1. Introduction

The magnitude of the climate crisis now demands the complete decarbonization of the economy, rather than merely reducing emissions. This means not just improving the efficiency of fossil fuel use but eliminating them entirely. Achieving this goal requires transitioning to zero-carbon energy, primarily through the electrification of sectors that have traditionally relied on non-electric energy sources and rethinking the role of energy efficiency in decarbonization of society [

1]. The industry sector generated 9.0 Gt of CO

2 in 2022, which is about 25% of global emissions, according to the International Energy Agency (IEA) [

2]. This amount must be reduced by ambitious 7.0 Gt of CO

2 by 2030 according to Net Zero Emissions by 2050 Scenario (NZE Scenario) [

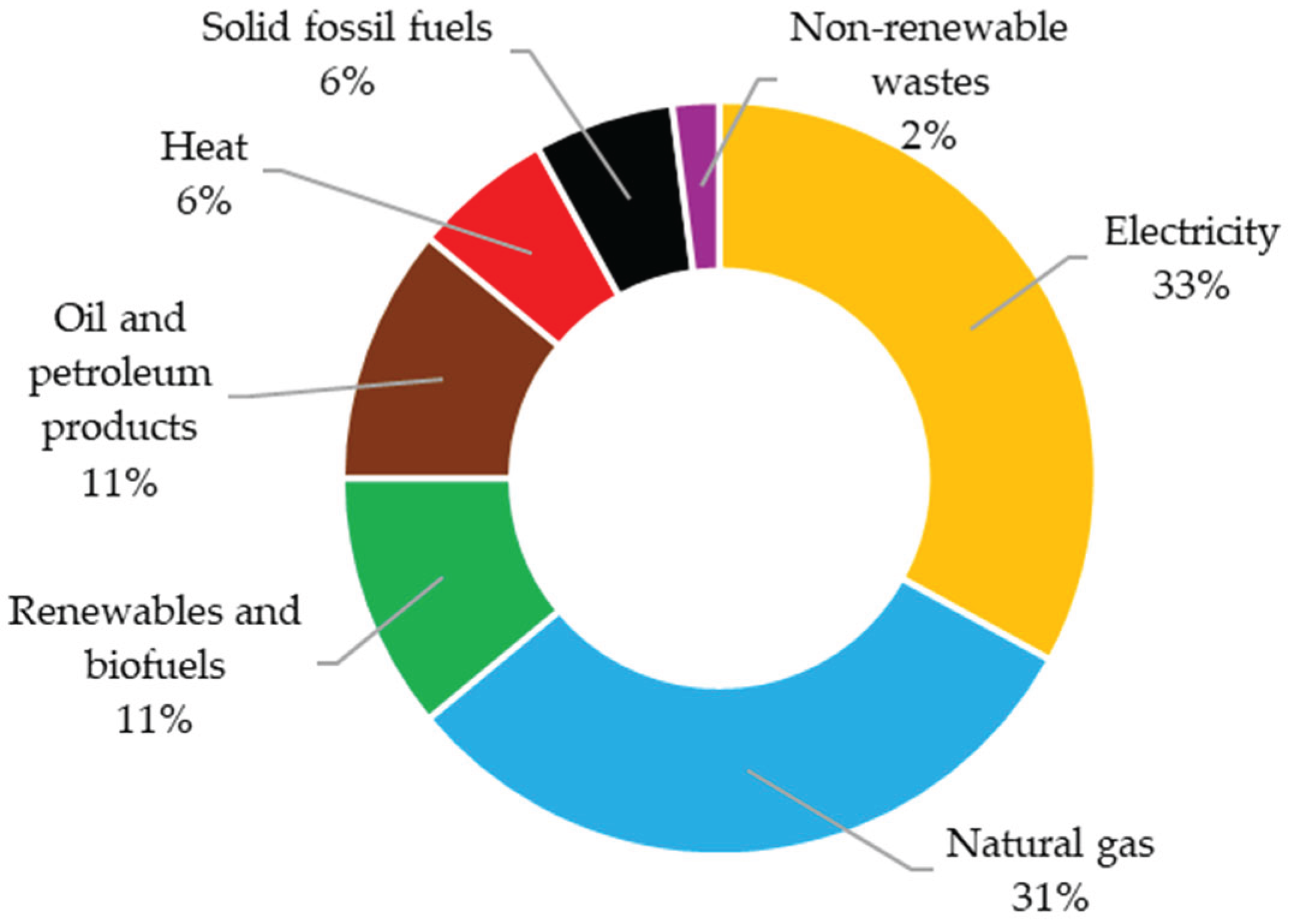

3]. In 2022, the heat process accounted for approximately two-thirds of greenhouse gas emissions from the industrial sector. Achieving a climate-neutral industry necessitates a transition in process heat generation, shifting to carbon-neutral energy sources. Since the industrial sector primarily uses fossil fuels, and renewables are still not used in industry, these emissions can be relevant to energy consumption. For example, according to Eurostat, the European Union (EU) industry was responsible for 25.6% of total energy consumption in 2022 [

4] and is based mostly on electricity and natural gas, while renewables and biofuels account for 11%, as shown in

Figure 1.

A detailed analysis of the technological potential of hydrogen and electricity as alternative sources for process heat identified the primary barriers to adoption and outlines necessary actions for effective policy frameworks [

5]. The electrification of the chemical industry necessitates the identification of well-defined targets for chemical processes that can significantly influence the energy-carbon nexus [

6]. Prioritising such processes is crucial for maximising the impact on energy efficiency and carbon reduction. By focusing on these key areas, the industry can accelerate the transition towards sustainable and low-carbon production methods, thereby addressing the dual challenges of reducing greenhouse gas emissions and optimising energy use [

7]. The impact of industry electrification within the framework of various 100% renewable energy system scenarios can be considered by different key stakeholders [

8]. It examined how the role of electrification may vary depending on the specific context. The findings indicate that direct electrification of industrial process heat demands is generally preferable to alternatives such as shifting to hydrogen-based process systems, despite the latter’s potential to offer greater flexibility. This preference for direct electrification highlights its superior efficiency and effectiveness in contributing to decarbonization efforts within industrial processes [

9].

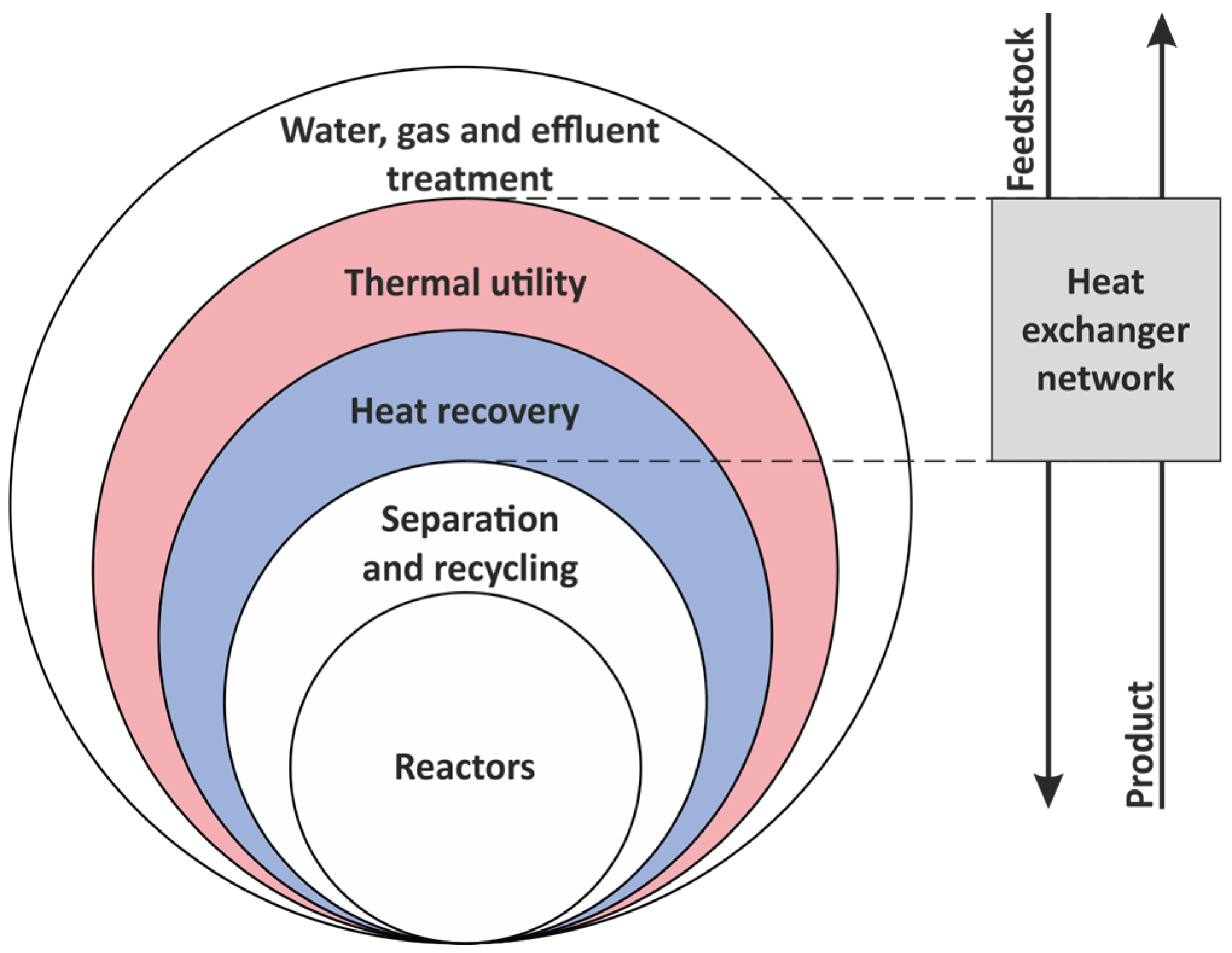

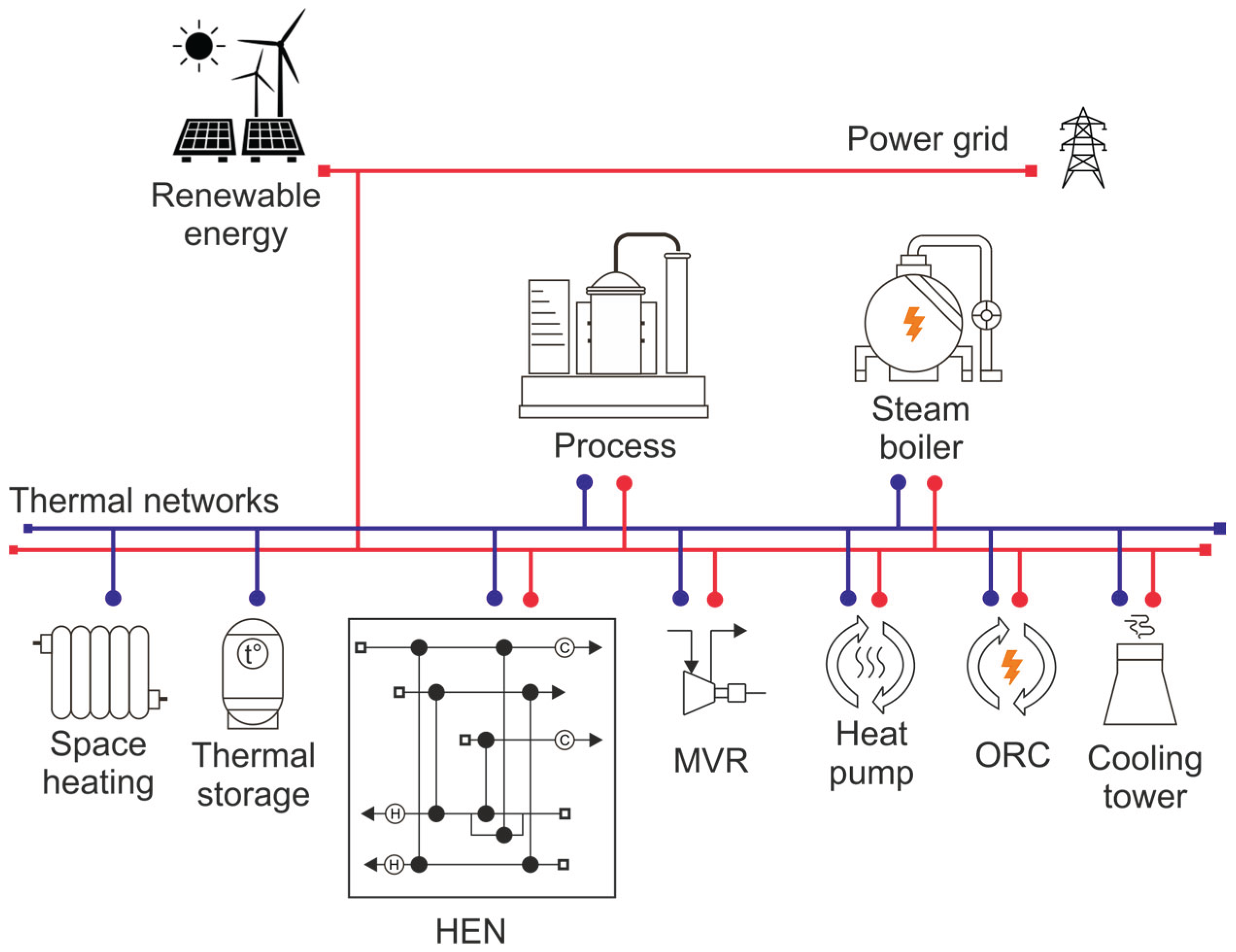

Process industries, where the target product requires chemical transformations, remain the primary energy consumers. They are chemical, petrochemical, pulp and paper, food and beverages, etc. The production system of these industries includes chemical reactors, product and by-product separators supplemented by a heat exchanger network (HEN) to supply and recover the energy of the main processes and utility (see

Figure 2). HEN has a crucial role in the energy use of process systems by heat recovery and supplying thermal utility for heating and cooling purposes; the main perspectives were described in [

10]. The negative emission technologies exhibit varying levels of permanence and durability in their carbon dioxide removal capabilities that may present significant challenges. However, established principles and process integration techniques can be effectively adapted to address the emerging complexities associated with planning carbon dioxide removal portfolios [

11].

Heat exchanger network synthesis [

12] and retrofit [

13] is a long-term objective that has been developed by many researchers [

14]. That was mainly related to fossil fuel-based industries with specific utility system features [

15] and HEN development approaches [

16]. Environmental challenges change the paradigm for industrial energy systems, applying electrification of fossil fuel-based utilities by replacing them with renewable energies.

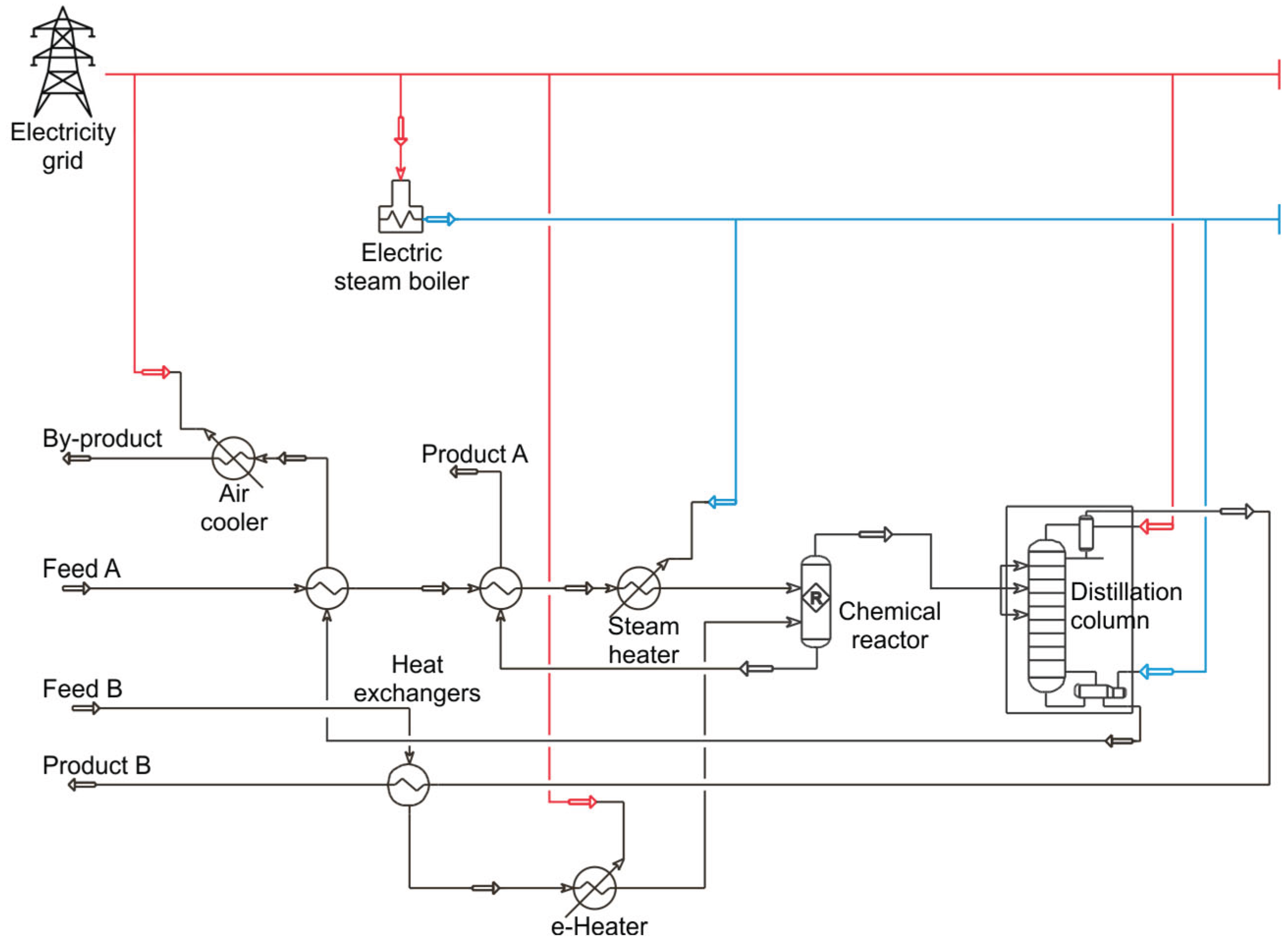

This assumes modified approaches for HEN synthesis and retrofit, applying new heating and cooling strategies, heat recovery, heat engine applications, trade-offs between capital expenditure (CAPEX) and operation cost (OPEX), etc. The chemical process with electrified thermal utility and heat exchanger network is illustrated in

Figure 3.

The diagram in

Figure 3 depicts a simple chemical process integrated with an electrified utility system, highlighting electricity’s role in facilitating thermal and mechanical operations within a sustainable industrial framework. Central to this system is an electrified boiler that utilises electrical energy, symbolised by the transmission tower, to produce high-pressure steam (illustrated by red lines). This steam is conveyed through a network of heat exchangers, where it transfers thermal energy to various process streams, thereby supporting endothermic chemical reactions or meeting heating requirements. Upon releasing its thermal energy, the steam is condensed (represented by blue lines) and converted back into water, which is then pumped through feedwater preheaters, completing the closed-loop system. The utility network substitutes traditional fossil-fueled boilers with electric heating solutions, promoting decarbonization and operational flexibility. Additionally, the presence of electrically driven compressors and pumps underscores the transition from fossil fuel-dependent mechanical processes to electrification. The interconnected loops and control valves signify an optimised heat exchanger network that maximises energy recovery, minimises emissions, and provides precise temperature control throughout the processes, all reliant on a centralised electric grid.

2. Challenges in Heat Exchanger Network Developments

2.1. Multiple Utility and Driving Forces

The electrification of industrial energy systems presumes using different types of utility heat transfer equipment such as electric furnaces [

17], electric heaters [

18], plasma heaters [

19], electric steam boilers [

20], etc. This means modifying the targeting procedure compared to a fossil fuel-based energy system [

21]. The main principle is keeping the hot utility colder, and cold utility hotter may remain unchanged, but there is no need to cascade the heat from high-temperature utility to lower levels, which makes cogeneration useless [

15].

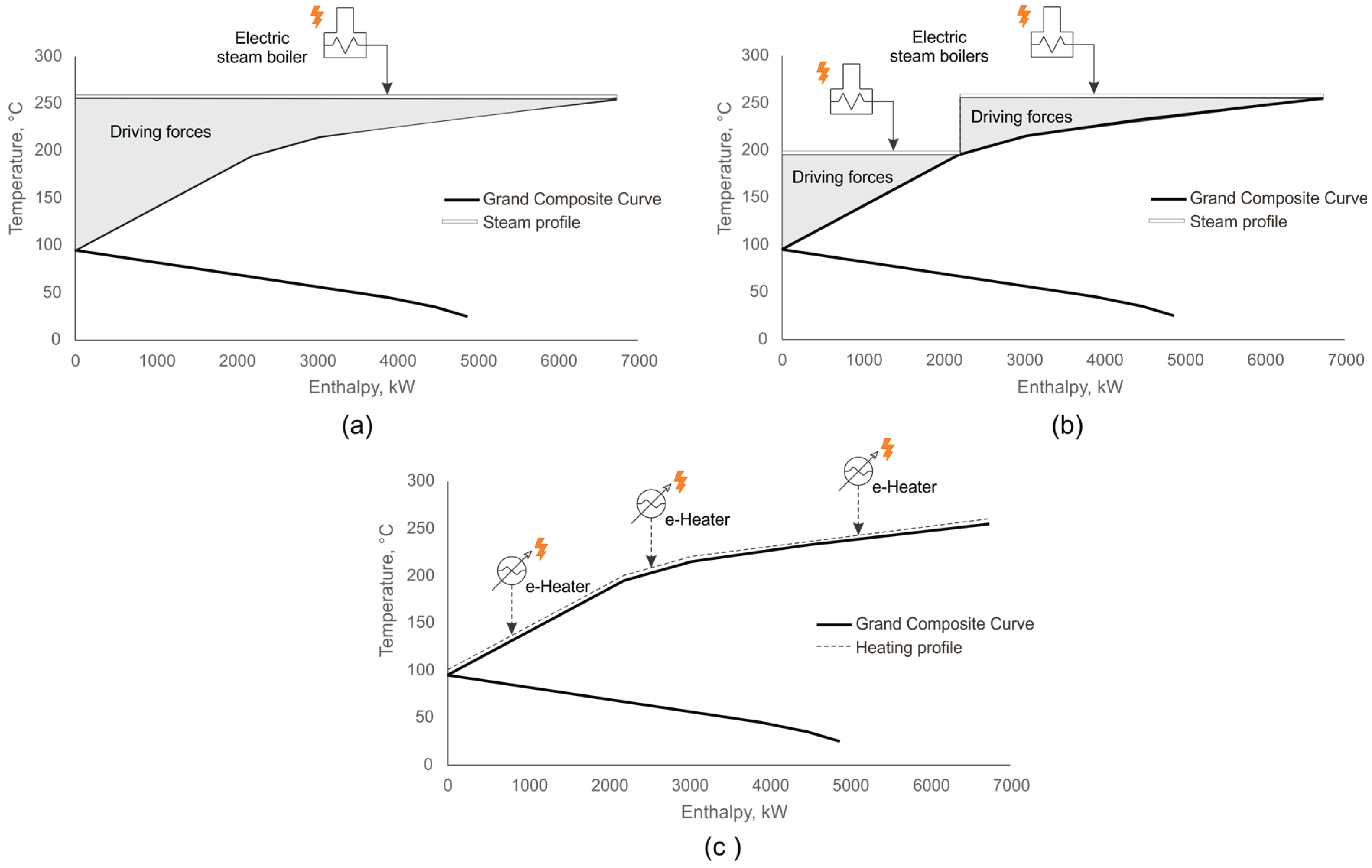

However, this problem becomes untrivial when considering different types of equipment for process stream heating. For instance, in the case of steam heaters, the heat transfer area of heat exchangers can be reduced when the steam temperature is higher [

22]. However, this may increase the equipment cost due to higher pressure and temperature levels of the vessel. The problem with energy capital trade-off may be reduced when using the direct heating of process streams with electric heaters, electric furnaces, etc. The diagrams in

Figure 4 can illustrate this issue.

Steam expansion is useless for electricity generation; the electricity originally obtained from cogeneration plants should be substituted by electricity exported from the grid or produced by renewable energies [

23]. Electricity-based heating systems offer greater flexibility in the HEN compared to fossil fuel-based systems. This increased flexibility can significantly reduce the design complexities associated with HEN under electrification. Modifying the industrial utility system also affects the development strategy for utility heat exchangers in the overall network context, and the number of units, unit type and temperature level should be defined. Site-wide energy systems can be engineered based on the thermal demands and specific types of utilities required at the process level. In industrial complexes with multiple units or processes, a centralised utility system is typically employed in non-electrified environments to generate and distribute steam to individual plants [

24].

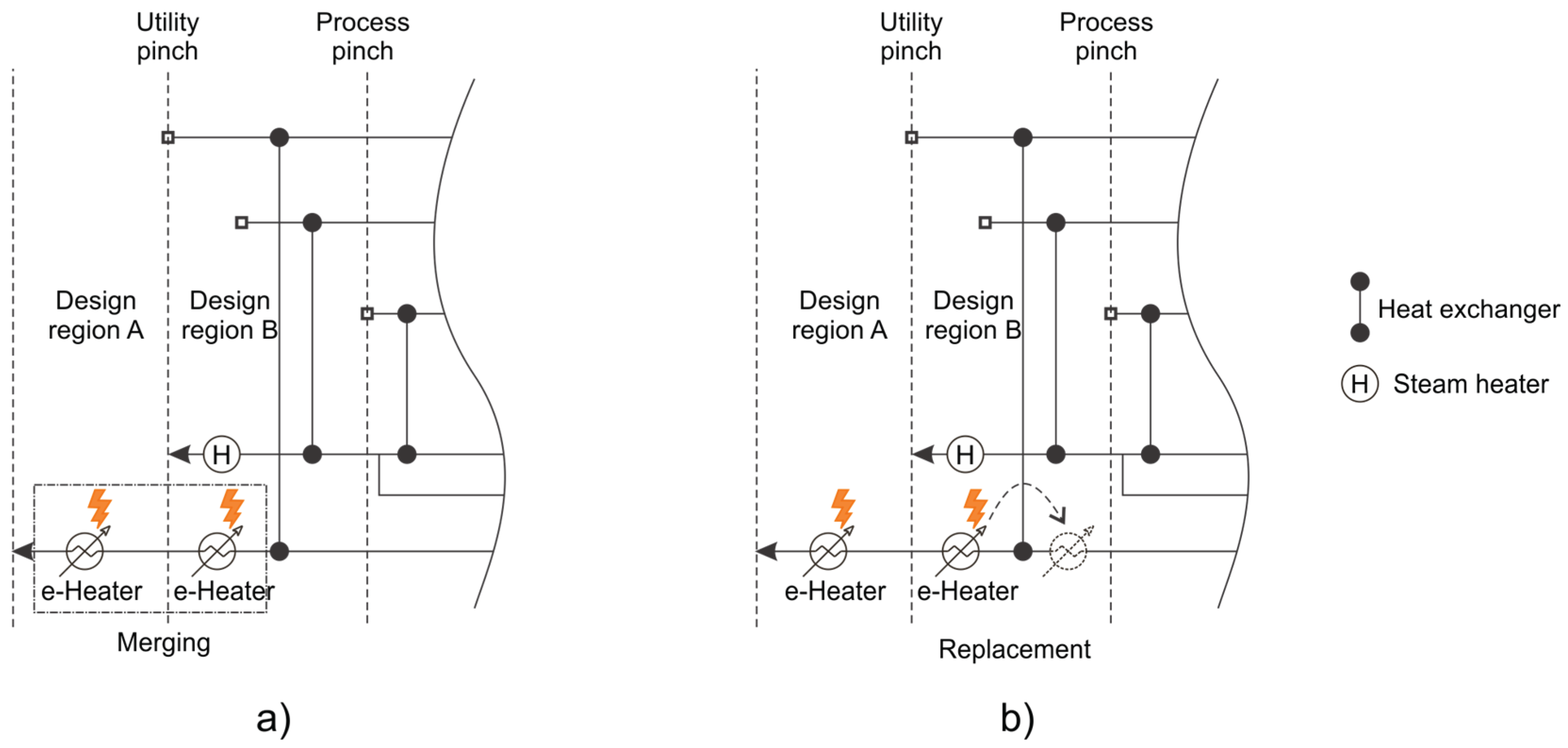

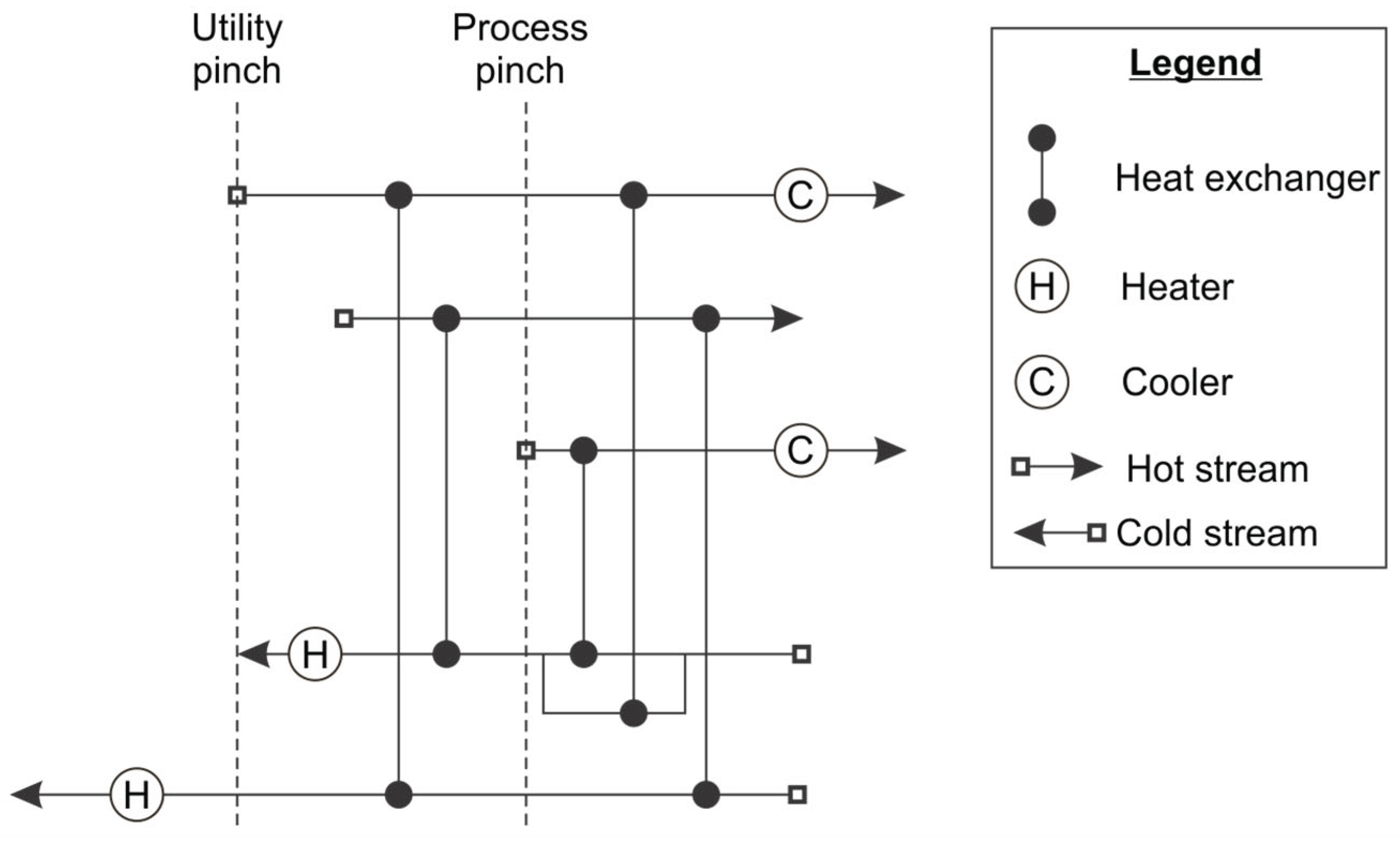

2.2. Multi-Pinch Problem

The utilisation of different temperature levels for utility heat transfer in HEN creates multiple pinch points, complicating the design and optimisation process. In conventional systems, this challenge is typically addressed by dividing the HEN into distinct design regions [

25], each balanced using appropriate utilities [

26], such as low- or medium-pressure steam, or process furnaces, to meet the remaining heat demands. Electric heaters can be employed in any design region in electrified processes, offering greater flexibility. However, the selection of heating units must be carefully tailored to the specific process conditions. Additionally, when integrating different design regions that are separated by utility pinches, the number and configuration of electric heaters, steam boilers, and furnaces must be optimized to ensure efficient energy utilization and minimize operational costs. Targeting procedure demonstrates the temperature profile for heating cold streams but different heaters can be used for different process streams at the same temperature level as presented in

Figure 5. Besides, an additional degree of freedom exists when using electric heaters, since they can be used at any temperatures not violating the pinch rules [

27], which creates additional variables when developing HEN with mathematical programming [

28].

When addressing high-dimensional problems in the synthesis HENs, achieving near-globally optimal solutions is paramount. This objective can be effectively pursued through a recently proposed two-step approach that integrates Mixed-Integer Linear Programming (MILP) and Mixed-Integer Nonlinear Programming (MINLP) techniques [

29]. The novel methodology capitalises on the decomposable structural characteristics inherent to HENs, enabling the independent synthesis of multiple HENs in the initial step [

30]. Subsequently, a compact and computationally efficient MINLP model is formulated in the second step, facilitating the cost-optimal design of HENs within each plant. Such approaches streamline the synthesis process and enhance the scalability and feasibility of solving complex HEN synthesis problems and process design in industrial applications [

31].

2.3. The Use of Heat Engines to Cut Energy Targets

The emerging paradigm of industrial energy systems, characterised by a high reliance on electricity, necessitates the integration of various heat engines to enhance energy integration and optimise the utilisation of low-grade heat, which is often dissipated into the environment [

32]. This consideration is increasingly essential in integrating renewable energy sources into industry [

33], where efficient energy management and waste heat recovery are critical for maximising overall system efficiency and sustainability [

34]. As renewable energies and CO

2 capture play a larger role [

35], effectively harnessing and repurposing low-grade heat becomes essential to achieving a more resilient and energy-efficient industrial infrastructure [

36].

2.3.1. Heat Pumps

This increasingly critical concept necessitates the development of an expanded suite of process analysis tools to thoroughly understand the complex interactions between heat recovery and process electrification, such as the integration of heat pumps [

37]. It can be solved with Exergy Pinch Analysis tools and methodologies to establish lower bound work targets by precisely balancing process heat recovery with heat pumping strategies [

38]. These advanced tools enable a more accurate assessment of the thermodynamic efficiency of industrial processes, providing a robust framework for optimising energy use and enhancing the sustainability of electrified industrial systems. The heat load flexibility of the process plant is crucial for efficient integration of heat pumps, as it may seriously affect economic performance that is confirmed by the increase in net present value (NPV) of 19.3% for a specific case study [

39]. The economic efficiency of heat pump integration into the industrial process can also be improved by varying the temperature of the refrigerant in condensers and reboilers, affecting the HEN [

40]. Dynamic Pinch Analysis Targeting improves heat pump integration into batch process plant, resulting in 33% less equipment size and decreased operating cost [

41]. An optimal heat-integrated water network with a heat pump can be developed by creating the superstructure with mathematical programming [

42]. The cost of energy inputs plays a significant role in determining the choice between a heat pump and a gas boiler, impacting the overall system efficiency and the marginal cost of the final solution [

43]. The use of heat pumps within the industrial systems was extensively summarised by Bobbo et al. [

44], the essential role of heat exchangers was underlined and described in different industrial environments.

Distillation remains the predominant and most widely utilised method for splitting components in condensable mixtures and needs enormous amounts of thermal energy. Heat pumps are vital for electrifying distillation systems [

45], which use around 30% of heat energy in chemical processes via utility heat exchangers. It could be a part of a heat recovery system utilising the heat of condensers to process stream heating. The electrification of distillation columns has been investigated intensively over the last decades [

46], delivering research insights and practical recommendations. The exergy-based optimisation allows for an improved heat load distribution that can significantly improve the internal efficiency and further enables a conceptual design of heat pump-assisted distillation. It was applied in azeotropic distillation of multi-component mixture [

47], natural gas liquid processing [

48], methanol-water distillation [

49], biofuel recovery [

50], and others. For instance, applying heat pump assisted distillation for light hydrocarbon separation generates an extensive HEN and results in a 60% reduction in thermal energy consumption [

51].

2.3.2. Mechanical Vapour Recompression

Some processes can be completely electrified by selecting alternatives between Mechanical Vapour Recompression (MVR) and heat pumps [

52]. Vapour recompression heat pumps play a supplementary role in decarbonising distillation processes by enhancing their efficiency and facilitating the electrification of process units. The use of intermediate heating methods, such as intermediate reboilers and feed evaporators, can further optimise the performance of these heat pumps [

53]. By lowering the temperature of the heat source, these methods contribute to reduced payback for investments, making them more economically viable. This may improve energy efficiency and support the transition towards sustainable and low-carbon distillation processes. Modifying milk production with MVR and Thermal Vapour Recompression (TVR) resulted in primary energy saving of 13.7 %–41.6 % and emissions saving of 14.5 %–47.3 %. Besides, such changes in energy and environmental benefits result in complications in HEN retrofit [

54]. The MVR is used for an ethane-ethylene distillation column with optimised process parameters; thus, the refrigerant consumption for the overhead vapour condensation is reduced by 34.29 % compared to the base case, and overall utility consumption is reduced by more than 50% [

55]. The final design requires both the involvement of new heat exchangers and the use of existing ones, which initiates a new optimisation problem for the generated heat recovery network. The investigation of MVR for milk production applying triple effect fouling film evaporators reveals the necessity of several control loops that also generate some limitations of the specific process [

56]. The vapour recompression is mostly used in the food industry due to low-temperature processes, and efficiency can be confirmed from both technical and economic sides. Different vapour recompression systems for the food industry were summarised, and heat transfer equipment configuration was demonstrated [

57]. However, the MVR can also be used to intensify different processes, e.g., biodiesel production, resulting in electrification of thermal utility and extension of the water coolers network and reassembling the main process flow diagram (PFD) [

58]. The application in sulfuric acid waste treatment demonstrated improved energy efficiency through recovering the latent heat of vaporization but the exergy efficiency is still low with high exergy destruction contributed by compressor [

59]. This confirms the opportunities for process improvements on the unit and system level, especially if such technology is a part of a large industrial facility. Optimisation of heat-integrated distillation sequences can be performed by stochastic optimisation employing MVR as the main vehicle of electrification [

60]. The generated flowsheets for five-component separation include the heat exchanger networks of condensers and evaporators with different total annual costs, where the detailed design is challenging due to condensation and evaporation in the same vessel. Both network optimisation and process intensification are vital to achieve CAPEX reduction. Intermittent mechanical vapour recompression is also considered to reduce the primary energy target, and the case study demonstrated 73.86% less energy compared to the single-effect evaporation [

61]. The synergetic effect of the MVR coupled with HEN optimisation may reduce the thermal energy targets and cut the electricity requirements that are very important when integrating renewable electricity within industrial processes [

53]. The batch processes require a completely different approach for process integration and optimisation [

62]. However, MVR can be applied with heat steam storage technology [

63]. The experimental results confirmed the batch evaporation process, consuming a small amount of electricity at a specific schedule. This issue should be additionally addressed when integrating heat pumps into the industrial environment. The control strategy becomes crucial and allows for integrating thermal energy storage into industrial facilities, improving the flexibility of electrified batch processes [

64].

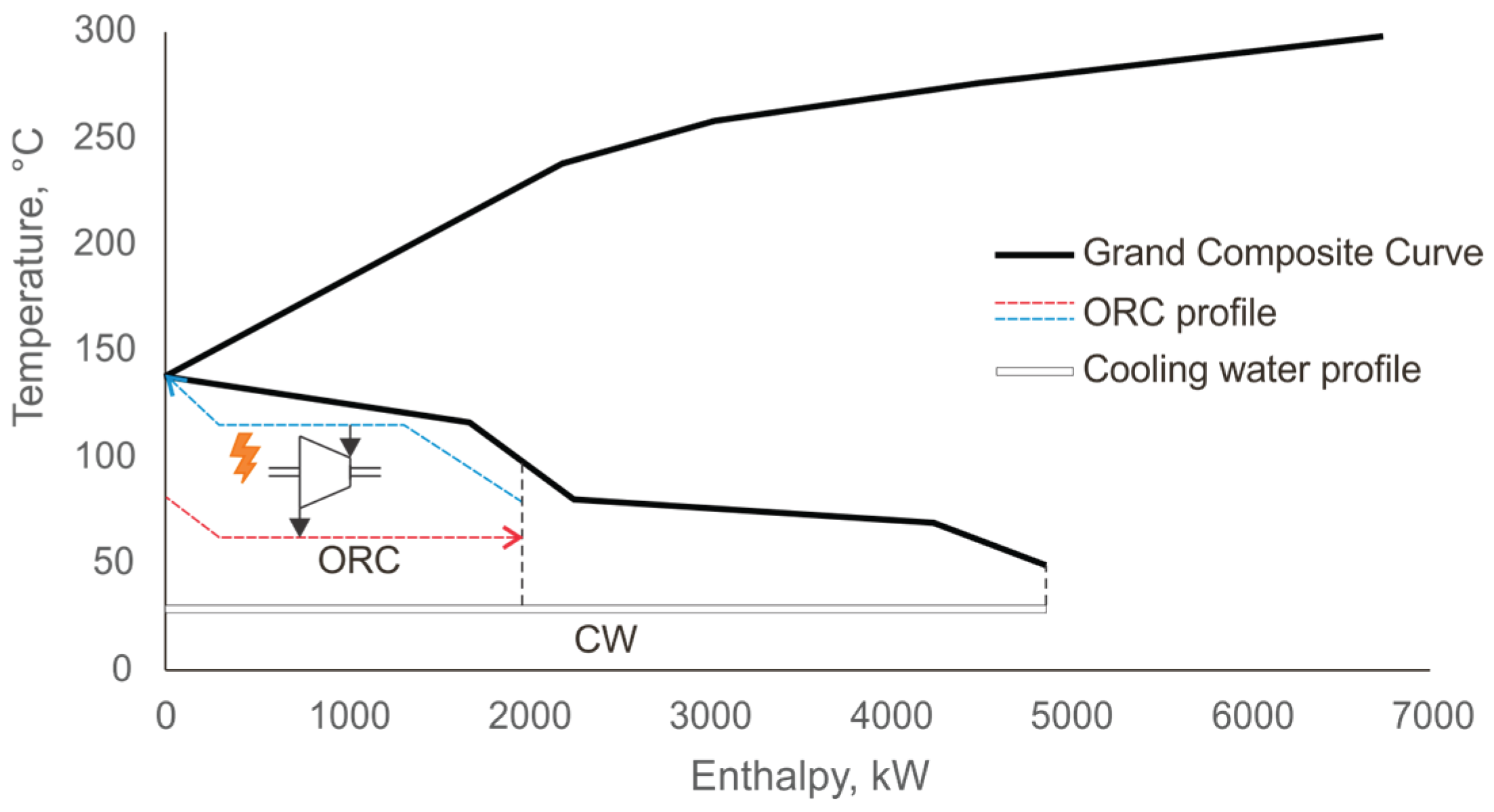

2.3.3. Organic Rankine Cycle

The electrified industrial energy system presumes that heating and cooling facilities are driven by electricity from the grid, which means a huge grid extension is needed to implement such a strategy. In this scope, industrial waste heat can be used for electricity generation to reduce energy export from the grid. Organic Rankine Cycle (ORC) is a long-term developing technology which can be used for these purposes. However, it faces many challenges when applied on an industrial scale [

65]. The energy targets of industrial clusters can be additionally investigated to find the maximum energy utilisation by ORC, as shown in

Figure 6.

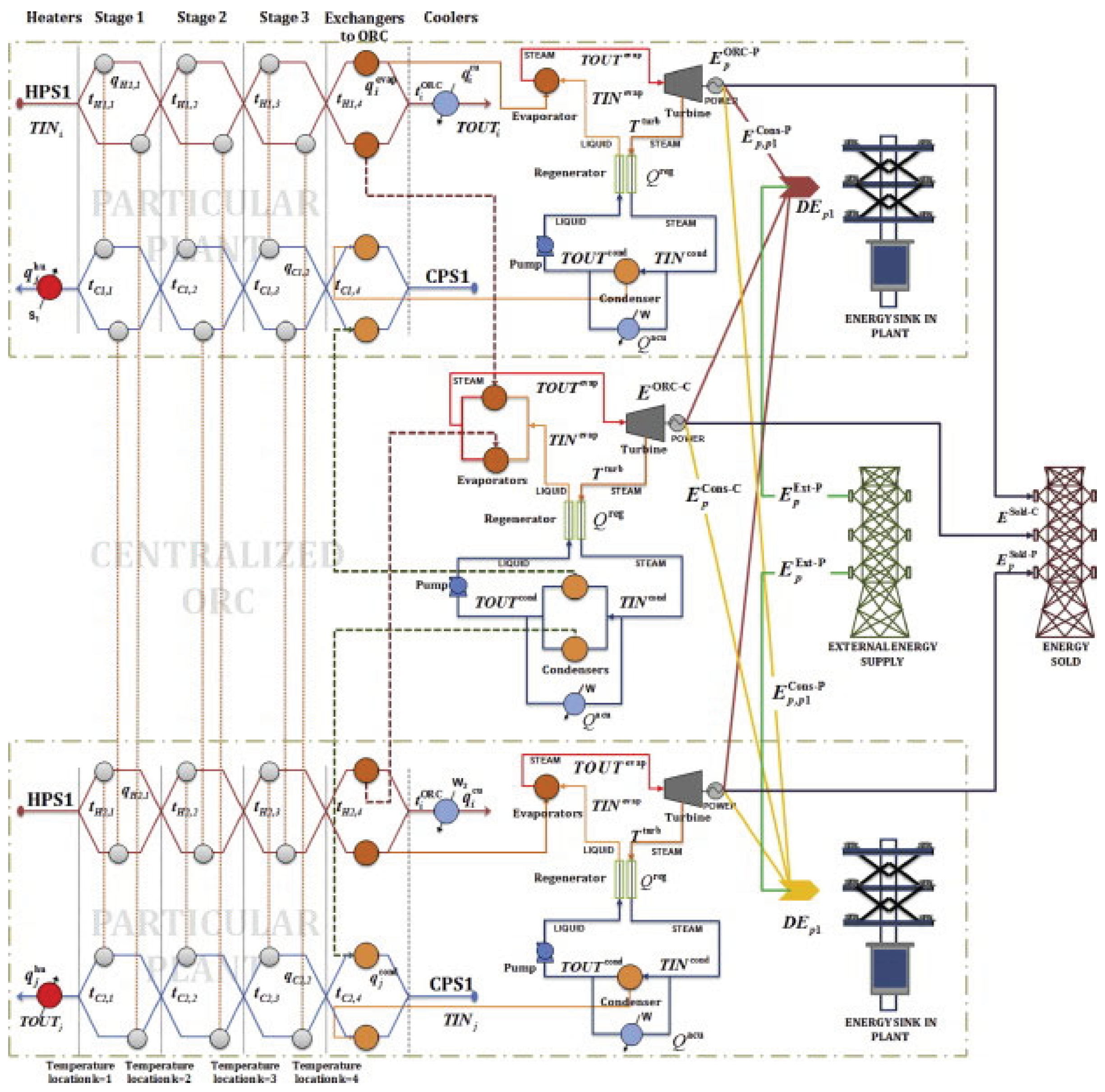

The integration of ORC generates a new problem for HEN development, especially when considering big industrial sites. It was well-illustrated by Hipólito-Valencia et al., demonstrating the complexity of the superstructure (see

Figure 7) and problem solving with the illustrative case studies where plants with two hot and cold streams are considered [

66]. A real industrial environment has many more process streams that increase the task complexity, e.g., a polymer plant’s specific pyrolysis and gas separation units have more than 120 streams, from which more than 60 are cold ones [

67].

The utilisation of industrial low-grade waste heat with a reversible high-temperature heat pump and ORC may generate both electricity and useful heat, but HEN performance should be optimised as well as the individual heat exchangers [

68]. The dynamic performance of the ORC for utilisation of industrial waste heat is crucial to maintain the pinch point while condensing the working media, which seriously affects heat exchanger performance and requires a modelling approach [

69]. A hybrid system can be used to use industrial waste heat, including a solid oxide fuel cell with a gas turbine and reverse osmosis for power and water production. The ORC can be used as a subsystem to utilise the waste heat generated by the system. The process flowsheet includes eight heat exchangers that have the potential for performance optimisation despite the proven economic efficiency of the system, which may generate additional operating cost reduction of up to 20 million euros [

70]. The prediction of the transport properties of hydrocarbon working fluids is important to define the proper sizing of all ORC components, especially heat exchangers [

71]. The availability of waste heat sources is often inconsistent, which adds more variables when integrating the ORC, resulting in an additional problem for heat transfer equipment to prove its techno-economic viability [

72].

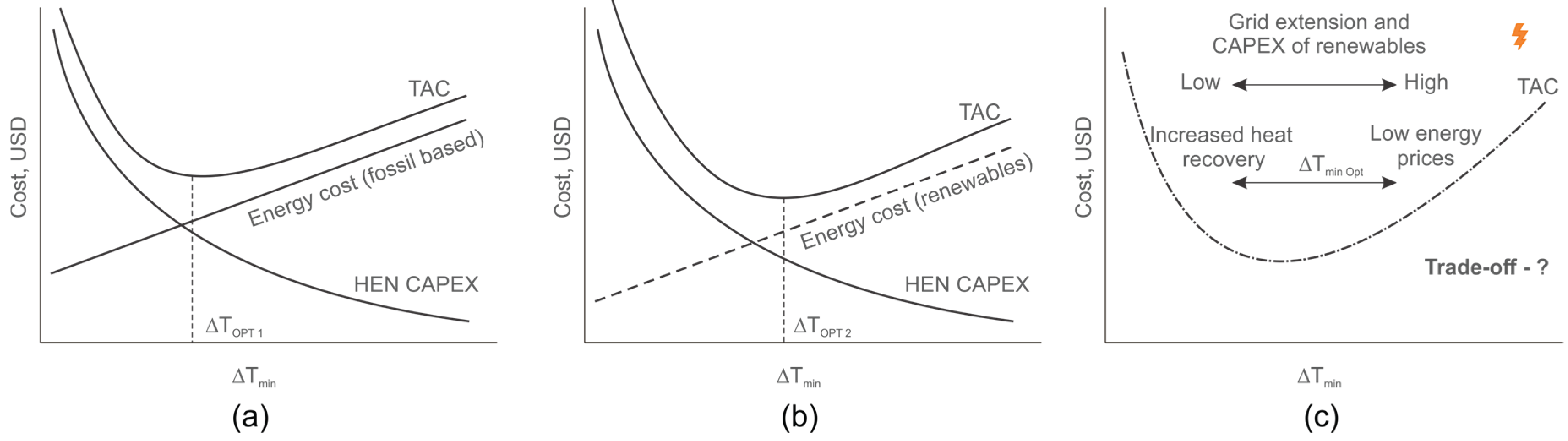

2.4. The Role of Energy Efficiency

The electrification of industrial processes will significantly increase the demand for renewable energy to achieve decarbonization on the supply side. This shift will necessitate substantial investments in energy generation infrastructure and grid expansion, which must ensure a reasonable return on investment. To alleviate the associated economic burden, the concept of energy recovery in process systems should be revisited. In traditional process systems, heat recovery targets are determined by balancing energy costs against the investment required for heat transfer areas (

Figure 8a) [

73]. The use of renewable energy may shift the optimal point to higher ΔT

min (

Figure 8b) due to last trends in renewable energy prices that went below fossil fuel according to Net Zero Emission by 2050 [

74]. However, when implementing electrified industrial utility systems, grid expansion and the potential need for new energy generation facilities must be considered when optimising such trade-offs. The selection of the optimal minimum temperature difference (ΔT

min) may involve a balance between grid extension and HEN investment (

Figure 8c).

When addressing such challenges, reducing the primary energy target is essential to achieving the economic feasibility of industrial energy systems. Enhanced heat recovery will likely play a dominant role, potentially supplemented by heat engines; however, optimisation remains necessary to ensure both technical and economic viability. In this context, maximising heat recovery leads to minimizing driving forces to their lowest possible values and will impose specific demands on heat transfer equipment. Various types of high-efficiency heat exchangers can be integrated into industrial environments [

75], though they may encounter additional operational challenges on the supply and demand sides [

76]. These include issues related to temperature and pressure levels [

77], installation space, pressure drop [

78], fouling [

79], exposure to aggressive media [

80], the use of specialised materials [

81], and reliability concerns [

82].

2.5. Heat Transfer Enhancement

Enhancing heat transfer is crucial for the effective performance of heat exchangers, electric heaters, and steam boilers, particularly for addressing operational challenges and minimising design CAPEX. In tube heat exchangers, the incorporation of helical grooves has significantly improved heat transfer efficiency by inducing turbulence and increasing the effective surface area. However, the optimal configuration of the helix angle remains to be established [

83]. Investigations into helical and segmental baffles are essential for improving the performance of electric heaters; the heat transfer coefficient markedly increases when optimal inclined angles for baffles are identified [

18]. Further advancements on the shell side of tube heat exchangers can be achieved through the implementation of Savonius-shaped baffles [

84], optimisation of circular baffles [

85], and the use of spiral perforated baffles within coiled elastic copper tubes [

86].

The twisted elliptical tube heat exchanger has improved overall performance for heat recovery processes, as evidenced in the context of MVR, although it warrants further precise application investigation [

87]. Integrating a fully twisted inner pipe combined with conical rings enhances the performance of heat exchangers, with configurations featuring six full twists and conical rings demonstrating substantial improvements in both flow directions [

88]. Innovative designs that mechanically influence and alter the boundary layer can further intensify heat transfer, utilising devices such as wide, thin, elongated vibrating turbulators made of latex [

89]. Cross-flow designs are employed for gas heating and cooling applications, focusing on increasing the low heat transfer coefficients within gas flows [

90].

The approach to temperature management is critical for developing reliable solutions, achievable through high-efficiency heat exchangers. Convectively enhanced radiant orifice panel heat exchangers improve thermal performance by combining forced convection with radiant panels, though this method is primarily applicable to air systems [

91]. For high-temperature applications, maximising heat utilisation hinges on the proper design of heat transfer equipment [

92]. The integration of phase change materials in heat recovery systems can reduce overall energy demand; however, effective strategies for heat transfer enhancement in shell-and-tube and plate designs must be established [

93]. Techniques such as additive manufacturing [

94], advanced computational fluid dynamics (CFD) analysis [

95], and machine learning algorithms [

96] can be leveraged to augment heat transfer across various heat recovery units.

The fouling phenomenon poses a significant threat to the operational efficacy of heat exchangers, particularly electric heaters, necessitating the exploration of various mitigation strategies [

79]. Recent proposals have suggested the efficacy of micro/nano-scale surface modifications and the application of electric currents to inhibit microbial fouling [

97]. Additionally, the variability inherent in supply-side operations presents challenges to heat exchanger networks (HEN), requiring investigations into network stability and implementing advanced regulatory strategies [

98]. An active control method employing micro cuboid vortex generators has been proposed, demonstrating a performance coefficient enhancement of up to 7.01% [

99].

2.6. Low-Grade Heat

Low-temperature process heat, often considered a by-product and typically discarded through cooling systems [

100], represents a significant and underutilised energy resource within industrial sectors. Instead of being yielded as waste, this thermal energy can be effectively repurposed for a variety of applications, including district heating networks [

101,

102], ORC systems [

103,

104], and comprehensive Total Site heat integration strategies [

105,

106]. This repurpose enhances energy efficiency and promotes sustainability within industrial processes.

A critical enabler of this transition from waste heat to valuable resource is the implementation of heat pumps to elevate low-grade thermal energy to more usable temperature levels, thereby expanding the potential applications of this previously neglected energy source [

107]. Heat pumps emerge as a foundational technology essential for optimising energy consumption, electrifying the process heat, decreasing operational costs, and minimising carbon emissions throughout industrial clusters by facilitating temperature lifting and addressing discrepancies between energy supply and demand.

The systematic harnessing of this “lost” energy creates new capacity for sustainable and circular energy use, marking a pivotal advancement in achieving resilience and sustainability in industrial operations [

108]. Furthermore, integrating low-temperature process heat into energy systems fosters a decentralised energy approach, reducing reliance on fossil fuels and promoting the incorporation of renewable energy sources [

109].

In addition to district heating and ORC systems, low-temperature heat recovery can support various applications such as agricultural heating, greenhouse operations, and residential heating solutions. The versatility of reusing this energy showcases its potential to alleviate pressure on existing energy infrastructures while providing economic benefits to industries that adopt these innovative solutions.

As industries seek to future-proof their operations against climate change and resource scarcity, leveraging low-temperature process heat through advanced heat pump technologies aligns with broader sustainability goals [

110]. This transformative approach supports compliance with regulatory standards for emissions reductions and enhances overall operational efficiency and economic viability, paving the way for a more sustainable industrial landscape. Maximising the utility of low-temperature process heat is not merely an option; it is becoming an imperative for industries striving to thrive in an increasingly environmentally conscious world.

2.7. CAPEX and OPEX Assessements

As industries increasingly transition to electrified energy systems, a comprehensive understanding of CAPEX and OPEX becomes crucial for making informed investment decisions. Recent studies have provided valuable insights into how the cost structures of energy systems evolve during this shift, highlighting both new opportunities and complexities [

111]. CAPEX is frequently observed between heat recovery systems and traditional fossil fuel-based configurations [

112]. This indicates that electrification does not necessarily entail a higher upfront investment for integrating new energy technologies [

113]. Industries can thus invest in electrified solutions without significant financial penalties compared to conventional systems.

However, the cost structures for utility exchangers exhibit substantial variability. Electric heaters [

114], steam boilers [

115], and electric furnaces [

116] carry distinct cost profiles that differ considerably from their fossil fuel-based equivalents. These variations affect the initial investment costs and have implications for the overall design and feasibility of the energy systems, necessitating careful consideration during the planning stages [

117]. On the OPEX front, the volatility of electricity prices plays a critical role in determining operational expenditures. In electrified systems, operational costs are increasingly influenced by fluctuations in dynamic energy markets[

118]. Therefore, strategies such as flexibility in energy consumption, implementation of smart control systems, and tariff optimisation become essential for enhancing cost efficiency and mitigating financial risks associated with energy price volatility.

Successfully balancing CAPEX and OPEX in this evolving landscape requires a nuanced and multifaceted approach. Such an approach must integrate economic considerations, technological advancements, and environmental frameworks [

119]. For a resilient and future-ready energy system, industries must carefully evaluate and adapt to the changing dynamics of energy costs [

120]. Moreover, as markets evolve and the demand for electrification increases, there is an opportunity for businesses to invest in emerging technologies that enhance energy efficiency and sustainability. For instance, utilising demand response strategies, energy storage solutions, and innovative grid technologies can further optimise CAPEX and OPEX [

121]. By thoroughly analysing the interplay between CAPEX and OPEX and adopting forward-thinking strategies, industries can position themselves not only for compliance with future regulations but also for competitive advantages in an increasingly electrified world. This proactive stance is essential for fostering sustainable growth and ensuring long-term operational resilience in evolving energy market dynamics.

2.8. Equipment Challenges

The transition to electrified heating in industrial processes entails many technical and operational challenges, particularly concerning the design and integration of heat exchanger networks. Some process streams are well-suited for direct electric heating, utilising technologies such as electric immersion heaters [

122], resistance heaters [

123], or induction coils[

124]. The successful integration of these technologies often necessitates considerable upgrades to existing electrical infrastructure. This includes enhancements to power distribution systems, advancements in control mechanisms, and the implementation of robust safety measures to accommodate the increase in electrical load and maintain operational safety. It is crucial to note that not all process streams can be electrified effectively. For instance, high-viscosity fluids, streams containing reactive components, or sensitive product lines may necessitate continued steam heating due to safety concerns, quality control mandates, or compatibility issues. Consequently, steam heating networks must often remain operational, resulting in hybrid systems that can complicate overall system design and increase maintenance requirements [

125,

126].

Electrified heating solutions can lead to elevated wall temperatures within equipment [

127]. This increase may exacerbate fouling and material degradation, particularly in streams known to be prone to fouling [

128]. The existing literature extensively documents these challenges, underlining the necessity for meticulous thermal management practices and proper material selection to ensure long-term operational reliability [

79]. Effective strategies may include using advanced coatings or self-cleaning technologies that help mitigate fouling rates. While electrification offers significant energy and environmental advantages, it necessitates fundamentally reevaluating equipment design and operational strategies to maximise its potential benefits. This involves not only adapting existing infrastructure but also exploring new designs for heat exchanger networks that can optimise heat transfer and ensure efficient integration of electric and steam heating solutions. Additionally, implementing advanced control strategies [

129] and predictive maintenance [

130] can enhance hybrid systems’ efficiency. Leveraging data analytics and real-time monitoring can facilitate better decision-making and operational adjustments, ultimately leading to improved energy utilisation and reduced operational costs [

131].

3. Rethinking of Heat Exchanger Networks for Electrified Industrial Energy Systems

The new paradigm of electrified industry presents the prospective role of HENs within an industrial energy system, highlighting the significance of renewable energy integration and electrification. This framework uses renewable energy sources such as solar and wind to supply the power grid and industrial processes. The HEN functions as a central hub for efficient heat recovery and redistribution, linking various thermal network components as illustrated in

Figure 9. This includes the provision of process heating and integrating technologies such as MVR, heat pumps, and ORC, which enhance energy conversion and facilitate thermal recycling.

Furthermore, the system accommodates low-temperature heat distribution for district heating systems and applications like water and space heating, thus expanding its utility beyond industrial operations. Incorporating thermal storage units boosts operational flexibility, while cooling towers are employed to manage excess heat. This interconnected strategy enables significant energy savings, reductions in greenhouse gas emissions, and overall system optimisation, promoting sustainable industrial practices.

3.1. Interpretation and Development of HEN for Industrial Energy Systems

The existing interpretation of HEN within grid diagrams necessitates a comprehensive reevaluation. Traditionally, HENs are conceptualised as simplified conduits for thermal integration [

132], as presented in

Figure 10. However, this oversimplification may obscure critical elements such as energy transfer pathways, pinch point considerations, and the system’s operational flexibility. A more nuanced representation of HENs should elucidate distinctions among direct heat exchange processes, utility integrations, and intermediate thermal storage systems. This modified framework would ensure that the grid diagrams accurately reflect the intricate thermal and operational interdependencies critical to efficient thermal energy management.

There is a pressing need for a structured methodology to create grid diagrams that incorporate contemporary and varied thermal technologies. Notable inclusions in this approach should feature:

Heat pumps that should be clearly delineated into input and output streams, along with annotations of their COP, should aptly represent the efficiency of these systems.

The illustration of MVR systems must encompass both thermal and mechanical flow metrics to reflect their dual operational characteristics.

A thorough integration of ORCs should capture the nuances of waste heat recovery mechanisms and the associated power generation cycles.

Energy storage, utilising both the process waste heat and process heating under varying energy supply and waste heat demand sides.

Steam boilers, electric heaters/furnaces, plasma heaters, or microwave heaters are also available. These components should be represented with comprehensive inflows illustrating fuel or electric inputs, juxtaposed against their thermal output. It is essential to distinctly differentiate the roles of utility heat and process heat.

This methodological framework must prioritise consistency in symbols, clear flow directional indicators, and a representation of energy quality (temperature levels), ultimately enabling comprehensive comparability across diverse systems and configurations.

The representation of equipment types within the grid diagram should be significantly improved to clearly differentiate their functional roles in heating, cooling, recovery, or conversion alongside their energy sources (thermal, electrical, or renewable) and thermodynamic properties (temperature lift and heat duty). Implementing standardised icons and colour-coding, complemented by a legend for reference, would mitigate ambiguity and facilitate automated analysis of the thermal systems. The interpretation of HEN within the grid diagram was previously implemented in different software and utilities that support different process system engineering simulation environments.

Integrating a synthesised overview of the current system design state into the grid diagrams is crucial for illuminating key operational attributes, identifying inefficiencies, and recognising opportunities for improvement. This should include the following analytical items representing the equipment listed above:

Identification of underutilised heat sources or sinks to enhance energy efficiency.

Visualisation of energy recirculation loops, enabling assessment of their efficiency and performance.

Assessment of dependencies on external energy utilities, allowing for enhanced resilience and sustainability.

Highlighting modular or scalable components to facilitate adaptability in the face of changing energy demands or technological advancements.

Such synthesis supports refined design decisions and enhances operational strategies, particularly as facilities pivot towards low-carbon or electrified heating solutions. Incorporating these advanced methodologies and representational strategies will ultimately contribute to new trends and updates in HEN development and representation, contributing to engineering practice.

3.2. Revisiting the Approaches for Heat Exchanger Network Design and Retrofit in the Age of Industrial Electrification

The accelerating shift towards electrification in industrial processes has prompted a critical reassessment of established design and retrofit methodologies for HENs. As enhanced electrification introduces new variables such as incorporating electric heating and cooling methods, fluctuations in heat demand, decarbonization imperatives, and integrating renewable energy, selecting an appropriate methodological framework becomes essential. The three principal paradigms for HEN development and retrofit, such as Mathematical Programming (MP), insights-based approaches, and hybrid methods, each present unique capabilities and inherent trade-offs crucial for navigating modern electrified environments’ complexities.

Mathematical programming techniques have proven to be robust optimisation methodologies that enable systematic synthesis and retrofit of HENs amidst intricate constraints [

133]. These methods typically employ formulations such as Mixed-Integer Nonlinear Programming (MINLP) [

134] or Mixed-Integer Linear Programming (MILP) [

135] to account for both thermodynamic viability and economic feasibility. In the context of industrial electrification, MP approaches can be augmented to consider integrating electric heating and cooling systems, variable demand response mechanisms, and fluctuating electricity pricing models. Recent studies have focused on optimising networks that include electrified technologies like MVR systems [

136] and electric boilers [

137], enabling a holistic approach to network optimisation. A heat integration superstructure that facilitates multiple thermodynamic pathways for streams may undergo changes in pressure and temperature. The superstructure is linked to a HEN superstructure, allowing for the integration of hot and cold streams identified within the work and heat integration framework [

138]. MP approaches excel in tackling large-scale, complex problems with multi-objective optimisation, integrating diverse techno-economic, environmental, and operational constraints [

139]. They are also highly compatible with automation and support scenario analysis. However, these methods face challenges, such as high computational costs and a lack of transparency, making interpretation difficult for end users and impeding decision-making.

Insights-based methodologies leverage thermodynamic principles, graphical analysis tools (such as composite curves and grid diagrams, etc.)[

140], and heuristic strategies to guide the HEN design and retrofit endeavours [

141]. In the electrification context, these approaches prove invaluable for promptly identifying retrofit opportunities, visualising heat surpluses and deficits, making them particularly useful during preliminary evaluations and design phases [

142]. With the growing utilisation of electrified technologies, graphical methods have evolved to accommodate non-conventional heat sources and sinks, facilitating intuitive examination of electrification prospects and potential shifts in pinch points due to electric heating or cooling strategies. Insights-based approaches offer enhanced transparency and interpretability, making them particularly beneficial for users during the initial design stages and applicable to small to medium-scale systems due to their minimal computational requirements. However, these methods often result in suboptimal outcomes when compared to MP approaches, and they may encounter challenges in scaling larger or more constrained systems [

143].

Hybrid techniques encapsulate the advantages of MP and insights-based methods, establishing a balance between computational accuracy and conceptual clarity [

144]. These methods typically employ heuristic or graphical insights to define boundaries or structural frameworks for optimisation problems, thereby reducing complexity and improving problem solvability [

145]. Within electrified systems, hybrid approaches can effectively pre-screen retrofit options or decarbonization strategies using pinch analysis, followed by detailed MP-based optimisation [

146]. Moreover, emerging hybrid frameworks increasingly integrate dynamic simulations and multi-period optimisation strategies, vital in contexts where electrification introduces operational variability, such as time-of-use electricity pricing or intermittent renewable energy sources. Hybrid methods provide an improved balance between achieving optimal solutions and ensuring user interpretability [

119], making them adaptable to multi-objective or multi-period optimisation scenarios while remaining scalable to accommodate the evolving landscape of electrification technologies. However, their effective implementation necessitates meticulous integration of various methodologies and may require iterative processes throughout different design stages to refine outcomes effectively [

147].

4. Case Studies in Different Industries

As global industries strive for decarbonization and enhanced operational efficiency, integrating advanced energy systems has become a strategic necessity. Among the most significant advancements are HEN and the electrification of thermal utilities, which facilitate considerable energy savings, emissions reductions, and process performance improvements. Several case studies illustrate how various sectors utilise HEN optimisation and electrified thermal systems to achieve sustainability targets while preserving or enhancing profitability.

Electricity-based heating systems provide greater flexibility in the design of HEN compared to fossil fuel-based systems, thereby significantly simplifying the design complexities associated with electrification. This is exemplified by several case studies of heat recovery systems, where capital costs and design complexities are minimised by effectively integrating the characteristics of the electrified energy supply into the overall system design [

23]. The HEN of the gas separation plant in Thailand was retrofitted by reducing the temperature approach by applying two NLP optimisation steps, resulting in environmental and financial benefits [

148]. A novel optimisation approach was proposed to achieve solutions in a multi-objective context efficiently. The case study focuses on a real industrial-scale crude oil distillation preheat configuration. The findings demonstrate that prioritising carbon compensation for the waste heat recovery option can substantially reduce carbon emissions and transform energy distribution within the system [

149]. A highly efficient, fully electric milk evaporation system was developed through strategic integration and selection of heat pump and MVR technologies. In this context, the study presents an effective process integration and electrification method, resulting in a 32% OPEX reduction and 82% lower emissions [

52]. Another effective application for a hydrogen plant with carbon dioxide capture was investigated [

150]. Integrating decentralised heat pumps that facilitate heat exchange between process streams and electric heaters yields a modest reduction in energy consumption of approximately 56% in the milk industry, and profitability was proved with energy price forecasts from 2020 [

151].

The reconfiguration for electrification and the reduction of carbon emissions in conventional chemical processes was examined, with a particular emphasis on the indirect electrification of processes and the direct electrification of utilities. The research utilises a case study of the advanced Coal-to-Ethylene Glycol process with energy efficiency improvement of about 50% and reduced carbon dioxide emissions [

152]. To decarbonise the petrochemical industry, a utility system was modelled to supply electricity and heat to an olefins plant located in the Port of Rotterdam. Mathematical optimisation techniques were employed to determine the optimal hourly operations of the plant in response to fluctuating energy prices. The analysis reveals that the cost-optimal utility system comprises electric boilers, integrated thermal energy storage, and technologies for the on-site production, storage, and utilisation of hydrogen [

153]. Seasonal availability of renewables is crucial for an electrified industrial system. A multi-period graph-theoretical methodology to identify the optimal retrofit strategy for achieving electrification was introduced, taking into account economic and environmental considerations [

154]. Another case study in the chemical industry explores the adjustment of stream temperature and HEN synthesis for combining high-temperature co-electrolysis and the Fischer-Tropsch process for carbon capture, reducing electricity targets and increasing plant revenue [

155]. The integration of electrification with the inherent storage capacity of the steam network has led to a potential average increase in profits for industrial facilities with a large steam network. A reduction in emissions was estimated at 18 tCO₂/d, and additionally, a potential decrease in blow-off steam of 0.24 t/h [

156].

The model-based approach for the indirect integration of multiple parallel ORCs was introduced in [

157]. The comprehensive model encompasses the extraction of waste heat and power generation. A modified superstructure was proposed to facilitate heat extraction modelling, which streamlines the HEN development and minimises computation time. The application of ORC solutions for cement factories may achieve 43% self-coverage of power demand or grid supply, increasing the profitability of the existing production facility [

158]. In the cement industry, the electrification of clinker and calcination processes also represents a viable decarbonization strategy [

159]. Integrating MVR and bottom flash technologies with the ORC system enhances the recovery and reutilization of low-temperature waste heat in ethyl acetate/cyclohexane separation. Energy efficiency of the process was improved by 17 %, reducing total annual cost by 8 % [

160]. MVR technology is widely used in distillation processes. An exergy-based optimisation method that facilitates enhanced heat load distribution was introduced for acetone-water mixture distillation, resulting in significant improvements in internal efficiency. This optimisation further supports the conceptual design of heat pump-assisted distillation, utilising MVR to supply heat loads to the intermediate heat exchangers [

161]. The concurrent implementation of HEN retrofitting and MVR in a calcium chloride evaporation facility reduced carbon dioxide emissions by 19 ktCO

2/y and achieved a 51% decrease in steam consumption. This significant reduction in steam usage presents opportunities for CAPEX savings when transitioning the process to electric steam boilers [

162].

In addition to the insights gained from these case studies, it is beneficial to incorporate thermal energy storage systems, especially when integrated with electrified utilities, as illustrated in reference [

163]. This combination enhances the efficiency and reliability of energy supply and allows for better management of energy consumption during peak demand periods. By leveraging thermal energy storage, facilities can store excess energy generated during off-peak times and utilise it when demand increases, effectively reducing reliance on grid energy and leading to a more sustainable energy strategy.

5. Conclusions

The electrification of industrial energy systems marks a critical advancement in the quest for deep decarbonization, necessitating the reconfiguration of HENs as both a technical imperative and an avenue for innovation. This review systematically explores the complex challenges and emerging strategies in designing, optimising, and retrofitting HENs within electrified contexts. Significant technological shifts, such as the substitution of fossil-fuel-based utilities with electric boilers, heaters, and advanced heat engines, are reshaping utility configurations, heat recovery methodologies, and the balance between capital and operating expenditures.

A particularly transformative element is the integration of utilities operating across multiple temperature levels, including heat pumps, MVR, and ORC. These innovations introduce new thermodynamic and economic complexities, particularly within multi-pinch network architectures. Concurrently, the electrification process has broadened the potential for low-grade heat recovery, driving the adoption of advanced heat transfer enhancement techniques and investigating novel materials and geometries in heat exchanger design.

This evolving landscape necessitates a reevaluation of traditional HEN methodologies. Mathematical programming techniques provide accuracy and robustness for large-scale, multi-objective optimisation problems, while insights-based and hybrid methodologies facilitate conceptual clarity and computational efficiency. Future research efforts must emphasise the integration of dynamic system behaviours, variable energy pricing, and the variability of renewable electricity within HEN optimisation frameworks.

In addition to technical design considerations, aligning economic and environmental performance metrics is essential. Assessments of CAPEX and OPEX, fluctuations in energy pricing, and the integration of thermal energy storage will be crucial in justifying investments in electrified HENs. Moreover, graphical and simulation tools should be updated to accurately represent the complexities of modern electrified utility systems.

The advancement of next-generation HENs for electrified industrial processes is foundational to meeting climate objectives, improving energy efficiency, and enhancing operational resilience. Industrial HENs can evolve from fossil-fuel-dependent frameworks to flexible, intelligent, and sustainable energy networks by combining methodological innovation, digital integration, and system-level thinking.

Author Contributions

Conceptualization, S.B.; methodology, S.B.; validation, G.K., and S.B.; formal analysis, G.K.; investigation, S.B.; resources, G.K., and S.B.; data curation, G.K., and S.B.; writing—original draft preparation, S.B.; writing—review and editing, G.K., and S.B.; visualization, S.B.; supervision, G.K., and S.B.; project administration, G.K., and S.B.; funding acquisition, G.K., and S.B. All authors have read and agreed to the published version of the manuscript.

Funding

The European Commission supported this research under the LIFE programme, project 101119793 – LIFE22-CET-SET_HEAT and HORIZON Europe programme, project 101136775 INITIATE.

Data Availability Statement

The data is available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosenow, J.; Eyre, N. Reinventing Energy Efficiency for Net Zero. Energy Research & Social Science 2022, 90, 102602. [CrossRef]

- Industry - Energy System Available online: https://www.iea.org/energy-system/industry (accessed on 15 July 2024).

- Net Zero Emissions by 2050 Scenario (NZE) – Global Energy and Climate Model – Analysis Available online: https://www.iea.org/reports/global-energy-and-climate-model/net-zero-emissions-by-2050-scenario-nze (accessed on 15 July 2024).

- Final Energy Consumption in Industry - Detailed Statistics Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics (accessed on 14 May 2025).

- Fleiter, T.; Rehfeldt, M.; Neusel, L.; Hirzel, S.; Neuwirth, M.; Schwotzer, C.; Kaiser, F.; Gondorf, C. CO2-Neutral Process Heat Using Electrification and Hydrogen. 2024.

- Schiffer, Z.J.; Manthiram, K. Electrification and Decarbonization of the Chemical Industry. Joule 2017, 1, 10–14. [CrossRef]

- Mallapragada, D.S.; Dvorkin, Y.; Modestino, M.A.; Esposito, D.V.; Smith, W.A.; Hodge, B.-M.; Harold, M.P.; Donnelly, V.M.; Nuz, A.; Bloomquist, C.; et al. Decarbonization of the Chemical Industry through Electrification: Barriers and Opportunities. Joule 2023, 7, 23–41. [CrossRef]

- Sorknæs, P.; Johannsen, R.M.; Korberg, A.D.; Nielsen, T.B.; Petersen, U.R.; Mathiesen, B.V. Electrification of the Industrial Sector in 100% Renewable Energy Scenarios. Energy 2022, 254, 124339. [CrossRef]

- Tang, C.; Zhang, Q. Green Electrification of the Chemical Industry Toward Carbon Neutrality. Engineering 2023, 29, 22–26. [CrossRef]

- Li, N.; Klemeš, J.J.; Sunden, B.; Wu, Z.; Wang, Q.; Zeng, M. Heat Exchanger Network Synthesis Considering Detailed Thermal-Hydraulic Performance: Methods and Perspectives. Renewable and Sustainable Energy Reviews 2022, 168, 112810. [CrossRef]

- Tan, R.R.; Migo-Sumagang, M.V.; Aviso, K.B. Plan Durable Carbon Dioxide Removal with Pinch Analysis. Process Integr Optim Sustain 2024. [CrossRef]

- Yee, T.F.; Grossmann, I.E. Simultaneous Optimization Models for Heat Integration—II. Heat Exchanger Network Synthesis. Computers & Chemical Engineering 1990, 14, 1165–1184. [CrossRef]

- Ciric, A.R.; Floudas, C.A. A Retrofit Approach for Heat Exchanger Networks. Computers & Chemical Engineering 1989, 13, 703–715. [CrossRef]

- Klemeš, J.J.; Kravanja, Z. Forty Years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP). Current Opinion in Chemical Engineering 2013, 2, 461–474. [CrossRef]

- Varbanov, P.S.; Doyle, S.; Smith, R. Modelling and Optimization of Utility Systems. Chemical Engineering Research and Design 2004, 82, 561–578. [CrossRef]

- Čuček, L.; Boldyryev, S.; Klemeš, J.J.; Kravanja, Z.; Krajačić, G.; Varbanov, P.S.; Duić, N. Approaches for Retrofitting Heat Exchanger Networks within Processes and Total Sites. Journal of Cleaner Production 2019, 211, 884–894. [CrossRef]

- Abadi, M.M.; Tang, H.; Rashidi, M.M. A Review of Simulation and Numerical Modeling of Electric Arc Furnace (EAF) and Its Processes. Heliyon 2024, 10, e32157. [CrossRef]

- Wang, M.C.; Chen, Y.P.; Wu, J.F.; Dong, C. Heat Transfer Enhancement of Folded Helical Baffle Electric Heaters with One-plus-Two U-Tube Units. Applied Thermal Engineering 2016, 102, 586–595. [CrossRef]

- Mineev, A.B. Chapter 9 - Plasma Heating Systems. In Fundamentals of Magnetic Thermonuclear Reactor Design; Glukhikh, V., Filatov, O., Kolbasov, B., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing, 2018; pp. 281–290 ISBN 978-0-08-102470-6.

- Schoeneberger, C.; Zhang, J.; McMillan, C.; Dunn, J.B.; Masanet, E. Electrification Potential of U.S. Industrial Boilers and Assessment of the GHG Emissions Impact. Advances in Applied Energy 2022, 5, 100089. [CrossRef]

- Shenoy, U.V.; Sinha, A.; Bandyopadhyay, S. Multiple Utilities Targeting for Heat Exchanger Networks. Chemical Engineering Research and Design 1998, 76, 259–272. [CrossRef]

- Linnhoff, B.; Ahmad, S. Cost Optimum Heat Exchanger Networks—1. Minimum Energy and Capital Using Simple Models for Capital Cost. Computers & Chemical Engineering 1990, 14, 729–750. [CrossRef]

- Kim, J.-K.; Son, H.; Yun, S. Heat Integration of Power-to-Heat Technologies: Case Studies on Heat Recovery Systems Subject to Electrified Heating. Journal of Cleaner Production 2022, 331, 130002. [CrossRef]

- Kim, J.-K. Studies on the Conceptual Design of Energy Recovery and Utility Systems for Electrified Chemical Processes. Renewable and Sustainable Energy Reviews 2022, 167, 112718. [CrossRef]

- Trivedi, K.K.; O’Neill, B.K.; Roach, J.R. Synthesis of Heat Exchanger Networks Featuring Multiple Pinch Points. Computers & Chemical Engineering 1989, 13, 291–294. [CrossRef]

- Pavão, L.V.; Costa, C.B.B.; Ravagnani, M.A.S.S. Multiple Utilities Targeting in Energy Integration Considering Rigorous Temperature-Enthalpy Relations. Chemical Engineering Science 2023, 276, 118763. [CrossRef]

- Linnhoff, B.; Smith, R. PINCH PRINCIPLE. Mechanical Engineering 1988, 110, 70–73.

- Floudas, C.A.; Ciric, A.R.; Grossmann, I.E. Automatic Synthesis of Optimum Heat Exchanger Network Configurations. AIChE Journal 1986, 32, 276–290. [CrossRef]

- Nemet, A.; Isafiade, A.J.; Klemeš, J.J.; Kravanja, Z. Two-Step MILP/MINLP Approach for the Synthesis of Large-Scale HENs. Chemical Engineering Science 2019, 197, 432–448. [CrossRef]

- Zhou, W.; Liu, L.; Xing, Y.; Du, J. A Novel Two-Step Approach for Multi-Plant Indirect HENs Design. Chemical Engineering Science 2024, 285, 119559. [CrossRef]

- Huber, D. Multi-Objective Heat Exchanger Network Synthesis: Simultaneous Optimization of Heat Integration and Process Design. Thesis, Technische Universität Wien, 2024.

- Meng, W.; Wang, D.; Zhou, H.; Liao, Z.; Hong, X.; Li, G. Design and Analysis for Chemical Process Electrification Based on Renewable Electricity: Coal-to-Methanol Process as a Case Study. Energy Conversion and Management 2023, 292, 117424. [CrossRef]

- Pierri, E.; Hellkamp, D.; Thiede, S.; Herrmann, C. Enhancing Energy Flexibility through the Integration of Variable Renewable Energy in the Process Industry. Procedia CIRP 2021, 98, 7–12. [CrossRef]

- Boldyryev, S.; Gil, T. Debottlenecking of Existing Hydrocracking Unit by Improved Heat Recovery for Energy and Carbon Dioxide Savings. Energy Conversion and Management 2021, 238, 114164. [CrossRef]

- Cormos, C.-C.; Petrescu, L.; Cormos, A.-M.; Dragan, S.; Dinca, C.; Sandru, M. Integration of Renewable Energy and CO2 Capture and Utilization Technologies for Decarbonization of Energy Intensive Process Industries. In Computer Aided Chemical Engineering; Kokossis, A.C., Georgiadis, M.C., Pistikopoulos, E., Eds.; 33 European Symposium on Computer Aided Process Engineering; Elsevier, 2023; Vol. 52, pp. 2777–2784.

- Boldyryev, S.; Ilchenko, M.; Kaldybaeva, B.; Krajacic, G. Modelling of the Use of Renewable Energies and Energy-Saving Measures for Polymer Chemical Plant. Chemical Engineering Transactions 2023, 103, 535–540. [CrossRef]

- Wallerand, A.S.; Kermani, M.; Kantor, I.; Maréchal, F. Optimal Heat Pump Integration in Industrial Processes. Applied Energy 2018, 219, 68–92. [CrossRef]

- Walmsley, T.G.; Lincoln, B.J.; Padullés, R.; Cleland, D.J. Advancing Industrial Process Electrification and Heat Pump Integration with New Exergy Pinch Analysis Targeting Techniques. Energies 2024, 17, 2838. [CrossRef]

- Walden, J.V.M.; Stathopoulos, P. The Impact of Heat Pump Load Flexibility on Its Process Integration and Economics. Journal of Cleaner Production 2024, 462, 142643. [CrossRef]

- Boldyryev, S.; Ilchenko, M.; Krajačić, G. Improving the Economic Efficiency of Heat Pump Integration into Distillation Columns of Process Plants Applying Different Pressures of Evaporators and Condensers. Energies 2024, 17, 951. [CrossRef]

- Walden, J.V.M.; Wellig, B.; Stathopoulos, P. Heat Pump Integration in Non-Continuous Industrial Processes by Dynamic Pinch Analysis Targeting. Applied Energy 2023, 352, 121933. [CrossRef]

- Ibrić, N.; Ahmetović, E.; Kravanja, Z.; Gundersen, T. Synthesis of Heat-Integrated Water Networks: Integration of Heat Pumps. Applied Thermal Engineering 2024, 254, 123760. [CrossRef]

- Flórez-Orrego, D.; Domingos, M.E.R.; Maréchal, F. Techno-Economic and Environmental Analysis of High Temperature Heat Pumps Integration into Industrial Processes: The Ammonia Plant and Pulp Mill Cases. Sustainable Energy Technologies and Assessments 2023, 60, 103560. [CrossRef]

- Bobbo, S.; Lombardo, G.; Menegazzo, D.; Vallese, L.; Fedele, L. A Technological Update on Heat Pumps for Industrial Applications. Energies 2024, 17, 4942. [CrossRef]

- Mekidiche-Martinez, Z.; Caballero, J.A.; Labarta, J.A. Efficient Use of Energy in Distillation: Advancing towards the Electrification of the Chemical Industry. In Computer Aided Chemical Engineering; Manenti, F., Reklaitis, G.V., Eds.; 34 European Symposium on Computer Aided Process Engineering / 15 International Symposium on Process Systems Engineering; Elsevier, 2024; Vol. 53, pp. 103–108.

- Cui, C.; Qi, M.; Zhang, X.; Sun, J.; Li, Q.; Kiss, A.A.; Wong, D.S.-H.; Masuku, C.M.; Lee, M. Electrification of Distillation for Decarbonization: An Overview and Perspective. Renewable and Sustainable Energy Reviews 2024, 199, 114522. [CrossRef]

- Yu, A.; Ye, Q.; Li, J.; Wang, Y.; Rui, Q. Energy-Saving Improvement of Heat Integration and Heat Pump for Separating Multi-Azeotropes Mixture via Novel Pressure Swing Distillation. Chemical Engineering Science 2023, 282, 119239. [CrossRef]

- Boldyryev, S.; Kuznetsov, M.; Ryabova, I.; Krajačić, G.; Kaldybaeva, B. Assessment of Renewable Energy Use in Natural Gas Liquid Processing by Improved Process Integration with Heat Pumps. e-Prime - Advances in Electrical Engineering, Electronics and Energy 2023, 5, 100246. [CrossRef]

- Cui, C.; Zhang, X.; Qi, M.; Lyu, H.; Sun, J.; Kiss, A.A. Fully Electrified Heat Pump Assisted Distillation Process by Flash Vapour Circulation. Chemical Engineering Research and Design 2024, 206, 280–284. [CrossRef]

- Janković, T.; Straathof, A.J.J.; Kiss, A.A. Thermally Self-Sufficient Heat Pump-Assisted Azeotropic Dividing-Wall Column for Biofuels Recovery from Isopropanol-Butanol-Ethanol Fermentation. Chemical Engineering and Processing - Process Intensification 2024, 197, 109689. [CrossRef]

- Miao, G.; Ma, Y.; Yang, C.; Tong, B.; Li, G.; Xiao, J. The Effective Synthesis of Heat-Pump Assisted Distillation Process with Multiple Columns for Light Hydrocarbon Separation. Chemical Engineering Science 2023, 269, 118449. [CrossRef]

- Lincoln, B.J.; Kong, L.; Pineda, A.M.; Walmsley, T.G. Process Integration and Electrification for Efficient Milk Evaporation Systems. Energy 2022, 258, 124885. [CrossRef]

- Zhu, J.; Chen, L.; Liu, Z.; Hao, L.; Wei, H. Synergy of Electrification and Energy Efficiency Improvement via Vapor Recompression Heat Pump and Heat Exchanger Network to Achieve Decarbonization of Extractive Distillation. Separation and Purification Technology 2022, 293, 121065. [CrossRef]

- Lincoln, B.J.; Kong, L.; Schlosser, F.; Walmsley, T.G. Process Integration and Electrification for Retrofit: Case Studies of Milk Evaporator Systems. Case Studies in Thermal Engineering 2024, 60, 104601. [CrossRef]

- Wang, H.; Yu, P.; Chen, L.; Chen, L.; Sun, B. Simulation and Modification of an Ethane-Ethylene Separation Unit Using Vapor Recompression Heat Pump: Energy, Exergy, and Economic Analyses. Applied Thermal Engineering 2024, 239, 121993. [CrossRef]

- Aeowjaroenlap, H.; Strohm, J.; Udugama, I.; Yu, W.; Young, B. Dynamic Modelling of a Milk Triple Effect Falling Film Evaporator with Mechanical Vapor Recompression. In Computer Aided Chemical Engineering; Manenti, F., Reklaitis, G.V., Eds.; 34 European Symposium on Computer Aided Process Engineering / 15 International Symposium on Process Systems Engineering; Elsevier, 2024; Vol. 53, pp. 475–480.

- Atalar, I.; Tugrul, K.M.; Gorgulu, A.; Konar, N. 5 - Vapor Recompression Systems for Food Processing Evaporators. In Evaporation Technology in Food Processing; Jafari, S.M., Çapanoglu, E., Karaca, A.C., Eds.; Woodhead Publishing, 2024; pp. 85–101 ISBN 978-0-12-818764-7.

- Guedes do Nascimento, L.; Costa Monteiro, L.P.; de Cássia Colman Simões, R.; Prata, D.M. Eco-Efficiency Analysis and Intensification of the Biodiesel Production Process through Vapor Recompression Strategy. Energy 2023, 275, 127479. [CrossRef]

- Si, Z.; Han, D.; Gu, J.; Song, Y.; Liu, Y. Exergy Analysis of a Vacuum Membrane Distillation System Integrated with Mechanical Vapor Recompression for Sulfuric Acid Waste Treatment. Applied Thermal Engineering 2020, 178, 115516. [CrossRef]

- Yuan, H.; Luo, Y.; Yuan, X. Synthesis of Heat-Integrated Distillation Sequences with Mechanical Vapor Recompression by Stochastic Optimization. Computers & Chemical Engineering 2022, 165, 107922. [CrossRef]

- Han, D.; Si, Z.; Chen, J. Analysis of an Intermittent Mechanical Vapor Recompression Evaporation System. Applied Thermal Engineering 2021, 193, 116996. [CrossRef]

- Woolway, M.; Majozi, T. On the Application of a Metaheuristic Suite with Parallel Implementations for the Scheduling of Multipurpose Batch Plants. Computers & Chemical Engineering 2019, 126, 371–390. [CrossRef]

- Chen, J.; Han, D.; Hang, Z.; Si, Z. Experimental Investigation of a Novel Batch Evaporation System Coupled Mechanical Vapor Recompression Technology and Steam Heat Storage Technology. Innovative Food Science & Emerging Technologies 2021, 68, 102616. [CrossRef]

- Agner, R.; Gruber, P.; Wellig, B. Model Predictive Control of Heat Pumps with Thermal Energy Storages in Industrial Processes. Energies 2024, 17, 4823. [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A Review of Industrial Waste Heat Recovery System for Power Generation with Organic Rankine Cycle: Recent Challenges and Future Outlook. Journal of Cleaner Production 2021, 287, 125070. [CrossRef]

- Hipólito-Valencia, B.J.; Rubio-Castro, E.; Ponce-Ortega, J.M.; Serna-González, M.; Nápoles-Rivera, F.; El-Halwagi, M.M. Optimal Design of Inter-Plant Waste Energy Integration. Applied Thermal Engineering 2014, 62, 633–652. [CrossRef]

- Boldyryev, S.; Gil, T.; Krajačić, G.; Khussanov, A. Total Site Targeting with the Simultaneous Use of Intermediate Utilities and Power Cogeneration at the Polymer Plant. Energy 2023, 279, 128034. [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Amat-Albuixech, M. Multi-Objective Optimization of a Novel Reversible High-Temperature Heat Pump-Organic Rankine Cycle (HTHP-ORC) for Industrial Low-Grade Waste Heat Recovery. Energy Conversion and Management 2019, 197, 111908. [CrossRef]

- Pili, R.; Romagnoli, A.; Jiménez-Arreola, M.; Spliethoff, H.; Wieland, C. Simulation of Organic Rankine Cycle – Quasi-Steady State vs Dynamic Approach for Optimal Economic Performance. Energy 2019, 167, 619–640. [CrossRef]

- Eveloy, V.; Rodgers, P.; Qiu, L. Integration of an Atmospheric Solid Oxide Fuel Cell - Gas Turbine System with Reverse Osmosis for Distributed Seawater Desalination in a Process Facility. Energy Conversion and Management 2016, 126, 944–959. [CrossRef]

- White, M.T.; Oyewunmi, O.A.; Haslam, A.J.; Markides, C.N. Industrial Waste-Heat Recovery through Integrated Computer-Aided Working-Fluid and ORC System Optimisation Using SAFT-Γ<math><mrow Is=“true”><mi Is=“true”>γ</Mi></Mrow></Math> Mie. Energy Conversion and Management 2017, 150, 851–869. [CrossRef]

- Pili, R.; Romagnoli, A.; Spliethoff, H.; Wieland, C. Techno-Economic Analysis of Waste Heat Recovery with ORC from Fluctuating Industrial Sources. Energy Procedia 2017, 129, 503–510. [CrossRef]

- Linnhoff, B.; Ahmad, S. SUPERTARGETING: Optimum Synthesis of Energy Management Systems. Journal of Energy Resources Technology 1989, 111, 121–130. [CrossRef]

- World Energy Outlook 2023 – Analysis Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 18 October 2024).

- Hesselgreaves, J.E.; Law, R.; Reay, D. Compact Heat Exchangers: Selection, Design and Operation; Butterworth-Heinemann, 2016; ISBN 978-0-08-100306-0.

- Alizadeh Zolbin, M.; Tahouni, N.; Panjeshahi, M.H. Total Site Integration Considering Wind /Solar Energy with Supply/Demand Variation. Energy 2022, 252, 123928. [CrossRef]

- Das, S.; Rasouli, E.; Ziev, T.; Lamprinakos, N.; Seo, J.; Rollett, A.; Vaishnav, P.; Narayanan, V. Design and Techno Economic Optimization of an Additively Manufactured Compact Heat Exchanger for High Temperature and High Pressure Applications. Applied Thermal Engineering 2024, 245, 122778. [CrossRef]

- Colgan, N.; Nellis, G.; Anderson, M. Experimental Measurement of the Pressure Drop and Heat Transfer Characteristics of a Cross-flow Heat Exchanger in Low-Density Flows. International Journal of Heat and Mass Transfer 2024, 219, 124782. [CrossRef]

- Klemes, J.J.; Arsenyeva, O.; Kapustenko, P.; Tovazhnyanskyy, L. Compact Heat Exchangers for Energy Transfer Intensification: Low Grade Heat and Fouling Mitigation; CRC Press: Boca Raton, 2016; ISBN 978-0-429-16104-9.

- Kiepfer, H.; Stannek, P.; Grundler, M.; Bart, H.-J. Development and Thermal Performance of a Thermoplastic-Graphite-Composite Based Plate Heat Exchanger for Use in Corrosive Media. Applied Thermal Engineering 2024, 236, 121581. [CrossRef]

- Güler, O.V.; Gürel, B.; Kurtuluş, K.; Aryanfar, Y.; Castellanos, H.G.; Göltaş, M.; Keçebaş, A.; Akkaya, V.R. Thermo-Hydraulic Efficiency of Lung-Inspired Compact Plate Heat Exchangers Made Using Additive Manufacturing Techniques with Steel, Aluminum and Titanium Powders. Chemical Engineering Science 2024, 283, 119378. [CrossRef]

- Jafari-Asl, J.; Lara Montaño, O.D.; Mirjalili, S.; Faes, M.G.R. A Meta-Heuristic Approach for Reliability-Based Design Optimization of Shell-and-Tube Heat Exchangers. Applied Thermal Engineering 2024, 248, 123161. [CrossRef]

- Babaelahi, M.; Sadri, S.; Al-Jaberi, O. Numerical Modeling and Multi-Objective Optimization of Helically Grooved Tube Geometry in Shell-and-Tube Heat Exchangers: A Comprehensive Analysis of Heat Transfer Enhancement, Turbulence Characteristics, and Pressure Drop Using COMSOL Multiphysics. Chemical Engineering Science 2025, 311, 121638. [CrossRef]

- Alipour, R.; Alipour, R.; Rezaeimanesh, M.; Tahan, M.H.; Dehghan, M. Heat Transfer Enhancement in a Tubular Heat Exchanger Fitted with a Novel Baffle: A Numerical Study and Experimental Validation. International Journal of Thermal Sciences 2025, 215, 109936. [CrossRef]

- Beigzadeh, R.; Soltanian, S.; Tofangchi, D. Enhancing Heat Transfer Efficiency in Heat Exchangers: A Fusion of Computational Fluid Dynamics and Genetic Algorithm for Circular Baffle Optimization. International Journal of Heat and Fluid Flow 2025, 112, 109726. [CrossRef]

- Sun, Y.; Li, D.; Ji, J.; Hua, Z. Numerical Study of Structural Parameters of Perforated Baffle on Heat Transfer Enhancement in Coiled Elastic Copper Tube Heat Exchanger. Applied Thermal Engineering 2025, 260, 124993. [CrossRef]

- Liu, S.; Chen, Z.; Yin, S.; Tu, A.; Zhu, D. Heat Transfer Enhancement Characteristic of Twisted Elliptical Tube Heat Exchanger at High Re Condition and Its Energy-Saving Application in Mechanical Vapor Recompression System. Chemical Engineering and Processing - Process Intensification 2025, 210, 110214. [CrossRef]

- Rinik, R.A.; Bhuiyan, A.A.; Karim, Md.R. Enhancement of Heat Transfer Using Elliptical Twisted Inner Pipe with Convergent Conical Ring Turbulator for Turbulent Flow in Double Pipe Heat Exchanger. International Journal of Thermal Sciences 2025, 210, 109558. [CrossRef]

- Boujelbene, M.; Mehryan, S.A.M.; Abidi, A.; Ahmed Alashaari, G.A.; Alshehery, S.; Khedher, N.B.; Mahariq, I.; Shah, N.A. Experimental Investigation of a Novel Approach to Enhance Heat Transfer in Double-Tube Heat Exchangers through the Utilization of a Vibrating Latex Strip Turbulator. International Communications in Heat and Mass Transfer 2025, 160, 108371. [CrossRef]

- Crystal, R.V.; Crittenden, T.; Glezer, A.; Garimella, S. Enhancement of Air-Side Heat Transfer in Cross-flow Heat Exchangers Using Auto-Fluttering Reeds. Applied Thermal Engineering 2025, 258, 124617. [CrossRef]

- Hu, W.; Du, Y.; Hu, P.; Wang, D. Numerical Characterization of Heat Transfer in a Convection-Enhanced Perforated Tube-Plate Radiant Heat Exchanger. Applied Thermal Engineering 2025, 274, 126573. [CrossRef]

- Mahmoudinezhad, S.; Sadi, M.; Ghiasirad, H.; Arabkoohsar, A. A Comprehensive Review on the Current Technologies and Recent Developments in High-Temperature Heat Exchangers. Renewable and Sustainable Energy Reviews 2023, 183, 113467. [CrossRef]

- Erdinç, M.T.; Dalgıç, İ.; Kutlu, C.; Dik, A.; Tokgoz, N.; Su, Y.; Riffat, S. A Comprehensive Review of Miscellaneous Heat Transfer Enhancement Designs of Phase Change Material Integrated Heat Exchanger. International Communications in Heat and Mass Transfer 2025, 164, 108791. [CrossRef]

- Wang, J.; Qian, C.; Yu, B.; Zhang, F.; Ma, R.; Shi, J.; Chen, J. Design and Optimization of Additive Manufactured Fischer-Koch-Structured Heat Exchanger for Enhanced Heat Transfer Efficiency. International Communications in Heat and Mass Transfer 2024, 159, 108078. [CrossRef]

- Dabestani, A.; Kahani, M. CFD Analysis of Rotation Effect on Flow Patterns and Heat Transfer Enhancement in a Horizontal Spiral Tube Heat Exchanger. Case Studies in Thermal Engineering 2024, 64, 105494. [CrossRef]

- Riyadi, T.W.B.; Herawan, S.G.; Tirta, A.; Ee, Y.J.; Hananto, A.L.; Paristiawan, P.A.; Yusuf, A.A.; Venu, H.; Irianto; Veza, I. Nanofluid Heat Transfer and Machine Learning: Insightful Review of Machine Learning for Nanofluid Heat Transfer Enhancement in Porous Media and Heat Exchangers as Sustainable and Renewable Energy Solutions. Results in Engineering 2024, 24, 103002. [CrossRef]

- Sun, J.; Wu, Z.; Li, W.; Liu, Z. Coupling Effects of Micro/Nano-Scale Surface Modification and Electric Current Application on Fouling Resistance and Heat Transfer. International Journal of Heat and Mass Transfer 2024, 235, 126178. [CrossRef]

- Sun, L.; Wan, C.; Zhu, T.; Luo, X. Inverse System Based Decoupling Design and Control Strategy for Crude Oil Heat Exchanger Networks. Applied Thermal Engineering 2025, 258, 124509. [CrossRef]

- Niu, J.; Wang, J.; Liu, X.; Dong, L. An Active Control Strategy for Simultaneously Achieving Turbulent Drag Reduction and Heat Transfer Enhancement in Heat Exchangers: Oscillation of Micro Cuboid Vortex Generators. International Communications in Heat and Mass Transfer 2024, 159, 108315. [CrossRef]

- Liu, B.; Wang, Y.; Feng, X. Optimal Design of Industrial Cooling Water Systems Considering Economic Performance and Water Savings. Computers & Chemical Engineering 2022, 167, 108021. [CrossRef]