1. Introduction

1.1. Circular Focus

In a rapid change scenario, humanity is faced with a series of challenges that require adaptive and resolute responses to ensure progress and global welfare. Waste production is a global concern due to the adverse effects both on the environment and health of human beings [

1].

From the decade of 2000, on a global scale, the circular economy has become a core issue in many political, industrial and academic discourses, with initiatives aimed at rethinking the traditional economic models towards circular and sustainable systems, to reduce wastes, reuse materials and look for more environmentally responsible production processes [

2,

3]. “Circular economy is an industrial system that is restorative or regenerative by intention and design. It replaces the end-of-life concept with restoration, and moves toward the use of renewable energy eliminating the use of toxic chemicals, which affect reusing and being focused on waste disposal through superior design of materials, products, and systems and, within this, business models.” [

4]. Several studies have been focused on consumers and the industry awareness in environmental responsibility [

5,

6]. There is a growing tendency, among consumers, to extend life of products, motivated both by emotions and the increased environmental awareness [

7,

8,

9], showing change of behaviour which give value to products that respond to functional, emotional and environmental factors [

10,

11,

12]. This evolution focus, as well as the imminent need to reduce the polluting process in every level, have impact on the manufacturers' decisions regarding what and how to produce [

13,

14]. Sustainable development raises the urgent need to implement actions to gradually dispense fossil resources. From this perspective, the bioeconomy emerges as an alternative that provides bio-based materials to find new solutions for reducing dependence on non-renewable sources and reducing environmental impact [

15,

16].

1.2. Agro-Industrial Wastes and Bio-Based Textile Materials

The use of waste as raw material to manufacture products has opened new ways that contribute to the environmental sustainability. Bio-based materials are those derived from biomass [

17] of renewable origin; these are characterized as more biodegradable and generate a lower carbon footprint, compared to traditional materials [

18,

19]. Currently, 2010 million tons of agro-industrial waste is produced worldwide and is estimated to increase to 3400 million tons by 2050 [

20]. The use of agro-industrial waste is creating great interest in textile industry, as result of a growing demand for environmentally friendly materials [

21]. This type of residues represents a significant opportunity to improve sustainability in textile industry, innovate in materials and respond to a growing demand for products which prevent environmental damage [

22,

23]. They could become alternative to replace highly polluting materials in this sector [

24]. This use would allow converting waste into valuable resources and favor the innovation under sustainable approach, which attracts an increasingly environmentally conscious market [

25,

26]. The textile industry could reduce its dependence on conventional raw materials, such as cotton and polyester, which have a high environmental impact in terms of water use, land use and emissions. Sawdust is a global agro-industrial residue obtained from wood processing and exploitation activities. This storage under uncontrolled conditions results in environmental problems derived from toxic chemicals, the greenhouse emissions as well as the generation of leachates that affect surrounding groundwater and surface water sources [

27]. Sawdust presents valuable properties such as good mechanical stability, rough surface, high porosity, high surface area, absorbency, high carbon content, easy biodegradation and easy modification, which allows its application in different areas, as is the case of bio-based textile materials [

28,

29,

30,

31].

1.3. Transdisciplinary Collaboration

The experience of devising and manufacturing materials has evolved substantially and is moving to incorporate new ways of thinking and designing, with an increasing prevalence of design practices driven by a changing role of materials. Therefore, transdisciplinary collaboration emerges as a need to get solutions to complex problems, which disciplines individually cannot solve [

32,

33]. Design is a favorable discipline to take transdisciplinary actions, due to its multidisciplinary nature [

34,

35], while the materials design requires a whole approach to get significant advances in the definition of materials with positive projection with respect to the environment, user and market acceptance. Determining the use of industrial residues to design materials requires continuous collaboration during all phases of research project. Additionally, material design supposes sometimes a prior or separate step of product design, making innovation process to be more complex. In field of bio-based materials design [

36] transdisciplinary collaboration is even more demanding, as the number of research variables increases. To this extent, research in this field can trigger the development of closer transdisciplinary collaborations, contributing to the construction of a holistic approach to reach viable solutions based on knowledge integration [

37]. This way of seeing the world, from an integrative rather than additive perspective, emerges when researchers from different disciplines overcome their theoretical and methodological boundaries, to develop a common conceptual framework [

38]. Research in the field of materials design fosters transdisciplinary collaborations, as it is an area that requires knowledge from chemistry, engineering, design and sociology, generating a point of convergence for experts from different fields and public and private sectors [

39].

1.4. Methodological Focus

Methodology applied in this research considers a transdisciplinary approach, integrating knowledge and experiences from disciplines of industrial design, textile design, transdisciplinary design, chemical engineering, wood industry engineering and sociology. This transdisciplinary approach allowed addressing complex problems in a holistic way, to generate coherent solutions to reuse wastes from MASISA S.A, the main industry of wood panels in Chile, whose processes generate about 300 tons of sawdust per month, revaluing only 28%. The research was focused on the development of textile coatings by using radiata Pine sawdust. The materials used in coatings, as well as in textile substrates are bio-based to obtain a sustainable approach material [

40]. The concept of mono-material design is explored to improve mechanical recycling potential of clothing at the end of their life cycle [

41]. Mechanical recycling prototypes were manufactured at CITEVE theTechnological Center of Textile and Clothing Industry in Portugal. Studies of sawdust perceived quality were carried out in original format provided by the company and coatings were implemented under quantitative, descriptive-correlational, cross-sectional and non-experimental methodological approach.

2. Materials and Methods

2.1. Transdisciplinary Approach

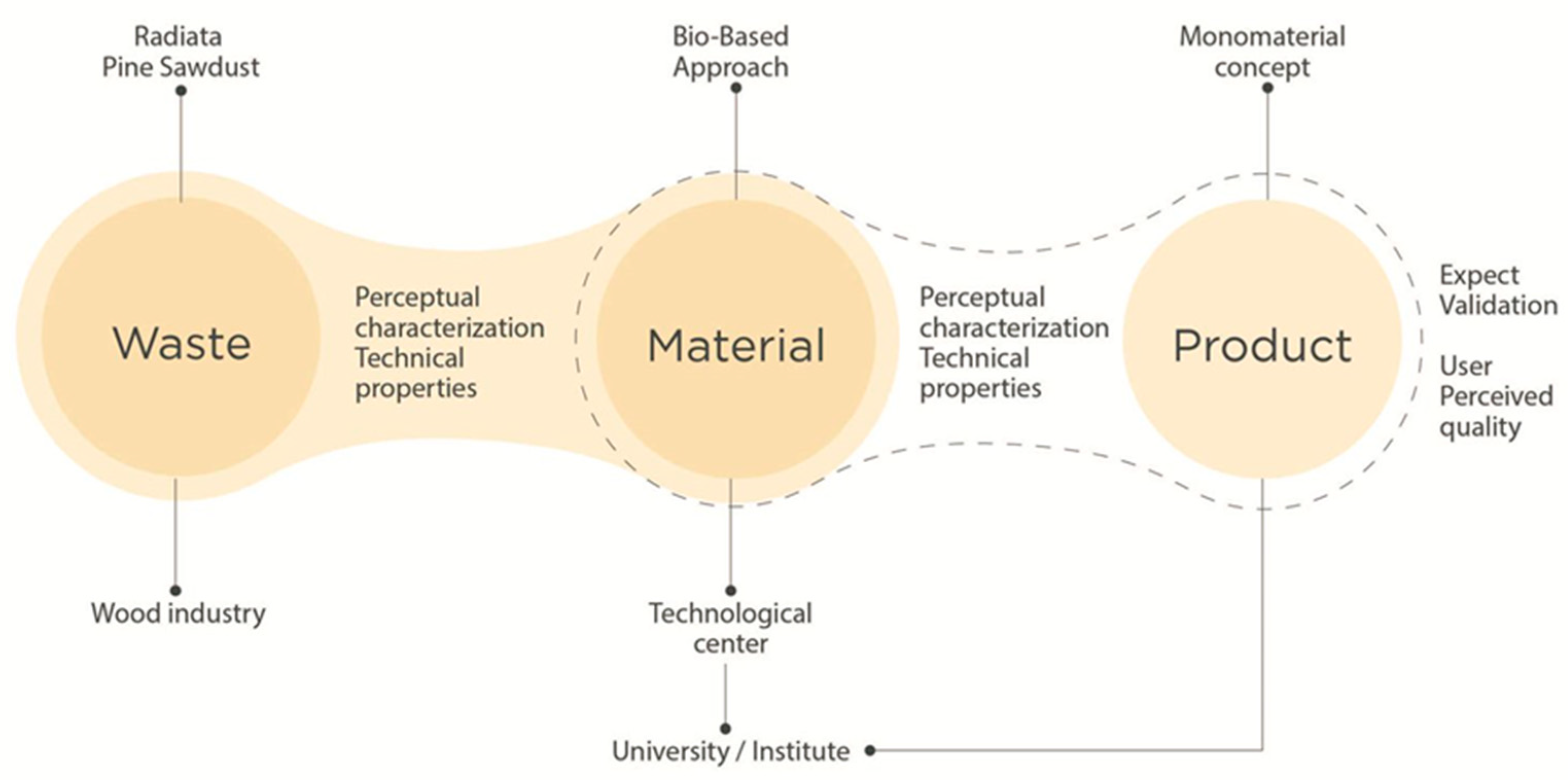

Disciplines involved in the current research are industrial design, textile design, transdisciplinary design, chemical engineering, wood industry engineering and sociology, coming from organizations in Europe and Latin America. The main concept is the development of a mono-material solution of clothing for craft work, manufactured with bio-based materials, including a lyocell textile structure made from cellulosic wood and a coating made with radiata Pine sawdust, a wood industry waste. Mono-material favours mechanical recycling at the end of product using cycle, which favours a circular economy approach. Chemical engineering is in charge of waste characterization and technical treatment, assessing formulas for coating mixtures, definition of the application of coating techniques and selection of textile substrates consistent with the sustainable approach. Engineering in wood industries performs testing of material prototypes in laboratory and interprets technical data. Industrial design area has a crossed and collaborative participation in every action carried out. It leads perceptual characterization of residues, conducts material and clothing prototyping experiments together with chemical engineers and textile designers. It collaborates with elaboration of instruments to gather perceptual information related to sawdust and prototypes of the two materials developed. It validates clothing process, endorsed by experts and users. Sociology specialist makes adjustments to perceptual information, gathering instruments and interprets data collected, evaluating the user acceptance level. When dealing with materials that integrate waste in their composition, prospecting user acceptance is especially important. Transdisciplinary design approach provides a structure focused on the collaboration and interrelation of disciplines involved in the research. It helps to see the problem as an opportunity to think of a systemic solution that revalues the sawdust generated by the wood industry and gives an impulse to the organization of the disciplines, institutions and their roles (

Figure 1).

2.2. Phases of the Transdisciplinary Process

The research process is structured in three main phases, consisting of co-design, co production and reintegration [

42,

43]. In co-design phase, common objectives are defined, and the problem is jointly conceptualized among research participants coming from academia, the industry and technology center. This phase is crucial to develop shared understanding of problem and ensure the disciplines and entities to be aligned with the project challenge. During the co-production phase, collaborative knowledge generation, integrating scientific knowledge with technical knowledge are emphasized. Iterative processes are developed to continuously improve concept, design and experimentation, through material and clothing prototypes. Reintegration phase allows proposing strategy that makes the co-created knowledge visible. In this research, relationship between the stakeholders involved as well as the transfer system for the integration of product into the market consists of the generation of synergies between public and private entities. MASISA S.A., primary supplier of residues, seeks to strengthen its corporate social responsibility, committing itself to the preservation of environment and adopt practices focused towards sustainability and circular economy. Education and research entities are articulating agents for knowledge generated to be transferred to various actors of territorial system.

2.3. Exploratory Design Phases

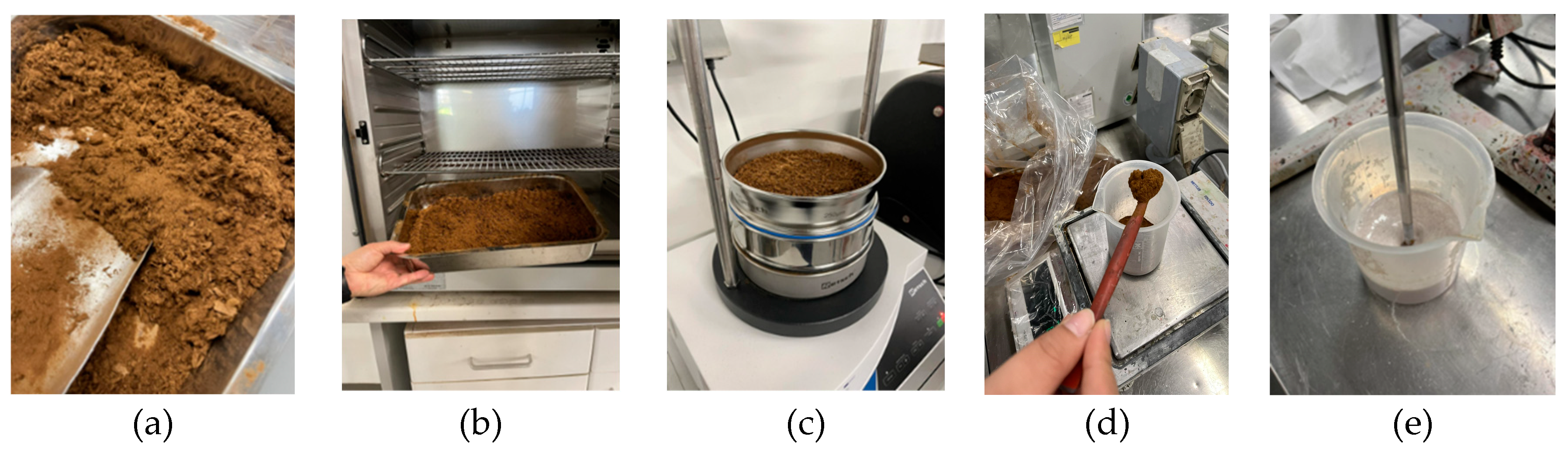

2.3.1. Exploration of Coating

Sawdust provided by MASISA S.A. is processed through a dehydration process at 40°C for 72 hours to eliminate residual moisture. Subsequently, it is introduced into an electric sieve until it reaches a particle size of 200 microns. The textile substrate used was a Lyocell knitted fabric, a fiber produced from wood pulp derived from sustainable grown trees, with the advantage that it does not require the use of environmentally harmful chemicals. The coating was composed of a bio-based polymer blend with 89.7% of a biobased polyurethane polymer (from CHT), 10% of sawdust and 0.3% of a water based crosslinker (from Covestro), homogenized with a mechanical stirrer (

Figure 2).

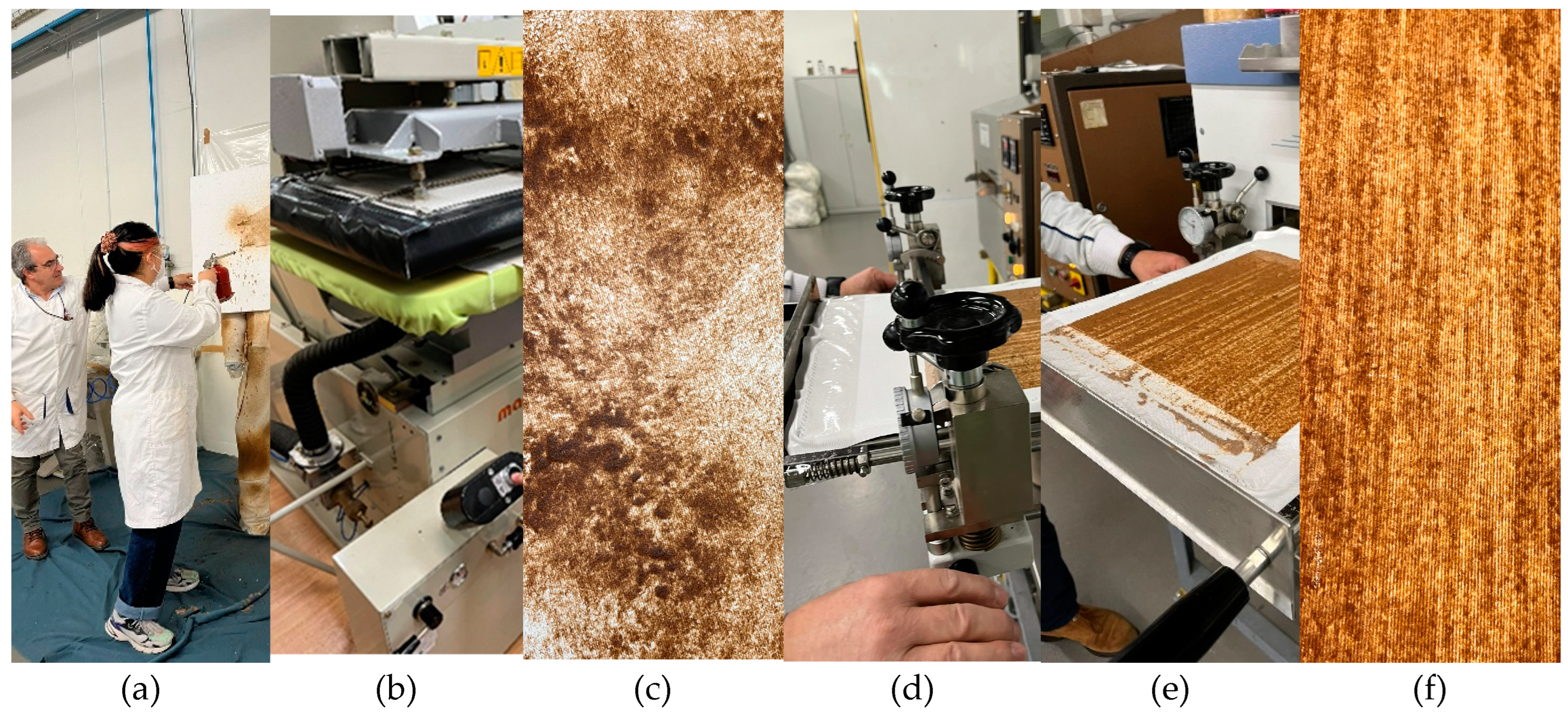

Two types of coatings were performed on the textile substrate. Coating 1 was done by spraying with a compressed air gun, adding 50% of water to make it compatible with the equipment used. Once coated, textile fabric was introduced into a hot air tunnel at 100°C and 5 m/min to evaporate water and reach optimum drying conditions. Coating 2 was carried out by means of a knife-on-roller process in Mathis AG LABCOATER type “LTE-S” multifunctional equipment, with a thickness of 1 millimeter. Subsequently, it is submitted to a thermosetting process at 100°C and 5 m/min to improve adhesion of coating to textile substrate. A topcoat was applied using an opaque biobased polyurethane, with transparency and flexibility (from Lamberti) to improve mechanical properties of material. The entire process was carried out at a temperature of 100°C and 5 m/min (

Figure 3).

2.3.2. Applied Exploration of Materials

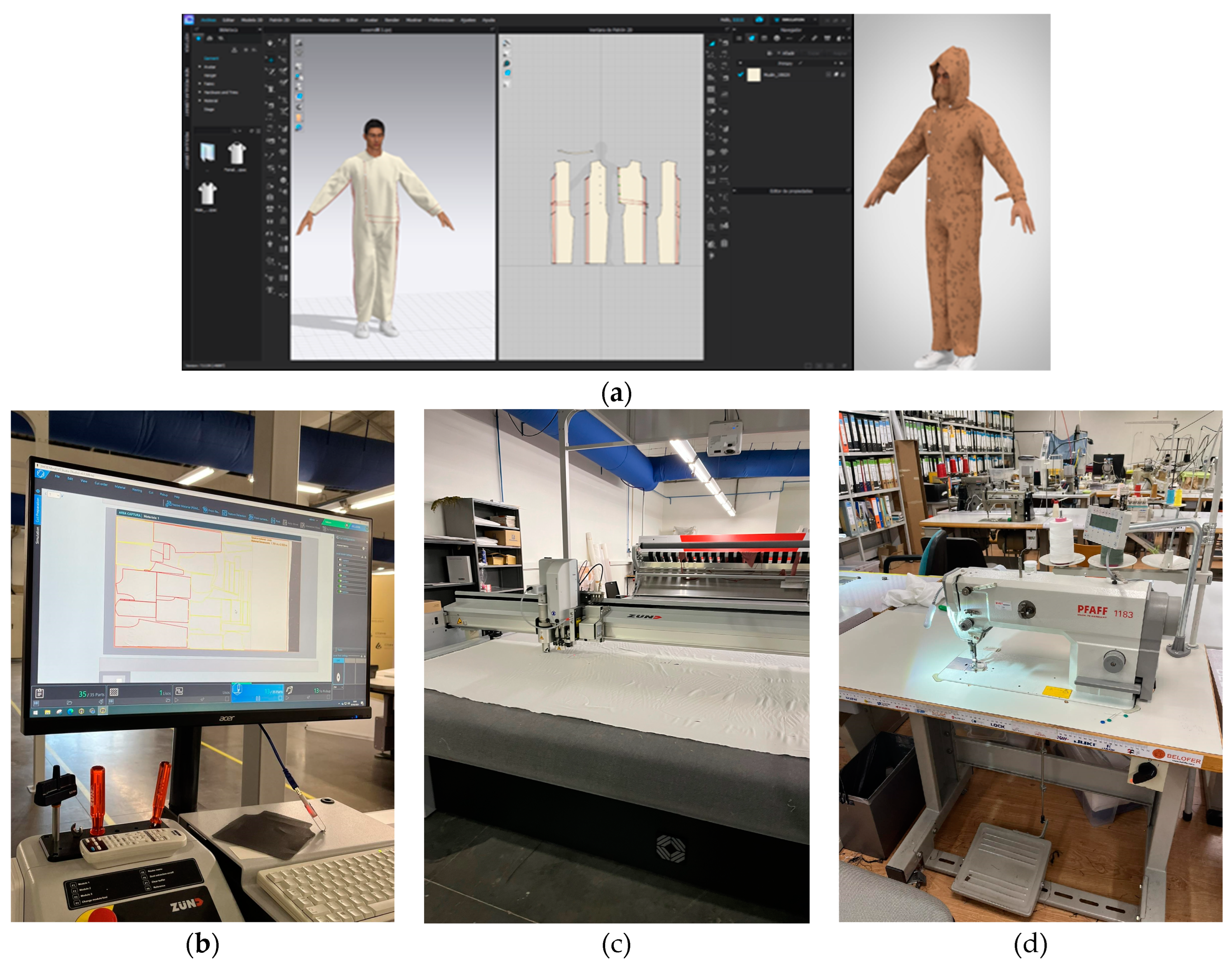

Clothing design is aimed at users who carry out craft work, such as painters and ceramist, among others. Conceptual idea considers proposal of mono-material approach, that is, that garment solves every function with designed material to favor mechanical recycling at the end of its life cycle. Three clothing models were designed by using CLO 3D software, which allows modelling in three dimensions and generating two-dimensional patterns simultaneously. Patterns were rectified and processed on a Zünd G3 cutter. The sewing was performed using straight machines and industrial overlock (

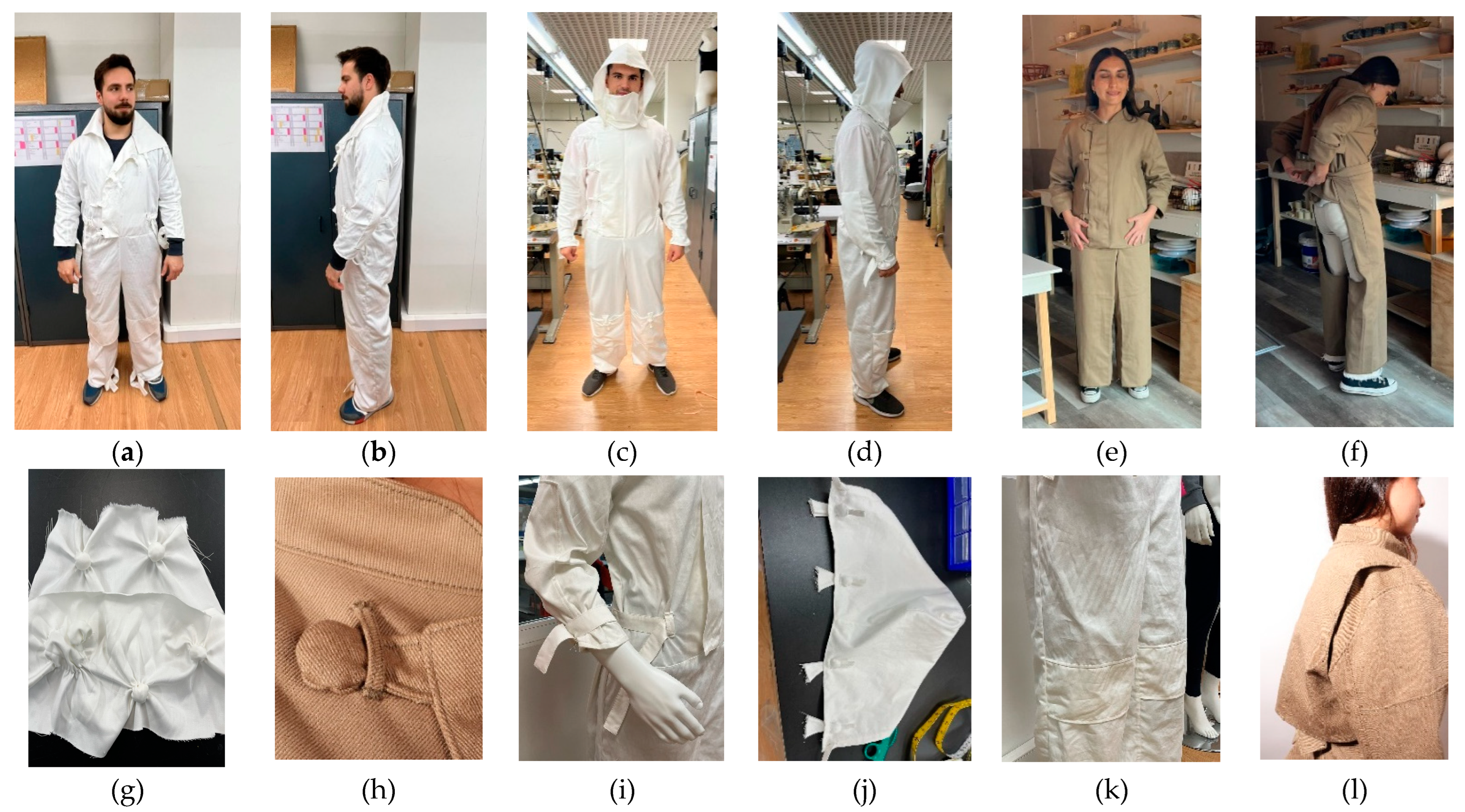

Figure 4).

The first prototype was a mono-material coverall that incorporates a head and face protection cup. A fitted system in lumbers, waist and fist was incorporated in order to provide a better coverall fitting for users. The second prototype incorporates removable head and face protection cup, as well as adaptable gussets to favor the mobility. The third prototype is a two-piece coverall, reinforced stitching is incorporated for better durability and resistance. Buttons and adjustment systems were manufactured with the same textile material and fibers ground in a Retsch SM 300 Cutting Mill machine (

Figure 5).

2.3.3. Perceived Quality Studies

2.3.3.1. Sawdust Study Method

In a first approach, the sawdust supplied by MASISA S.A. was evaluated by end-users to understand its natural properties and its influence on the potential application to products used daily by users. The methodological approach adopted was quantitative, descriptive-correlational, cross-sectional and non-experimental in nature. Non-probabilistic purposive sample in a controlled environment was considered, selecting 85 participants in a controlled environment. Sample is non-probabilistic and used purposive convenience sampling. Self-administered questionnaire was implemented with semantic differential tables and quantifiable options for data collection, using Likert-type response scale. Dimensions assessed included visual, olfactory, tactile, instrumental, associative and emotional aspects. Scale is based on an axis that represent one attribute, while the other axis indicates the opposite attribute, on a 1 to 5 scale, with value 3 as neutral point. Cronbach's alpha was used to assess reliability, which measures internal consistency correlating the means of every item. The test gave value of 0.69 and the inter-item correlation average was within the range established by Clark and Watson (1995) [

44], therefore, internal consistency of instrument was considered acceptable. To systematize superficial, associative and emotional perceptions, database was downloaded in MS Office© Excel sheet, so data were cleaned, transformed and processed in RStudio© interface version 2024.04.02, using R programming language version 4.1.1. Correlational of material analysis presented perception, potential usefulness description and relevant characteristics for purchase were carried out. Spearman's correlation, appropriate for common variables and non-parametric data, was used to analyse relationships between variables [

45].

2.3.3.2. Coating Study Method

The coated samples were also subjected to a perceived quality study by 32 users. Statistical analysis of perceptions was carried out to individuals in sample with respect the two options of coatings developed. In order to systematize visual, olfactory, tactile, instrumental, associative and emotional perceptions, the database was downloaded into MS Office© Excel spreadsheet, then data were cleaned, transformed and processed in RStudio© interface version 2024.04. 02, by using the R programming language version 4.1.1. To measure perceptions, semantic differential scales were used, where one axis represents one attribute, while the other axis points to opposite attribute, on 1 to 5 scale, with value 3 as neutral point. Correlational analysis of perception of materials presented and their potential use as a coating was carried out, as well as potential usefulness description and relevant characteristics for purchase. These analyses made possible to establish relationships between participant’s survey perceptions and commercial viability of analysed coatings. Internal consistency of items was measured by Cronbach's alpha, which yielded index 0.67 with 95% confidence value of 0.41 in lower limit and 0.85 in upper limit being within range of acceptability.

2.3.3.3. Clothing Validation by Users

Finally, the physical and psychological comfort validation of clothing prototypes was also carried out with 10 potential users, subjecting a high-fidelity prototype of craft work clothing to functional testing. The validation process lasts for eight working hours, making a physical and audiovisual record by users during one working day in a pottery workshop. At the end of the day, a structured interview was carried out, through the application of qualitative questionnaire and open questions. The results were processed using RStudio© software version 2024.04.02. and qualitative evaluation.

2.3.3.4. Material Tearing Strength Testing

The developed material samples were tested for their mechanical properties according to ASTM D 5587 Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure. For this test, five specimens from the machine direction to moisture equilibrium in the standard atmosphere were considered. Sample format was rectangular, 75mm width and 150 mm large, an outline of an isosceles trapezoid was marked on the specimen. The specimen was slit at the center of the smallest base of the trapezoid to start the tear. This test was carried out at speed of 300 ± 10 mm (12 ± 0.5 in./min) in the Instron 4468 machine.

2.3.3.5. Water Vapor Transmission Rate

The samples were tested for their thermal insulation and breathability properties, by determining their water vapor transmission rate, according to standard ASTM E96/96M, using the Desiccant Method. The sample test specimens (in triplicate), with 70 mm of diameter, were placed in a test dish of 200 cm3 containing 20 g of desiccant. The test dish is then sealed and incubated in a climate chamber at 23 °C and 50% (±3) of relative humidity. The weight variation was controlled with a precision of 0.01 g in regular intervals every 24 hours. The weight variation represents the amount of water vapor that is transferred from the environment to the desiccant. The weight is then plotted against time, and a regression curve is taken, to enable the calculation of the Water Vapor Transmission, using the following equation:

where:

WVT = rate of water vapor transmission, g/h.m2

G = weight change (from the straight line), in g

t = time, in h

G/t = slope of the straight line, in g/h

A = test area (cup mouth area), in m2

2.3.3.6. Determination of Volatile Loss

To evaluate the emission of volatile organic compounds (VOC) from the selected textile materials, the methodology described in ASTM D1203 – 94 was employed. The test samples are placed in direct contact with activated carbon, which captures the volatile compounds emitted by the material during the test. A 500 cm3 container was used to place the sample and the activated carbon distributed in 120 cm3 layers, which was heated in an oven at 70°C for a period of 24 hours. The samples were then removed, left at room temperature for 24 hours, and then weighed again to calculate the weight loss due to volatilization of the organic compounds present. The weight loss of VOCs was calculated according to equation 2:

where:

3. Results

3.1. Sawdust Validation by Users

The sawdust used in this work was subjected to a perceived quality study by 85 participants, as described in the previous section. Regarding gender distribution, most of respondents identified themselves as female (55.29%), followed by those who identified themselves as male (40%). Only one person (1.18%) did not identify with any gender and three (3.53%) preferred not to respond. With respect to age, a marked difference was observed, where 97.65% of participants was in the 18 to 28 age range and 2.35% in the 29 to 41 age range.

Regarding the occupation, 80% of participants are undergraduate design students, 12.94% design academics, 2.35% unemployed people and 4.71% are in other situations, such as informal jobs unrelated to design.

In sawdust perceptual study, sensory dimensions were evaluated and gave significant results in terms of visual, olfactory, tactile, instrumental, associative and emotional perceptions. For visual dimension, sawdust was predominantly perceived as having a matte finish, with 50% of frequency and perception index of 0.49. It was considered mostly opaque, with 48.2% of responses indicating a high level of opacity, and perception index of 0.15 for medium and low opacity levels. Texture of material was a relevant characteristic, with over 80% of total frequency, evenly distributed among textures, resulting in a perception index of 10. In olfactory, in spite that many participants could not identify or were indifferent to this characteristic, some indices indicated trends. Sawdust was perceived as pleasant (index of 2.06), natural (3.71), relaxing (1.50), defined (1.09) and soft (1.33). In tactile dimension, results showed it as warm with index of 1.48, and ductile with index of 1.62. In case of the Instrumental dimension, participants evaluated sawdust as versatile (index of 6.50), durable (3.00) and adaptable (1.00), showing that the material has diverse practical applications with potential acceptance by users. In associative dimension, sawdust was related to characteristics of naturalness, with index of 2.43 and frequency of 31.8% in extreme value of naturalness axis. It was also perceived as familiar with index of 2.10, indicating a connection with previous or known experiences. The Emotional dimension showed a notable neutral response, except from comfortable/uncomfortable axis. However, sawdust was perceived as welcoming (index of 2.14) attractive (2.05) comfortable (2.17) and calm (2.32). Other emotional aspects highlighted were confidence (1.31), cheerfulness (1.35), and comfort (1.95) (

Table 1).

Results indicated positive disposition of respondents towards sawdust questions, with acceptance of 59.52%. This suggests favourable openness by potential users towards its application in commonly used objects as well as living environments. Regarding the type of use, 33.73% indicated it should be used as a non-visible material, and 34.94% indicated the best option is as covering for visible surface. 59.09% consider it should be used in functional objects, while 40.91% consider it is appropriate for decorative objects. 61.36% indicated that it could be used in coatings for frequently used products. 69.88% stated they have seen objects with visual appearance similar to sawdust; 48.19% have seen coatings similar to sawdust. In general, olfactory dimension presents good correlation with emotional view, as well as the natural odor correlates mostly with associative dimension, both with natural and familiar axis. Therefore, sawdust presents positive user acceptance conditions in the studied environment, derived from analysis of variables submitted for questioning. The application referred to coatings and the exploration of non-conventional substrates such as natural textile fabrics stand out.

3.2. Coatings Validation by Users

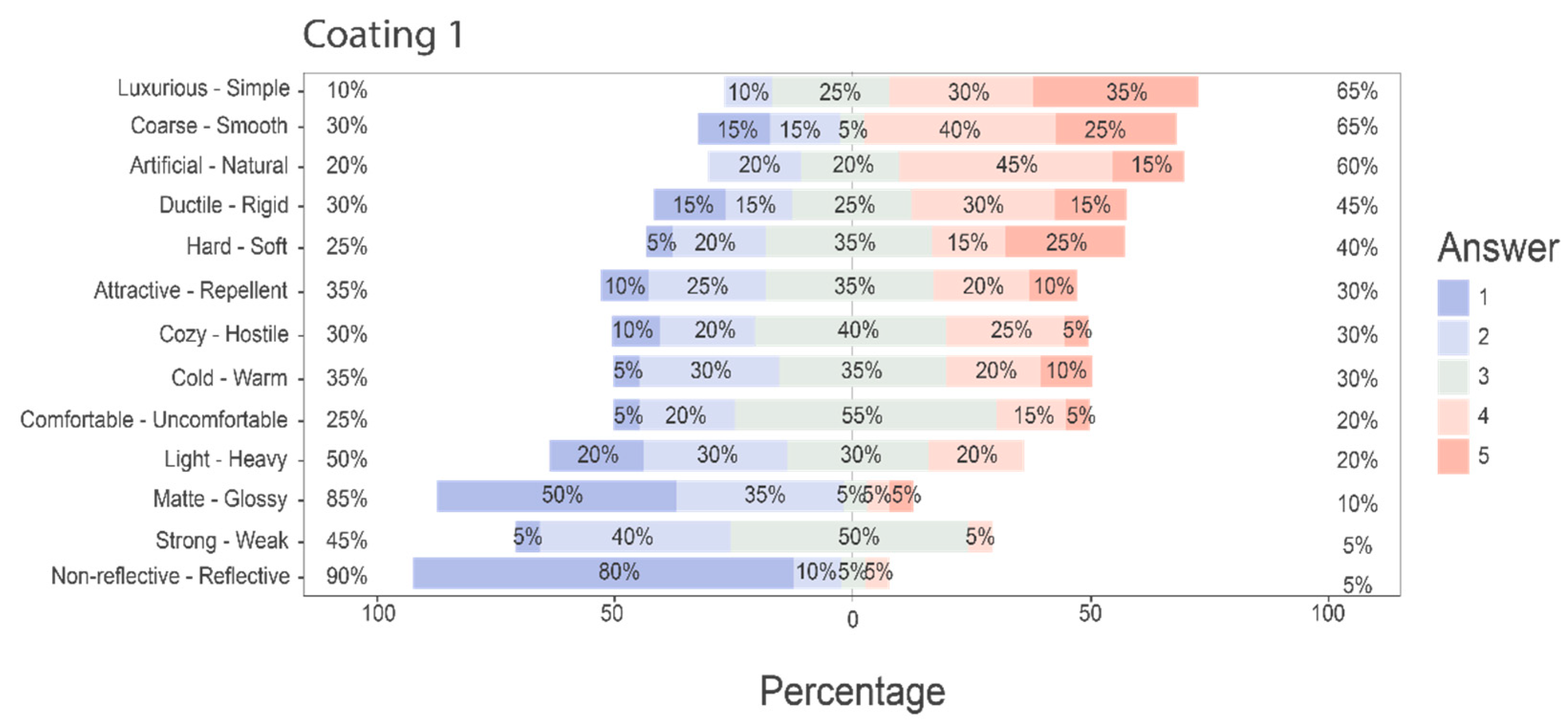

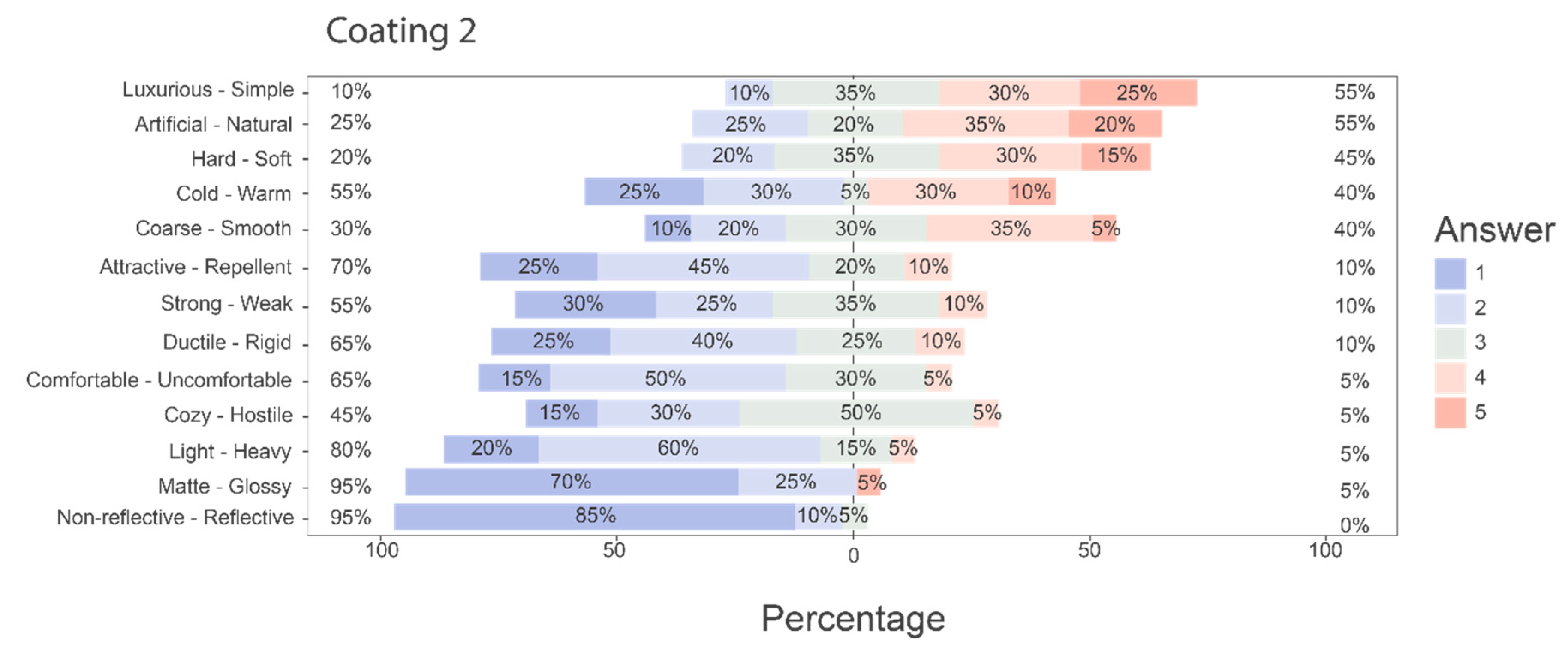

In what concern the materials developed within this work, a lyocell fabric with coating 1 and 2, were subjected to a perceived quality study, as described in materials and methods section. Perceptual study of coatings evaluated sensory dimensions (

Figure 6 and

Figure 7), which yielded significant results in terms of visual, olfactory, tactile, instrumental, associative and emotional perceptions. For visual dimension, material with coating 1 was mainly perceived with a matte finish reaching 85% of responses, being considered non-reflective by 90% of respondents. On the other hand, material with coating 2 showed an even more accentuated perception of these characteristics, where 95% of respondents described it as matte and non-reflective. Regarding texture, material with coating 1 was identified as smooth by 45% of participants, while material with coating 2 was perceived in the same way by 40%. In tactile dimension, results showed that in the thermal sensation variable, coating 1 was perceived as cold by 35% of respondents, warm by 30%, and remained 35% did not answer. Coating 2 was perceived as cold by 55%, a 40% perceived warm and only 5% were not decided. Material with coating 1 was considered soft by 40% of participants, compared to 45% of material with coating 2. Coating 1 was described as light by 50% of respondents, while coating 2 reached 80% in this perception. Material with coating 1 was perceived as strong by 45% of participants, compared to 55% who perceived same way material with coating 2. Material with coating 1 was perceived as rigid by 35%, compared to 30% who found it ductile and 25% did not decide. Material with coating 2 was perceived as rigid by 10% of participants, while 65% perceived it as ductile and 25% did not decide. In the Instrumental dimension, material with coating 1 was described as light by 50% of respondents and material with coating 2 reached 80% in this perception. In associative dimension, coating 1 was perceived as simple by 65% of respondents, while coating 2 reached 55% in this perception. In terms of naturalness, 60% of participants considered material with coating 1 as natural, compared to 55% for material with coating 2. Finally, in emotional dimension, coated material 1 was perceived as comfortable by 25% of respondents, uncomfortable by 20%. In contrast, coated material 2 was seen as comfortable by 65%, uncomfortable by 5%, with 30% not decided. Additionally, 30% perceived material with coating 1 as warm and 30% as inhospitable. Material with coating 2 was considered warm by 45%, inhospitable by 5%. In terms of attractiveness, coated material 1 was perceived as attractive by 35%, repellent by 30%, and 35% did not decide. On the other hand, coated material 2 was perceived as attractive by 70% of the participants.

Wilcoxon-Mann-Whitney test (W=104, p=0.01, effect=0.43), determined coated material 2 as the one with better acceptance in terms of coating potential, with 100% acceptance. As for category where coating would present a better utility, similar tendency was observed in both samples, where both materials are more associated with the use in craft work clothing (40% for coated material 1 and 47.37% for coated material 2) then, as casual/urban clothing (30% for coated material 1 and 31.58% for coated material 2) and as protective or safety clothing (25% for material with coating 1 and 21.05% for material with coating 2), where only coated material 1 was related to sports clothing. From the above, it can be concluded that, in spite that both materials present similar hierarchy in association, craft work clothing had higher association in coated material 2, as well as in casual/urban clothing, while for material with coating 1, the use as safe protection clothing was higher than coated material 2. Regarding reasons for purchase, 30% of respondents would prefer to buy coated material 1 due to accessibility; 50% would do so for aesthetic reasons; 40% of respondents would value its resistance; 30% would prefer it for the easy maintenance; and 5% would buy for comfort. For material with coating 2, 65% would choose for durability; 45% would choose for aesthetic reasons and 45% for resistance. Twenty-five percent of respondents would choose coated material 2 because of the easy maintenance. Finally, coated material 2 shows better acceptance, as a whole, compared to material with coating 1. This is evidenced by respondents' inclination towards more positive perceptions in terms of attractiveness, comfort and ductility of coated material 2. Although preferences in material utility categories are similar, tendency is the use in workwear, material with coating 2 stands out in accessibility, making it a more valued option for consumers.

3.3. Clothing Validation by users

The physical and psychological comfort validation of the clothing prototypes was carried out as described in the materials and methods section with 10 potential users, that used the prototype for eight working hours (one working day) in a pottery workshop. After that, the users were interviewed and invited to reply to a qualitative questionnaire. Users positively valued the minimalist and mono-material approach in clothing. The characteristics of fabric in terms of its technical constitution and perceived quality were well appreciated. Clothing flexibility was an appreciated item, indicating the product allowed them to move easily during tasks on site. In addition, comfort was highlighted, mentioning they always felt safe wearing clothing. Additionally, to positive evaluation, they suggested ideas to improve which could increase product's functionality, such as integrating additional hooks and pockets for tools. Their feedback will be guidelines for design optimization, aiming at getting better practical requirements of users in craft work environments

3.4. Material Tearing Strength Testing

The developed material samples, ie, Lyocell control fabric (without coating), Lyocell fabric with spray-applied coating (Coating 1), and Lyocell with coating and topcoat (Coating 2), were tested for their mechanical properties, as previously described in the materials and methods section. The obtained results are shown in

Table 2.

Tensile test results show significant differences with respect to evaluated materials. Lyocell control sample (without coating) reached a maximum load of 0.27 kN and a significantly higher extension of 86 mm, compared with coated samples.

Coated material 1 showed a higher tensile strength, with a maximum load of 0,53 kN, but the elongation was significantly lower (only around 11 mm), meaning that the comfort properties of the coated fabric, in terms of stretchability, were compromised. Finally, it was seen that coated material 2 showed a slight improvement of tensile strength (around 0,31 kN), but the elongation attained was in a similar range (around 60 mm), meaning that the coating was not interfering with the mechanical properties of the base Lyocell fabric. These results confirm the perception studies with the users in relation with the comfort dimension.

3.5. Water Vapor Transmission Rate

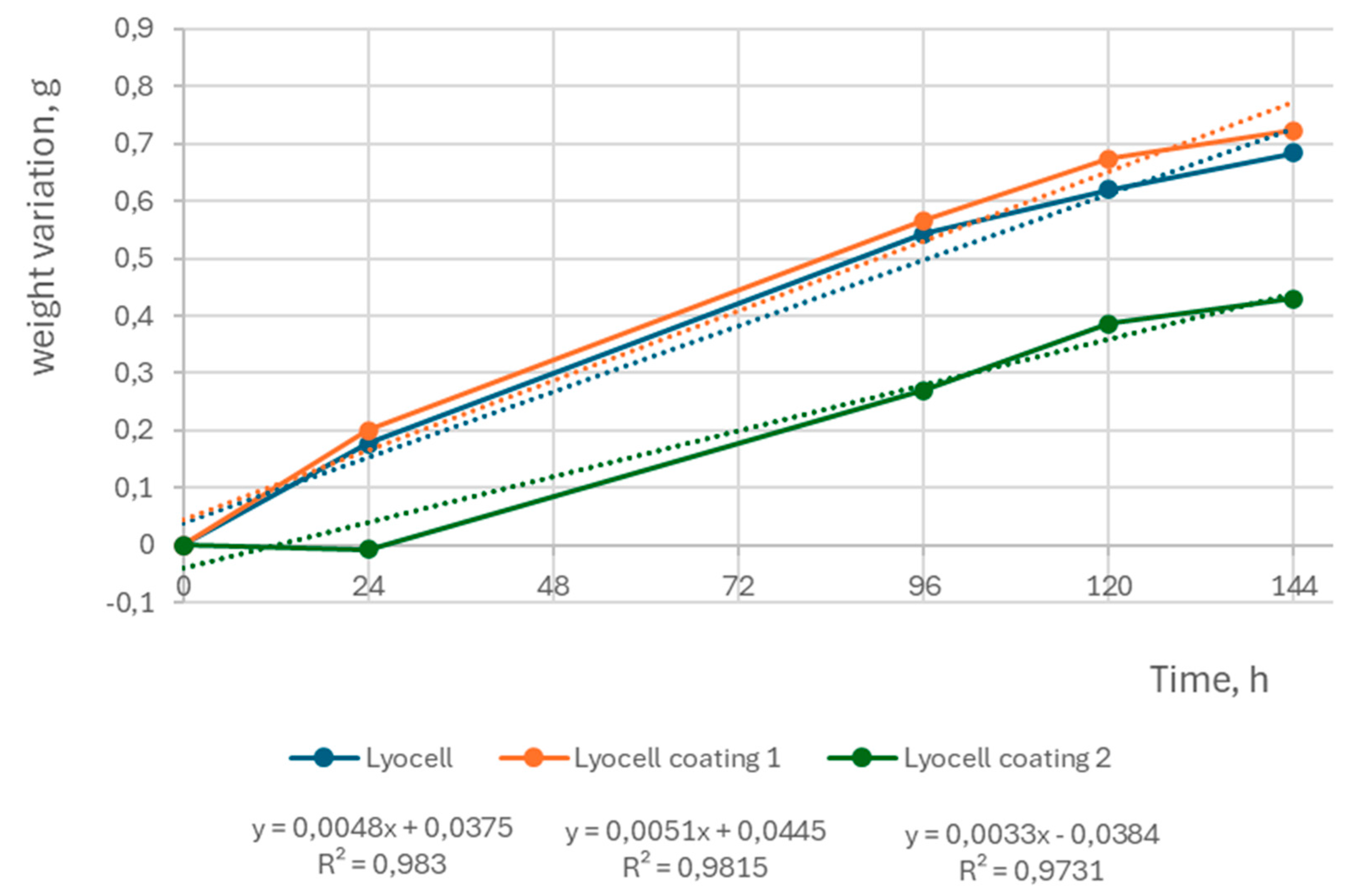

For determining the breathability properties of the developed materials, the water vapor transmission rate was determined, according to standard ASTM E96/96M.

The weight variation was followed for 7 days, being the sample weight registered in function of the time (

Figure 8). A regression analysis was performed for each regression curve, and the WVT calculated (

Table 3).

Lyocell fabric presented a WVT of 1.25 g/h.m2. Regarding the coated material 1, there was a slight increase in the WVT (1.32 g/h.m2), that can be explained by the adsorption of humidity by the sawdust. Contrarily, coated material 2 showed a decrease in the WVT to 0.86 g/h.m2, that can be explained by the homogeneous coating at the fabric surface, that might block the passage of water vapor through the sample. Water vapor transmission (WVT) and water resistance (WR) are two important properties of functional textiles for thermo-physiological comfort to the human body. WVT will maximize the comfort level of the human body, and the higher the better, since it means that the fabric breathability is increased, and water vapor can pass easily through the fabric surface (

Figure 9).

Finally, the emission of volatile compounds from the selected textile materials was also evaluated according to standard ASTM D1203 – 94, as described in the materials and methods section (

Figure 10). This test is essential to evaluate the stability of materials and their possible impact on air quality in workspaces, being considered low when the weight loss variation is below 1%.

Table 3 shows the results for the weight loss variation by the emission of VOCs from the samples. As can be seen, only sample material with coating 1 has a higher emission of VOCs, showing a weight loss variation of 3.6 %. This value can be explained by the adsorption and desorption of VOCs from the sawdust, that is sprayed onto the fabric. When the sawdust was encapsulated by a top coating finishing, the emissions were greatly reduced and a value of 1.1 % for the weight loss was attained, very similar to the control sample. These results are also in agreement with the WVT results.

The materials characterisation results are in agreement with the results of the perceived quality studies and motivated the selection of coated material 2 manufacturing the craft work clothing prototypes, that were built with lyocell with coating and topcoat.

4. Discussion

In the European Union, consumers produce about 5.8 million tons of textile waste each year, of which 25% is recycled and 75% is landfilled or incinerated [

46,

47]. Although this industry has a great impact on the economy, generating US

$2.5 trillion dollars annually [

48] the overuse of water, polluting materials, chemicals, etc., has significant socio-environmental impact. Mitigating the permanent damage generated is consistent with contributions that come from a transdisciplinary approach. The integration of various disciplines allows addressing problems from multiple perspectives, favoring the identification of opportunities to design new solutions for textile industry and revealing the revaluation of industrial waste as a possible alternative.

This research highlights how textile materials design can act as trigger for transdisciplinary collaboration, underlining the importance of integrating knowledge from various disciplines to holistically address challenges, which are inherent to bio-based materials research. When it comes to projecting a bio-based material, the process of research and definition of answers is more complex [

49] as it involves considering additional variables, such as waste use and treatment, carbon footprint minimization and a controlled life cycle [

50] aspects which are perfectly aligned with circular economy principles [

51,

52,

53]. The assessment of perceived quality and user acceptance is crucial to develop comprehensive and systemic solutions [

54,

55,

56]. In this scenario, design, technical innovation, user acceptance and market prospection are required, which is favored by transdisciplinary research.

From a sustainable approach, the mono-material design is presented as a key strategy to address some of the most critical challenges in waste management. Mono-material design simplifies recycling process by using a single type of material in product manufacturing [

57]. This avoids the need to separate different materials at the end-of-life cycle, reducing costs and improving recycling efficiency. By eliminating barriers presented by products made of composite or mixed materials, recyclability rate is significantly increased. In addition, the design of mono-material products reduces cross-contamination during recycling that, in turn, reduces the non-recyclable waste generation. This approach contributes to reduce environmental footprint of products, aligning with global sustainability goals [

58,

59].

Results provide a positive view of feasibility of coating textiles with blends including sawdust. Exploring the use of these residues in the field of clothing could become an opportunity for MASISA S.A. and other similar companies to find a solution to revalue higher percentage of wastes. To make this real, a complete management system is necessary to allow the whole logistics and value chain to work together in one territory, so as to ensure the waste transfer, treatment and processing cycle to be carried out properly. Additional actions could be developed to solve the systemic and logistical aspects [

60].

This research experience is a proof of the transdisciplinary collaboration power as a fundamental part of generating positive and empathetic synergies between actors and agents involved, in the search for innovative solutions that benefit both the industry and the environment. Future research could be focused on developing this methodological approach in different contexts, as well as on the integration of other professionals and waste management from different sectors, broadening impacts and applicability. To introduce improvements to the surface of the material, textures can be designed to increase the emotional appeal of the fabric and contribute to other dimensions of empathy with user preferences in different contexts of use, such as urban, everyday-domestic, among others.

5. Conclusions

Transdisciplinary is shown as an essential process for technical innovation and acceptance both by user and market, making it possible to address complex problems that would be difficult to solve from a single discipline. In addition, relationships are established between disciplinary and non-disciplinary actors, working through a holistic approach which considers cultural, social, economic and educational areas. This approach is closely aligned with the principles of circular economy, showing that the use of wood industry waste not only reduces environmental impact, but also adds value by converting by-products into useful materials.

The research also highlights the importance of assessing perceived quality and user acceptance, crucial elements for the development of comprehensive and systemic solutions. The transdisciplinary research process facilitates the creation of innovative solutions and generates collective learning among participants, allowing the acquisition of new skills and knowledge applicable in other contexts. This experience demonstrates the transformative power of transdisciplinary collaboration in generating positive and empathetic synergies among the actors involved.

6. Acknowledgments and Funding

The authors thank the Chilean National Agency for Research and Development (ANID), through research project FONDECYT REGULAR code 1221361 as well as the integrated project be@t – Textile Bioeconomy (TC-C12-i01, Sustainable Bioeconomy No. 02/C12- i01.01/2022), promoted by the Recovery and Resilience Plan (RRP), Next Generation EU, for the period 2021 – 2026, led by CITEVE. Both projects have provided financing. Finally, the authors acknowledge MASISA S.A. Chile for the sawdust provided.

References

- Gaur, V. K.; Sharma, P.; Sirohi, R.; Varjani, S.; Taherzadeh, M. J.; Chang, J. S.; Kim, S. H. Production of biosurfactants from agro-industrial waste and waste cooking oil in a circular bioeconomy: An overview. Bioresour. Technol. 2022, 343, 126059. [Google Scholar] [CrossRef]

- Murthy, V.; Ramakrishna, S. A review on global E-waste management: Urban mining towards a sustainable future and circular economy. Sustainability 2022, 14(2), 647. [Google Scholar] [CrossRef]

- Eberhardt, L. C. M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18(2), 93–113. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. 2012, p- 7, disponible en: www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf.

- Jaeger-Erben, M.; Jensen, C.; Hofmann, F.; Zwiers, J. There is no sustainable circular economy without a circular society. Resour. Conserv. Recycl. 2021, 168, 105476. [Google Scholar] [CrossRef]

- Scott, K. A.; Weaver, S. T. To repair or not to repair: What is the motivation? J. Res. Consum. 2014, 26(1), 43–44. [Google Scholar]

- Magnier, L.; Mugge, R. Replaced too soon? An exploration of Western European consumers’ replacement of electronic products. Resour. Conserv. Recycl 2022, 185. [Google Scholar] [CrossRef]

- Terzioğlu, N. Repair motivation and barriers model: Investigating user perspectives related to product repair towards a circular economy. J. Clean. Prod. 2021, 289, 125644. [Google Scholar] [CrossRef]

- Roskladka, N.; Jaegler, A.; Miragliotta, G. From “right to repair” to “willingness to repair”: Exploring consumers' perspective to product lifecycle extension. J. Clean. Prod. 2023, 432, 139705. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; Den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Schallehn, H.; Seuring, S.; Strähle, J.; Freise, M. Customer experience creation for after-use products: A product–service systems-based review. J. Clean. Prod. 2019, 210, 929–944. [Google Scholar] [CrossRef]

- Van Der Velden, M.; Maitre-Ekern, E.; Wanja, D. K. The role of independent repair in a circular and regenerative economy. Circ. Econ. Sustain. 2023, 1–26. [Google Scholar] [CrossRef]

- Ackermann, L.; Mugge, R.; Schoormans, J. Consumers' perspective on product care: An exploratory study of motivators, ability factors, and triggers. J. Clean. Prod. 2018, 183, 380–391. [Google Scholar] [CrossRef]

- Ackermann, L.; Tuimaka, M.; Pohlmeyer, A. E.; Mugge, R. Design for product care—development of design strategies and a toolkit for sustainable consumer behaviour. J. Sustain. Res. 2021, 3(2), e210013. [Google Scholar]

- König, C. C.; Pinsky, V. C. Bioeconomy: Brazilian Potential and Challenges. In Sustainability Challenges of Brazilian Agriculture: Governance, Inclusion, and Innovation; Springer Int. Publ.: Cham, 2023; pp. 271–291. [Google Scholar]

- Huber, P.; Kurttila, M.; Hujala, T.; Wolfslehner, B.; Sanchez-Gonzalez, M.; Pasalodos-Tato, M.; Vacik, H. Expert-based assessment of the potential of non-wood forest products to diversify forest bioeconomy in six European regions. Forests 2023, 14(2), 420. [Google Scholar] [CrossRef]

- Kawashima, N.; Yagi, T.; Kojima, K. How do bioplastics and fossil-based plastics play in a circular economy? Macromol. Mater. Eng. 2019, 304(9), 1900383. [Google Scholar] [CrossRef]

- Mahari, W. A. W.; Waiho, K.; Fazhan, H.; Necibi, M. C.; Hafsa, J.; Mrid, R. B.; Sillanpää, M. Progress in valorisation of agriculture, aquaculture, and shellfish biomass into biochemicals and biomaterials towards sustainable bioeconomy. Chemosphere 2022, 291, 133036. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Agarwal, M. Biobased building materials for sustainable future: An overview. Mater. Today: Proc. 2021, 43, 2895–2902.

- Ahmad Khorairi, A. N. S.; Sofian-Seng, N. S.; Othaman, R.; Abdul Rahman, H.; Mohd Razali, N. S.; Lim, S. J.; Wan Mustapha, W. A. A review on agro-industrial waste as cellulose and nanocellulose source and their potentials in food applications. Food Rev. Int. 2023, 39(2), 663–688. [Google Scholar] [CrossRef]

- Priya, A. K.; Alagumalai, A.; Balaji, D.; Song, H. Bio-based agricultural products: A sustainable alternative to agrochemicals for promoting a circular economy. RSC Sustainability 2023, 1(4), 746–762. [Google Scholar] [CrossRef]

- Thorenz, A.; Wietschel, L.; Stindt, D.; Tuma, A. Assessment of agroforestry residue potentials for the bioeconomy in the European Union. J. Clean. Prod. 2018, 176, 348–359. [Google Scholar] [CrossRef] [PubMed]

- Barati, B.; Karana, E. Affordances as materials potential: What design can do for materials development. Int. J. Des. 2019, 13(3), 105–123. [Google Scholar]

- Bekkering, J. D.; Nan, C.; Schröder, T. W. A. Circularity and Biobased Materials in Architecture and Design. Circular Report 2021, available in: https://downloads.ctfassets.net/h0msiyds6poj/4cUyquZDX8Zx6WlmxEgw94/b32f801bbb24050527d10a00108617b9/CIRCULAR_Report.pdf.

- Van Der Velden, M. “Fixing the world one thing at a time”: Community repair and a sustainable circular economy. J. Clean. Prod. 2021, 304, 127151. [Google Scholar] [CrossRef]

- Van den Berge, R.; Magnier, L.; Mugge, R. Until death do us part? In-depth insights into Dutch consumers’ considerations about product lifetimes and lifetime extension. J. Ind. Ecol. 2023, 27(3), 908–922. [Google Scholar] [CrossRef]

- Adegoke, K. A.; Adesina, O. O.; Okon-Akan, O. A.; Adegoke, O. R.; Olabintan, A. B.; Ajala, O. A.; Bello, O. S. Sawdust-biomass-based materials for sequestration of organic and inorganic pollutants and potential for engineering applications. Curr. Res. Green Sustain. Chem. 2022, 5, 100274. [Google Scholar] [CrossRef]

- Özkan, İ. G. M.; Aldemir, K.; Alhasan, O.; Benli, A.; Bayraktar, O. Y.; Yılmazoğlu, M. U.; Kaplan, G. Investigation on the sustainable use of different sizes of sawdust aggregates in eco-friendly foam concretes: Physico-mechanical, thermal insulation and durability characteristics. Constr. Build. Mater. 2024, 438, 137100. [Google Scholar] [CrossRef]

- Mallakpour, S.; Sirous, F.; Hussain, C. M. Sawdust, a versatile, inexpensive, readily available bio-waste: From mother earth to valuable materials for sustainable remediation technologies. Adv. Colloid Interface Sci. 2021, 295, 102492. [Google Scholar] [CrossRef]

- Reis, A.; Coelho, L.; Rosa, M.; Batista, P.; Carvalho, M.; Moura, B.; Fernandes, S. M.; et al. Chapter: Innovation of textiles through natural by-products and wastes. 2020.

- [Aigbomian, E. P.; Fan, M. Development of Wood-Crete building materials from sawdust and waste paper. Constr. Build. Mater. 2013, 40, 361–366. [Google Scholar] [CrossRef]

- Hadorn, G. H.; Hoffmann-Riem, H.; Biber-Klemm, S.; Grossenbacher-Mansuy, W.; Joye, D.; Pohl, C.; Zemp, E. Handbook of Transdisciplinary Research. Springer 2008, 10, 978–1. [Google Scholar]

- O’Brien, W.; Soibelman, L.; Elvin, G. Collaborative design processes: An active- and reflective-learning course in multidisciplinary collaboration. J. Constr. Educ. 2003, 8(2), 78–93. [Google Scholar]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Nguyen, M.; Mougenot, C. A systematic review of empirical studies on multidisciplinary design collaboration: Findings, methods, and challenges. Des. Stud. 2022, 81, 101120. [Google Scholar] [CrossRef]

- European Committee for Standardization. Bio-based products—Vocabulary. EN16575:2014. 2014, available in: https://standards.cen.eu.

- Tramontin, V.; Trois, C. Implementing a holistic approach to foster higher education for sustainability. In Proc. 2016 World Congr. Sustain. Technol. 2016, pp 12–13.

- Zeiler, W.; Savanovic, P.; van Houten, R. Multidisciplinary master design projects based on workshops for professionals. In Proc. Int. Des. Eng. Tech. Conf. Comput. Inf. Eng. Conf. 2009, 49057, 439–450. [Google Scholar]

- Orozco-Messana, J.; de la Poza-Plaza, E.; Calabuig-Moreno, R. Experiences in transdisciplinary education for the sustainable development of the built environment: The ISAlab workshop. Sustainability 2020, 12(3), 1143. [Google Scholar] [CrossRef]

- Miassi, Y. E.; Dossa, K. F. Circular economy initiatives for forest-based bioeconomy:Harnessing the potential of non-wood biomaterials. Waste Manag. Bull. 2024. [Google Scholar]

- Pollini, B.; Rognoli, V. Early-stage material selection based on life cycle approach: Tools, obstacles, and opportunities for design. Sustain. Prod. Consum. 2021, 28, 1130–1139. [Google Scholar] [CrossRef]

- Bergmann, M.; Schäpke, N.; Marg, O.; Stelzer, F.; Lang, D. J.; Bossert, M.; Gantert, M.; Häußler, E.; Marquardt, E.; Piontek, F. M.; Potthast, T.; Rhodius, R.; Rudolph, M.; Ruddat, M.; Seebacher, A.; Sußmann, N. Transdisciplinary sustainability research in real-world labs: success factors and methods for change. Sustain. Sci. 2021, 16(2), 541–564. [Google Scholar] [CrossRef]

- Schäpke, N.; Omann, I.; Wittmayer, J. M.; Van Steenbergen, F.; Mock, M. Linking transitions to sustainability: A study of the societal effects of transition management. Sustainability 2017, 9(5), 737. [Google Scholar] [CrossRef]

- Clark, L.; Watson, D. Constructing validity: Basic issues in objective scale development. Psychol. Assess. 1995, 7, 309–319. [Google Scholar] [CrossRef]

- Bryman, A. Social research methods. Oxford Univ. Press 2016. [Google Scholar]

- Zhou, Q.; Le, Q. V.; Meng, L.; Yang, H.; Gu, H.; Yang, Y.; Peng, W. Environmental perspectives of textile waste, environmental pollution, and recycling. Environ. Technol. Rev. 2022, 11(1), 62–71. [Google Scholar] [CrossRef]

- Grazzini, L.; Acuti, D.; Aiello, G. Solving the puzzle of sustainable fashion consumption: The role of consumers’ implicit attitudes and perceived warmth. J. Clean. Prod. 2021, 287, 125579. [Google Scholar] [CrossRef]

- Brydges, T. Closing the loop on take, make, waste: Investigating circular economy practices in the Swedish fashion industry. J. Clean. Prod. 2021, 293, 126245. [Google Scholar] [CrossRef]

- Huang, J.; Chen, F.; Chen, L. Acceptance of biobased materials in the market: The influence of knowledge, perceived value, and eco-labels. Sustainability 2020, 12(7), 2850. [Google Scholar] [CrossRef]

- Köhler, J.; Geels, F. W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Boon, W. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef]

- Zikopoulos, C. On the effect of upgradable products design on circular economy. Int. J. Prod. Econ. 2022, 254, 108629. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Gaziulusoy, A. İ.; Ryan, C. Roles of design in sustainability transitions projects: A case study of Visions and Pathways 2040 project from Australia. J. Clean. Prod. 2017, 162, 1297–1307. [Google Scholar] [CrossRef]

- Zhang, C.; Xue, J.; Yang, X.; Ke, Y.; Ou, R.; Wang, Y.; Wang, Q. From plant phenols to novel bio-based polymers. Prog. Polym. Sci. 2022, 125, 101473. [Google Scholar] [CrossRef]

- Rognoli, V.; Petreca, B.; Pollini, B.; Saito, C. Materials biography as a tool for designers’ exploration of bio-based and bio-fabricated materials for the sustainable fashion industry. Sustainability: Science, Practice and Policy 2022, 18(1), 749–772. [Google Scholar] [CrossRef]

- Provin, A. P.; de Aguiar Dutra, A. R.; Machado, M. M.; Cubas, A. L. V. New materials for clothing: Rethinking possibilities through a sustainability approach—A review. J. Clean. Prod. 2021, 282, 124444. [Google Scholar] [CrossRef]

- Gonçalves, A.; Henriques, E.; Ribeiro, I. Towards plastics circular economy: Sustainability assessment of mono-material design for recycling. Procedia CIRP 2024, 122, 401–406. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Kiruba, T. Bacterial cellulose—A potential material for sustainable eco-friendly fashion products. J. Nat. Fibers 2022, 19(9), 3275–3287. [Google Scholar] [CrossRef]

- Kamp Albæk, J.; Shahbazi, S.; McAloone, T. C.; Pigosso, D. C. Circularity evaluation of alternative concepts during early product design and development. Sustainability 2020, 12(22), 9353. [Google Scholar] [CrossRef]

- Palacios, A. F.; Glen, C. P.; Galindez, A. C.; Munchmeyer, A. W.; Narvaez, M. J. B. Prototype of a self-sufficient biofabrication protocol for remote territories. Dearq 2020, 26, 110–118. [Google Scholar] [CrossRef]

Figure 1.

Transdisciplinary approach process with stakeholders and waste pathing.

Figure 1.

Transdisciplinary approach process with stakeholders and waste pathing.

Figure 2.

(a) Sawdust put on tray to enter the drying oven, (b) Sawdust in drying oven, (c) Sawdust in Retsch AS 200 CONTROL analytical sieve shaker, (d) Sawdust weighing in Mettler Toledo PG5002-S Delta Range, (e) Homogenization of coating mixture in a mechanical agitator Techmatic S2.

Figure 2.

(a) Sawdust put on tray to enter the drying oven, (b) Sawdust in drying oven, (c) Sawdust in Retsch AS 200 CONTROL analytical sieve shaker, (d) Sawdust weighing in Mettler Toledo PG5002-S Delta Range, (e) Homogenization of coating mixture in a mechanical agitator Techmatic S2.

Figure 3.

(a) Application of coating mixture by spraying with a compressed air gun, (b) Pressing in industrial flat bonding press Macpi 553.37-9124, applying pressure and heat, (c) Visual aspect coating 1, (d) and (e) Application of mixture with knife on roller technique in Mathis AG LABCOATER type “LTE-S” equipment, (f) Visual aspect coating 2.

Figure 3.

(a) Application of coating mixture by spraying with a compressed air gun, (b) Pressing in industrial flat bonding press Macpi 553.37-9124, applying pressure and heat, (c) Visual aspect coating 1, (d) and (e) Application of mixture with knife on roller technique in Mathis AG LABCOATER type “LTE-S” equipment, (f) Visual aspect coating 2.

Figure 4.

(a) Use of CLO 3D software for 3D modeling and 2D pattern making, (b) Pattern / fabric optimization in CLO 3D software, (c) Zünd G3 fabric cutting table, (d) Pfaff 1183 industrial straight sewing machine.

Figure 4.

(a) Use of CLO 3D software for 3D modeling and 2D pattern making, (b) Pattern / fabric optimization in CLO 3D software, (c) Zünd G3 fabric cutting table, (d) Pfaff 1183 industrial straight sewing machine.

Figure 5.

(a) Prototype 1, front view, (b) Prototype 1, side view, (c) Prototype 2, front view, (d) Prototype 2, side view, (e) Prototype 3, side view, (f) Prototype 3, front view, (g) mono-material stuffing experiment, (h) mono-material button experiment, (i) adjustment straps, (j) front buttons, (k) reinforcement seams, (l) adaptable gussets.

Figure 5.

(a) Prototype 1, front view, (b) Prototype 1, side view, (c) Prototype 2, front view, (d) Prototype 2, side view, (e) Prototype 3, side view, (f) Prototype 3, front view, (g) mono-material stuffing experiment, (h) mono-material button experiment, (i) adjustment straps, (j) front buttons, (k) reinforcement seams, (l) adaptable gussets.

Figure 6.

Summary of evaluation of material with coating 1 sensory dimensions.

Figure 6.

Summary of evaluation of material with coating 1 sensory dimensions.

Figure 7.

Summary of evaluation of material with coating 2 sensory dimensions 2.

Figure 7.

Summary of evaluation of material with coating 2 sensory dimensions 2.

Figure 8.

(a) Overview of the samples in the sealed test vessels before water adsorption, (b) Overview of the samples in the sealed test vessels after water adsorption and climate chamber conditions used in the determination of the water vapor transmission rate.

Figure 8.

(a) Overview of the samples in the sealed test vessels before water adsorption, (b) Overview of the samples in the sealed test vessels after water adsorption and climate chamber conditions used in the determination of the water vapor transmission rate.

Figure 9.

Regression curves for the data obtained for the weight variation in function of the time, for the different tested samples (lyocell, coated material 1 and coated material 2).

Figure 9.

Regression curves for the data obtained for the weight variation in function of the time, for the different tested samples (lyocell, coated material 1 and coated material 2).

Figure 10.

(a) Visualization of the textile samples in the test vessel containing the activated carbon: a) during the trial, (b) Visualization of the textile samples in the test vessel containing the activated carbon at the end of the trial.

Figure 10.

(a) Visualization of the textile samples in the test vessel containing the activated carbon: a) during the trial, (b) Visualization of the textile samples in the test vessel containing the activated carbon at the end of the trial.

Table 1.

Summary sawdust characteristics with the highest perceived repetition in each dimension:.

Table 1.

Summary sawdust characteristics with the highest perceived repetition in each dimension:.

| Dimension |

Main characteristics |

| Visual |

Matte, Opaque, Textured |

| Olfactory |

Natural, Relaxing, Definite, Smooth |

| Tactile |

Warm, Ductile, Light, Soft, Rough |

| Instrumental |

Versatile, Durable, Adaptable |

| Associative |

Natural, Familiar |

| Emotional |

Friendly, Attractive, Calm, Confident, Cheerful, Pleasant, Comfortable |

Table 2.

Tensile test results.

Table 2.

Tensile test results.

| Test sample |

Material |

Load (kN) |

Elongation (mm) |

| Control fabric |

Lyocell |

0,27 |

86 |

| Coating 1 |

Material 1 (lyocell with spray-applied coating) |

0,53 |

11 |

| Coating 2 |

Material 2 (lyocell with coating and topcoat) |

0,31 |

60 |

Table 3.

WVT and weight loss results.

Table 3.

WVT and weight loss results.

| Test sample |

Material |

WVT (g/h.m2) |

Weight loss (%) |

| Control fabric |

Lyocell |

1.25 ± 0,18 |

0.8 ± 0.7 |

| Coating 1 |

Lyocell with spray-applied coating |

1.32 ± 0,19 |

3.6 ± 0.3 |

| Coating 2 |

Lyocell with coating and topcoat |

0.85 ± 0,12 |

1.1 ± 0.4 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).