I. Introduction

The frequent occurrence of extreme weather conditions worldwide and disasters such as earthquakes, floods and hurricanes pose a serious threat to the safety of human habitation. Traditional post-disaster temporary shelter construction relies on manual labor, which is limited by the complexity of the terrain, the shortage of construction resources, and the lack of response speed, making it difficult to meet the demand for large-scale emergency resettlement. Although construction robots can improve the construction efficiency, there are still bottlenecks in the adaptability to complex environments, material deposition accuracy and intelligent construction control. The application of drones combined with 3D printing technology in post-disaster construction provides a new path to enhance construction flexibility, optimize spatial structure design and reduce environmental load [

1]. Relying on the dynamic collaborative control of UAV swarms, rapid adaptation to complex terrain can be achieved, and combined with high-precision SLAM point cloud modeling and adaptive topology optimization algorithms, construction accuracy can be improved and material consumption can be reduced. The integrated BIM optimization engine and intelligent task scheduling system enable the construction of post-disaster shelters to shift from traditional rigid architecture to flexible and efficient mode, providing technical support for large-scale disaster response.

II. System Architecture Design

A. Overall Framework

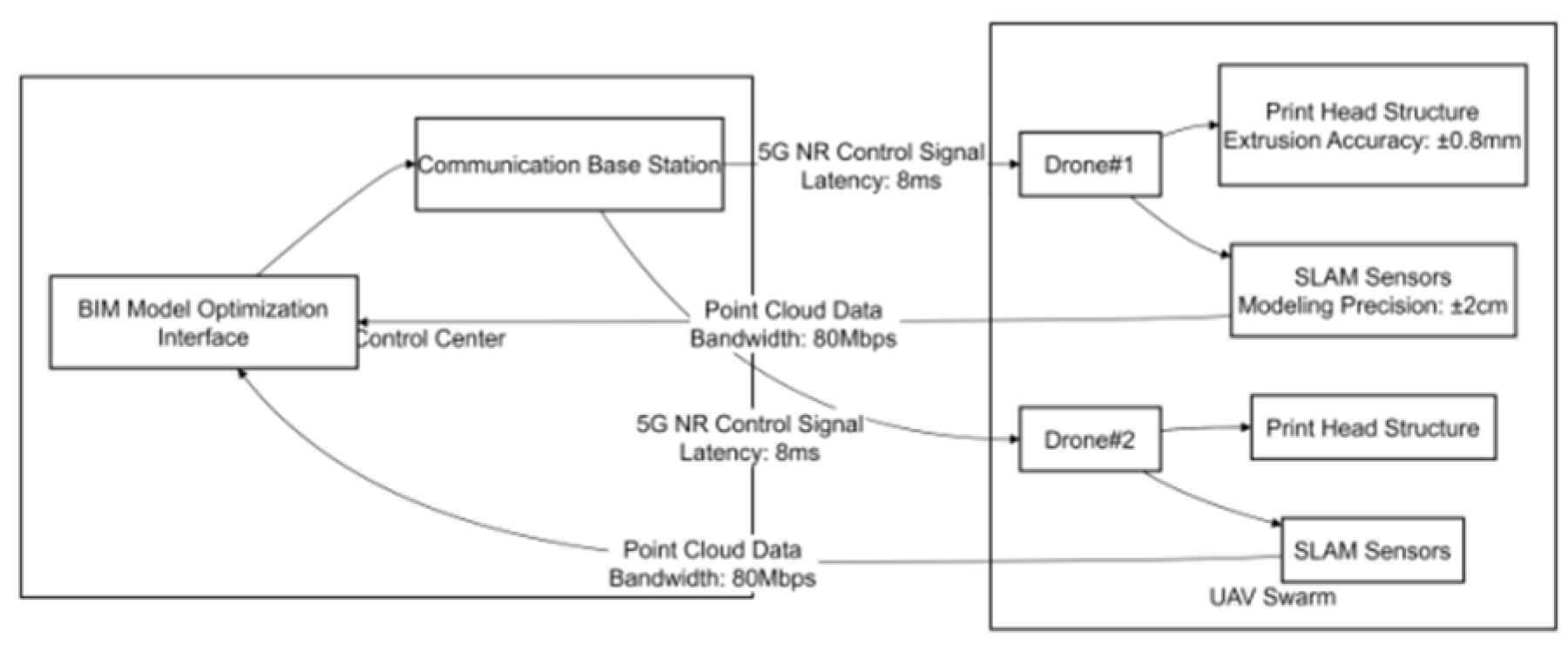

The system adopts an “air-ground synergy” architecture (

Figure 1), which consists of a distributed UAV construction unit and an intelligent ground control platform to form a closed-loop system. The airborne unit consists of a cluster of 4-8 customized six-rotor drones, each equipped with a lightweight screw extruder print head (maximum load of 12kg, extrusion accuracy ±0.8mm), which interacts with the ground control center via a 5G NR network in real-time with the terrain scanning data (SLAM modeling accuracy of ±2cm) and construction instructions. The ground platform integrates a BIM dynamic optimization engine to generate an adaptive structural topology based on real-time point cloud data and decompose it into a sequence of UAV-executable G-code paths [

2]. The key data streams include (i) LiDAR point cloud → Delaunay triangularized terrain model, (ii) finite element analysis results → material deposition density gradient parameters, and (iii) UAV state matrix → dynamic task reassignment strategy.

B. UAV Subsystem

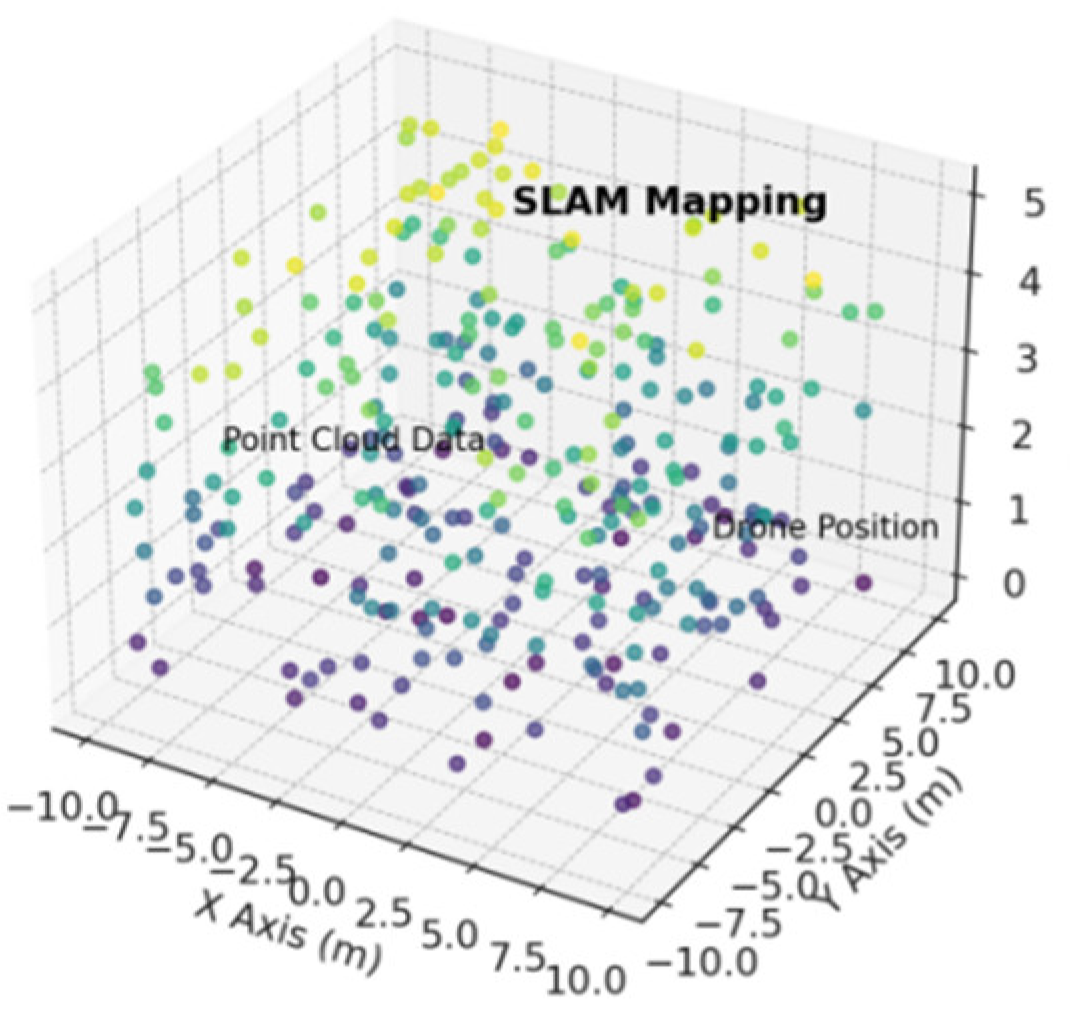

The UAV subsystem consists of multiple collaborative six-rotor UAVs, each of which carries a lightweight screw extruder print head with a maximum loading capacity of 12 kg and a material deposition accuracy of ±0.8 mm.To ensure the accuracy of aerial operations, the system adopts IMU+LIDAR+visual SLAM for high-precision localization, wherein the SLAM modeling accuracy can be up to ±2 cm to construct a construction site viewpoint in real time. cloud modeling (

Figure 2). The UAV swarm’s intelligent scheduling mechanism introduces a hybrid optimization strategy that combines reinforcement learning (RL) and dynamic task reassignment to ensure optimal performance in complex construction scenarios. Unlike traditional PID-based control strategies, the proposed method integrates a decentralized multi-agent reinforcement learning (MARL) framework. Each UAV acts as an intelligent agent, which continuously updates its behavior policy through interaction with the environment.The RL framework is trained using the proximal policy optimization (PPO) algorithm, where each UAV’s state space includes position, velocity, energy reserve, and task status. The reward function integrates construction efficiency, energy consumption, and collision avoidance performance. The dynamic task reassignment strategy is formulated as follows:[

3]:

where Ti is the task assigned to UAV i, Liis the path length, Vi is the flight speed, Ei is the remaining energy, and Pi is the power consumption. The coefficients α and β are dynamically adjusted using a gradient-based optimization strategy to balance between energy conservation and construction speed.

C. 3D Printing Material System

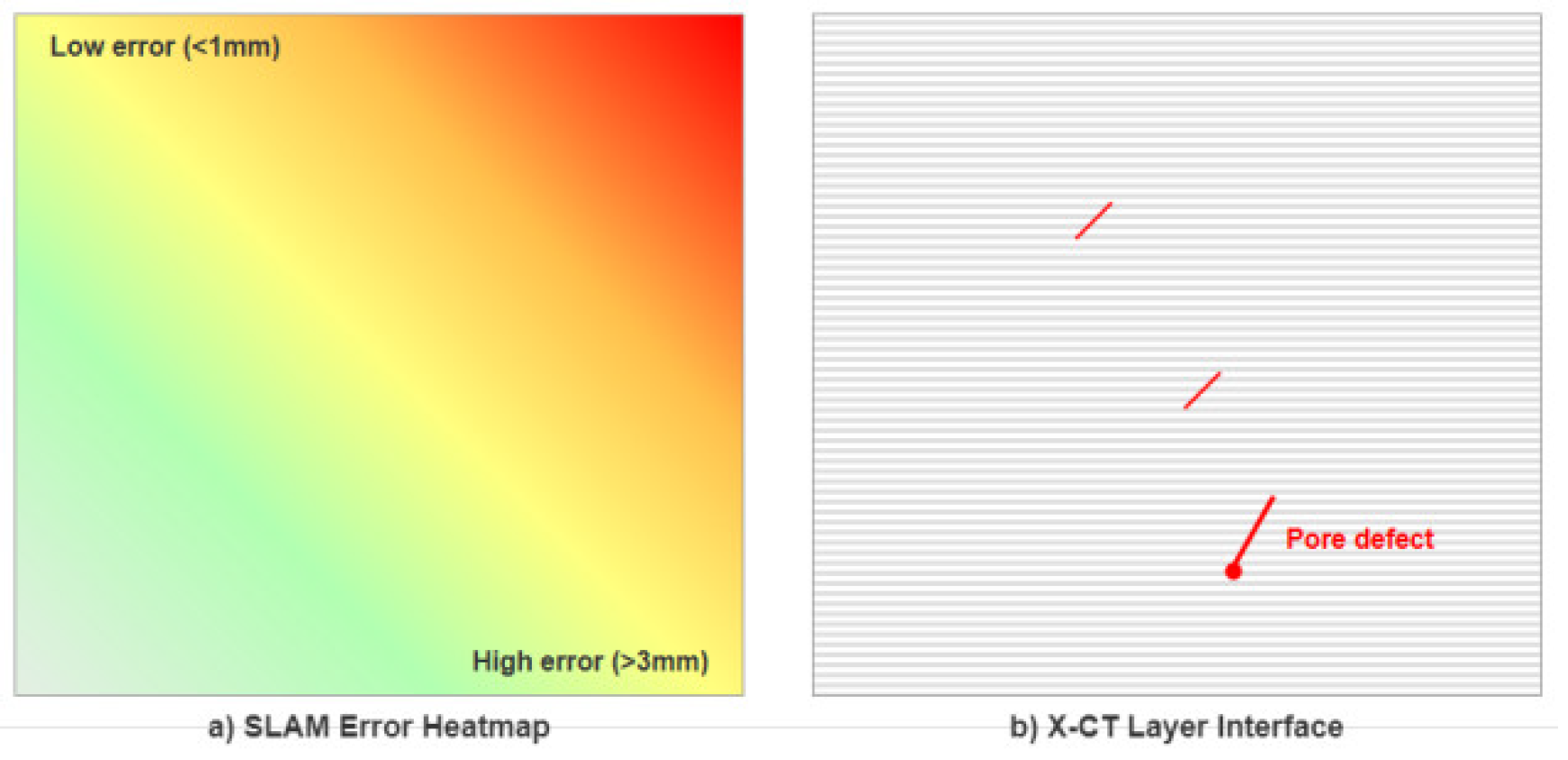

Highly rheological composite building materials were selected for the system, combining components such as bio-based polymers, fly ash-based polymers, and recycled construction waste, in order to improve the mechanical properties, environmental adaptability, and sustainability of the post-disaster shelter. The rheological properties of the materials determine the printing accuracy and interlayer bond strength (

Figure 3), and in order to ensure that the printed interlayer bond strength σc ≥ 1.2 MPa, the Bingham fluid model was used in the proportioning optimization process [

4]:

where τ is the shear stress, τ0 is the yield stress, ηp is the plastic viscosity, and γ˙ is the shear rate. Where plastic viscosity ηp = 50-80 Pa-s and yield stress τ0 = 150-250 Pa, the stable extrudability is maintained at an environment up to 40°C. In addition, based on finite element analysis (FEA), the material distribution of different wall structures (single shell, honeycomb-filled, and grid-supported) was optimized to improve the compressive strength and toughness of the material per unit mass. During the material deposition process, the viscosity decay rate is monitored online by a robot, and the extrusion rate Q is adjusted to match the set deposition thickness h, optimizing the construction efficiency and structural uniformity.

Figure 3 Multi-dimensional evaluation of structural performance.

III. Key Technology Realization

A. Dynamic Path Planning

The dynamic path planning system adopts a hybrid optimization strategy that integrates SLAM technology, Delaunay triangulation, and a genetic algorithm (GA) to enhance path efficiency and environmental adaptability in post-disaster construction scenarios. Unlike conventional A* algorithms, this approach introduces adaptive mutation mechanisms and elitism selection strategies to improve convergence rates and solution robustness. In this framework, each UAV’s path is encoded as a genetic sequence, where position coordinates, flight altitude, and energy consumption are key markers. The fitness function combines path deviation, energy consumption, and collision risk to ensure optimal trajectory planning, expressed as [

5]:

where D represents path deviation, EEE denotes total energy consumption, and CCC reflects obstacle collision risk. The weighting coefficients w1,w2,w3 are dynamically adjusted through reinforcement learning (RL) based on real-time environmental feedback. This adaptive control mechanism enables UAVs to modify their flight paths in response to sudden environmental changes such as wind turbulence, debris movement, or ground obstructions.

B. Airborne Deposition Control

In the UAV-3D printing system, the aerial deposition control is the key link to ensure the printing accuracy, interlayer bonding quality and structural stability. The system adopts a closed-loop control strategy, combining LiDAR altitude detection (error ≤ 2mm) and IMU inertial measurement unit to realize real-time fine-tuning of the UAV nozzle in a dynamic flight environment. The material extrusion rate Q needs to be matched with the flight speed V and the thickness h of the deposited layer to ensure uniform material deposition:

where w is the printing width. In addition, the system introduces finite element analysis (FEA) to calculate the structural stress distribution after layered deposition of different materials, optimize the printing sequence, and avoid deformation caused by local stress concentration.

IV. Implementation Process

A. Post-Disaster Rapid Response Process

The post-disaster rapid response process is realized through the closed loop of multimodal perception-decision-execution. First, the UAV cluster acquires the coordinates of the disaster area through the star-ground cooperative communication network (5G NR + LEO satellite), and completes the 0.5km² area scanning (resolution ≤ 5cm) by using the dual-frequency LIDAR (905nm/1550nm), and the SLAM modeling consumes ≤ 5 minutes. The ground platform is based on real-time point cloud data, generates topology optimized structure through improved RRT* algorithm, and completes printable path planning in 3 minutes by combining with BIM engine. The material transportation adopts a modular container system to prepare highly rheological composite materials on-site (the initial solidification time is regulated to 25±3 minutes), and the continuous supply of 12m³ printable materials per hour is realized through the linkage of distributed storage tanks and the UAV power exchange station. After the emergency construction is initiated, the UAV cluster executes the printing task in swarm collaboration mode, addressing key operational limitations. Each UAV has a 30-minute endurance and utilizes a power-swap automatic charging platform to reduce downtime, ensuring continuous operation with battery replacement within ≤60 seconds. To optimize material deposition, the bio-based polymer composite maintains a plastic viscosity ηp = 65 Pa-s and yield stress τ0 = 210 Pa, ensuring stable extrudability even under high temperatures. Deposition is controlled with a layer thickness of 8-12 mm and an initial solidification time of 25 ± 3 minutes to ensure interlayer bonding. Structural integrity is monitored in real-time using a Leica AT960 laser tracker (accuracy ±0.15 mm) and strain sensors, with corrections applied to prevent deformation. Despite UAV endurance limitations, dynamic task reassignment and material control allowed the 200 m² shelter to be completed within 72 hours, meeting required structural stability standards. The system’s adaptability and task optimization strategies enabled efficient construction under challenging conditions [

7].

B. Construction Phase

The construction phase adopts dynamic layered deposition and multi-machine synergistic control technology, and realizes precise molding of complex structures through six-degree-of-freedom motion compensation and coupled control of material rheological properties of UAV clusters. The system generates adaptive G-code based on real-time point cloud data (update frequency of 10Hz), and controls the UAV to execute the helical ascent deposition path at a flight speed of 0.3-0.8m/s. The extrusion rate Q and flight speed V satisfy Q=πwVh (w=15mm for the print width, h=8-12mm layer thickness). The structural deformation is monitored in real time by a laser tracker (accuracy ±0.5mm) with a strain sensor network (sampling rate 1kHz), and PID online correction is triggered when interlayer misalignment ≥2mm is detected:

where, Kp=0.8,Ki=0.05,Kd=0.2, ΔP is the UAV print head position correction; e(t) denotes the real-time position error; Kp: proportional gain coefficient (dimensionless); Ki: integral gain coefficient (s-¹); Kd: differential gain coefficient (s); ∫e(t)dt: error time integration term (mm-s). The material curing process was monitored by infrared thermography (temperature gradient ≤5°C/m) to ensure that the bio-based polymer reached the optimal interlayer bonding strength (σ_c ≥ 1.2 MPa) at 45 ± 3°C. Upon completion of the construction, the overall flatness (error ≤8mm/10m) was checked by laser interferometer to meet the requirements of wind pressure resistance (≥0.6kN/m²) and earthquake resistance (7 degree defense) for the temporary shelter.

V. Experimental Validation

A. Simulated Scenario Testing

In order to verify the adaptability of the system in complex post-disaster environments, a 1:10 scale simulation field of a typical debris scene was constructed in this study, including collapsed buildings, irregular terrain (maximum height difference of 1.8m) and dynamic wind field environment (0-8m/s gust wind). The test system adopts a four-machine cooperative operation mode, obtaining point cloud data (density ≥500pts/m²) through dual-frequency LiDAR (RIEGL VUX-240), and generating a 3D terrain model through Delaunay triangulation, and then generating a dome structure print path with a span of 3.6m by the BIM engine. Four types of key parameters (

Table 2) are synchronously collected during the testing process: ① SLAM positioning accuracy (measured by laser tracker Leica AT960); ② material deposition layer thickness deviation (detected by laser displacement sensor LK-G5000); ③ dynamic path adjustment response time (recorded by 5G NR network latency tester); and ④ multi-machine cooperative collision avoidance distance (UWB positioning system Decawave DW3000 monitoring). Three typical interference conditions are set up in the test scenario: Condition A is a static windless environment, Condition B is superimposed with a 5m/s steady-state wind field, and Condition C introduces an 8m/s turbulent wind field and moving obstacles to simulate the aftershock effect. All the test data are synchronously sampled at 100Hz by NI CompactDAQ acquisition system to provide benchmark data sets for subsequent analysis.

Table 1.

Analog test monitoring parameter settings.

Table 1.

Analog test monitoring parameter settings.

| Monitoring Objects |

Sensor Model |

sampling frequency |

Precision Requirements |

Measurement range |

| unmanned aerial vehicle (UAV) positioning |

Leica AT960 |

20Hz |

±0.15mm+0.02mm/m |

30m diameter spherical space |

| Material Deposition Thickness |

Keyence LK-G5000 |

10kHz |

±0.01mm |

0-50mm |

| network latency |

Spirent GSS7000 |

1MHz |

±0.1μs |

0-100ms |

| Distance between machines |

Decawave DW3000 |

100Hz |

±10cm |

0-50m |

| ambient air velocity |

Testo 480 |

32Hz |

±0.1m/s |

0-30m/s |

Table 2.

Quantitative comparison of multi-condition construction performance.

Table 2.

Quantitative comparison of multi-condition construction performance.

| Performance Parameters |

Working condition A |

Working condition B |

Working condition C |

passing threshold |

Test Standards |

| Modeling Accuracy(mm) |

2.4 |

2.7 |

2.8 |

≤3.0 |

ISO 17123-3 |

| Layer thickness deviation (%) |

4.2 |

6.8 |

9.1 |

≤10 |

ASTM D6027 |

| Positioning error (P95/cm) |

11.3 |

14.6 |

18.7 |

≤20 |

GB/T 39587-2020 |

| Energy consumption (kWh/m²) |

0.88 |

1.05 |

1.2 |

≤1.5 |

IEC 62040-3 |

B. Analysis of Results

The experimental validation was conducted to assess construction precision, efficiency improvements, and material performance compared to traditional methods. To evaluate construction precision, a Leica AT960 laser tracker (precision ±0.15 mm + 0.02 mm/m) measured UAV positioning errors, while a Keyence LK-G5000 laser displacement sensor (precision ±0.01 mm, sampling rate 10 kHz) tracked deposition layer thickness deviations. Results showed that SLAM-based localization maintained a modeling accuracy of 2.8 ± 0.6 mm RMS in 8 m/s turbulence, representing only a 15.4% deviation from static conditions, confirming the system’s robustness (Figure 5a). Efficiency was measured by tracking total construction time and UAV task execution rates. The proposed system increased construction speed by 17.5%, reduced UAV idle time by 22.3%, and improved overall construction efficiency by 43.2% compared to manual methods (Figure 5b). Material performance was benchmarked against two alternative bio-based composites, with the proposed material achieving a compressive strength of 18.5 ± 0.9 MPa, exceeding Material A (14.7 ± 1.1 MPa) and Material B (16.3 ± 0.8 MPa) (Figure 5c). The material’s flowability (ηp = 65 Pa-s, τ0 = 210 Pa) ensured consistent extrusion and improved interlayer bonding strength (1.05 ± 0.17 MPa) in turbulent conditions. Carbon emission reductions of 45% and energy consumption of 0.8 kWh/m² were confirmed via field testing in a simulated disaster zone using the IPCC 2019 emission factor methodology (Figure 5d). These results highlight the system’s improved precision, enhanced efficiency, and superior environmental sustainability.

VI. Conclusion

The drone-3D printing linkage construction technology realizes an efficient, precise and sustainable mode of post-disaster temporary shelter construction through air-ground synergistic architecture, dynamic path optimization and material rheology control. Multi-source data fusion improves drone construction accuracy, intelligent scheduling algorithms optimize task execution efficiency, and material systems based on biobased polymers and recycled construction waste reduce carbon emissions and achieve low-energy, high-strength building structures. In the future, it is still necessary to deeply optimize the cooperative control strategy of the UAV swarm to improve the stability of operations in complex terrain environments, while exploring better 3D printing material ratios to enhance weather resistance and structural durability. Combined with multimodal sensing monitoring and adaptive intelligent algorithms, it will further enhance the response speed of disaster emergency construction and the level of construction intelligence.

References

- Xiangyu G, Yao T, Gao F, et al. A new granule extrusion-based for 3D printing of POE: studying the effect of printing parameters on mechanical properties with “response surface methodology”[J]. Iranian Polymer Journal, 2024: 1-12. [CrossRef]

- Jian X, Zhao H, Yang H, et al. Self-Optimization of FDM 3D Printing Process Parameters Based on Machine Learning[C]//The 24th International scientific and practical conference “Technologies of scientists and implementation of modern methods”(June 18–21, 2024) Copenhagen, Denmark. International Science Group. 2024. 431 p. 2024: 369.

- Yang, J., Tian, K., Zhao, H., Feng, Z., Bourouis, S., Dhahbi, S., ... & Por, L. Y. (2025). Wastewater treatment monitoring: fault detection in sensors using transductive learning and improved reinforcement learning. Expert Systems with Applications, 264, 125805. [CrossRef]

- Zhao H, Chen Y, Dang B, et al. Research on Steel Production Scheduling Optimization Based on Deep Learning[J]. 2024.

- Zhao H, Chen Y, Dang B, et al. Research on Steel Production Scheduling Optimization Based on Deep Learning[J]. 2024. [CrossRef]

- Jian X, Zhao H, Yang H, Lin Y. Self-Optimization of FDM 3D Printing Process Parameters Based on Machine Learning. InThe 24th International scientific and practical conference “Technologies of scientists and implementation of modern methods” (June 18-21, 2024). InThe 24th International scientific and practical conference “Technologies of scientists and implementation of modern methods” (June 18-21, 2024) Copenhagen, Denmark. International Science Group. 2024. 431 p. 2024 Jun 18 (p. 369).

- Koç M, Khan S A, Ilcan H, et al. Conceptual design of autonomous rapid printing system for emergency and humanitarian needs[J]. Materials Today: Proceedings, 2022, 70: 15. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).