Submitted:

18 June 2025

Posted:

19 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

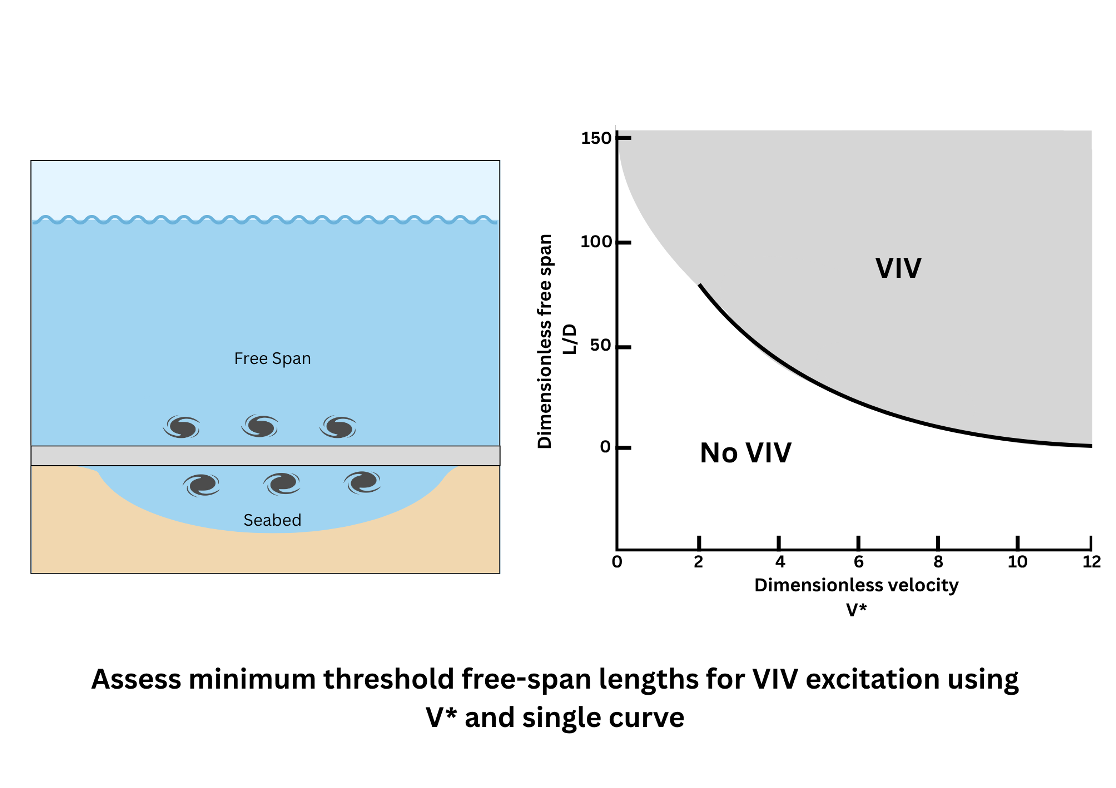

The Onset of VIV

2. Non-Dimensional Analysis

Identification of Relevant Variables and Dimensions

- Characteristic outside diameter D [L]

- Current velocity, V [LT−1]

- Fluid density ρf [ML−3]

- Mass density of structure (cable or pipe) ρS [ML−3]

- Characteristic free span length, L [L]

- Cable or pipe bending stiffness, EI [MLT−2.L2 = ML3T-2]

- Cable or pipe as-laid effective tension, Teff [MLT−2]

- D (geometric),

- V (kinematic), and

- ρf (dynamic).

Simplified Governing Equations

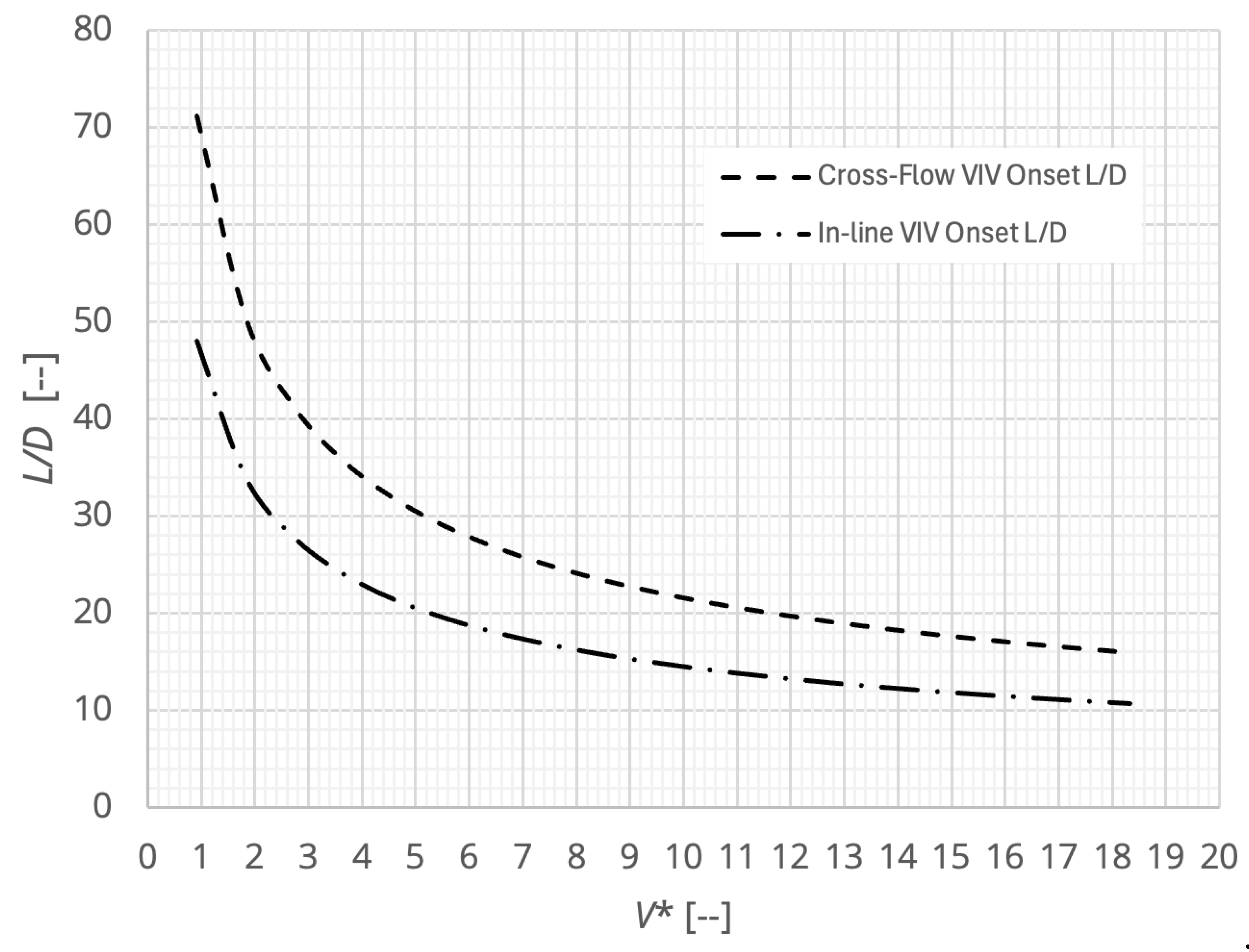

3. Simplified Response Curve

- Clamped-clamped end condition (per DNV [2] single span recommendation)

- Ca = 1.0

- Safety factor on onset value for in-line, γonIL = 1.1; (cross-flow onset safety factor not applied in determining cross-flow VIV onset condition in [2] )

- Safety factor on in-line and cross-flow natural frequencies, γ fIL = 1, γ fCF = 1

- Lowest natural frequencies in in-line and cross-flow directions for a given span are termed fIL,1 and fCF,1 and computed per Section 2.2 in [2]

- VR onset for cross-flow VIV is effectively 2.0 (Section 2.3.3 [2])

- No multi-spans, interactions between spans or significant sagging is considered

- This covers screening for fatigue (FLS), not local buckling of ultimate stress (ULS)

4. Case Studies

Power Cable Free Span Screening – Minimum Velocity

- Free-span length, L = 5 m

- Diameter, D = 0.176 m

- Bending Stiffness, EI = 12 kN·m²

- Mass/Length = 77.3 kg/m (

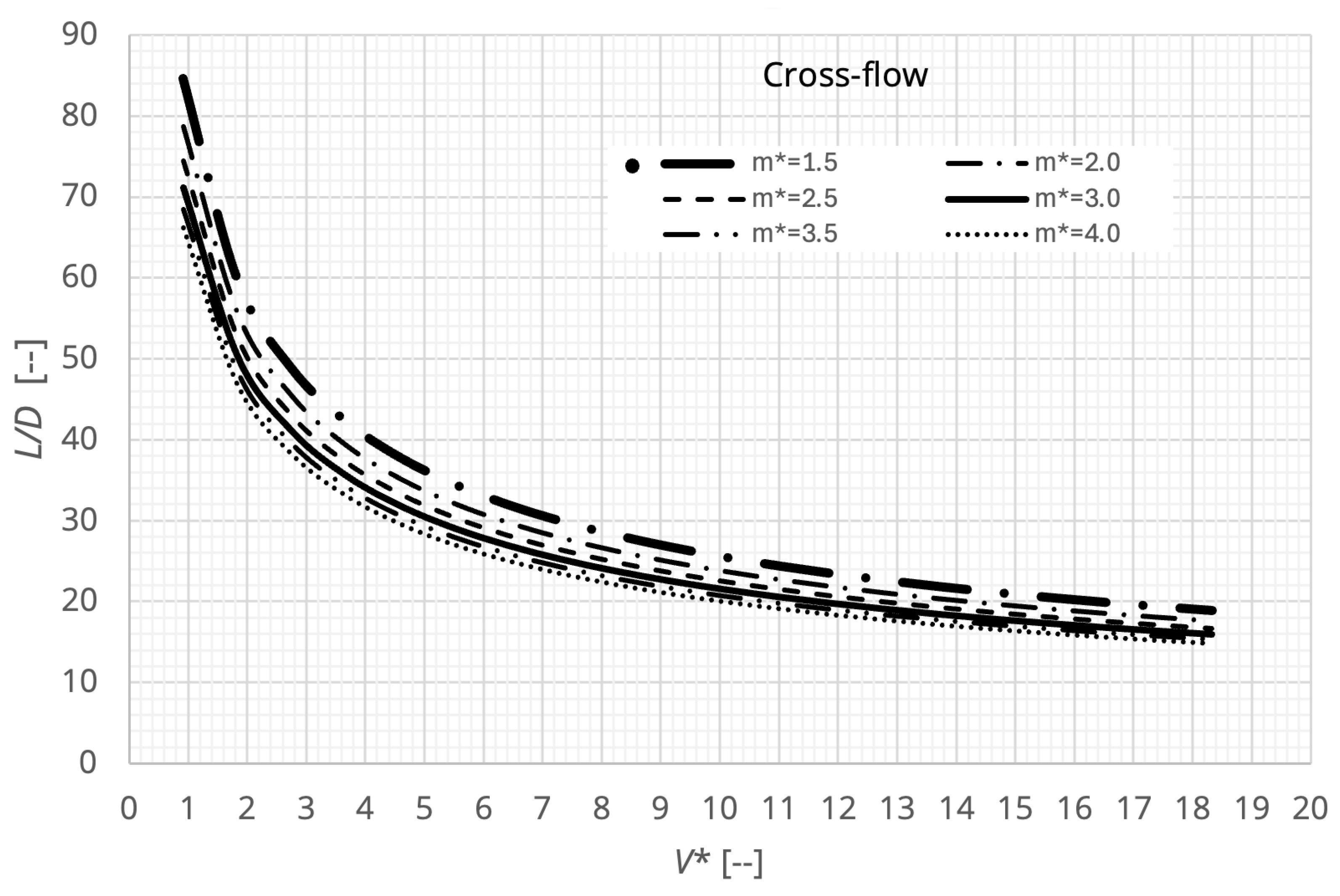

- L/D = 28, m* ~ 3 (from Equation 1) (as ~3, use Figure 1)

- VIL* ~ 2.8, VCF* ~ 5.9 (from Fig 2)

- Onset velocities VIL ~ 0.3 m/s, VCF ~ 0.65 m/s (from Equation 4)

Pipeline Free Span screening – Maximum Span Length

- Diameter, D = 0.483 m (19 inch)

- Maximum V: 1.7 m/s

- Bending Stiffness, EI: 4.68e7 N·m²

- Mass/Length = 518 kg/m

- m* = 2.8 (from Equation 1) (as ~3, use Figure 1)

- V* = 1.85 (from Equation 4)

- Critical minimum span lengths: (L/D)IL = 34, (L/D)CF = 50, ∴LIL = 16 m, LCF = 24 m

5. Discussion

6. Conclusions

- The non-dimensionalisation of a free span under VIV revealed three dominant physical mechanisms, mass ratio, aspect ratio and bending stiffness curvature loading.

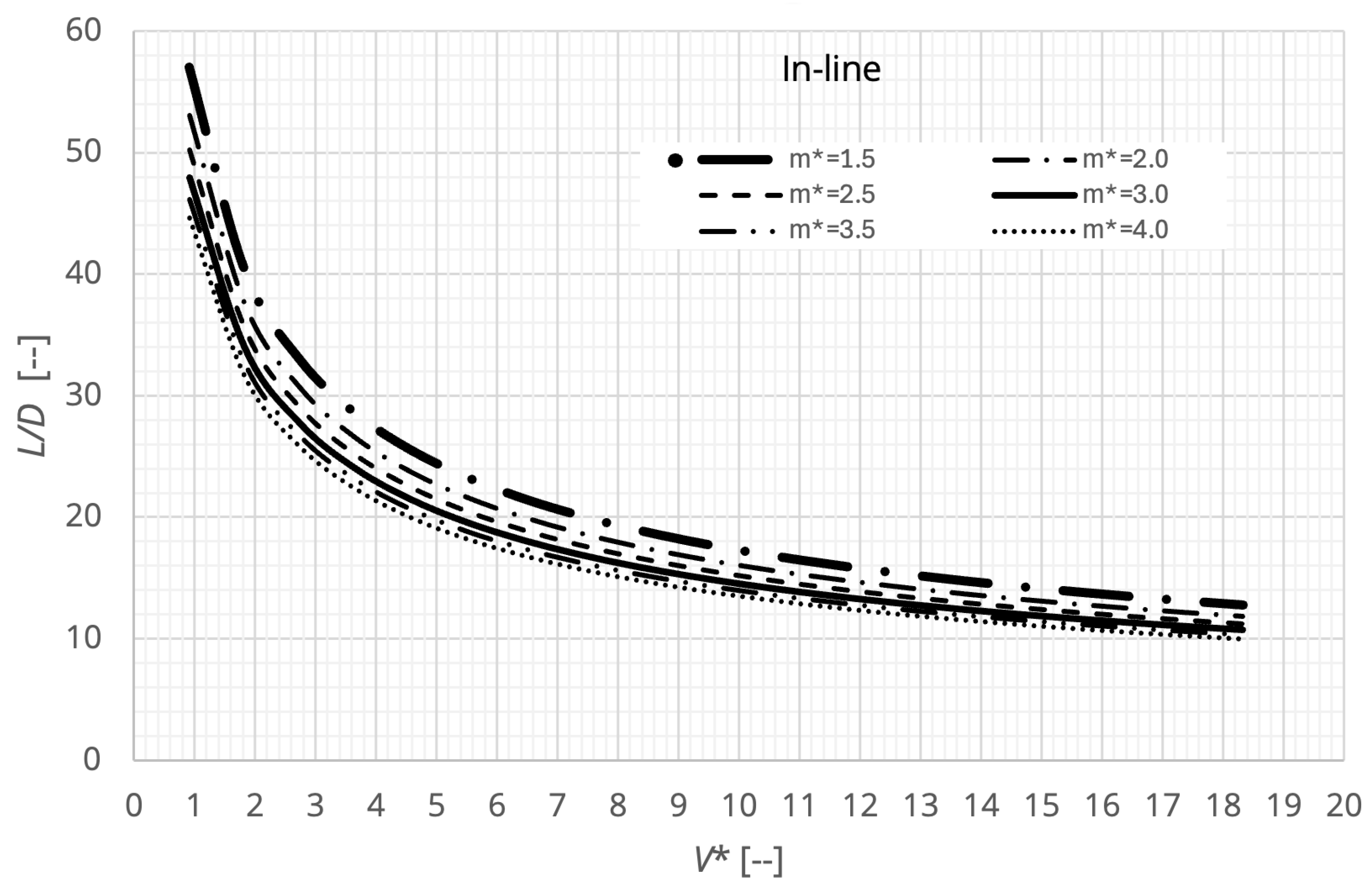

- The mass ratio within the range investigated does not show significant influence on the critical free span length for a given non-dimensional flow velocity.

Abbreviations

| CF | Cross-Flow |

| IL | Inline |

| LGS | Longitudinal Grooved Suppression |

| VIV | Vortex Induced Vibration |

Data Sharing

References

- Martins, R.R.; Cardoso, C.O.; Matt, C.G.C.; Nunes, L.A.N.; Góes, R.C.O.; Rosa, A.S.; Silveira, E.S.S. Improving the Free Span Analysis of Subsea Rigid Pipelines for Life Extension Through Integration and Automation and Efficiency. In Proceedings of the Offshore Technology Conference; OTC: Houston, Texas, USA, April 28 2025; p. D021S022R008.

- Free spanning pipelines. DNV-GL-RP-F105. Edition 2017-06 - Amended 2021-09. Recommended Practice.

- shear7.com accessed 10 June 2025.

- https://sesam.dnv.com/download/userdocumentation/fatfree-user-manual.pdf accessed 10 June 2025.

- Kelly, S.G. Fundamentals of Mechanical Vibrations; McGraw-Hill series in mechanical engineering; McGraw-Hill: New York, 1993; ISBN 978-0-07-911533-1. [Google Scholar]

- Vandiver, J.K. Dimensionless Parameters Important to the Prediction of Vortex-Induced Vibration of Long, Flexible Cylinders in Ocean Currents. Journal of Fluids and Structures 1993, 7, 423–455. [Google Scholar] [CrossRef]

- Rao, S.S. Mechanical Vibrations; Sixth edition.; Pearson: Hoboken, NJ London Toronto, 2017; ISBN 978-0-13-436130-7. [Google Scholar]

- https://www.nrel.gov/docs/fy21osti/76968.pdf accessed 10 June 2025.

- Jayasinghe, K.; Marcollo, H.; Potts, A.E.; Dillon-Gibbons, C.; Kurts, P.; Pezet, P. Mitigation of Pipeline Free Span Fatigue Due to Vortex Induced Vibration Using Longitudinally Grooved Suppression. In Proceedings of the Volume 5: Pipelines, Risers, and Subsea Systems; American Society of Mechanical Engineers: Madrid, Spain, June 17 2018.

- Zhu, J.; Ren, B.; Dong, P.; Chen, W. Vortex-Induced Vibrations of a Free Spanning Submarine Power Cable. Ocean Engineering 2023, 272, 113792. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).