Submitted:

08 April 2025

Posted:

08 April 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

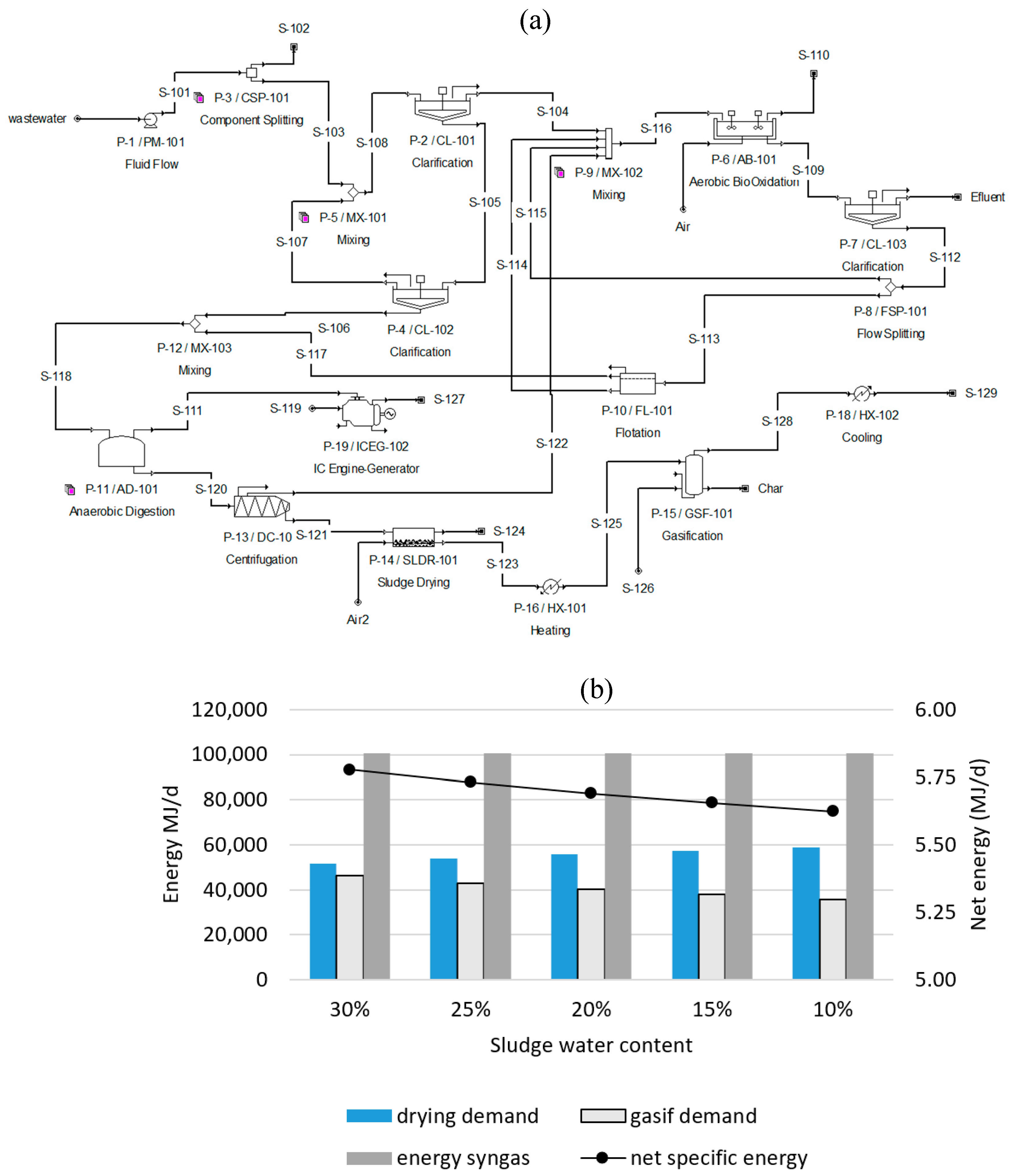

2. Materials and Methods

3. Results and Discussion

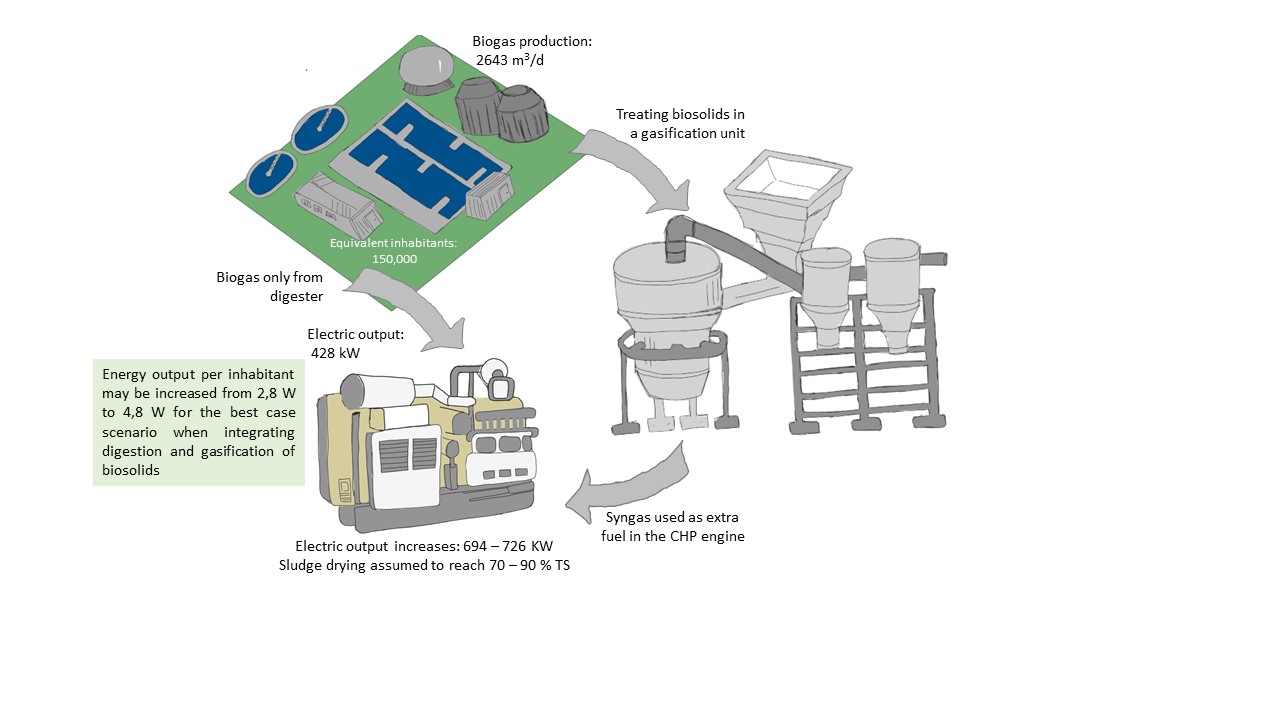

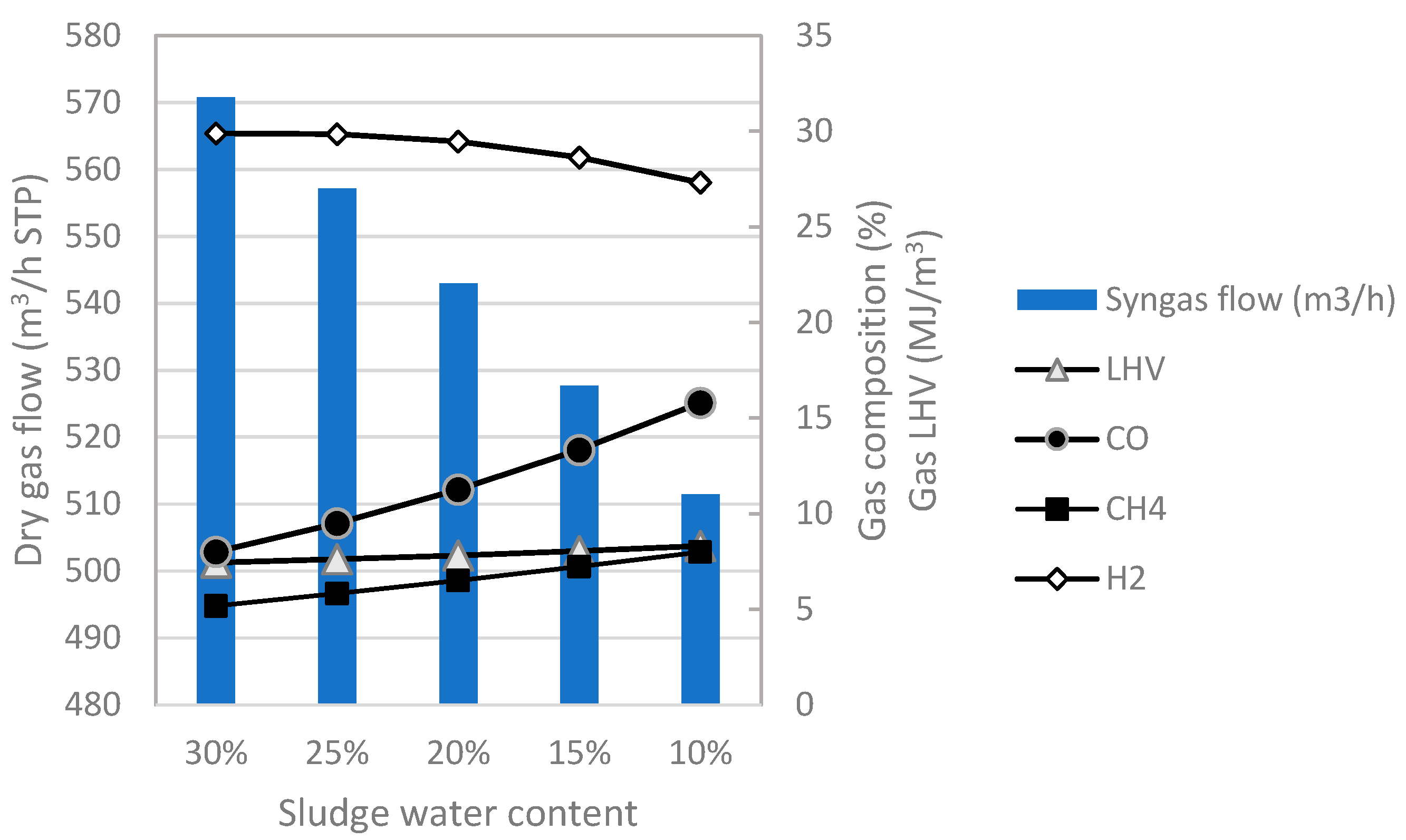

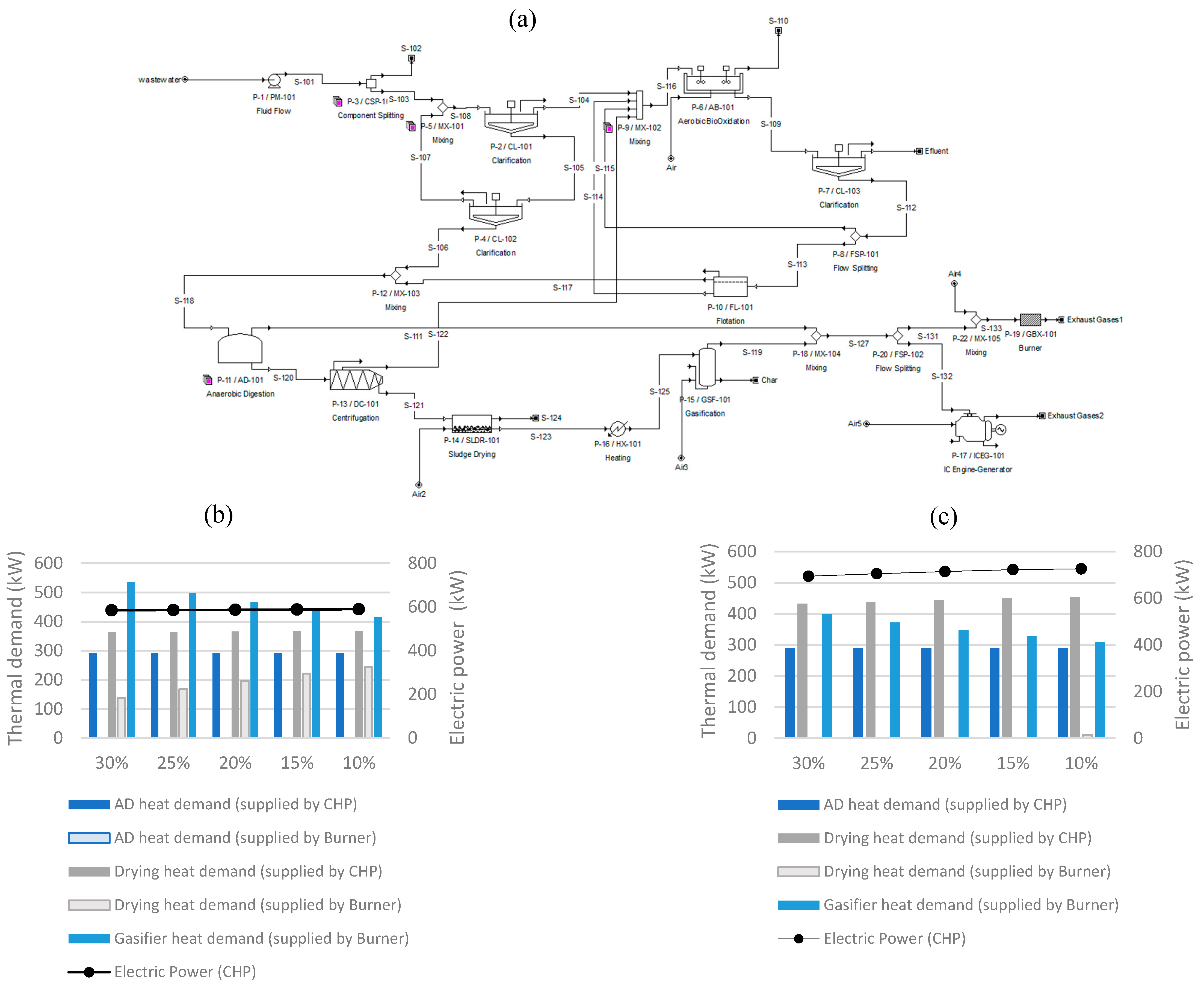

3.1. Sludge Gasification

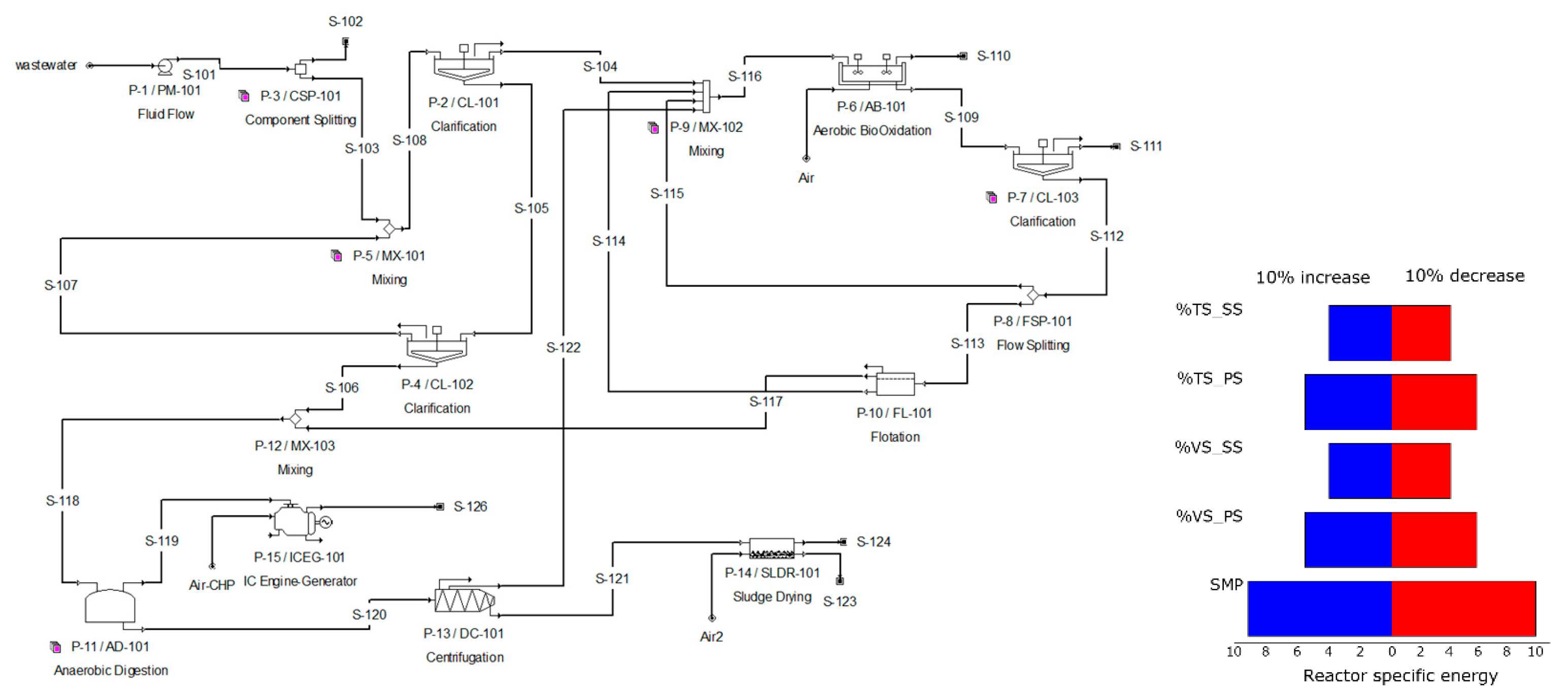

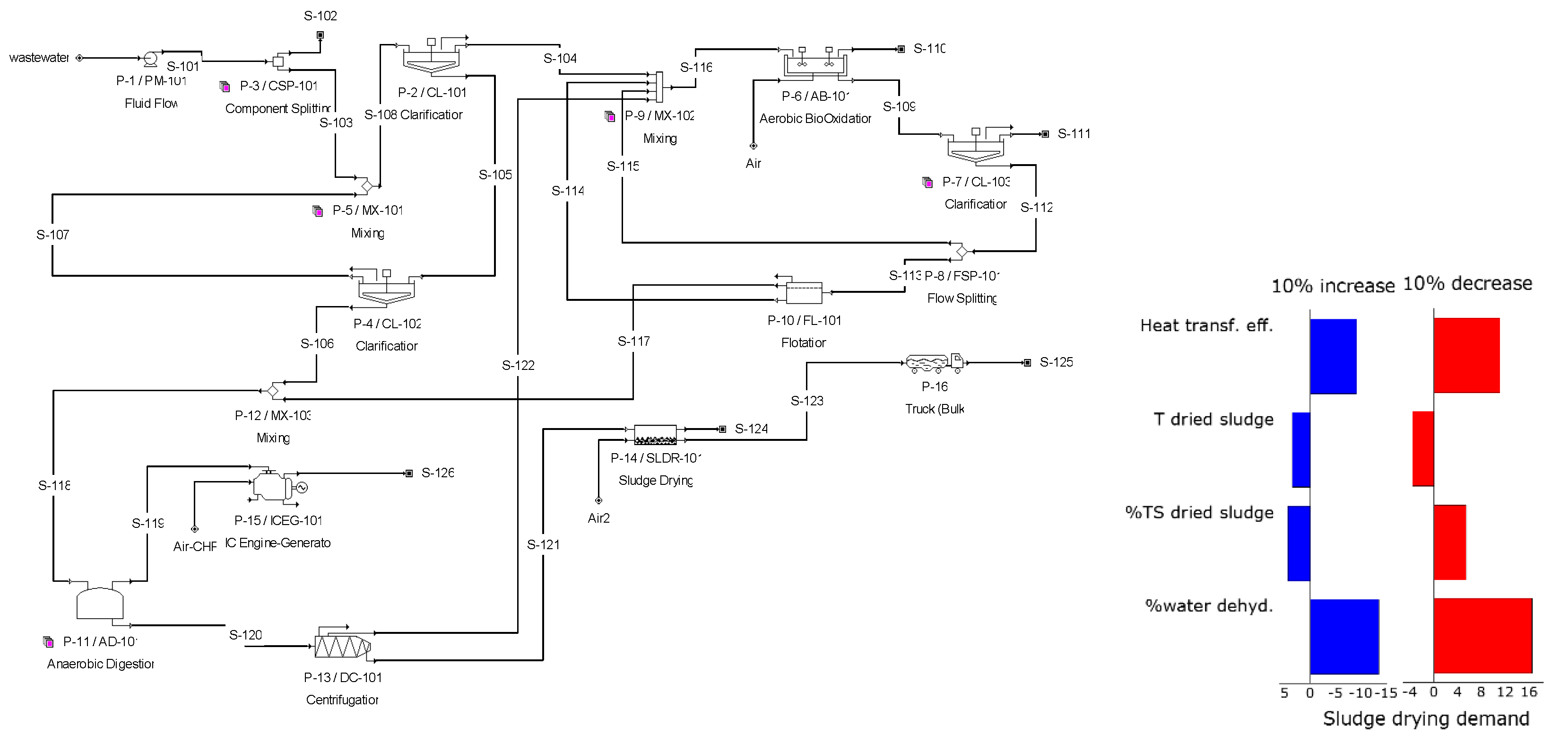

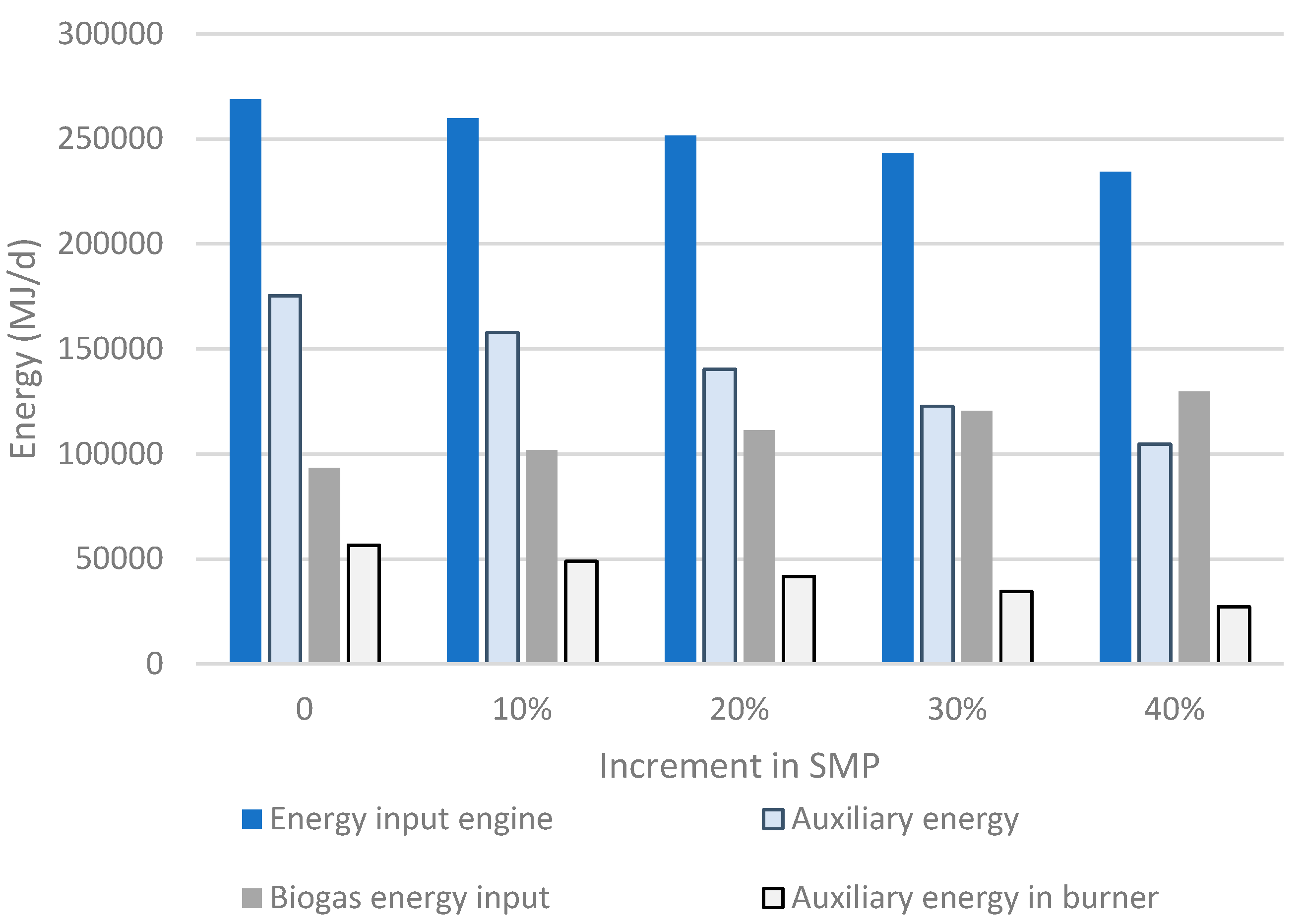

3.2. Analyzing the Effect of Sludge Mineralization

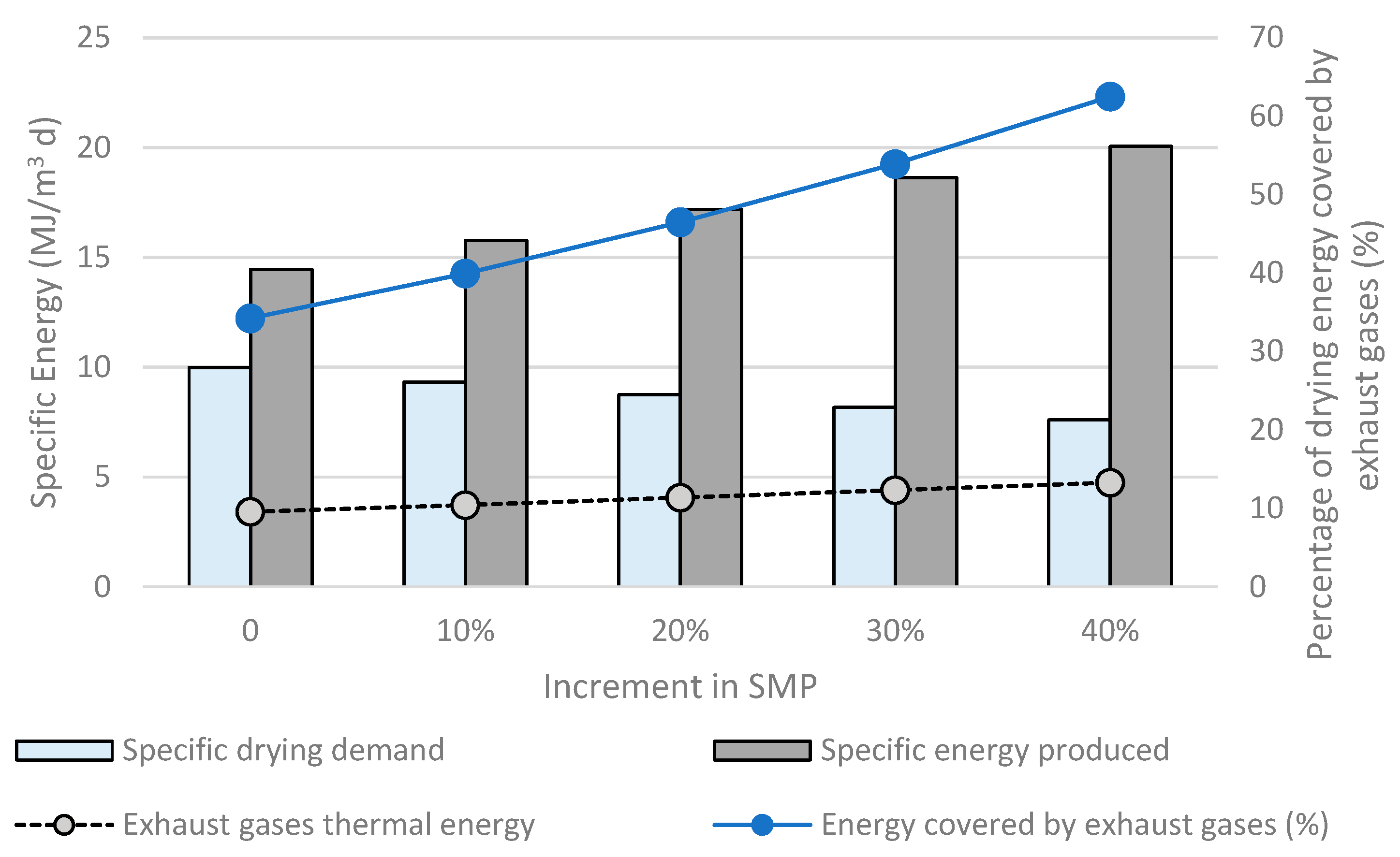

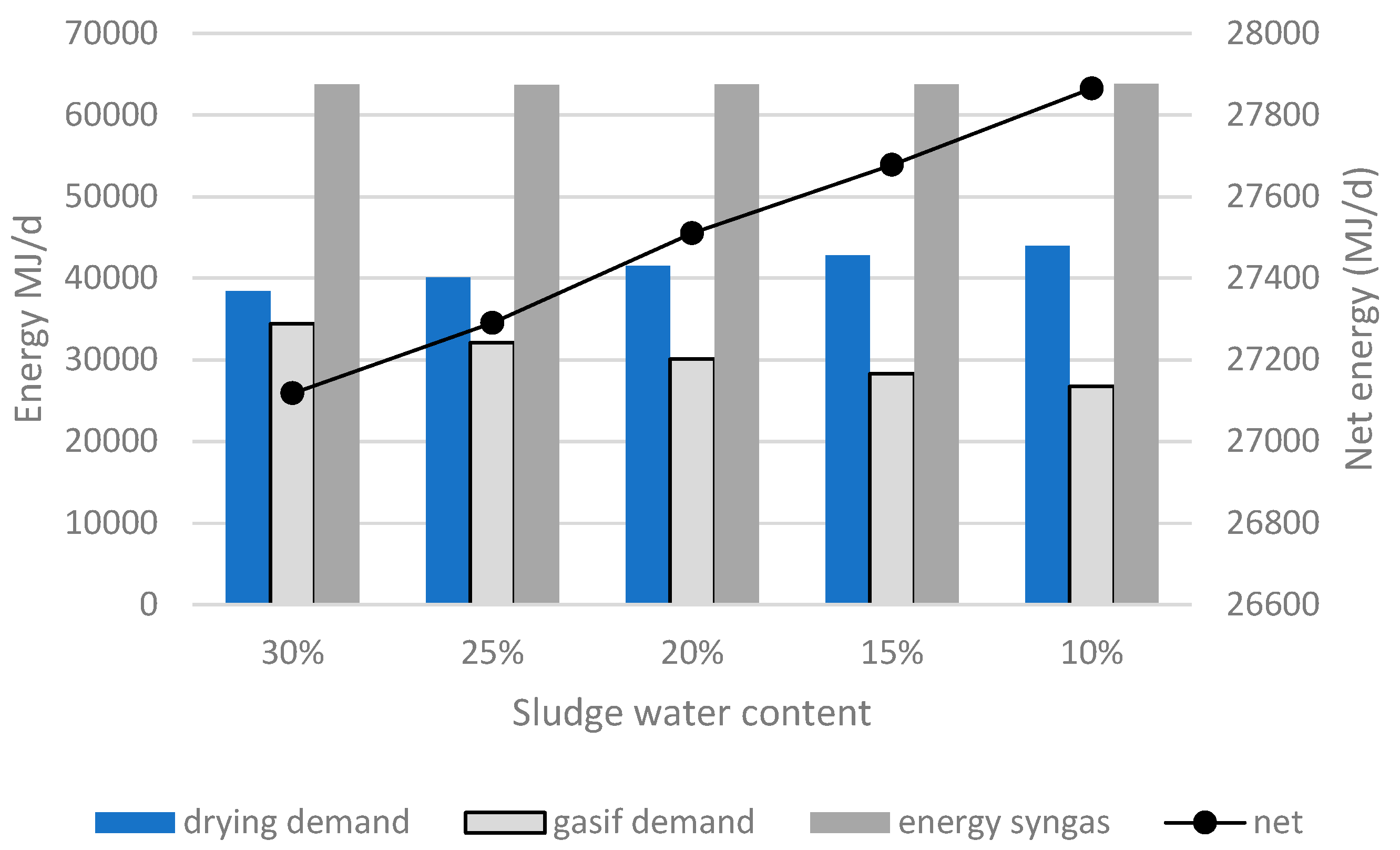

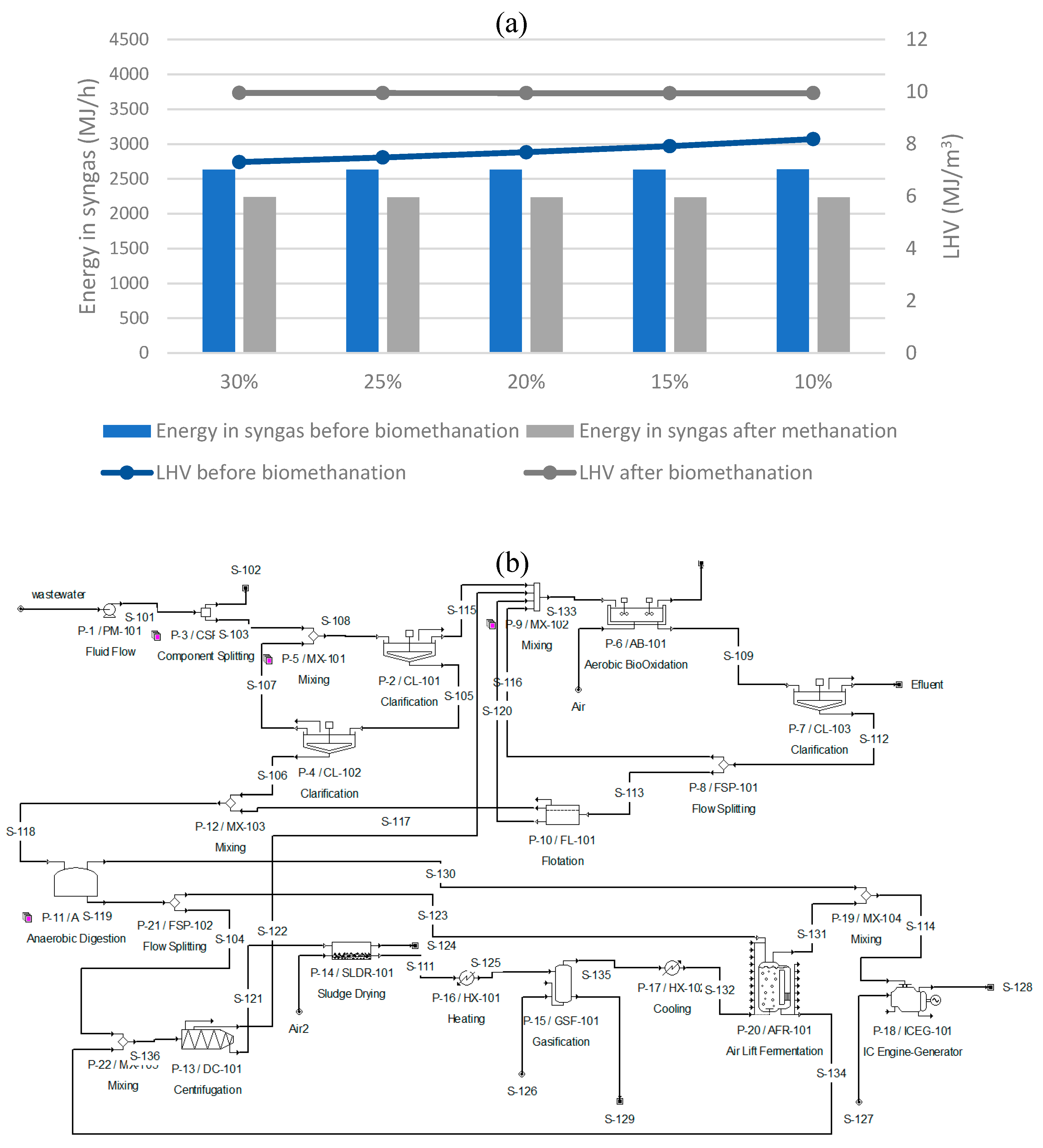

3.3. Syngas Conversion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CHP | Combined heat and power |

| ER | Equivalence ratio |

| HRT | Hydraulic retention time |

| OLR | Organic loading rate |

| LHV | Lower heating value |

| SMP | Specific methane production |

| VS | Volatile solids |

| TS | Total solids |

| WWTP | Wastewater treatment plant |

References

- Sivaramakrishnan, S. 120,000 tonnes of Faecal Sludge: Why India Needs a Market for Human Waste. World Econ. Forum. 2019. Available online: https://www.weforum.org/agenda/2019/09/how-to-improve-sanitation-in-india/#:~:text=India’s%20urban%20areas%20produce%20120%2C000,connected%20to%20the%20sewer%20system (accessed on 11 November 2024).

- Capodaglio, A.G. Biorefinery of Sewage Sludge: Overview of Possible Value-Added Products and Applicable Process Technologies. Water 2023, 15, 1195. [Google Scholar] [CrossRef]

- Nipattummakul, N.; Ahmed, I.I.; Kerdsuwan, S.; Gupta, A.K. Hydrogen and syngas production from sewage sludge via steam gasification. Int. J. Hydrogen Energy 2010, 35(21), 11738–11745. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Kan, T.; Al Shoaibi, A.; Srinivasakannan, C.; Strezov, V. Characterization of food waste and its digestate as feedstock for thermochemical processing. Energ. Fuel 2016, 30(3), 1589–1597. [Google Scholar] [CrossRef]

- Sun, Y.; Nakano, J.; Liu, L.; Wang, X.; Zhang, Z. Achieving waste to energy through sewage sludge gasification using hot slags: syngas production. Sci. Rep. 2015, 5, 11436. [Google Scholar] [CrossRef]

- Werle, S.; Sobek, S. Gasification of sewage sludge within a circular economy perspective: a Polish case study. Environ. Sci. Pollut. Res. 2019, 26, 35422–35432. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Guo, Q.; Zhang, R.; Wang, C.; Yan, B.; Lin, F.; Chen, G.; Hou, L. Evaluation on energetic and economic benefits of the coupling anaerobic digestion and gasification from agricultural wastes. Renew. Energy 2021, 176, 494–503. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas Production from Organic Wastes: Integrating Concepts of Circular Economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- González-Rojo, S.; Carrillo-Peña, D.; González, R.G.; Gómez, X. Assessing Digestate at Different Stabilization Stages: Application of Thermal Analysis and FTIR Spectroscopy. Eng 2024, 5, 1499–1512. [Google Scholar] [CrossRef]

- Angelidaki, I.; Karakashev, D.; Batstone, D.J.; Plugge, C.M.; Stams, A.J. Biomethanation and its potential. In Methods in enzymology, Academic Press, USA, San Diego, 2011; Volume 494, pp. 327–351.

- Gómez, X.; Cuetos, M.J.; García, A.I.; Morán, A. Evaluation of digestate stability from anaerobic process by thermogravimetric analysis. Thermochim. Acta. 2005, 426(1-2), 179–184. [Google Scholar] [CrossRef]

- González, R.; Peña, D.C.; Gómez, X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Appl. Sci. 2022, 12, 8884. [Google Scholar] [CrossRef]

- Molinuevo-Salces, B.; Gómez, X.; Morán, A.; García-González, M.C. Anaerobic co-digestion of livestock and vegetable processing wastes: fibre degradation and digestate stability. Waste Manage. 2013, 33(6), 1332–1338. [Google Scholar] [CrossRef]

- Fierro, J.; Martinez, E.J.; Rosas, J.G.; Fernández, R.A.; López, R.; Gómez, X. Co-Digestion of swine manure and crude glycerine: Increasing glycerine ratio results in preferential degradation of labile compounds. Water. Air Soil. Pollut. 2016, 227, 78. [Google Scholar] [CrossRef]

- González, R.; Smith, R.; Blanco, D.; Fierro, J.; Gómez, X. Application of thermal analysis for evaluating the effect of glycerine addition on the digestion of swine manure. J. Therm. Anal. Calorim. 2019, 135, 2277–2286. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; Cascallana, J.G.; González, R.; Gómez, X. High-solid anaerobic digestion: Reviewing strategies for increasing reactor performance. Environments 2021, 8, 80. [Google Scholar] [CrossRef]

- Nkuna, R.; Roopnarain, A.; Rashama, C.; Adeleke, R. Insights into organic loading rates of anaerobic digestion for biogas production: a review. Crit. Rev. Biotechnol. 2022, 42(4), 487–507. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.J.; González, R.; Ellacuriaga, M.; Gómez, X. Valorization of Fourth-Range Wastes: Evaluating Pyrolytic Behavior of Fresh and Digested Wastes. Fermentation (Basel) 2022, 8, 744. [Google Scholar] [CrossRef]

- González-Arias, J.; Fernández, C.; Rosas, J.G.; Bernal, M.P.; Clemente, R.; Sanchez, M.E.; Gomez, X. Integrating anaerobic digestion of pig slurry and thermal valorisation of biomass. Waste Biomass Valori. 2020, 11, 6125–6137. [Google Scholar] [CrossRef]

- González, R.; González, J.; Rosas, J.G.; Smith, R.; Gómez, X. Biochar and energy production: Valorizing swine manure through coupling co-digestion and pyrolysis. C 2020, 6, 43. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Antoniou, N.; Barakat, A.; Zabaniotou, A. A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process. Appl. Energy 2015, 148, 32–38. [Google Scholar] [CrossRef]

- Diaz Perez, N.; Lindfors, C.; van den Broek, L.A.; van der Putten, J.; Meredith, W.; Robinson, J. Comparison of bio-oils derived from crop digestate treated through conventional and microwave pyrolysis as an alternative route for further waste valorization. Biomass Convers. Biorefin. 2024, 14, 15739–15754. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Zhang, R.; Liu, Z.; Ouyang, C.; Zhang, Z.; Zhou, L.; Guo, Y. Pyrolysis Characteristics of Anaerobic Biogas Solid Residue from Kitchen Waste. Waste Biomass Valori. 2024, 15, 1141–1153. [Google Scholar] [CrossRef]

- Rasi, S.; Kilpeläinen, P.; Rasa, K.; Korpinen, R.; Raitanen, J.E.; Vainio, M.; Kitunen, V.; Pulkkinen, H.; Jyske, T. Cascade processing of softwood bark with hot water extraction, pyrolysis and anaerobic digestion. Bioresour. Technol. 2019, 292, 121893. [Google Scholar] [CrossRef] [PubMed]

- Liaw, S.S.; Perez, V.H.; Westerhof, R.J.; David, G.F.; Frear, C.; Garcia-Perez, M. Biomethane Production from pyrolytic aqueous phase: biomass acid washing and condensation temperature effect on the bio-oil and aqueous phase composition. BioEnergy Res. 2020, 13, 878–886. [Google Scholar] [CrossRef]

- Seyedi, S.; Venkiteshwaran, K.; Zitomer, D. Current status of biomethane production using aqueous liquid from pyrolysis and hydrothermal liquefaction of sewage sludge and similar biomass. Rev. Environ. Sc. Bio. 2021, 20, 237–255. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, C.; Qiu, L.; Yao, Y.; Sun, G.; Guo, X. Anaerobic digestion of swine manure using aqueous pyrolysis liquid as an additive. Renew. Energy 2020, 147, 2484–2493. [Google Scholar] [CrossRef]

- González-Arias, J.; de la Rubia, M.A.; Sánchez, M.E.; Gómez, X.; Cara-Jiménez, J.; Martínez, E.J. Treatment of hydrothermal carbonization process water by electrochemical oxidation: Assessment of process performance. Environ. Res. 2023, 216, 114773. [Google Scholar] [CrossRef] [PubMed]

- Aznar, M.; Anselmo, M.S.; Manya, J.J.; Murillo, M.B. Experimental study examining the evolution of nitrogen compounds during the gasification of dried sewage sludge. Energ. Fuel 2009, 23(6), 3236–3245. [Google Scholar] [CrossRef]

- Bijesh, R.; Arun, P.; Muraleedharan, C. Modified stoichiometric equilibrium model for sewage sludge gasification and its validation based on experiments in a downdraft gasifier. Biomass Convers. Biorefin. 2021, 13, 9023–9043. [Google Scholar] [CrossRef]

- Freda, C.; Cornacchia, G.; Romanelli, A.; Valerio, V.; Grieco, M. Sewage sludge gasification in a bench scale rotary kiln. Fuel 2018, 212, 88–94. [Google Scholar] [CrossRef]

- Campoy, M.; Gómez–Barea, A.; Ollero, P.; Nilsson, S. Gasification of wastes in a pilot fluidized bed gasifier. Fuel Process. Technol. 2014, 121, 63–69. [Google Scholar] [CrossRef]

- Chen, Y.H.; Ngo, T.N.L.T.; Chiang, K.Y. Enhanced hydrogen production in co-gasification of sewage sludge and industrial wastewater sludge by a pilot-scale fluidized bed gasifier. Int. J. Hydrogen Energy 2021, 46(27), 14083–14095. [Google Scholar] [CrossRef]

- Chen, A.; Tian, Z.; Han, R.; Wei, X.; Hu, R.; Chen, Y. Preparation of Ni-based steel slag catalyst by impregnation method for sludge steam gasification. Sustain. Energy Technol. Assessments 2021, 47, 101553. [Google Scholar] [CrossRef]

- Hong, S.P.; Dong, J.I.; Yeo, S.K.; Park, I.H.; Chung, M.S.; Kim, D.I.; Park, Y.K. Reduction of tar using cheap catalysts during sewage sludge gasification. J. Mater. Cycles Waste Manag. 2011, 13, 186–189. [Google Scholar] [CrossRef]

- Santos, M.P.; Hanak, D.P. Sorption-enhanced gasification of municipal solid waste for hydrogen production: a comparative techno-economic analysis using limestone, dolomite and doped limestone. Biomass. Convers Biorefin. 2022, 14, 7857–7872. [Google Scholar] [CrossRef] [PubMed]

- Gai, C.; Guo, Y.; Liu, T.; Peng, N.; Liu, Z. Hydrogen-rich gas production by steam gasification of hydrochar derived from sewage sludge. Int. J. Hydrogen Energy 2016, 41(5), 3363–3372. [Google Scholar] [CrossRef]

- Manya, J.J.; Sánchez, J.L.; Abrego, J.; Gonzalo, A.; Arauzo, J. Influence of gas residence time and air ratio on the air gasification of dried sewage sludge in a bubbling fluidised bed. Fuel 2006, 85(14-15), 2027–2033. [Google Scholar] [CrossRef]

- Gil, M.V.; González-Vázquez, M.P.; García, R.; Rubiera, F.; Pevida, C. Assessing the influence of biomass properties on the gasification process using multivariate data analysis. Energy Convers. Manag. 2019, 184, 649–660. [Google Scholar] [CrossRef]

- Andreides, D.; Pokorna, D.; Zabranska, J. Assessing the syngas biomethanation in anaerobic sludge digestion under different syngas loading rates and homogenisation. Fuel 2022, 320, 123929. [Google Scholar] [CrossRef]

- Robazza, A.; Welter, C.; Kubisch, C.; Baleeiro, F.C.; Ochsenreither, K.; Neumann, A. Co-Fermenting Pyrolysis Aqueous Condensate and Pyrolysis Syngas with Anaerobic Microbial Communities Enables L-Malate Production in a Secondary Fermentative Stage. Fermentation (Basel) 2022, 8(10), 512. [Google Scholar] [CrossRef]

- Westman, S.Y.; Chandolias, K.; Taherzadeh, M.J. Syngas Biomethanation in a Semi-Continuous Reverse Membrane Bioreactor (RMBR). Fermentation (Basel) 2016, 2(2), 8. [Google Scholar] [CrossRef]

- Cheng, G.; Gabler, F.; Pizzul, L.; Olsson, H.; Nordberg, Å.; Schnürer, A. Microbial community development during syngas methanation in a trickle bed reactor with various nutrient sources. Appl. Microbiol. Biotechnol. 2022, 106, 5317–5333. [Google Scholar] [CrossRef]

- Bredwell, M.D.; Srivastava, P.; Worden, R.M. Reactor design issues for synthesis-gas fermentations. Biotechnol. Prog. 1999, 15(5), 834–844. [Google Scholar] [CrossRef]

- Kimmel, D.E.; Klasson, K.T.; Clausen, E.C.; Gaddy, J.L. Performance of trickle-bed bioreactors for converting synthesis gas to methane. Appl. Biochem. Biotechnol. 1991, 28, 457–469. [Google Scholar] [CrossRef] [PubMed]

- Klasson, K.T.; Elmore, B.B.; Vega, J.L.; Ackerson, M.D.; Clausen, E.C.; Gaddy, J.L. Biological production of liquid and gaseous fuels from synthesis gas. Appl. Microbiol. Biotechnol. 1990, 24, 857–873. [Google Scholar] [CrossRef]

- Klasson, K.T.; Cowger, J.P.; Ko, C.W.; Vega, J.L.; Clausen, E.C.; Gaddy, J.L. Methane production from synthesis gas using a mixed culture of R. rubrum M. barkeri, and M. formicicum. Appl. Microbiol. Biotechnol. 1990, 24, 317–328. [Google Scholar] [CrossRef]

- Bachmann, M.; Völker, S.; Kleinekorte, J.; Bardow, A. Syngas from What? Comparative Life-Cycle Assessment for Syngas Production from Biomass, CO2, and Steel Mill Off-Gases. ACS Sustain. Chem. Eng. 2023, 11(14), 5356–5366. [Google Scholar] [CrossRef]

- Figueras, J.; Benbelkacem, H.; Dumas, C.; Buffière, P. Biomethanation of syngas by enriched mixed anaerobic consortium in pressurized agitated column. Bioresour. Technol. 2021, 338, 125548. [Google Scholar] [CrossRef]

- Schwede, S.; Bruchmann, F.; Thorin, E.; Gerber, M. Biological syngas methanation via immobilized methanogenic archaea on biochar. Energy Procedia 2017, 105, 823–829. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, G.; Xu, S. Simultaneous tar reforming and syngas methanation for bio-substitute natural gas. Ind. Eng. Chem. Res. 2018, 57(32), 10905–10914. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; Gil, M.V.; Gómez, X. Syngas Fermentation: Cleaning of Syngas as a Critical Stage in Fermentation Performance. Fermentation (Basel) 2023, 9(10), 898. [Google Scholar] [CrossRef]

- Martínez, E.J.; Sotres, A.; Arenas, C.; Blanco, D.; Martínez, O.; Gómez, X. Improving Anaerobic Digestion of Sewage Sludge by Hydrogen Addition: Analysis of Microbial Populations and Process Performance. Energies (Basel) 2019, 12(7), 1228. [Google Scholar] [CrossRef]

- Longo, S.; Mauricio-Iglesias, M.; Soares, A.; Campo, P.; Fatone, F.; Eusebi, A.L.; Akkersdijk, E.; Stefrani, L.; Hospido, A. ENERWATER–A standard method for assessing and improving the energy efficiency of wastewater treatment plants. Appl. Energy 2019, 242, 897–910. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; González, R.; Gómez, X. Feasibility of coupling hydrogen and methane production in WWTP: Simulation of sludge and food wastes co-digestion. Energy Nexus 2024, 14, 100285. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Morán, A.; Gómez, X. Effect of ultrasound pretreatment on sludge digestion and dewatering characteristics: Application of particle size analysis. Water 2015, 7(11), 6483–6495. [Google Scholar] [CrossRef]

- Arenas, C.B.; González, R.; González, J.; Cara, J.; Papaharalabos, G.; Gómez, X.; Martínez, E.J. Assessment of electrooxidation as pre-and post-treatments for improving anaerobic digestion and stabilisation of waste activated sludge. J. Environ. Manage. 2021, 288, 112365. [Google Scholar] [CrossRef]

- González, R.; García-Cascallana, J.; Gómez, X. Energetic valorization of biogas. A comparison between centralized and decentralized approach. Renew. Energy 2023, 215, 119013. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M. Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renew. Energy 2008, 33(12), 2623–2630. [Google Scholar] [CrossRef]

- Yilmaz, N. Comparative analysis of biodiesel–ethanol–diesel and biodiesel–methanol–diesel blends in a diesel engine. Energy 2012, 40(1), 210–213. [Google Scholar] [CrossRef]

- Jenbacher de tipo 2: J208. 2019. Available online: https://www.innio.com/es/productos/jenbacher/tipo-2 (accessed on 11 November 2024).

- García-Cascallana, J.; Carrillo-Peña, D.; Morán, A.; Smith, R.; Gómez, X. Energy Balance of Turbocharged Engines Operating in a WWTP with Thermal Hydrolysis. Co-Digestion Provides the Full Plant Energy Demand. Appl. Sci. 2021, 11(23), 11103. [Google Scholar] [CrossRef]

- Magdziarz, A.; Werle, S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manage. 2014, 34(1), 174–179. [Google Scholar] [CrossRef]

- Mun, T.Y.; Kim, J.W.; Kim, J.S. Air gasification of dried sewage sludge in a two-stage gasifier: Part 1. The effects and reusability of additives on the removal of tar and hydrogen production. Int. J. Hydrogen Energy 2013, 38(13), 5226–5234. [Google Scholar] [CrossRef]

- Mun, T.Y.; Kim, J.S. Air gasification of dried sewage sludge in a two-stage gasifier. Part 2: Calcined dolomite as a bed material and effect of moisture content of dried sewage sludge for the hydrogen production and tar removal. Int. J. Hydrogen Energy 2013, 38(13), 5235–5242. [Google Scholar] [CrossRef]

- Rafrafi, Y.; Laguillaumie, L.; Dumas, C. Biological methanation of H2 and CO2 with mixed cultures: current advances, hurdles and challenges. Waste Biomass. Valori. 2021, 12, 5259–5282. [Google Scholar] [CrossRef]

- Asimakopoulos, K.; Gavala, H.N.; Skiadas, I.V. Biomethanation of syngas by enriched mixed anaerobic consortia in trickle bed reactors. Waste Biomass Valori. 2019, 11, 495–512. [Google Scholar] [CrossRef]

- Rachbauer, L.; Voitl, G.; Bochmann, G.; Fuchs, W. Biological biogas upgrading capacity of a hydrogenotrophic community in a trickle-bed reactor. Appl. Energy 2016, 180, 483–490. [Google Scholar] [CrossRef]

- Nylen, J.; Sheehan, M. Review of the Integration of Drying and Thermal Treatment Processes for Energy Efficient Reduction of Contaminants and Beneficial Reuse of Wastewater Treatment Plant Biosolids. Energies 2023, 16(4), 1964. [Google Scholar] [CrossRef]

- Garske, B.; Ekardt, F. Economic policy instruments for sustainable phosphorus management: taking into account climate and biodiversity targets. Environ. Sci. Eur. 2021, 33, 56. [Google Scholar] [CrossRef]

- Walsh, M.; Schenk, G.; Schmidt, S. Realising the circular phosphorus economy delivers for sustainable development goals. NPJ Sustain. Agric. 2023, 1, 2. [Google Scholar] [CrossRef]

- Guilayn, F.; Rouez, M.; Crest, M.; Patureau, D.; Jimenez, J. Valorization of digestates from urban or centralized biogas plants: a critical review. Rev. Environ. Sci. Bio. 2020, 19, 419–462. [Google Scholar] [CrossRef]

- Barrios, J.A.; Duran, U.; Cano, A.; Cisneros-Ortiz, M.; Hernández, S. Sludge electrooxidation as pre-treatment for anaerobic digestion. Water Sci. Technol. 2017, 75(4), 775–781. [Google Scholar] [CrossRef]

- Climent, M.; Ferrer, I.; del Mar Baeza, M.; Artola, A.; Vázquez, F.; Font, X. Effects of thermal and mechanical pretreatments of secondary sludge on biogas production under thermophilic conditions. Chem. Eng. J. 2007, 133(1-3), 335–342. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Liu, W.; Zou, S. Optimized alkaline pretreatment of sludge before anaerobic digestion. Bioresour. Technol. 2012, 123, 189–194. [Google Scholar] [CrossRef]

- Sahu, A.K.; Mitra, I.; Kleiven, H.; Holte, H.R.; Svensson, K. Cambi Thermal Hydrolysis Process (CambiTHP) for sewage sludge treatment. In Clean Energy and Resource Recovery. Ed: An A, Tyagi V, Kumar M, Cetecioglu Z (pp. 405–422). Elsevier (2022). [CrossRef]

- Liu, J.; Smith, S.R. A multi-level biogas model to optimise the energy balance of full-scale sewage sludge conventional and THP anaerobic digestion. Renew. Energy 2020, 159, 756–766. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Biochemical methane potential tests to evaluate anaerobic digestion enhancement by thermal hydrolysis pretreatment. BioEnergy Res. 2019, 12, 722–732. [Google Scholar] [CrossRef]

- Liu, X.; Lee, C.; Kim, J.Y. Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J. Mater. Cycles Waste Manag. 2020, 22, 1370–1381. [Google Scholar] [CrossRef]

- “Full scale demonstration of energy positive sewage treatment plant concepts towards market penetration” (POWERSTEP). WP3 – Biogas valorization and efficient energy management. D3.1: Best practices for improved sludge digestion. 2016. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5af252ade&appId=PPGMS (accessed on 11 November 2024).

- García-Cascallana, J.; Barrios, X.G.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11(3), 964. [Google Scholar] [CrossRef]

- Bronson, B.; Gogolek, P.; Mehrani, P.; Preto, F. Experimental investigation of the effect of physical pre-treatment on air-blown fluidized bed biomass gasification. Biomass Bioenergy 2016, 88, 77–88. [Google Scholar] [CrossRef]

- Mirmoshtaghi, G.; Skvaril, J.; Campana, P.E.; Li, H.; Thorin, E.; Dahlquist, E. The influence of different parameters on biomass gasification in circulating fluidized bed gasifiers. Energy Convers. Manag. 2016, 126, 110–123. [Google Scholar] [CrossRef]

- Wu, C.Z.; Yin, X.L.; Ma, L.L.; Zhou, Z.Q.; Chen, H.P. Operational characteristics of a 1.2-MW biomass gasification and power generation plant. Biotechnol. Adv. 2009, 27(5), 588–592. [Google Scholar] [CrossRef]

- Xie, L.P.; Tao, L.I.; Gao, J.D.; Fei, X.N.; Xia, W.U.; Jiang, Y.G. Effect of moisture content in sewage sludge on air gasification. J. Fuel Chem. Technol. 2010, 38(5), 615–620. [Google Scholar] [CrossRef]

- Ayol, A.; Yurdakos, O.T.; Gurgen, A. Investigation of municipal sludge gasification potential: Gasification characteristics of dried sludge in a pilot-scale downdraft fixed bed gasifier. Int. J. Hydrogen Energy 2019, 44(32), 17397–17410. [Google Scholar] [CrossRef]

- Chen, G.; Guo, X.; Cheng, Z.; Yan, B.; Dan, Z.; Ma, W. Air gasification of biogas-derived digestate in a downdraft fixed bed gasifier. Waste Manage. 2017, 69, 162–169. [Google Scholar] [CrossRef]

- Elbl, P.; Baláš, M.; Lisý, M.; Lisá, H. Sewage sludge and digestate gasification in an atmospheric fluidized bed gasifier. Biomass. Convers. Biorefin. 2023, 14, 21821–21829. [Google Scholar] [CrossRef]

- Tezer, Ö.; Karabağ, N.; Öngen, A.; Ayol, A. Syngas production from municipal sewage sludge by gasification Process: Effects of fixed bed reactor types and gasification agents on syngas quality. Sustain. Energy Techn. 2023, 56, 103042. [Google Scholar] [CrossRef]

- Cano, R.; Pérez-Elvira, S.I.; Fdz-Polanco, F. Energy feasibility study of sludge pretreatments: a review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Gurieff, N.; Hoejsgaard, S.; Nielsen, B.; Boyd, J.; Kline, M. Successful application of the first EXELYS™ continuous thermal hydrolysis system in an operational WWTP in Denmark. Proc. Water Environ, Fed. 2012, 16, 1011–1024. [Google Scholar] [CrossRef]

- Pérez-Elvira, S.I.; Sapkaite, I.; Ferreira, L.C.; Fdz-Polanco, F. Thermal hydrolysis pre-treatment of biosolids: a review on commercial processes. In 13th world congress on anaerobic digestion. June 25-28 (2013). Santiago, Spain.

- Tyagi, V.K.; Lo, S.L. Sludge: a waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Seggiani, M.; Vitolo, S.; Puccini, M.; Bellini, A. Cogasification of sewage sludge in an updraft gasifier. Fuel 2012, 93, 486–491. [Google Scholar] [CrossRef]

- Rabou, L.P.; Zwart, R.W.; Vreugdenhil, B.J.; Bos, L. Tar in biomass producer gas, the Energy research Centre of the Netherlands (ECN) experience: an enduring challenge. Energy Fuels 2009, 23(12), 6189–6198. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Adhikari, S.; Kulkarni, A.; Chattanathan, S. A review on biomass gasification syngas cleanup. Appl. Energy 2015, 155, 294–307. [Google Scholar] [CrossRef]

- Patuzzi, F.; Basso, D.; Vakalis, S.; Antolini, D.; Piazzi, S.; Benedetti, V.; Cordioli, E.; Baratieri, M. State-of-the-art of small-scale biomass gasification systems: An extensive and unique monitoring review. Energy 2021, 223, 120039. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Inlet wastewater flow (m3/d) | 49,500 |

| Equivalent Inhabitants | 150,000 |

| Primary sludge flow (m3/d) | 133 |

| Secondary sludge flow (m3/d) | 127 |

| Air flotation energy consumption (kWh/m3) | 0.015 |

| Methane production (m3/d) | 2643 |

| Methane production per volume of reactor (m3/m3 reactor d) | 0.41 |

| Energy in biogas (MJ/d) | 94,614 |

| Energy in biogas per unit of inlet wastewater flow (MJ/m3 inlet water d) | 1.91 |

| Biogas energy per equivalent inhabitant (E.I.) (MJ/E.I. d) | 0.63 |

| Biogas energy per unit of digester volume (MJ/m3 reactor d) | 14.6 |

| Electricity production (kW) | 410 |

| Digester thermal demand (MJ/d) | 26,700 |

| VS removal in digestion (%) | 43.7 |

| Dewatered digestate (m3/d) | 32.3 |

| Decanter energy consumption (kWh/m3) | 10 |

| Sludge drying daily energy demand (MJ/d) | 62,900 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).