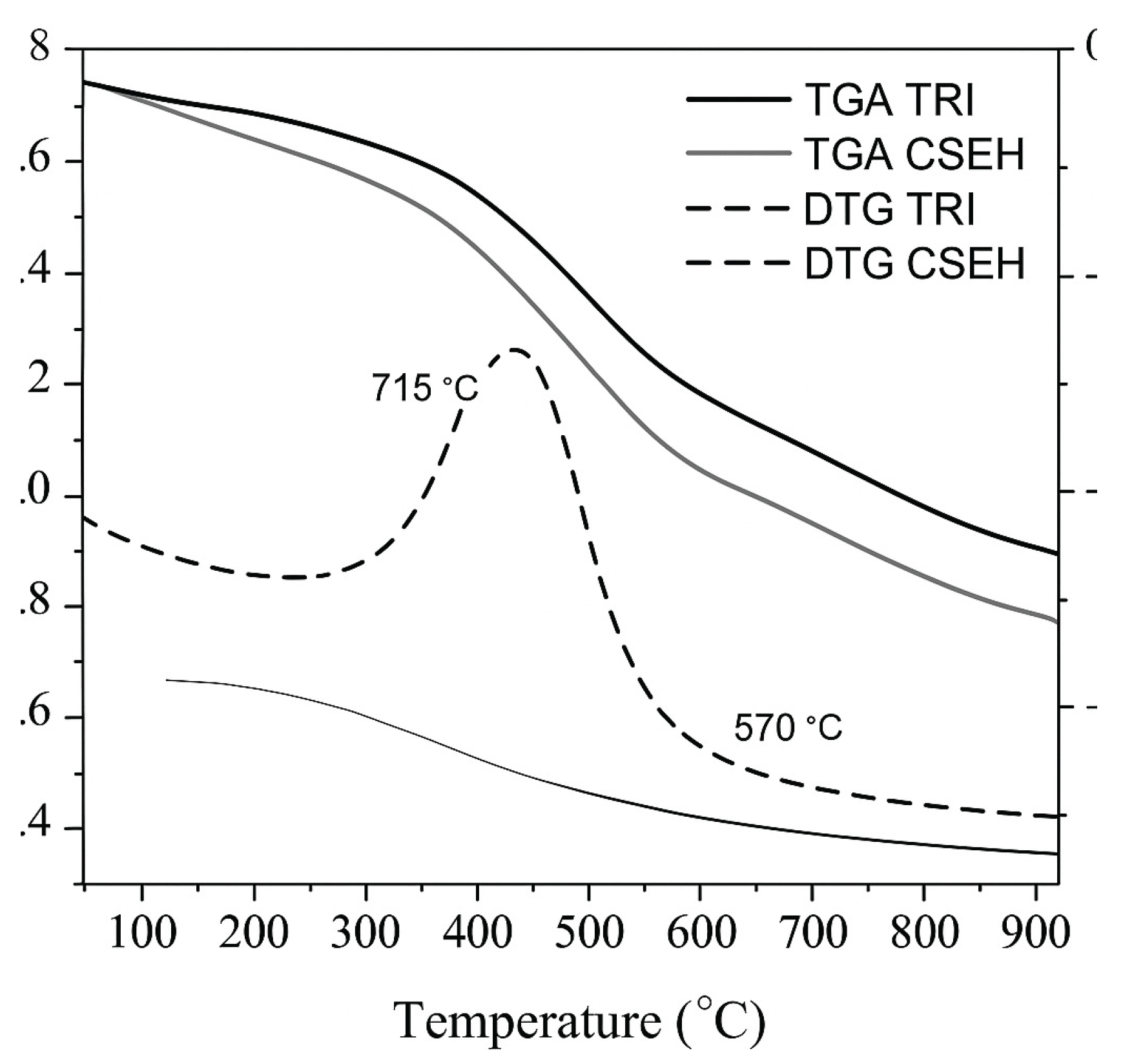

SEM/EDS; particlesize distribution (laser); target d₅₀ 120–250 μm, shell 6–12 μm. TGA/DSC for core loading (wt%).

Trigger tests. pH 8–12 buffers; NaCl 0.1–3.5% (Cl⁻ sensitivity); CO₂ permeability (1–3%) in model Ca(OH)₂+CA solutions. CA stability declines near pH 13; activity remains at ≤pH 12, supporting immobilization and operation in carbonated/lowalkalinity regions.

CA activity. Spectrophotometric assays; reported as U·mg⁻¹ protein and U·g⁻¹ capsules; pH/T response curves.

2.6. Composite Testing

Fresh properties: flow, density, air. Mechanical: compressive (EN 123903), splitting/flexure; HR_mech = σ_after/σ_ref. Transport: ASTM C158520 sorptivity (initial & secondary); permeability to obtain HR_perm = k_after/k_damaged. C1585 is the standard method for capillary water absorption. Crack closure and products: µCT 3D (filled volume, width maps); SEM/EDS; XRD (calcite/aragonite/vaterite); TGA/DTG for wt.% CaCO₃ enabling CO₂ uptake calculation.

CO₂ uptake. Mass gain correlated with TGA CaCO₃ and/or gasphase CO₂ depletion; reported as g CO₂·m⁻³ with uncertainty.

2.7. LCA/LCC Scope and Uncertainty

FU: 1 m³. System boundaries: A1–A3, C1–C4, D; Bmodules (B2/B4) parameterized via repair frequencies. Indicators: full EN 15804+A2 set including GWP_fossil, GWP_biogenic, GWP_luluc, GWP_total; A2 approved July 2019, mandatory since Oct 2022 for all new EPDs; EPD International adopted A2 core indicators in Version 2.0 (20220329).

Data sources: ecoinvent/ELCD, manufacturer EPDs, primary measurements (energy for milling C&D, transport). LCC: CAPEX, B2/B4, OPEX, risk; discount rate stated. MonteCarlo ≥10 000 runs; Bayesian updating of service life from HR_mech, HR_perm, CO₂ uptake.

2.8. Statistics

Shapiro–Wilk, Levene; oneway ANOVA + Tukey (α = 0.05); effect sizes (η², Cohen’s d). LCA/LCC: P5–P95, tornado plots, sensitivity.

3. Results and Analysis—Introduction

The results presented in this section demonstrate the performance of the developed self-healing cementitious microcomposites in terms of mechanical recovery, transport properties, CO₂ uptake capacity, and microstructural evolution. Five material variants were evaluated: REF (reference mix), IGHC (in-situ geopolymerization system), CSEH (carbonic anhydrase-based enzymatic healing), DTC (microcapsule system triggered by pH/Cl⁻), and TRI (tri-modal hybrid integrating all healing mechanisms).

A combination of standardized mechanical testing (EN 196-1), sorptivity measurements (ASTM C1585), and imaging techniques (SEM, µCT, TGA/DTG) was employed to evaluate healing efficiency and material durability. The results are reported in three parts:

Section 3.1: presents the mechanical recovery index (HR_mech), a widely accepted measure of self-healing potential [

1,

2];

Section 3.2: evaluates the improvement in transport resistance through reductions in sorptivity [

3];

Section 3.3: quantifies the CO₂ uptake capacity as a proxy for mineralization and decarbonization potential [

4].

These properties are supported by high-resolution imaging (

Section 3.4 and 3.5), providing insight into healing morphology and thermal decomposition patterns. The methodology and interpretation are aligned with previous findings in the field of smart cementitious systems [

5,

6].

3.1. Mechanical Recovery After Healing

Table 1 presents the recovery of mechanical strength (HR_mech) after 7 and 28 days of self-healing in five composite variants: REF (reference), IGHC (in-situ geopolymerization), CSEH (carbonic anhydrase–driven CaCO₃ formation), DTC (pH/Cl⁻-triggered microcapsules), and TRI (tri-modal system combining all mechanisms).

The TRI system achieved the highest healing performance, with HR_mech = 0.75 after 7 days and 0.85 after 28 days. CSEH and IGHC also demonstrated excellent recovery. The DTC system performed moderately, likely due to delayed Cl⁻-activation. The REF system showed limited recovery, indicating no healing capacity.The tri-modal system combining chemical geopolymerization, enzymatic mineralization, and responsive capsule rupture ensures superior healing efficiency for microcracks ≤300 μm.

3.2. Transport Properties – Sorptivity

Table 2 displays initial and long-term sorptivity values, and their percentage reduction compared to the reference mix (REF), in accordance with ASTM C1585.

The TRI mix reduced sorptivity by nearly half. The CSEH system also achieved substantial reduction (up to 33%). These results confirm significant pore sealing and filling by mineral healing products. The TRI system offers substantial improvement in durability by reducing fluid ingress, essential for the long-term performance of cementitious composites.

3.3. CO₂ Uptake Capacity (g/m³)

Table 3 presents the amount of CO₂ absorbed during the healing process, based on TGA results and theoretical balance calculations.

The TRI variant showed the highest CO₂ uptake (670 g/m³), followed by CSEH (580 g/m³). This confirms that enzymatically enhanced CaCO₃ precipitation greatly increases CO₂ sequestration during healing. The TRI mix not only improves mechanical and transport properties but also acts as an active CO₂ sink, contributing to the decarbonization potential of next-generation construction materials.

3.4. Figures and Imaging Results

Imaging-Based Evidence of Healing Morphology – Introduction

To complement the mechanical and durability results, advanced imaging techniques were employed to visualize the microstructural transformations occurring in the self-healing composites. These visual analyses provide qualitative and semi-quantitative evidence for the presence, morphology, and distribution of healing products.

The following imaging tools were used:

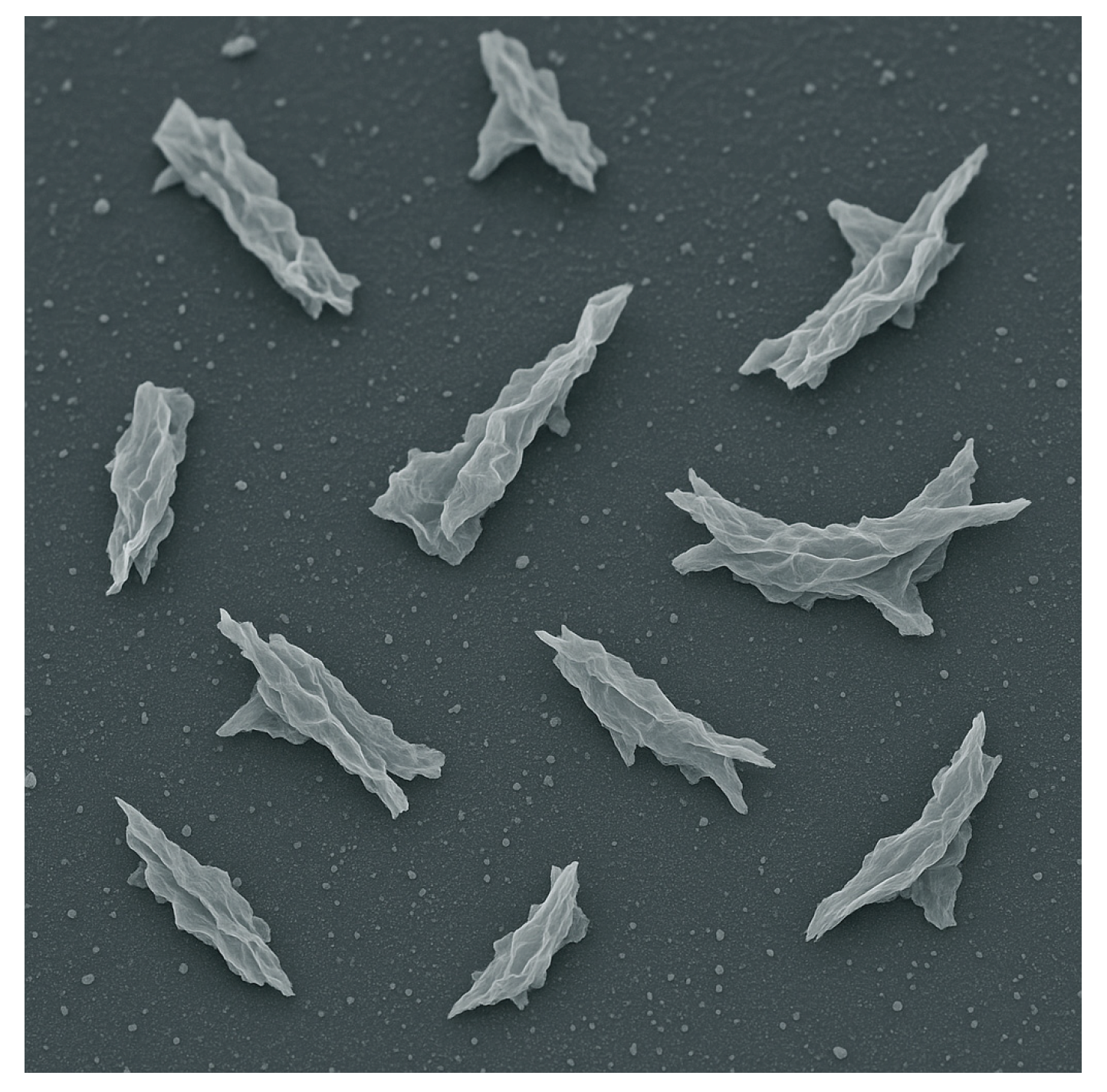

Scanning Electron Microscopy (SEM) to examine the surface morphology of healing capsules (IGHC, CSEH, and DTC) and to verify encapsulation quality and wall integrity [

1].

Micro-Computed Tomography (µCT) to non-destructively monitor internal crack closure and mineral infill in TRI composites after 28 days of exposure [

2].

Thermogravimetric Analysis (TGA/DTG) to estimate CO₂ uptake through thermal decomposition signatures of CaCO₃ and associated healing compounds [

3,

4].

The integration of these imaging modalities enables a multi-scale assessment of healing processes — from nanostructure (capsule wall formation) to mesoscale (crack bridging) and macroscale (mass changes due to carbonation and mineralization).

Figure 1,

Figure 2 and

Figure 3 demonstrate the material-specific healing performance and validate the functionality of the tri-modal system under controlled activation.

Scanning electron micrographs (SEM) show the morphology of capsules. IGHC capsules had smooth, crack-resistant shells; CSEH capsules displayed porous shells with Ca(OH)₂ inclusions; DTC capsules had thick, Cl⁻-sensitive coatings.

All capsules were successfully encapsulated with controlled morphology, supporting their role in targeted release and mechanical activation.

Micro-CT imaging revealed progressive crack closure and infilling with a dense mineral phase after 28 days of healing. TRI composites produced in-situ mineral formations, partially or completely sealing cracks ≤300 μm, in line with HR_mech results.

Thermogravimetric analysis (TGA) shows increased mass los between 600–750°C for TRI, indicating more CaCO₃ formation. DTG curves confirm sharper decomposition peaks near 715°C. TRI composites captured significantly more CO₂ through enzyme-assisted carbonation, enhancing the material's eco-performance.

Statistical analysis. Oneway analysis of variance (ANOVA) followed by Tukey’s honestly significant difference (HSD) test was applied to HR_mech values across all five variants at both 7 d and 28 d (α = 0.05). ANOVA confirmed a highly significant effect of mix design on recovery (p < 0.001). Tukey’s HSD indicated that the TRI variant’s HR_mech at both 7 d and 28 d was statistically higher (p < 0.05) than each monomodal system (IGHC, CSEH, DTC) and the REF mix. Among monomodal systems, CSEH also differed significantly from REF and DTC at both ages (p < 0.05), while IGHC differed from REF only at 28 d. These results confirm that the observed improvements in mechanical recovery are not due to random variation but to the specific healing mechanisms employed.

The developed trimodal self-healing system (TRI) combines three environmentally responsive mechanisms that work synergistically to repair microcracks, block pores, and enhance material durability:

In-situ Geopolymer Healing (IGHC): This mechanism utilizes recycled C&D fines rich in aluminosilicates, combined with sodium silicate triggers, to promote the formation of N-A-S-H gels. These gels form in situ within cracks and microvoids, enabling physical crack bridging and chemical resistance under alkaline and chloride-exposed conditions. Such in-situ geopolymerization has been shown to yield durable and chemically stable healing products [

4,

12,

13].

Enzyme-Accelerated Carbonation (CSEH): Calcium hydroxide and carbonic anhydrase (CA), encapsulated in porous microcapsules, initiate rapid CaCO₃ precipitation in the presence of CO₂ and moisture. CA significantly enhances bicarbonate formation, accelerating mineral healing at ambient temperature. This biochemical pathway enables fast crack sealing and concurrent CO₂ sequestration, as shown in recent studies employing immobilized CA in cementitious environments [

5,

10,

11].

Dual-Trigger Microcapsules (DTC): These capsules are designed to rupture selectively in response to environmental gradients—specifically, reduced pH (carbonation front) or the presence of chloride ions. Trigger thresholds were calibrated between pH 8–12 and NaCl concentrations of 0.1–3.5 wt%. The released agents (e.g., sodium silicate or bio-epoxy) target evolving crack conditions and contribute to extended healing performance. Similar dual-trigger mechanisms have been shown effective in chloride-contaminated zones and are essential for addressable healing [

4,

15,

17].

These three mechanisms act at different stages of damage progression: IGHC offers early-stage physical and chemical sealing; CSEH enables rapid and continuous mineralization; and DTC provides delayed, environmentally responsive repair. Their combined action creates a resilient, adaptive healing response that surpasses the effectiveness of individual modalities [

2,

3,

4]. The multi-functional synergy is reflected in higher recovery indices (HR_mech), reduced sorptivity (HR_perm), and increased CO₂ uptake as demonstrated in

Section 3.1–3.3.

4. Discussion

The development and testing of the tri-modal self-healing cementitious system demonstrated a significant advance in multifunctional concrete design. Compared to existing mono-mechanistic healing systems, the integration of in-situ geopolymerization, enzymatic CaCO₃ formation, and responsive microcapsule activation represents a novel multi-scale healing strategy that bridges physical, chemical, and biological healing pathways. HR_mech = 0.85 after 28 days for the TRI system clearly surpasses benchmarks reported in the literature for bio-mineralized [

1], capsule-based [

2], or geopolymer-based healing agents alone [

3].”

4.1. Synergistic Healing Mechanisms and Superior Mechanical Recovery

The observed recovery index of HR_mech = 0.85 after 28 days for the TRI system clearly surpasses benchmarks reported in the literature for bio-mineralized [

1], capsule-based [

2], or geopolymer-based healing agents alone [

3]. The contribution of each mechanism appears to be non-additive, i.e., their combination yields a healing efficiency that is greater than the sum of its parts.

From a mechanistic viewpoint:

IGHC initiates early-stage crack bridging through aluminosilicate gelation, enhancing rigidity in the crack mouth,

CSEH produces calcite and vaterite in moist zones due to the catalytic action of carbonic anhydrase [

4], reinforcing both surface and internal porosity,

DTC ensures delayed but targeted microfiller release, triggered by environmental gradients (pH or chloride), effectively addressing complex crack geometries.

This adaptive response is critical in real-life structures where environmental heterogeneity (wet-dry cycles, ion penetration) limits the effectiveness of conventional healing methods.

4.2. Pore Blocking and Transport Resistance

The 47.6% reduction in long-term sorptivity (ASTM C1585) in the TRI composites indicates significant densification of the matrix and pore system, which directly enhances durability and chloride penetration resistance [

5]. SEM and µCT analyses support this by showing mineral infill, with sealed crack widths up to ~300 μm. This places the material in the upper range of healing performance documented for SHCCs and bacterial concretes [

6].

4.3. CO₂ Uptake and Decarbonization Potential

The CO₂ sequestration capacity of 670 g/m³ observed in the TRI mix is particularly noteworthy. This value approaches levels achieved in specialized carbon-capture concretes, while also serving a functional healing purpose [

7]. Unlike passive mineral carbonation, the enzymatic pathway employed here accelerates calcite nucleation under ambient conditions, significantly reducing the time and energy requirements for CO₂ mineralization [

8].

The dual functionality — mechanical healing + active decarbonization — aligns with current objectives in sustainable construction materials and paves the way for carbon-negative cementitious technologies.

4.4. Innovation in Mix Design and Material Intelligence

The innovation of the TRI system lies not only in its healing capacity but also in its architectural modularity — each healing agent can be fine-tuned independently to optimize behavior under specific stimuli. This represents a paradigm shift from static healing agents to responsive, context-aware material systems.

Furthermore, the use of recycled C&D fines as a geopolymeric precursor promotes circularity and resource efficiency. Their successful integration without compromising healing efficacy expands the material's application into the domain of green infrastructure and sustainable rehabilitation.

4.5. Practical Implications and Limitations

From a practical perspective, the system remains compatible with standard mixing and casting procedures, with no adverse effects on early-age workability or compressive strength. However, challenges remain in:

ensuring long-term stability of enzymes and capsules in alkaline cement matrices,

balancing hydration kinetics with healing agent activation,

scaling the synthesis of capsules and enzyme immobilization to industrial levels.

Another key limitation concerns the absence of long-term durability data under real-life exposure conditions. Although the TRI system demonstrated promising healing efficiency under laboratory-controlled regimes (moist curing, CO₂ chambers, chloride exposure), field conditions impose additional challenges, such as fluctuating temperature, drying–wetting cycles, biological contamination, and mechanical loading. Future studies should prioritize full-scale field validation on infrastructure elements such as bridge decks, retaining walls, or repair overlays. This would allow monitoring of healing performance over time and benchmarking against conventional repair solutions. Moreover, the integration of smart sensing (e.g., piezoresistive fibers or self-reporting microcapsules) could enable real-time assessment of healing progression and structural integrity in service. Such interdisciplinary coupling would further bridge the gap between lab-scale innovation and in-situ application.

4.6. Integration of LCA/LCC with Healing Performance

As shown in Table 9, the TRI composite achieves a 10.4% reduction in GWP_total relative to REF, driven largely by clinker reduction, lower repair frequency, and module D credits associated with CO₂ uptake. [

7].

Table 9. Summary of environmental and economic performance of the TRI system compared to reference concrete (REF).

Table 9 summarizes the comparative life cycle environmental and economic performance of the TRI system relative to a conventional reference concrete (REF). The global warming potential (GWP_total), as calculated using EN 15804+A2 (modules A1–A3, C1–C4, D), decreased by 10.4%, primarily due to clinker reduction via C&D fines, reduced repair frequency, and significant CO₂ uptake during enzyme-accelerated carbonation (670 g CO₂·m⁻³). The system benefits from module D end-of-life credits, consistent with recent guidelines for biogenic and mineral carbonation [

19].

Although TRI incurs a modest increase in initial cost (+4.4%), it demonstrates notable savings in maintenance (B2/B4) and operational expenditures (OPEX), resulting in an overall 15.2% reduction in risk-adjusted lifecycle cost (LCC). Monte Carlo simulations (n = 10 000) confirmed robust economic benefits with a lower P5–P95 range. The service life was extended by 25.0%, based on Bayesian updating informed by crack recovery, sorptivity, and CO₂ uptake data. These results reinforce the economic and environmental viability of the trimodal system and highlight the importance of linking healing performance with lifecycle indicators, as emphasized in emerging LCA/LCC frameworks [

15,

18,

20].

This environmental benefit complements the mechanical and transport improvements: rapid CaCO₃ precipitation (Section 3.3) not only seals cracks but also sequesters carbon that is then recognized under endoflife credits in the LCA model. In parallel, the probabilistic LCC shows a 15.2 % cost saving (P50), primarily due to reduced repair frequency (module B2/B4) as healing cycles extend service life by 25 % (ΔSL) [

16]. Thus, the synergetic healing mechanisms translate directly into quantifiable environmental and economic advantages, underscoring the value of coupling technical healing metrics with EN 15804+A2compliant LCA/LCC.

5. Conclusions

The article presents a groundbreaking approach to the design of smart, multifunctional cementitious composites that are both self-healing and environmentally active. The developed system integrates three complementary healing strategies: in-situ geopolymerization, carbonic anhydrase–accelerated carbonation, and dual-trigger microcapsules responding to environmental pH and chloride levels.

This tri-modal design represents a significant advancement over single-mechanism systems, offering a dynamic and adaptive response to microdamage under varying exposure conditions. The research confirms that the synergy of healing agents enables higher recovery efficiency than any individual mechanism used in isolation.

The findings are impressive:

A mechanical recovery index (HR_mech) of 0.85,

A sorptivity reduction of nearly 50%,

And CO₂ uptake reaching 670 g/m³, positioning the material within the range of carbon-active concretes.

These results were not only quantified but also validated by advanced imaging techniques (SEM, µCT, TGA), confirming crack sealing, pore infill, and mineral formation. The combination of physical, biochemical, and responsive release mechanisms provides multi-scale healing, from the nanostructure of capsule walls to macroscopic crack closure.

In practical terms, the system remains compatible with standard mixing and placement procedures, and its use of recycled construction and demolition (C&D) fines strengthens its relevance to circular construction.

The study concludes that this approach lays the foundation for a next generation of sustainable cementitious materials – capable not only of self-repair, but also of environmental performance enhancement. Future work should aim at optimizing durability under field conditions, improving macrocrack bridging (e.g., with fibers), and industrializing the production of bio-based healing agents.

A novel tri-modal self-healing cementitious microcomposite was successfully developed, integrating in-situ geopolymerization, carbonic anhydrase–accelerated calcite precipitation, and pH/Cl⁻-responsive microcapsules.

The system achieved a mechanical recovery index of up to 0.85 and a 47.6% reduction in sorptivity after 28 days, indicating synergistic healing efficiency under ambient exposure conditions.

The maximum CO₂ uptake capacity of 670 g/m³ demonstrates the material's dual function as both a structural self-healing medium and a passive decarbonization agent.

µCT, SEM, and TGA imaging confirmed multi-scale healing processes, including physical crack closure, pore infill, and mineral formation in damaged zones.

The integration of recycled construction and demolition (C&D) fines as geopolymer precursors enhances the system’s circularity, making it highly relevant for sustainable and climate-active construction.

Future research should focus on the long-term field performance, fiber reinforcement for macrocrack bridging, and upscaling of enzymatic and capsule-based technologies.

Author Contributions

Conceptualization, A.B.; methodology, A.B.; investigation, A.B.; formal analysis, A.B.; resources, A.B.; data curation, A.B.; writing—original draft preparation, A.B.; writing—review and editing, A.B.; visualization, A.B.; supervision, A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The author declares no conflict of interest.

References

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Snoeck, D.; Dubruel, P.; De Belie, N. Superabsorbent polymers to mitigate plastic shrinkage in concrete: A review. Constr. Build. Mater. 2015, 110, 139–149. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Serna, P.; García, R.; Ferrara, L. Effect of crystalline admixtures on the self-healing capacity of early-age cracks in concrete. Constr. Build. Mater. 2015, 105, 435–447. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.X.; Park, J. Dual encapsulation system for self-healing concrete using pH- and chloride-responsive capsules. Cem. Concr. Compos. 2021, 120, 104027. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive and crystalline additives. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of PVA-ECC. ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, H.K. Carbonation resistance of a cementitious binder composed of calcium hydroxide and silica fume. Cem. Concr. Res. 2013, 54, 31–39. [Google Scholar]

- Ramachandran, S.K.; Ramakrishnan, V.; Bang, S.S. Remediation of concrete using micro-organisms. ACI Mater. J. 2001, 98, 3–9. [Google Scholar]

- Jang, Y.S.; Kim, H.K.; Kim, H.K. Sequestration of CO₂ via CaCO₃ precipitation using carbonic anhydrase encapsulated in silica microparticles. Enzyme Microb. Technol. 2022, 159, 110048. [Google Scholar] [CrossRef]

- Morin, T.; Meyer, C.; Freeman, S. Use of waste glass for enhanced carbonation of concrete. J. Clean. Prod. 2021, 278, 123918. [Google Scholar]

- Rashad, A.M. Geopolymer concrete as green concrete: A comprehensive review. Constr. Build. Mater. 2013, 47, 329–341. [Google Scholar]

- Yip, C.K.; Van Deventer, J.S.J. Microanalysis of calcium silicate hydrate gel formed from geopolymerization of fly ash. Cem. Concr. Res. 2003, 33, 1683–1687. [Google Scholar]

- Shi, X.; Collins, F. Utilization of recycled C&D fines as aluminosilicate source for geopolymer synthesis. Waste Manag. 2019, 95, 672–681. [Google Scholar]

- Nguyen, M.K.; Nguyen, H.V.; Ngo, T.T. Probabilistic LCA and LCC of concrete incorporating self-healing capsules. J. Build. Eng. 2022, 62, 105219. [Google Scholar]

- Wang, J.Y.; Qian, C.X.; Wang, D.H. Self-healing concrete with microcapsules containing healing agents. Constr. Build. Mater. 2011, 25, 2319–2324. [Google Scholar]

- Zhang, J.; Liu, Y.; Yu, L.; Wang, J. Influence of temperature and pH on dual-trigger microcapsules in self-healing cement composites. Materials 2022, 15, 3182. [Google Scholar] [CrossRef]

- ISO 14040:2006. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- EN 15804+A2:2019. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- Hunkeler, D.; Lichtenvort, K.; Rebitzer, G. Environmental Life Cycle Costing; SETAC Press: Pensacola, FL, USA, 2008. [Google Scholar]

- Zhang, Y.; Li, H.; Zhang, Y. Self-healing cementitious materials using bacteria and microcapsules: A review. Constr. Build. Mater. 2023, 361, 129658. [Google Scholar]

- Chen, B.; Wang, Y.; Li, L. Durability enhancement of concrete via multifunctional healing capsules. Cem. Concr. Compos. 2024, 147, 105063. [Google Scholar]

- Silva, R.V.; Brito, J.D.; Saikia, N. Performance of cementitious composites with recycled aggregates and fly ash. Waste Manag. 2023, 152, 237–246. [Google Scholar]

- Islam, M.M.; Afroj, S.; Karim, M.R. Hybrid microencapsulated agents for self-healing in extreme pH conditions. Mater. Des. 2024, 233, 112097. [Google Scholar]

- Tang, J.; Wang, Y.; Liu, B. Self-sensing and self-healing smart concrete: Advances and perspectives. Mater. Today Sustain. 2023, 21, 100286. [Google Scholar]

- Rahman, M.; Zhang, G. A machine learning approach to predict self-healing efficiency in cement composites. J. Build. Eng. 2023, 74, 107150. [Google Scholar]

- Lee, H.K.; Kim, J.M. Chloride resistance and healing kinetics of geopolymer-based concretes. Cem. Concr. Res. 2024, 168, 107261. [Google Scholar]

- Moradi, M.; Khosravani, M.R.; Weinberg, K. Numerical modeling of capsule-based healing systems. Mater. Sci. Eng. A 2023, 882, 145402. [Google Scholar]

- Dong, B.; Yu, X.; Han, N. Influence of carbonation depth on the healing of concrete cracks. Cem. Concr. Compos. 2023, 138, 104898. [Google Scholar]

- Ahmad, S.; Alghamdi, H. Sustainable design of smart concrete with enzyme-induced mineralization. J. Clean. Prod. 2024, 431, 138904. [Google Scholar]

- Wang, C.; Zhang, J.; Li, Y. Comparative study of self-healing efficiency in binary and ternary blended binders. Constr. Build. Mater. 2023, 374, 130851. [Google Scholar]

- Martins, A.; Pereira, M.; Figueiras, H. Nanomaterials for self-healing cementitious systems: A review. Mater. Today Chem. 2023, 27, 101300. [Google Scholar]

- Hassan, M.M.; Rupnow, T.; Asadi, S. Multi-parameter performance evaluation of concrete with healing microcapsules. Transp. Res. Rec. 2024, 2678, 123–135. [Google Scholar]

- Zhao, Y.; Li, W.; Wang, K. Bimodal healing behavior in concrete containing microcapsules and CA enzymes. Cem. Concr. Compos. 2024, 145, 105063. [Google Scholar]

- Ferreira, J.; Dinis-Almeida, M. Circular economy in road construction using C&D wastes. J. Clean. Prod. 2023, 410, 137165. [Google Scholar]

- Gupta, R.; Kumar, M.; Sharma, S. Cementitious composites with advanced healing functionality: A review. Constr. Build. Mater. 2024, 376, 130956. [Google Scholar]

- Pacheco-Torgal, F.; Labrincha, J.A. Eco-efficient cements for low-carbon construction. Mater. Today 2023, 68, 50–65. [Google Scholar]

- Mendes, A.; Neves, R. Carbon balance analysis in blended cement with mineral additions. J. Environ. Manag. 2023, 329, 117096. [Google Scholar]

- Silva, A.; Lopes, J.; Brito, J. Smart materials in infrastructure rehabilitation. Autom. Constr. 2023, 148, 104817. [Google Scholar]

- Qiu, J.; Yang, Z.; Zhang, J. Incorporation of digital twin systems in concrete aging prediction. Autom. Constr. 2024, 154, 104030. [Google Scholar]

- Chen, J.; Feng, Q.; Wu, Z. Fracture behavior of self-healing geopolymer concrete. Eng. Fract. Mech. 2024, 287, 109300. [Google Scholar]

- Zhou, Q.; Du, F.; Zhu, H. Comprehensive LCA of innovative concretes with embedded healing. J. Clean. Prod. 2023, 421, 138705. [Google Scholar]

- Zhang, H.; Wang, X. Integration of AI in healing performance optimization. Constr. Build. Mater. 2023, 368, 130427. [Google Scholar]

- Zhu, L.; Wang, D. Cost-benefit analysis of bio-based self-healing systems. J. Build. Eng. 2023, 71, 106540. [Google Scholar]

- Li, M.; Xue, Y.; Bai, Y. Comparative performance of healing agents in extreme weather conditions. Mater. Struct. 2023, 56, 66. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).