1. Advanced Materials and Composites Revolutionizing Bullet-Resistant Vests

New bullet-proof vests are moving ahead of traditional materials like Kevlar to encompass advanced composites and new materials for improved protection, sustainability, and cost-effectiveness. Composites made of polymers like Rame-Kevlar, carbon nanotube-polymer, and natural fiber-reinforced polymers are being explored. Natural fibers like kenaf, flax, and hemp are being found promising owing to their renewability and sustainability. Researchers are also looking at complete replacements for Kevlar like TWIP steel, Cordura, ballistic nylon, and graphene. These innovations aim to create lighter, more durable vests with improved ballistic performance against a wider range of threats, focusing on hybrid composites that take advantage of the best properties of natural and synthetic materials, avoiding the limitations of current vest technology (Lee et al., 2003; Magadum, Garg, et al., 2025a; Parimala & Vijayan, 1993; Rout et al., 2025).

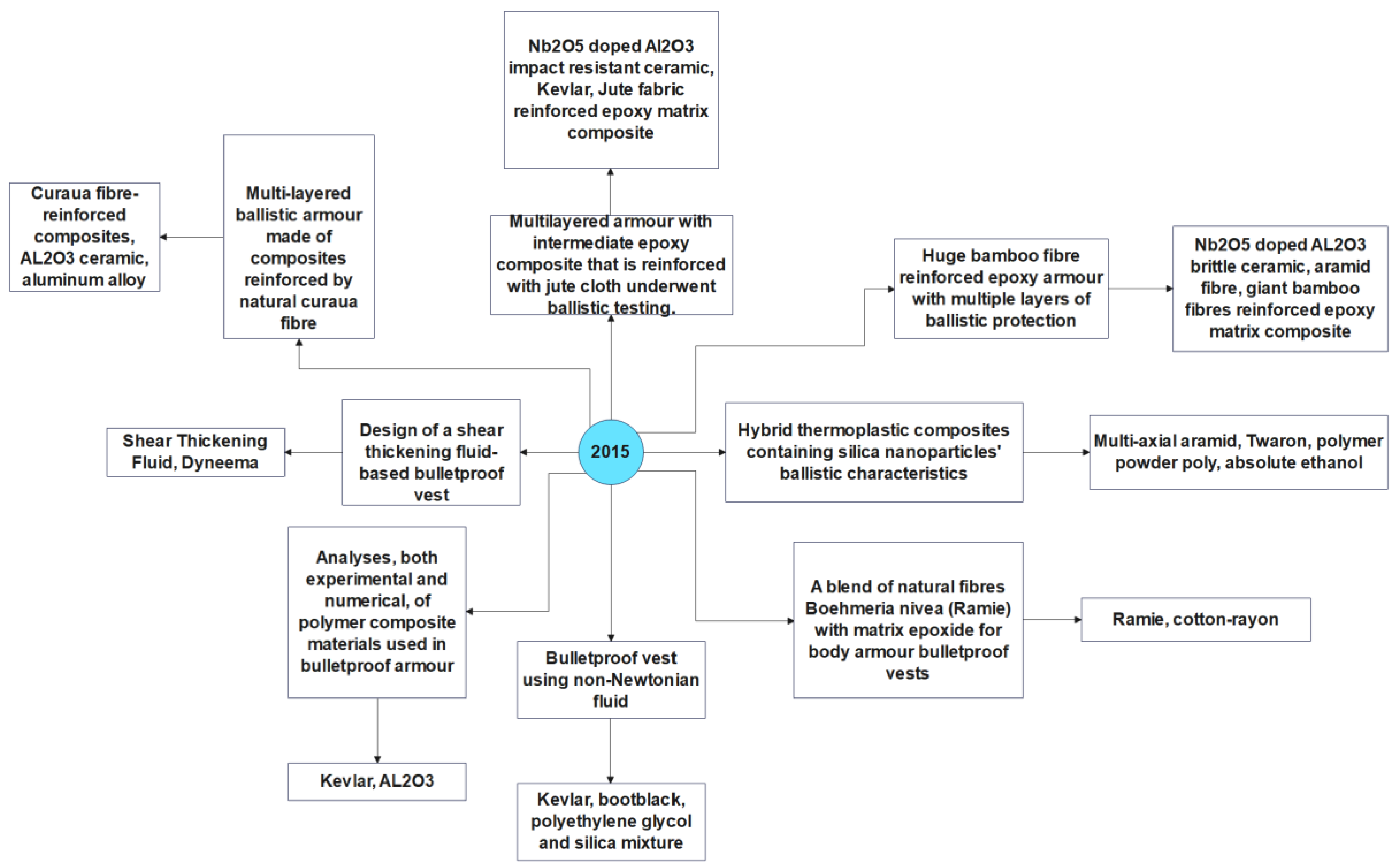

Figure 1.

Ballistic developments timeline since 2015.

Figure 1.

Ballistic developments timeline since 2015.

2. Ballistic Protection Using Kevlar and Graphene Composites

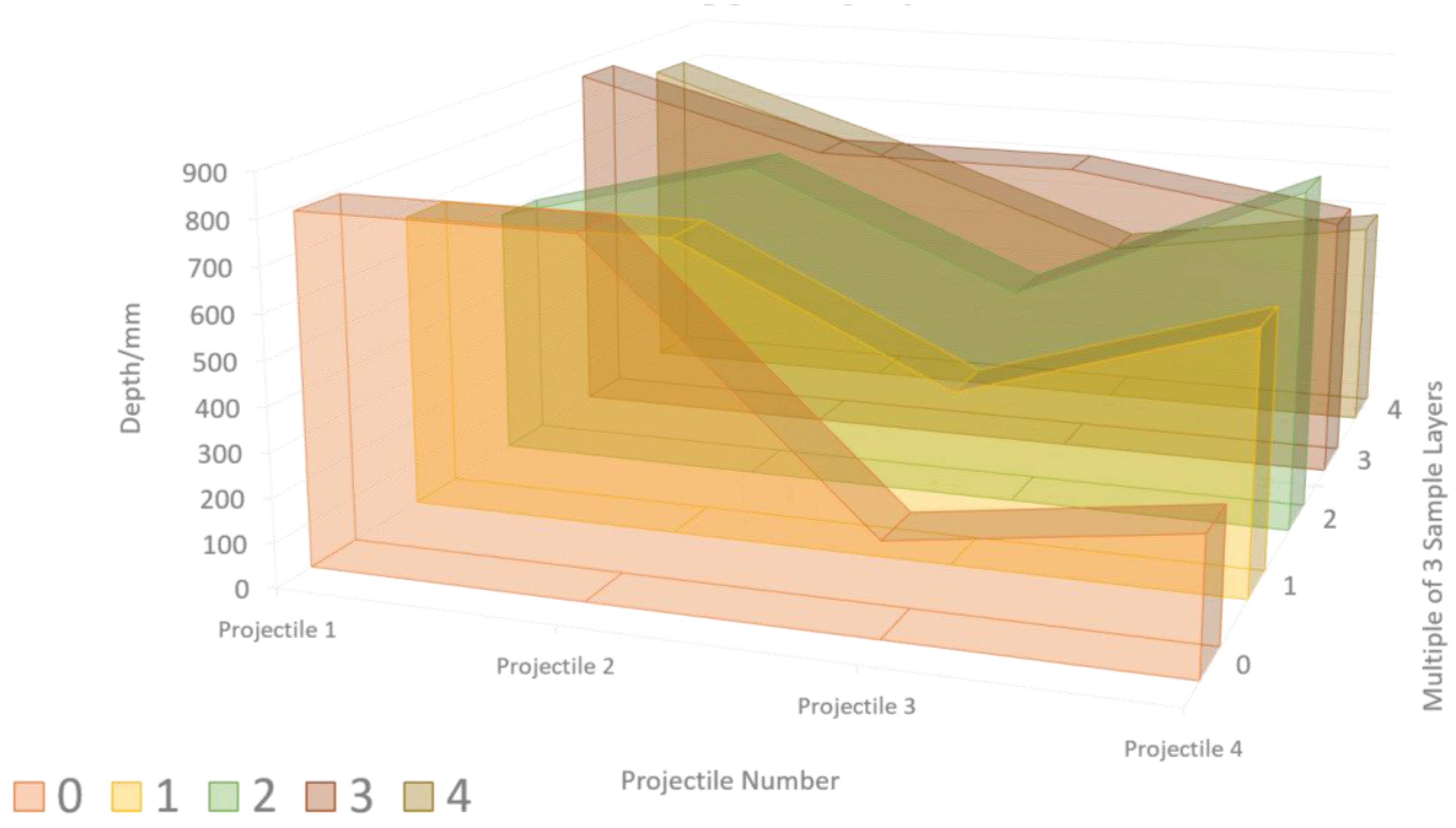

Based on its excellent tensile strength and low mass, Kevlar is widely utilized in bullet-proof jackets to dissipate and efficiently deflect ballistic energy. Test study shows that layers of Kevlar considerably influence its performance; with fewer layers giving deeper penetration of projectiles into ballistic gel, yet at least 21 layers of 200 GSM Kevlar are needed for halting a 9 mm projectile. However, Kevlar’s vulnerability to compressive stress and UV light-induced photo-oxidative degradation has made it imperative to come up with technologies such as graphene reinforcement. Graphene, possessing improved mechanical properties, increases the strength and stability of Kevlar and minimizes distortion to a significant degree. Despite the drawbacks such as increased impact holes, graphene composites have the potential to lead to a next-generation design for armor (Fernando et al., 2015; Garg et al., 2025a; Stopforth & Adali, 2019).

Figure 2.

Distance covered by the projectiles after piercing through various layers of 160 GSM Kevlar.

Figure 2.

Distance covered by the projectiles after piercing through various layers of 160 GSM Kevlar.

3. Production of Ballistic Armor from Natural Fibers and Carbon Nanotube Composites

Natural fiber-reinforced polymer composites (NFRPCs) are proposed to serve as environmentally friendly substitutes for synthetic fibers such as Kevlar, offsetting the environmental issues caused by wasted man-made fibers. They include fibers like basalt, pineapple leaf (PALF), and Cocos nucifera sheath, which possess benefits like low cost, biodegradability, lightness, and acceptable specific strength (Garg et al., 2025b; Magadum, Garg, et al., 2025b; Magadum, Murgod, et al., 2025a; Murgod et al., 2025a; R et al., 2015; Soorya Prabha et al., 2021; Stopforth & Adali, 2020). Their use in armor systems for energy absorption and dissipation properties positions them at a high rank as a potential choice for ballistic applications. Also, carbon nanotube (CNT) polymer composites possess better mechanical, thermal, and electrical properties with 10–100 times the strength of steel. CNTs cut weight while optimizing ballistic protection and heat transfer, the future belongs to inexpensive next-generation body armor solutions (Gao et al., 2017; Gómez-Gualdrón et al., 2011; Pumera, 2009).

4. Kenaf/X-Ray Film Hybrid Composites and Rubber-Enhanced Kevlar for Ballistic Armor

Kenaf/X-ray film hybrid composites provide a sustainable solution for ballistic protection using chemically treated kenaf fibers and recyclable X-ray films. The composites have acceptable tensile strength (396.9 MPa) and flexural modulus (6.24 GPa), which are rigid and strong enough to stop bullets with velocities up to 230 m/s.Weak points, however, are low interfacial bonding and stiffness. Additionally, Kevlar-reinforced polymer composites reinforced with rubber particles have been shown to possess increased impact resistance and energy absorption that mitigates blunt trauma and back signature. Hybrid composites made from natural fibers such as kenaf or ramie and Kevlar exhibit promising innovation in lightweight high-performance bullet-resistant vest technology (Jeong et al., 2008; Luz et al., 2015; Mittal, Kushwaha, et al., 2024; Murgod et al., 2025b).

5. Polymer Laminates and Outer Shell Material Development for Body Armor Vests

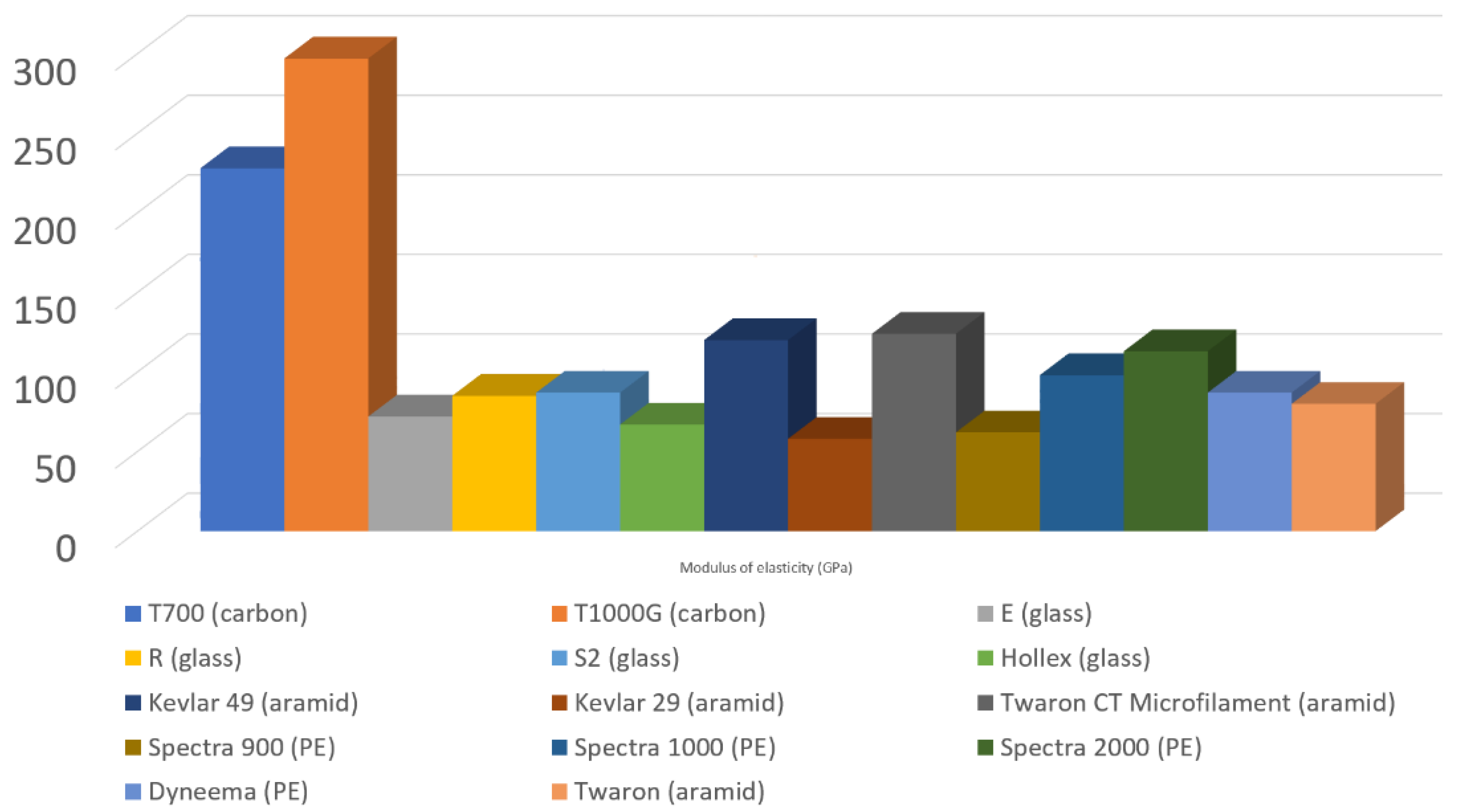

Polymer laminates, including polyethylene (Spectra, Dyneema) and aramid fibers (Kevlar, Twaron), are the most widely used in light bulletproof vests since they can stop small-caliber bullets with kinetic energy below 700J. These laminates work extremely well in low-threat regions and are often blended with ceramic plates for added protection. Outer shell materials such as Cordura and ballistic nylon also have significant contributions to resistance and durability. Cordura has improved puncture resistance, while ballistic nylon is better in abrasion resistance. Both of these materials complement each other to balance strength, flexibility, and weight to meet various ballistic protection requirements effectively (Magadum, Murgod, et al., 2025b; Matveev et al., 1997; Mittal, Yadav, et al., 2024; Praveenkumar et al., 2024; Sliwinski et al., 2018).

Figure 3.

High strength fibers modulus of elasticity analysis.

Figure 3.

High strength fibers modulus of elasticity analysis.

6. TWIP Steel, Water, and Polymer Sandwich Composites for Enhanced Ballistic Protection

A new sandwich composite made of twinning-induced plastic (TWIP) steel, polypropylene-polyethylene polymer, and water has performed well in ballistic applications. Computations show that a configuration of 2 mm steel, 20 mm water, and 2 mm steel can successfully defeat a 9 mm bullet of velocity 360 m/s with negligible inner surface displacement. The use of both polymers and water and both of them separately is better than using either one alone. This composite presents a low, cost-effective option for bulletproof vests using the unique characteristics of TWIP steel and water to dampen and share impact energy. In addition to this, structures like textile fabric reinforced by polyurethane, ceramic, or steel are currently being investigated as a source to impart greater resistance and hardness to bulletproof vests (Bhat et al., 2021; Mittal & Kushwaha, 2024a; Nyanor et al., 2018).

7. Development of Ballistic Inserts and Composite Material for Bulletproof Vesting

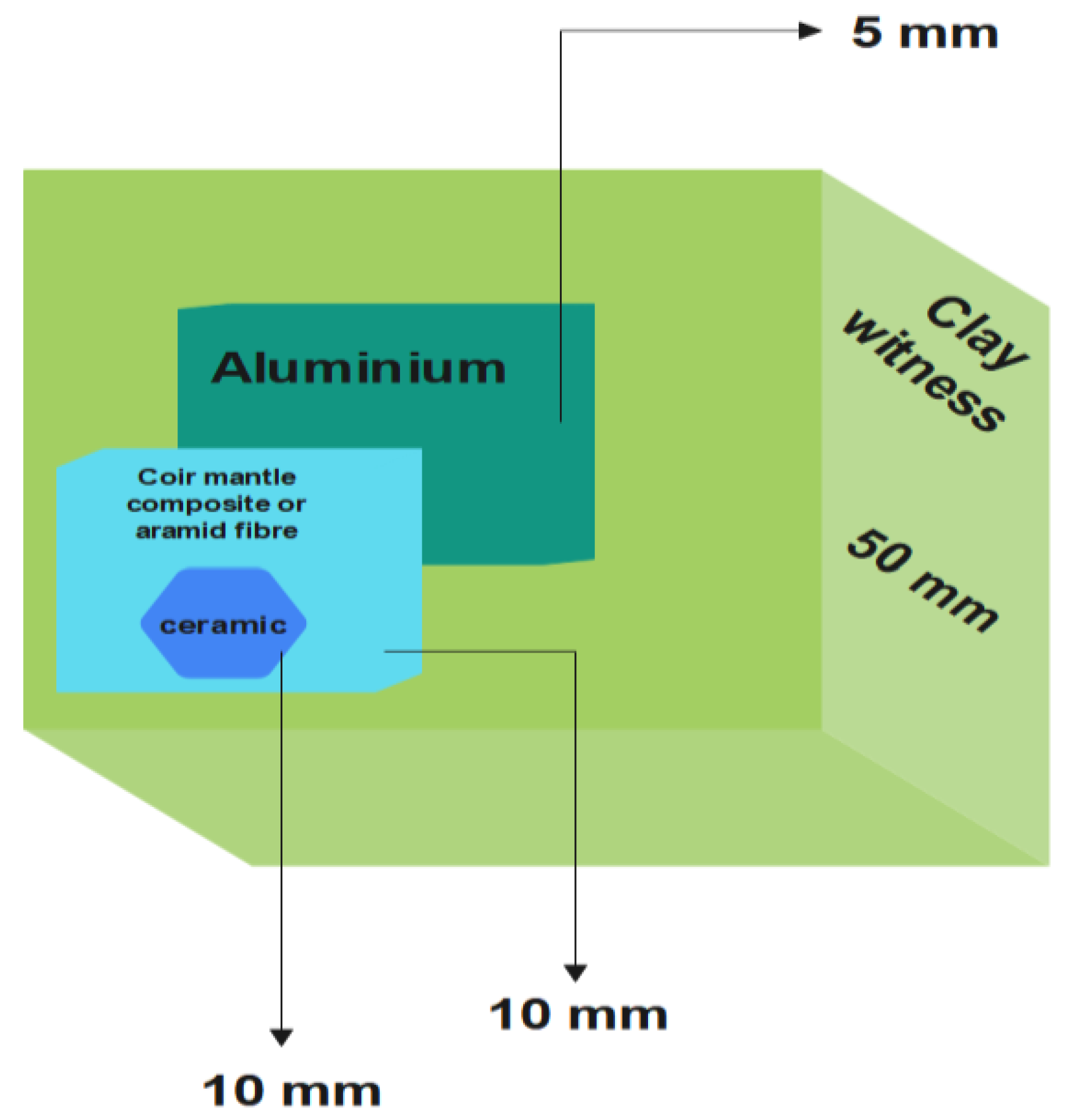

Twaron CT 750 aramid fiber reinforced ply layer and printed titanium components show good ballistic protection and effectively stopped 9x19 mm FMJ Parabellum bullets in testing. They, along with Kevlar/polyurea composite reinforced with shear-thickening fluids (STF), are good and light Class IIIA-standard protective materials Natural fibers such as jute, kenaf, and flax have been used more frequently due to their high specific strength and low price tag. Multi-layered ballistic systems (MBAS) composed of natural and man-made fibers also provide further energy absorption with minimal environmental effects (Anggoro & Kristiana, 2015a, 2015b; Mittal & Kushwaha, 2024c, 2024b; Nurazzi et al., 2021; Nyanor et al., 2018).

Figure 4.

Standard MBAS setup model to test.

Figure 4.

Standard MBAS setup model to test.

8. Conclusions

Recent studies on next-generation body armor materials point to drastic advancements in boosting ballistic protection, sustainability, and affordability. Yet, the majority of innovations like graphene-enhanced Kevlar, shear-thickening fluids (STF), and composite natural fibers are still in the R&D phase with minimal practical experimentation. Computational modeling outshines experimentation, and its success in actual application is unproven. Major findings are increased strength with graphene-Kevlar composites, better performance of natural fibers using nano-cellulose and rubber additives, and cost-effectiveness of natural fibers. Laminate systems can be used for low-risk purposes, while Cordura and ballistic nylon are the best in terms of durability and abrasion resistance. More funding and practical testing are needed to successfully commercialize light, inexpensive, and efficient vests for both military and civilian use.

References

- Anggoro, D. D., & Kristiana, N. (2015a). Combination of natural fiber Boehmeria nivea (ramie) with matrix epoxide for bullet proof vest body armor. 040002. [CrossRef]

- Bhat, A., Naveen, J., Jawaid, M., Norrrahim, M. N. F., Rashedi, A., & Khan, A. (2021). Advancement in fiber reinforced polymer, metal alloys and multi-layered armour systems for ballistic applications – A review. Journal of Materials Research and Technology, 15, 1300–1317. [CrossRef]

- Fernando, E., Niles, S., Morrison, A., Pranavan, P., Godakanda, I., & Mubarak, M. (2015). Design of a bullet-proof vest using shear thickening fluid. International Journal of Advanced Scientific and Technical Research, 434–444.

- Garg, K., Mittal, H., Yadav, V., Sehrawat, A., Shah, V., & Kushwaha, O. (2025a). Municipal Solid Waste (MSW) Management Prediction Through Machine Learning Models: An Ensemble Tree Regressor Analysis. [CrossRef]

- Jeong, H.-K., Noh, H.-J., Kim, J.-Y., Jin, M. H., Park, C. Y., & Lee, Y. H. (2008). X-ray absorption spectroscopy of graphite oxide. EPL (Europhysics Letters), 82(6), 67004. [CrossRef]

- Lee, Y. S., Wetzel, E. D., & Wagner, N. J. (2003). The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. Journal of Materials Science, 38(13), 2825–2833. [CrossRef]

- Luz, F. S. da, Lima Junior, E. P., Louro, L. H. L., & Monteiro, S. N. (2015). Ballistic Test of Multilayered Armor with Intermediate Epoxy Composite Reinforced with Jute Fabric. Materials Research, 18(suppl 2), 170–177. [CrossRef]

- Magadum, T., Garg, K., Murgod, S., Yadav, V., Mittal, H., & Kushwaha, O. (2025a). Geospatial Analysis in Machine Learning for CO2 Emissions Prediction Analysis in 2100: A Continent-Wise Analysis. [CrossRef]

- Magadum, T., Murgod, S., Garg, K., Yadav, V., Mittal, H., & Kushwaha, O. (2025a). Renewable Energy Transition in South America: Predictive Analysis of Generation Capacity by 2050.

- Magadum, T., Murgod, S., Garg, K., Yadav, V., Mittal, H. N., & Kushwaha, O. (2025b). Africa Renewable Energy Development to 2050: Forecast Analysis through a Machine Learning Perspective. [CrossRef]

- Matveev, V. S., Budnitskii, G. A., Mashinskaya, G. P., Aleksandrova, L. B., & Sklyarov, N. M. (1997). Structural and mechanical characteristics of aramid fibres for bullet-proof vests. Fibre Chemistry, 29(6), 381–384. [CrossRef]

- Mittal, H., & Kushwaha, O. S. (2024a). Biogas and Biofuel Production from Biowaste: Modelling and Simulation Study. In From Waste to Wealth (pp. 379–400). Springer Nature Singapore. [CrossRef]

- Mittal, H., & Kushwaha, O. S. (2024b). Machine Learning in Commercialized Coatings. In Functional Coatings (pp. 450–474). Wiley. [CrossRef]

- Mittal, H., & Kushwaha, O. S. (2024c). Policy Implementation Roadmap, Diverse Perspectives, Challenges, Solutions Towards Low-Carbon Hydrogen Economy. Green and Low-Carbon Economy. [CrossRef]

- Mittal, H., Kushwaha, O. S., Nadagouda, M., Hegde, G., Allen, S., & M. Aminabhavi, T. (2024). Adsorption and storage of hydrogen- A computational model approach. Environmental Research, 260, 119606. [CrossRef]

- Mittal, H., Yadav, V., & Kushwaha, O. (2024). Carbon Capture Advancements in Metal-Organic Frameworks. [CrossRef]

- Murgod, S., Garg, K., Magadum, T., Yadav, V., Mittal, H., & Kushwaha, O. (2025a). AI Powered Renewable Energy Balancing, Forecasting and Global Trend Analysis using ANN-LSTM Integration. [CrossRef]

- Murgod, S., Garg, K., Magadum, T., Yadav, V., Mittal, H., & Kushwaha, O. S. (2025b). CO₂ Emissions Projections for 2100: A Comparative Machine Learning Study of U.S. and Multimodal Approach of Global Trends. [CrossRef]

- Nurazzi, N. M., Asyraf, M. R. M., Khalina, A., Abdullah, N., Aisyah, H. A., Rafiqah, S. A., Sabaruddin, F. A., Kamarudin, S. H., Norrrahim, M. N. F., Ilyas, R. A., & Sapuan, S. M. (2021). A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers, 13(4), 646. [CrossRef]

- Nyanor, P., Hamada, A. S., & Hassan, M. A.-N. (2018). Ballistic Impact Simulation of Proposed Bullet Proof Vest Made of TWIP Steel, Water and Polymer Sandwich Composite Using FE-SPH Coupled Technique. Key Engineering Materials, 786, 302–313. [CrossRef]

- Parimala, H. V., & Vijayan, K. (1993). Effect of thermal exposure on the tensile properties of Kevlar fibres. Journal of Materials Science Letters, 12(2). [CrossRef]

- Praveenkumar, V., Mittal, H. N., & Kushwaha, O. S. (2024). Analysing Industrial Scale-Up of Carbon Dioxide Capture in Aqueous Amino Acids for Sustainable Technologies (pp. 39–55). [CrossRef]

- R, S., G, V. V., & Alexander, A. M. (2015). Bullet Proof Vest using Non-Newtonian Fluid. International Journal of Students’ Research in Technology & Management, 3(8), 451–454. [CrossRef]

- Rout, D., Shyamsukha, N., Mittal, H., & Kushwaha, O. S. (2025). Solar energy generation and power prediction through computer vision and machine intelligence. In Computer Vision and Machine Intelligence for Renewable Energy Systems (pp. 103–123). Elsevier. [CrossRef]

- Sliwinski, M., Kucharczyk, W., & Guminski, R. (2018). Overview of polymer laminates applicable to elements of light-weight ballistic shields of special purpose transport means. Scientific Journal of the Military University of Land Forces, 189(3), 228–243. [CrossRef]

- Soorya Prabha, P., Ragavi, I. G., Rajesh, R., & Pradeep Kumar, M. (2021). FEA analysis of ballistic impact on carbon nanotube bulletproof vest. Materials Today: Proceedings, 46, 3937–3940. [CrossRef]

- Stopforth, R., & Adali, S. (2019). Experimental study of bullet-proofing capabilities of Kevlar, of different weights and number of layers, with 9 mm projectiles. Defence Technology, 15(2), 186–192. [CrossRef]

- Stopforth, R., & Adali, S. (2020). Experimental Investigation of the Bullet-proof Properties of Different Kevlar, Comparing .22 Inch with 9 mm Projectiles. Current Materials Science, 13(1), 26–38. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).