Submitted:

27 April 2024

Posted:

28 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Research Significance

3. Materials

3.1. Cement

3.2. Ceramic Waste Powder

3.3. Fine and Coarse Aggregates

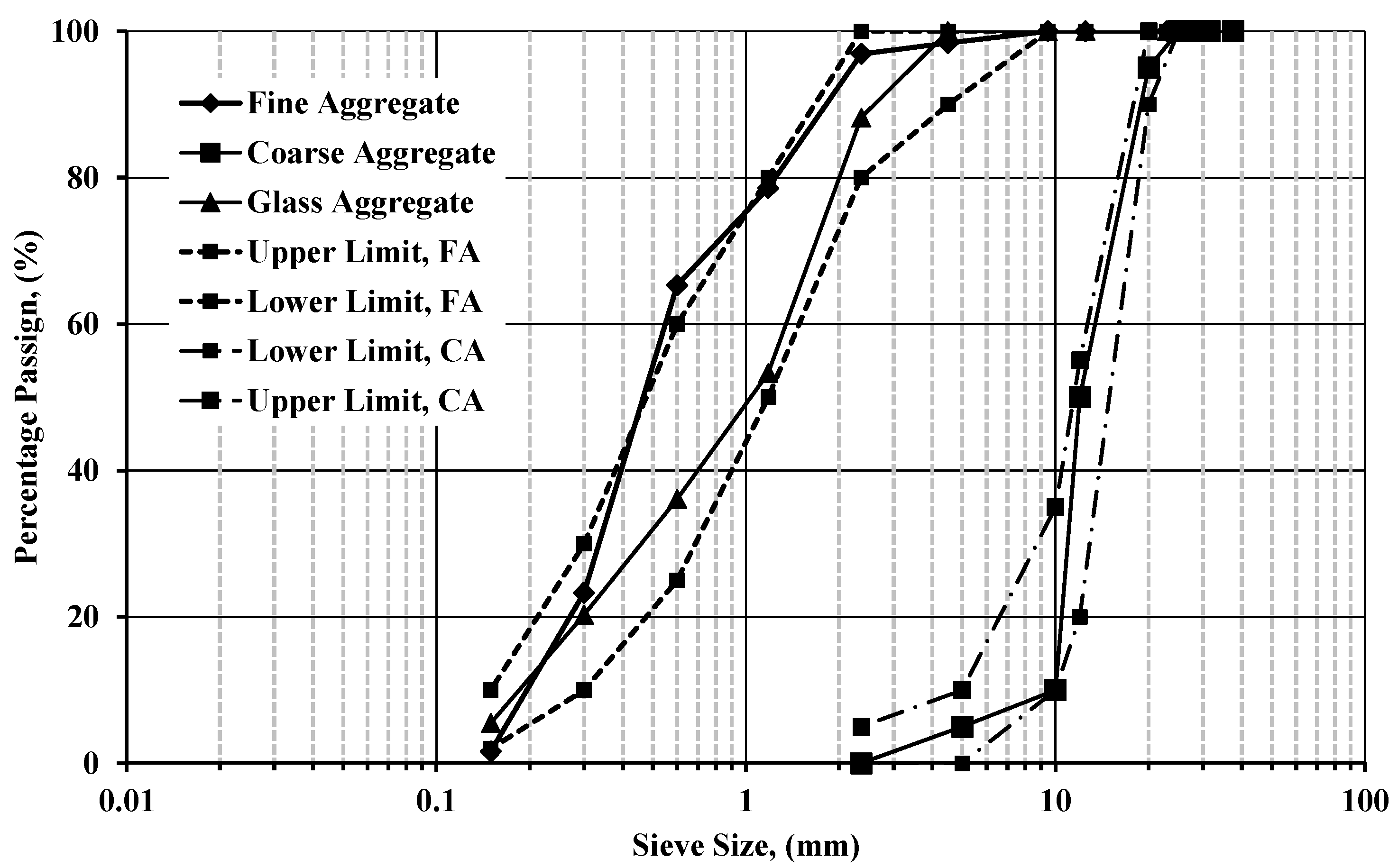

3.4. Superplasticizer

3.5. Glass

4. Specimens Preparation

5. Testing Method

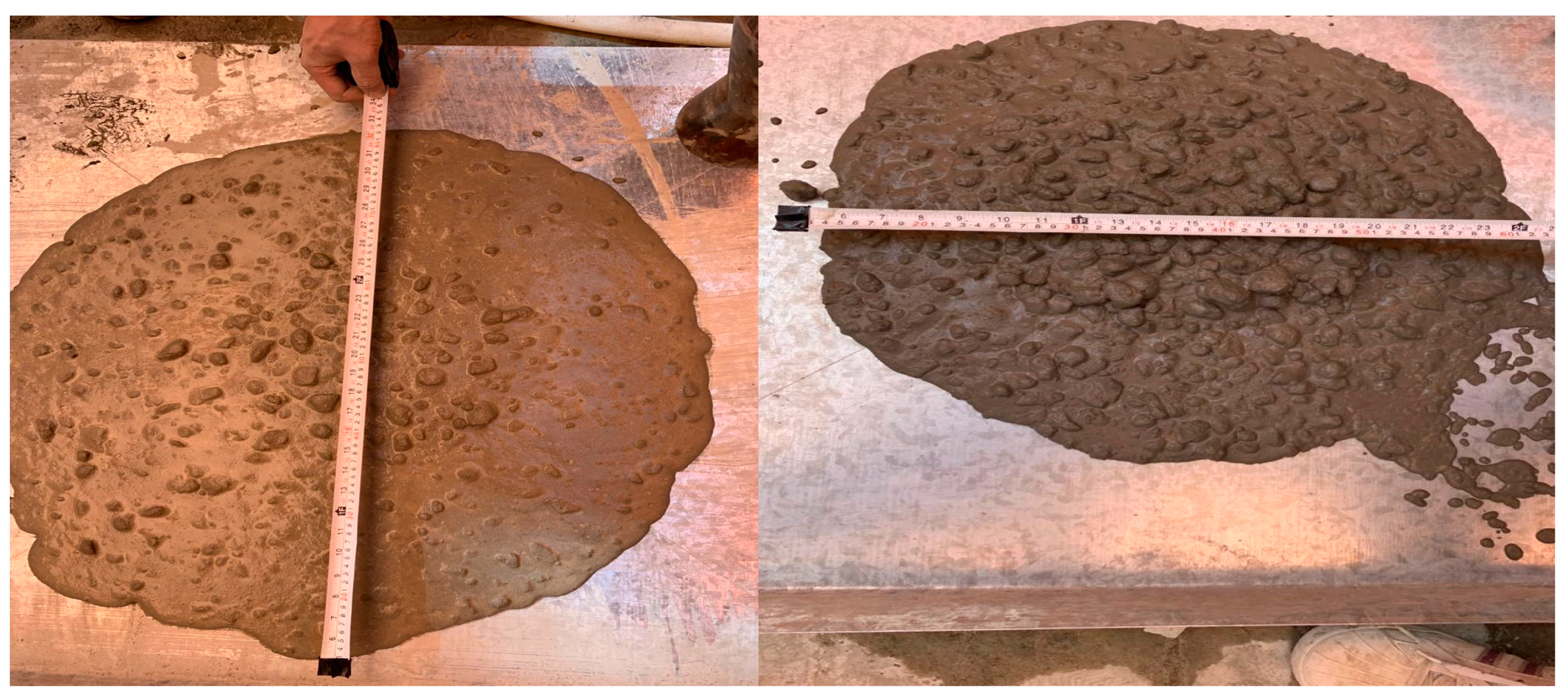

- a)

- Slump flow test

- b)

- Slump flow time at T50 cm

- c)

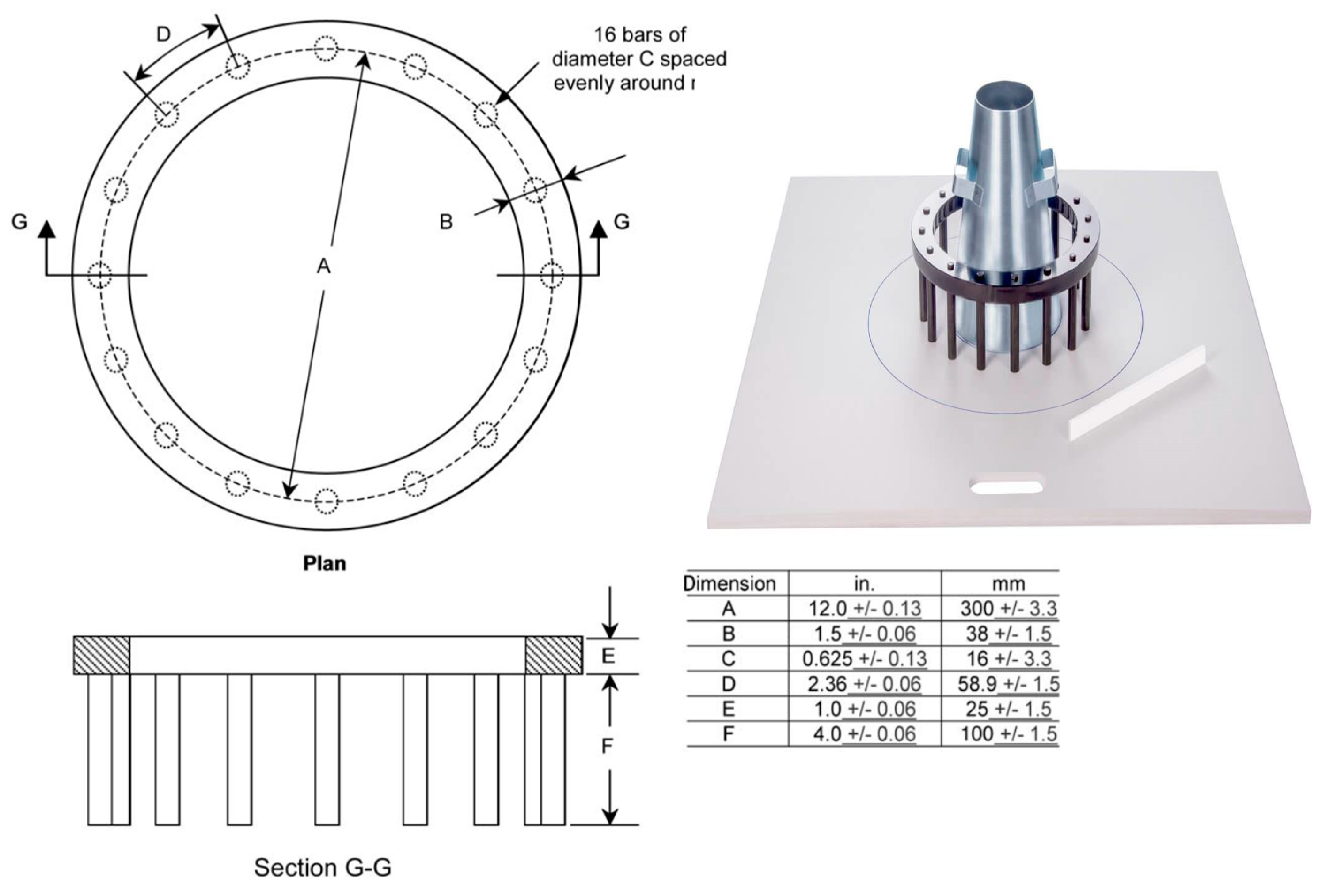

- J-ring flow

- d)

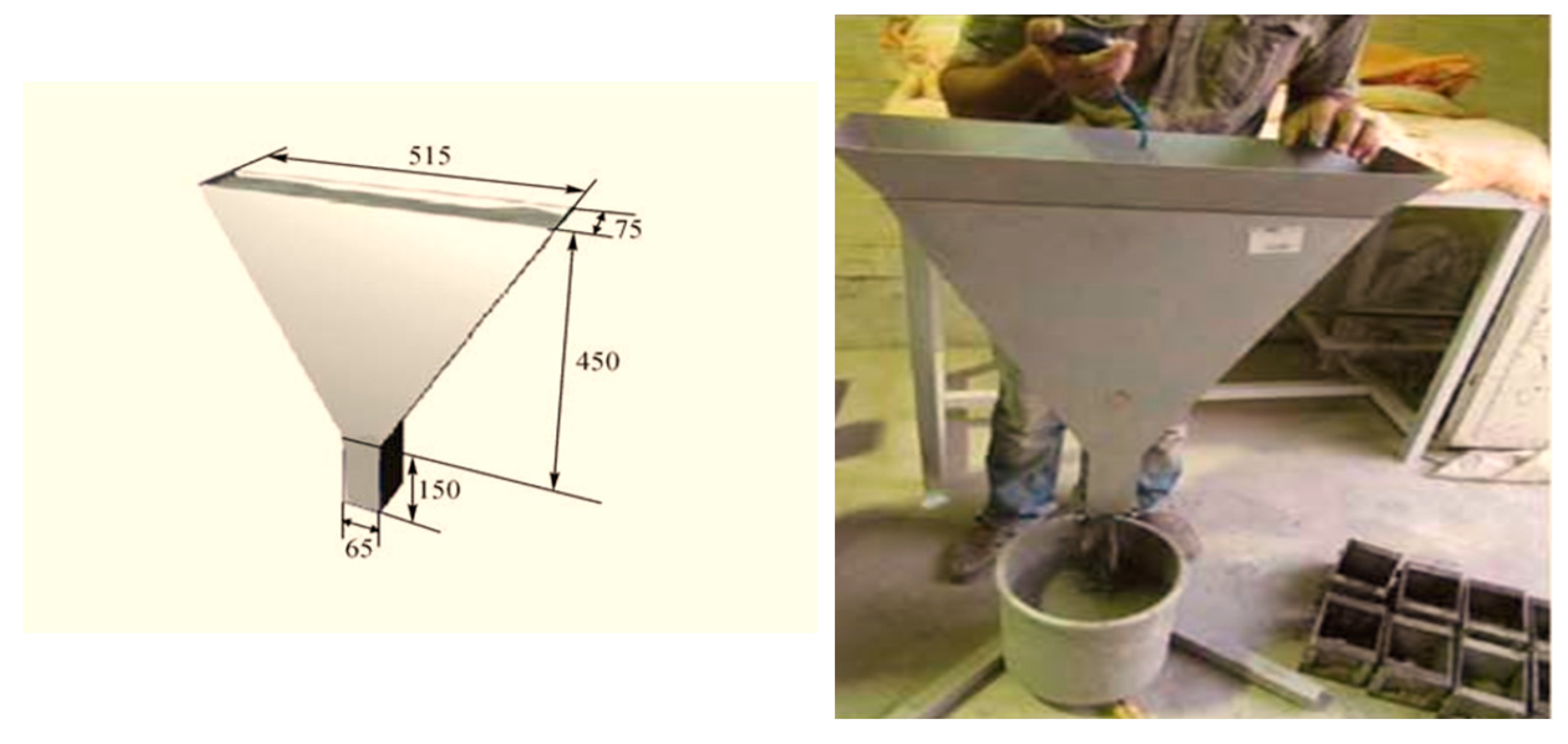

- V-funnel

- e)

- V-funnel after 5 minutes

- f)

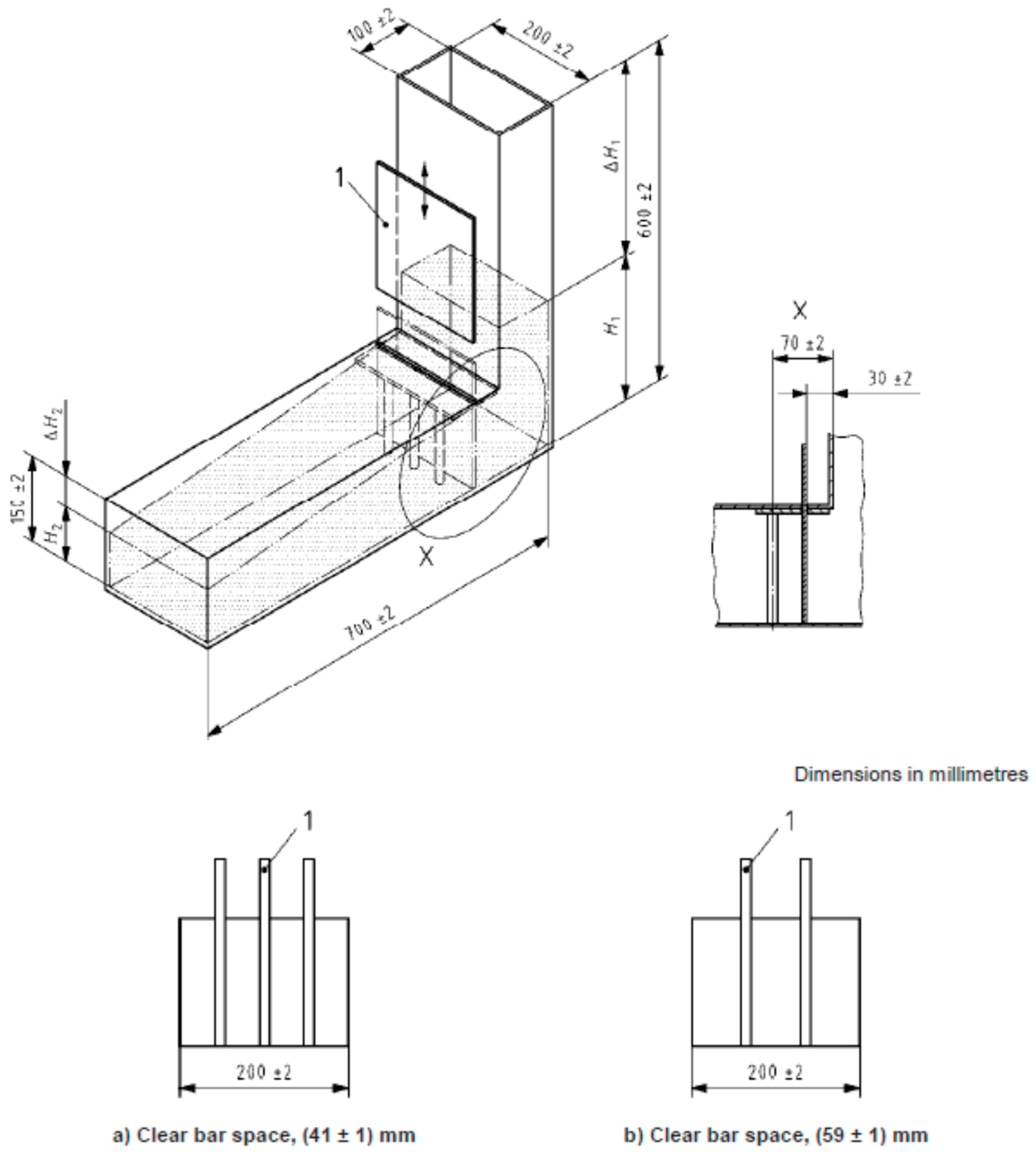

- L-box test

6. Results and Discussion

6.1. Fresh State Properties

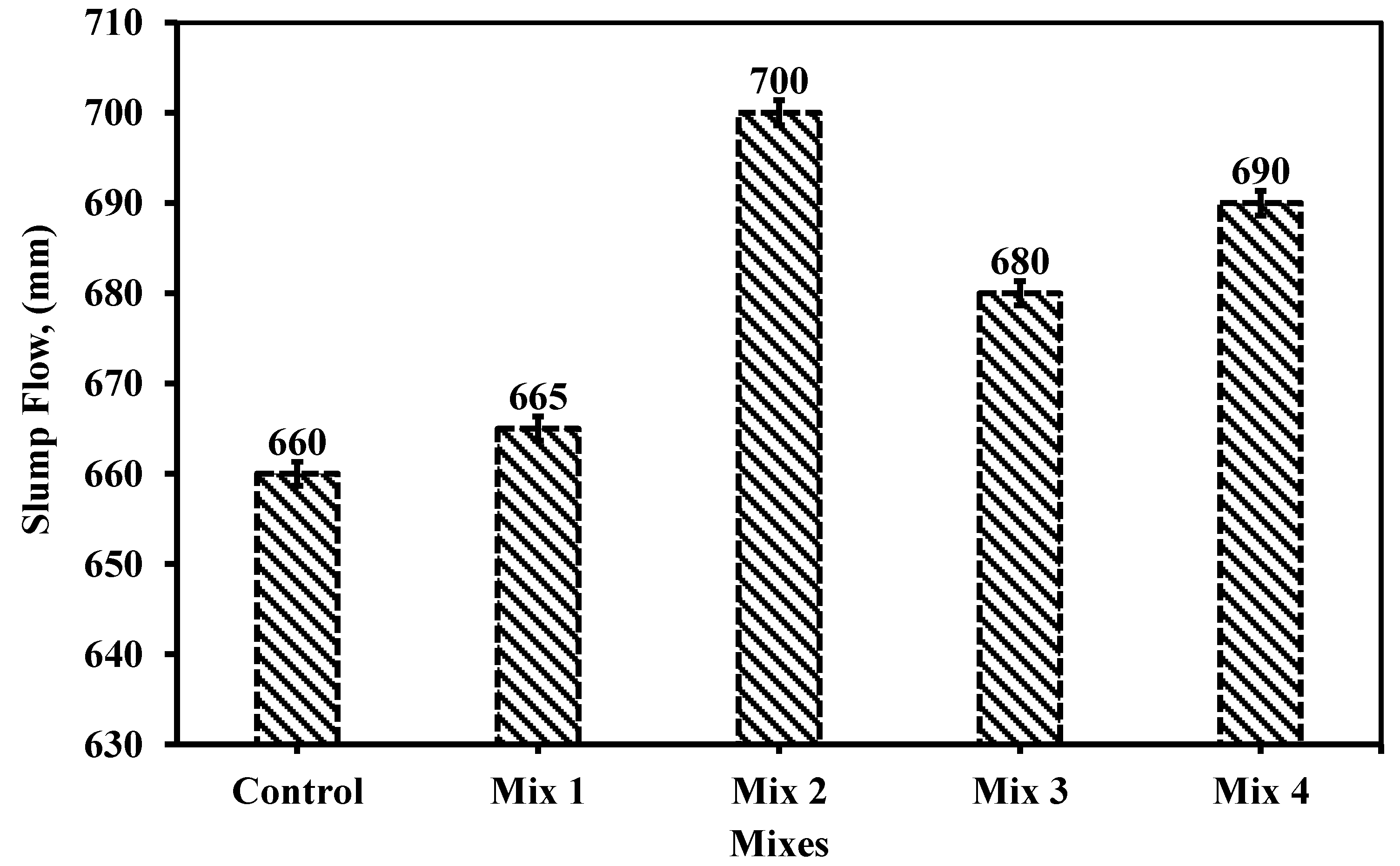

6.1.1. Slump Flow

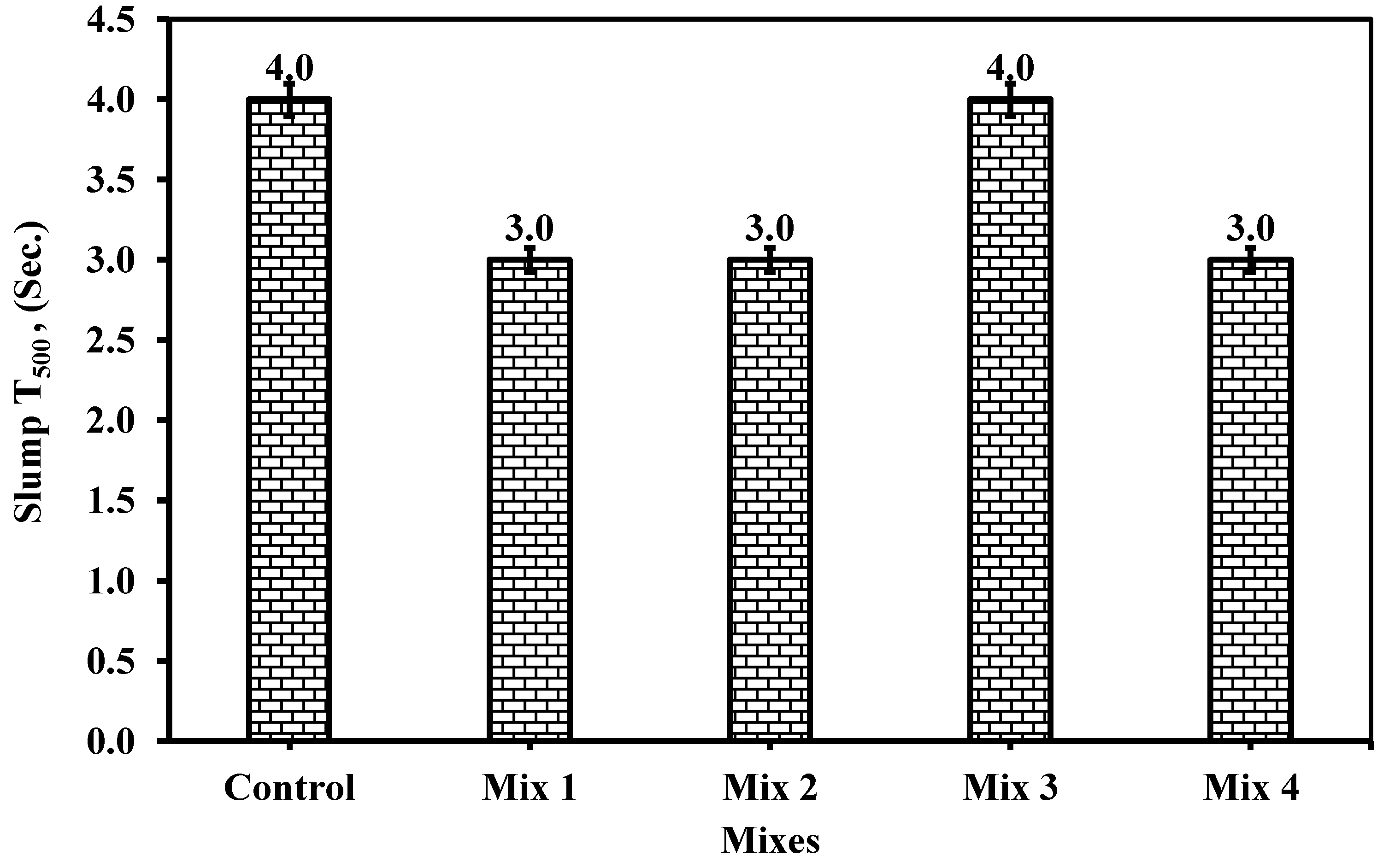

6.1.2. Slump T500

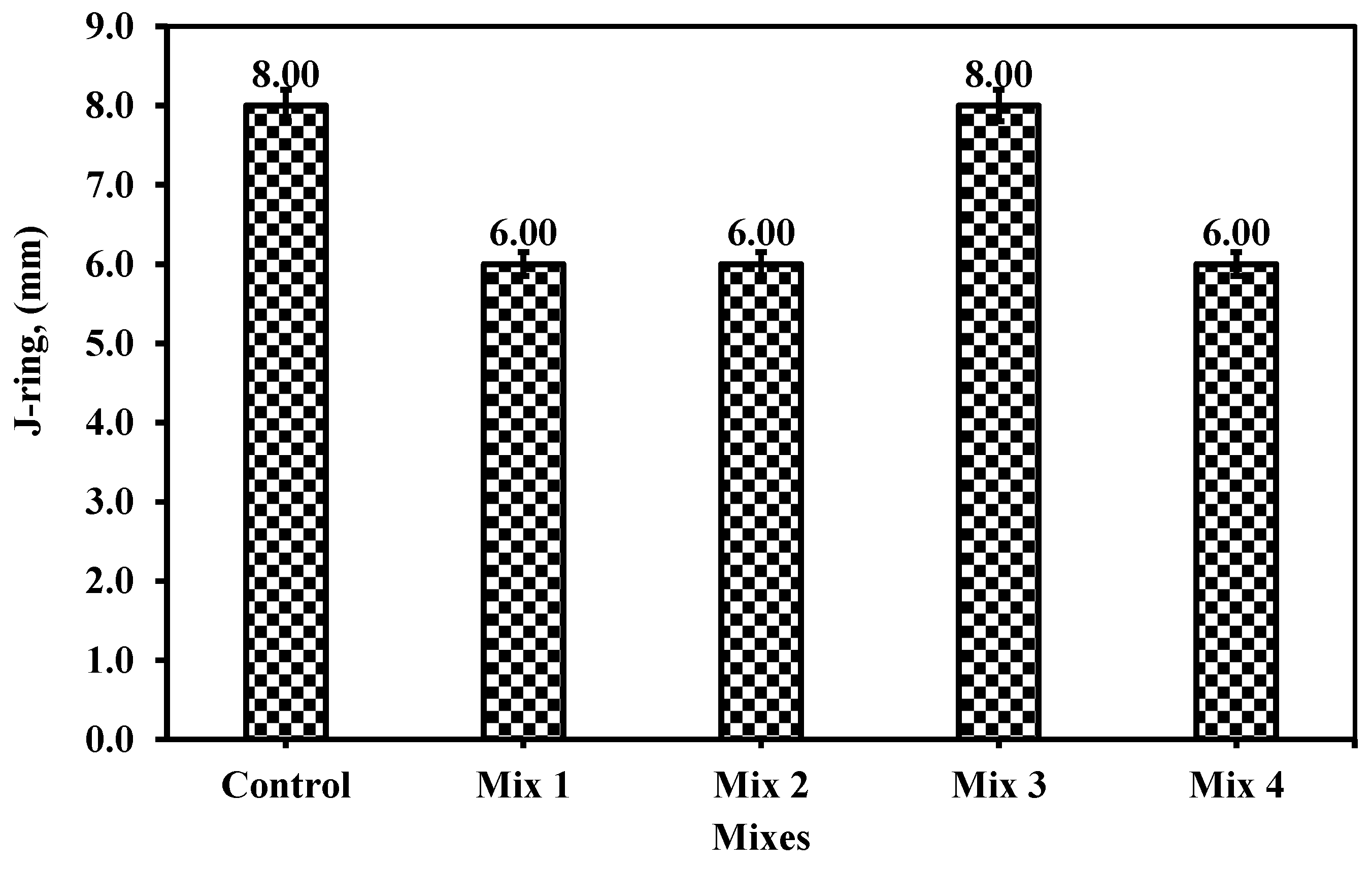

6.1.3. J-Ring

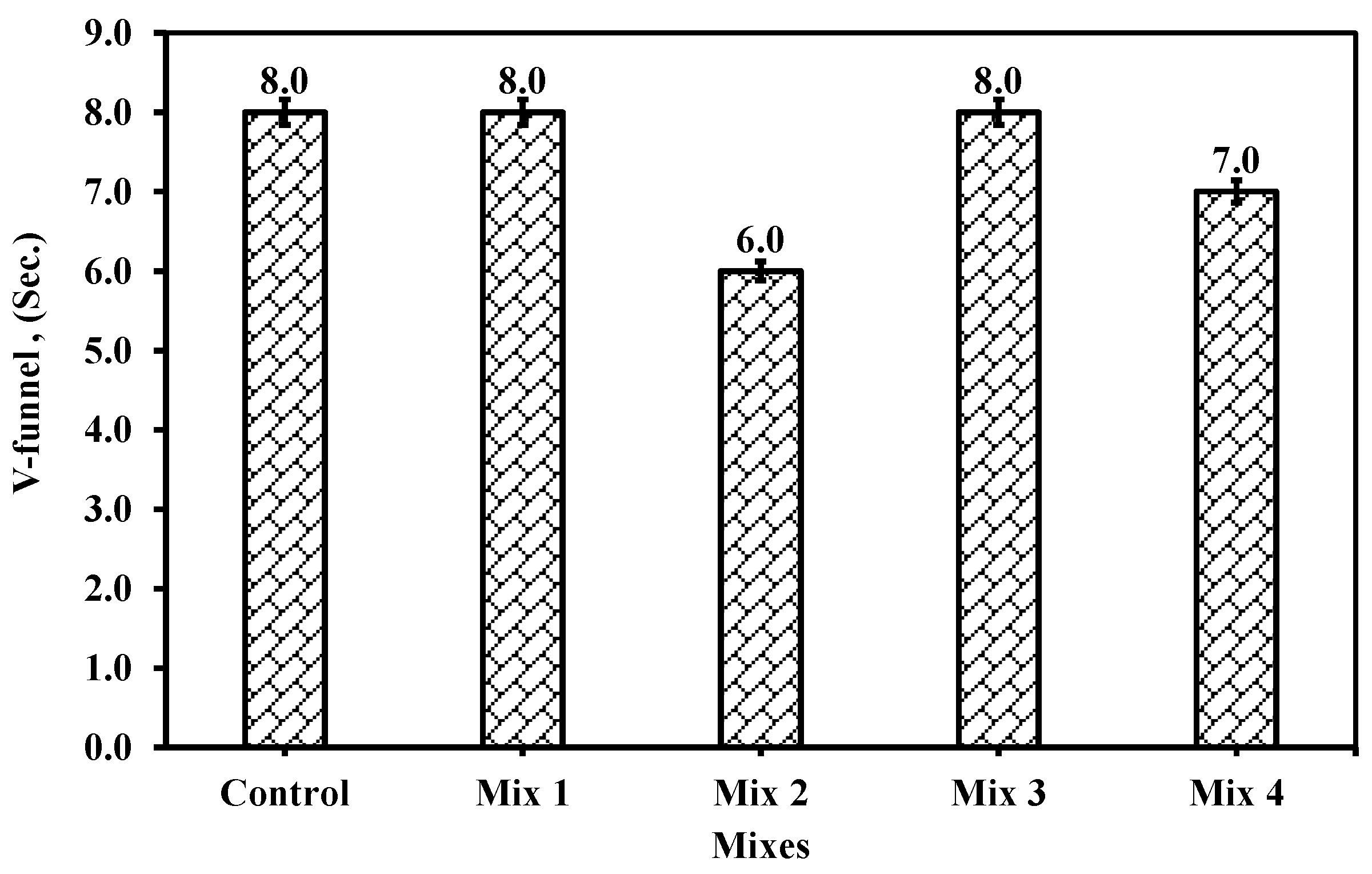

6.1.4. V-Funnel

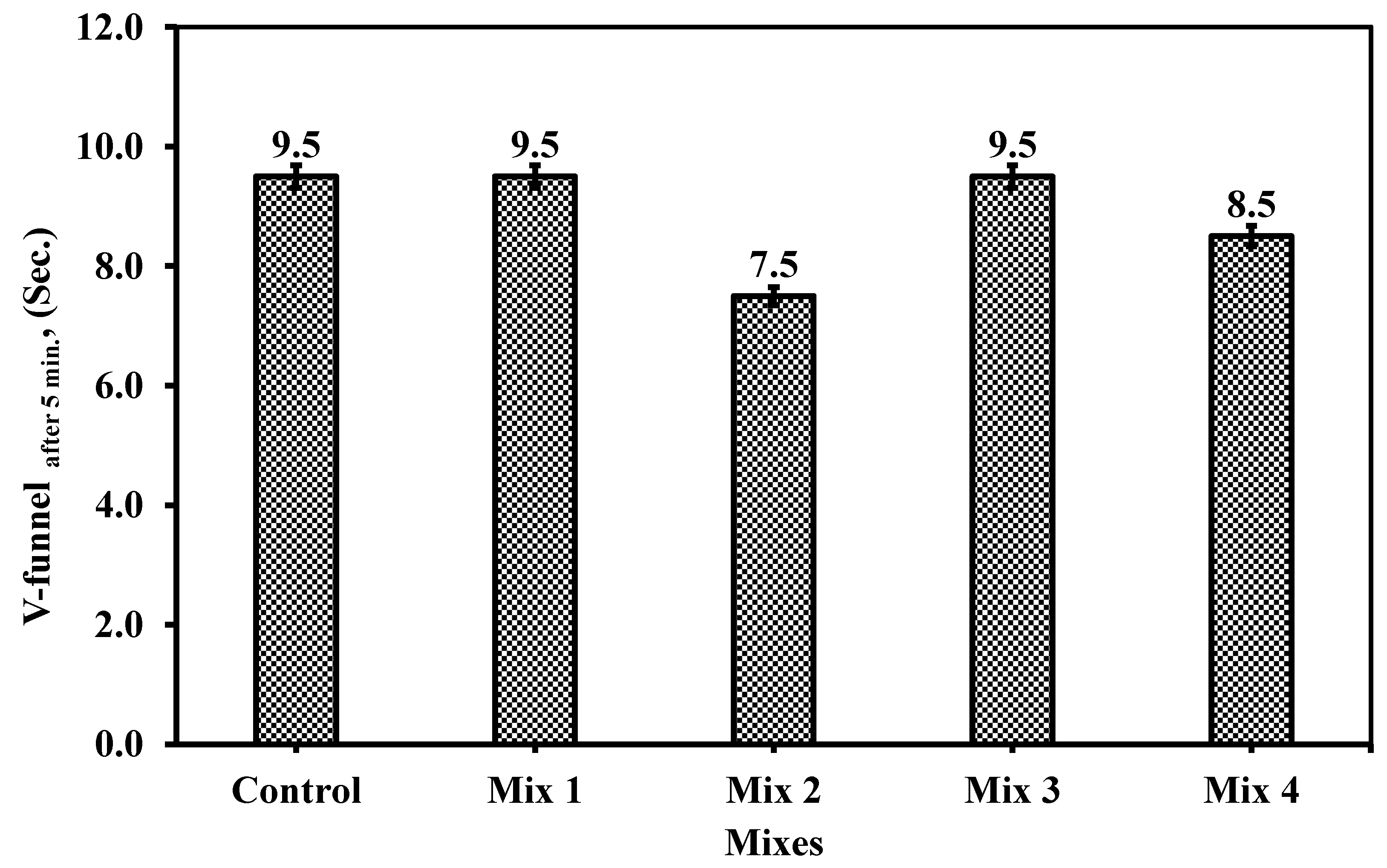

6.1.5. V-Funnel after 5 Minutes

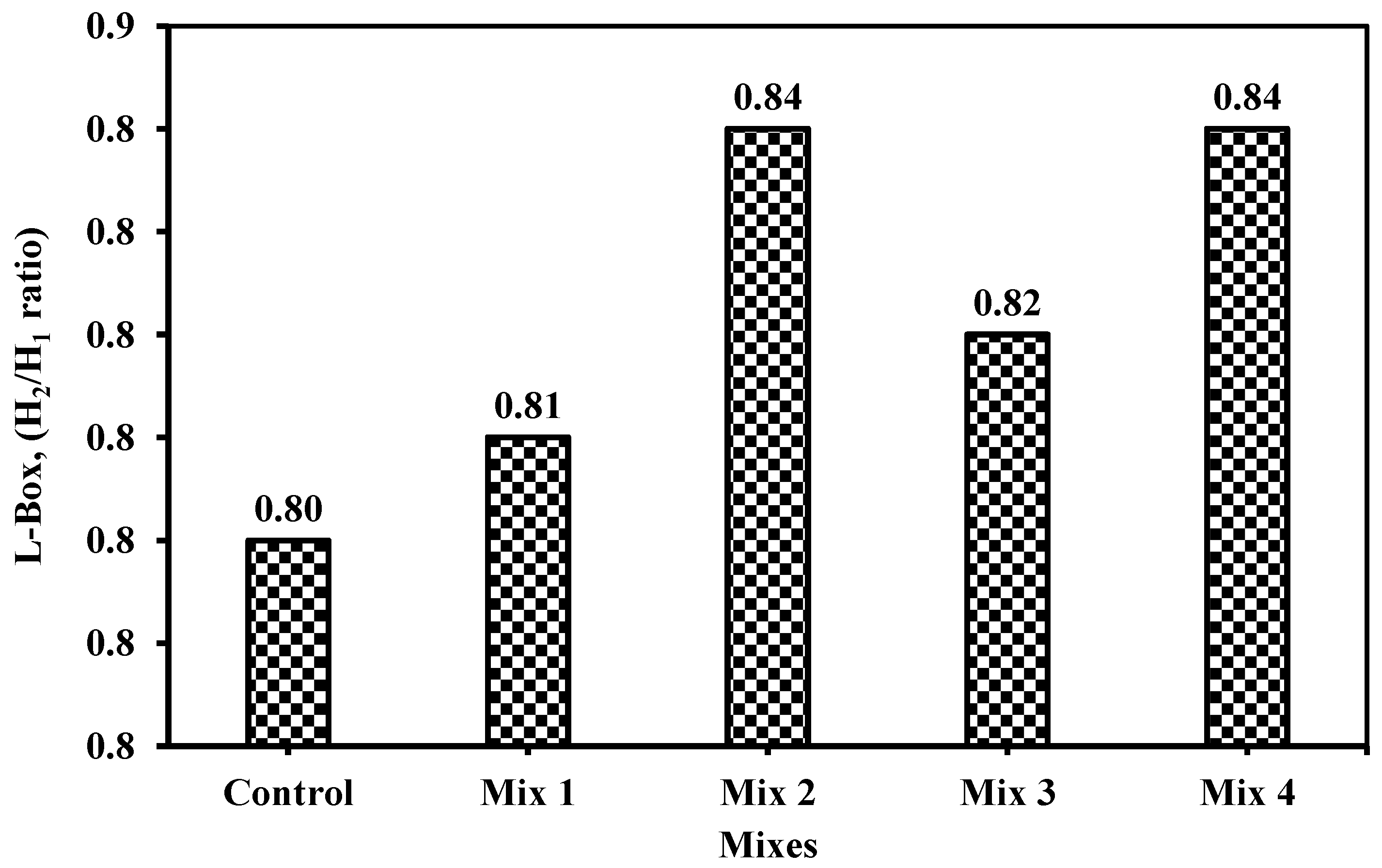

5.1.6. L-Box

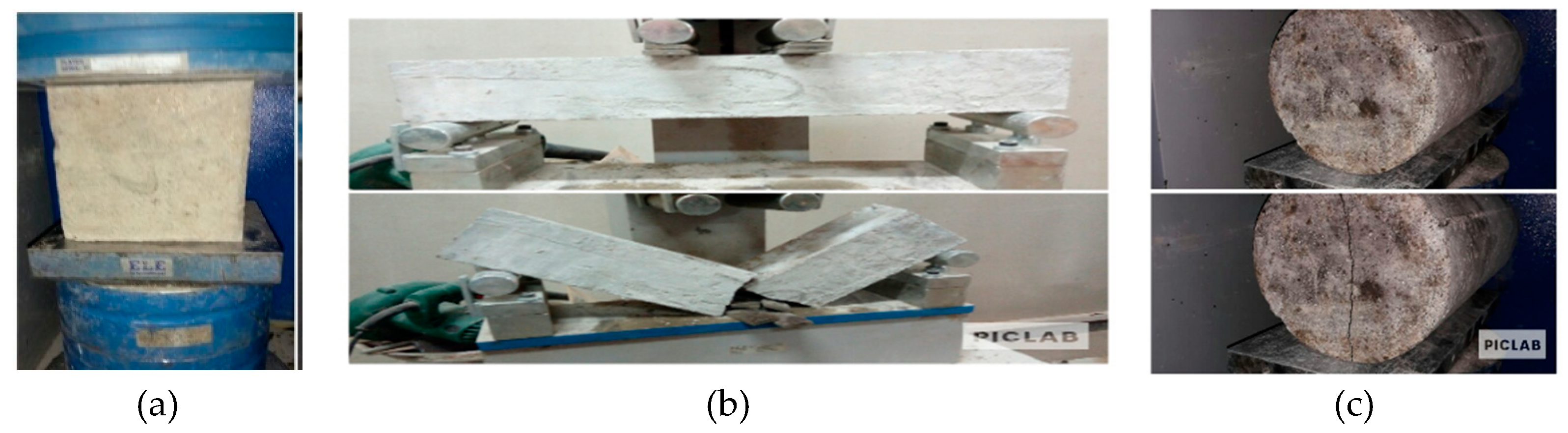

6.2. Hardened State Properties

6.2.1. Compressive Strength

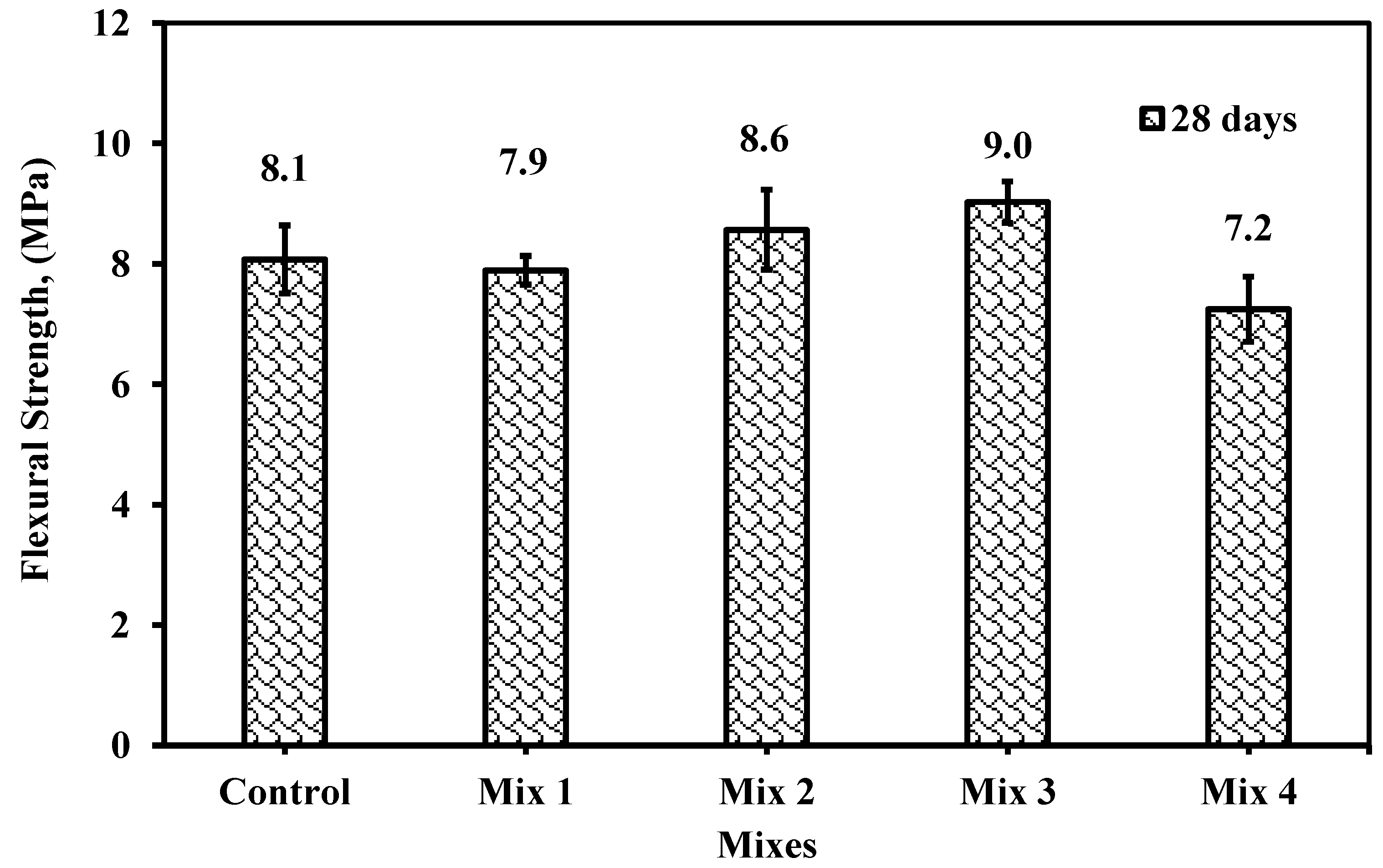

6.2.2. Flexural Strength

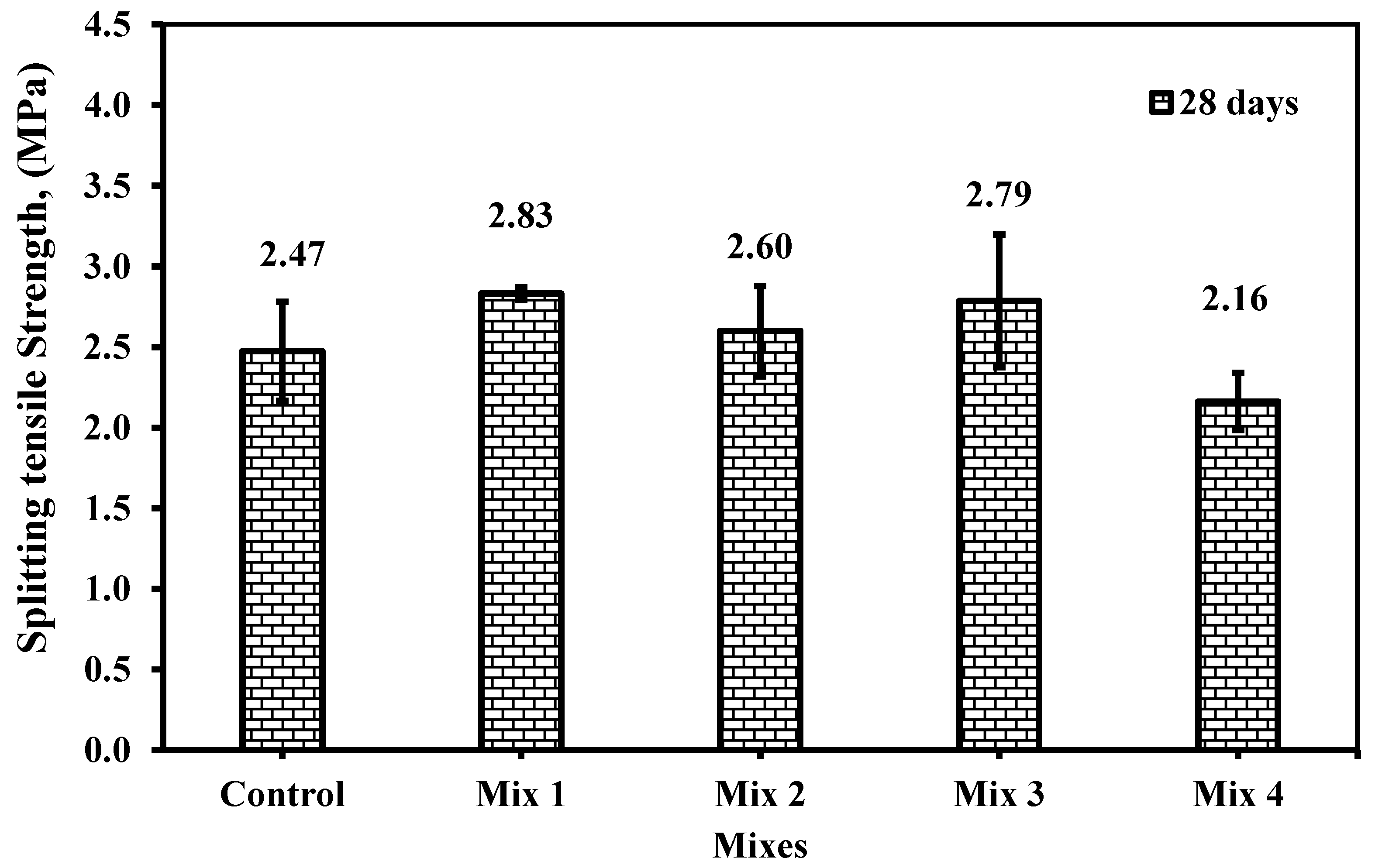

6.2.3. Splitting Tensile Strength

6.3. Relationships between the Mechanical Strength (Compressive, Flexural, and Tensile)

7. Conclusions

- 1)

- A possible effective solution for using CWP and RG in SCC manufacturing, reducing the environmental impact of waste deposition, cement, and concrete manufacturing.

- 2)

- The results revealed good rheological properties that comply with code and guidelines, especially ECP 203

- 3)

- Partial replacement cement with 15 to 20% CWP and fine aggregate by 5 to 10% RG would enhance the flowability due to their hydrophobic properties.

- 4)

- The passing ability of SCC while utilizing the CWP and RG provides privilege in congested reinforcement members.

- 5)

- Generally, the compressive strength is reduced slightly, which is not critical, however, the flexural strength is enhanced, which is a good achievement

- 6)

- Compressive, flexural, and tensile strengths were reduced as CWP was replaced by more than 20% cement and over 10% RG as a fine aggregate replacement.

- 7)

- The optimum and best performance was achieved at 15% CWP and 10% RG replacement of cement and fine aggregate, especially in flexural and tensile strengths corresponding to the control mix of SCC

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Jain, A.; Gupta, R.; Chaudhary, S. (2019). Performance of self-compacting concrete comprising granite cutting waste as fine aggregate. In Construction and Building Materials (Vol. 221, pp. 539–552). Elsevier BV. [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; A Tayeh, B.; Sivalingam, S.; Rosli, M.F. B.; Haruna, S.; Khan, M.I. (2020). Mechanical and deformation properties of rubberized engineered cementitious composite (ECC). In Case Studies in Construction Materials (Vol. 13, p. e00385). Elsevier BV. [CrossRef]

- Gautam, L.; Jain, J.K.; Kalla, P.; Danish, M. (2021). Sustainable utilization of granite waste in the production of green construction products: A review. In Materials Today: Proceedings (Vol. 44, pp. 4196–4203). Elsevier BV. [CrossRef]

- Subaşı, S.; Öztürk, H.; Emiroğlu, M. (2017). Utilizing waste ceramic powders as filler material in self-consolidating concrete. In Construction and Building Materials (Vol. 149, pp. 567–574). Elsevier BV. [CrossRef]

- Tayeh, B.A.; Al Saffar, D.M.; Aadi, A.S.; Almeshal, I. (2020). The sulfate resistance of cement mortar contains glass powder. In Journal of King Saud University - Engineering Sciences (Vol. 32, Issue 8, pp. 495–500). Elsevier BV. [CrossRef]

- Agrawal, A.; Singh, A.; Imam, A. (2020, August). Utilization of Ceramic Waste as a Sustainable Building Material. In August 2020 National Conference on Structural Engineering NCRASE–2020.

- Gautam, L.; Jain, J.K.; Kalla, P.; Choudhary, S. (2021). A review on the utilization of ceramic waste in sustainable construction products. In Materials Today: Proceedings (Vol. 43, pp. 1884–1891). Elsevier BV. [CrossRef]

- Gautam, L.; Kumar Jain, J.; Alomayri, T.; Meena, N.; Kalla, P. (2022). Performance evaluation of self-compacting concrete comprising ceramic waste powder as fine aggregate. In Materials Today: Proceedings (Vol. 61, pp. 204–211). Elsevier BV. [CrossRef]

- El-Dieb, A.S.; and Kanaan, D.M. (2018). Ceramic waste powder an alternative cement replacement – Characterization and evaluation. In Sustainable Materials and Technologies (Vol. 17, p. e00063). Elsevier BV. [CrossRef]

- Aly, S.T.; El-Dieb, A.S.; Taha, M.R. (2019). Effect of High-Volume Ceramic Waste Powder as Partial Cement Replacement on Fresh and Compressive Strength of Self-Compacting Concrete. In Journal of Materials in Civil Engineering (Vol. 31, Issue 2). American Society of Civil Engineers (ASCE). [CrossRef]

- Li, L.G.; Zhuo, Z.Y.; Zhu, J.; Chen, J.J.; Kwan, A.K. H. (2019). Reutilizing ceramic polishing waste as powder filler in mortar to reduce cement content by 33% and increase strength by 85%. In Powder Technology (Vol. 355, pp. 119–126). Elsevier BV. [CrossRef]

- Sivaprakash, G.; Saravana, K.V.; Saikia, L.J. (2016). Experimental study on partial replacement of sand by ceramic waste in concrete. Int. J. Chem. Sci, 14(2016), 266-274.

- Mohit, M.; Ranjbar, A.; Sharifi, Y. (2021). Mechanical and microstructural properties of mortars incorporating ceramic waste powder exposed to the hydrochloric acid solution. In Construction and Building Materials (Vol. 271, p. 121565). Elsevier BV. [CrossRef]

- Alsaif, A. (2021). Utilization of ceramic waste as partially cement substitute – A review. In Construction and Building Materials (Vol. 300, p. 124009). Elsevier BV. [CrossRef]

- El-Dieb, A.S.; Taha, M.R.; Kanaan, D.; Aly, S.T. (2018). Ceramic waste powder: from landfill to sustainable concretes. In Proceedings of the Institution of Civil Engineers - Construction Materials (Vol. 171, Issue 3, pp. 109–116). Thomas Telford Ltd. [CrossRef]

- Chen, X.; Zhang, D.; Cheng, S.; Xu, X.; Zhao, C.; Wang, X.; Wu, Q.; Bai, X. (2022). Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability, and microstructure assessment. In Journal of Building Engineering (Vol. 52, p. 104418). Elsevier BV. [CrossRef]

- Mohit, M.; Sharifi, Y. (2019). Thermal and microstructure properties of cement mortar containing ceramic waste powder as alternative cementitious materials. In Construction and Building Materials (Vol. 223, pp. 643–656). Elsevier BV. [CrossRef]

- Kannan, D.M.; Aboubakr, S.H.; EL-Dieb, A.S.; Reda Taha, M.M. (2017). High-performance concrete incorporating ceramic waste powder as a large partial replacement of Portland cement. In Construction and Building Materials (Vol. 144, pp. 35–41). Elsevier BV. [CrossRef]

- Shayan, A.; Xu, A. (2006). Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs. In Cement and Concrete Research (Vol. 36, Issue 3, pp. 457–468). Elsevier BV. [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B. (2022). Effect of recycled waste glass on the properties of high-performance concrete: A critical review. In Case Studies in Construction Materials (Vol. 17, p. e01149). Elsevier BV. [CrossRef]

- Sharifi, Y.; Houshiar, M.; Aghebati, B. (2013). Recycled glass replacement as fine aggregate in self-compacting concrete. In Frontiers of Structural and Civil Engineering (Vol. 7, Issue 4, pp. 419–428). Springer Science and Business Media LLC. [CrossRef]

- Kou, S.C.; Poon, C.S. (2009). Properties of self-compacting concrete prepared with recycled glass aggregate. In Cement and Concrete Composites (Vol. 31, Issue 2, pp. 107–113). Elsevier BV. [CrossRef]

- Shiva Srikanth, K.; Lalitha, G. (2022). Durability properties of self-compacting concrete partial replacement of fine aggregate with waste crushed glass. In Materials Today: Proceedings (Vol. 51, pp. 2411–2416). Elsevier BV. [CrossRef]

- Singh, H.; Siddique, R. (2022). Utilization of crushed recycled glass and metakaolin for the development of self-compacting concrete. In Construction and Building Materials (Vol. 348, p. 128659). Elsevier BV. [CrossRef]

- Ketov, A.; Rudakova, L.; Vaisman, I.; Ketov, I.; Haritonovs, V.; Sahmenko, G. (2021). Recycling of rice husks ash for the preparation of resistant, lightweight and environment-friendly fired bricks. In Construction and Building Materials (Vol. 302, p. 124385). Elsevier BV. [CrossRef]

- Mohamed, H.A. (2011). Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. In Ain Shams Engineering Journal (Vol. 2, Issue 2, pp. 79–86). Elsevier BV. [CrossRef]

- ASTM C33 (2011). Specification for Concrete Aggregates. ASTM International. [CrossRef]

- ECP 203 (2020), "Egyptian Code of Practice for Reinforced Concrete Design and Construction ECP-203-2020", ECP, Egypt, (2020).

- BS 882 (1992). Specification for Aggregates from Natural Resources for Concrete.

- ASTM C494 / C494M (2019). Specification for Chemical Admixtures for Concrete. ASTM International. [CrossRef]

- ASTM C1017 / C1017M (2013), Standard Specification for Chemical Admixtures for Use in Producing Flowing Concrete, ASTM International, West Conshohocken, PA, 2013.

- ASTM C1611 (2021). Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International. [CrossRef]

- ASTM C1621 (2017). Test Method for Passing Ability of Self-Consolidating Concrete by J-Ring. ASTM International. [CrossRef]

- EN 12350-9 (2010) Testing Fresh Concrete—Part 9: Self-Compacting Concrete—V-Funnel Test.

- EN 12350-9 (2010) Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L-box Test.

- Ali, E.E.; Al-Tersawy, S.H. (2012). Recycled glass as a partial replacement for fine aggregate in self-compacting concrete. In Construction and Building Materials (Vol. 35, pp. 785–791). Elsevier BV. [CrossRef]

- Hesami, S.; Salehi Hikouei, I.; Emadi, S.A. A. (2016). Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. In Journal of Cleaner Production (Vol. 133, pp. 228–234). Elsevier BV. [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Manso, J.M.; Ortega-López, V. (2020). Self-compacting concrete manufactured with recycled concrete aggregate: An overview. In Journal of Cleaner Production (Vol. 262, p. 121362). Elsevier BV. [CrossRef]

- Tang, W.C.; Ryan, P.C.; Cui, H.Z.; Liao, W. (2016). Properties of Self-Compacting Concrete with Recycled Coarse Aggregate. In Advances in Materials Science and Engineering (Vol. 2016, pp. 1–11). Hindawi Limited. [CrossRef]

- Jassam, S.H.; Qasim, O.A.; Maula, B.H. (2022). Impact of Glass on Concrete Properties as Substitution of Aggregate. In Key Engineering Materials (Vol. 929, pp. 155–165). Trans Tech Publications, Ltd. [CrossRef]

| Mix Code | Designation | Water (kg/ m3) |

Cement (kg/m3) |

CWP. (kg/m3) |

CA. (kg/m3) |

FA. (kg/m3) |

RG. (kg/m3) |

|---|---|---|---|---|---|---|---|

| Control | 100% C + 100% FA | 231 | 550 | - | 612 | 909 | 0 |

| Mix 1 | 20% CWP + 5% RG | 231 | 440 | 110 | 612 | 863.55 | 45.45 |

| Mix 2 | 20% CWP + 15% RG | 231 | 440 | 110 | 612 | 772.65 | 136.35 |

| Mix 3 | 15% CWP + 10% RG | 231 | 467.5 | 82.5 | 612 | 818.1 | 90.9 |

| Mix 4 | 25% CWP + 10% RG | 231 | 412.5 | 137.5 | 306 | 818.1 | 90.9 |

| CWP: Ceramic Waste Powder; CA: Coarse Aggregate; FA: Fine Aggregate; RG: Recycled Glass | |||||||

| Materials | Cement | Ceramic powder (CWP.) | Glass (RG.) |

|---|---|---|---|

| SiO2 | 25.3 | 63.9 | 81.98 |

| Al2O3 | 6.64 | 18.29 | 0.86 |

| Fe2O3 | 6.68 | 4.32 | 0.23 |

| CaO | 58.44 | 4.46 | 10.67 |

| MgO | 2.29 | 0.72 | 5.63 |

| P2O5 | 0 | 0.16 | 0.12 |

| K2O | 0.25 | 2.18 | 0.23 |

| Na2O | 0.66 | 0.75 | - |

| SO3 | 2.04 | 0.1 | 0.19 |

| Cl | 0.06 | 0.005 | - |

| TiO2 | - | 0.61 | - |

| SrO2 | - | 0.02 | - |

| Mn2O3 | - | 0.05 | - |

| LOI | 4 | 1.61 | - |

| The rheological test | Units | Limits | |

|---|---|---|---|

| Min. | Max. | ||

| Slump Flow (diameter) | mm | 600 | 800 |

| Time for reaching slump flow with a diameter of 500 mm (T50 cm) | sec. | 2 | 5 |

| J-ring slump flow (diameter) | mm | 0 | 20 |

| V-funnel after immediate mixing (to) | sec | 6 | 12 |

| V-funnel after 5 minutes from mixing (t5min.) | sec | to | to + 3 |

| L-box (H2/H1) | ratio | 0.80 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).