Submitted:

05 May 2025

Posted:

13 May 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Background

1.2. Development of Residual Stress Within Cast Irons

2. Material and Methods

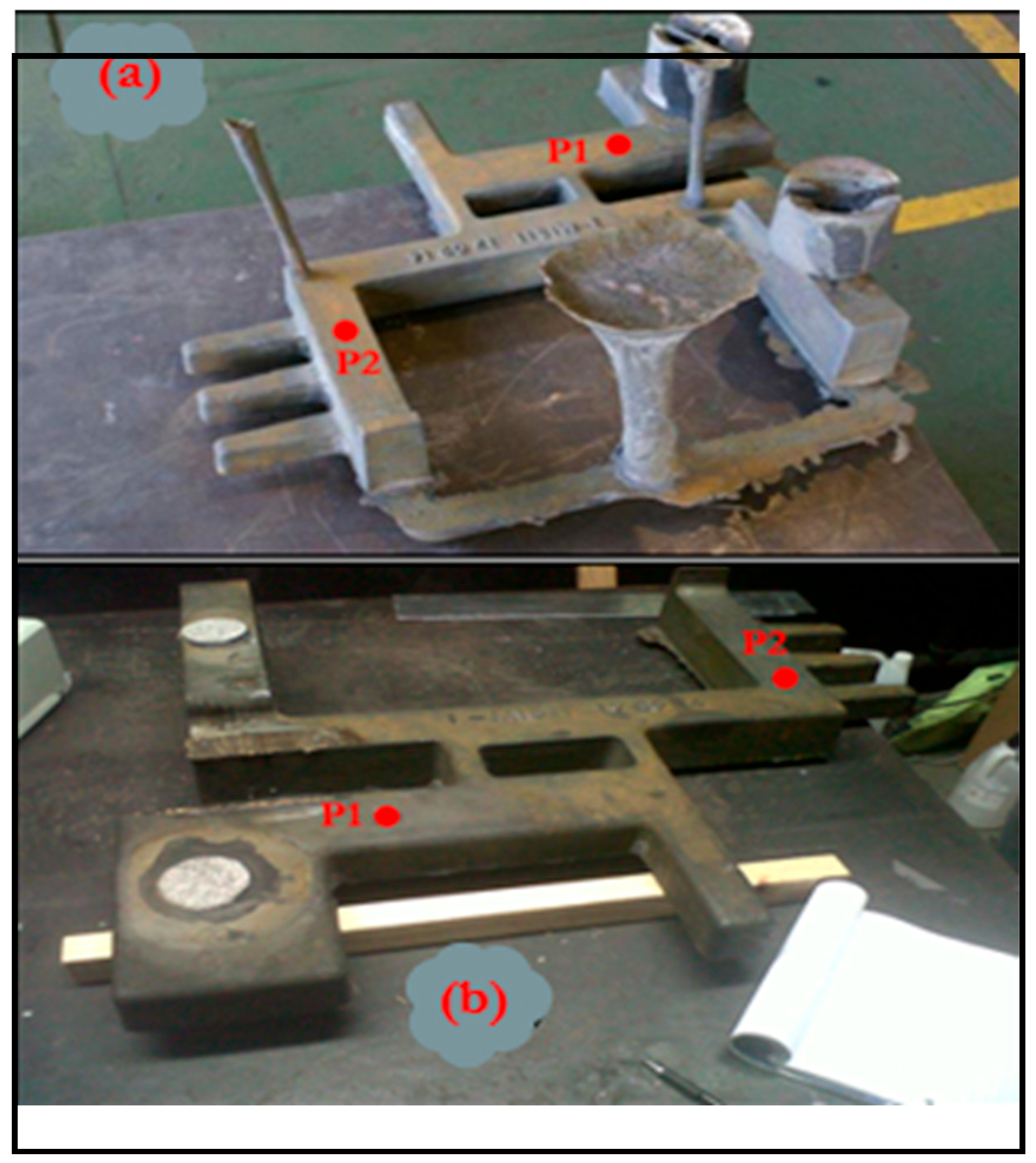

2.1. Melting and Casting Processes

2.2. Experiential Procedures

2.2.1. Chemical Composition

2.2.2. Hardness Evaluation

2.2.3. Residual Stress Measurements

3. Results and Discussion

3.1. Chemical Analysis

3.2. Hardness Evaluation

3.3. Residual Stress Analysis

3.3.1. Sample-A (S/A Alloy)

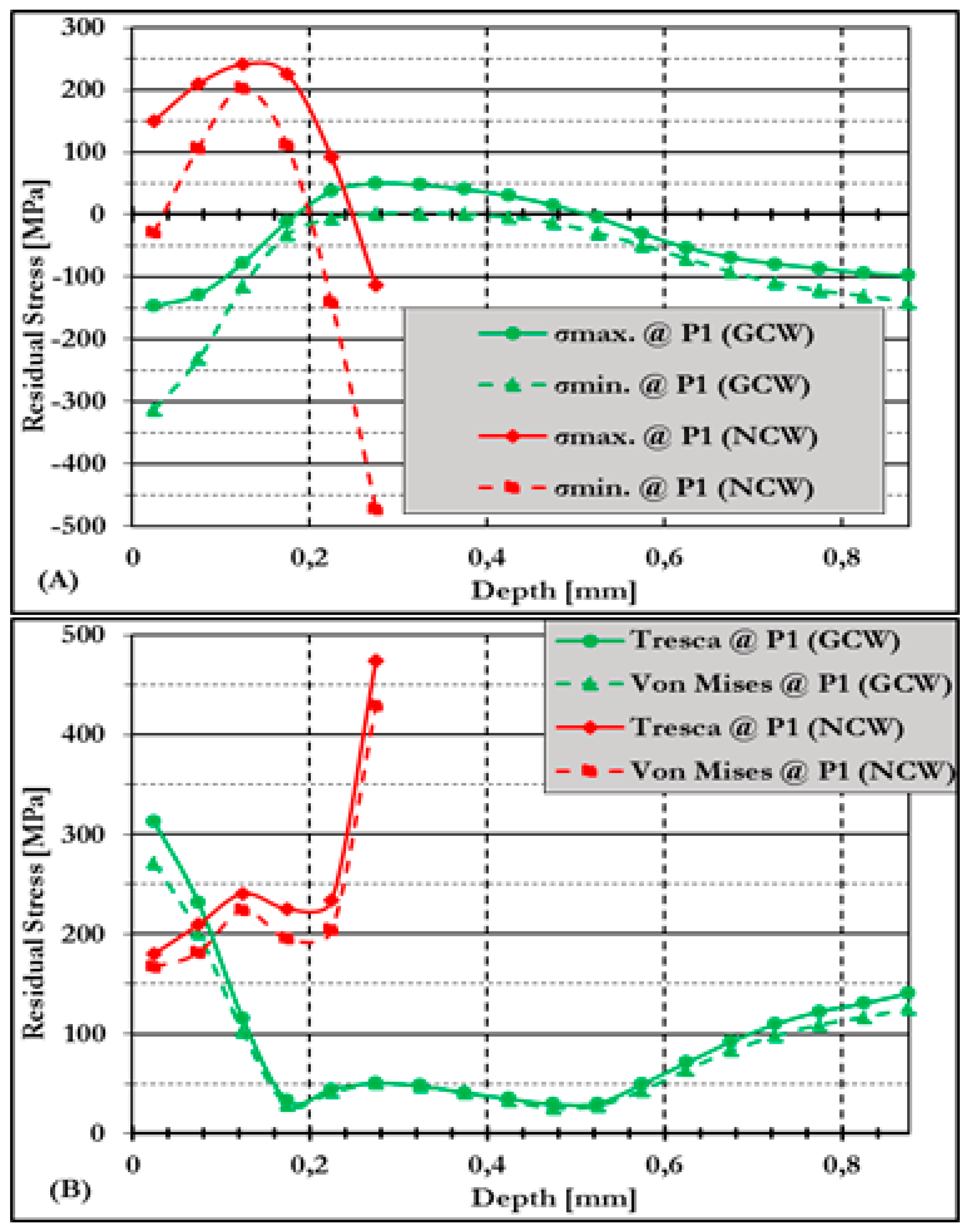

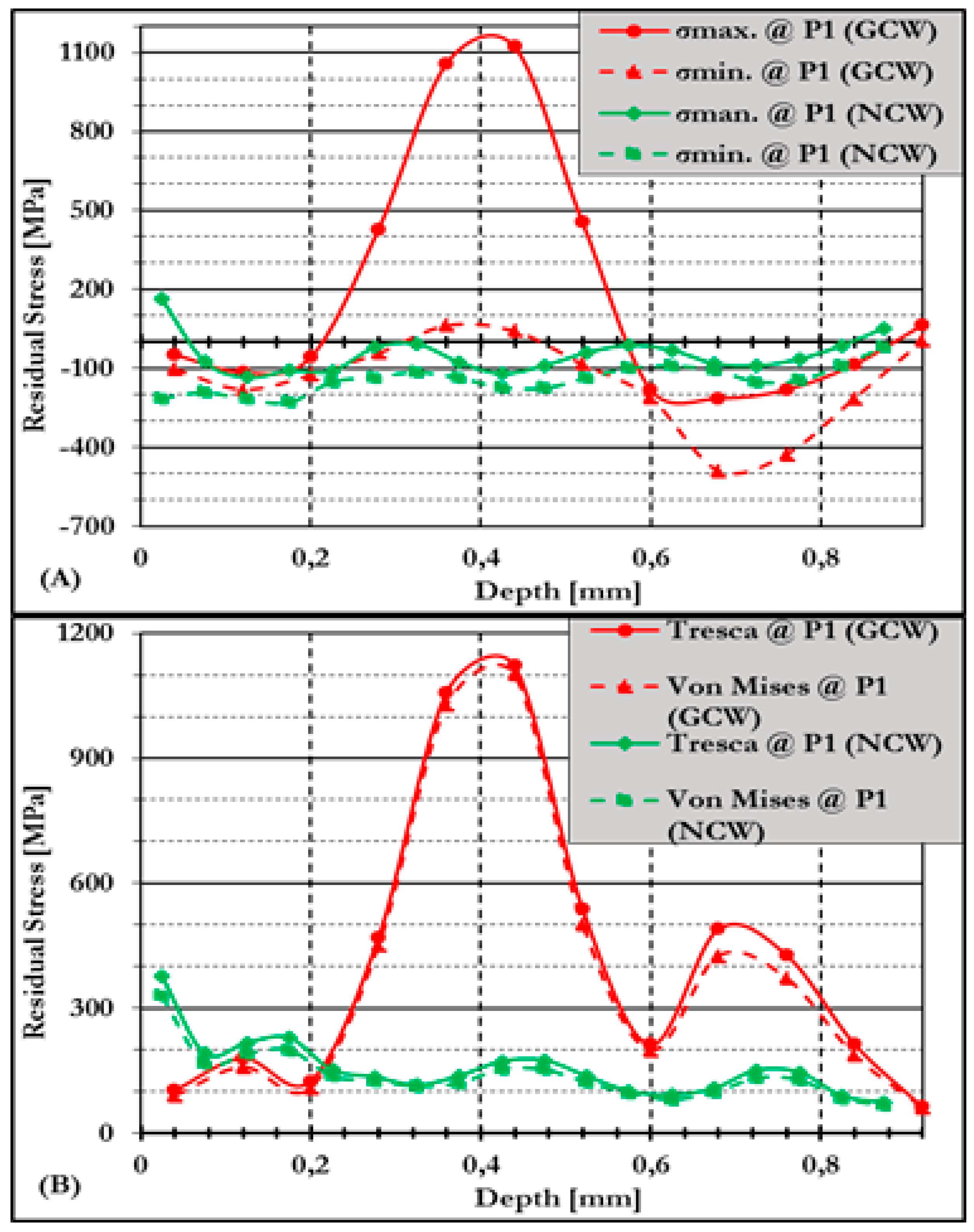

Residual Stresses at P1 of GCW and NCW in S/A

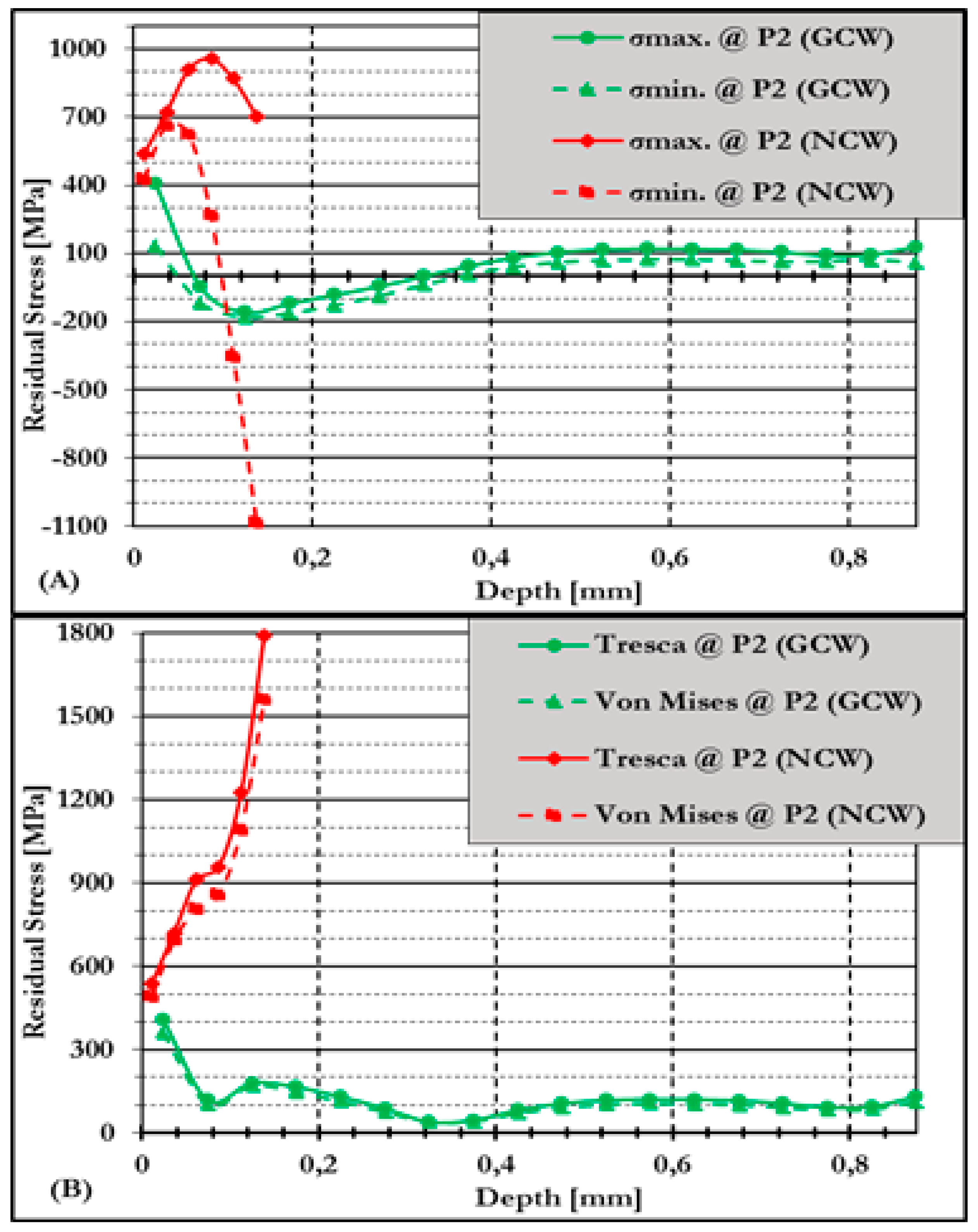

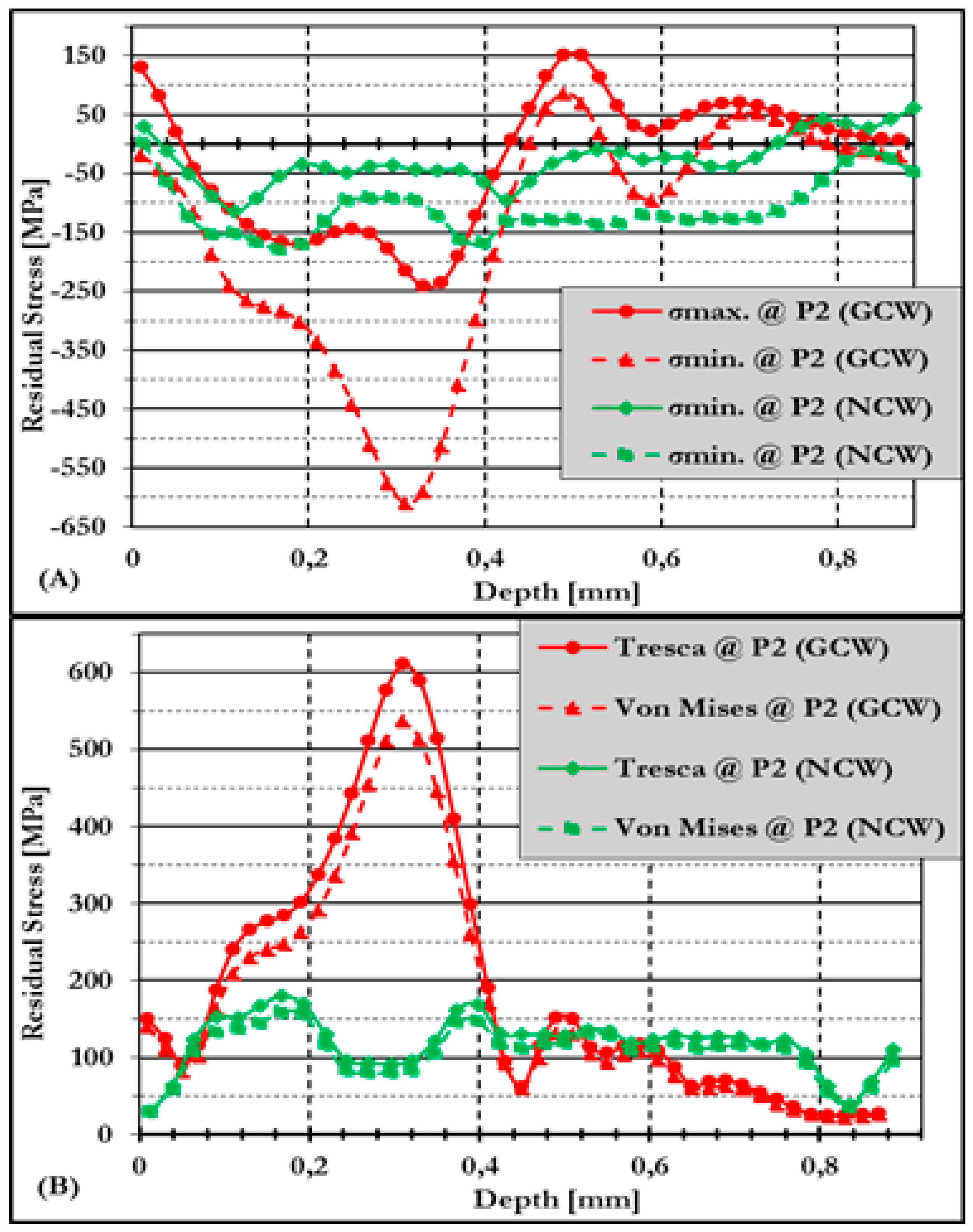

Residual Stresses at P2 of GCW and NCW in S/A

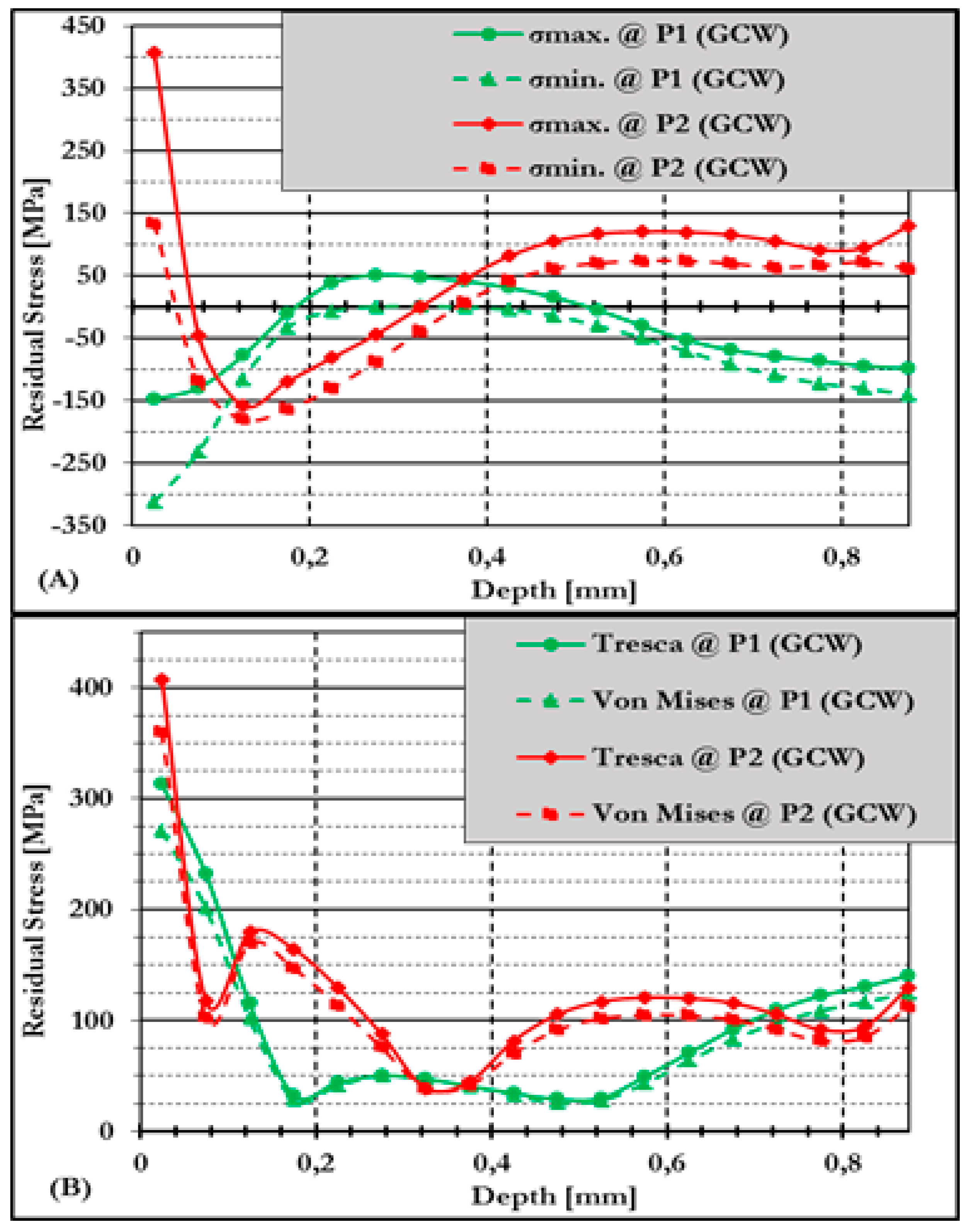

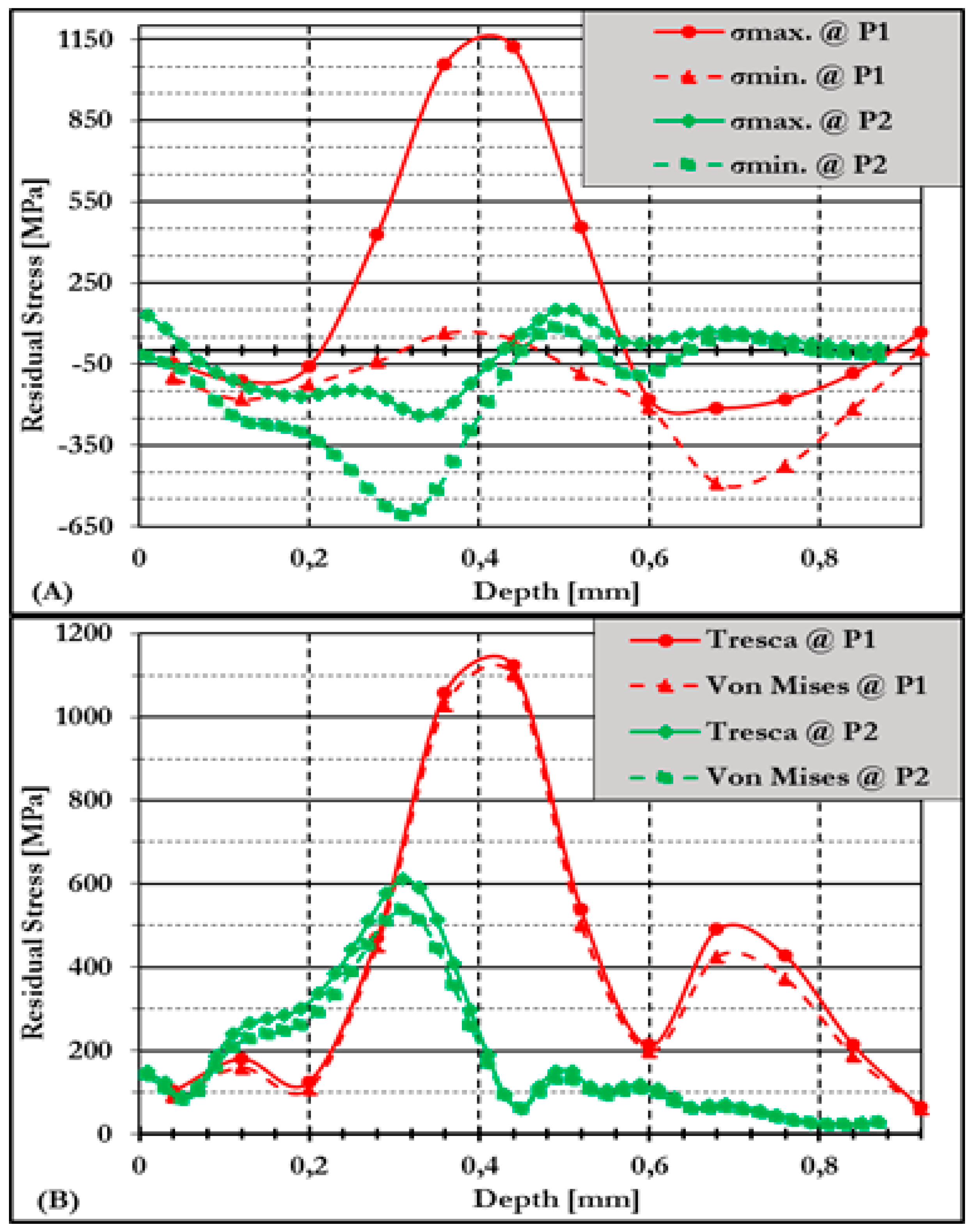

Residual Stresses on GCW at P1 and P2 in S/A

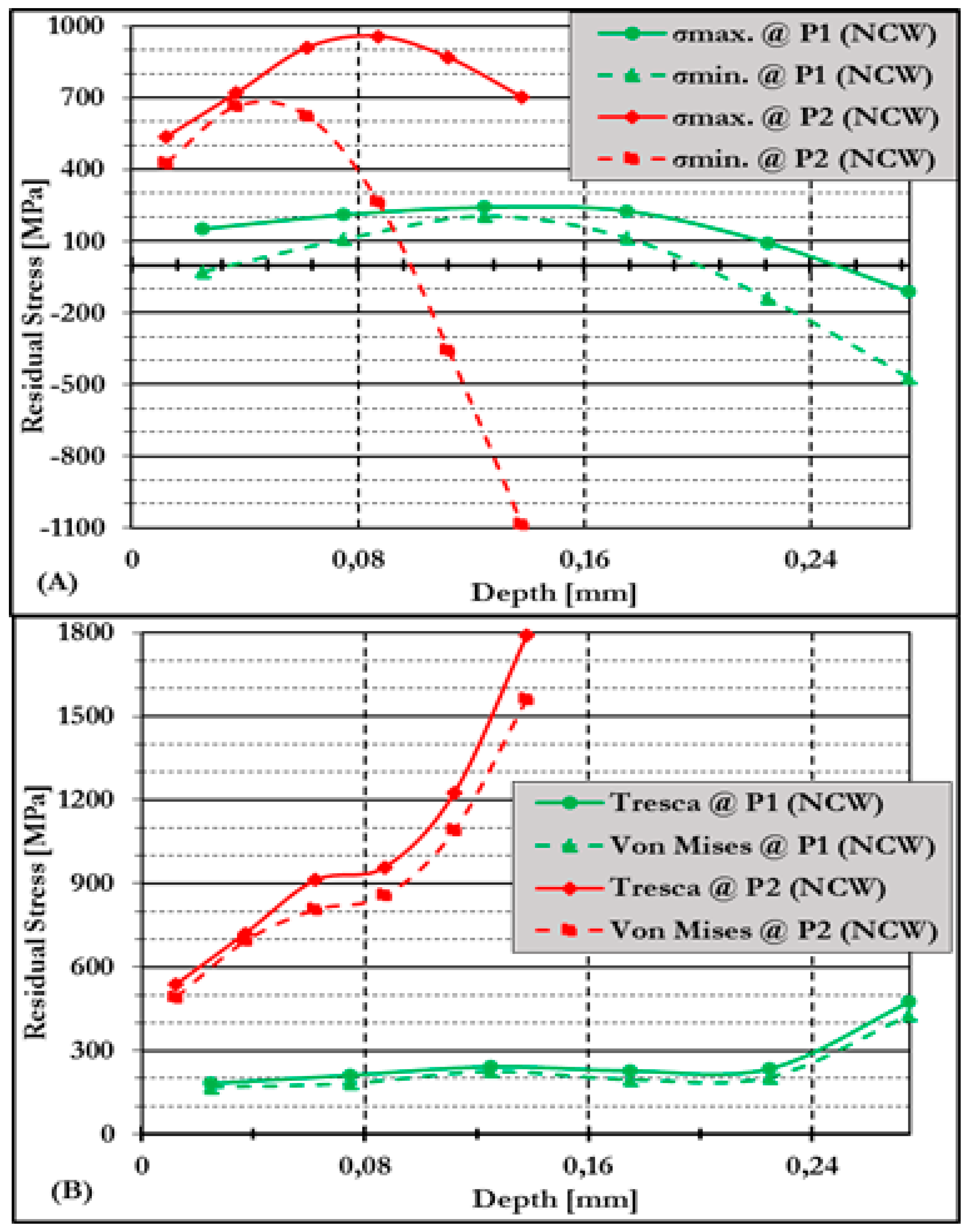

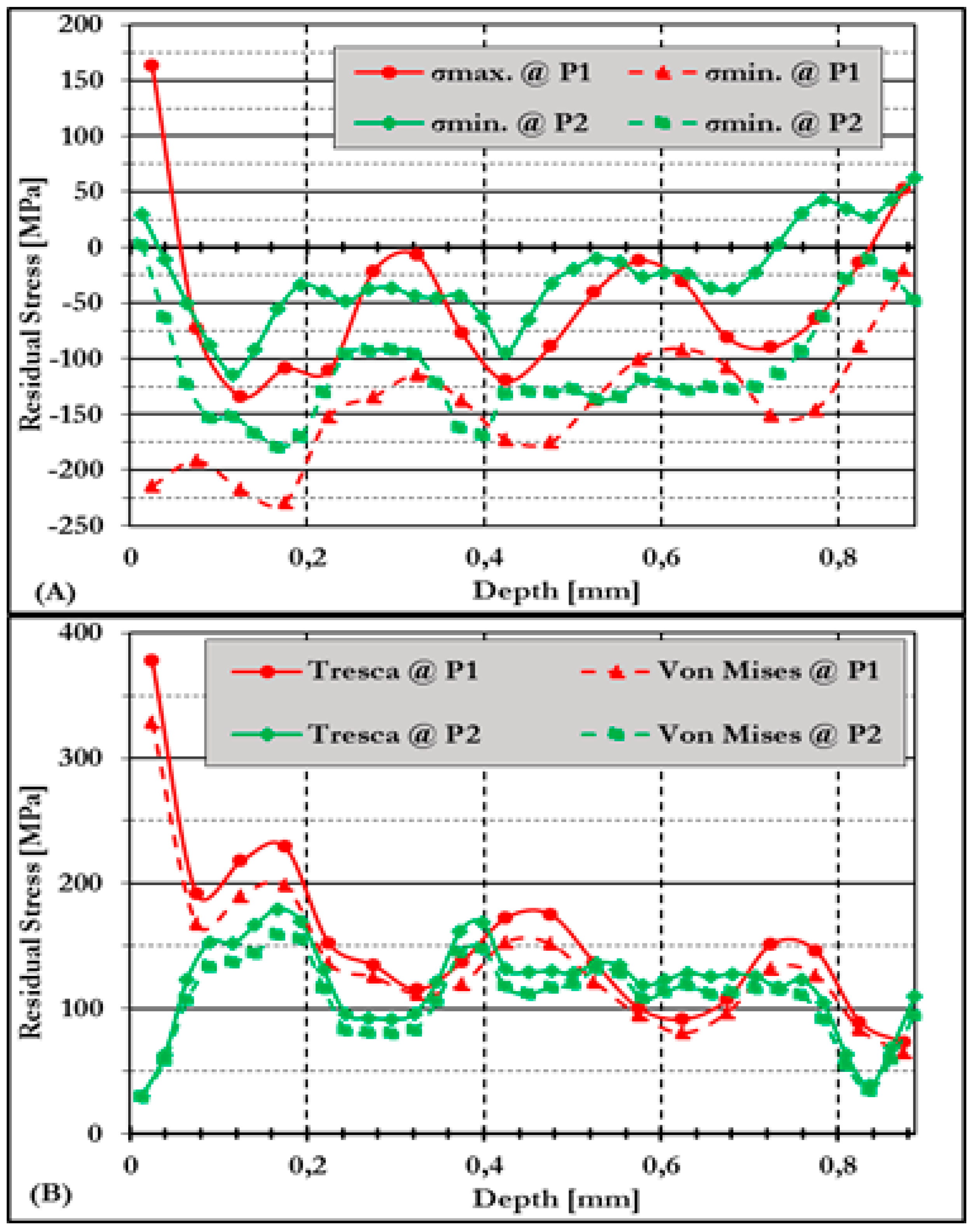

Residual Stresses on NCW at P1 and P2 in S/A

3.3.2. Sample-B (S/B Alloy)

Residual Stresses at P1 of GCW and NCW in S/B

Residual Stresses at P2 of GCW and NCW in S/B

Residual Stresses on GCW at P1 and P2 in S/B

Residual Stresses on NCW at P1 and P2 in S/B

3.3.3. Residual Stresses on S/A and S/B

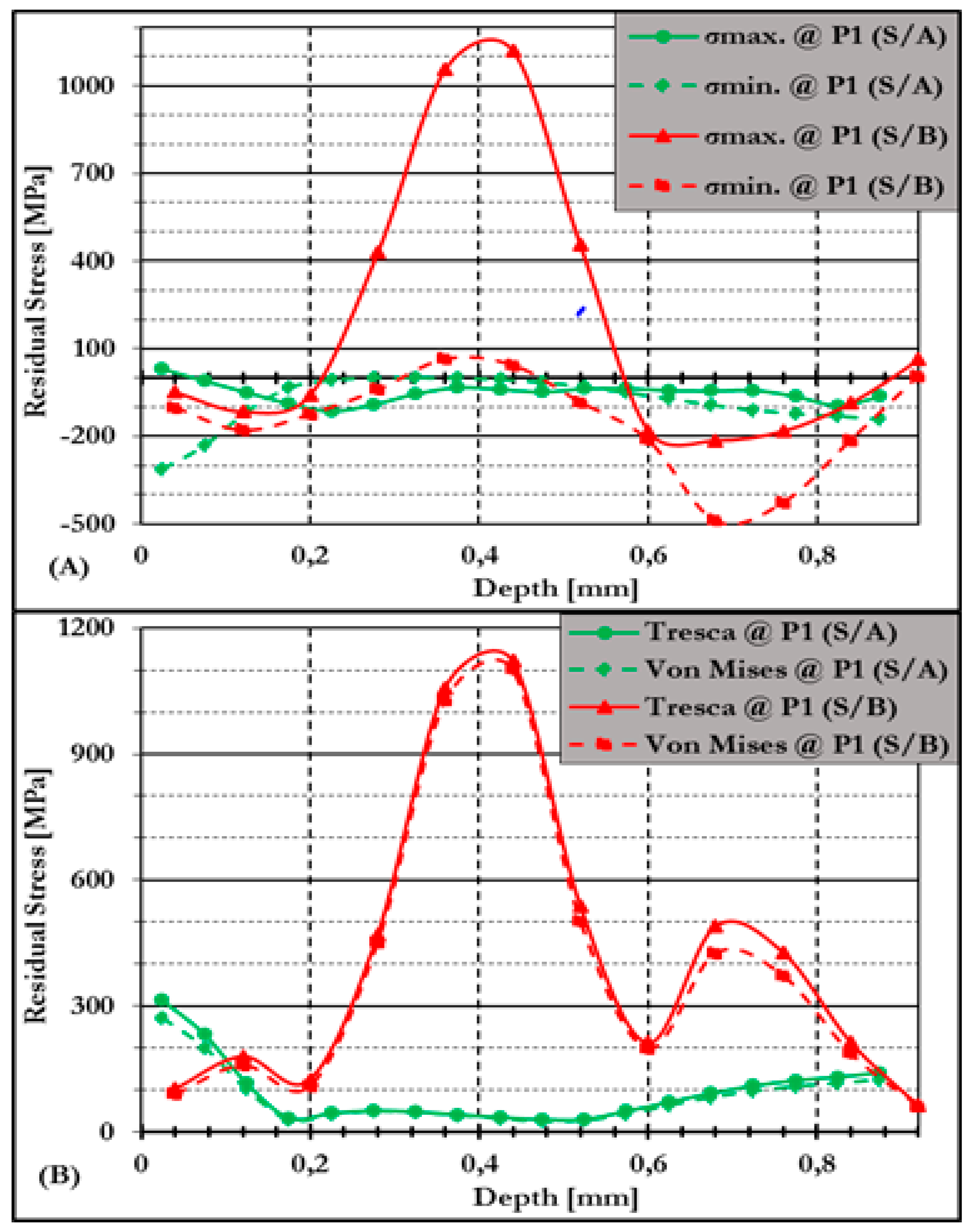

Residual Stresses at P1 of GCW on S/A and S/B

Residual Stresses at P1 of GCW on S/A and S/B

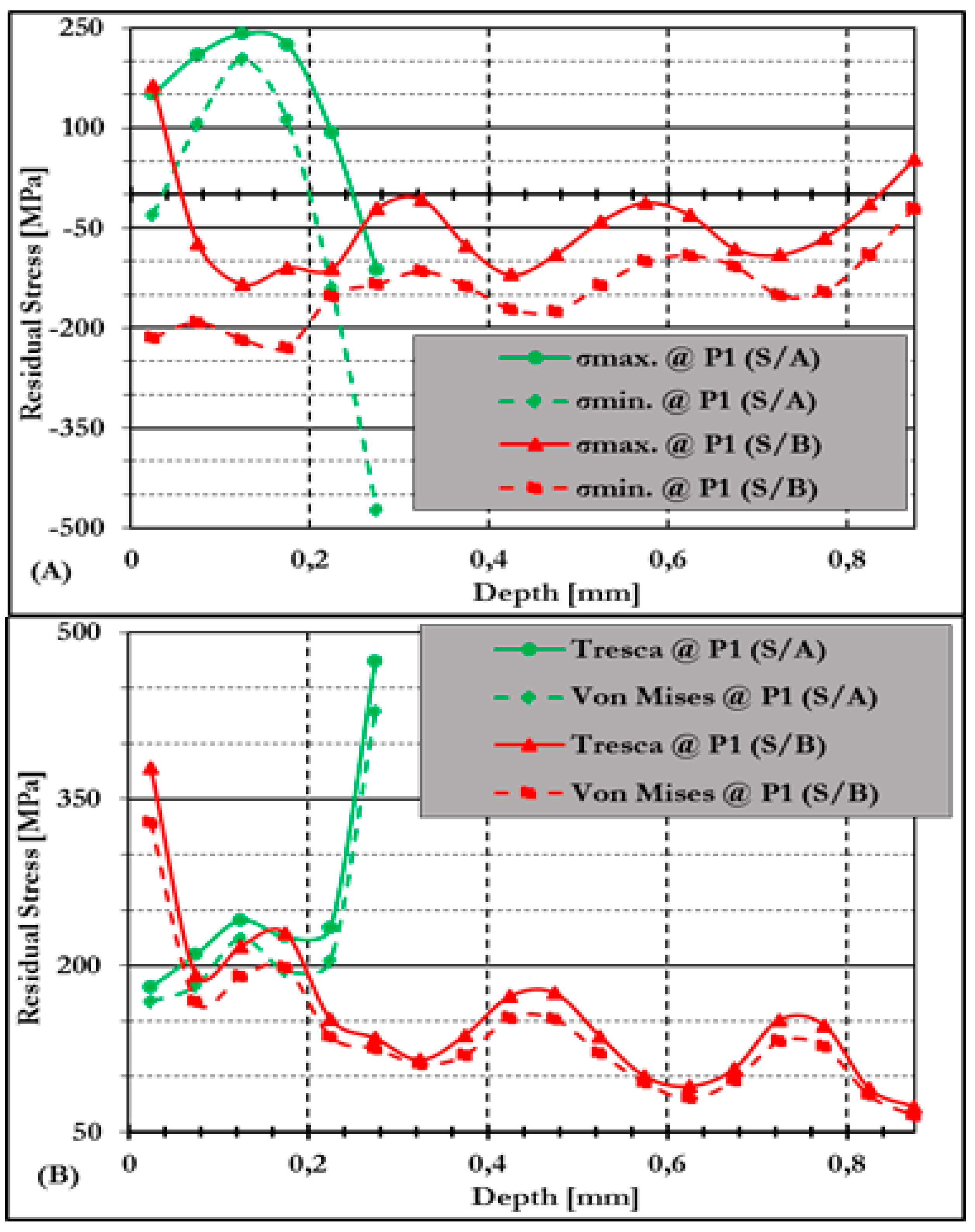

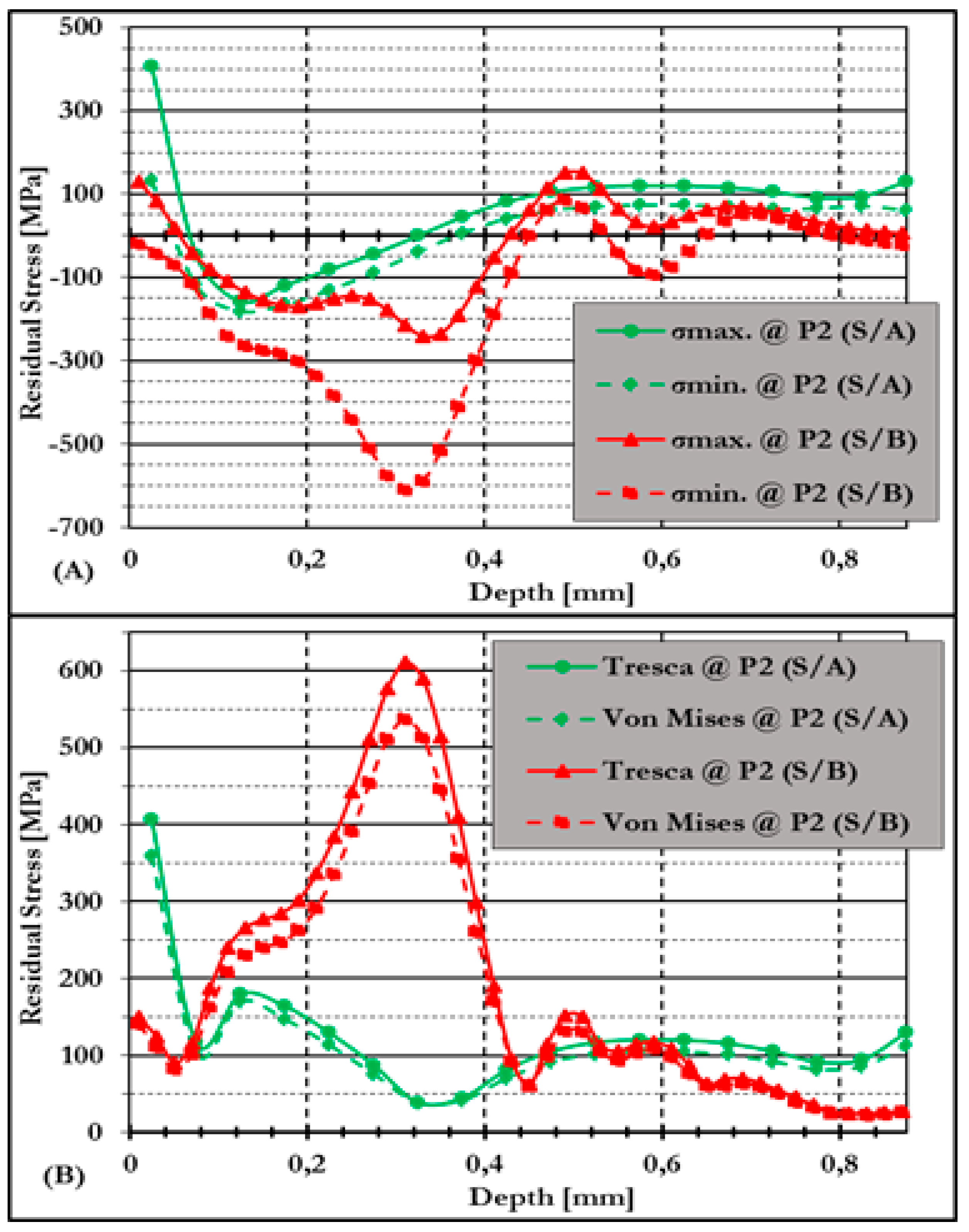

Residual Stresses at P2 of GCW on S/A and S/B

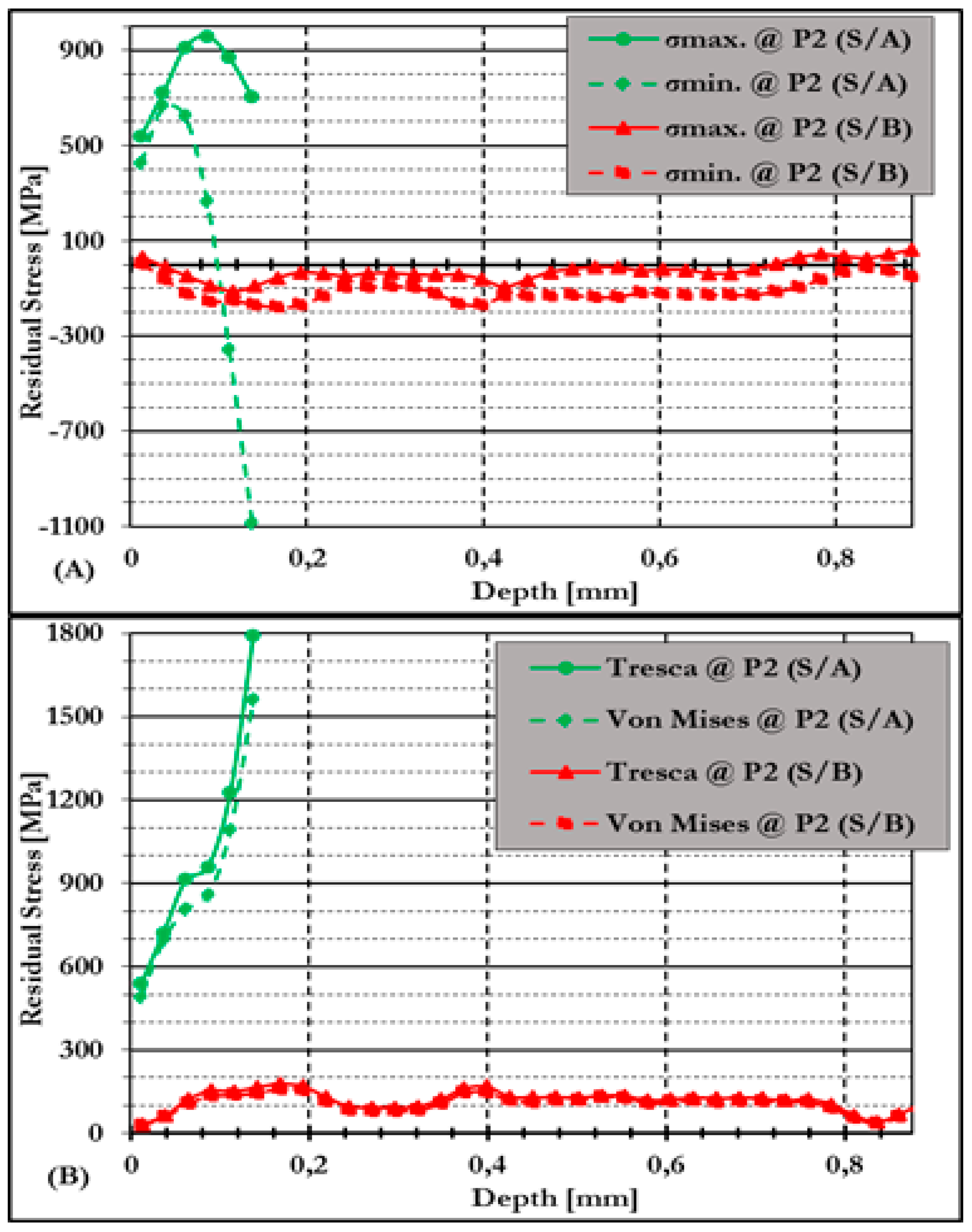

Residual Stresses at P2 of NCW on S/A and S/B

4. Conclusions

- (1)

- Higher casting shakeout temperatures encourage optimum hardness values.

- (2)

- Non-uniform RS distribution is normally detected.

- (3)

- Thinner casting section thickness led to minimum magnitudes of RSs as compared to thicker section thickness, which introduced optimum RS magnitudes.

- (4)

- Separating and/or removing junk material from NCW led to a modification of RS state.

- (5)

- RSs within NCW are forever in the opposite direction of the GCW RS distribution.

- (6)

- Castings shakeout at elevated temperatures led to advanced tensile RSs.

- (7)

- Shakeout at elevated temperatures led to steady compressive RSs on NCW.

5. Future Work

Acknowledgments

References

- Oh, J.-S., Song, Y.-G., Choi, B.-G., Bhamornsut, C., Nakkuntod, R., Jo, C.-Y. & Lee, J.-H., 2021. Effect of Dendrite Fraction on the M23C6 Precipitation Behavior and the Mechanical Properties of High Cr White Irons. Multidisciplinary Digital Publishing Institute (MDPI), 3 October, 11(1576), p. 19. [CrossRef]

- Fashu, S. & Trabadelo, V., 2023. Development and Performance of High Chromium White Cast Irons (HCWCIs) for Wear-Corrosive Environments: A Critical Review. Metals, 13(1831), pp. 1–26. [CrossRef]

- Zhang, Y., Shimizu, k., Yaer, X., Kusumoto K. & Efremenko, V. G., 2017. Erosive Wear Performance of Heat Treated Multi-Component Cast Iron Containing Cr, V, Mn and Ni Eroded by Alumina Spheres at Elevated Temperatures. Wear, pp. 1–20. [CrossRef]

- Islak, S., Ozorak, C., Kir, D., Kucuk, O., Akkas, M. & Sezgin, C. T., 2015. The Effect of Different Carbon Content on the Microstructural Characterization of High Chromium White Cast Irons. Karabuk, Turkey, s.n., p. 4.

- Li, H., Zhuang, M., Li, C., Wu, S. & Rong, S., 2018. Effect of Carbon Element Change on Microstructure and Properties of Fe-Cr-C Surfacing Alloy. Earth and Environmental Science, Volume 186, p. 6.

- Tian, Y., Ju, J., Fu, H., Shengqiang M. S., Lin, J. & Lei, Y., 2019. Effect of Chromium Content on Microstructure, Hardness, and Wear Resistance of As-Cast Fe-Cr-B Alloy. Journal of Materials Engineering and Performance, p. 11.

- Ngqase, M. Nheta, W., Madzivhandila, T., Phasha, M. & Pan, X., 2024. Exploring Residual Stress Analysis in the Machining of Hypoeutectic High Chromium White Cast Iron Alloys Through the Hole-Drilling Method. Engineering Research Express, 6(045414), pp. 1–19.

- Mabeba, A. D., 2021. Development of High Vanadium Grinding Media Materials for the Comminution of Gold Ore, Pretoria, Republic of South Africa: University of Pretoria.

- Moema, J. S., 2018. The Role of Retained Austenite on the Performance of High Chromium White Cast Iron and Carbidic Austempered Nodular Iron for Grinding Ball Applications, Pretoria, Republic of South Africa: University of Pretoria.

- Ngoc, Q. H. T., Diem, N. T. V., Hoang, V. N., Hong, H. N., Thu, H. L. & Duong, N. N., 2022. Effect of Residual Stress Distribution on the Formation, Growth and Coalescence of Voids of 27Cr White Cast Iron Under Impact. 63(2), pp. 170–175. [CrossRef]

- Motsumi, V. M., 2021. Investigation of the Micro- and Macroscopic Wear Properties of Cemented Tungsten Carbide for the Wear Lining Material Selection of Chutes, Johanneburg: s.n.

- Ngqase, M. & Pan, X., 2019. Microstructural Investigation on Heat Treatment of Hypoeutectic High. s.l., IOP Publishing, p. 12.

- Tupaj, M., Orłowicz, A. W., Trytek, A., Mróz, M., Wnuk, G. & Dolata, A. J., 2020. The Effect of Cooling Conditions on Martensite Transformation Temperature and hardness of 15%Cr Chromium Cast Irons. Materials, 13(2760), p. 13. [CrossRef]

- Ngqase, M., 2018. Validation of Physical Properties of HCWCI Alloys Towards Comprehensive Process Simulation Capabilities, Doorfontein, Johannesburg, South Africa: University of Johannesburg.

- Baghani, A., Davami, P., Varahram, N. & Shabani, M. O., 2014. Investigation on the Effect of Mold Constraints and Cooling Rate on Residual Stress During the Sand-Casting Process of 1086 Steel by Employing a Thermomechanical Model. Metallurgical and Materials Transactions B, p. 13. [CrossRef]

- Elmquist, L., Brehmer, A., Schmidt, P. & Israelsson, B., 2018. Residual Stresses in Cast Iron Components—Simulated Results Verified by Experimental Measurements. Material Science Forum, Volume 925, pp. 326–333. [CrossRef]

- Chaudry, U. M., Tekumalla, S., Gupta, M., Jun, T. -S. & Hamad, K., 2022. Designing Highly Ductile Magnesium Alloys: Current Status and Future Challenges. Critical Reviews in Solid State and Materials Sciences, 47(2), pp. 194–281.

- Egan, P. F., 2023. Design for Additive Manufacturing: Recent Innovations and Future Directions. Design, 7(83), p. 32. [CrossRef]

- Samuel, E., Samuel, A. M., Songmene, V. & Samuel, F. H., 2023. A Review on the Analysis of Thermal and Thermodynamic Aspects of Grain Refinement of Aluminum-Silicon-Based Alloys. Materials, 16(5639), p. 29. [CrossRef]

- Nemyrovskyi, Y., Shepelenko, I. & Storchak, M., 2023. Plasticity Resource of Cast Iron at Deforming Broaching. Metals, 13(551), p. 19. [CrossRef]

- Gong, L., Fu, H. & Zhi, X., 2023. Corrosion Wear of Hypereutectic High Chromium Cast Iron: A Review. Metals, 13(308), p. 21. [CrossRef]

- Akhtar, R. A., 2017. A Study of Residual Stresses in Low Alloy Steel Theta Ring Casting, Sheffield, South Yorkshire, England: ProQuest.

- Yang, Y., 2020. Development of a Method to Measure Residual Stresses in Cast Components with Complex Geometries, Stockholm, Sweden: KTH.

- Torres, I. N., Gilles, G., Tchuindjang, J. T., Lecomte-Beckers, J., Sinnaeve, M. & Habraken, A. M., 2014. Study of Residual Stresses in Bimetallic Work Rolls. Advanced Materials Research, Volume 996, pp. 580–585. [CrossRef]

- Alipooramirabad, H., Kianfar, S., Paradowska, A. & Ghomashchi, R., 2024. Residual Stress Measurement in Engine Block—An Overview. The International Journal of Advanced Manufacturing Technology, Volume 131, pp. 1–27.

- Tabatabaeian, A., Ghasem, H. R., Shokrieh, M. M., Marzbanrad, B., Baraheni, M. & Fotouhi, M., 2022. Residual Stress in Engineering Materials: A Review. Advanced Engineering Materials, 24(2100786), p. 28. [CrossRef]

- Akhtar, W., Lazoglu, I. & Liang, S. Y., 2022. Prediction and Control of Residual Stress-Based Distortions in the Machining of Aerospace Parts: A Review. Journal of Manufacturing Processes, Volume 76, pp. 106–122. [CrossRef]

- Qutaba, S., Asmelash, M., Saptaji, K. & Azhari, A., 2022. A Review on Peening Processes and its Effect on Surfaces. The International Journal of Advanced Manufacturing Technology, 120, Volume 120, pp. 4233–4270.

- Franceschi, A., Stahl, J., Kock, C., Selbmann, R., Ortmann-Ishkina, S., Jobst, A., Merklein, M., Kuhfuß, B., Bergmann, M., Behrens, B. -A., Volk, W. & Groche, P., 2021. Strategies for Residual Stress Adjustment in Bulk Metal Forming. Archive of Applied Mechanics, Volume 91, pp. 3557–3577.

- Hayama, M., Kikuchi, S., Tsukahara, M. & Misaka, Y., 2024. Estimation of Residual Stress Relaxation in Low Alloy Steel with Different Hardness during Fatigue by in Situ X-Ray Measurement. International Journal of Fatigue, Volume 178, pp. 1–11. [CrossRef]

- Bastola, N., Jahan, M. P., Rangasamy, N. & Rakurty, C. S., 2023. A Review of the Residual Stress Generation in Metal Additive Manufacturing: Analysis of Cause, Measurement, Effects, and Prevention. Micromachines, 14(1480). [CrossRef]

- Ammar, M. M. A. & Shirinzadeh, B., 2022. Evaluation of Robotic Fiber Placement Effect on Process-Induced Residual Stresses Using Incremental Hole-Drilling Method. Polymer Composites, Volume 43, pp. 4417–4436. [CrossRef]

- Yesudhas, S., Levitas, V. I., Lin, F., Pandey, K. K., & Smith, J. S., 2024. Unusual Plastic Strain-Induced Phase Transformation Phenomena in Silicon. Article, 15(7054), p. 13. [CrossRef]

- Mohamed, S. S., Samuel, A. M. & Samuel, F. H., 2018. Development of Residual Stresses in Al–Si Engine Blocks Subjected to Different Metallurgical Parameters. International Journal of Metal Casting, p. 13. [CrossRef]

- Nenchev, B., 2020. Modeling and Analysis of Solidification Shrinkage and Defect Prediction in Metals, Leicester, England: s.n.

- Soar, P., Kao, A., Djambazov, G., Shevchenko, N., Eckert, S. & Pericleous, K., 2020. The Integration of Structural Mechanics into Microstructure Solidification Modelling. Materials Science and Engineering, Volume 861, p. 9.

- Wang, G.-H. & Li, Y.-X., 2020. Thermal conductivity of cast iron—A Review. Special Review, 17(2), pp. 85–95. [CrossRef]

- Malik, I., Sani, A. A. & Medi, A., 2020. Study on using Casting Simulation Software for Design and Analysis of Riser Shapes in a Solidifying Casting Component. Journal of Physics: Conference Series, Volume 1500, pp. 1–7.

- Pant, G., Reddy, M. S. S., Praveen, Parashar, A. K., Kareem, S. A. & Nijhawan, G., 2023. Advanced Casting Techniques for Complex-Shaped Components: Design, Simulation and Process Control. ICMPC, Volume 430, pp. 1–10.

- Donghong, W., Yu, J., Yang, C., Hao, X., Zhang, L. & Peng, Y., 2022. Dimensional Control of Ring-to-Ring Casting with a Data-Driven Approach During Investment Casting. The International Journal of Advanced Manufacturing Technology, Volume 119, pp. 691–704. [CrossRef]

- Prikhod’ko, O. G., Deev, V. B., Prusov, E. S. & Kutsenko, A. I., 2020. Influence of Thermophysical Characteristics of Alloy and Mold Material on Casting Solidification Rate. Steel in Translation, 50(5), pp. 296–302. [CrossRef]

- Xu, J., Kang, J., Shangguan, H., Deng, C., Hu, Y., Yi, J. & Mao, W., 2022. Chimney Structure of Hollow Sand Mold for Casting Solidification. Metals, 12(415), p. 17. [CrossRef]

- Gurusamy, P., Bhattacharjee, B., Dutta, H. & Bhowmik, A., 2024. Study of Microstructural, Machining and Tribological Behaviour of AA-6061/SiC MMC Fabricated Through the Squeeze Casting Method and Optimized the Machining Parameters by Using Standard Deviation-PROMETHEE Technique. Silicon, Volume 16, pp. 675–686.

- Zhiguo, Z., Chengkai, Y., Peng, Z. & Wei, L., 2014. Microstructure and Wear Resistance of High Chromium Cast Iron Containing Niobium. Reaserch & Development, May, 11(3), pp. 179–184.

- Lundberg, M. & Elmquist, L., 2018. Hole Drilling Residual Stress Evaluations in Cast Iron. Jönköping, Sweden, ECRS-10, pp. 89–94.

- Venu, B. & Ramachandra, R., 2017. Simulation of Residual Stresses in Castings. International Journal of Scientific Research in Science and Technology, 3(8), pp. 875–890.

- Demirer, E., Pourasiabi, H. & Gates, J. D., 2022. Effects of Particle Impingement and Coarse Particle Abrasion on Wear Performance of White Cast Irons in Sliding Bed Applications. Society of Tribologists and Lubrication Engineers, pp. 1–16. [CrossRef]

- Duflou, J. R., Wegener, K., Tekkaya, A. E., Hauschild, M., Bleicher, F., Yan, J. & Hendrickx, B., 2024. Efficiently Preserving Material Resources in Manufacturing: Industrial Symbiosis Revisited. CIRP Annals- Manufacturing Technology, Volume 73, pp. 695–721. [CrossRef]

- Alsaihati, A. & Elkatatny, S., 2023. A New Method for Drill Cuttings Size Estimation Based on Machine Learning Technique. Arabian Journal for Science and Engineering, Volume 28, pp. 16739–16751. [CrossRef]

- Sivan, S. S. S., Mrinal, B. D. J., Natarajan, S. & Chauhan, N., 2018. Analysis of Residual Stresses, Thermal Stresses, Cutting Forces and other Output Responses of Face Milling Operations on ZE41 Magnesium Alloy. International Journal of Modern Manufacturing Technologies, X(1), pp. 92–100.

- Schröder, J., Evans, A., Mishurova, T., Ulbricht, A., Sprengel, M., Serrano-Munoz, I., Fritsch, T., Kromm, A., Kannengießer, T. & Bruno, G., 2021. Diffraction-Based Residual Stress Characterization in Laser Additive Manufacturing of Metals. Metals, 11(1830), p. 34. [CrossRef]

- Mohsen, S. & Behrooz, A., 2022. A Review in Machining-Induced Residual Stress. 12(1), pp. 64–68.

- Guo, J., Fu, H., Pan, B. & Kang, R., 2021. Recent Progress of Residual Stress Measurement Methods: A Review. Chinese Journal of Aeronautics, 34(2), pp. 54–78. [CrossRef]

- Chiu, S. M.; Wu, C. Y.; Chuang, T. L.; Wang, K. K.; Ma, N. Y., 2015. The Microstructure and Residual Stress Analysis of Gray Casting by Ultrasonic Technique. Taipei, Taiwan, s.n., pp. 1–5.

- Mehr, F. F., Cockcroft, S. & Maijer, D., 2020. A Fully-Coupled Thermal-Stress Model to Predict the Behavior of the Casting-Chill Interface in an Engine Block Sand Casting Process. International Journal of Heat and Mass Transfer, Volume 152, pp. 1–15. [CrossRef]

- Andriollo, T., Hellström, K., Sonne, M. R., Thorborg, J., Tiedje, N. & Hattel, J., 2018. Uncovering the Local Inelastic Interactions during Manufacture of Ductile Cast Iron: How the Substructure of the Graphite Particles can Induce Residual Stress Concentrations in the Matrix. Journal of the Mechanics and Physics of Solids, Volume 111, pp. 333–357. [CrossRef]

- Smit, T. C., Nobre, J. P., Reid, R. G., Wu, T., Niendorf, T., Marais, D. & Venter, A. M., 2022. Assessment and Validation of Incremental Hole-Drilling Calculation Methods for Residual Stress Determination in Fiber-Metal Laminates. Advances in Residual Stress Technology, Volume 62, pp. 1289–1304. [CrossRef]

- Barile, C., Casavola, C., Pappalettera, G. & Pappalettere, C., 2014. Remarks on Residual Stress Measurement by Hole-Drilling and Electronic Speckle Pattern Interferometry. The Scientific World Journal, Volume 2014, pp. 1–7. [CrossRef]

- Ngqase, M. & Pan, X., 2020. An Overview on Types of White Cast Irons and High Chromium White Cast Irons. International Conference on Multifunctional Materials (ICMM-2019)–Journal of Physics: Conference Series, p. 13.

- Ngqase, M. & Pan, X., 2020. XRD Investigation on Heat Treatment of High Chrome White Cast Irons. s.l., IO Pushiling, p. 11.

- Seidu, S. O., Oloruntoba, D. T. & Otunniyi, I. O., 2014. Effect of Shakeout Time on Microstructure and Hardness Properties of Grey Cast Iron. Journal of Minerals and Materials Characterization and Engineering, Volume 2, pp. 346–350. [CrossRef]

- Borle, S. D., 2014. Microstructural Characterisation of Chromium Carbide Overlays and a Study of Alternative Welding Processes for Industrial Wear Applications, Admonton, Alberta: Spring.

- Zhang, Y. B., Andriollo, T., Fæster, S., Liu, W., Hattel, J. & Barabash, R. I., 2016. Three-Dimensional Local Residual Stress and Orientation Gradients Near Graphite Nodules in Ductile Cast Iron. Acta Materialia, Volume 121, pp. 173–180. [CrossRef]

- Milenin, A., Kustra, P., Kuziak, R. & Pietrzyk, M., 2014. Model of Residual Stresses in Hot-Rolled Sheets with Taking into Account Relaxation Process and Phase Transformation. Procedia Engineering, Volume 81, pp. 108–113. [CrossRef]

- Song, J., Huang, Y., Gan, W. & Hort, N., 2014. Residual Stresses of the As-Cast Mg-xCa Alloys with Hot Sprues by Neutron Diffraction. Advanced Materials Research, Volume 996, pp. 592–597. [CrossRef]

- Keste, A. A., Gawande, H. S. & Sarkar, C., 2016. Design Optimization of Precision Casting for Residual Stress Reduction. Volume 3, pp. 140–150. [CrossRef]

- Feng, Q., Zeng, Y., Li, J., Wang, Y., Tang, G. & Wang, Y.,, 2024. Effect of Carbides on Thermos-Plastic and Crack Initiation and Expansion of High-Carbon Chromium-Bearing Steel Castings. Metals, 14(335), pp. 1–19. [CrossRef]

- Li, X., Liu, J., Wu, H., Miao, K., Wu, H., & Li, R., 2024. Review Article: Research Progress of Residual Stress Measurement Methods. Heliyon 10 (2024) e28348, 10(e28348), pp. 1–25.

- Sroka, J., 2021. Residual Stresses in lLarge Sizes Forgings, Sheffield, England: s.n.

- Lundberg, M., 2018. Residual Stresses, Fatigue and Deformation in Cast Iron, s.l.: LiU-Tryck.

| Casting Parameters | Casting Identity Number (CId) | |

|---|---|---|

| S/A | S/B | |

| Melting Temperature (TM) in oC | 1480.00 | 1480.00 |

| Casting Temperature (TC) in oC | 1384.00 | 1390.00 |

| Casting Shakeout Temperature (CST) in oC | 60.00 | 180.00 |

| Knockout Period (CKP) in minutes (mins) | 1645.00 | 1295.00 |

| Pouring Time (PT) in seconds (secs) | 22.00 | 23.00 |

| Gross Casting Weight in Kilograms (kg) | 114.28 | 113.48 |

| Net Casting Weight in Kilograms (kg) | 90.16 | 88.25 |

| Element | Composition (wt. %) | Casting Identity Number (CId) | |

|---|---|---|---|

| S/A | S/B | ||

| C | 2.0–3.3 | 2.50 | 2.70 |

| Si | ≤ 1.50 | 0.60 | 0.73 |

| Mn | ≤ 2.00 | 0.66 | 0.66 |

| S | ≤ 0.100 | 0.054 | 0.075 |

| P | ≤ 0.060 | 0.026 | 0.070 |

| Cr | 23.0–30.0 | 24.09 | 25.65 |

| Mo | ≤ 3.00 | 0.19 | 0.17 |

| Ni | ≤ 2.50 | 0.36 | 0.44 |

| Cu | ≤ 1.20 | 0.20 | 0.12 |

| Fe | bal. | 71.00 | 69.00 |

| CVF (%) | 28.87 | 32.19 | |

| Cr/C Ratio | 9.6 | 9.50 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).