Submitted:

15 July 2025

Posted:

16 July 2025

You are already at the latest version

Abstract

Keywords:

Introduction

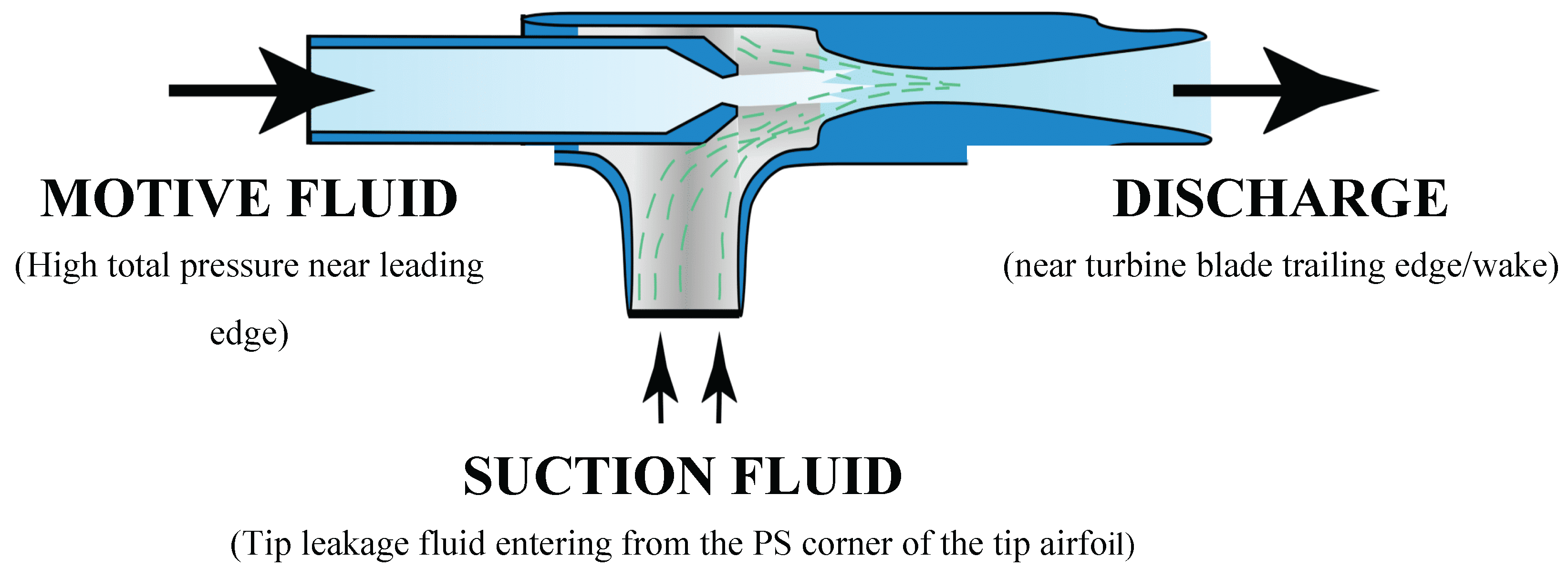

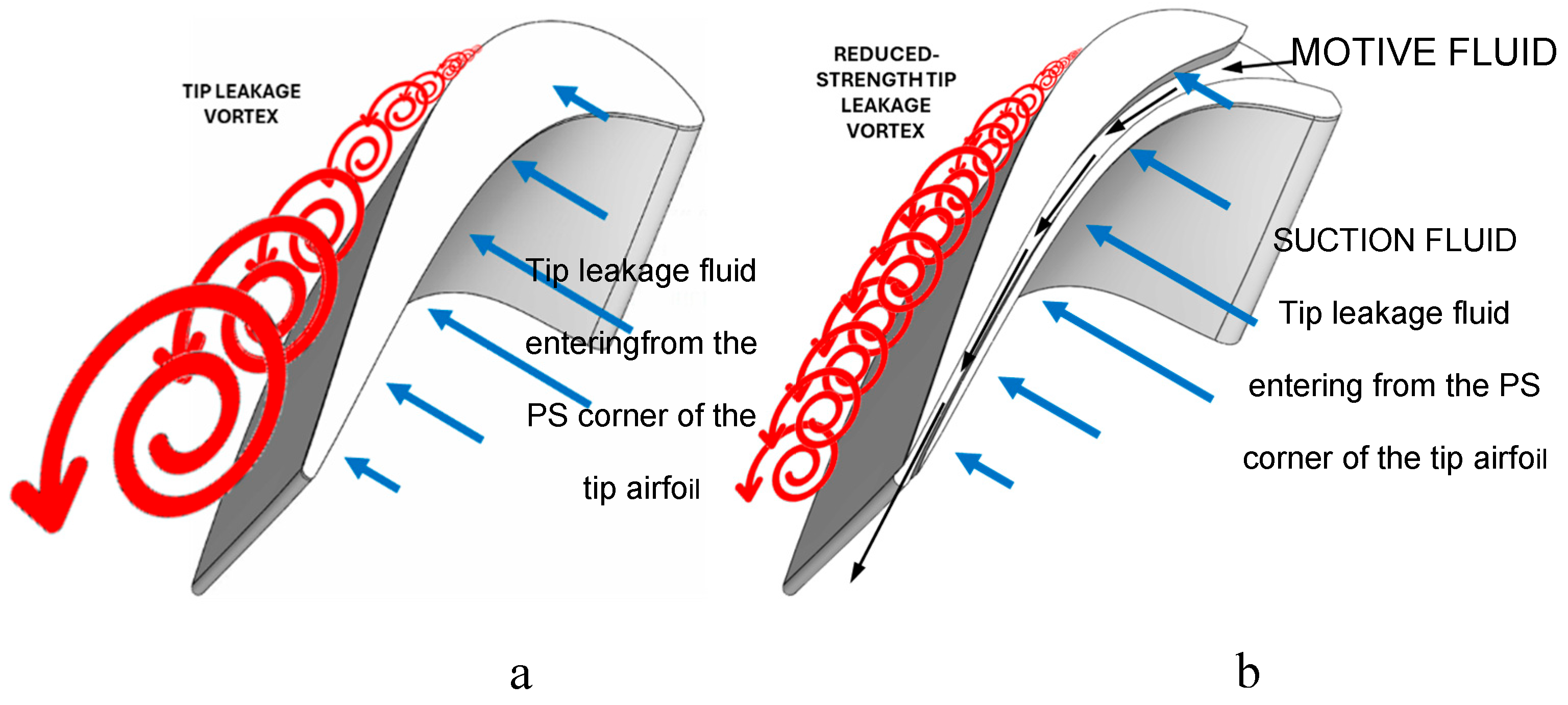

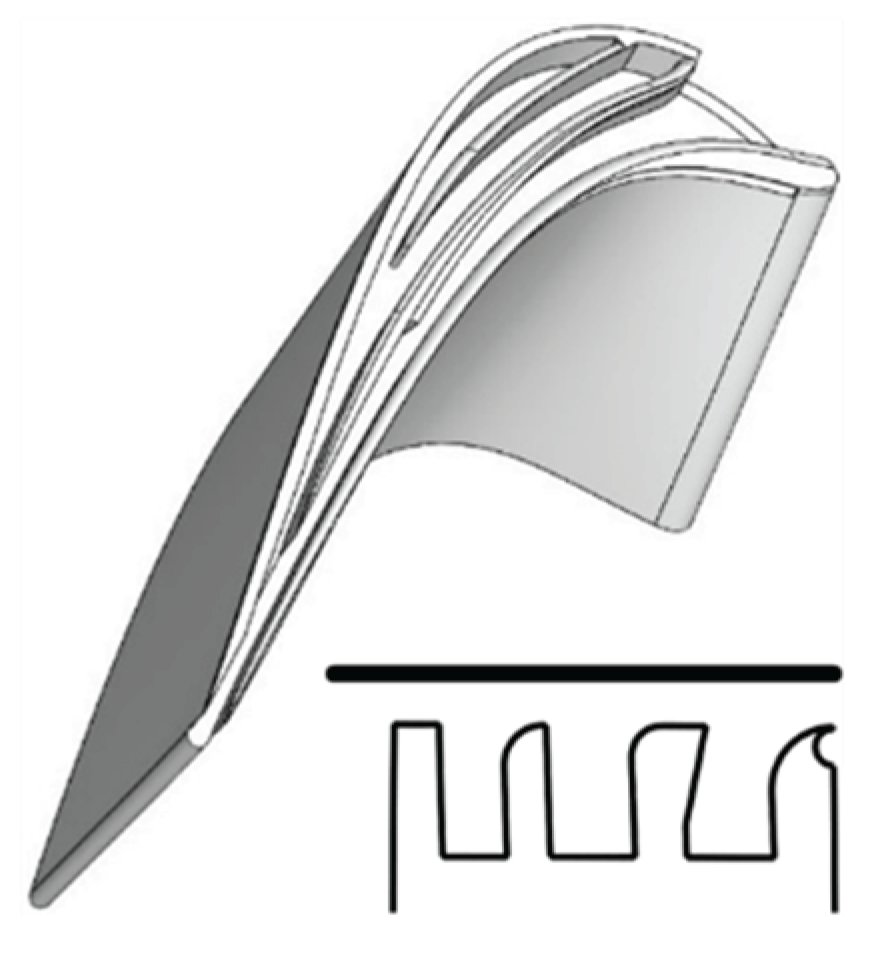

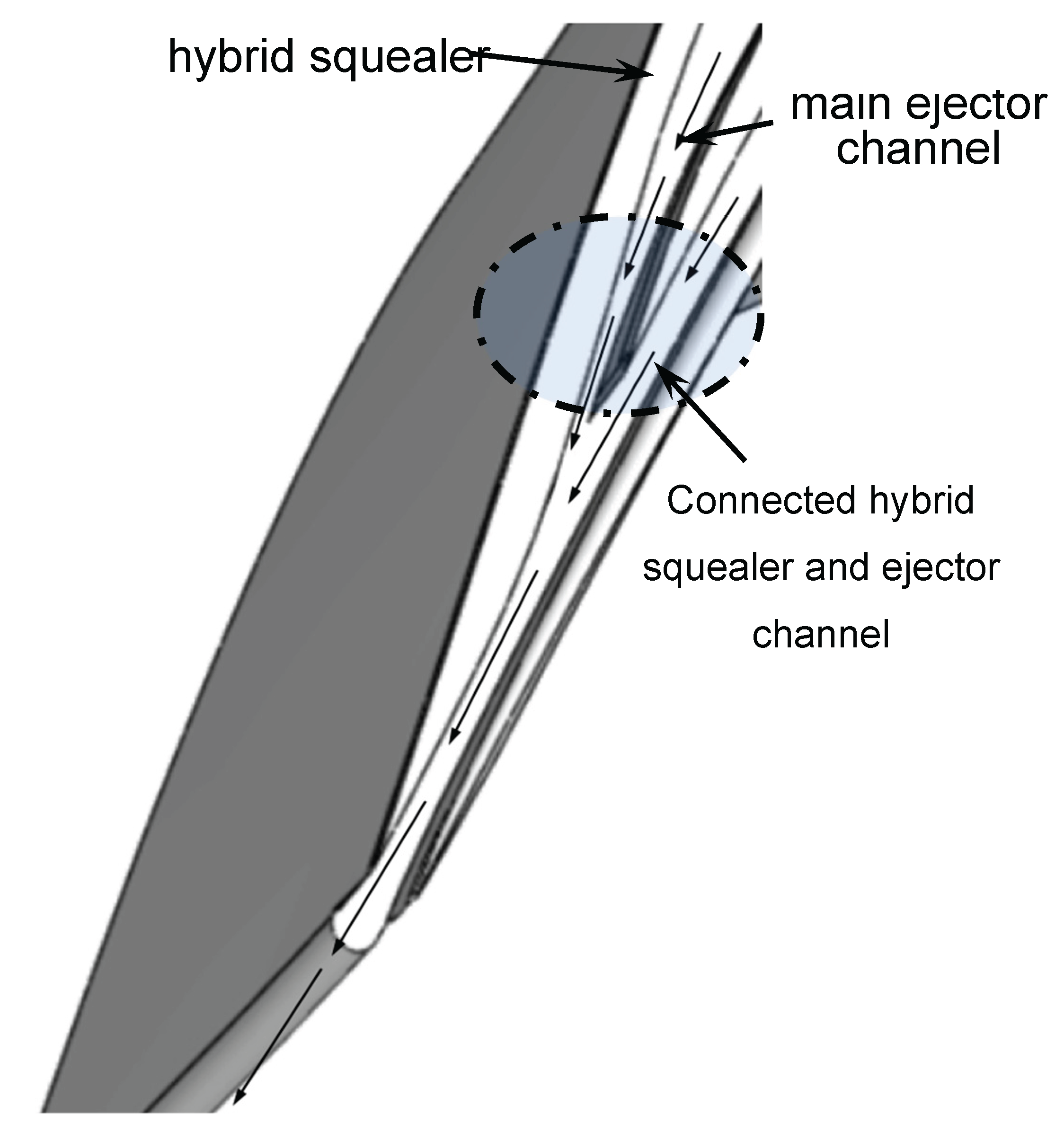

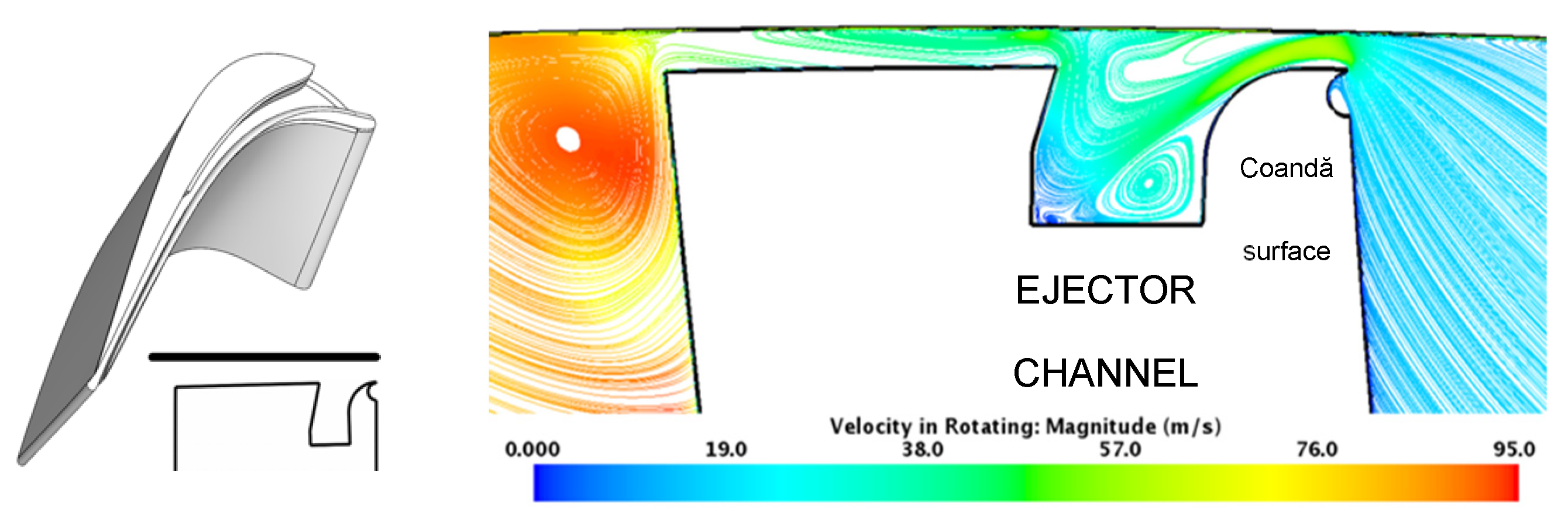

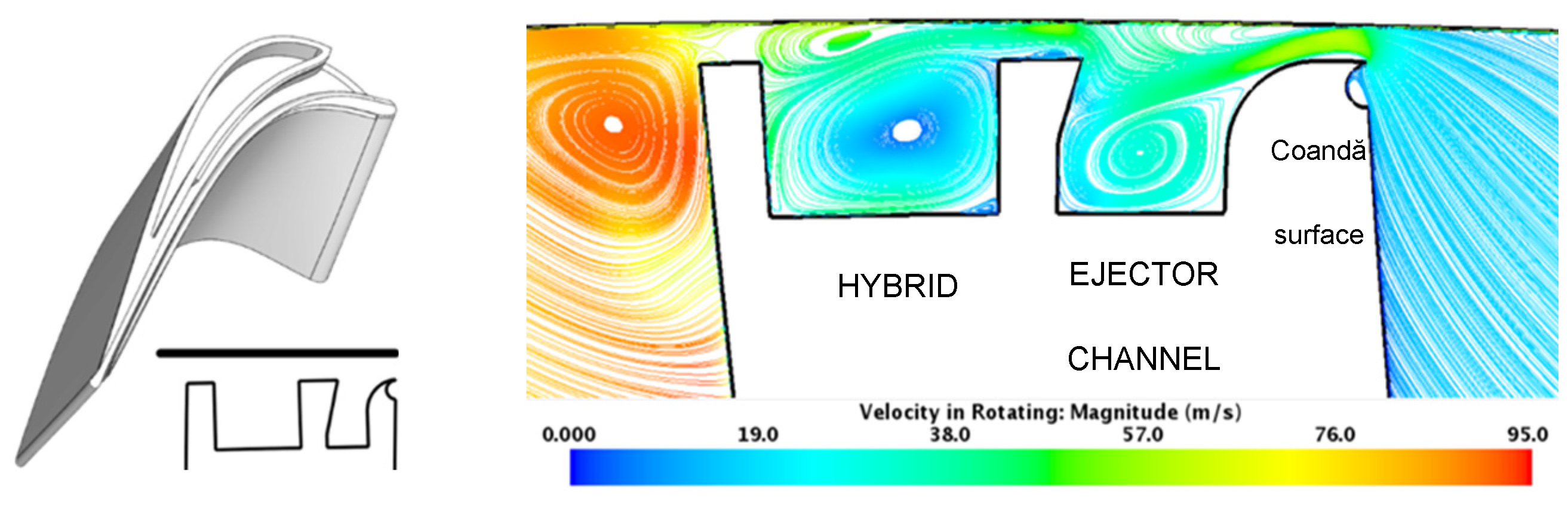

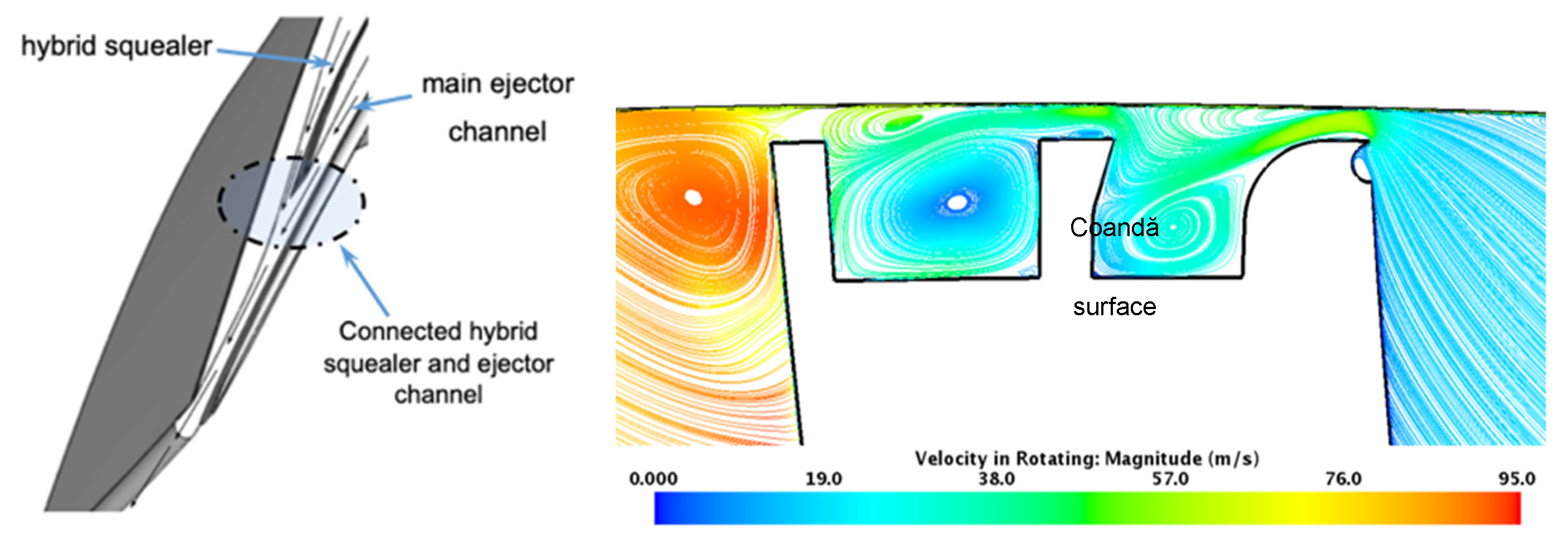

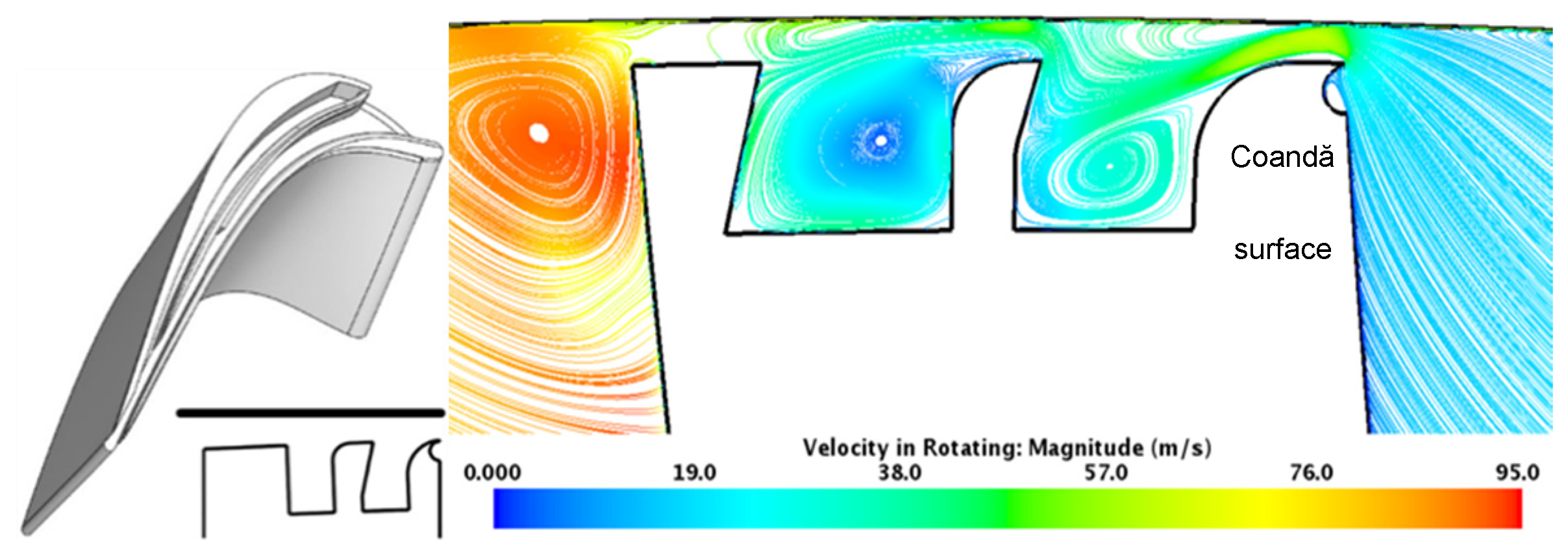

Ejector-Based Tip Leakage Mitigation Concept

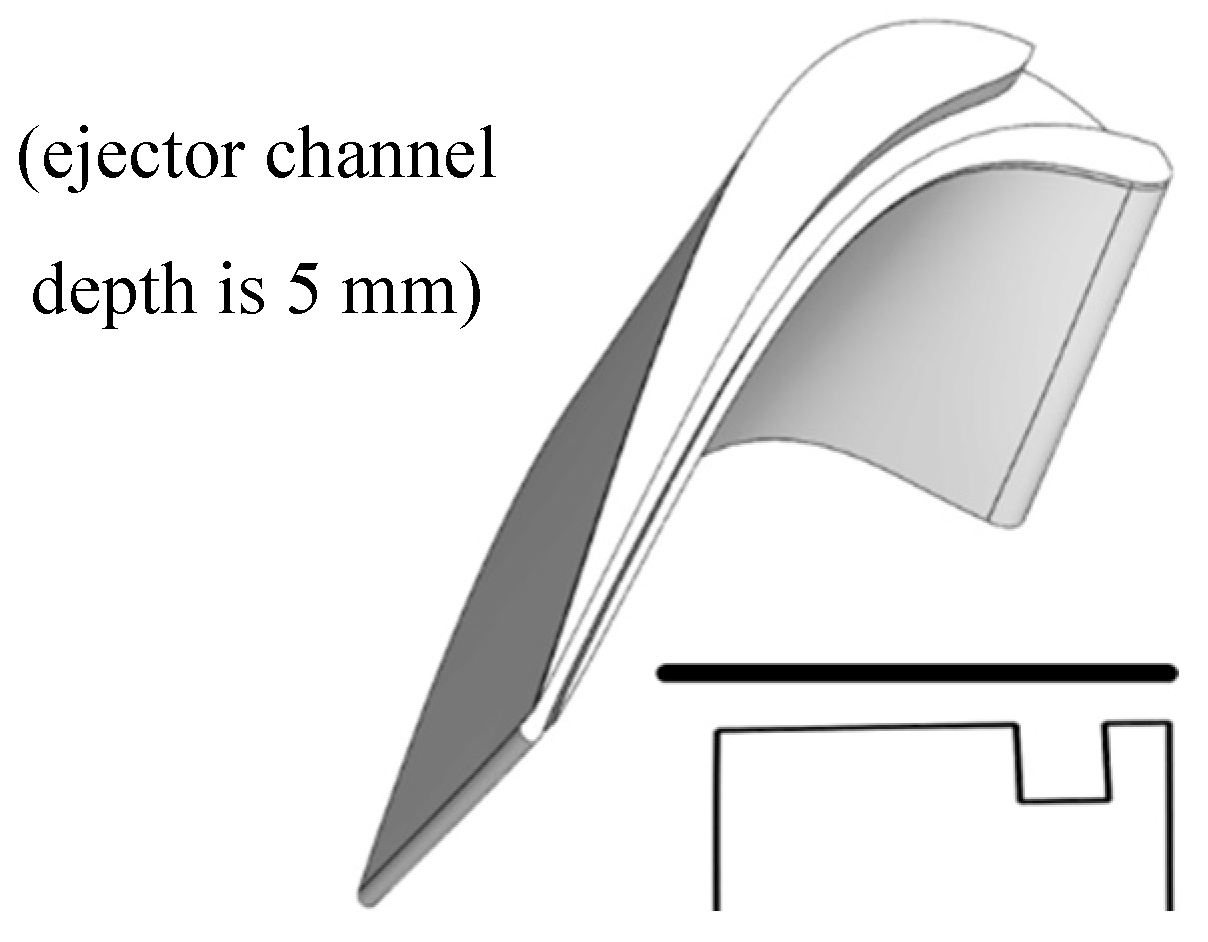

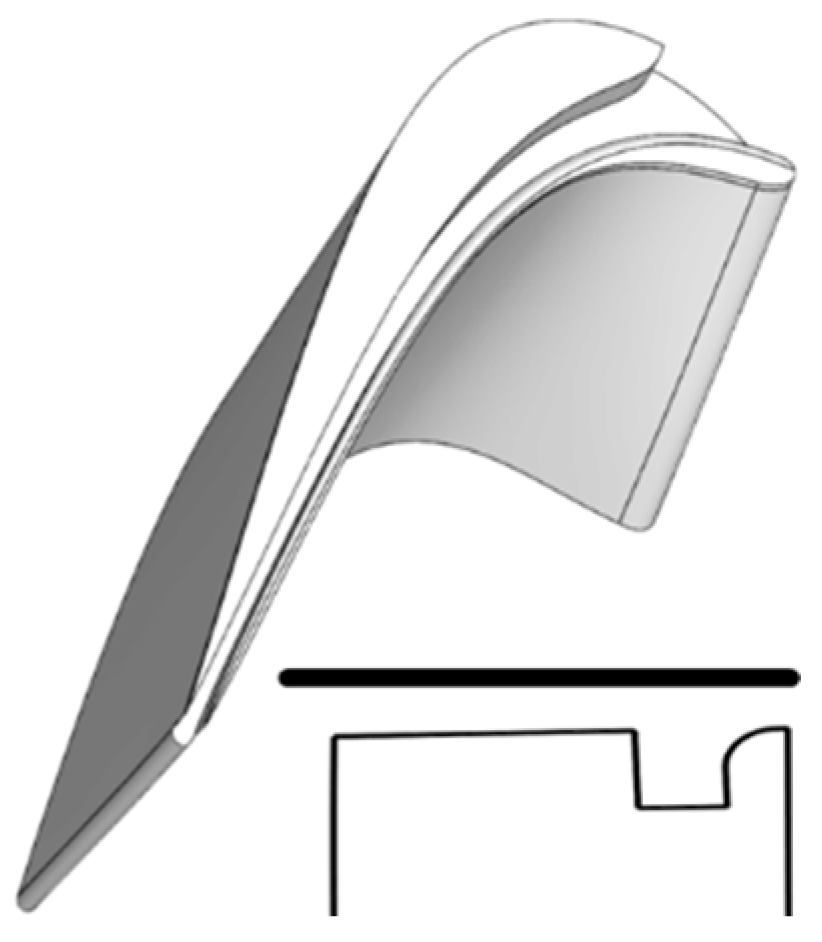

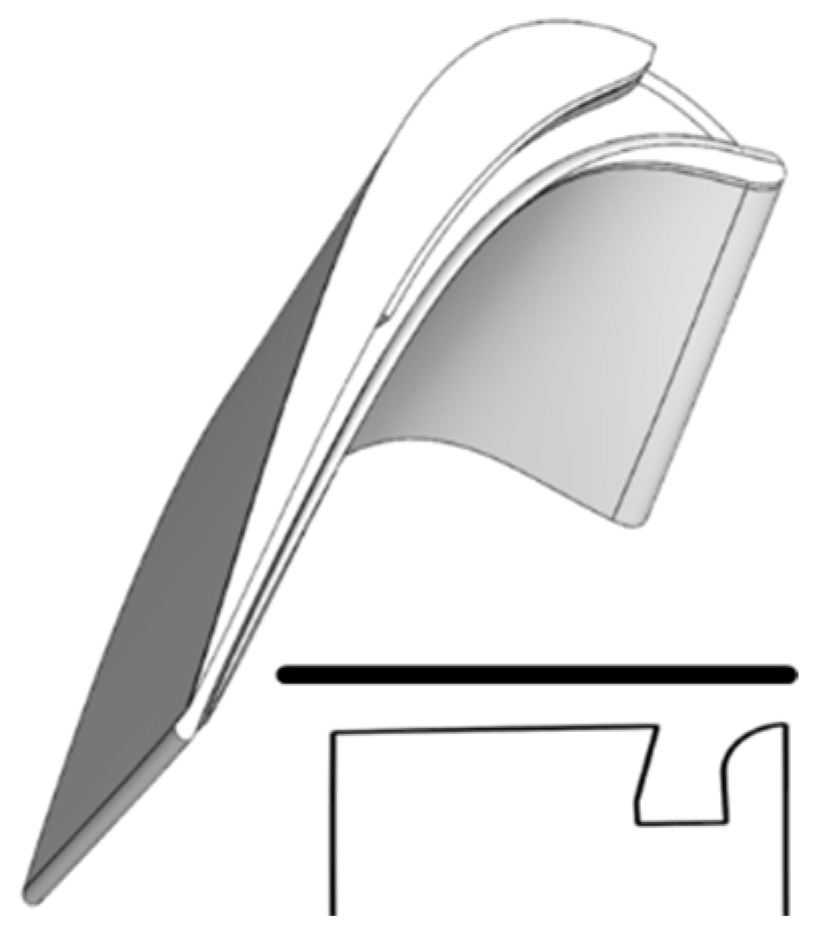

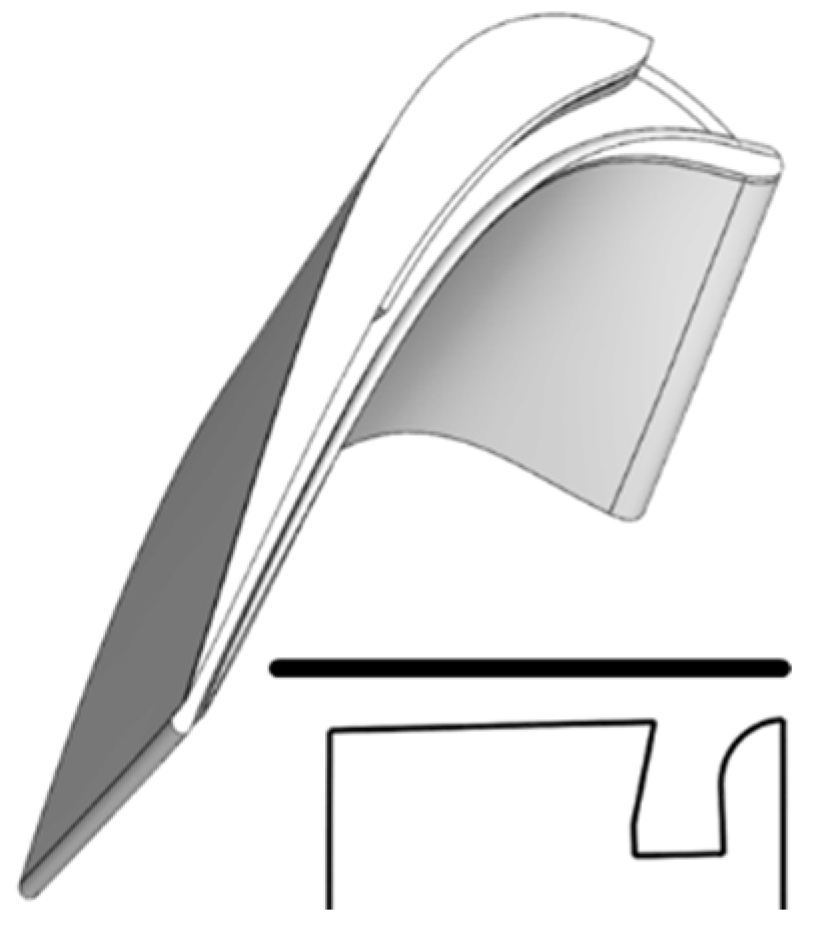

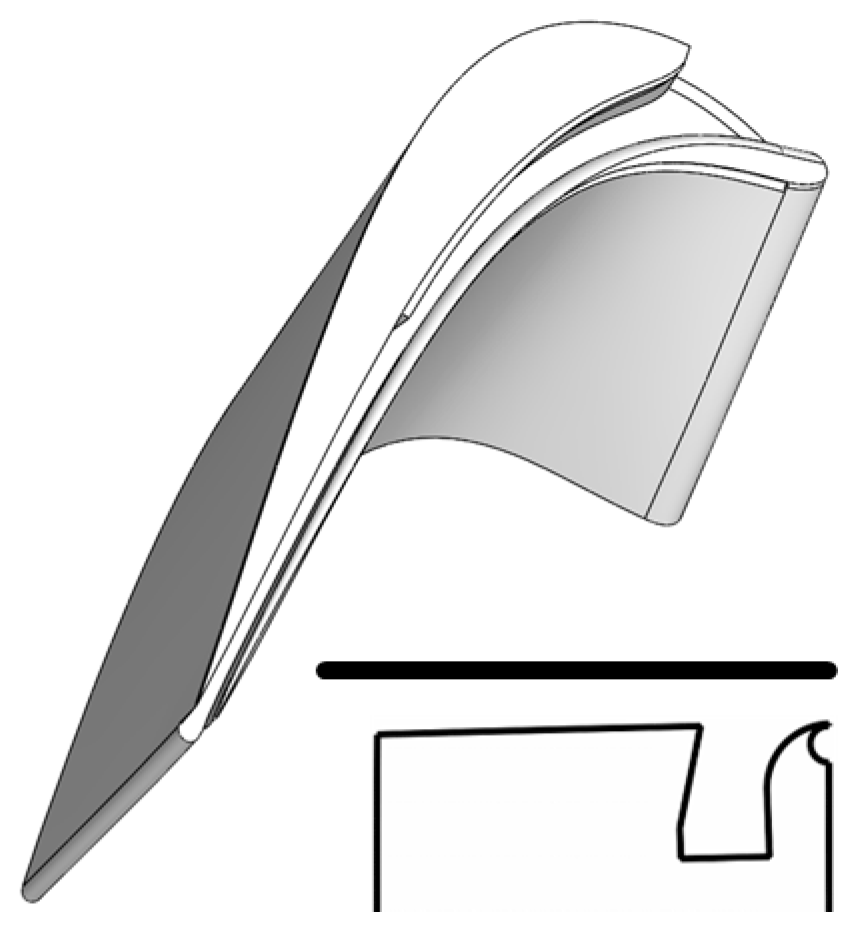

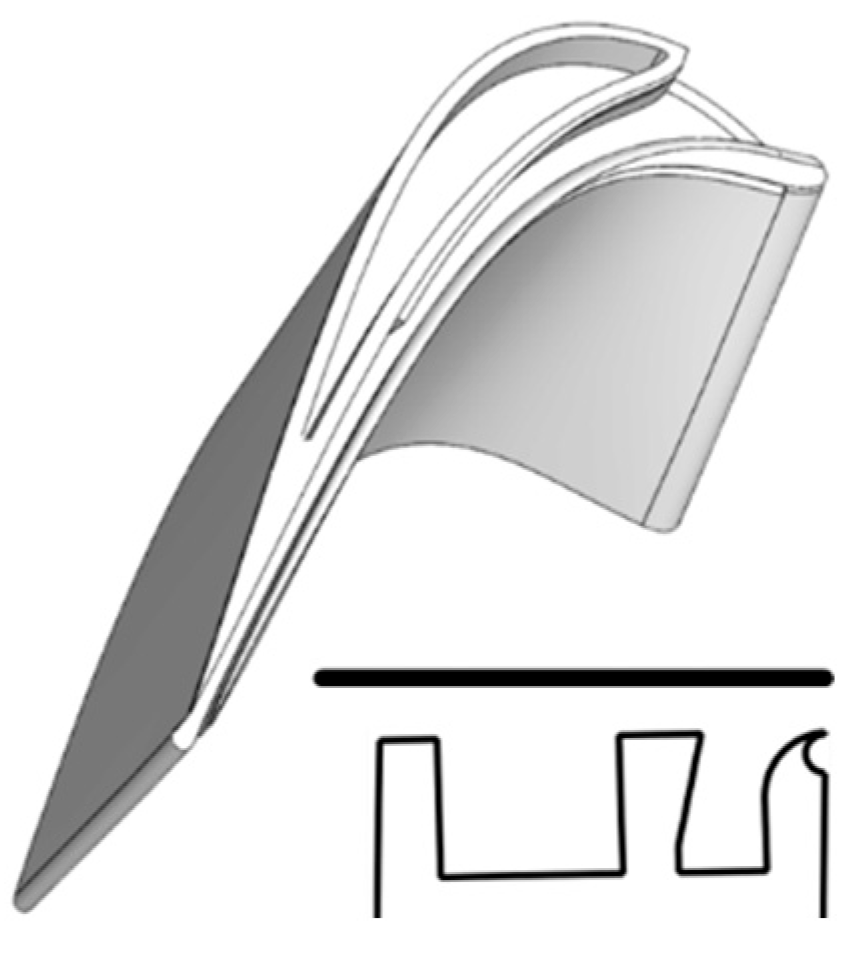

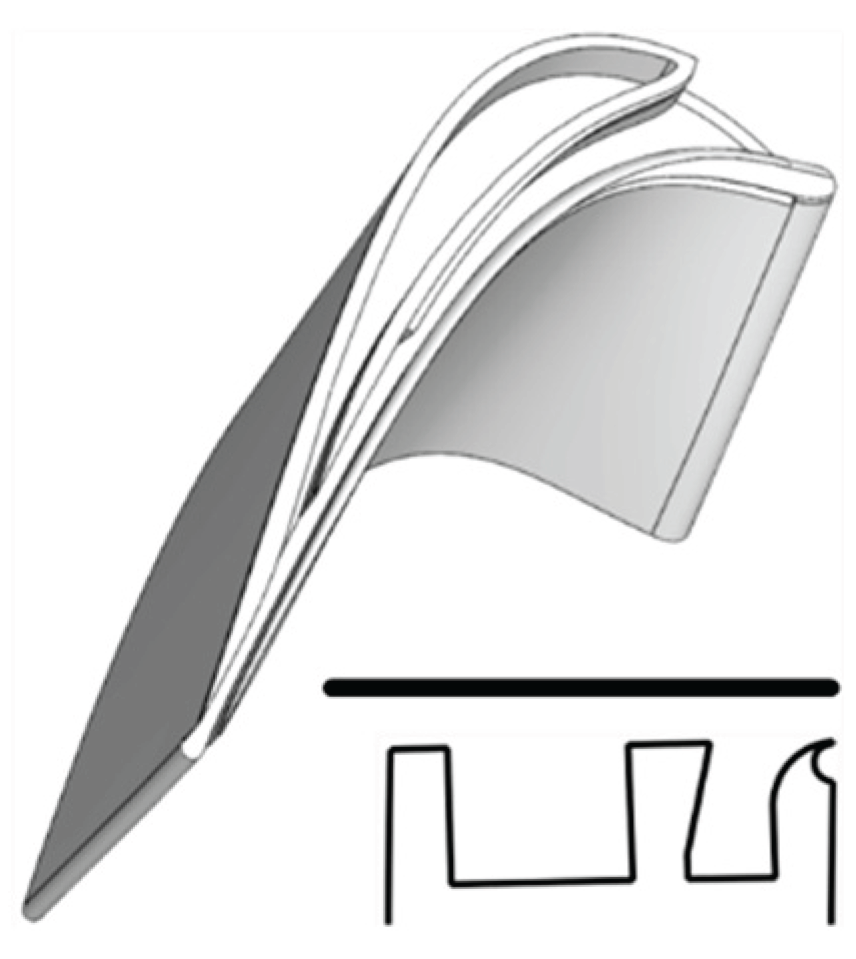

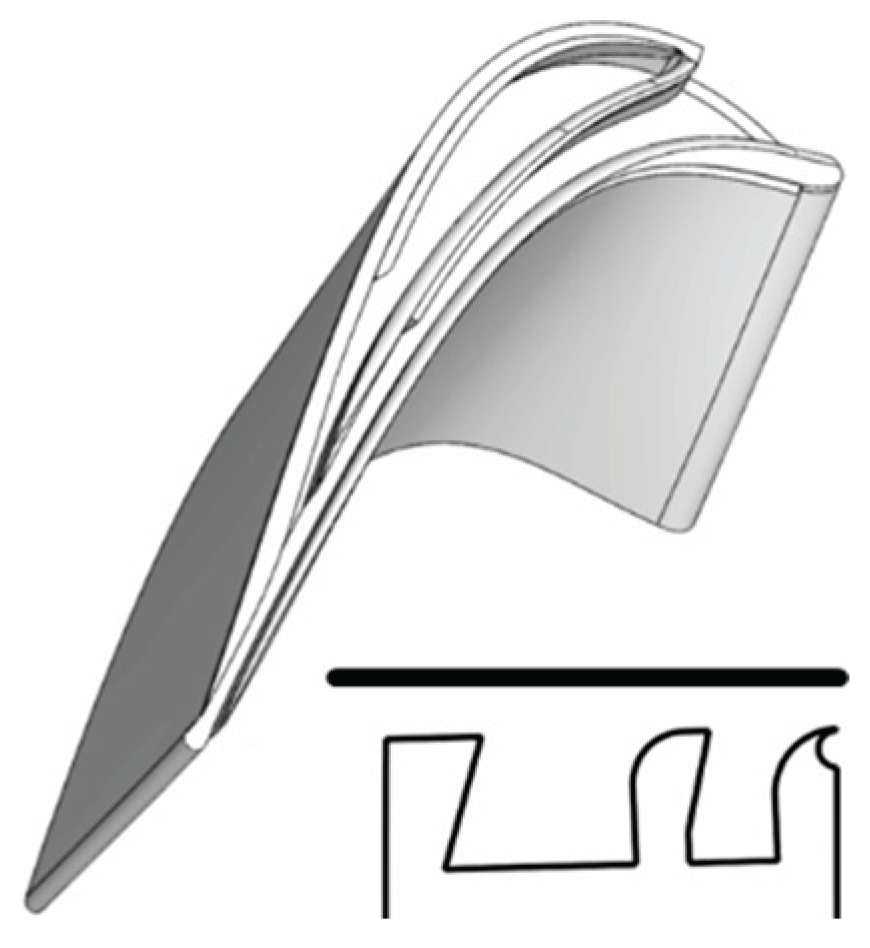

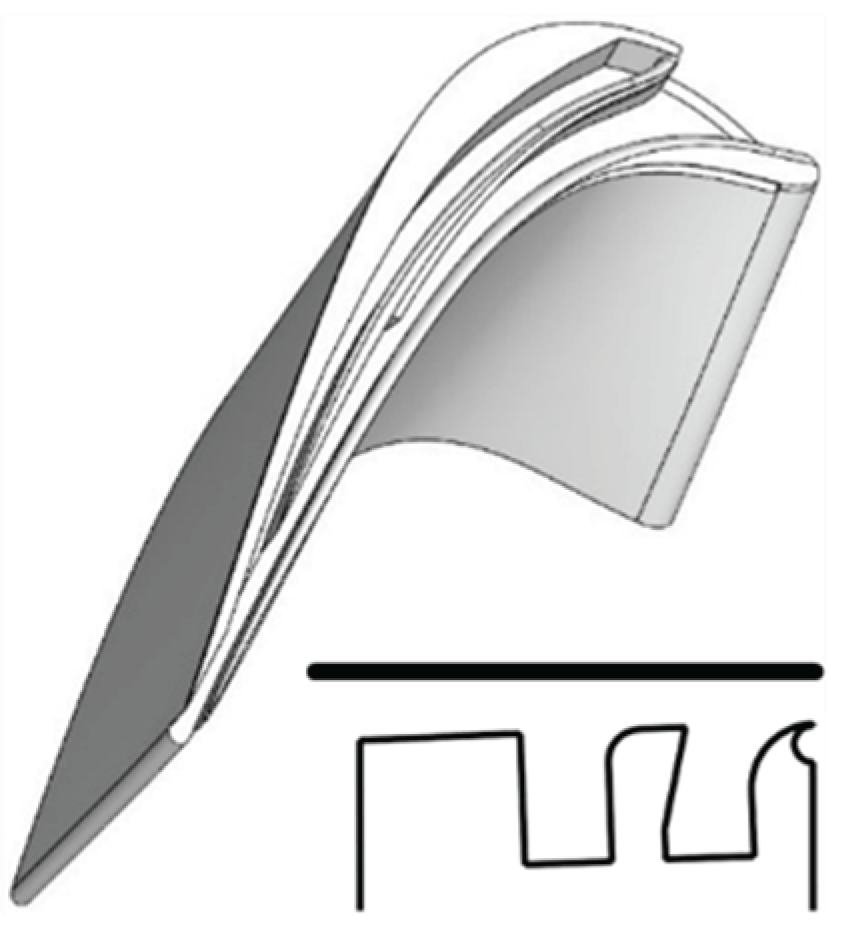

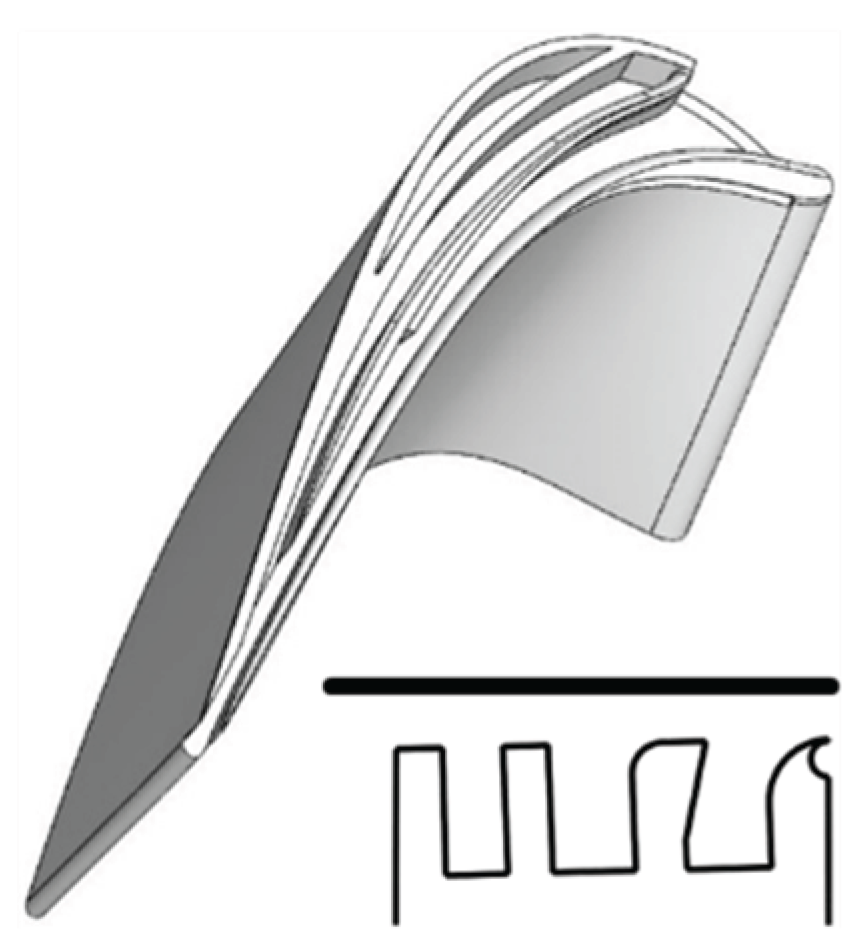

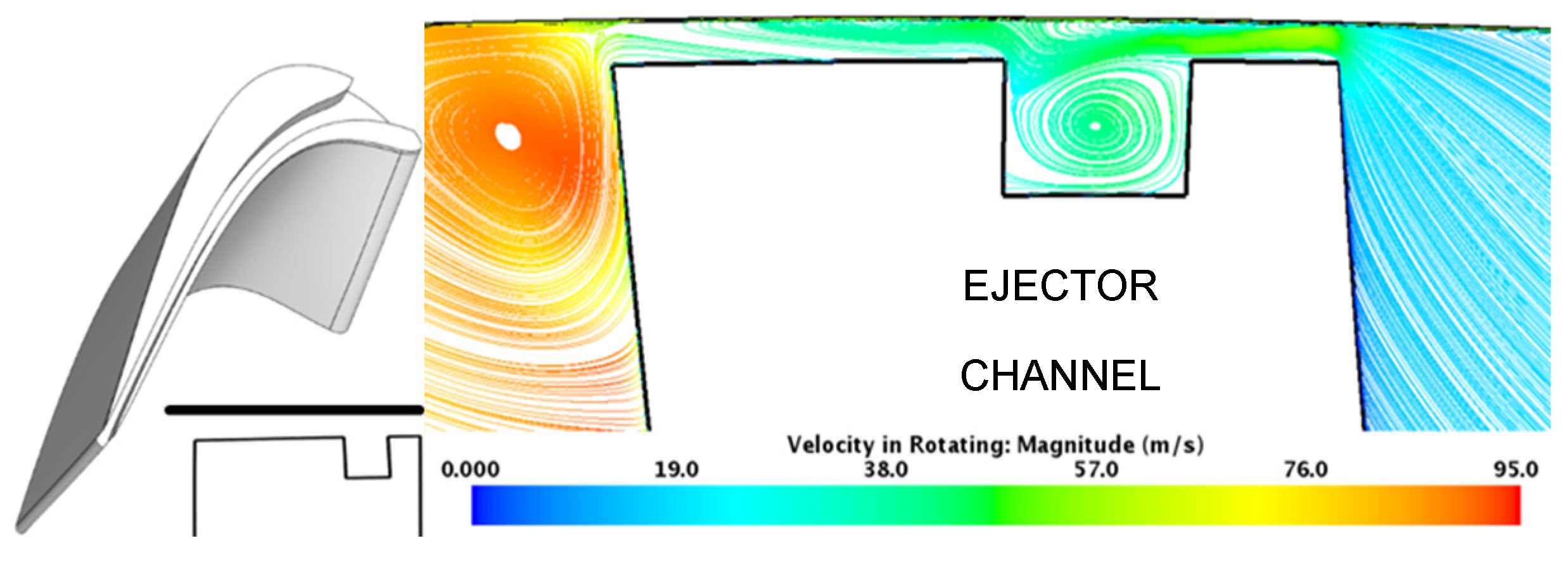

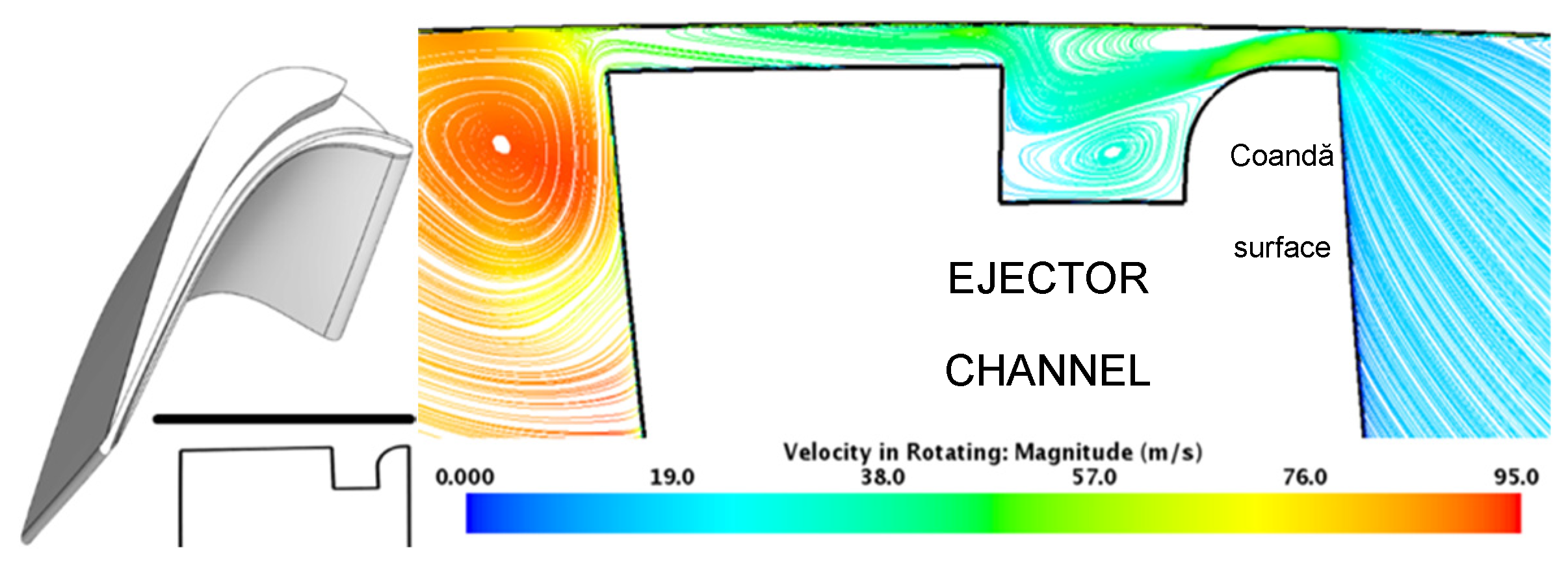

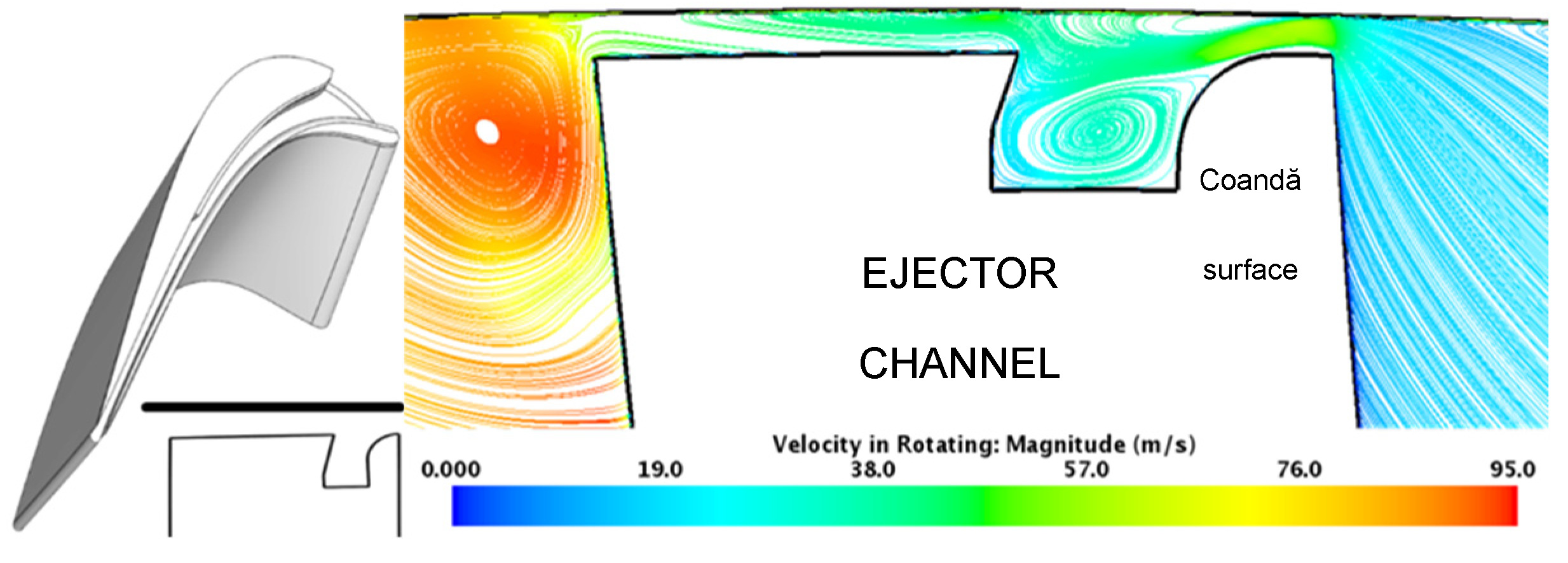

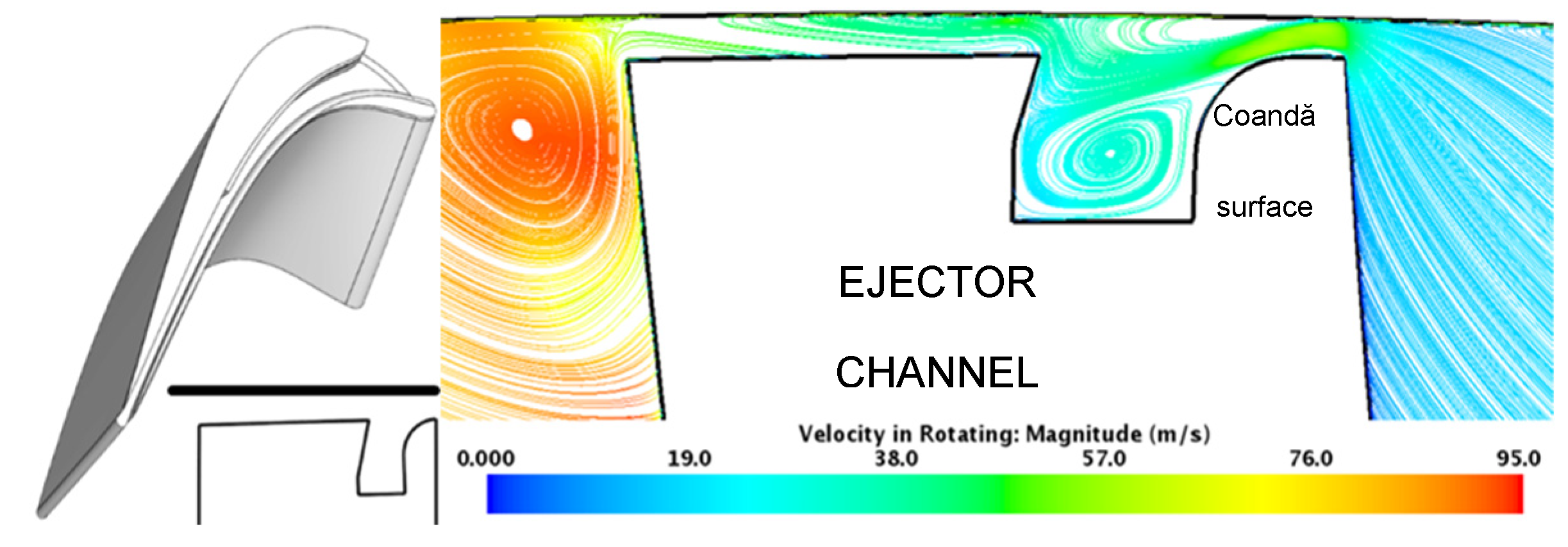

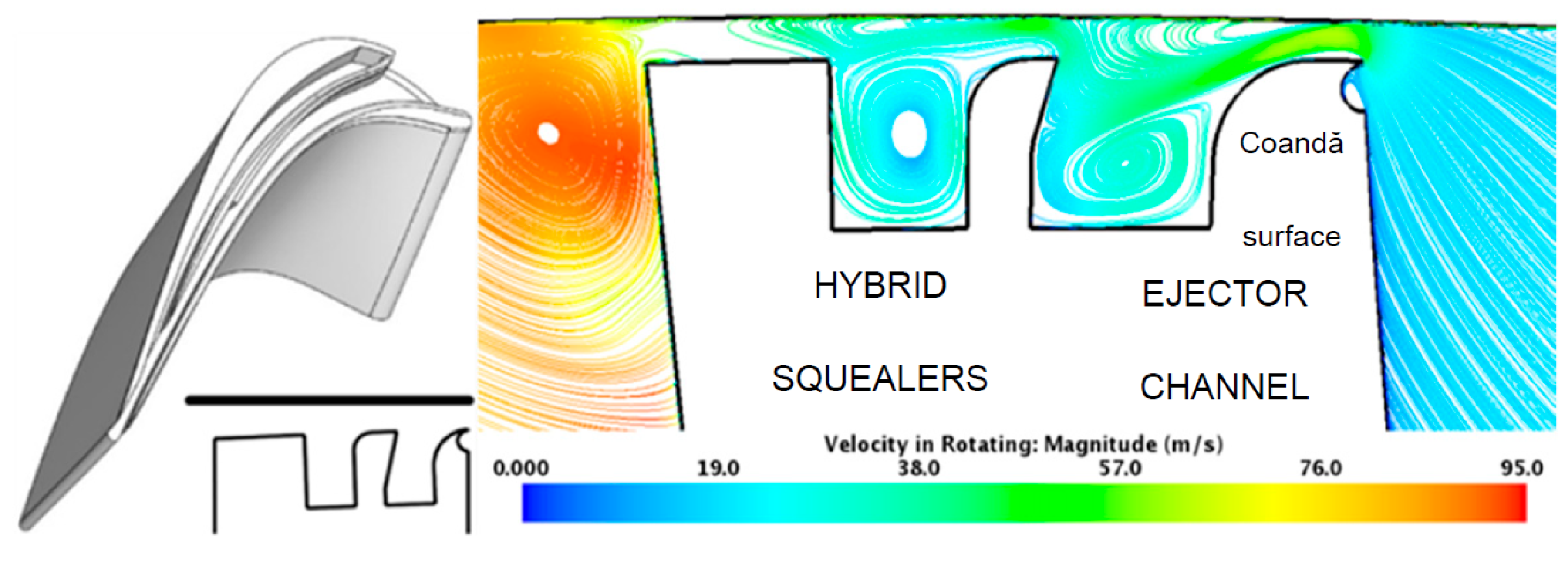

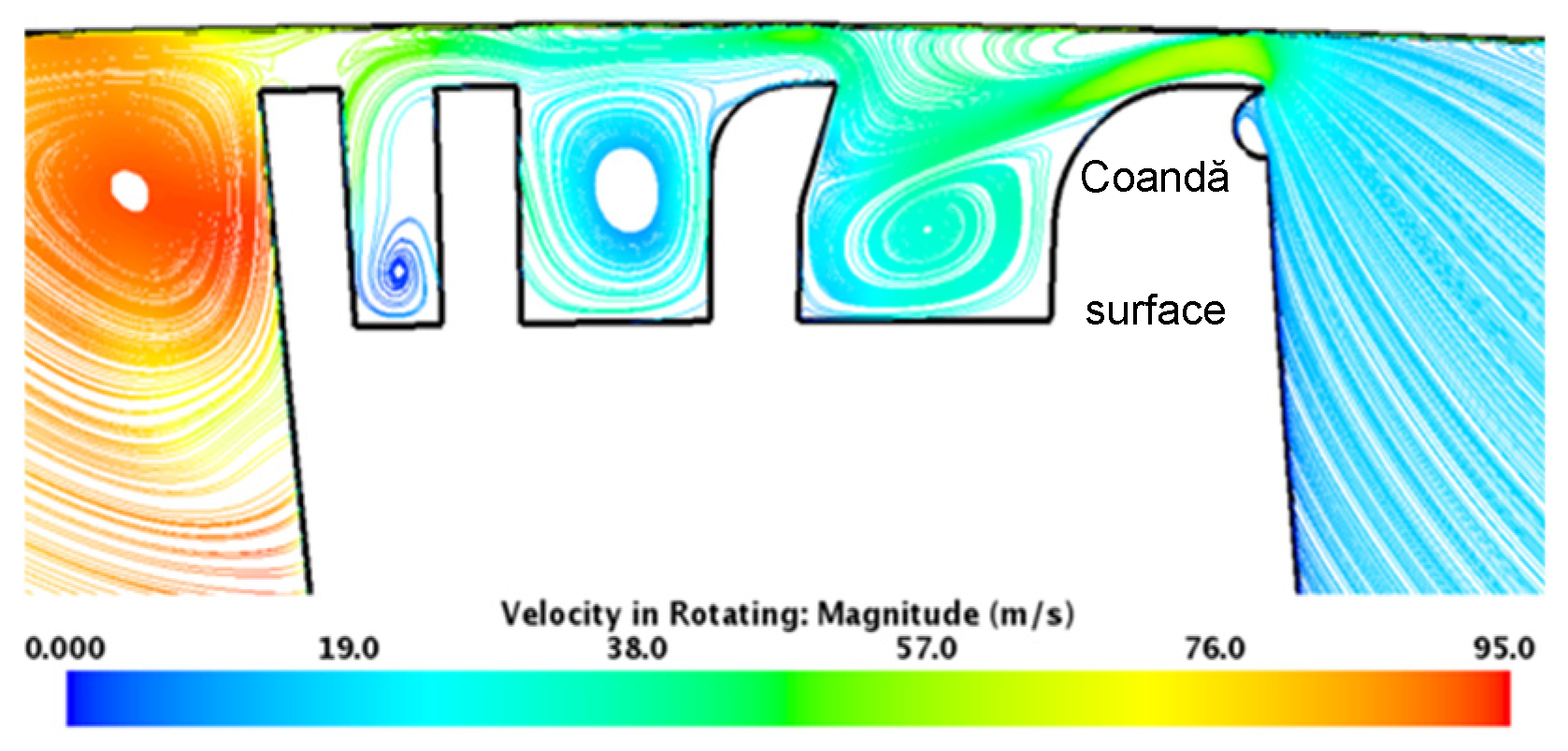

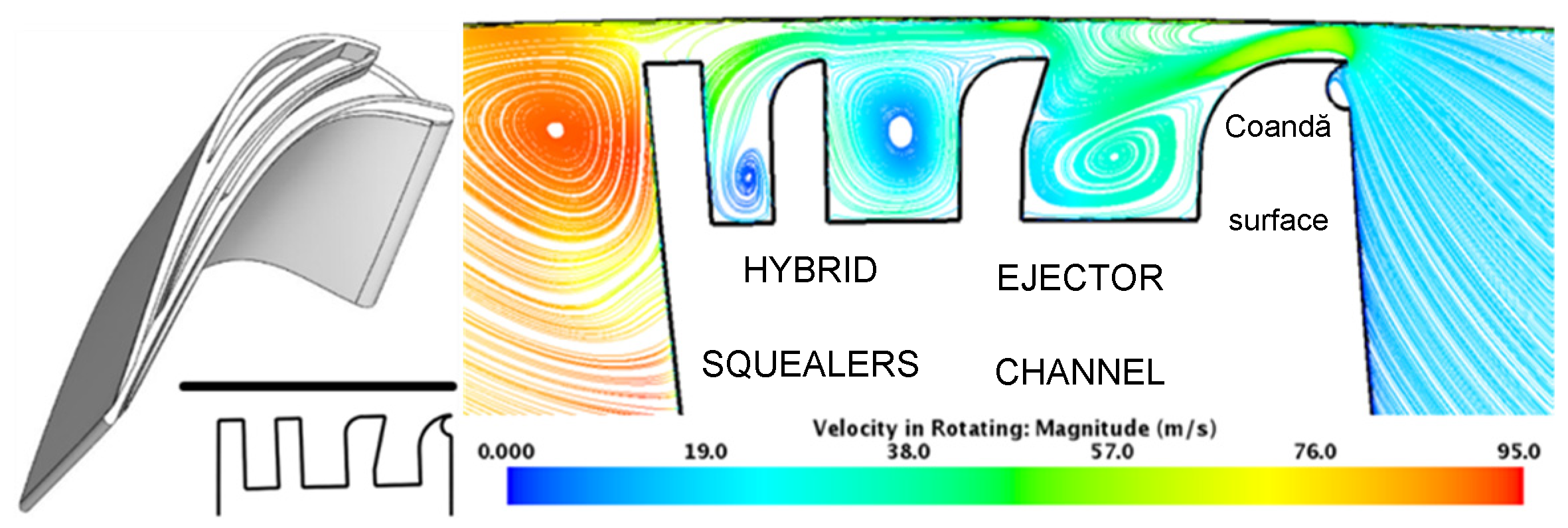

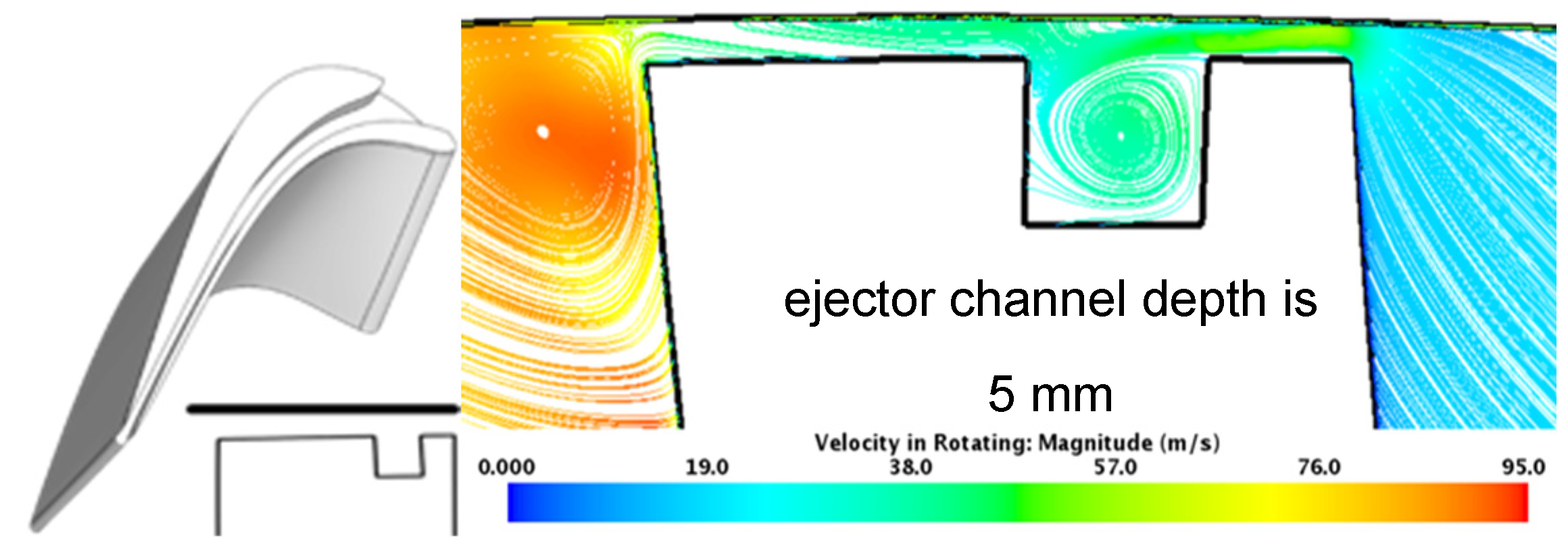

Ejector-Based Tip Leakage Mitigator Designs

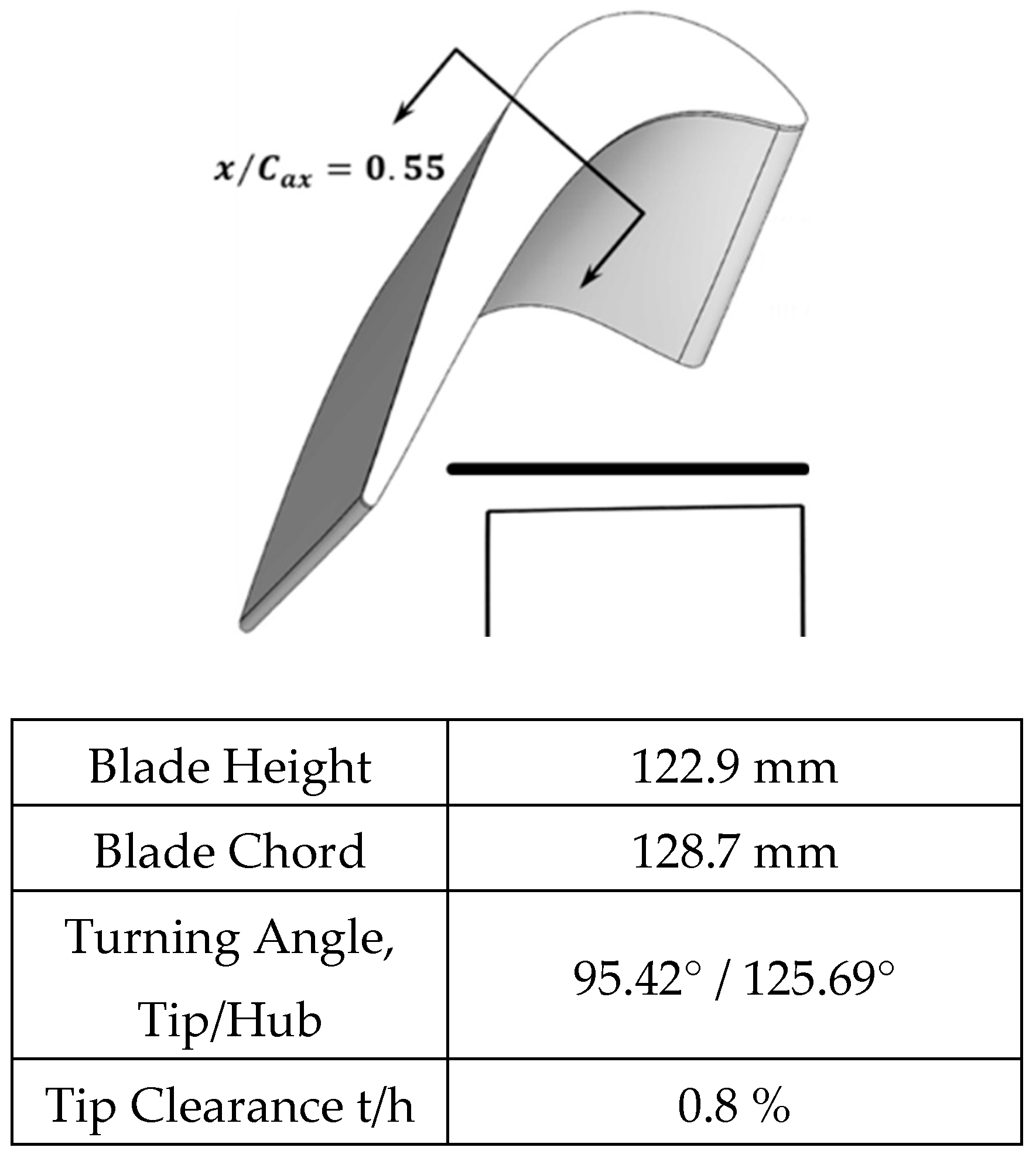

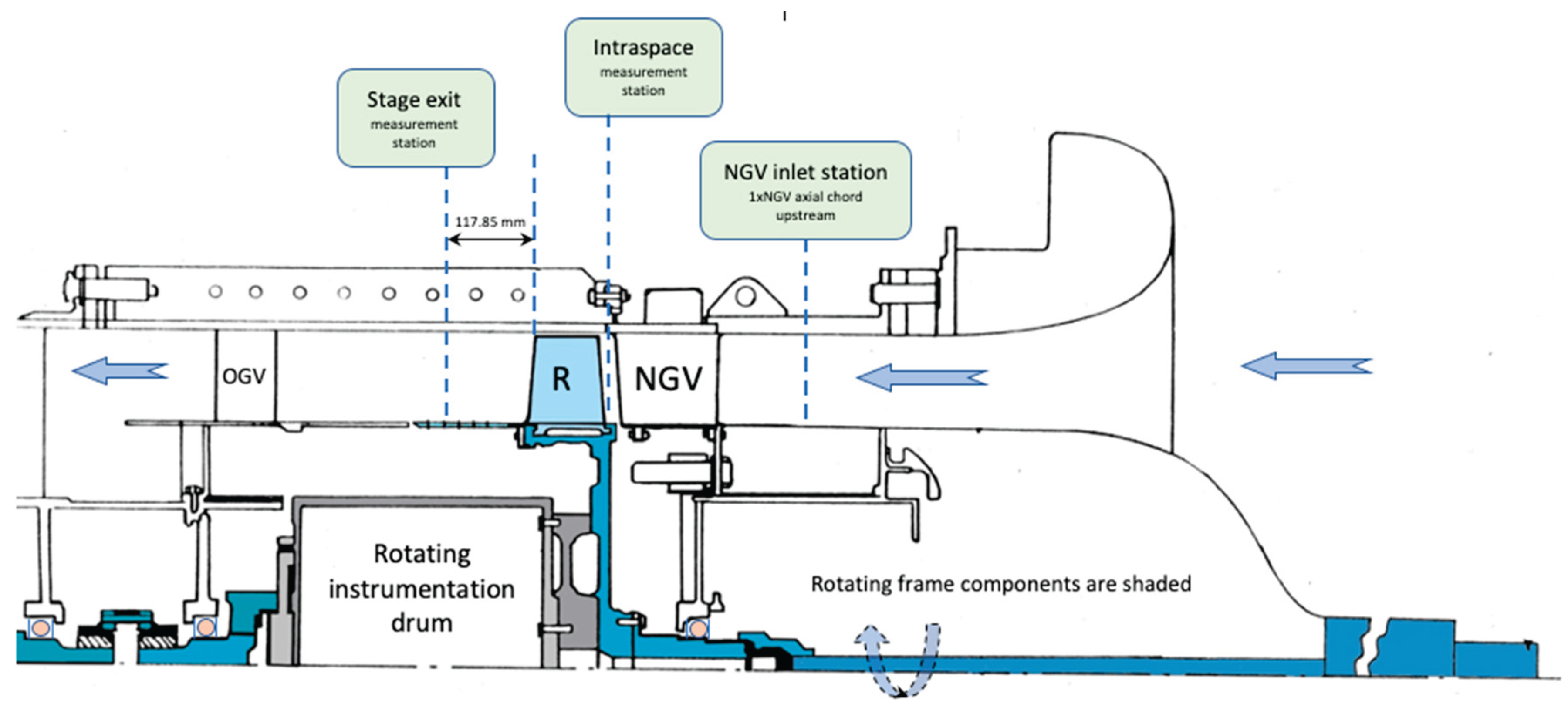

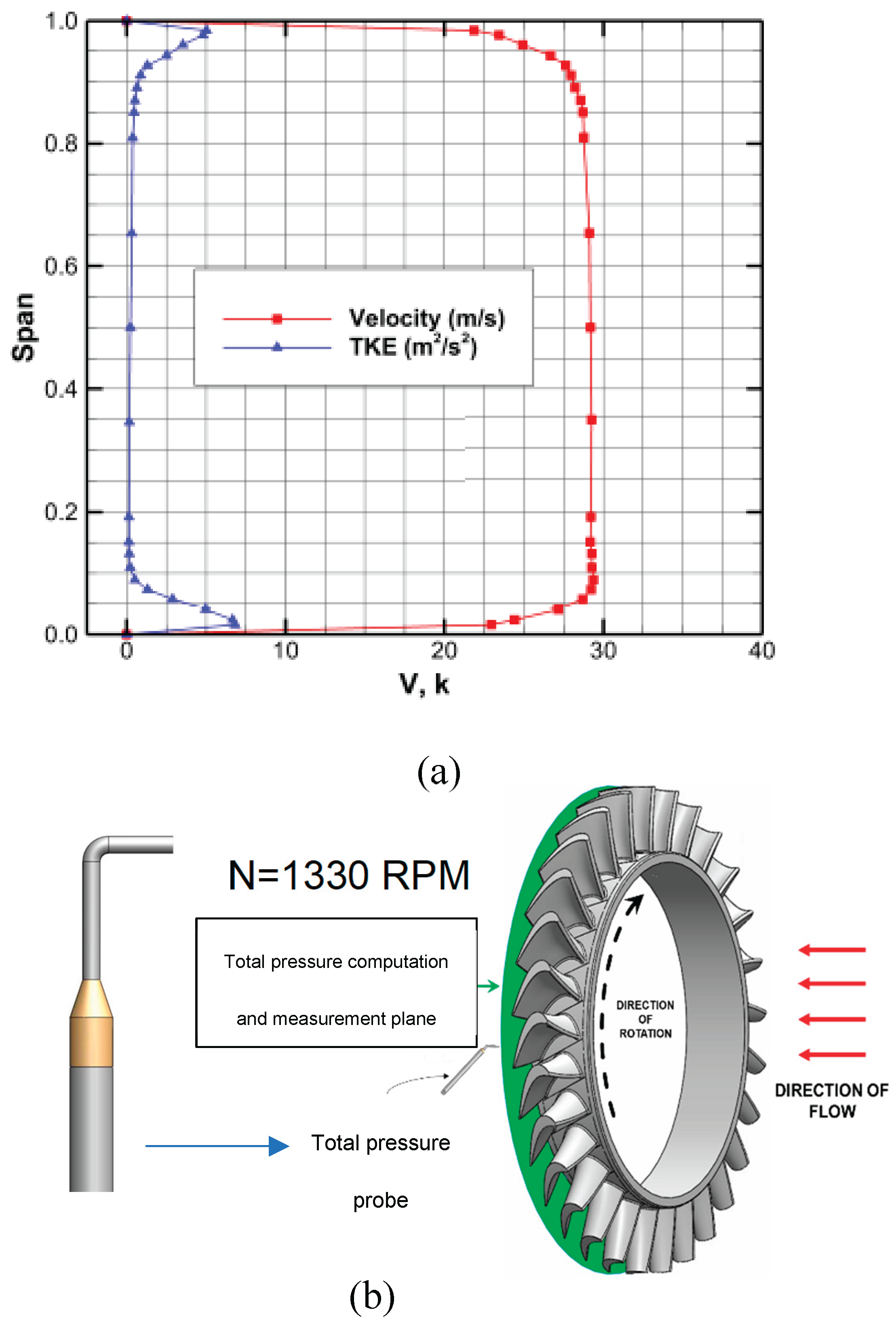

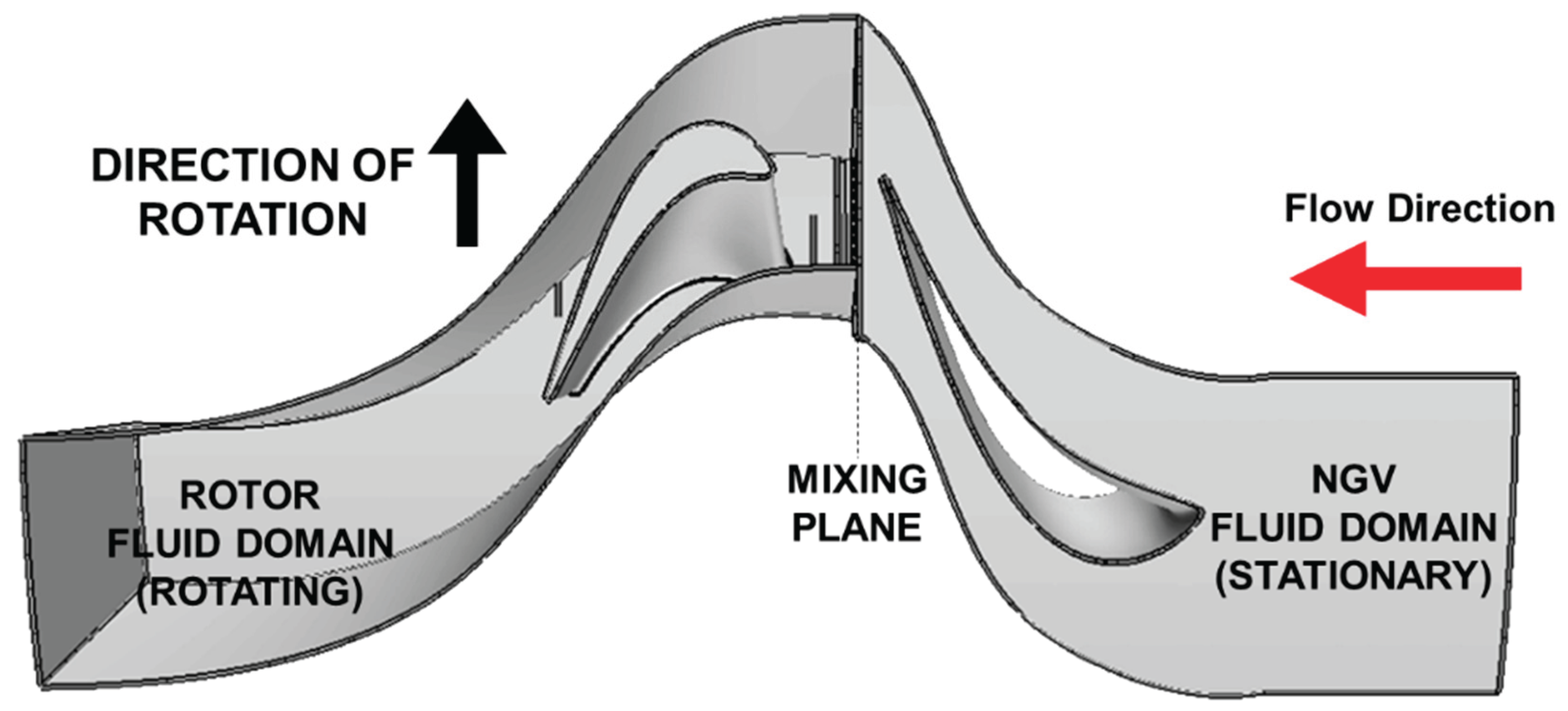

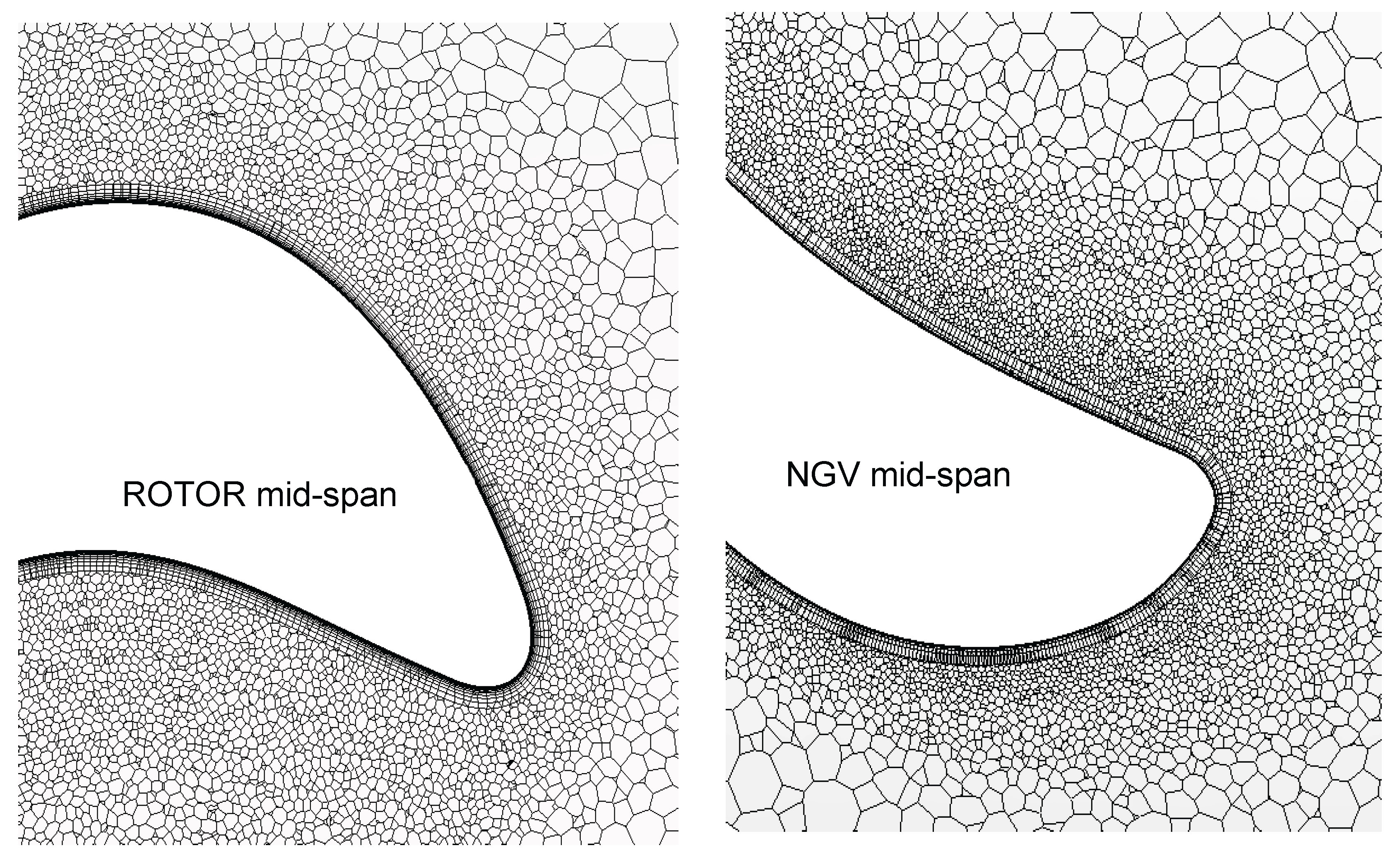

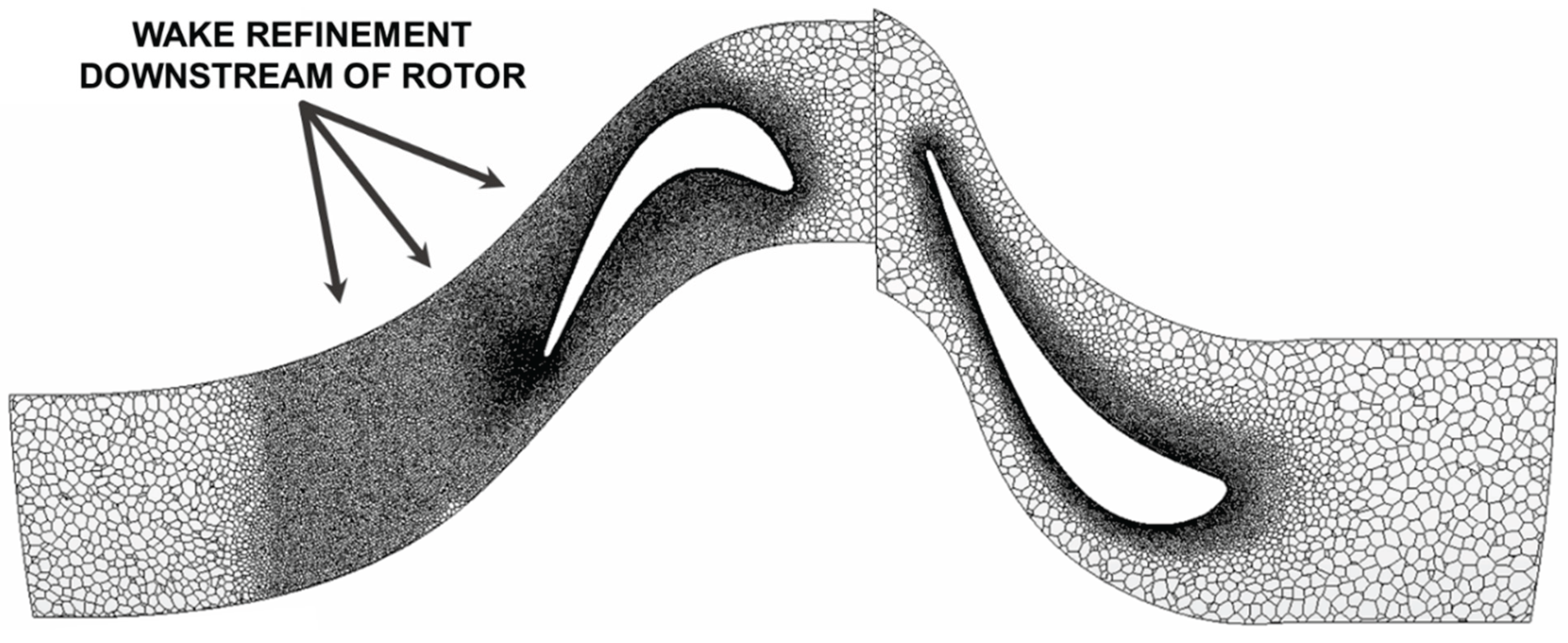

Computational Model of Aftrf

- ○

- Total pressure δ(ΔP0,) = ±8 Pa

- ○

- Temperature δTin = ±0.5 K

- ○

- Static pressure δP = ±5 Pa

- ○

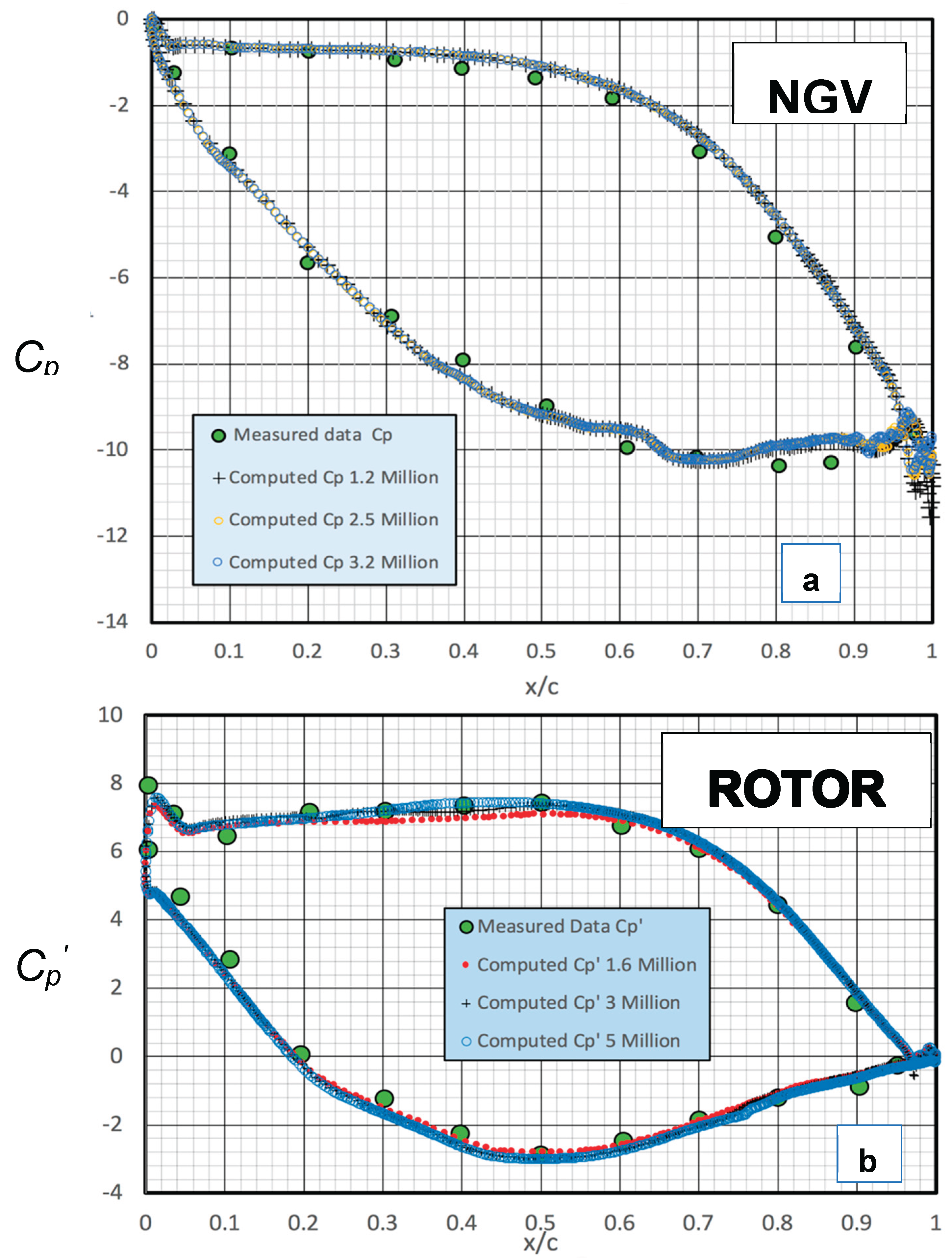

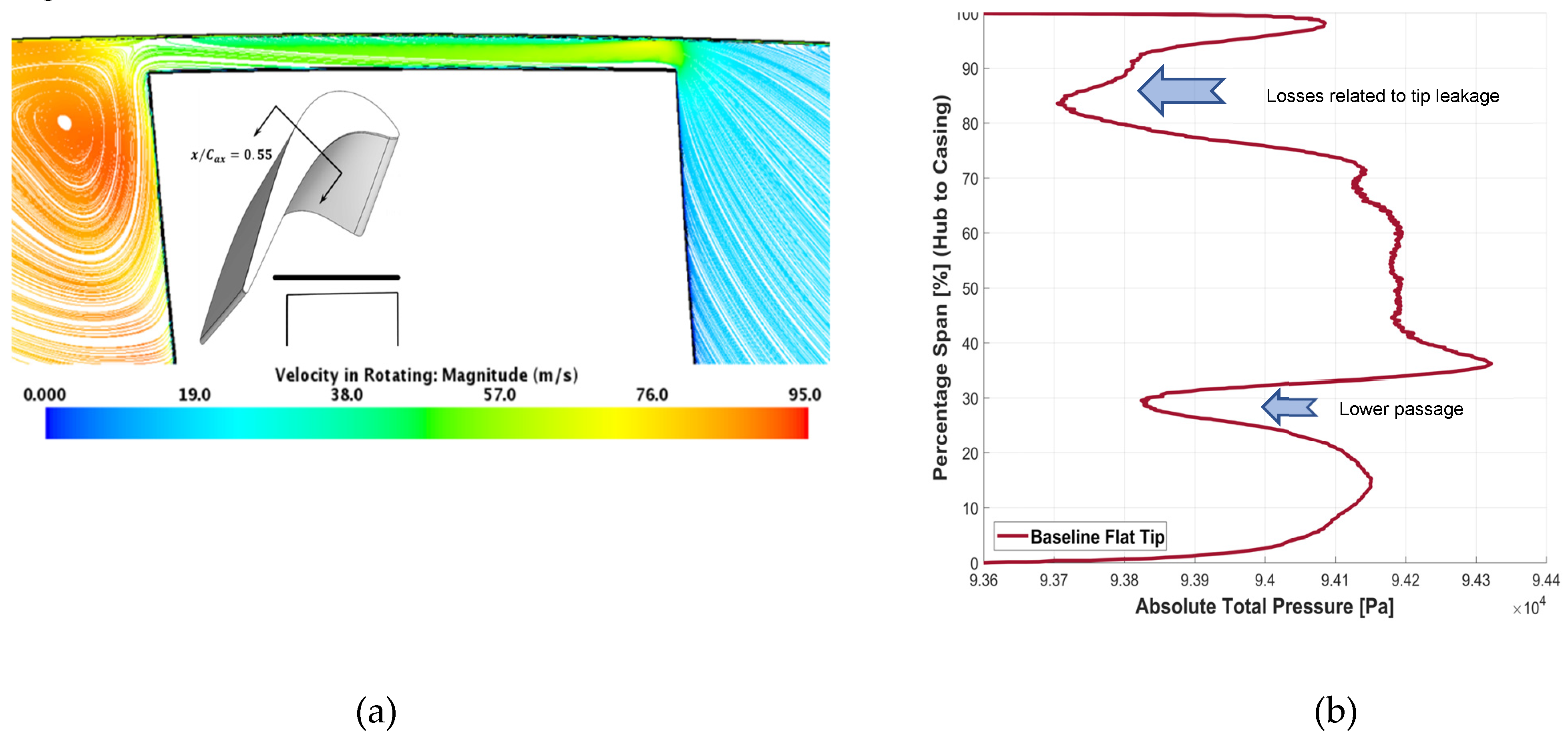

Baseline Flat Tip Computations

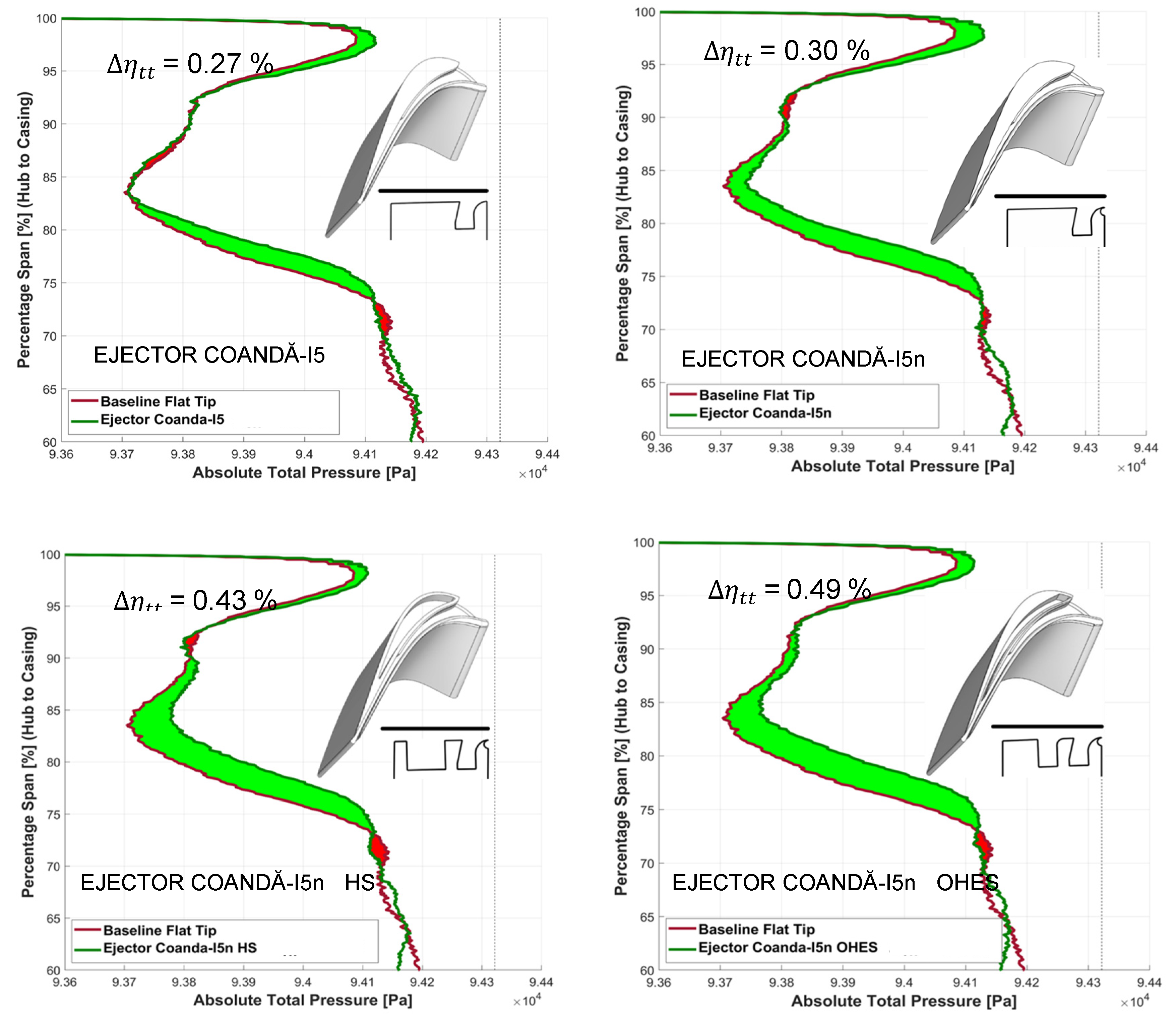

Results and Discussion of Coandă Ejector-Based Designs

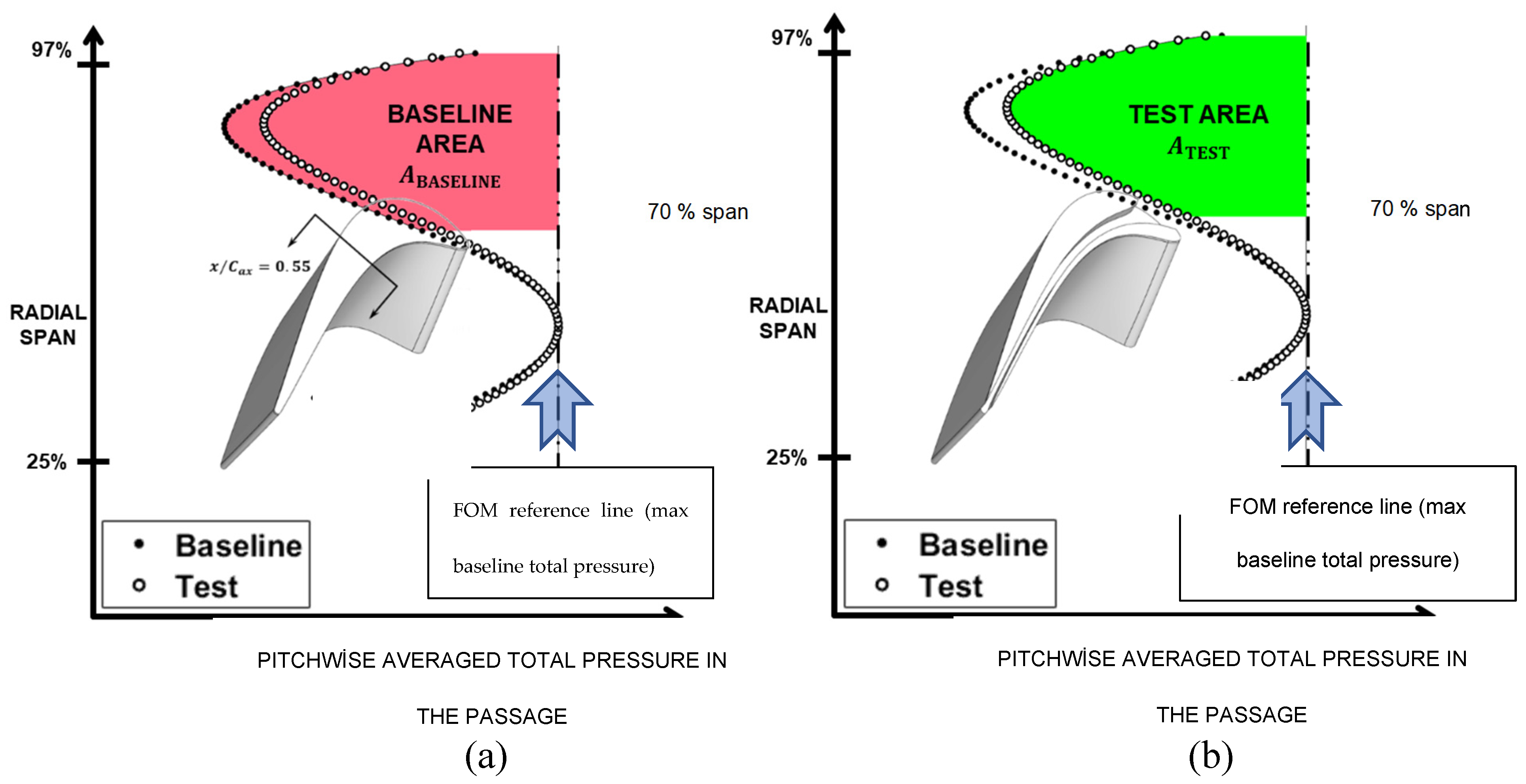

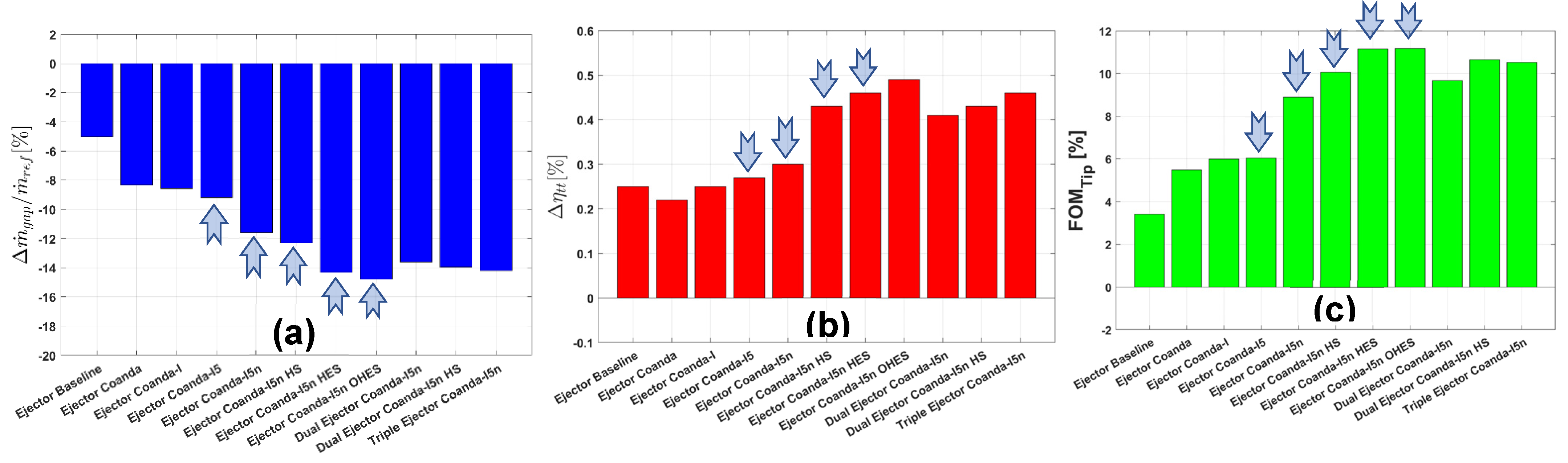

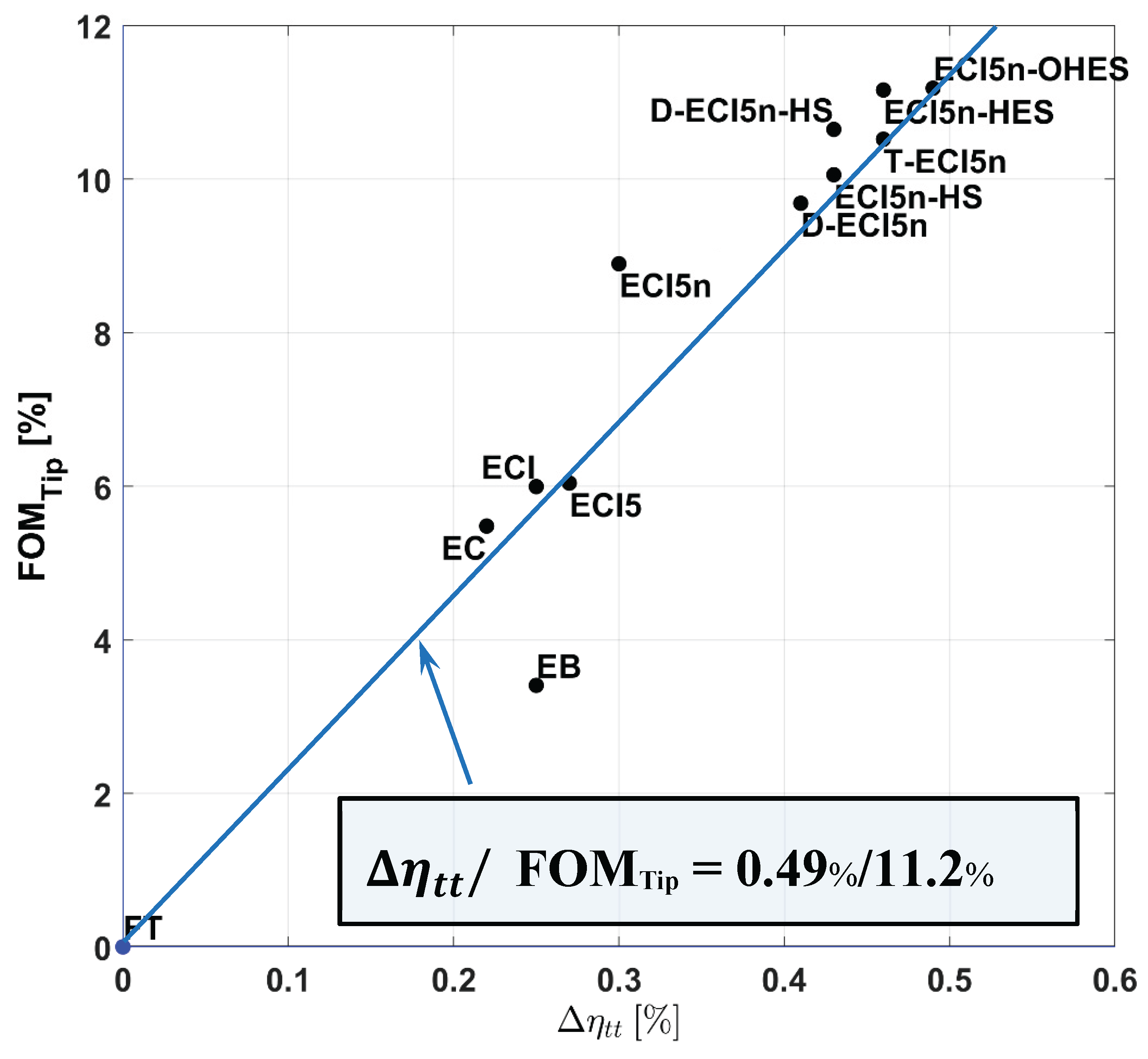

Comparison of 11 Tip Leakage Mitigator Design Cases

Conclusions

Acknowledgments

Nomenclature

| Baseline area for FOM calculation | |

| Test area for FOM calculation | |

| Area of turbine blade tip | |

| AFTRF | Axial Flow Turbine Research Facility |

| Blade axial chord | |

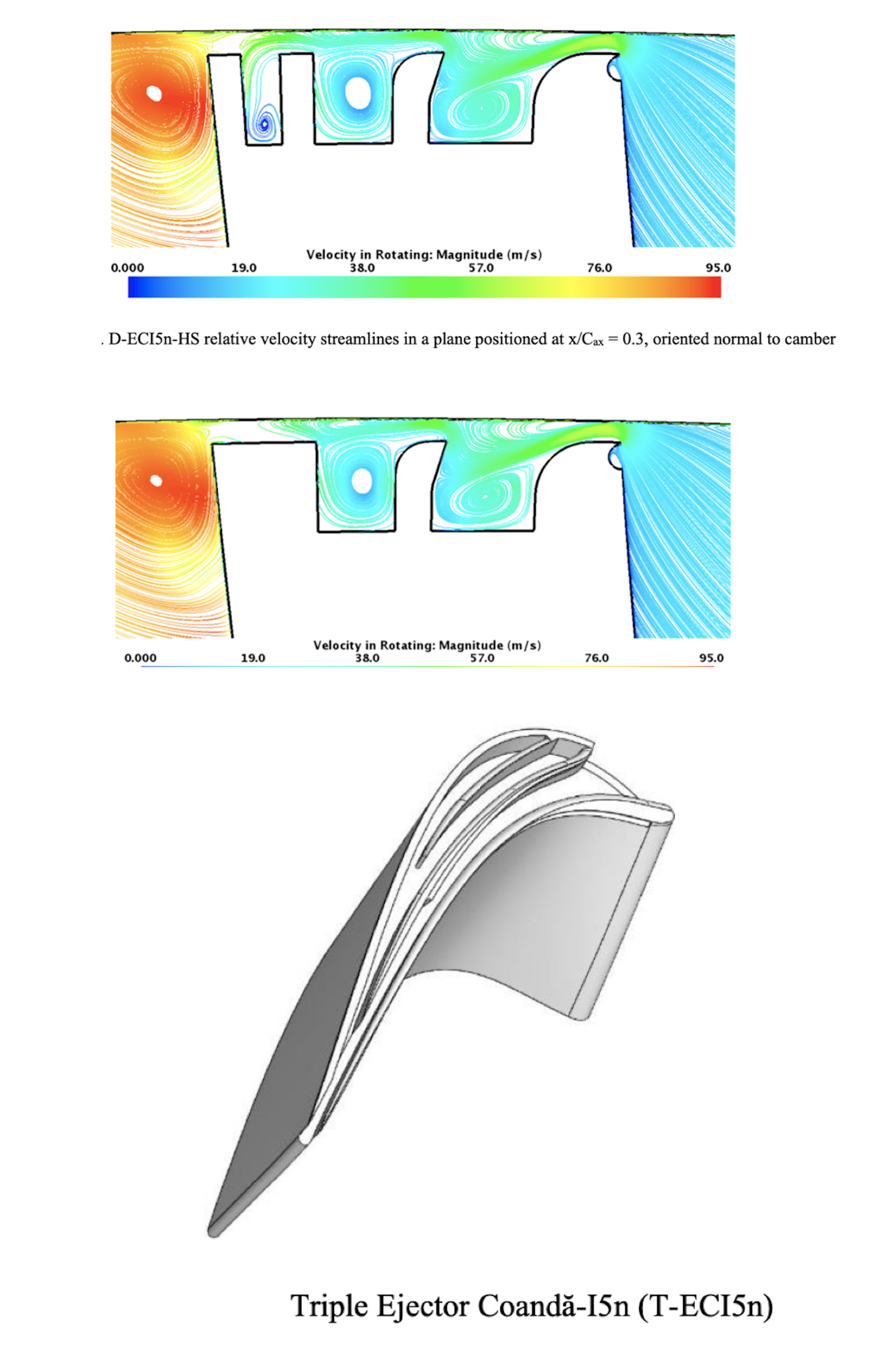

| D-ECI5n | Dual Ejector Coandă-I5n |

| D-ECI5n-HS | Dual Ejector Coandă-I5n Hybrid Squealer |

| DTP | Dynamic total pressure |

| E3 | Energy Efficient Engine |

| EB | Ejector Baseline |

| EB5 | Ejector Baseline-5 |

| EC | Ejector Coandă |

| ECI | Ejector Coandă-I |

| ECI5 | Ejector Coandă-I5 |

| ECIn | Ejector Coandă-In |

| ECI5n | Ejector Coandă-I5n |

| ECIn-HS | Ejector Coandă-In Hybrid Squealer |

| ECI5n-HS | Ejector Coandă-I5n Hybrid Squealer |

| ECI5n-HES | Ejector Coandă-I5n Hybrid Ejection Squealer |

| ECI5n-OHES | Ejector Coandă-I5n Optimized Hybrid Ejection Squealer |

| FT | Flat Tip |

| FOMTip | Total pressure-based tip figure of merit |

| h | blade height |

| HP | High pressure |

| LE | Leading edge |

| Tip gap mass flow rate | |

| Reference tip gap mass flow rate | |

| N | Turbine rotational speed |

| NGV | Nozzle guide vane |

| Total Pressure | |

| Ambient pressure | |

| PS | Pressure side |

| RPM | Revolutions per minute |

| r | Radial component |

| SS | Suction side |

| SLA | Stereolithography |

| SQT | Squealer Tip |

| TKE | Turbulent Kinetic Energy |

| t | Effective tip clearance |

| Total temperature | |

| TE | Trailing edge |

| T-ECI5n | Triple Ejector Coandă-I5n |

| Velocity vector | |

| x | Axial component |

|

SUBSCRIPTS 1, 2, 3 |

Stage inlet, intra-space, rotor exit |

| GREEK | |

| Specific heat capacity ratio | |

| Total-to-total isentropic efficiency | |

| Density | |

| θ | Tangential direction |

| Angular velocity |

References

- R. S. Bunker, “Axial Turbine Blade Tips: Function, Design, and Durability,” AIAA Journal of Propulsion and Power, vol. 22, no. 2, pp. 271–285, Mar. 2006. [CrossRef]

- J. D. Denton, “The 1993 IGTI Scholar Lecture: Loss Mechanisms in Turbomachines,” ASME Journal of Turbomachinery, vol. 115, no. 4, pp. 621–656, Oct. 1993. [CrossRef]

- J.-C. Han, S. Dutta, and S. Ekkad, Gas Turbine Heat Transfer and Cooling Technology, 2nd edition. Boca Raton, FL: CRC Press, 2012.

- B. Sunden and G. Xie, “Gas Turbine Blade Tip Heat Transfer and Cooling: A Literature Survey,” Heat Transfer Engineering, Jun. 2010. [CrossRef]

- Y. W. Kim and D. E. Metzger, “Heat Transfer and Effectiveness on Film Cooled Turbine Blade Tip Models,” ASME Journal of Turbomachinery, vol. 117, no. 1, pp. 12–21, Jan. 1995. [CrossRef]

- L. M. da Silva and J. T. Tomita, “A Study of the Heat Transfer in Winglet and Squealer Rotor Tip Configurations for a Non-Cooled HPT Blade Based on CFD Calculations,” presented at the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition. [CrossRef]

- P. Vass and T. Arts, “Numerical Investigation of High-pressure Turbine Blade Tip Flows: Analysis of Aerodynamics,” Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, Sep. 2011. [CrossRef]

- A. Ameri, E. Steinthorsson, and D. L. Rigby, “Effect of Squealer Tip on Rotor Heat Transfer and Efficiency,” Journal of Turbomachinery, vol. 120, no. 4, pp. 753–759, Oct. 1998. [CrossRef]

- Camci, D. Dey, and L. Kavurmacioglu, “Aerodynamics of Tip Leakage Flows Near Partial Squealer Rims in an Axial Flow Turbine Stage,” ASME Journal of Turbomachinery, vol. 127, no. 1, pp. 14–24, Feb. 2005. [CrossRef]

- G. S. Azad, J.-C. Han, R. S. Bunker, and C. P. Lee, “Effect of Squealer Geometry Arrangement on a Gas Turbine Blade Tip Heat Transfer,” Journal of Heat Transfer, vol. 124, no. 3, pp. 452–459, May 2002. [CrossRef]

- N. L. Key and T. Arts, “Comparison of Turbine Tip Leakage Flow for Flat Tip and Squealer Tip Geometries at High-Speed Conditions,” Journal of Turbomachinery, vol. 128, no. 2, pp. 213–220, Mar. 2004. [CrossRef]

- S. E. Lee, S. W. Lee, and H. S. Kwak, “Tip Leakage Aerodynamics Over Stepped Squealer Tips in a Turbine Cascade,” Experimental Thermal and Fluid Science, vol. 35, no. 1, pp. 135–145, Jan. 2011. [CrossRef]

- Dey, “Tip Desensitization in an Axial Flow Turbine,” Ph.D. Dissertation, The Pennsylvania State University, 2001.

- S. W. Lee and S. U. Kim, “Tip Gap Height Effects on the Aerodynamic Performance of a Cavity Squealer Tip in a Turbine Cascade in Comparison With Plane Tip Results: Part 1—Tip Gap Flow Structure,” Exp Fluids, vol. 49, no. 5, pp. 1039–1051, Nov. 2010. [CrossRef]

- Y. Liu, T.-L. Zhang, M. Zhang, and M.-C. Zhang, “Numerical and Experimental Investigation of Aerodynamic Performance for a Straight Turbine Cascade With a Novel Partial Shroud,” Journal of Fluids Engineering, vol. 138, no. 031206, Oct. 2015. [CrossRef]

- S. W. Lee, J. H. Cheon, and Q. Zhang, “The Effect of Full Coverage Winglets on Tip Leakage Aerodynamics Over the Plane Tip in a Turbine Cascade,” International Journal of Heat and Fluid Flow, vol. 45, pp. 23–32, Feb. 2014. [CrossRef]

- Zhou and F. Zhong, “A Novel Suction-Side Winglet Design Philosophy for High-Pressure Turbine Rotor Tips,” Journal of Turbomachinery, vol. 139, no. 111002, Jul. 2017. [CrossRef]

- K. Zhou and C. Zhou, “Aerodynamic Effects of an Incoming Vortex on Turbines With Different Tip Geometries,” Journal of Turbomachinery, vol. 143, no. 081009, Apr. 2021. [CrossRef]

- J. H. Cheon and S. W. Lee, “Tip Leakage Aerodynamics Over the Cavity Squealer Tip Equipped With Full Coverage Winglets in a Turbine Cascade,” International Journal of Heat and Fluid Flow, vol. 56, pp. 60–70, Dec. 2015. [CrossRef]

- J. S. Joo and S. W. Lee, “Heat/mass Transfer Over the Cavity Squealer Tip Equipped With a Full Coverage Winglet in a Turbine Cascade: Part 1 – Data on the Winglet Top Surface,” International Journal of Heat and Mass Transfer, vol. 108, pp. 1255–1263, May 2017. [CrossRef]

- S. W. Lee and J. S. Joo, “Heat/Mass Transfer Over the Cavity Squealer Tip Equipped With a Full Coverage Winglet in a Turbine Cascade: Part 2 – Data on the Cavity Floor,” International Journal of Heat and Mass Transfer, vol. 108, pp. 1264–1272, May 2017. [CrossRef]

- J. D. Coull, N. R. Atkins, and H. P. Hodson, “High Efficiency Cavity Winglets for High Pressure Turbines,” presented at the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. [CrossRef]

- Zhong and C. Zhou, “Effects of Tip Gap Size on the Aerodynamic Performance of a Cavity-Winglet Tip in a Turbine Cascade,” Journal of Turbomachinery, vol. 139, no. 101009, May 2017. [CrossRef]

- N. W. Harvey and K. Ramsden, “A Computational Study of a Novel Turbine Rotor Partial Shroud,” Journal of Turbomachinery, vol. 123, no. 3, pp. 534–543, Feb. 2000. [CrossRef]

- Y. Fu, F. Chen, H. Liu, and Y. Song, “Experimental and Numerical Study of Honeycomb Tip on Suppressing Tip Leakage Flow in Turbine Cascade,” Journal of Turbomachinery, vol. 140, no. 061006, Apr. 2018. [CrossRef]

- K. Du, Z. Li, J. Li, and B. Sunden, “Influences of a Multi-Cavity Tip on the Blade Tip and the Over Tip Casing Aerothermal Performance in a High Pressure Turbine Cascade,” Applied Thermal Engineering, vol. 147, pp. 347–360, Jan. 2019. [CrossRef]

- V. C. Andichamy, G. T. Khokhar, and C. Camci, “An Experimental Study of Using Vortex Generators As Tip Leakage Flow Interrupters in an Axial Flow Turbine Stage,” presented at the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition. [CrossRef]

- V. C. Andichamy, “An Investigation Using Tip Leakage Interrupter and Blade Slit to Mitigate Aerodynamic Losses in Axial Turbine Stage,” Ph.D. dissertation, The Pennsylvania State University.

- L. A. Kavurmacioglu, C. B. Senel, H. Maral, and C. Camci, “Casing Grooves to Improve Aerodynamic Performance of a Hp Turbine Blade,” Aerospace Science and Technology, vol. 76, pp. 194–203, May 2018. [CrossRef]

- Y. Zheng, X. Jin, H. Yang, Q. Gao, and K. Xu, “Effects of Circumferential Nonuniform Tip Clearance on Flow Field and Performance of a Transonic Turbine,”. [CrossRef]

- J. Gao, Q. Zheng, Y. Li, and G. Yue, “Effect of Axially Non-uniform Rotor Tip Clearance on Aerodynamic Performance of an Unshrouded Axial Turbine,” Proceedings of the Institution of Mechanical Engineers, Part A, vol. 226, no. 2, pp. 231–244, Mar. 2012. [CrossRef]

- S. Chen, Q. Meng, W. Li, Z. Zhou, and S. Wang, “Experimental Study on Axially Non-uniform Clearances in a Linear Turbine Cascade With a Cavity Squealer Tip,” Proceedings of the Institution of Mechanical Engineers, Part G, vol. 233, no. 5, pp. 1645–1655, Apr. 2019. [CrossRef]

- N. M. Rao and C. Camci, “Axial Turbine Tip Desensitization by Injection From a Tip Trench: Part 1 — Effect of Injection Mass Flow Rate,” presented at the ASME Turbo Expo 2004: Power for Land, Sea, and Air. [CrossRef]

- N. M. Rao and C. Camci, “Axial Turbine Tip Desensitization by Injection From a Tip Trench: Part 2 — Leakage Flow Sensitivity to Injection Location,” presented at the ASME Turbo Expo 2004: Power for Land, Sea, and Air. [CrossRef]

- Chen, W. Dawes, and H. Hodson, “Numerical and Experimental Investigation of Turbine Tip Gap Flow,” in 29th Joint Propulsion Conference and Exhibit, American Institute of Aeronautics and Astronautics. [CrossRef]

- R. J. Volino, “Control of Tip Leakage in a High-Pressure Turbine Cascade Using Tip Blowing,” Journal of Turbomachinery, vol. 139, no. 061008, Feb. 2017. [CrossRef]

- Z. Tao, W. Li, Z. Guo, Y. Chen, L. Song, and J. Li, “Aerothermal optimization of a turbine rotor tip configuration based on free-form deformation approach,” International Journal of Heat and Fluid Flow, vol. 110, p. 109644, Dec. 2024. [CrossRef]

- C. De Maesschalck, S. Lavagnoli, and G. Paniagua, “Blade Tip Carving Effects on the Aerothermal Performance of a Transonic Turbine,” Journal of Turbomachinery, vol. 137, no. 021005, Sep. 2014. [CrossRef]

- B. C. Cernat, M. Pátý, C. De Maesschalck, and S. Lavagnoli, “Experimental and Numerical Investigation of Optimized Blade Tip Shapes—Part I: Turbine Rainbow Rotor Testing and Numerical Methods,” Journal of Turbomachinery, vol. 141, no. 011006, Dec. 2018. [CrossRef]

- Maral, E. Alpman, L. Kavurmacıoğlu, and C. Camci, “A Genetic Algorithm Based Aerothermal Optimization of Tip Carving for an Axial Turbine Blade,” International Journal of Heat and Mass Transfer, vol. 143, p. 118419, Nov. 2019. [CrossRef]

- T.-J. Qin, Z.-X. Tong, D. Li, Y.-L. He, and T.-C. Hung, “Aerothermal Performance of Cavity Tip With Flow Structure Effects in a Transonic High-pressure Turbine Blade,” Energy, vol. 291, p. 130411, Mar. 2024. [CrossRef]

- B. D. Power, High Vacuum Pumping Equipment. London: Chapman & Hall, 1966.

- L. P. Timko, “Energy Efficient Engine High Pressure Turbine Component Test Performance Report,” NASA-CR-168289, Jan. 1984.

- C. Henri, “Device for Deflecting a Stream of Elastic Fluid Projected Into an Elastic Fluid,” US2052869A, Sep. 01, 1936.

- U. H. Von Glahn, “Use of the Coandă Effect for Jet Deflection and Vertical Lift with Multiple-flat-plate and Curved-plate Deflection Surfaces,” Sep. 1958.

- T. Khokhar, “An Aerothermal Study of Ejector-Based, Coandă-Surface-Driven, Gas Turbine Tip Leakage Mitigation Schemes: A Computational and Experimental Approach,” Ph.D. dissertation,The Pennsylvania State University, 2022.

- M. Doshi, “Computational Prediction of a Large-scale Hp Turbine Flow Against Measured Aerodynamic Data,” Master Thesis, The Pennsylvania State University, 2018.

- B. Lakshminarayana, C. Camci, I. Halliwell, and M. Zaccaria, “Design and Development of a Turbine Research Facility to Study Rotor-Stator Interaction Effects,” International Journal of Turbo and Jet Engines, vol. 13, no. 3, pp. 155–172, 1996.

- V. C. Andichamy, “An Investigation of Using Tip Leakage Interrupter and Blade Slit to Mitigate Aerodynamic Losses in Axial Turbine Stage,” Doctoral dissertation, The Pennsylvania State University, 2019.

- Ö. H. Turgut and C. Camci, “Factors Influencing Computational Predictability of Aerodynamic Losses in a Turbine Nozzle Guide Vane Flow,” Journal of Fluids Engineering, vol. 138, no. 051103, Jan. 2016. [CrossRef]

- M. A. Zaccaria, “An Experimental Investigation into the Steady and Unsteady Flow Field in an Axial Flow Turbine,” Ph.D. dissertation, The Pennsylvania State University, 1994.

- Town, “An Investigation of Rim Seal/Disk Cavity Flow and Its Interaction with High Pressure Turbine Rotor Flows,” Ph.D. dissertation, The Pennsylvania State University, 2015.

- R. Taylor, Propagation of Uncertainties. Sausalito, CA: University Science Books, 1997.

- M. Zaccaria and B. Lakshminarayana, “Investigation of Three-dimensional Flowfield at the Exit of a Turbine Nozzle,” AIAA Journal of Propulsion and Power, vol. 11, no. 1, pp. 55–63, Jan. 1995. [CrossRef]

| Inlet Total Temperature (K) | 289 |

| Inlet Total Pressure (KPa) | 101.36 |

| Mass Flow Rate(kg/s) | 11.4 |

| Rotational Speed(RPM) | 1333 |

| Total Pressure Ratio(/) | 1.0778 |

| Total Temperature Ratio(/) | 0.981 |

| Pressure Drop(mmHg); - | 56.04 |

| Power (KW) | 60.6 |

| Rotor Hub Tip Ratio | 0.7269 |

| Tip Radius (m) | 0.4582 |

| Blade Height h (m) | 0.1229 |

| Tip Relative Mach Number | 0.24 (max) |

| Nozzle Guide Vane | |

| Number | 23 |

| Mid-span axial chord (m) | 0.1123 |

| Turning angle (deg) | 70 |

| Reynolds number based on inlet velocity | 3~4 x |

| rotor-stator axial spacing at hub (mm) | 36.32 |

| Rotor Blade | |

| Number | 29 |

| Mid-span axial chord (m) | 0.0929 |

| Turning at tip angle (deg) Turning angle at hub (deg) |

94.42 125.69 |

| Tip clearance t/h | 0.8 % |

| Reynolds number based on inlet velocity | 2.5~5.0x |

| Concept | Tip Gap Mass Flow Rate |

Percent Change |

Total-to-Total Isentropic Efficiency |

(from Baseline FT) |

FOMTip |

|---|---|---|---|---|---|

| Flat Tip (FT) |

8.38 g/s | 0.00% | 89.44% | 0.00% | 0.00% |

| Ejector Baseline (EB) |

7.96 g/s | -5.01% | 89.69% | 0.25% | 3.41% |

| Ejector Coandă (EC) |

7.68 g/s | -8.35% | 89.66% | 0.22% | 5.48% |

| Ejector Coandă-I (ECI) |

7.66 g/s | -8.59% | 89.69% | 0.25% | 5.99% |

| Ejector Coandă-I5 (ECI5) |

7.61 g/s | -9.91% | 89.71% | 0.27% | 6.04% |

| Ejector Coandă-I5n (ECI5n) |

7.41 g/s | -11.58% | 89.74% | 0.30% | 8.90% |

| Ejector Coandă-I5n Hybrid Squealer (ECI5n-HS) |

7.35 g/s | -12.29% | 89.87% | 0.43% | 10.05% |

| Ejector Coandă-I5n Hybrid Ejection Squealer (ECI5n-HES) |

7.18 g/s | -14.32% | 89.90% | 0.46% | 11.16% |

| Ejector Coandă-I5n Optimized Hybrid Ejection Squealer (ECI5n-OHES) | 7.14 g/s | -14.80% | 89.93% | 0.49% | 11.18% |

| Dual Ejector Coandă-I5n (D-ECI5n) |

7.24 g/s | -13.60% | 89.85% | 0.41% | 9.68% |

| Dual Ejector Coandă-I5n Hybrid Squealer (D-ECI5n-HS) |

7.21 g/s | -13.96% | 89.87% | 0.43% | 10.65% |

| Triple Ejector Coandă-I5n (T-ECI5n) |

7.19 g/s | -14.20% | 89.90% | 0.46% | 10.52% |

| Ejector Baseline-5 (EB5) |

7.91 g/s | -5.61% | 89.60% | 0.16% | 3.61% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).