Submitted:

06 January 2025

Posted:

07 January 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Identifying safety-critical load cases and operational scenarios for the concept tank.

- Assessing potential safety hazards posed by the tank to the aircraft and its environment, with particular emphasis on leakage and tank rupture scenarios.

- Modelling and analysing risk levels associated with identified safety hazards within relevant safety scenarios.

- Establishing risk acceptance criteria, proposing risk-reducing measures, and defining corresponding safety requirements.

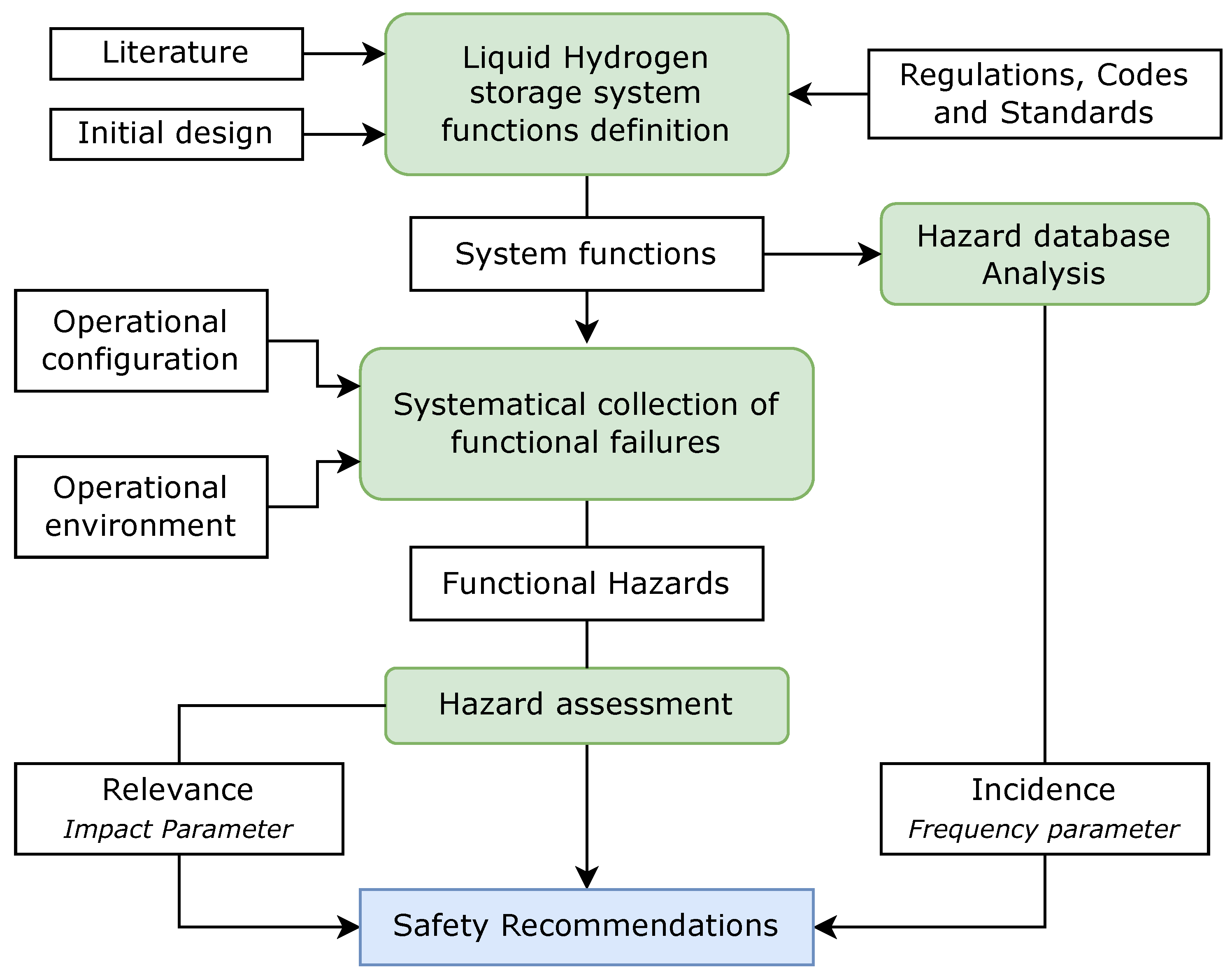

2. Materials and Methods

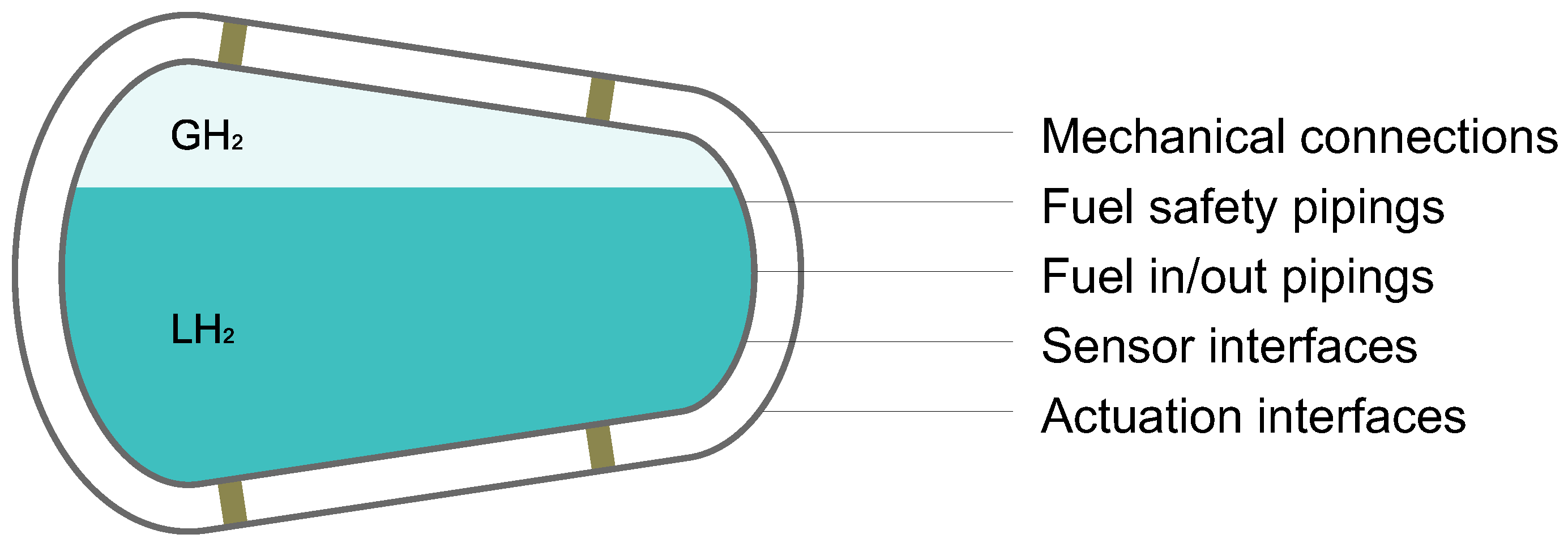

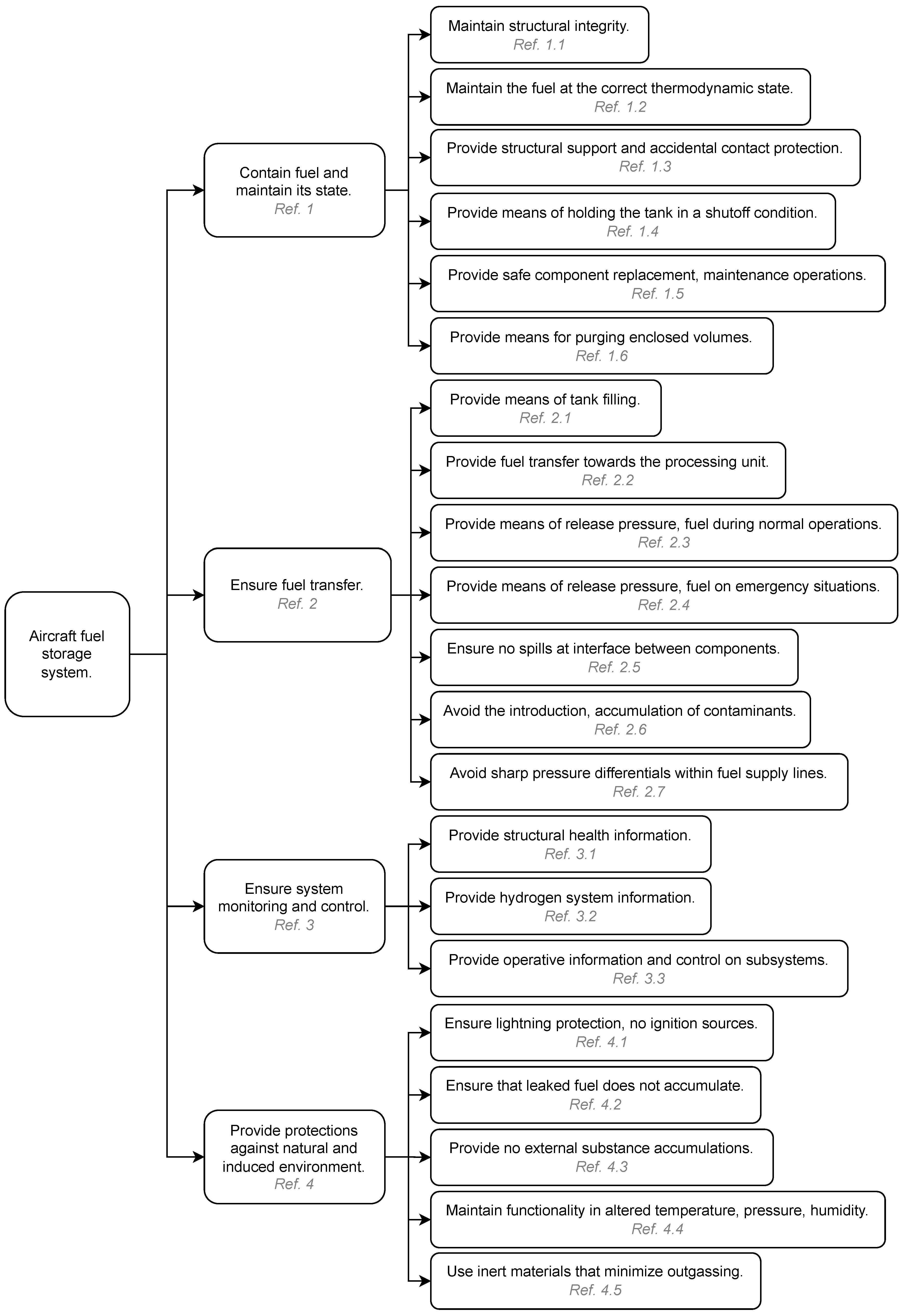

2.1. Functions of the Liquid Hydrogen Fuel Storage System

- Contain fuel and maintain its thermodynamic state.

- Enable fuel transfer.

- Ensure system monitoring and control.

- Provide protection against natural and induced environment.

2.1.1. Operational Configurations and Environments

- Configuration mode 0 – Manufacturing

- Configuration mode 1 – Handling

- Configuration mode 2 – Fuelling

- Configuration mode 3 – Flight

- Configuration mode 4 – Dormancy

- Configuration mode 5 – Maintenance

- Environment mode 0 – Normal operation

- Environment mode 1 – Fire

- Environment mode 2 – Power loss

- Environment mode 3 – Saturated gas environment

- Environment mode 4 – Mechanical contact

- Environment mode 5 – Arc discharge

2.2. Systematic Collection of Failures

2.2.1. Functional Hazard Assessment

- Loss of function

- Partial loss of function

- Function provided when not needed

- Unannounced loss of function

- Malfunction

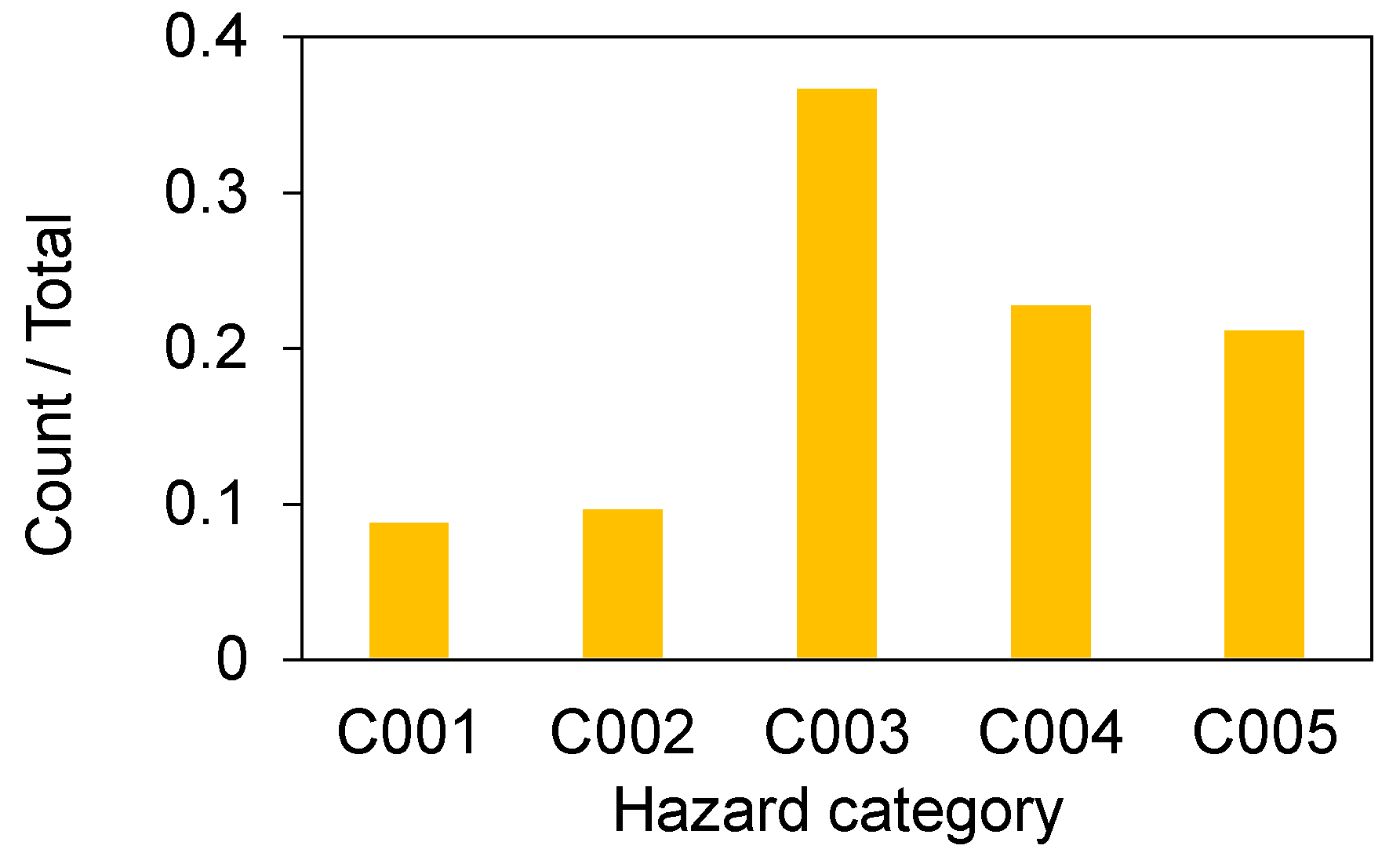

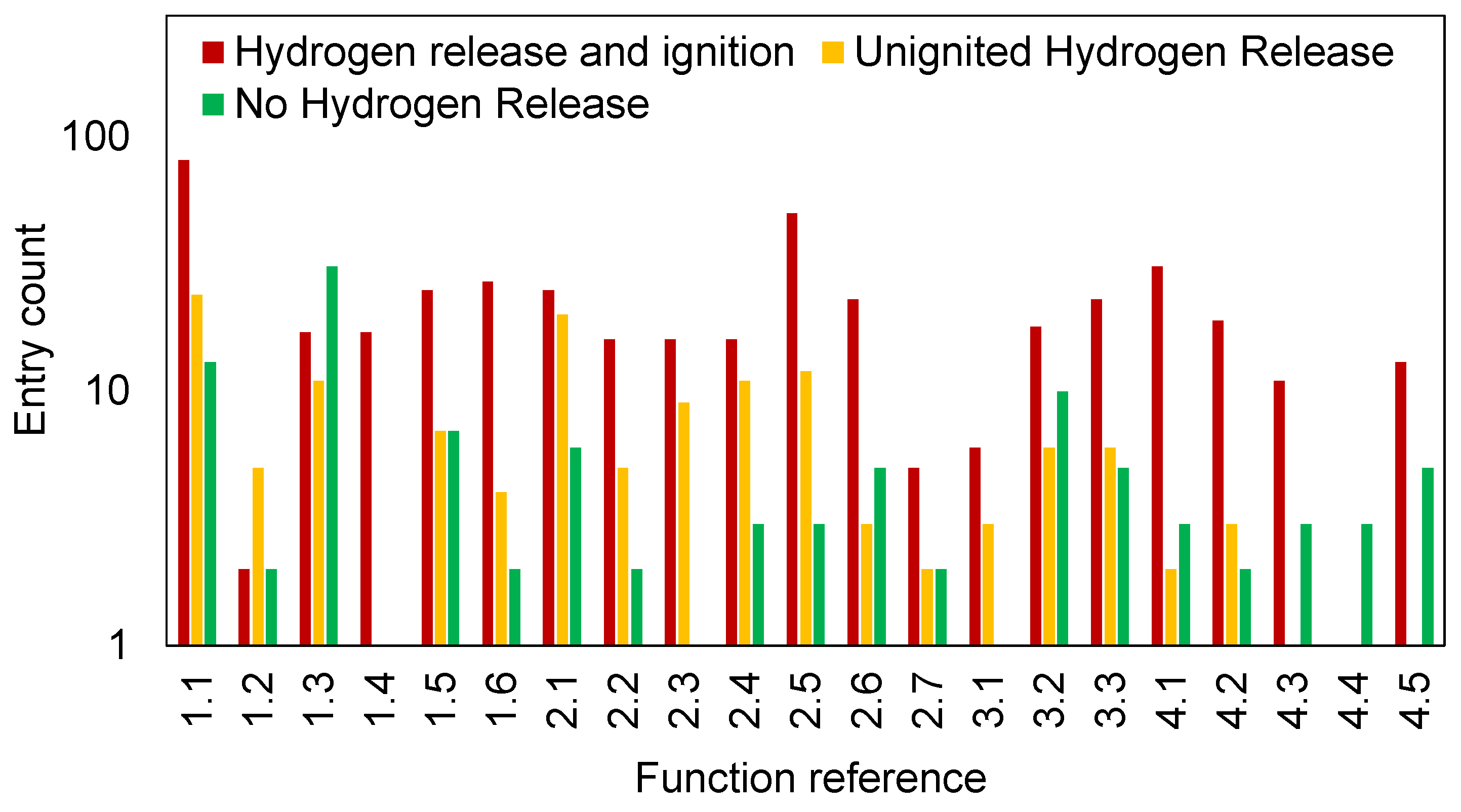

2.2.2. Hazard Database Analysis

2.2.3. Safety Recommendations

3. Results and Discussion

3.1. Main Hazards in LH2 Storage Systems

- Low flow rate release: This is usually caused by small leaks or significant permeation. It leads to a small release of gaseous hydrogen that may result in asphyxiation hazard. Combustion may occur if the mixing ratio with air exceeds a critical level called lower flammability limit, which is quite low, being around 4-7 vol%H2 depending on temperature, and an ignition source is present, being established at an energy level of 0.02 mJ, requiring just a small electrostatic discharge [13]. The resulting flame has a low emissivity, making it non visible and difficult to recognize. The consequence of hydrogen accumulation without initial ignition are discussed later in the explosion paragraph, introducing the need of ventilation.

- High flow rate release: This occurs when hydrogen is rapidly discharged trough a breach in the equipment in a focused stream, which can be either gaseous or in a two-phase state. Aside from the risks arising from direct contact with the stream, which may cause cutting blasts, the main hazard associated with jet releases is the potential for deflagration, which refers to the accelerated propagation of flames and can lead to highly dangerous pressure waves.

- Pool Vaporization: This type of hazard involves the spillage of liquid hydrogen, which then transitions to a gaseous state and accumulates [32]. The primary risk is an increased likelihood of combustion due to the accumulation of hydrogen gas, followed by severe cryo-burns if the fluid contacts skin.

- Explosions: This scenario might occur as a result of different causes, involving different physics. First, it is identified as boiling liquid expanding vapour explosion (BLEVE) the explosion of liquefied gas vessels [33]. This happens following a catastrophic rupture of the vessel from other causes, and the outcome depends on the initial thermodynamic state. Ustolin et al. [34] modelled this phenomenon for LH2 storage systems and validated their results with prior experiments from literature. The study concluded that, in the case of insulated vessels, means of rapid discharge or venting of the hydrogen need to be put in place, employing safety features such as pressure relief devices (PRD). Secondly, explosion could occur from delayed ignition of mixtures of gaseous hydrogen with air. The potential for explosion in this case is concerning from the rapid combustion which results in the release of pressure waves, leading to design choices which avoid confinement of gaseous releases in areas such as dead ends and ceilings. The risk associated with explosive releases is severe, with the potential for significant damage to the surrounding area [35].

3.2. Safety Recommendations for LH2 Storage Systems

- Prevent leaks: Implement measures to minimize the risk of hydrogen leaks from equipment and piping.

- Prevent accumulation of hydrogen: Ensure proper ventilation to avoid the build-up of hydrogen, reducing the risk of explosive mixtures through effective ventilation systems. Ensure potential releases of hydrogen do not reach regions occupied by people.

- Prevent ignition sources: Eliminate or control potential ignition sources to prevent fires or explosions in hydrogen-rich environments.

- Prevent component failures: Use materials that are resistant to hydrogen embrittlement and select components that are reliable, ensure that system and components are robust and regularly inspected.

- Follow design guidelines: Ensure design is in accordance with latest regulations codes and standards (RCS), provide third party review of the design choices.

- Ensure effective operational protocols: Follow stringent operational guidelines, and implement rigorous training to reduce human error and ensure safe operations, establish evacuation plans.

- Ensure fail safe capabilities: Provide that the system can revert to a safe condition in case of accidental damage, allowing for hydrogen to be released in a safe manner in the most extreme situation.

- Continuous monitoring and detection alarms: Perform regular monitoring and inspections for the health condition of the vessel to address potential failures promptly, monitor for hydrogen leaks, providing evacuation alarms.

3.3. Review Activity

- Do I agree with the purpose of this safety recommendation?

- Is this recommendation relevant for the demonstrator or TRL9 development level?

- I think that current design implementation is good/ satisfactory/ unsatisfactory to comply with the issued safety recommendation.

- Is this recommendation already covered by other measures, which redesign can further improve the safety in this direction?

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BLVE | Boiling Liquid Vapour Explosion |

| CGA | Compressed Gas Association |

| COCOLIH2T | COnformal COmposite LIquid Hydrogen Tank |

| DoD | Department of Defence |

| FHA | Functional Hazard Assessment |

| HIAD | Hydrogen Incidents and Accident Database |

| LH2 | Liquid Hydrogen |

| PRD | Pressure Relief Device |

| RCS | Regulation Codes and Standards |

| TRL | Technology readiness Level |

| FO | Failure Occurrence |

References

- Fuel Cells and Hydrogen 2 Joint Undertaking. Hydrogen-powered aviation, A fact-based study of hydrogen technology, economics, and climate impact by 2050; Publications Office, 2020. [CrossRef]

- Ustolin, F.; Campari, A.; Giannini, L.; Baboi, E.; Paltrinieri, N. Identification of Consequences of Failure for Hydrogen Equipment. Chemical Engineering Transactions 2023, 98, 189–194. [CrossRef]

- Aziz, M. Liquid Hydrogen: A Review on Liquefaction, Storage, Transportation, and Safety. Energies 2021, 14. [CrossRef]

- Dafedar, A.A.; Verma, S.S.; Yadav, A. Hydrogen Storage Techniques for Stationary and Mobile Applications: A Review. In Proceedings of the Recent Advances in Sustainable Technologies, Singapore, 2021; pp. 29–40.

- Züttel, A. Hydrogen storage methods. Naturwissenschaften 2004, 91, 157–172. [CrossRef]

- OCED. Risk-based Regulatory Design for the Safe Use of Hydrogen; OCED Publishing, 2023. [CrossRef]

- Wen, J.X.; Marono, M.; Moretto, P.; Reinecke, E.A.; Sathiah, P.; Studer, E.; Vyazmina, E.; Melideo, D. Statistics, lessons learned and recommendations from analysis of HIAD 2.0 database,. International Journal of Hydrogen Energy, 2022, 47 (38), 17082–17096. [CrossRef]

- NASA. TM X-71565, 1974. Review of hydrogen accidents and incidents in NASA operations.

- SAE. ARP4761, 1996. Guideline and methods for conducting the safety assessment process on civil airborne systems and equipment.

- Neugebauer, R. Hydrogen Technologies; Vol. Fraunhofer-Forschungsfokus, Springer, 2022. [CrossRef]

- Al Ghafri, S.Z.S.; Swanger, A.; Jusko, V.; Siahvashi, A.; Perez, F.; Johns, M.L.; May, E.F. Modelling of Liquid Hydrogen Boil-Off. Energies 2022, 15 (3), 1149. [CrossRef]

- Peterson, T.; Weisend II, J.G. Cryogenic Safety: A Guide to Best Practice in the Lab and Workplace; Springer, 2019. [CrossRef]

- Kotchourko, A.; Jordan, T. Hydrogen Safety for Energy Applications; Butterworth-Heinemann, 2022. [CrossRef]

- Brewer, G.D. Hydrogen aircraft techology; CRC Press, 1991. [CrossRef]

- NASA. TM-2009-215521, 2009. Hydrogen Fuel system design trades for high atitude long-endurance remotely operatied aircraft.

- Spencer, R. Certification considerations for the configuration of a hydrogen-fuelled aeroplane. The Aeronautical Journal 2023, 127, 213–231. [CrossRef]

- Gavrilovic, N.; Mertika, S.; Moschetta, J.M.; Schimpf, J.; Park, G.; Kim, S.Y. Experimental Study on a Liquid Hydrogen Tank for Unmanned Aerial Vehicle Applications. Journal of Aircraft 2024, pp. 1–12. [CrossRef]

- Wetzel, F.J. Improved handling of liquid hydrogen at filling stations: review of six years of experience. International Journal of Hydrogen Energy 1998, 23 (5), 339–348. [CrossRef]

- Hoelzen, J.; Flohr, M.; Silberhorn, D.; Mangold, J.; Bensmann, A.; Hanke-Rauschenbach, R. H2-powered aviation at airports – Design and economics of LH2 refueling systems. Energy Conversion and Management: X 2022, 14, 100206. [CrossRef]

- Mangold, J.; Silberhorn, D.; Moebs, N.; Dzikus, N.; Hoelzen, J.; Zill, T.; Strohmayer, A. Refueling of LH2 Aircraft—Assessment of Turnaround Procedures and Aircraft Design Implication. Energies 2022, 15. [CrossRef]

- Eytan J. Adler, J.R.M. Hydrogen-powered aircraft: Fundamental concepts, key technologies, and environmental impacts. Progress in Aerospace Sciences 2023, 141, 100922. [CrossRef]

- EUROCODE. SAF.ET1.ST03.1000-MAN, 2009. EUROCONTROL’s Guidance Material for the application of SAM-FHA.

- Badia, E.; Navajas, J.; Sala, R.; Paltrinieri, N.; Sato, H. Analysis of Hydrogen Value Chain Events: Implications for Hydrogen Refueling Stations’ Safety. Safety 2024, 10. [CrossRef]

- AIAA. G-095-2017, 2017. Guide to safety of hydrogen and hydrogen systems.

- Jennifer, W. Statistics, lessons learnt and recommendations from the analysis of the Hydrogen Incidents and Accidents Database (HIAD 2.0); Fuel Cells and Hydrogen 2 Joint Undertaking, 2021.

- Campari, A.; Nakhal Akel, A.J.; Ustolin, F.; Alvaro, A.; Ledda, A.; Agnello, P.; Moretto, P.; Patriarca, R.; Paltrinieri, N. Lessons learned from HIAD 2.0: Inspection and maintenance to avoid hydrogen-induced material failures,. Computers & Chemical Engineering 2023, 173, 108199. [CrossRef]

- h2tools.org, retrieved Dec 2023. U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE).

- llis.nasa.gov, retrieved Dec 2023. NASA Office of the Chief Engineer.

- European Hydrogen Incidents and Accidents database HIAD 2.1, retrieved Dec 2023. Joint Research Centre, European Commission.

- Melideo, D.; Wen, J.; P., M. HIAD 2.0 - HYDROGEN INCIDENT AND ACCIDENT DATABASE. In Proceedings of the Proceedings of the 8th International Conference on Hydrogen Safety. ICHS, 2019.

- Pio, G.; Salzano, E. Accidental Combustion Phenomena at Cryogenic Conditions. Safety 2021, 7. [CrossRef]

- Ustolin, F.; Ferrari, F.; Paltrinieri, N. Prediction of Condensed Phase Formation during an Accidental Release of Liquid Hydrogen. Chemical Engineering Transactions 2022, 91, 439–444. [CrossRef]

- van Wingerden, K.; Kluge, M.; Habib, A.; Ustolin, F.; Paltrinieri, N. Medium-scale Tests to Investigate the Possibility and Effects of BLEVEs of Storage Vessels Containing Liquified Hydrogen. Chemical Engineering Transactions 2022, 90, 547–552. [CrossRef]

- Ustolin, F.; Tolias, I.C.; Giannissi, S.G.; Venetsanos, A.G.; Paltrinieri, N. A CFD analysis of liquefied gas vessel explosions. Process Safety and Environmental Protection 2022, 159, 61–75. [CrossRef]

- Kim, W.; Shentsov, V.; Makarov, D.; Molkov, V. Simulations of Blast Wave and Fireball Occurring Due to Rupture of High-Pressure Hydrogen Tank. Safety 2017, 3. [CrossRef]

- Sápi, Z.; Butler, R. Properties of cryogenic and low temperature composite materials – A review. Cryogenics 2020, 111, 103190. [CrossRef]

- Hohe, J.; Neubrand, A.; Fliegener, S.; Beckmann, C.; Schober, M.; Weiss, K.P.; Appel, S. Performance of fiber reinforced materials under cryogenic conditions—A review. Composites Part A: Applied Science and Manufacturing 2021, 141, 106226. [CrossRef]

- Zhang, J.; Lei, L.; Zhou, W.; Li, G.; Yan, Y.; Ni, Z. Cryogenic mechanical and hydrogen-barrier properties of carbon fiber composites for type V cryo-compressed hydrogen storage vessels. Composites Communications 2023, 43, 101733. [CrossRef]

- Grogan, D.; Leen, S.; Semprimoschnig, C.; Ó Brádaigh, C. Damage characterisation of cryogenically cycled carbon fibre/PEEK laminates. Composites Part A: Applied Science and Manufacturing 2014, 66, 237–250. [CrossRef]

- Hosseini, S.; den Otter, A.; Zevenbergen, J.; Atli-Veltin, B.; Dransfeld, C. Methodology for the identification of hydrogen gas permeation path in damaged laminates. In Proceedings of the 20th European Conference on Composite Materials: Composites Meet Sustainability. EPFL Lausanne, Composite Construction Laboratory, 2022, Vol. 5, pp. 306–313.

- SANDIA. SAND2012-7321, 2012. Technical reference for hydrogen compatibility of materials.

- DOD. 6055.9-STD, 2008. DOD AMMUNITION AND EXPLOSIVES SAFETY STANDARDS.

- CGA. G-5.5, 2021. Standard for Hydrogen Vent Systems.

- ASME. BPVC VIII, 2019. Boiler and pressure vessels code.

- CFR. 29CFR1910.103, 2022. Hydrogen.

- EIGA. Doc 100/20, 2020. Hydrogen cylinder and transport vessels.

- ISO. 15916, 2015. Basic consideration for the safety of hydrogen systems.

- NFPA. 55, 2023. Compressed Gases and Cryogenic Fluids Code.

- CGA. H-7, 2024. Standard Procedures for Hydrogen Supply Systems.

| Functional failure severity | WFHA |

|---|---|

| Catastrophic | 2 |

| Hazardous | 1 |

| Major | 0.5 |

| Minor | 0.1 |

| No effect | 0 |

| Function input | Output |

|---|---|

| < 2 | 1 |

| < 3 | 1.25 |

| < 4 | 1.5 |

| >= 4 | 2 |

| ID | Description | Risk |

|---|---|---|

| S031 | Prevent fuel leaks through fittings by using pressure locking, failproof strategies, and systematic inspections, while avoiding welded connections, inadequate surface preparation, incorrect usage, vibration. | 3.14 |

| S002 | Prevent collisions and crashes of the storage system during operations by installing sufficient mechanical barriers. | 3.00 |

| S050 | Ensure discharge path for lightnings are provided, and the surface of the vessel and the attached component is ESD compliant as indicated in AIAA G-095. | 3.00 |

| S005 | Ensure the tank wall permeation rate stays below the dormancy threshold under panel cryogenic conditions. Test tank wall samples for permeation under the operative cryogenic conditions. | 2.67 |

| S021 | Implement technologies for hydrogen release as a failsafe for emergencies, ensuring safe fuel dumping is always possible. Provide remote operation. | 2.64 |

| S024 | Designate an unsafe zone around the demonstrator during testing and install ventilation barriers to safeguard operators in the event of a hydrogen release. | 2.50 |

| S047 | Establish a procedure for purging and purge verification of tank and tubing. | 2.50 |

| S003 | Ensure that the frequency of valve failure remains consistently below a defined frequency threshold per flight hour for all applicable fluid flow conditions. | 2.36 |

| S035 | Provide redundancy in PRDs, ensuring they are installed on all isolated lines and connected properly to the vent line. | 2.29 |

| S009 | Design a safe venting system as defined in related standards such as CGA 5.5 to prevent risks such as backfire or detonation. | 2.25 |

| S022 | Prevent overfill by using diverse technologies for hydrogen metering and by pre-calculating the applicable flow from the fuel source. | 2.25 |

| S034 | Verify fuel and its quality (purity, vapor mass fraction, spin state) before filling to prevent accumulation of unwanted substances. | 2.25 |

| S049 | Ensure the control system can enforce operative limits determined following the system specifications. | 2.25 |

| S040 | Ensure that the percentage of tank wall voids due to improper manufacturing process conditions remains below a critical threshold and is not localized. | 2.00 |

| S023 | Implement automated systems to monitor and guide the fuelling process steps, halting openings if detachment or errors such as missing connection of ground venting are detected. | 1.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).