Submitted:

21 April 2025

Posted:

22 April 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental Program:

2.1. Materials:

| Chemical Composition | OPC Type I (42.5 R) |

|---|---|

| CaO | 65.10% |

| SiO2 | 19.10% |

| Al2O3 | 4.20% |

| Fe2O3 | 2.70% |

| SO3 | 2.90% |

| MgO | 1.40% |

| Na2O | 0.65% |

| K2O | 0.98 |

| Physical Properties | OPC Type I (42.5 R) |

| Specific Gravity (g/m3) | 3.16 |

| Specific surface area (m2/kg) | 325.2 |

| Loss on ignition | 3.9% |

| Physical Properties | Course Aggregate | Fine Aggregate |

|---|---|---|

| Specific Gravity (g/m3) | 2.64 | 2.68 |

| Water Absorption % | 0.41 | 0.24 |

| Fineness Modulus | 6.4 | 2.75 |

| Physical Properties | Recycled Course Aggregate |

|---|---|

| Specific Gravity (g/m3) | 2.52 |

| Water Absorption % | 4.3 |

| Fineness Modulus | 7.1 |

| Physical Properties | Recycled Steel Fiber |

|---|---|

| Diameter(mm) | 0.25—0.3 |

| Length(mm) | 20--35 |

| Specific Gravity | 7.85 |

| Tensile Strength (Mpa) | 1250 |

| Chemical Compositions and Physical Properties | Superplasticizer |

|---|---|

| Form | Liquid |

| Color | Light Yellow |

| Odor | Slight/Faint |

| Boiling Point (C) | > 100 |

| Freezing point | -4 |

| Relative Density | 1.05- 1.08 |

| Water Solubility | Soluble |

| Chemical Composition | OPC Type I (42.5 R) |

|---|---|

| CaO | 1.50% |

| SiO2 | 95.10% |

| Al2O3 | 1.20% |

| Fe2O3 | 1 % |

| SO3 | 0.12% |

| MgO | 0.9% |

| Na2O | 0.24% |

| K2O | 0.78 |

| Physical Properties | OPC Type I (42.5 R) |

| Specific Gravity (g/m3) | 2.21 |

| Specific surface area (m2/kg) | 2.0 |

| Loss on ignition | 1.5% |

2.2. Mix Proportions:

2.3. Casting and Testing Methods:

2.3.1. Rheological Properties:

2.3.2. Mechanical Properties:

2.3.3. Density and Ultrasonic Pulse Velocity Testing:

3. Test Results & Discussion:

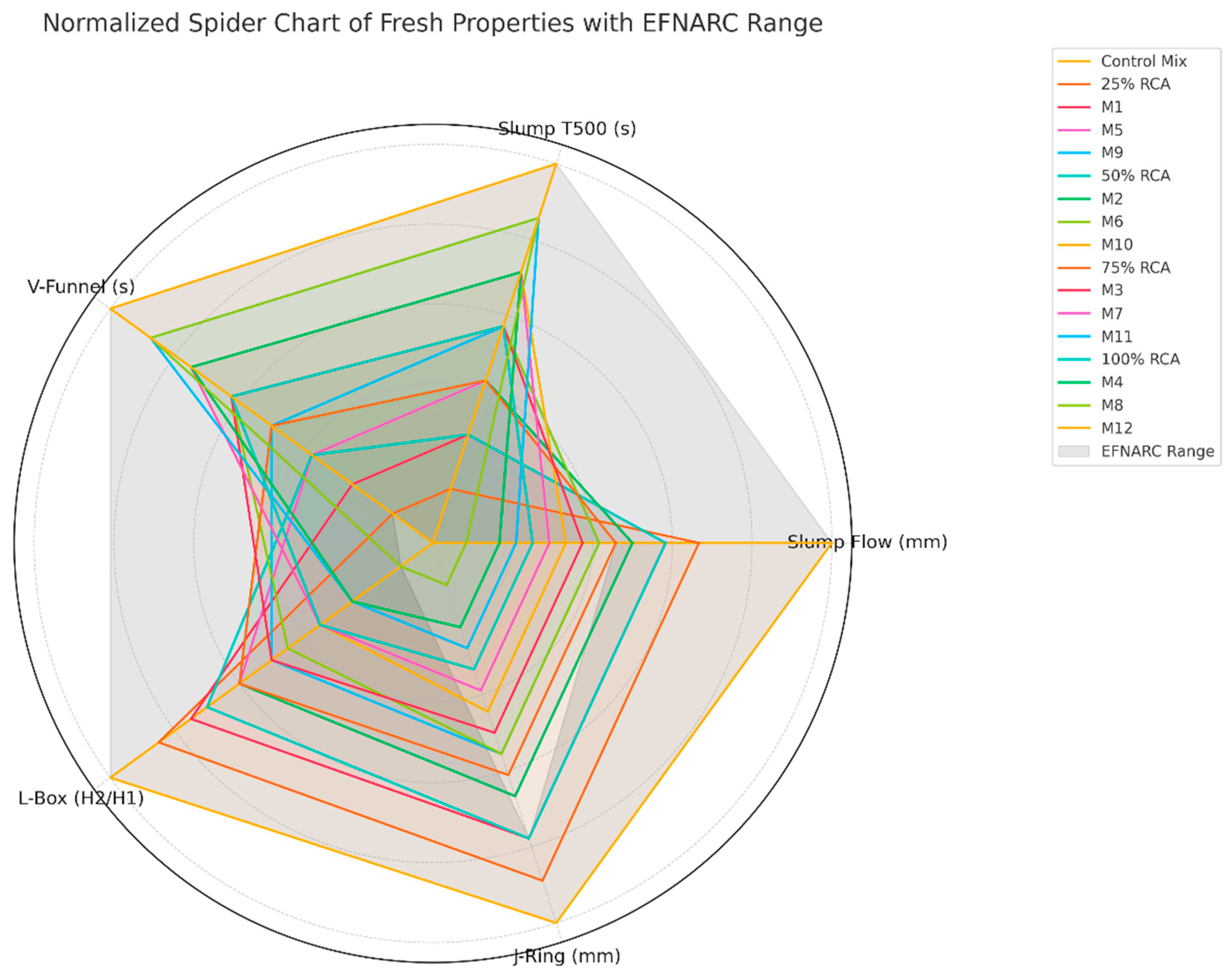

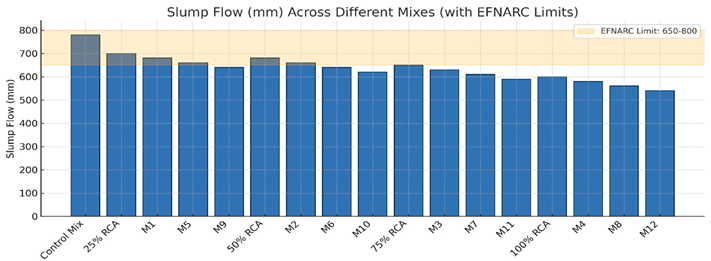

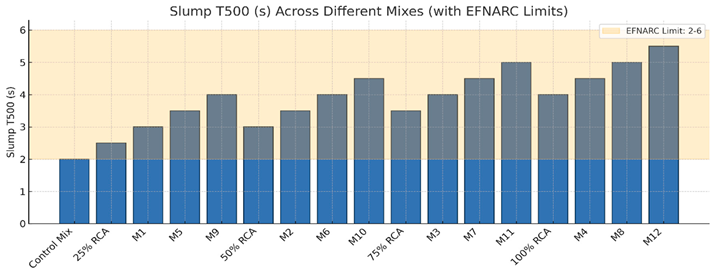

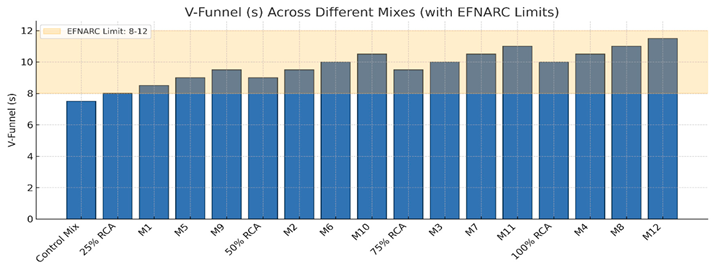

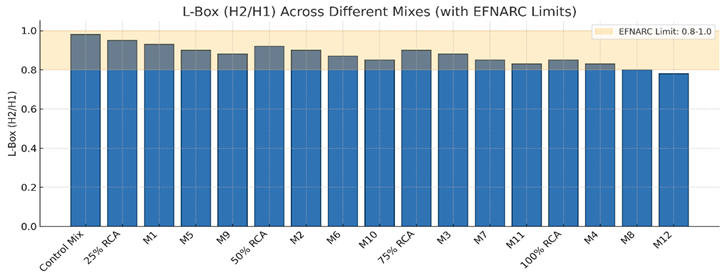

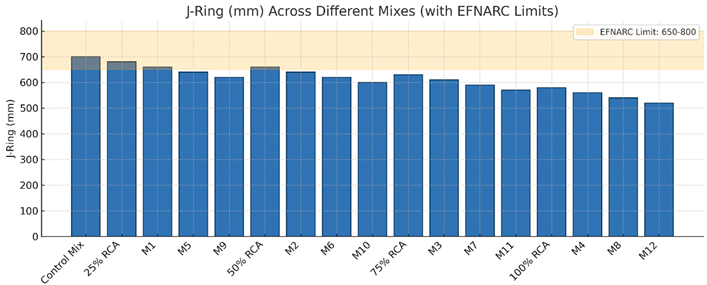

3.1. The Rheological Parameters:

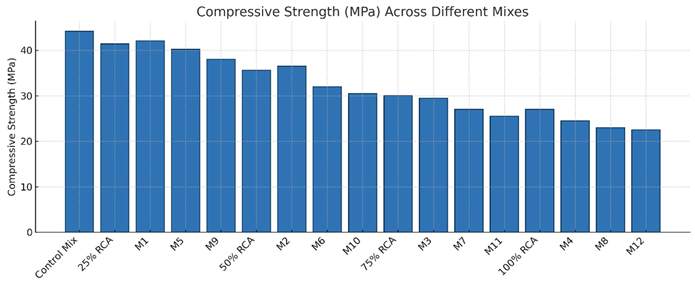

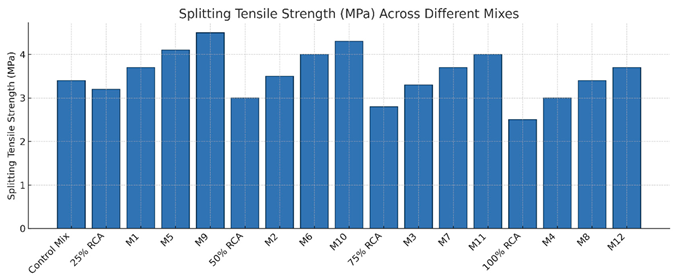

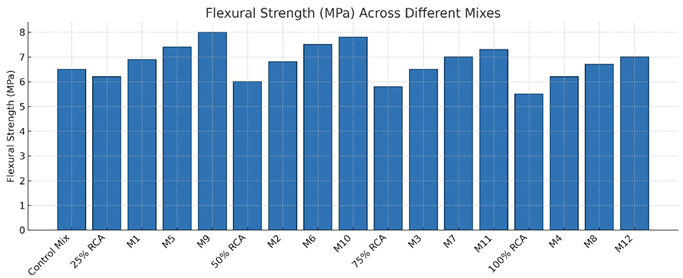

3.2. The Mechanical Properties:

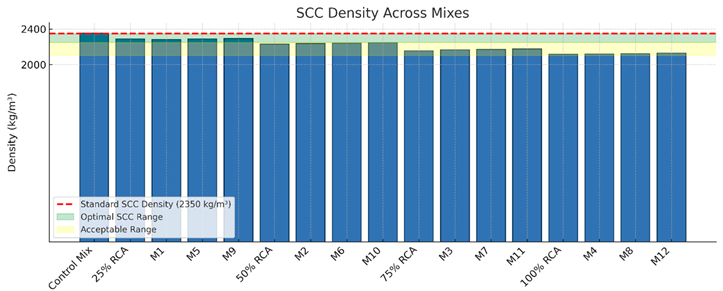

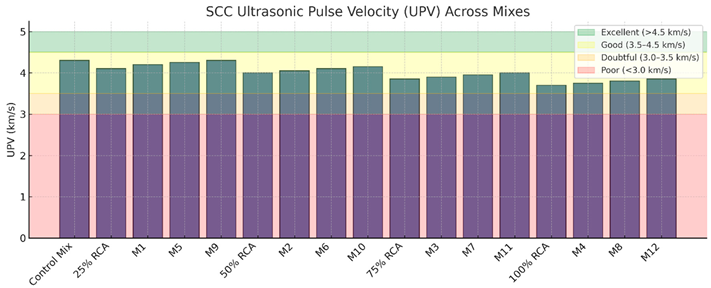

3.3. Density and Ultrasonic Pulse Velocity Testing:

| Mix Code | RCA Content (%) | RSF Content (%) | Density (Kg/m3) |

Ultrasonic Pulse Velocity UPV (km/s) |

|---|---|---|---|---|

| Control Mix | 0% | 0% | 2355 | 4.3 |

| 25% | 0% | 2290.4 | 4.1 | |

| M1 | 0.25% | 2284.5 | 4.2 | |

| M5 | 0.5% | 2289.2 | 4.25 | |

| M9 | 0.75% | 2294.8 | 4.3 | |

| 50% | 0% | 2230.5 | 4.0 | |

| M2 | 0.25% | 2237.2 | 4.05 | |

| M6 | 0.5% | 2242.7 | 4.1 | |

| M10 | 0.75% | 2247.4 | 4.15 | |

| 75% | 0% | 2155.5 | 3.85 | |

| M3 | 0.25% | 2166.9 | 3.9 | |

| M7 | 0.5% | 2171.3 | 3.95 | |

| M11 | 0.75% | 2176.8 | 4 | |

| 100% | 0% | 2115.8 | 3.7 | |

| M4 | 0.25% | 2119.1 | 3.75 | |

| M8 | 0.5% | 2124.5 | 3.8 | |

| M12 | 0.75% | 2129.6 | 3.85 |

4. Conclusions:

- Effect of RCA on Rheology: Increasing the RCA content generally leads to a slight decrease in workability, as reflected in lower slump flow values and slightly higher V-funnel, T500, and J-ring times. This is because recycled aggregates often have a rougher texture and higher porosity, reducing the flowability of the mix.

- Effect of Steel Fiber on Rheology: As steel fiber content increases, workability decreases due to the higher viscosity of the mix caused by the fibers. This is evident in the decreasing slump flow and increasing T500, V-funnel, and J-ring values.

- Optimal Fiber Content: While higher fiber contents improve mechanical properties like splitting tensile strength and flexural strength, they can reduce flowability, the optimum fiber content might lie within the 0.25% to 0.5% range. Care must be taken when designing mixes to ensure sufficient workability, particularly for SCC, which requires good flowability and stability.

- Rheological Behavior: Steel fibers tend to improve the strength of SCC but reduce the flowability, which means that it may be necessary to adjust the mix design (e.g., using superplasticizers or adjusting the fine aggregate content) to achieve the desired workability and strength balance.

- Compressive Strength: There is a slight decrease in compressive strength as steel fiber content increases, likely due to higher viscosity and reduced compactability of the concrete mix, especially with higher RCA content. However, the values are still within an acceptable range for most applications.

- Splitting Tensile Strength: Steel fibers significantly enhance splitting tensile strength, especially at 0.75% fiber content. Even with increasing RCA content, the tensile strength shows a steady improvement.

- Flexural Strength: Similar to tensile strength, flexural strength improves consistently with steel fiber addition, showing the highest values at 0.75% fiber and 25% RCA.

- Density& UPV: Results showed that increasing RCA content led to a gradual reduction in both physical properties, due to the lighter and more porous nature of recycled aggregates. However, the inclusion of RSF improved these properties by enhancing internal matrix integrity and reducing microstructural defects.

- RCA Content: The RCA content inversely affects mechanical properties, especially compressive strength, but the addition of steel fibers mitigates some of this loss, especially in tensile and flexural strength. This analysis suggests that steel fibers are highly effective at improving tensile and flexural strengths in recycled SCC, even when RCA content is high, making it a promising material for sustainable concrete applications.

References

- EFNARC (2005). The European Guidelines for self-compacting concrete: specification, production, and use. Retrieved from http://www.efnarc.org/.

- Younis, K. H. (2016). Mechanical performance of concrete reinforced with recycled steel fibres extracted from post-consumer tyres)” Proceedings of the (2nd IEC2016) 20 – 22 February, Erbil-Kurdistan-Iraq.

- Younis, K. H., Ahmed, F. S., & Najim, K. B. (2018). Self-Compacting Concrete Reinforced with Steel Fibers from Scrap Tires: Rheological and Mechanical Properties.

- Al-Bayati, G. H., Taha, M. R., & Hameed, A. M. (2023). Effect of Recycled Aggregate Concrete and Steel Fibers on the Fresh Properties of Self-Compacting Concrete. E3S Web of Conferences, 377, 02012.

- Khalaf, M. A., & Deeb, R. A. (2015). Effect of Steel Fibers on the Properties of Recycled Self-Compacting Concrete in Fresh and Hardened State. International Journal of Civil Engineering, 13(4), 396-407.

- Kumar, R., & Dhaka, R. (2021). Recycled Fibers for Sustainable Hybrid Fiber Cement-Based Material: A Review. Materials, 14(9), 2350.

- Kadhim, A. J., & Kareem, Q. A. (2020). Mix Proportioning of Recycled Steel Fiber Reinforced Self-Compacting Concrete. Eurasian Journal of Science & Eng. ,6(1),17.25.

- Soutsos, M. N., & Tang, K. (2019). Experimental analysis of fiber-reinforced recycled aggregate self-compacting concrete. Structural Concrete, 20(1), 277-286.

- Soutsos, M. N., & Tang, K. (2022). Environment-Friendly Recycled Steel Fibre Reinforced Concrete. Construction and Building Materials, 346, 128495.

- Hatungimana, Daniel and MARDANI, ALI and Mardani, Naz and Assaad, Joseph, Feasibility of Steel Fiber-Reinforced Self-Compacting Concrete Containing Recycled Aggregates-Compliance to Efnarc Guidelines. [CrossRef]

- Grdic ZJ, Toplicic-Curcic GA, Despotovic IM, Ristic NS. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate, Construction and Building Materials, 2010, No. 7, Vol. 24, pp. 1129-1133. [CrossRef]

- Khaleel OR, Al-Mishhadani SA, Abdual Razak H. The effect of coarse aggregate on fresh and hardened properties of self-compacting concrete (SCC), Procedia Engineering, 2011, Vol. 14, pp. 805-813. [CrossRef]

- Khayat K, Roussel Y. Testing and performance of fiber reinforced, self-consolidating concrete, Material & Structure, 2000, No. 6, Vol. 33, pp. 391-397.

- Dhonde HB, Mo Y, Hsu TT, Vogel J. fresh and hardened properties of self-consolidating fiber reinforced concrete, ACI Materials Journal, 2007, No. 5, Vol. 104, pp. 491 500.

- Simalti, A., & Singh, A. (2019). Mix proportioning of recycled steel fiber reinforced self-compacting concrete. Presented at the Proceeding of Int. UKIERI Concrete Congress.

- Nan Su, Kung-Chung Hsu, His-Wan Chai. “A simple mix design method for self-compacting concrete”, Cement and Concrete Research, 2001, pp. 1799 –1807. [CrossRef]

- Krishna Rao B, Ravindra V. Steel fiber reinforced self-compacting concrete incorporating class F fly ash, International Journal of Engineering Science and Technology, 2010, No. 9, Vol. 2, pp. 4936-4943.

- Qian CX, Stroeven P. Development of hybrid polypropylene-steel fibers-reinforced concrete, Cement and Concrete Research, 2000, No. 1, Vol. 30, pp. 63-69. [CrossRef]

- Nirmal Tamrakar. The effect of steel fibers type and content on the development of fresh and hardened properties and durability of self-consolidating concrete, Theses and dissertations, 2012, 794. p.

- Centonze, G., Leone, M., Aiello, A.M. (2012). Steel fibers from waste tires as reinforcement in concrete, Construction and Building Materials, 36, 45–67. [CrossRef]

- Prof. Y.V. akbari, Prof.Dr. K.B. parikh, Tejas H. raviya(2016).” A critical review of self-compacting concrete using recycled coarse aggregate.” IOSR journal of mechanical and civil engineering (IOSR-JMCE) vol 13, issue 1.

- Ajith V and Praveen Mathew (2015) ‘A study on the self-compacting properties of recycled concrete incorporating a new mix proportioning method. “International journal of science technology and engineering vol 2 issue 5.

- Pilakoutas, K., Neocleous, K., & Tlemat, H., (2004). Reuse of steel fibres as concrete reinforcement. Engineering Sustainability, 157, 131-138.

- C. S. Poon, Z. H. Shui, and L. Lam, “Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates,” Construction and Building Materials, vol. 18, no. 6, pp. 461–468, 2004. [CrossRef]

| Mix Code | Cement kg/m3 |

Fine Aggregate (Sand) kg/m3 |

Course Aggregate (Gravel) kg/m3 |

Recycled Course Aggregate kg/m3 |

Recycled Steel Fiber kg/m3 | Silica Fume kg/m3 |

Water Liter/m3 |

Admixture (SP) Liter/m3 |

|---|---|---|---|---|---|---|---|---|

| CM | 350 | 925 | 850 | 0 | 0 | 10 | 180 | 12 |

| M1 | 350 | 925 | 638 | 212 (25%) | 19 (0.25%) | 10 | 180 | 12 |

| M2 | 350 | 925 | 425 | 425 (50%) | 19 (0.25%) | 10 | 180 | 12 |

| M3 | 350 | 925 | 212 | 638 (75%) | 19 (0.25%) | 10 | 180 | 12 |

| M4 | 350 | 925 | 0 | 850 (100%) | 19 (0.25%) | 10 | 180 | 12 |

| M5 | 350 | 925 | 638 | 212 (25%) | 39 (0.50%) | 10 | 180 | 12 |

| M6 | 350 | 925 | 425 | 425 (50%) | 39 (0.50%) | 10 | 180 | 12 |

| M7 | 350 | 925 | 212 | 638 (75%) | 39 (0.50%) | 10 | 180 | 12 |

| M8 | 350 | 925 | 0 | 850 (100%) | 39 (0.50%) | 10 | 180 | 12 |

| M9 | 350 | 925 | 638 | 212 (25%) | 59 (0.75%) | 10 | 180 | 12 |

| M10 | 350 | 925 | 425 | 425 (50%) | 59 (0.75%) | 10 | 180 | 12 |

| M11 | 350 | 925 | 212 | 638 (75%) | 59 (0.75%) | 10 | 180 | 12 |

| M12 | 350 | 925 | 0 | 850 (100%) | 59 (0.75%) | 10 | 180 | 12 |

| Mix Code | RCA Content (%) | RSF Content (%) | Slump Flow (mm) |

Slump T500 (s) | V-Funnel (s) | L-Box (H2/H1) | J-Ring (mm) |

|---|---|---|---|---|---|---|---|

| Control Mix | 0% | 0% | 780 | 2.0 | 7.5 | 0.98 | 700 |

| 25% | 0% | 700 | 2.5 | 8.0 | 0.95 | 680 | |

| M1 | 0.25% | 680 | 3.0 | 8.5 | 0.93 | 660 | |

| M5 | 0.5% | 660 | 3.5 | 9.0 | 0.90 | 640 | |

| M9 | 0.75% | 640 | 4.0 | 9.5 | 0.88 | 620 | |

| 50% | 0% | 680 | 3.0 | 9.0 | 0.92 | 660 | |

| M2 | 0.25% | 660 | 3.5 | 9.5 | 0.90 | 640 | |

| M6 | 0.5% | 640 | 4.0 | 10.0 | 0.87 | 620 | |

| M10 | 0.75% | 620 | 4.5 | 10.5 | 0.85 | 600 | |

| 75% | 0% | 650 | 3.5 | 9.5 | 0.90 | 630 | |

| M3 | 0.25% | 630 | 4.0 | 10.0 | 0.88 | 610 | |

| M7 | 0.5% | 610 | 4.5 | 10.5 | 0.85 | 590 | |

| M11 | 0.75% | 590 | 5.0 | 11.0 | 0.83 | 570 | |

| 100% | 0% | 600 | 4.0 | 10.0 | 0.85 | 580 | |

| M4 | 0.25% | 580 | 4.5 | 10.5 | 0.83 | 560 | |

| M8 | 0.5% | 560 | 5.0 | 11.0 | 0.80 | 540 | |

| M12 | 0.75% | 540 | 5.5 | 11.5 | 0.78 | 520 | |

| EFNARK Limits | 650-800 | 2-6 | 8-12 | 0.8-1.0 | 650-800 |

| Mix Code | RCA Content (%) | RSF Content (%) | Compressive Strength (MPa) |

Splitting Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|---|

| Control Mix | 0% | 0% | 44.2 | 3.4 | 6.5 |

| 25% | 0% | 41.4 | 3.2 | 6.2 | |

| M1 | 0.25% | 42.1 | 3.7 | 6.9 | |

| M5 | 0.5% | 40.2 | 4.1 | 7.4 | |

| M9 | 0.75% | 38.0 | 4.5 | 8.0 | |

| 50% | 0% | 35.6 | 3.0 | 6.0 | |

| M2 | 0.25% | 36.5 | 3.5 | 6.8 | |

| M6 | 0.5% | 32.0 | 4.0 | 7.5 | |

| M10 | 0.75% | 30.5 | 4.3 | 7.8 | |

| 75% | 0% | 30.0 | 2.8 | 5.8 | |

| M3 | 0.25% | 29.5 | 3.3 | 6.5 | |

| M7 | 0.5% | 27.0 | 3.7 | 7.0 | |

| M11 | 0.75% | 25.5 | 4.0 | 7.3 | |

| 100% | 0% | 27.0 | 2.5 | 5.5 | |

| M4 | 0.25% | 24.5 | 3.0 | 6.2 | |

| M8 | 0.5% | 23.0 | 3.4 | 6.7 | |

| M12 | 0.75% | 22.5 | 3.7 | 7.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).