Submitted:

16 March 2025

Posted:

17 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Industrial Data Management Tools

1.2. Open-Source LL-GPT Models

1.3. Literature Review

| Bow-Tie Component | Description |

|---|---|

| Hazard and Top Event | A hazard is the potential source of risk (e.g., loss of containment of hydrocarbons). The top event is the incident that results from loss of control over the hazard (e.g., an oil spill or gas explosion). |

| Threats and Preventive Barriers | Threats are causes or initiating events that lead to the top event. These include equipment failures and human errors. Preventive barriers are safeguards to reduce the likelihood of these threats. These include engineering controls such as pressure relief systems and operational procedures. |

| Consequences and Mitigative Barriers | Consequences are potential negative outcomes, such as environmental damage, financial losses and human casualties. Mitigative barriers are measures that reduce the severity of these consequences. These include emergency response plans and fire suppression systems. |

2. Materials and Methods

| KPI Code | KPI Description | Notes |

|---|---|---|

| #LOPC (KPI1) | Number of Loss of Primary Containments | An increasing number indicates poor plant safety and integrity performance |

| #PRDActiv (KPI2) | Number of Pressure Relieve Device (PRD) Activations | An increasing number indicates operational challenges and system challenges requiring immediate attention. PRDs, including safety valves, are designed to release excess pressure when they exceed safe operating limits, acting as a safeguard to prevent equipment failure. |

| # SISAct(KPI3) | Number of Safety Instrumented Systems Activations | SIS activations reflect the effectiveness of safety mechanisms in responding to unsafe conditions. Frequent activations signal operational risks and inefficiencies, while low or decreasing activations indicate stable and well-managed processes. |

| # Ttrip (KPI4) | Number of Trips leading to Shutdown of Equipment, Unit or Whole plant | Frequent equipment trips indicate process inefficiencies, or inadequate maintenance, while a reduction in trips reflects improved system stability and operational control. This KPI provides critical insights into the health of the system, helping to minimize downtime, prevent damage, and maintain consistent production levels. |

| # PCI (KPI5) | Number of Primary Containment Inspections and Testing Results Outside Acceptable Limits |

This applies specifically to vessels, reactors and heat exchangers, where an increasing number reflects declining equipment integrity, potentially leading to catastrophic failures. |

| #SOLExc (KPI6) | Number of Safe Operating Limits (SOL) excursions | A higher frequency of SOL excursions suggests that the process is consistently operating at or beyond its established safety boundaries, often indicating underlying issues such as inadequate process control, subpar equipment performance, or deficient maintenance practices. |

| #FALSECAlam (KPI7) |

Number of False Critical Alarms Activations | A rising frequency of false critical alarm activations suggests potential shortcomings in alarm management and process control systems. This may be due to alarm thresholds that are set too loosely or too tightly, inaccurate sensor calibrations, or malfunctioning control loops, all of which contribute to misleading alarm signals that do not accurately reflect the system’s true status. |

| %OverdueSCEMain (KPI8) |

Percentage of Safety Critical Equipment Overdue for Maintenance | A growing backlog of overdue maintenance on safety-critical equipment clearly signals systemic deficiencies in asset management and maintenance scheduling. This trend not only points to potential resource limitations and misaligned organizational priorities but also undermines the overall reliability and integrity of essential safety systems. |

| %MoCComp (KPI9) | Percentage of Management of Change Non-Compliance | A higher frequency of Change non-compliance events signals a failure in the organization’s change control process modifications to processes, equipment, or procedures are not being adequately reviewed, documented, or approved. |

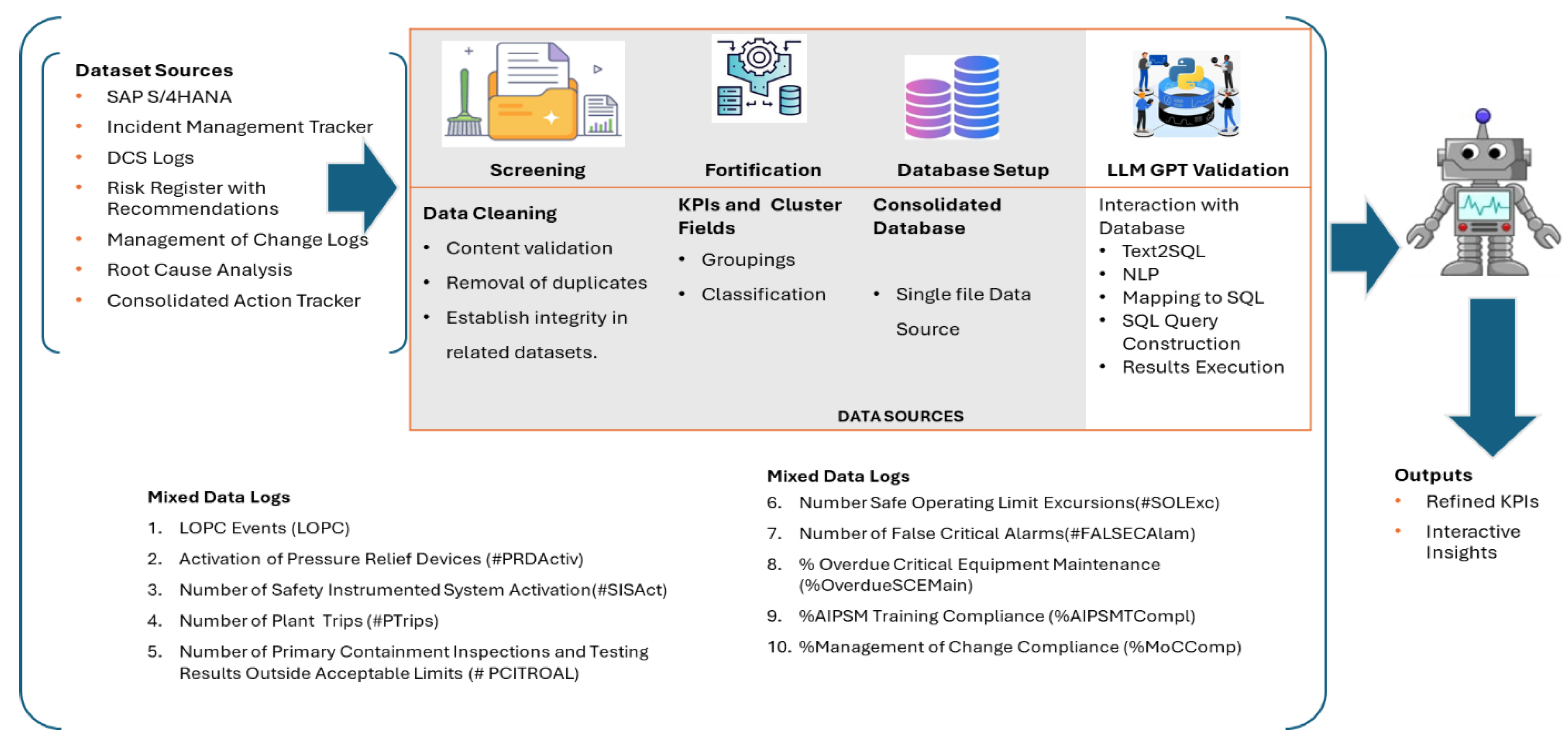

2.1. KPI Data Sourcing

- (1)

- General Incident Logs: This includes data from the Distributed Control System (DCS), Management of Change (MOC) logs, Root Cause Analysis (RCA) logs, overrides of process safeguarding systems, and downgraded situations, all of which are recorded in a standardized Excel-based spreadsheet for efficient tracking and analysis. The incidents are categorized into specific types, including near-misses, emergency incidents, equipment failures and process deviations.

- (2)

- SAP Asset and Maintenance Management: This is a tool for optimizing the lifecycle performance and reliability of physical assets across industries. It integrates tools for planning, monitoring, and executing maintenance tasks. The solution has powerful features like managing work orders, keeping track of assets, and planning preventative maintenance. It also helps with regulatory compliance by keeping detailed records of asset activities and speeding up safety processes.

- (3)

- SAP Incident Management Module: This is part of the SAP S/4HANA suite for managing safety, health, environmental, and operational performance incidents. The module provides a functionality for incident categorization and an actions tracker.

- (4)

- Meridiam Incident Database: Meridian software offers solutions designed to optimize engineering document control, incident management, regulatory compliance, and asset lifecycle management. It centralizes and secures critical equipment performance data while ensuring seamless access, making it an essential tool for industries that rely on complex engineering workflows.

2.2. Data Preparation

2.3. Data Refinement:

2.4. LLM GPT Application

3. Results

3.1. Predictive Insights

| Event iD | Metric | Root Causes | LLM Generated Incident Mitigation Insights |

|---|---|---|---|

| 200001 | Hydrocarbon Leak Upstream P002PC |

Pipeline material degradation, corrosion, lack of leak detection |

Process & Risk Assessment Regular HAZOP/LOPA studies and scenario simulations Mechanical Integrity Use corrosion-resistant materials; implement NDT and stress testing Instrumentation Install smart leak detection sensors with automatic shutdown capabilities Operational Practices Routine inspections and operator training on emergency shutdown procedures |

| 200004 |

Sulphuric Acid Leak at Tank V321 Main Outlet Valve |

Material incompatibility, seal degradation, valve failure |

Process and Risk Assessment Update risk analysis for corrosive substances Mechanical Integrity Upgrade valve materials and seals; perform frequent integrity tests Instrumentation Implement remote monitoring with early leak detection alarms Operational Practices Regular maintenance and pre-shift checklists for critical valves |

| 200005 |

Large Steam Leak from Boiler 322 Main Outlet Manifold |

High pressure/temperature stresses, joint failures |

Process and Risk Assessment Include thermal stress scenarios in digital twinsMechanical Integrity Conduct regular pressure and temperature tests; ensure high-standard welds and bolted joints Instrumentation Use thermal imaging and smart sensors to detect anomaliesOperational Practices Scheduled maintenance and operator drills for high-pressure systems |

| 200006 | H2S-Rich Lean Amine Leak from Pump 2-G-0303C Double Isolation Manifold |

H2S-Rich Lean Amine Leak from Pump 2-G-0303C Double Isolation Manifold |

Process and Risk Assessment Reassess double isolation design with risk ranking for H2S releases Mechanical Integrity Frequent testing of seals/gaskets and enhanced manifold designInstrumentation Install additional H2S sensors and alarms near critical pointsOperational Practices Strict maintenance schedules and emergency response training for H2S incidents |

| 200007 | Loss of High-Level Control at 554V101 Leading to Liquid Overflow | Control system failure, sensor malfunction, absence of redundancy |

Process and Risk Assessment Incorporate control system failure modes in hazard analysis Mechanical and Instrumentation Controls Retrofit with dual redundant level sensors; implement automatic shutdown/diversion systems Operational Practices Regular calibration checks and pre-emptive inspections; install secondary overflow containment systems |

3.2. AI assisted AIPS KPI Analysis

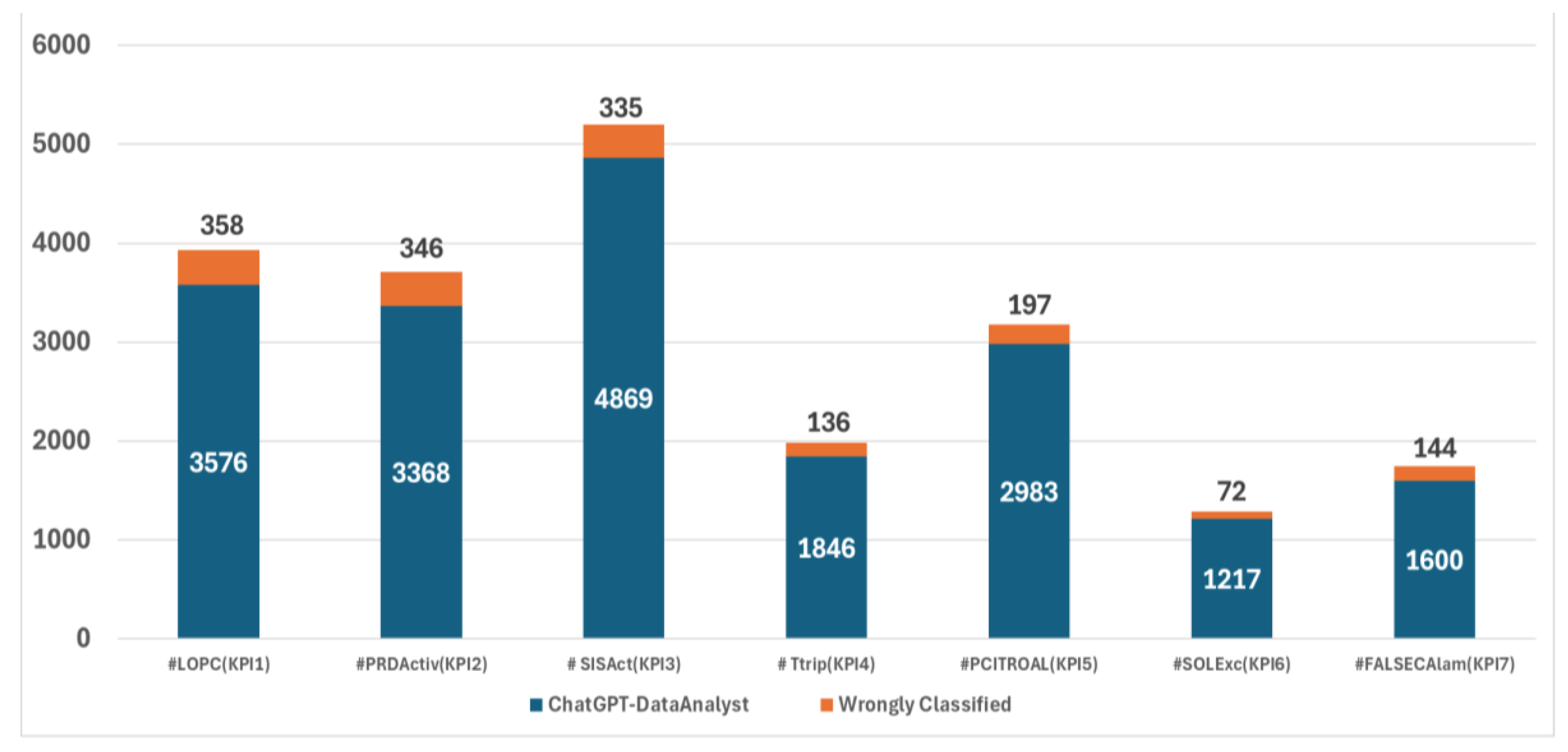

| Insights | #LOPC(KPI1) | #PRDActiv (KPI2) | # SISAct(KPI3) | # Ttrip (KPI4) | (#PCIROAL(KPI5) | #SOLExc (KPI6) | #FALSECAlam(KPI7) | Total Count | Analysis Time |

|---|---|---|---|---|---|---|---|---|---|

| GPTDataAnalyst | 3576 | 3368 | 4869 | 1846 | 2983 | 1217 | 1600 | 19458 | 50-70 minutes |

| Validated Results | 3934 | 3714 | 5204 | 1982 | 3179 | 1289 | 1744 | 21046 | 4-5 days |

| Wrongly Classified | 358 | 346 | 335 | 136 | 197 | 72 | 144 | 1588 | - |

| % Error | 9% | 9% | 6% | 7% | 6% | 6% | 8% | 8% | - |

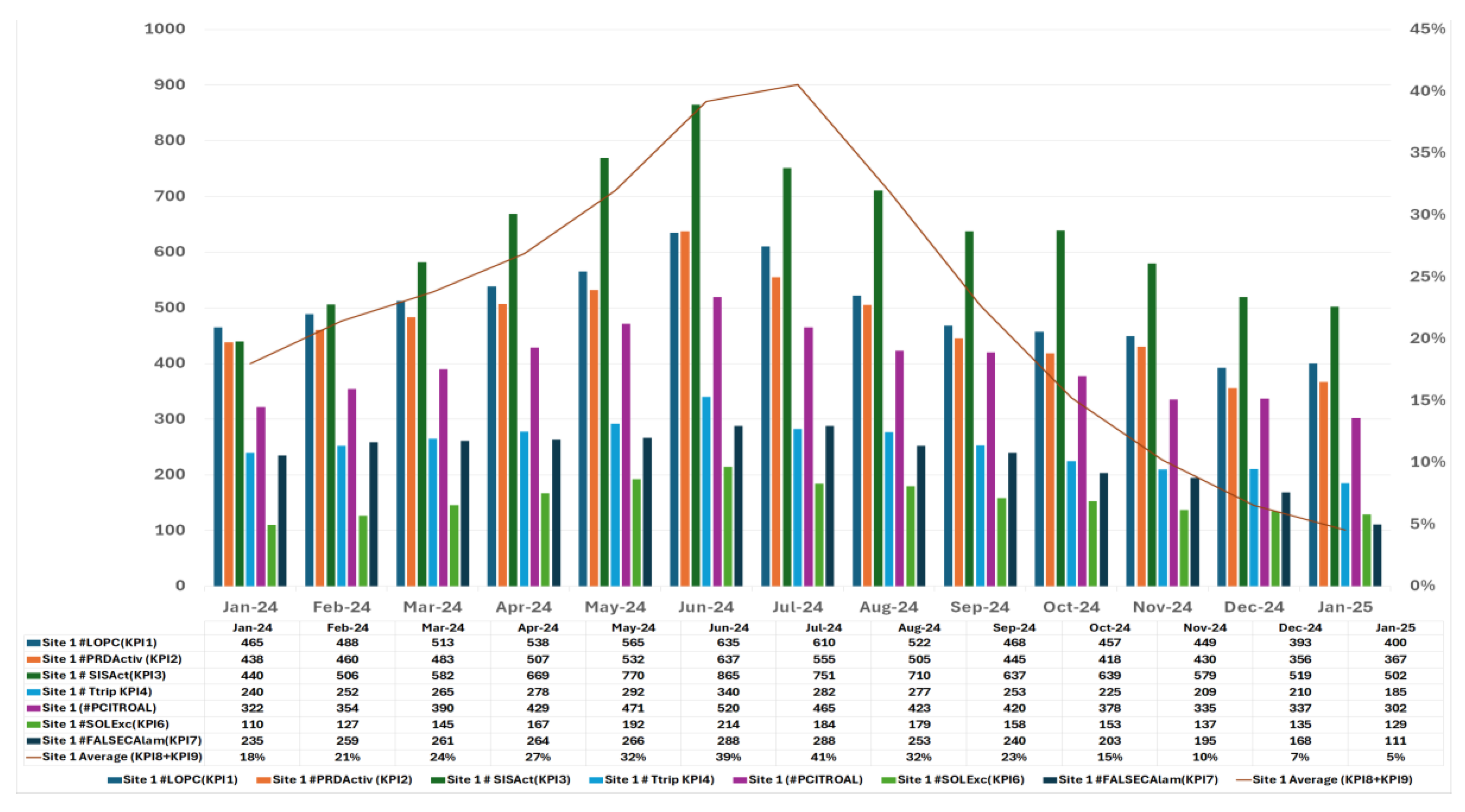

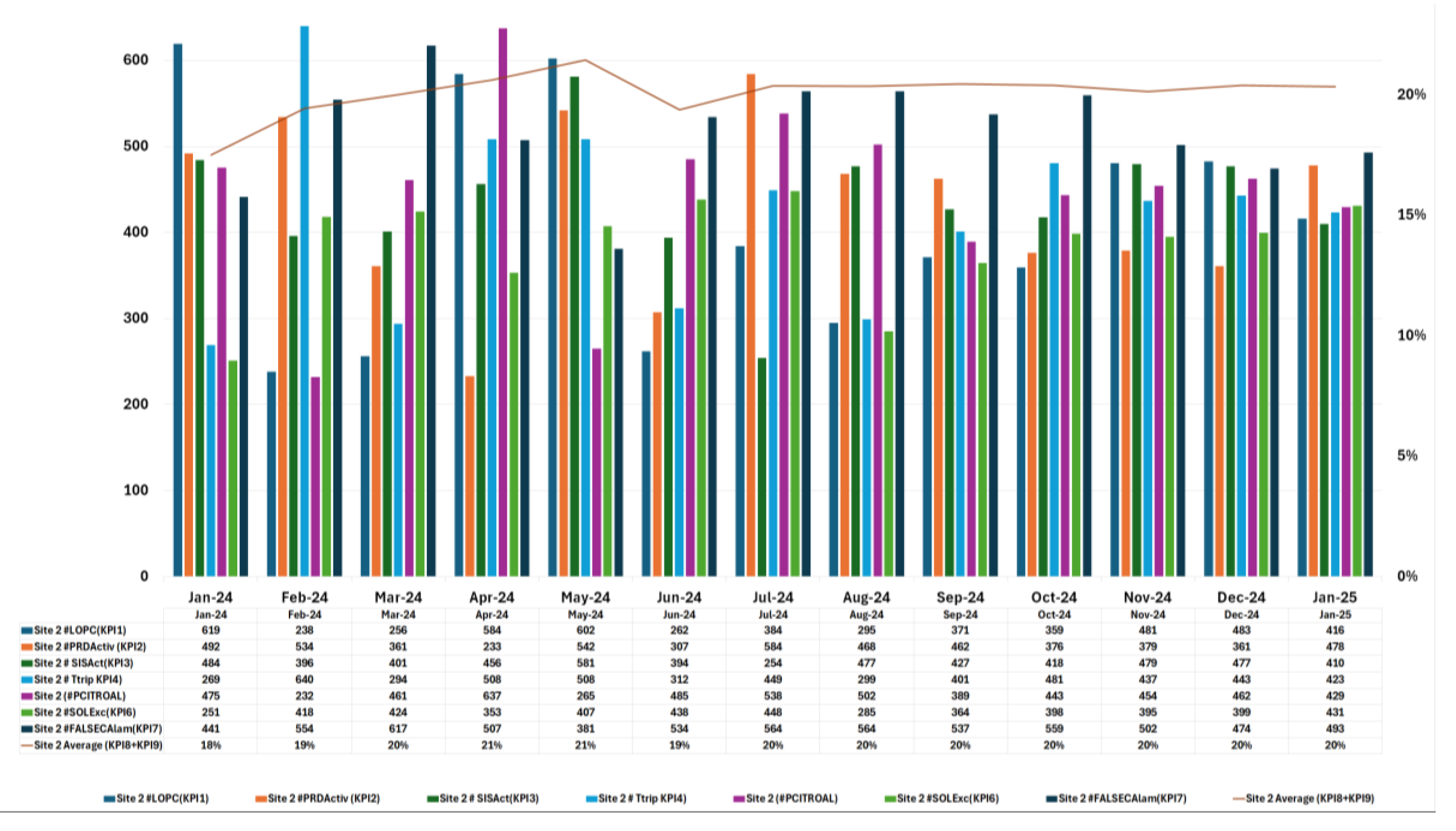

3.3. Comparative Assessment Between Site 1 and Site 2

4. Discussion

- i.

- Automated incident categorization: analysis of large volumes of shift logs, incident reports, and sensor alerts to classify AIPS incidents into predefined categories (e.g., equipment failure, human error, hazardous material release).

- ii.

- AI-assisted decision-making for AIPS: interpretation of historical safety reports, to generate contextual safety recommendations.

- iii.

- Knowledge-driven AIPS framework: Synthesising lessons learned from previous incidents, providing actionable insights for continuous AIPS improvement and risk reduction.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ADIPEC. ADIPEC 2024: ADNOC EnergyAI (Nov, 2024). Available online: https://www.adipec.com/energy-ai/ (accessed on 28 November 2024).

- Kulkov, I., Kulkova, J., Rohrbeck, R., Menvielle, L., Kaartemo, V. and Makkonen, H. Artificial intelligence-driven sustainable development: Examining organizational, technical, and processing approaches to achieving global goals. Sustainable Development 2024, 32, 2253–2267. [Google Scholar]

- Oke, A. and Fernandes, F.A.P. Innovations in teaching and learning: Exploring the perceptions of the education sector on the 4th industrial revolution (4IR). Journal of Open Innovation: Technology, Market, and Complexity 2020, 6, 31. [Google Scholar]

- .Darwin, Rusdin, D., Mukminatien, N., Suryati, N., Laksmi, E.D. and Marzuki, 2024. Critical thinking in the AI era: An exploration of EFL students’ perceptions, benefits, and limitations. Cogent Education, 11(1), p.2290342.

- Rampersad, G., 2020. Robot will take your job: Innovation for an era of artificial intelligence. Journal of Business Research, 116, pp.68-74.

- Rane, N., 2023. ChatGPT and Similar Generative Artificial Intelligence (AI) for Smart Industry: role, challenges and opportunities for industry 4.0, industry 5.0 and society 5.0. Challenges and Opportunities for Industry, 4.

- Ahmadi, A. Unravelling the Mysteries of Hallucination in Large Language Models: Strategies for Precision in Artificial Intelligence Language Generation. Journal of Computer Science and Technology 2024, 13, 1–10. [Google Scholar]

- Sharma, R. , 2023. The transformative power of AI as future GPTs in propelling society into a new era of advancement. IEEE Engineering Management Review.

- Sternad, S. and Bobek, S. (2013) ‘Enterprise Resource Planning Acceptance Model (ERPAM)’, Enterprise Resource Planning, pp. 407–432. [CrossRef]

- Liu, Y.; et al. (2018) ‘Brief valuation of systems, Applications & Products (SAP) corporation’, Global journal of Economics and Business Administration [Preprint]. [CrossRef]

- Schuchardt, K. and Schymik, R. (2000a) ‘Laboratory Information and Management Systems (LIMS)’, Ullmann’s Encyclopedia of Industrial Chemistry. [CrossRef]

- Ikegwu, A.C., Nweke, H.F., Anikwe, C.V., Alo, U.R. and Okonkwo, O.R., 2022. Big data analytics for data-driven industry: a review of data sources, tools, challenges, solutions, and research directions. Cluster Computing, 25(5), pp.3343-3387.

- Ahmad, R.W. , Salah, K., Jayaraman, R., Yaqoob, I. and Omar, M., 2022. Blockchain in oil and gas industry: Applications, challenges, and future trends. Technology in society, 68, p.101941.

- Aderamo, A.T., Olisakwe, H.C., Adebayo, Y.A. and Esiri, A.E., 2024. AI-driven HSE management systems for risk mitigation in the oil and gas industry. Comprehensive Research and Reviews in Engineering and Technology, 2(1), pp.1-22.

- Sufi, F.K. , 2024. A Systematic Review on the Dimensions of Open-Source Disaster Intelligence using GPT. Journal of Economy and Technology.

- Sufi, F. Sufi, F., 2024. An innovative GPT-based open-source intelligence using historical cyber incident reports. Natural Language Processing Journal, 7, p.100074.

- Seger, E. , Dreksler, N., Moulange, R., Dardaman, E., Schuett, J., Wei, K., Winter, C., Arnold, M., Ó hÉigeartaigh, S., Korinek, A. and Anderljung, M., 2023. Open-sourcing highly capable foundation models. Research paper, Centre for the Governance of AI.

- Katlariwala, M. and Gupta, A. (2024) ‘Product recommendation system using large language model: Llama-2’, 2024 IEEE World AI IoT Congress (AIIoT), pp. 0491–0495. [CrossRef]

- How to use CHATGPT’s Advanced Data Analysis Feature (2024) MIT Sloan Teaching & Learning Technologies. Available at: https://mitsloanedtech.mit.edu/ai/tools/data-analysis/how-to-use-chatgpts-advanced-data-analysis-feature/ (Accessed: 14 February 2025).

- Schmitz, Peter, Swuste, Paul, Reniers, Genserik, & Nunen, Karolien van 2020, ’Mechanical integrity of process installations: Barrier alarm management based on bowties’, Process Safety and Environmental Protection, vol. 138, pp. 139-147, ISSN 0957-5820, Elsevier BV. [CrossRef]

- McLeod, Ronald W. 2017, ’Human factors in barrier management: Hard truths and challenges’, Process Safety and Environmental Protection, vol. 110, pp. 31-42, ISSN 0957-5820, Elsevier BV. [CrossRef]

- Hassan, Jakiul, & Khan, Faisal 2012, ’Risk-based asset integrity indicators’, Journal of Loss Prevention in the Process Industries, vol. 25, no. 3, pp. 544-554, ISSN 0950-4230, Elsevier BV. [CrossRef]

- Ratnayake, R. M. Chandima, & Markeset, T. 2012, ’Asset integrity management for sustainable industrial operations: measuring the performance’, International Journal of Sustainable Engineering, vol. 5, no. 2, pp. 145-158, ISSN 1939-7038, Informa UK Limited. [CrossRef]

- Hernández-Chover, Vicent, Castellet-Viciano, Lledó, & Hernández-Sancho, Francesc 2020, ’Preventive maintenance versus cost of repairs in asset management: An efficiency analysis in wastewater treatment plants’, Process Safety and Environmental Protection, vol. 141, pp. 215-221, ISSN 0957-5820, Elsevier BV. [CrossRef]

- Wang, Qingfeng, Wenbin, Liu, Xin, Zhong, Jianfeng, Yang, & Qingbin, Yuan 2011, ’Development and application of equipment maintenance and safety integrity management system’, Journal of Loss Prevention in the Process Industries, vol. 24, no. 4, pp. 321-332, ISSN 0950-4230, Elsevier BV. [CrossRef]

- Shu, Yidan, & Zhao, Jinsong 2014, ’A simplified Markov-based approach for safety integrity level verification’, Journal of Loss Prevention in the Process Industries, vol. 29, pp. 262-266, ISSN 0950-4230, Elsevier BV. [CrossRef]

- Liaw, Horng-Jang 2019, ’Deficiencies frequently encountered in the management of process safety information’, Process Safety and Environmental Protection, vol. 132, pp. 226-230, ISSN 0957-5820, Elsevier BV. [CrossRef]

- Wang, Sun, Hao, Yang, Ming, & Haiqing 2022, ’Resilience-based approach to maintenance asset and operational cost planning’, Process Safety and Environmental Protection, vol. 162, pp. 987-997, ISSN 0957-5820, Elsevier BV. [CrossRef]

- Sultana, S. and Haugen, S. (2022) ‘Development of an inherent system safety index (ISSI) for ranking of chemical processes at the concept development stage’, Journal of Hazardous Materials, 421, p. 126590. [CrossRef]

- Severi, C.A. et al. (2022) ‘Identification of critical operational hazards in a biogas upgrading pilot plant through a multi-criteria decision-making and Ftopsis-Hazop approach’, Chemosphere, 307, p. 135845. [CrossRef]

- Baybutt, Paul 2012, ’Using risk tolerance criteria to determine safety integrity levels for safety instrumented functions’, Journal of Loss Prevention in the Process Industries, vol. 25, no. 6, pp. 1000-1009, ISSN 0950-4230, Elsevier BV. [CrossRef]

- Hu, Jinqiu, & Yi, Yan 2016, ’A two-level intelligent alarm management framework for process safety’, Safety Science, vol. 82, pp. 432-444, ISSN 0925-7535, Elsevier BV. [CrossRef]

- Iaiani, Matteo, Tugnoli, Alessandro, Macini, Paolo, & Cozzani, Valerio 2021, ’Outage and asset damage triggered by malicious manipulation of the control system in process plants’, Reliability Engineering & System Safety, vol. 213, p. 107685, ISSN 0951-8320, Elsevier BV. [CrossRef]

- Ayomoh, M. and Ongwae, B., 2025. A Systematic Review of Asset Integrity and Process Safety Management Sustainability for Onshore Petrochemical Installations. Sustainability, 17(1), p.286.

- Moktadir, M.A. , Ali, S.M., Kusi-Sarpong, S. and Shaikh, M.A.A., 2018. Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process safety and environmental protection, 117, pp.730-741.

- Khan, Faisal, Rathnayaka, Samith, & Ahmed, Salim 2015, ’Methods and models in process safety and risk management: Past, present and future’, Process Safety and Environmental Protection, vol. 98, pp. 116-147, ISSN 0957-5820, Elsevier BV. [CrossRef]

- Pan, Y. and Zhang, L., 2021. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Automation in Construction, 122, p.103517.

- Singh, S. , Sharma, P.K., Yoon, B., Shojafar, M., Cho, G.H. and Ra, I.H., 2020. Convergence of blockchain and artificial intelligence in IoT network for the sustainable smart city. Sustainable cities and society, 63, p.102364.

- Wong, L.W. , Tan, G.W.H., Ooi, K.B., Lin, B. and Dwivedi, Y.K., 2024. Artificial intelligence-driven risk management for enhancing supply chain agility: A deep-learning-based dual-stage PLS-SEM-ANN analysis. International Journal of Production Research, 62(15), pp.5535-5555.

- Manchana, R. , 2022. Optimizing Real Estate Project Management through Machine Learning, Deep Learning, and AI. Journal of Scientific and Engineering Research, 9(4), pp.192-208.

- Wamba, S.F. and Queiroz, M.M., 2020. Blockchain in the operations and supply chain management: Benefits, challenges and future research opportunities. International Journal of Information Management, 52, p.102064.

- Ogbu, A.D. , Ozowe, W. and Ikevuje, A.H., 2024. Data science’s pivotal role in enhancing oil recovery methods while minimizing environmental footprints: An insightful review.

- Ashry, I. , Mao, Y., Wang, B., Hveding, F., Bukhamsin, A.Y., Ng, T.K. and Ooi, B.S., 2022. A review of distributed fiber–optic sensing in the oil and gas industry. Journal of Lightwave Technology, 40(5), pp.1407-1431.

- Tabibian, S.S. and Sharifzadeh, M., 2023. Statistical and analytical investigation of methanol applications, production technologies, value-chain and economy with a special focus on renewable methanol. Renewable and Sustainable Energy Reviews, 179, p.113281.

- Prandner, D. , Wetzelhütter, D. and Hese, S. (2025) ‘CHATGPT as a data analyst: An exploratory study on AI-supported Quantitative Data Analysis in empirical research’, Frontiers in Education, 9. [CrossRef]

- Luengo, J., García-Gil, D., Ramírez-Gallego, S., García, S., Herrera, F., Luengo, J., García-Gil, D., Ramírez-Gallego, S., García, S. and Herrera, F., 2020. Imbalanced data preprocessing for big data. Big Data Preprocessing: Enabling Smart Data, pp.147-160.

- Fan, C., Chen, M., Wang, X., Wang, J. and Huang, B., 2021. A review on data preprocessing techniques toward efficient and reliable knowledge discovery from building operational data. Frontiers in energy research, 9, p.652801.

- Maharana, K., Mondal, S. and Nemade, B., 2022. A review: Data pre-processing and data augmentation techniques. Global Transitions Proceedings, 3(1), pp.91-99.

- Wang, S., Celebi, M.E., Zhang, Y.D., Yu, X., Lu, S., Yao, X., Zhou, Q., Miguel, M.G., Tian, Y., Gorriz, J.M. and Tyukin, I., 2021. Advances in data preprocessing for biomedical data fusion: An overview of the methods, challenges, and prospects. Information Fusion, 76, pp.376-421.

- Benhar, H. , Idri, A. and Fernández-Alemán, J.L., 2020. Data preprocessing for heart disease classification: A systematic literature review. Computer Methods and Programs in Biomedicine, 195, p.105635.

- Khan, F. , Rathnayaka, S. and Ahmed, S., 2015. Methods and models in process safety and risk management: Past, present and future. Process safety and environmental protection, 98, pp.116-147.

- Abioye, S.O. , Oyedele, L.O., Akanbi, L., Ajayi, A., Delgado, J.M.D., Bilal, M., Akinade, O.O. and Ahmed, A., 2021. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. Journal of Building Engineering, 44, p.103299.

| Category | System/Tool | Description |

|---|---|---|

| Enterprise Resource Planning (ERP) | SAP | Integrated management of core business processes such as procurement, production, inventory, and finance. |

| Oracle ERP | Modules for asset management, supply chain, and operational efficiency. | |

| IFS Applications | Asset management, project management, and real-time operational visibility. | |

| Microsoft Dynamics 365 | Cloud-based solutions for operational data, financials, and asset management. | |

| Process Control and Automation | Honeywell Process Solutions (HPS) | Process automation, real-time monitoring, and optimization. |

| Emerson DeltaV | Distributed Control System (DCS) for production and operational control. | |

| Schneider Electric’s EcoStruxure | Manages operational data with energy and asset optimization. | |

| Laboratory Information Management Systems (LIMS) | LabWare LIMS | Manages lab samples, test results, and compliance. |

| STARLIMS | Quality control and data tracking for testing petrochemical products. | |

| PerkinElmer Informatics | Solutions for research, development, and production analytics. | |

| Asset and Maintenance Management | Maximo (IBM) | Asset management software for predictive maintenance and reliability. |

| Infor EAM | Lifecycle and performance management of physical assets. | |

| Production and Operation Management | AspenONE (AspenTech) | Process optimization; production planning. |

| LLM GPT Model | AIPS KPI Reporting | Predictive Risk Insights | Strengths | Limitations |

|---|---|---|---|---|

| GPT-Neo | Basic KPI reporting requires extensive fine-tuning for domain-specific applications. | Limited capabilities require external tools for predictive modelling. | Accessible, flexible. | Limited contextual understanding and scalability. |

| GPT-J | Generates detailed, context-aware reports; handles terminology with fine-tuning. | Better pattern recognition; still relies on external predictive frameworks. | Improved contextual capabilities. | Lacks built-in advanced predictive features. |

| Bloom | Multilingual reporting for diverse geographies; effective for large-scale operations. | Limited predictive capabilities; relies on supplementary tools. | Multilingual, contextually rich. | High computational requirements for real-time use. |

| LLaMA | Efficient real-time structured data reporting; highly adaptable to fine-tuning. | Supports integration with external tools for predictive insights. | Lightweight, efficient for real-time tasks. | Predictive capabilities require supplementary tools. |

| ChatGPT-DataAnalyst | High-speed, precise reporting for structured and unstructured data. | Strong pattern recognition for proactive risk assessment. | Scalable, minimal fine tuning needed. | Less established for specific industrial terminologies. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).