Submitted:

19 November 2023

Posted:

20 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

2.1. Materials

2.2. Mix Design and Mixing Procedure

2.3. Testing

3. Results and Discussion

3.1. Rheological Properties

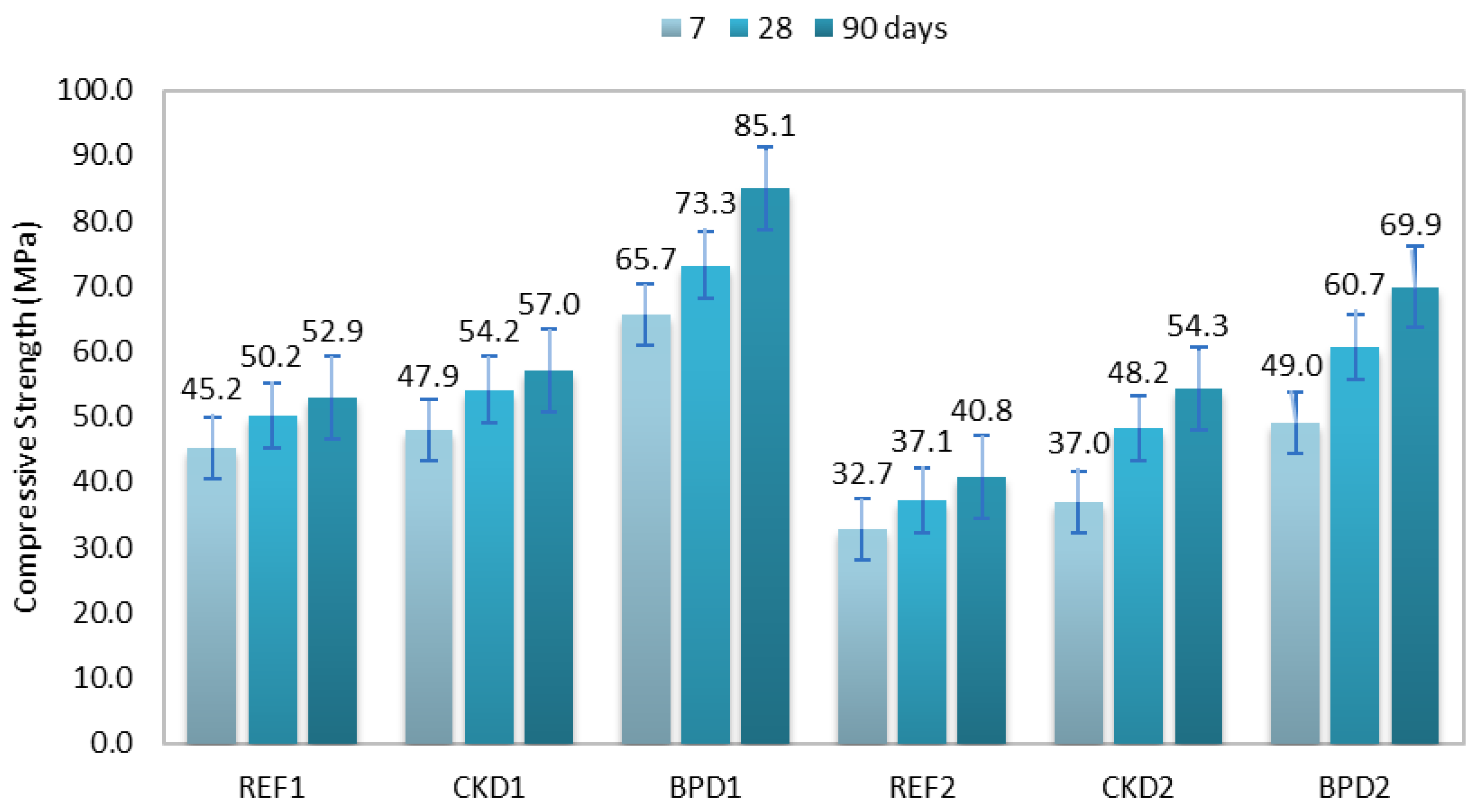

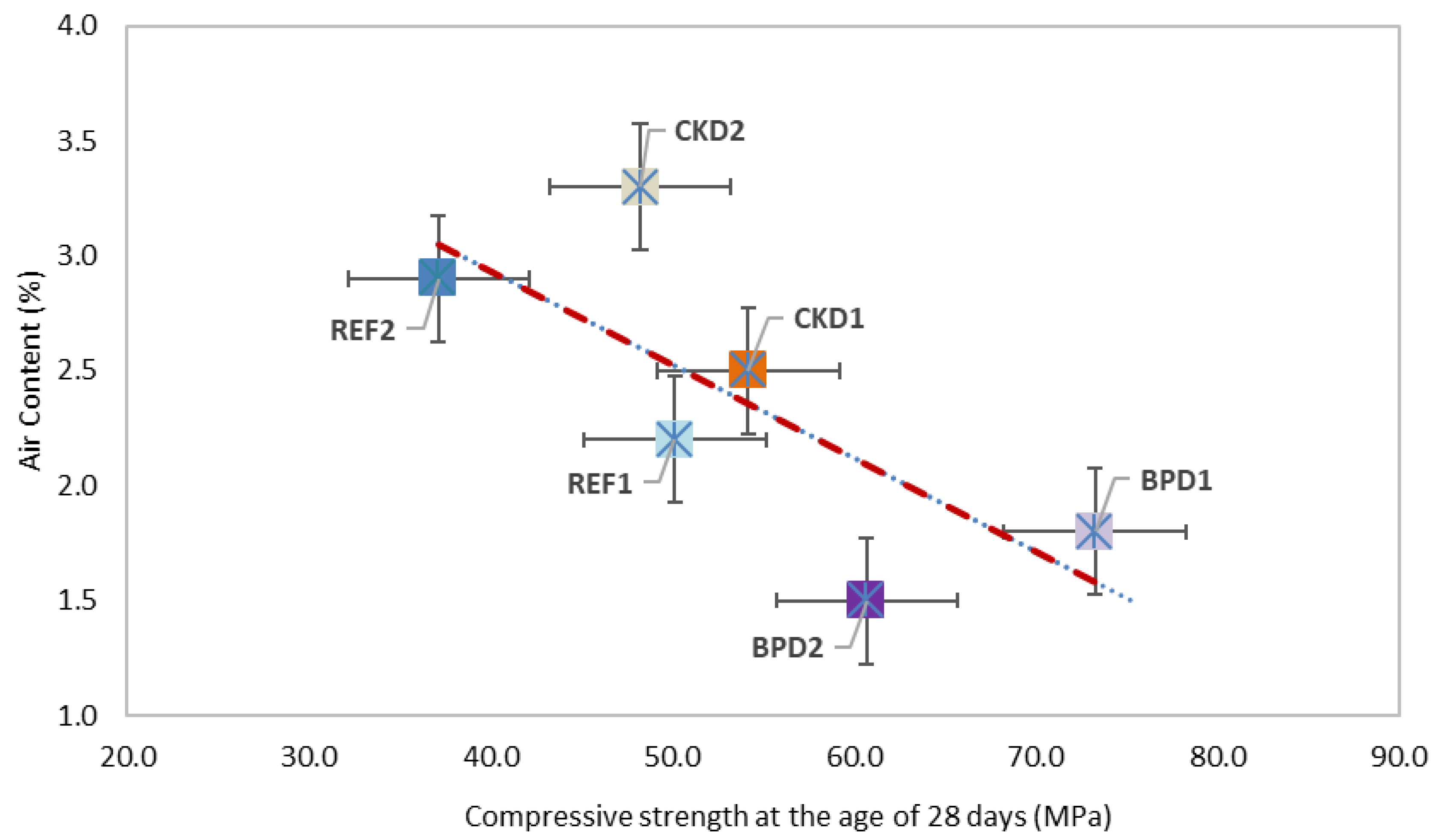

3.2. Compressive Strength

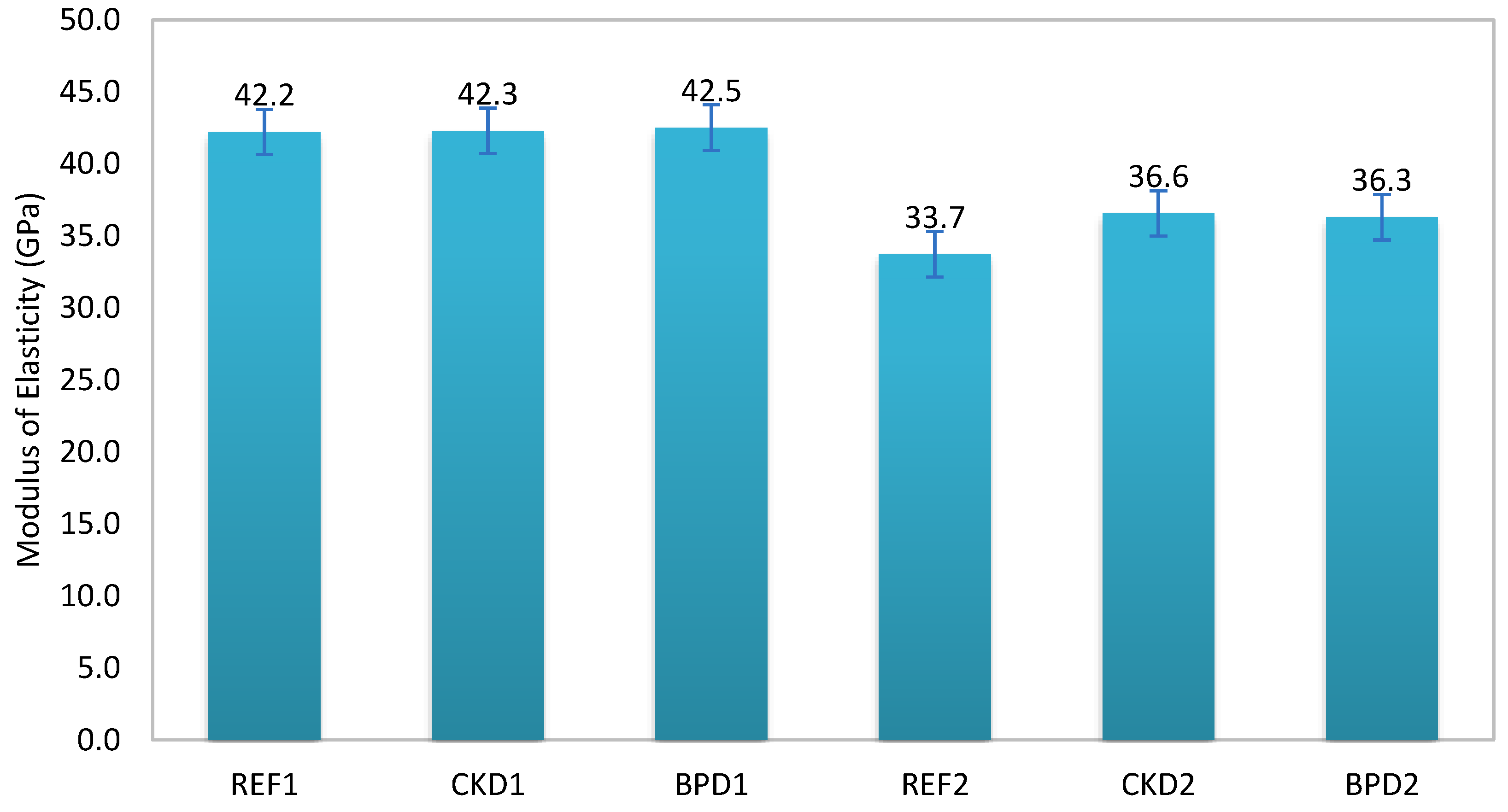

3.3. Modulus of Elasticity

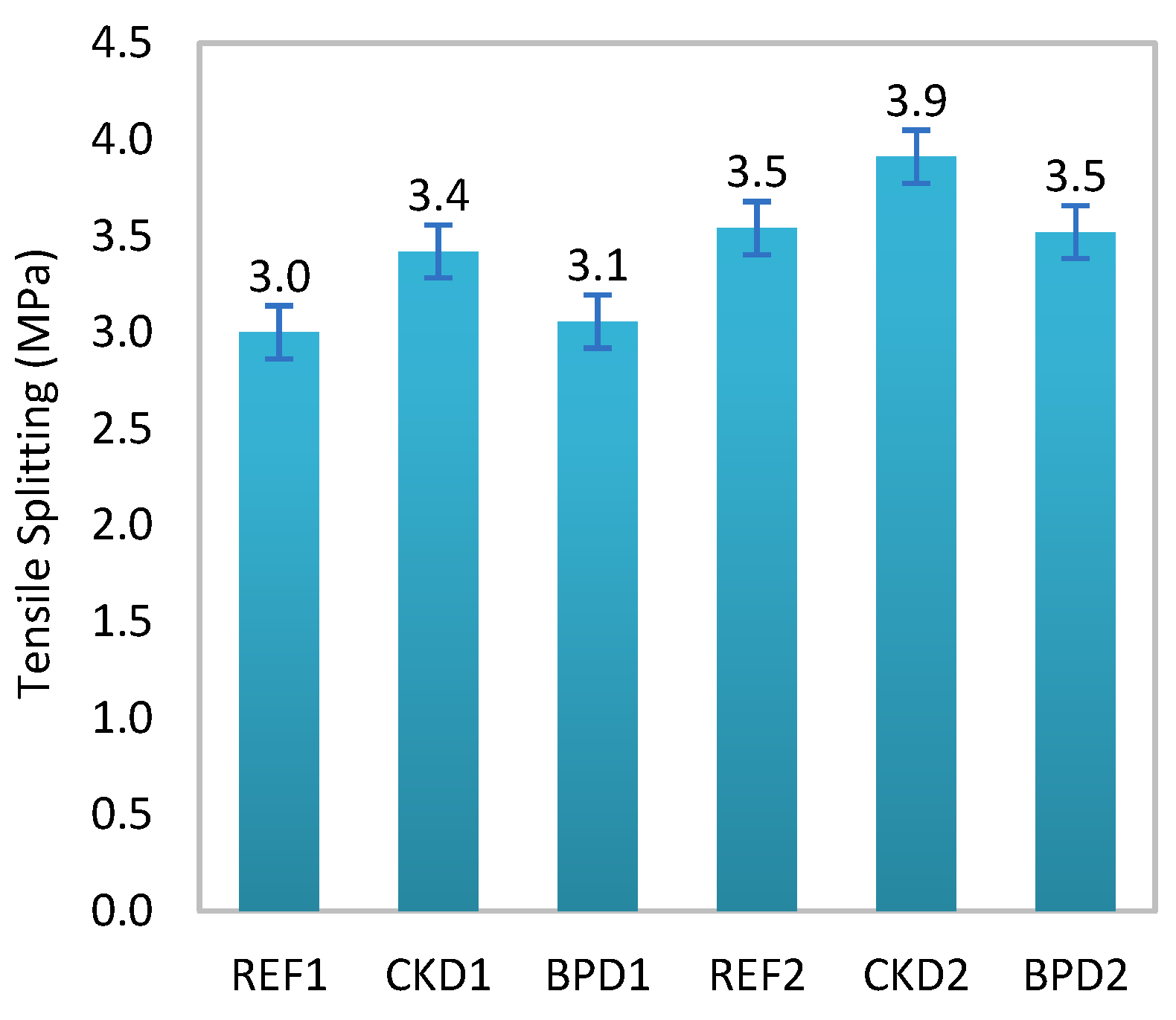

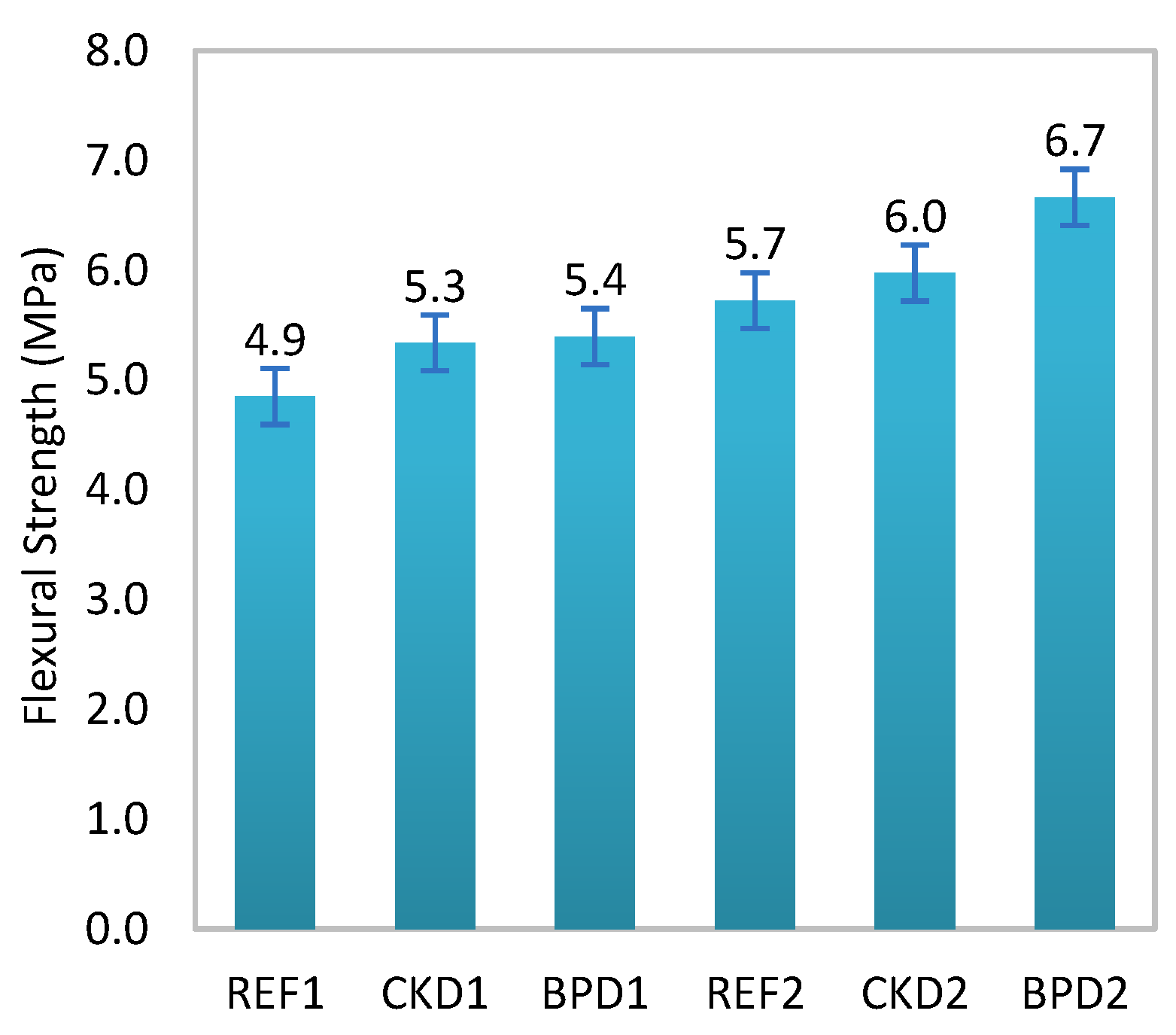

3.4. Tensile Splitting and Flexural Strength

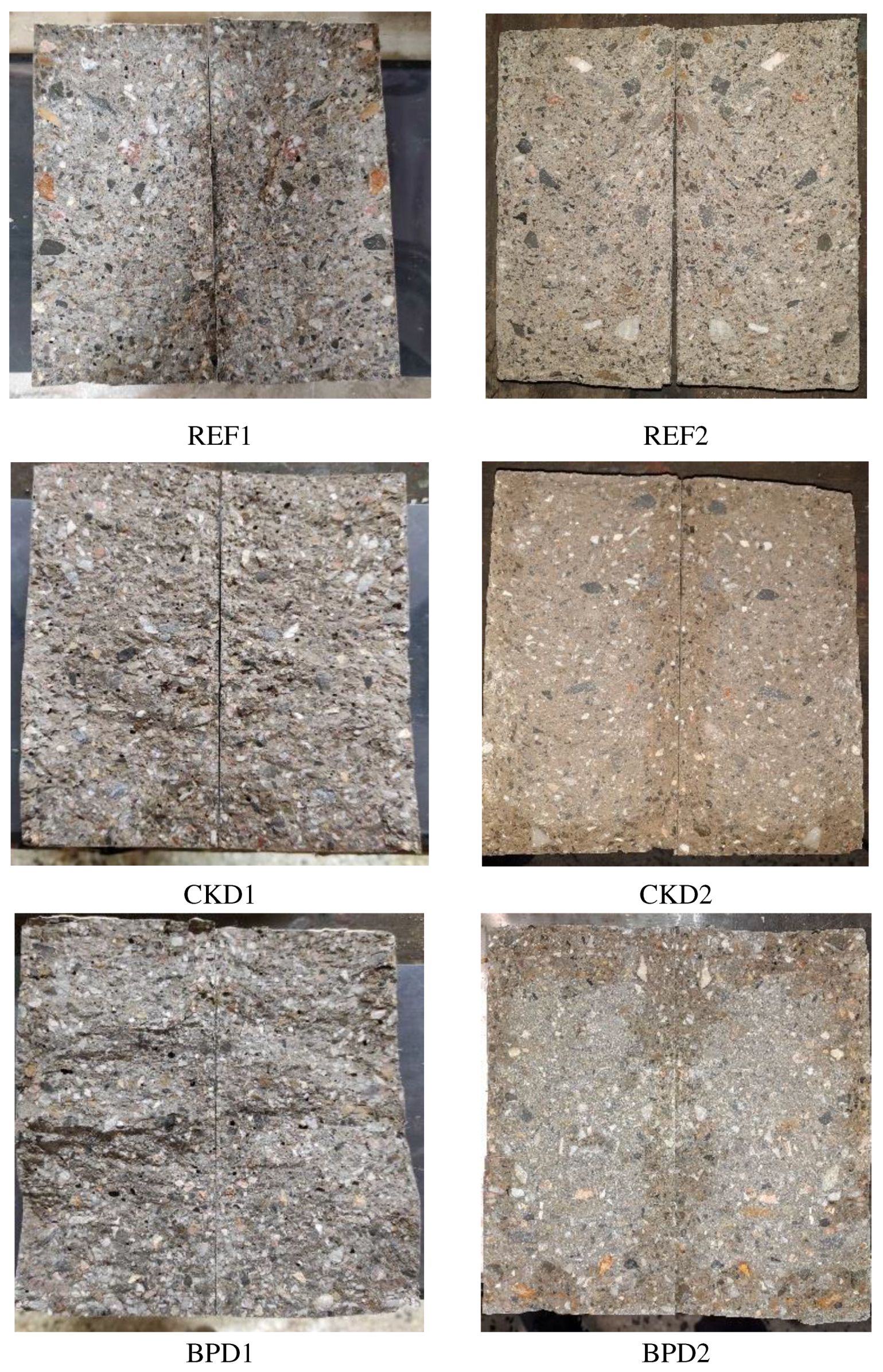

3.5. Hardened Visual Stability Index

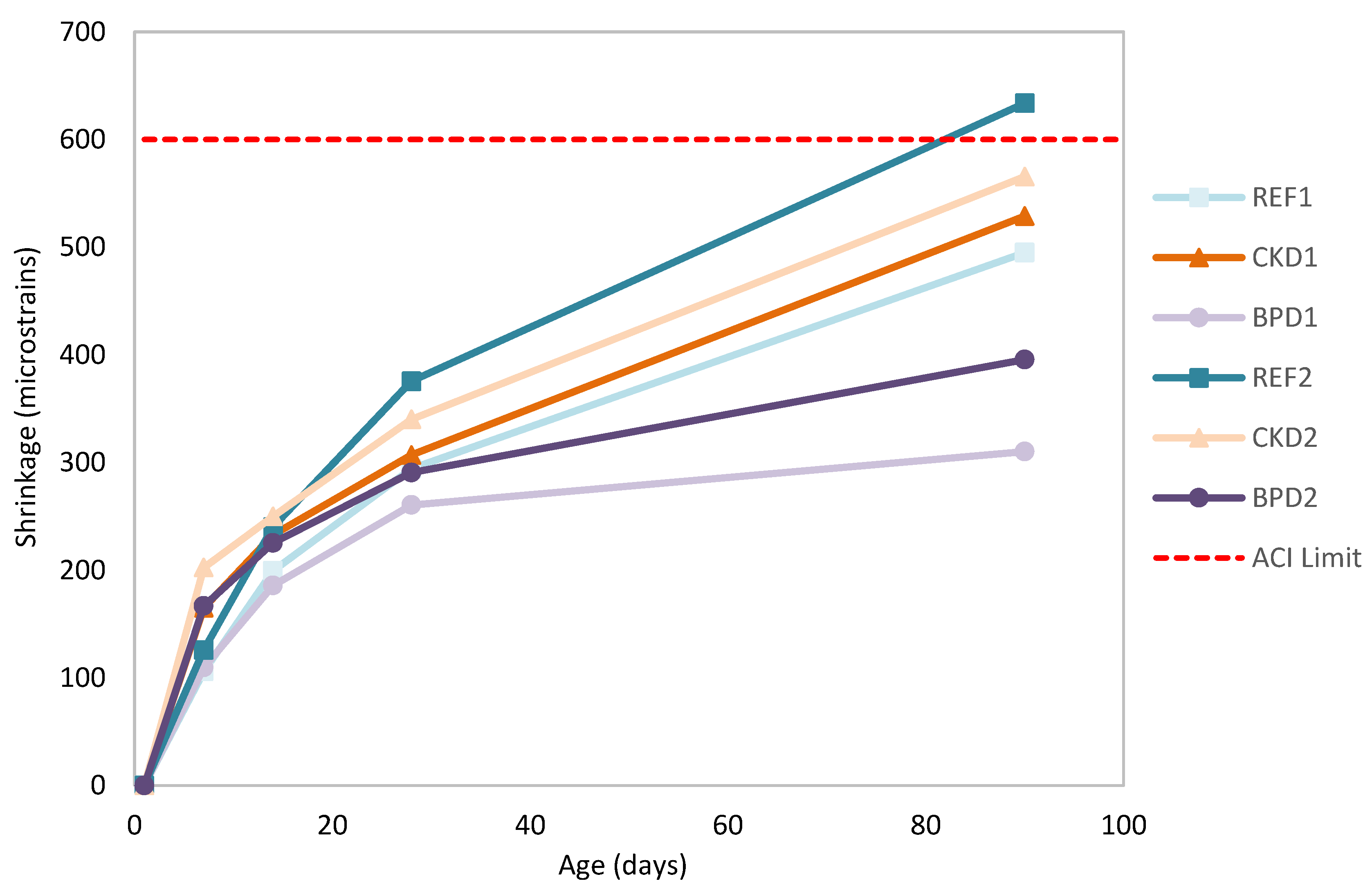

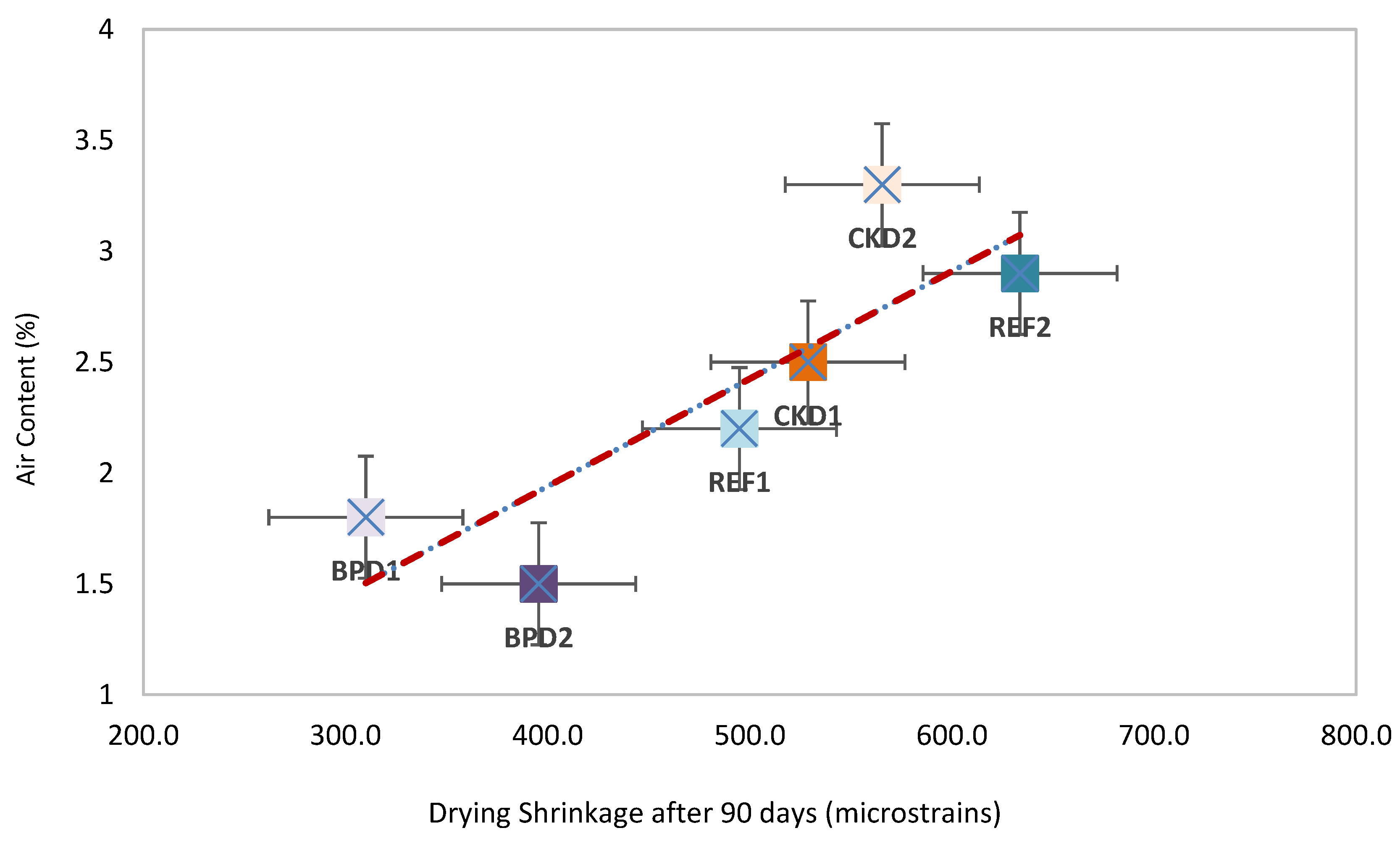

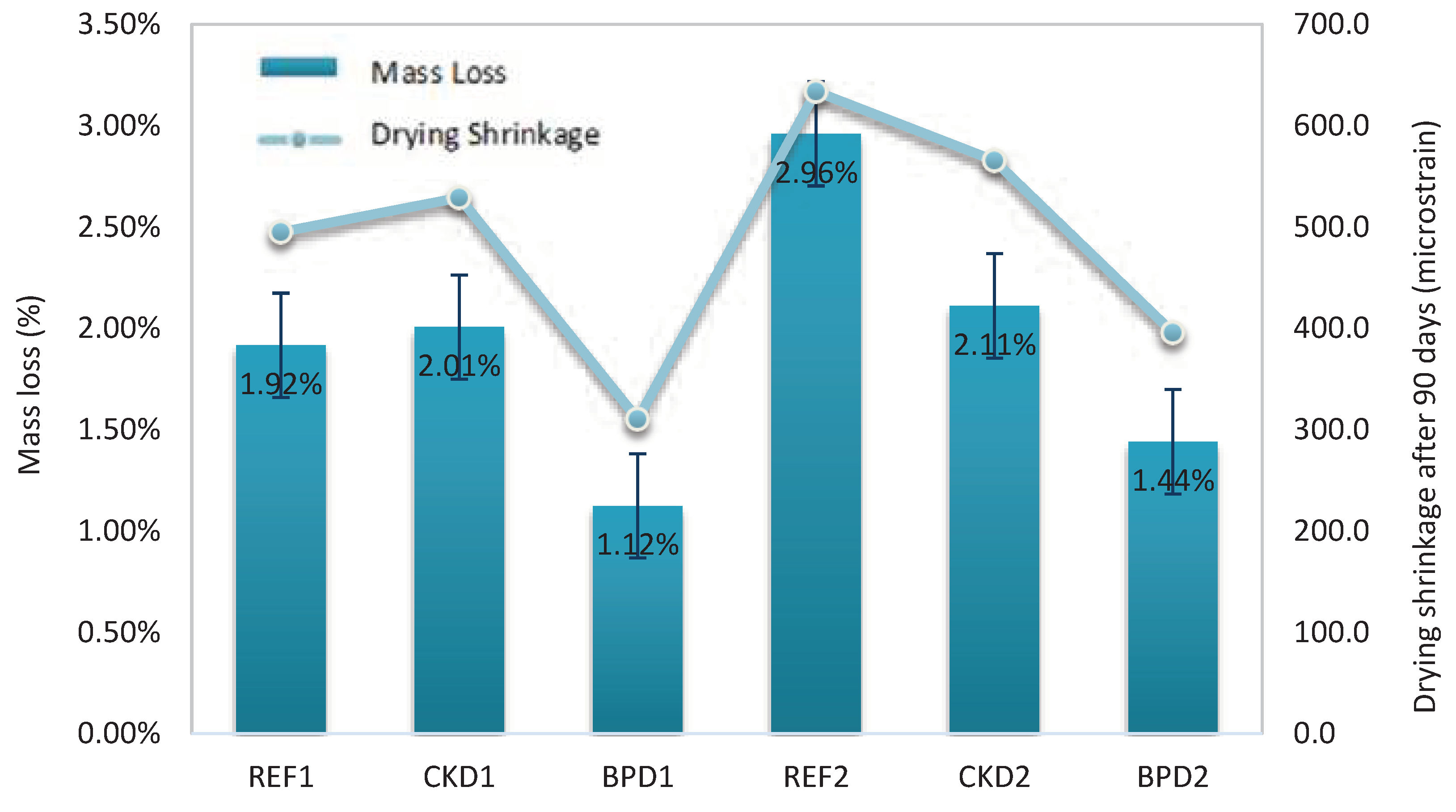

3.6. Drying Shrinkage

4. Conclusions

- BPD is appropriate as a reactive alternative waste material, as it contributes to the development of excellent mechanical properties at any testing age with a low drying shrinkage. The compressive strength was at least 50% higher than the corresponding strength of the reference compositions, and the drying shrinkage approximately 50% lower.

- BPD incorporation in the designed proportion increases the viscosity, creating a potential barrier for those applications that require low-viscosity SCCs, while a higher SP dosage is also required to reach an equal yield stress to other compositions. Specific investigation and parametric analysis will disclose the effect of BPD on the rheological behaviour of SCC and define its finest content for optimal performance.

- The addition of CKD to the SCC constitutes a potential sustainable solution as it improves the compressive strength, drying shrinkage, and substantially improves the tensile strength by almost 15%.

- At the same time, by partially replacing MP with CKD, more than acceptable rheological properties are acquired, achieving the desirable slump flow with 20-30% less SP than BPD.

- Testing the durability (e.g., chloride diffusion, water permeability carbonation resistance, corrosion resistance, etc.) of SCCs containing the alternative fillers that were studied in this work, is a critical topic of high interest for future research due to the presence of alkalies, sulphates and chlorides in their chemical composition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khayat, K.; Schutter, G. De. State-of-the-Art Report on the Mechanical Properties of Self-Compacting Concrete (SCC); 2014.

- Shi, C.; Wu, Z.; Lv, K.; Wu, L. A Review on Mixture Design Methods for Self-Compacting Concrete. Constr. Build. Mater. 2015, 84, 387–398. [Google Scholar] [CrossRef]

- The European Project Group. The European Guidelines for Self-Compacting Concrete. Eur. Guidel. Self Compact. Concr. 2005, No. May, 63.

- Ting, T.Z.H.; Rahman, M.E.; Lau, H.H.; Ting, M.Z.Y. Recent Development and Perspective of Lightweight Aggregates Based Self-Compacting Concrete. Constr. Build. Mater. 2019, 201, 763–777. [Google Scholar] [CrossRef]

- Łaźniewska-Piekarczyk, B. The Influence of Admixtures Type on the Air-Voids Parameters of Non-Air-Entrained and Air-Entrained High Performance SCC. Constr. Build. Mater. 2013, 41, 109–124. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Abd Elmoaty, A.E.M.; Mohamed, B. Effect of Filler Types on Physical, Mechanical and Microstructure of Self Compacting Concrete and Flow-Able Concrete. Alexandria Eng. J. 2014, 53(2), 295–307. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R.; Belarbi, R. Sustainable and Greener Self-Compacting Concrete Incorporating Industrial By-Products: A Review. J. Clean. Prod. 2021, 284. [Google Scholar] [CrossRef]

- Meko, B.; Ighalo, J.O.; Ofuyatan, O.M. Enhancement of Self-Compactability of Fresh Self-Compacting Concrete: A Review. Clean. Mater. 2021, 1, 100019. [Google Scholar] [CrossRef]

- Benjeddou, O.; Soussi, C.; Jedidi, M.; Benali, M. Experimental and Theoretical Study of the Effect of the Particle Size of Limestone Fillers on the Rheology of Self-Compacting Concrete. J. Build. Eng. 2017, 10, 32–41. [Google Scholar] [CrossRef]

- Siddique, R.; Kunal; Mehta, A. Utilization of Industrial By-Products and Natural Ashes in Mortar and Concrete Development of Sustainable Construction Materials; Elsevier Ltd, 2019. [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A Review on Effects of Limestone Powder on the Properties of Concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Sfikas, I.P.; Badogiannis, E.G.; Trezos, K.G. Rheology and Mechanical Characteristics of Self-Compacting Concrete Mixtures Containing Metakaolin. Constr. Build. Mater. 2014, 64, 121–129. [Google Scholar] [CrossRef]

- Abukhashaba, M.I.; Mostafa, M.A.; Adam, I.A. Behavior of Self-Compacting Fiber Reinforced Concrete Containing Cement Kiln Dust. Alexandria Eng. J. 2014, 53(2), 341–354. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of Cement Kiln Dust (CKD) in Cement Mortar and Concrete-an Overview. Resour. Conserv. Recycl. 2006, 48(4), 315–338. [Google Scholar] [CrossRef]

- Bagheri, S.M.; Koushkbaghi, M.; Mohseni, E.; Koushkbaghi, S.; Tahmouresi, B. Evaluation of Environment and Economy Viable Recycling Cement Kiln Dust for Use in Green Concrete. J. Build. Eng. 2020, 32, 101809. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Al-Amoudi, O.S.B.; Rahman, M.K.; Ali, M.R.; Barry, M.S. Properties of Cement Kiln Dust Concrete. Constr. Build. Mater. 2009, 23(6), 2357–2361. [Google Scholar] [CrossRef]

- Najim, K.B.; Mahmod, Z.S.; Atea, A.K.M. Experimental Investigation on Using Cement Kiln Dust (CKD) as a Cement Replacement Material in Producing Modified Cement Mortar. Constr. Build. Mater. 2014, 55, 5–12. [Google Scholar] [CrossRef]

- Rodríguez Viacava, I.; Aguado De Cea, A.; Rodríguez De Sensale, G. Self-Compacting Concrete of Medium Characteristic Strength. Constr. Build. Mater. 2012, 30, 776–782. [Google Scholar] [CrossRef]

- Ashteyat, A.M.; Haddad, R.H.; Obaidat, Y.T. Case Study on Production of Self Compacting Concrete Using White Cement by Pass Dust. Case Stud. Constr. Mater. 2018, 9, e00190. [Google Scholar] [CrossRef]

- EN 12620:2013, “Aggregates for Concrete”, 2013.

- EN 197-1:2011, “Cement. Composition, Specifications and Conformity Criteria for Common Cements”, 2011.

- ΕΝ 934-2:2009, “Admixtures for Concrete, Mortar and Grout - Concrete Admixtures. Definitions, Requirements, Conformity, Marking and Labelling”, 2009.

- Kounadis, A.; Badogiannis, E.G.; Retsa, N.; Angelopoulos, P.M.; Marinos, I. Hydration Heat, Rheology and Strength of Self-Compacting Sustainable Mortars Containing Alternative Filler Materials. J. Mater. Civ. Eng. 2022, 34(2021), 1–10. [Google Scholar] [CrossRef]

- EN 12350-8:2010, “Testing Fresh Concrete – Part 8: Slump-Flow Test”, 2010.

- EN 12350-9:2010, “Testing Fresh Concrete – Part 9: V-Funnel Test”, 2010.

- EN 12350-11:2010, “Testing Fresh Concrete – Part 11: Sieve Segregation Test”, 2010.

- EN 12350-10:2010, “Testing Fresh Concrete – Part 10: L Box Test”, 2010.

- UNI 11044:2003, “Testing Fresh Self Compacting Concrete - Determination of Confined Flowability in U-Shape Box”, 2003.

- EN 12350-6:2009, “Testing Fresh Concrete – Part 6: Density”, 2009.

- EN 12350-7:2009, “Testing Fresh Concrete – Part 7: Air Content – Pressure Methods”, 2009.

- EN 12390-3:2009, “Testing Hardened Concrete – Part 3: Compressive Strength of Test Specimens”, 2009.

- EN 12390-6:2010, “Testing Hardened Concrete - Part 6: Tensile Splitting Strength of Test Specimens”, 2010.

- ASTM C469 / C469M-14e1, Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression, ASTM International, West Conshohocken, PA, 2014, Www.Astm.Org.

- Illinois Test Procedure SCC-6, Standard Test Method for Static Segregation of Hardened Self-Consolidating Concrete Cylinders.

- EN 12390-16:2019, “Testing Hardened Concrete - Part 16: Determination of the Shrinkage of Concrete”, 2019.

- EN 12390-5:2009, “Testing Hardened Concrete - Part 5: Flexural Strength of Test Specimens”, 2009.

- Tzouvalas, G.; Dermatas, N.; Tsimas, S. Alternative Calcium Sulfate-Bearing Materials as Cement Retarders: Part I. Anhydrite. Cem. Concr. Res. 2004, 34(11), 2113–2118. [Google Scholar] [CrossRef]

- Shoaib, M.M.; Balaha, M.M.; Abdel-Rahman, A.G. Influence of Cement Kiln Dust Substitution on the Mechanical Properties of Concrete. Cem. Concr. Res. 2000, 30(3), 371–377. [Google Scholar] [CrossRef]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G. Limestone Addition Effects on Concrete Porosity. Cem. Concr. Compos. 2016, 72, 222–234. [Google Scholar] [CrossRef]

- Siddique, R.; Gupta, N. Limestone Dust; 2021. [CrossRef]

- Lea, F.M. The Chemistry of Cement and Concrete. Edward Arnold Ltd: London 1970, p 1092.

- Singh, N.B.; Bhattacharjee, K.N.; Shukla, A.K. Effect of Alkali Bypass Dust on the Hydration of Granulated Blast Furnace Slag Blended Cement. Cem. Concr. Res. 1995, 25(4), 883–892. [Google Scholar] [CrossRef]

- Mehta; Kumar, P.; and Monteiro P.J.M. Concrete: Microstructure, Properties, and Materials. 4th Ed. New York: McGraw-Hill Education. 2014.

- ACI 224R-01, “Control of Cracking in Concrete Structures”, 2001.

- Abdalhmid, J.M.; Ashour, A.F.; Sheehan, T. Long-Term Drying Shrinkage of Self-Compacting Concrete: Experimental and Analytical Investigations. Constr. Build. Mater. 2019, 202, 825–837. [Google Scholar] [CrossRef]

- Choudhary, R.; Gupta, R.; Alomayri, T.; Jain, A.; Nagar, R. Permeation, Corrosion, and Drying Shrinkage Assessment of Self-Compacting High Strength Concrete Comprising Waste Marble Slurry and Fly Ash, with Silica Fume. Structures 2021, 33, 971–985. [Google Scholar] [CrossRef]

- Valcuende, M.; Marco, E.; Parra, C.; Serna, P. Influence of Limestone Filler and Viscosity-Modifying Admixture on the Shrinkage of Self-Compacting Concrete. Cem. Concr. Res. 2012, 42(4), 583–592. [Google Scholar] [CrossRef]

- Sardinha, M.; de Brito, J.; Rodrigues, R. Durability Properties of Structural Concrete Containing Very Fine Aggregates of Marble Sludge. Constr. Build. Mater. 2016, 119, 45–52. [Google Scholar] [CrossRef]

- Piasta, W.; Sikora, H. Effect of Air Entrainment on Shrinkage of Blended Cements Concretes. Constr. Build. Mater. 2015, 99, 298–307. [Google Scholar] [CrossRef]

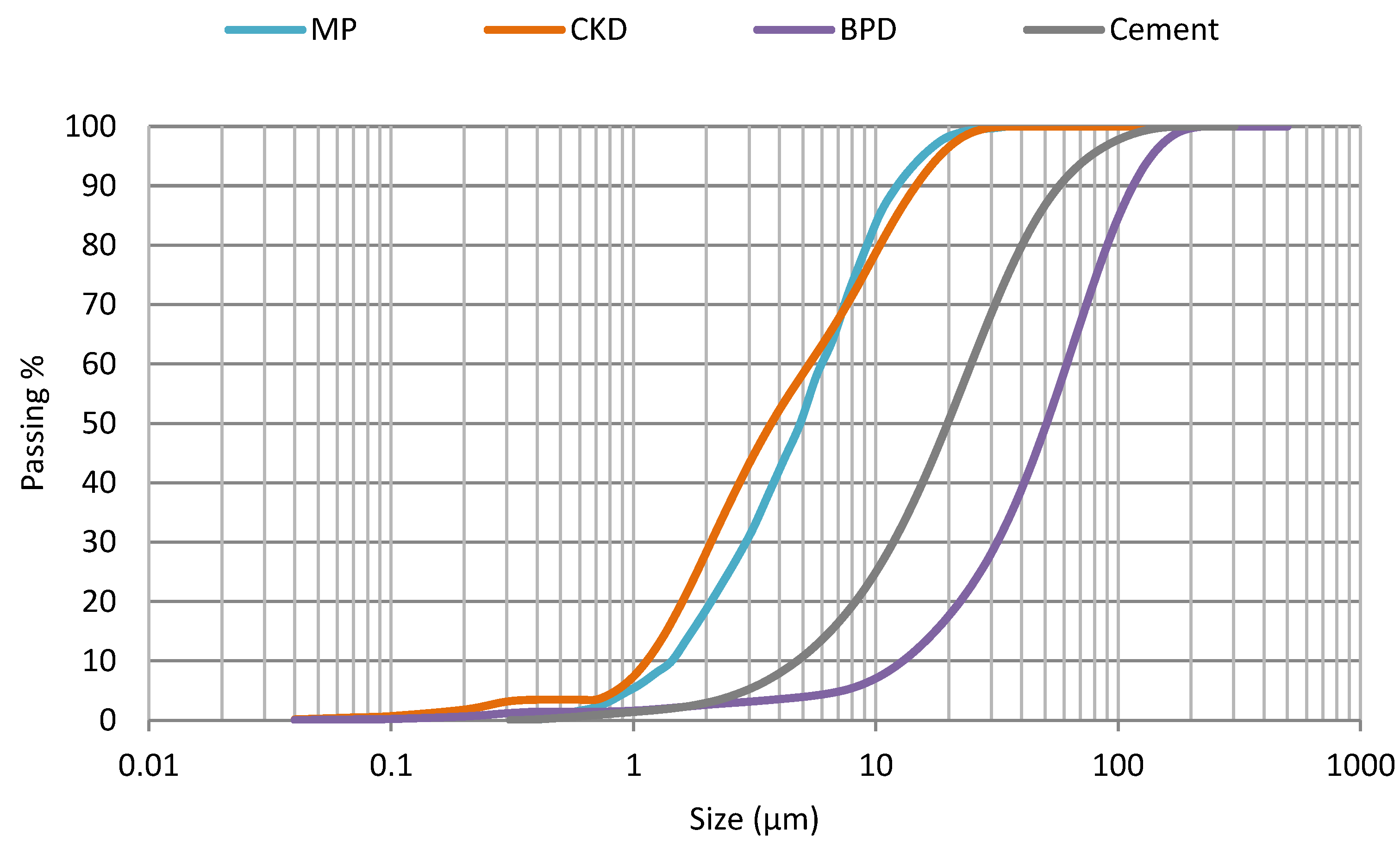

| Properties and size characteristics | Cement | MP | CKD | BPD |

|---|---|---|---|---|

| Specific Gravity (kg/m3) | 3150 | 2700 | 2700 | 2800 |

| Specific Surface Area (cm2/g) | 3470 | 12700 | 25000 | 5000 |

| d10 (μm) | 4.74 | 1.44 | 1.13 | 12.95 |

| d50 (μm) | 19.82 | 4.88 | 3.71 | 50.72 |

| d90 (μm) | 57.41 | 12.27 | 14.66 | 115.63 |

| Compound (%) | Cement | MP | CKD | BPD |

|---|---|---|---|---|

| SiO2 | 19.02 | 0.35 | 10.18 | 19.39 |

| Al2O3 | 4.59 | - | 3.64 | 5.13 |

| Fe2O3 | 3.63 | 0.07 | 2.06 | 3.46 |

| CaO | 63.43 | 55.41 | 43.53 | 52.73 |

| MgO | 2.02 | 0.76 | 1.31 | 2.22 |

| MnO | - | 0.01 | - | - |

| SO3 | 3.48 | - | 1.18 | 6.73 |

| K2O | 0.47 | - | 1.71 | 4.84 |

| Na2O | 0.28 | - | 0.37 | 0.46 |

| P2O5 | 0.17 | - | - | - |

| TiO2 | 0.28 | - | - | - |

| Cl | - | - | 0.35 | 2.16 |

| Loss of Ignition (LOI) | 2.62 | 43.4 | 35.65 | 2.88 |

| Mixture | Water | Cement | MP | CKD | BPD | Sand | g1 | g2 | w/c | w/p |

|---|---|---|---|---|---|---|---|---|---|---|

| REF1 | 180 | 300 | 200 | 0 | 0 | 900 | 560 | 240 | 0.60 | 0.36 |

| CKD1 | 180 | 300 | 100 | 100 | 0 | 900 | 560 | 240 | 0.60 | 0.36 |

| BPD1 | 180 | 300 | 100 | 0 | 100 | 900 | 560 | 240 | 0.60 | 0.36 |

| REF2 | 198 | 300 | 250 | 0 | 0 | 900 | 525 | 225 | 0.66 | 0.36 |

| CKD2 | 198 | 300 | 100 | 150 | 0 | 900 | 525 | 225 | 0.66 | 0.36 |

| BPD2 | 198 | 300 | 100 | 0 | 150 | 900 | 525 | 225 | 0.66 | 0.36 |

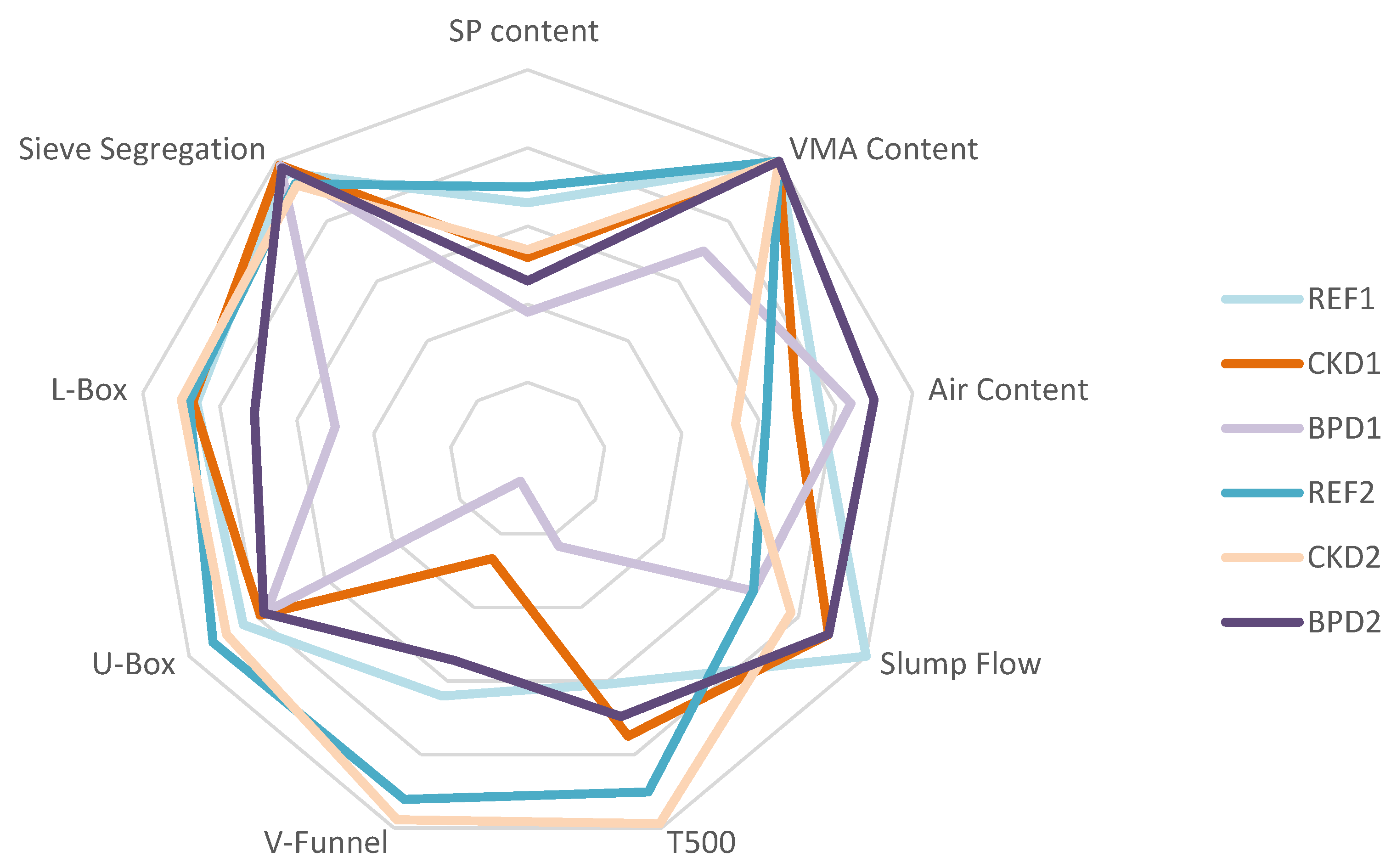

| SP/ Cement |

VMA/ Cement |

Unit Weight | Air Content |

Slump Flow | T500 | V-Funnel | U-Box | L-Box | Sieve Segregation |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Mixture | (%) | (%) | (kg/m3) | (%) | (mm) | (s) | (s) | - | - | (%) |

| REF1 | 1.7 | - | 2411 | 2.2 | 705 | 3.35 | 12.7 | 0.84 | 0.86 | 3.8 |

| CKD1 | 2.4 | - | 2365 | 2.5 | 700 | 2.50 | 22.8 | 0.79 | 0.87 | 1.3 |

| BPD1 | 3.1 | 0.3 | 2403 | 1.8 | 690 | 5.60 | 28.5 | 0.77 | 0.50 | 1.5 |

| REF2 | 1.5 | - | 2256 | 2.9 | 690 | 1.59 | 5.1 | 0.93 | 0.88 | 7.5 |

| CKD2 | 2.3 | - | 2264 | 3.3 | 695 | 1.07 | 3.6 | 0.89 | 0.90 | 8.0 |

| BPD2 | 2.7 | - | 2358 | 1.5 | 700 | 2.82 | 15.3 | 0.78 | 0.71 | 2.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).