Submitted:

22 January 2024

Posted:

24 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. The Methodological Logic

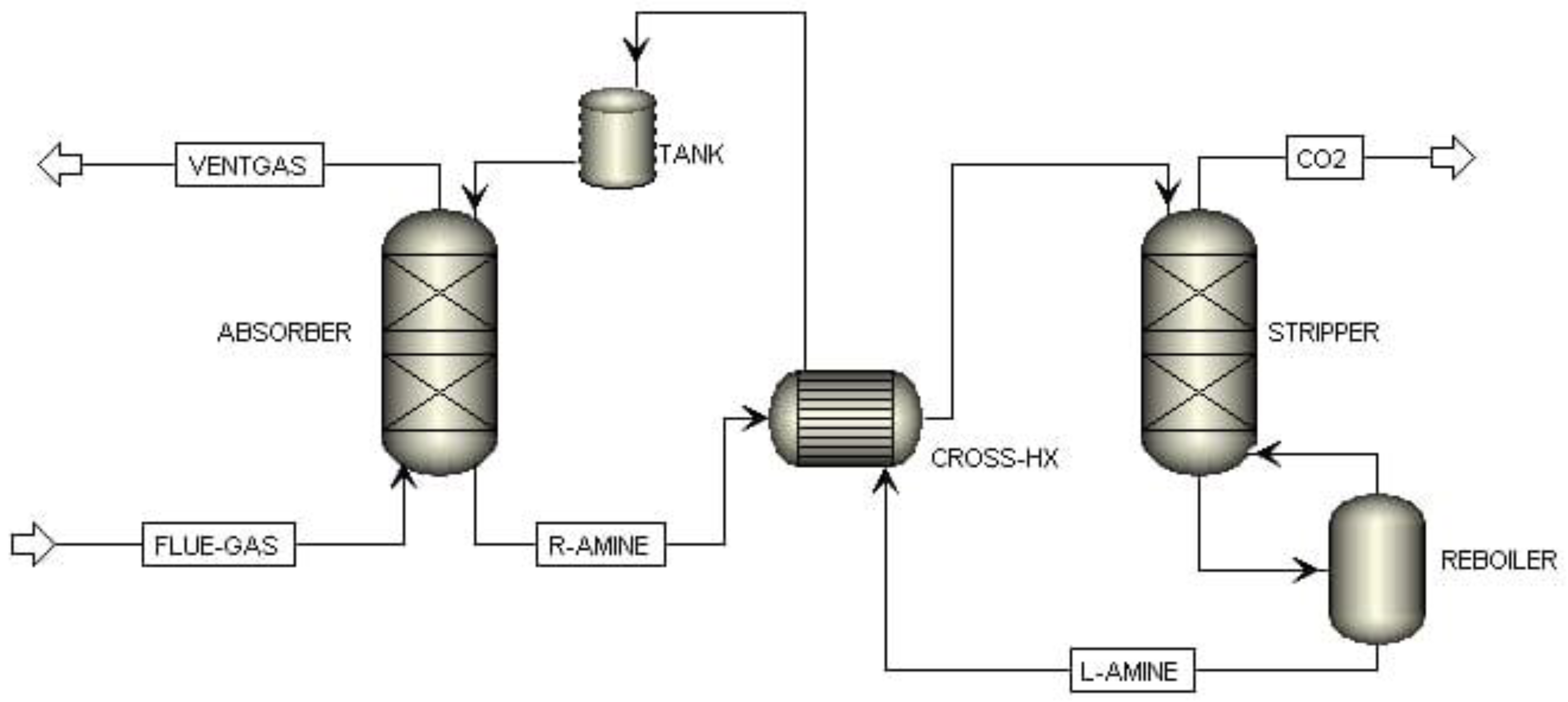

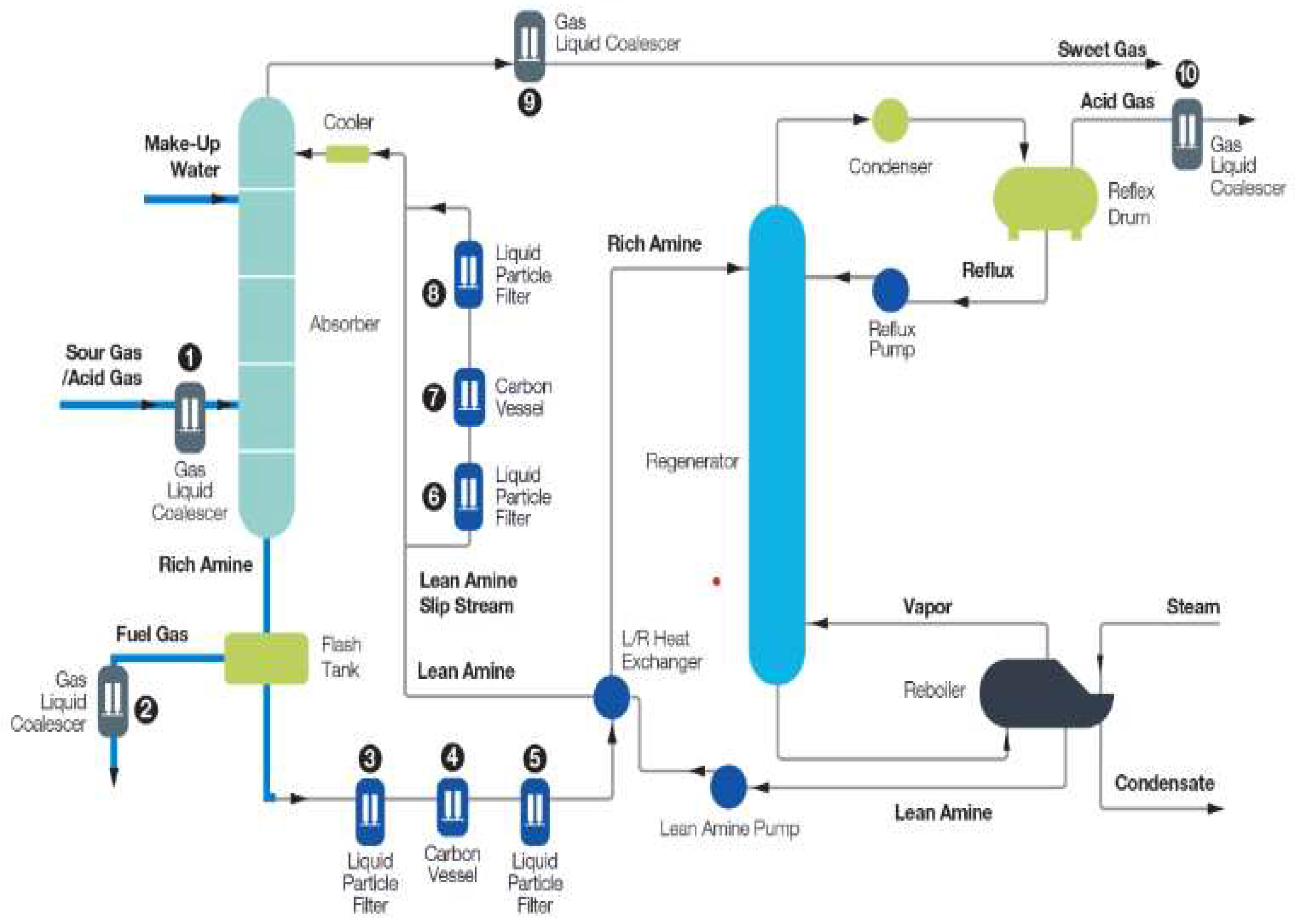

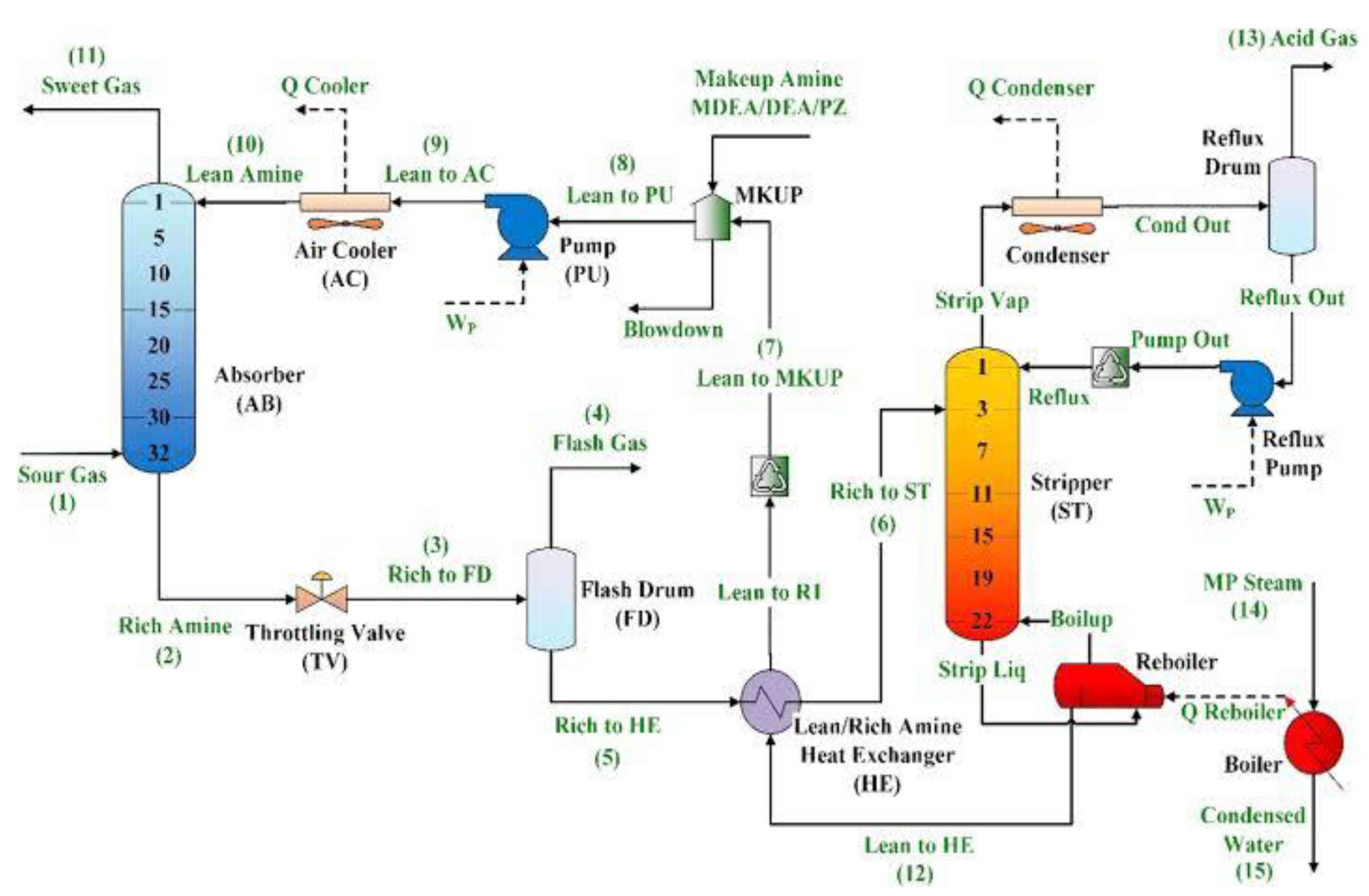

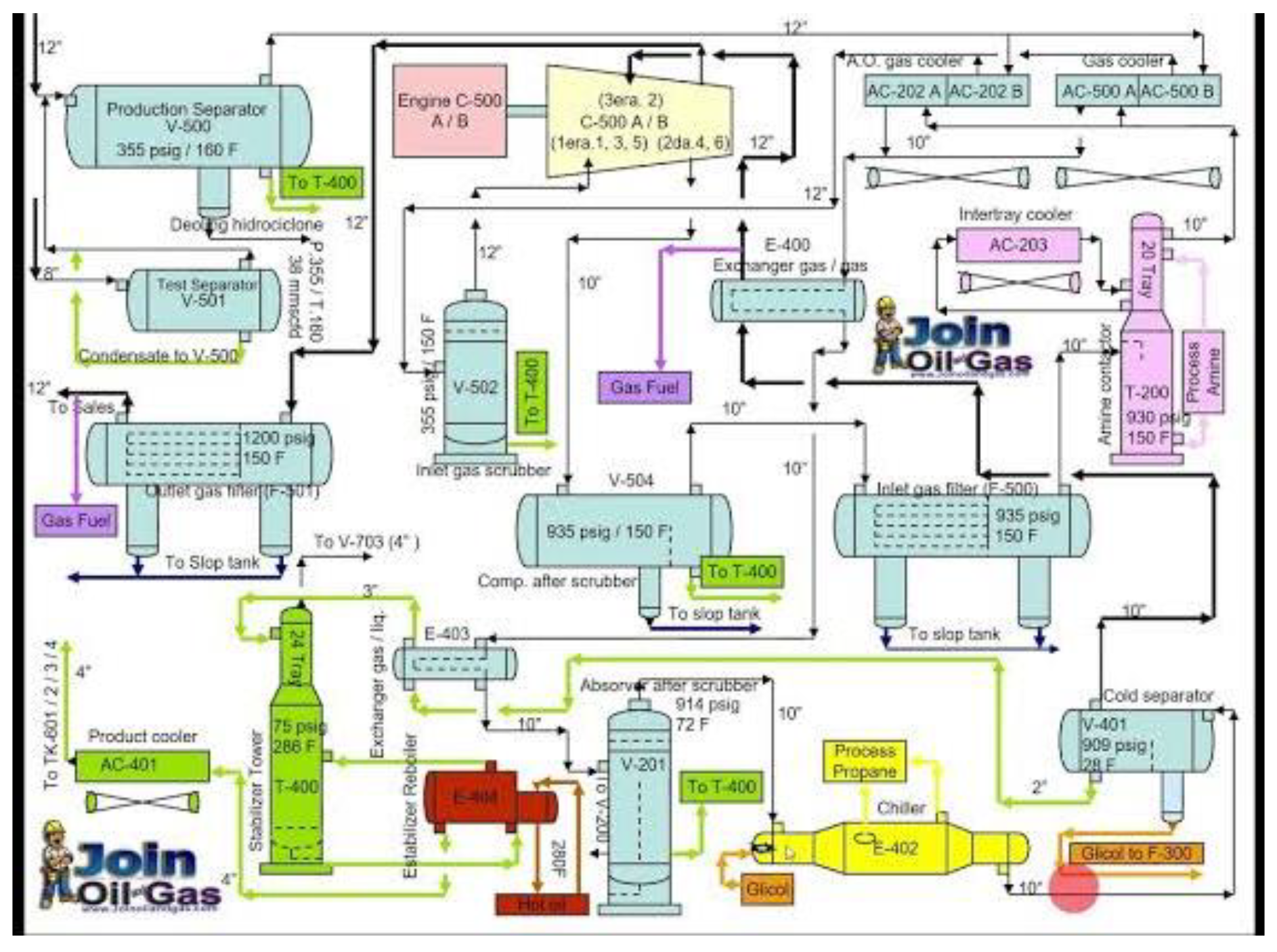

- Gas Inlet: This represents the entry point for the gas stream containing impurities, such as CO2 and H2S.

- Absorber Tower: This is where the absorption of acid gases takes place. The gas stream enters the absorber tower from the bottom, and a rich amine solution is introduced from the top. The amine solution acts as a solvent that selectively absorbs the acid gases.

- Lean Amine Solution: This refers to the amine solution that has been partially depleted of acid gases after passing through the absorber tower. The lean amine solution is typically located at the bottom of the absorber tower.

- Stripper Tower: This tower serves to regenerate the amine solution by removing the absorbed acid gases. Heat is usually applied to the stripper tower to facilitate the release of the acid gases from the amine solution.

- Acid Gas Outlet: This represents the exit point for the acid gases, which are separated from the regenerated amine solution in the stripper tower. 6. Treated Gas Outlet: This indicates the point where the purified gas, with reduced levels of acid gases, exits the gas purification unit. It's important to note that the specific design and configuration of the amine absorption process may vary depending on the application and requirements of the gas purification unit.

2.1. Drawdown from the desorption column on the side

2.2. Flash Unit

3. Modeling and Validation

- Absorption column:

- Type of column: The absorption column in this case is packed, meaning it contains a packing material (such as random or structured packing) to enhance contact between the gas and liquid phases.

- Number of stages: The absorption column consists of 30 stages, which indicate the number of discrete sections within the column where the absorption process takes place. Each stage allows for further interaction between the gas and liquid phases.

- H2S in gas feed (ppm): The H2S concentration in the gas feed to the absorption column is 1950 parts per million (ppm), indicating the presence of hydrogen sulfide as an impurity.

- Column pressure (bar): The column operates at a pressure of 55 bar, which provides the necessary driving force for the absorption process to occur.

- Gas feed temperature (°C): The gas feed to the absorption column is at a temperature of 40°C, which influences the thermodynamics of the absorption process.

- CO2 in gas feed (mol%): The gas feed to the absorption column contains 1.84 mole percent (mol%) of carbon dioxide (CO2), indicating the presence of CO2 as another impurity.

- Amine flow rate: The flow rate of the amine solution in the absorption column is 4715 gallons per minute (or any appropriate unit based on the context).

- Inlet lean Amine temperature: The temperature of the lean amine solution entering the absorption column is 35°C.

- Amine concentration in absorbent: The amine solution used as the absorbent in the absorption column has a concentration of 50% by weight. This indicates that the amine solution is composed of 50% amine and 50% other components (such as water or additives).

- Feed gas flow rate: The flow rate of the gas entering the absorption column is 15960 kilomoles per hour (or any appropriate unit based on the context). This value represents the amount of gas being treated in a given time frame.

- Desorption column:

- Type of column: The desorption column, in contrast to the absorption column, is a tray column. Tray columns incorporate trays or plates at regular intervals to facilitate the separation of different components.

- Number of stages: The desorption column comprises 24 stages, indicating the number of trays or stages within the column where the desorption process occurs.

- Condenser temperature (°C): The condenser, located in the desorption column, operates at a temperature of 34°C. The condenser is responsible for condensing the vapor phase and separating it from the liquid phase.

- Column pressure (bar): The desorption column operates at a lower pressure of 1.5 bar compared to the absorption column. This lower pressure allows for the desorption process to take place effectively.

- Feed temperature (°C): The feed to the desorption column enters at a temperature of 94.60°C, influencing the thermodynamics and heat transfer processes within the column.

- Feed stage location: The feed stage is located at tray number 3. This means that the feed mixture is introduced into the desorption column at the designated tray.

- ACID GAS:

- H2S in sweet gas (ppm): The concentration of hydrogen sulfide (H2S) in the treated gas stream, known as sweet gas, is 5.02 parts per million (ppm). This indicates that there is a relatively low level of H2S remaining in the gas after the acid gas removal process.

- Acid gas loading: The acid gas loading refers to the amount of acid gas (such as H2S and CO2) absorbed by the solvent (amine) in the acid gas removal process. In this case, the acid gas loading is 0.427, indicating the quantity of acid gas absorbed per unit volume of the amine solution.

- CO2 in sweet gas (mol%): The concentration of carbon dioxide (CO2) remaining in the sweet gas stream is 0.9934 mole percent (mol%). This suggests that there is still a small amount of CO2 present in the gas after the acid gas removal process.

- Lean Amine temperature: The temperature of the lean amine solution (amine with low acid gas concentration) in the acid gas removal unit is 21.81°C. This temperature is crucial for controlling the efficiency of the amine regeneration process.

- ELECNRTL:

- H2S in sweet gas (ppm): The simulation using the ELECNRTL package shows a slightly lower concentration of H2S in the sweet gas, measured at 4.12 ppm. This suggests that the ELECNRTL package may be more effective in removing H2S compared to the ACIDGAS package.

- Acid gas loading: The acid gas loading using the ELECNRTL package is 0.394, indicating the amount of acid gas absorbed by the amine solution per unit volume.

- CO2 in sweet gas (mol%): The concentration of CO2 in the sweet gas, after using the ELECNRTL package, is 1.5892 mol%. This implies that the ELECNRTL package may be slightly less effective in removing CO2 compared to the ACIDGAS package.

- Lean Amine temperature: The temperature of the lean amine solution in the ELECNRTL simulation is 21.68°C, slightly lower than the ACIDGAS simulation.

4. OUTCOMES AND DISCUSSION

4.1. Split- flow

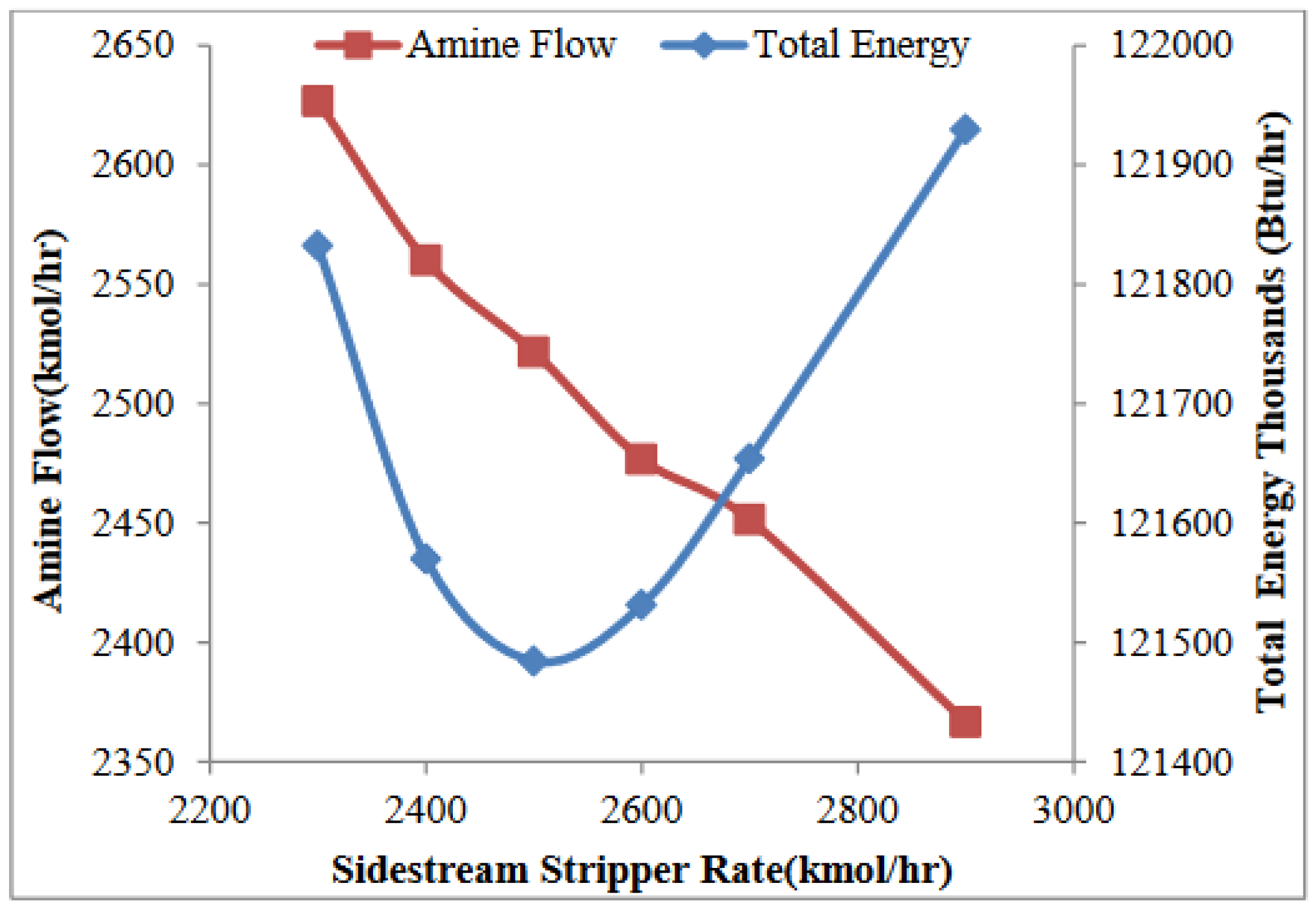

- Amine flow (kmol/h): This column indicates the flow rate of the amine solution in kilomoles per hour. It represents the quantity of amine being circulated through the system to remove acid gases.

- Stream side rate (kmole/hr): The stream side rate column represents the flow rate of the side stream in kilomoles per hour. The side stream is a portion of the amine solution diverted from the main process flow for regeneration or other purposes.

- Sidestream stage: This column specifies the number of stages in the side stream section. Each stage represents a discrete section within the side stream where separation or regeneration occurs.

- Loading (Rich): The loading column shows the acid gas loading in the rich side of the side stream. Acid gas loading refers to the amount of acid gases (such as H2S and CO2) absorbed by the amine solution in the rich side of the side stream section.

- Side stream of loading: This column represents the acid gas loading in the side stream section. It indicates the amount of acid gas absorbed by the amine solution in the side stream stages.

- Total Energy (Btu/hr): The Total Energy column gives the total energy consumption in British Thermal Units per hour (Btu/hr). It quantifies the amount of energy required for the entire system, taking into account the number of side stream stages and their respective flow rates.

- Amine flow rate (kmole/hr):

- Stream rate side (kmole/hr):

- Duty Reboiler (Btu/hr):

- Total Energy (Btu/hr):

4.2. Applying a flash unit

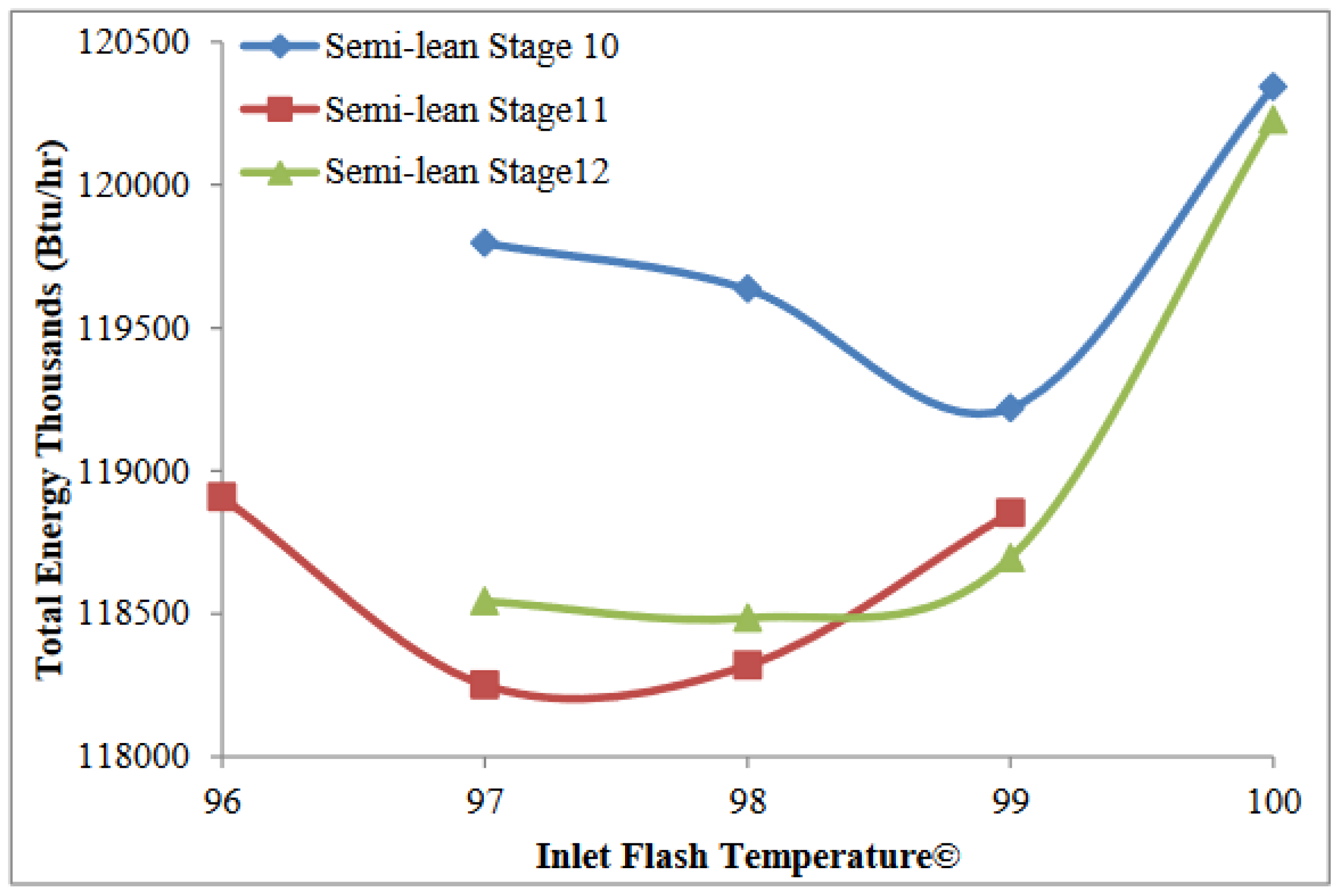

- Semi-lean feed stage

- Flash unit feed temperature:

- The table displays flash unit feed temperatures ranging from 96 to 100.

- Amine flow (kmol/hr):

- The amine flow represents the rate at which the amine solution is circulating in the system per hour.

- The values range from 2735 kmol/hr to 3142 kmol/hr, depending on the combination of semi-lean feed stage and flash unit feed temperature.

- Rich loading:

- Rich loading indicates the concentration of the absorbed gas in the rich amine solution.

- The values range from 0.3396 to 0.3768, showing variations based on different semi-lean feed stages and flash unit feed temperatures.

- Reboiler duty (Btu/hr).

- Total energy (Btu/hr):

- Total energy represents the overall energy utilization within the absorption column.

- The values range from 118,250,324 Btu/hr to 120,432,903 Btu/hr, based on different combinations of semi-lean feed stage and flash unit feed temperature

- Semi-lean feed stage:

- Flash unit feed temperature.

- Amine flow (kmol/hr):

- Rich loading:

- Reboiler duty (Btu/hr):

- Total energy (Btu/hr):

- Type of structure: - The table compares two types of structures: "The split flow" and "The flash unit splitflow."

- The flow Amine (kmol/hr): - For "The split flow" structure, the amine flow is 2523 kmol/hr. - In "The flash unit splitflow" structure, the amine flow is 2744 kmol/hr. - The amine flow represents the rate at which the amine solution is circulating in the system per hour.

- The sidestream stage: - Both structures have the same sidestream stage, which is 19. - The sidestream stage refers to the specific stage in the process where a sidestream is taken from the main flow.

- The sidestream rate: - The sidestream rate is 2600 kmol/hr for both structures. - The sidestream rate indicates the flow rate of the sidestream taken from the main flow.

- Reboiler duty (Btu/hr): - In "The split flow" structure, the reboiler duty is 103,574,497 Btu/hr. - For "The flash unit splitflow" structure, the reboiler duty is 99,897,896 Btu/hr. - Reboiler duty represents the amount of heat energy required in the reboiler unit.

- Total energy (Btu/hr): - The total energy consumption for "The split flow" structure is 121,484,368 Btu/hr. - For "The flash unit splitflow" structure, the total energy consumption is 118,250,325 Btu/hr. - Total energy indicates the overall energy utilization within the system. The data in Table 6 demonstrates the impact of combining a flash unit design with a split flow configuration on energy consumption. Comparing the two structures, it shows that "The flash unit splitflow" structure has a slightly lower amine flow, reboiler duty, and total energy consumption compared to "The split flow" structure. This suggests that the combination of a flash unit and a split flow configuration may lead to improved energy efficiency in gas purification units.

CONCLUSION AND RECOMMENDATIONS

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, X., Zhang, Y., & Wang, T. (2020). Application of semi-lean flows in gas purification units. Energy, 214, 118686.

- Smith, J., & Johnson, A. (2019). Unlocking the energy utilization of gas purification units through MDEA-based processes. Journal of Energy Engineering, 145(2), 04019018.

- Wang, L., Li, H., & Zhang, M. (2018). Transformative potential of semi-lean flows in gas purification units: A case study. Energy Conversion and Management, 166, 139-148.

- Johnson, R., & Thompson, S. (2017). A comprehensive analysis of MDEA-based processes for energy utilization in gas purification units. International Journal of Energy Research, 41(3), 339-352.

- Yang, G., Zhang, L., & Liu, H. (2016). Enhancing energy utilization in gas purification units with MDEA-based processes: A computational study. Fuel, 185, 126-136.

- Lee, C., Park, S., & Kim, J. (2015). Semi-lean flows for energy-efficient gas purification units: A performance evaluation. Journal of Industrial and Engineering Chemistry, 21, 969-976.

- Nguyen, T., & Nguyen, H. (2014). Assessing the transformative potential of semi-lean flows on gas purification units: A comparative study. Energy Procedia, 61, 1814-1817.

- Wang, P., Chen, K., & Zhang, Q. (2013). Analysis of MDEA-based processes for energy utilization in gas purification units: A lifecycle assessment perspective. Journal of Cleaner Production, 59, 161-170.

- Smith, M., & Brown, K. (2012). Semi-lean flows: A novel approach to energy utilization in gas purification units. Chemical Engineering Science, 82, 175-184.

- Kim, Y., Park, J., & Lee, H. (2011). Unlocking the energy utilization potential of gas purification units through MDEA-based processes: A case study. Applied Energy, 88(4), 1168-1176.

- Johnson, D., & Anderson, R. (2010). Transformative potential of semi-lean flows on gas purification units: A techno-economic analysis. Energy Policy, 38(6), 2896-2903.

- Wang, Q., Li, G., & Zhu, X. (2009). Comprehensive analysis of MDEA-based processes for energy utilization in gas purification units: A simulation study. Chemical Engineering Journal, 152(2-3), 447-455.

- Chen, Z., & Zhao, Y. (2008). Semi-lean flows in gas purification units: An experimental investigation. Energy Conversion and Management, 49(9), 2559-2566.

- Smith, L., & Johnson, C. (2007). Unlocking the potential of MDEA-based processes for energy utilization in gas purification units. Energy & Fuels, 21(6), 3466-3474.

- Wang, Y., & Li, W. (2006). Transformative potential of semi-lean flows on gas purification units: A case study in a petrochemical plant. Energy Policy, 34(15), 2246-2255.

- Anderson, A., & Harris, B. (2005). Assessing the energy utilization of gas purification units using MDEA-based processes: A comparative study. Energy Conversion and Management, 46(9-10), 1529-1539.

- Johnson, G., & Thompson, L. (2004). A comprehensive analysis of semi-lean flows in gas purification units: A comparative study. Industrial & Engineering Chemistry Research, 43(12), 3211-3221.

- Zhang, J., & Li, X. (2003). Enhancing energy utilization in gas purification units with MDEA-based processes: A case study in a natural gas processing plant. Journal of Natural Gas Science and Engineering, 11(1), 1-9.

- Smith, D., & Johnson, E. (2002). Semi-lean flows for energy-efficient gas purification units: A performance evaluation. Applied Thermal Engineering, 22(12), 1307-1316.

- Wang, C., & Liu, S. (2001). Unlocking the transformative potential of MDEA-based processes for energy utilization in gas purification units: A feasibility study. Fuel Processing Technology, 68(1), 1-9.

| Absorption column | Desorption column. | ||

|---|---|---|---|

| Type of column | Packed | Type of column | Tray |

| Number of stage | 30 | Number of stage | 24 |

| H2S In gas feed ppm | 1950 | Condenser temp.oC. | 34 |

| Column pressure bar. | 55 | Column pressure bar | 1.5 |

| Gas feed Temp.oC. | 40 | Feed Temp.oC. | 94.60 |

| CO2 in gas feed,mol% | 1.84 | Feed stage location. | 3 |

| Amine flow rate. | 4715 | ||

| Inlet lean Amine temp.0C. | 35 | ||

| Amine conc.in absorbent,wt% | 50 | ||

| Feed gas flow rate,Kmole h. | 15960 | ||

| ACIDGAS package. | |||

|---|---|---|---|

| ACID GAS | ELECNTRTL | PLANT. | |

| H2S in sweet gas,ppm | 5.02 | 4.12 | 4 |

| Acid gas loading | 0.427 | 0.394 | 0.428 |

| CO2 in sweet gas mol%. | 0.9934 | 1.5892 | 1.10757 |

| Lean Amine temp. | 21.81 | 21.68 | 212 |

| Reboiler Duty,Btu.hrs | 1.03e8 | 9.95e8 | 1.137e9 |

| Amine flow.(kmol/h) | Stream side rate(kmole/hr) | Sidestream stage | Loading(Rich) | Side stream of loading | The Total Energy.(Btu/hr) |

|---|---|---|---|---|---|

| 2830 | 2300 | 19 | 0.4261 | 0.02483 | 122407094 |

| 2627 | 2300 | 18 | 0.4454 | 0.02196 | 121831874 |

| 2777 | 2400 | 19 | 0.4335 | 0.02523 | 123676532 |

| 2560 | 2400 | 18 | 0.4514 | 0.02231 | 121769940 |

| 2762 | 3000 | 19 | 0.4271 | 0.02543 | 123790928 |

| 2650 | 2800 | 18 | 0.4481 | 0.02255 | 121484369 |

| 2600 | 2600 | 19 | 0.4228 | 0.02568 | 122000 |

| 2550 | 2600 | 18 | 0.4500 | 0.02285 | 121900 |

| 2500 | 2700 | 19 | 0.4215 | 0.02595 | 121800 |

| 2450 | 2700 | 18 | 0.4448 | 0.02307 | 121600 |

| 2400 | 2400 | 19 | 0.4290 | 0.02668 | 121500 |

| 2350 | 2200 | 18 | 0.4506 | 0.02369 | 121400 |

| Types of structure | Amine flow rate(kmole/hr) | The stream rate side (kmole/hr) | The duty Reboiler(Btu/hr) | The tital energy(Btu/hr) |

|---|---|---|---|---|

| The current configuratiion. | 4616 | - | 112744989 | 133415348 |

| Split-flow | 2622 | 2600 | 104574974 | 121584268 |

| Semi-lean feed stage. | Flash unit feed temp. | Amine flow(kmol/hr) | Rich loading | Reboiler duty.(btu/hr) | Total energy.(Btu/hr) |

| 10 | 98 | 2892 | 0.3592 | 100847678 | 119635106 |

| 10 | 99 | 2956 | 0.3528 | 100098253 | 119218708 |

| 10 | 100 | 3142 | 0.3396 | 100538336 | 120432903 |

| 11 | 96 | 2735 | 0.3768 | 100653151 | 118908196 |

| 11 | 97 | 2743 | 0.3738 | 99896896 | 118250324 |

| 11 | 98 | 2818 | 0.3628 | 99708836 | 118318888 |

| 12 | 97 | 2776 | 0.3663 | 10017463 | 118543610 |

| 12 | 98 | 2841 | 0.3583 | 99856210 | 118484552 |

| 12 | 99 | 2932 | 0.3498 | 99566283 | 118694581 |

| Type of structure | The flow Amine(kmol/hr) | The sidestream stage. | The sidestram rate | Reboiler duty(Btu/hr) | Total energy(Btu/hr) |

|---|---|---|---|---|---|

| The split flow | 2523 | 19 | 2600 | 103574497 | 121484368 |

| The flash unit splitflow. | 2744 | 19 | 2600 | 99897896 | 118250325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).