1. Introduction

Mega projects, including airports and smart cities faces many challenges in the operation period (Mckinsey, 2020) show that 30% of facility management budgets are wasted due to the unplanned maintenance and inefficient resource allocation. The appearance of new technologies such as Building Information Modeling (BIM) and Artificial Intelligence (AI) encourages stakeholders to control, calculate, and predict the maintenance cost for any building especially the establishing of large scale projects, whether between institutions or countries, has become a great importance impact in both economic and promotion uses. Hence, inefficiencies in large-scale construction projects can be solved by integrating AI and DT into facilities management (FM). AI helps facilities managers move from reactive to proactive management by improving data-driven decision-making and predictive maintenance (Piras et al., 2024; Agostinelli, 2021). DT technology improves operations and system monitoring by creating dynamic, real-time replicas of physical facilities (Zhao et al., 2022). Adding IoT and BIM to AI-powered DT frameworks has improved resource utilization and reduced maintenance costs (Omrany et al., 2023; Ryzhakova, 2022).

According to research, AI and DT technologies improve predictive maintenance, real-time monitoring, and energy optimization in smart buildings (Chew et al., 2020; Lv et al., 2022; Mahmoodian et al., 2022; Rafsanjani & Nabizadeh, 2023). Lv et al. (2022) and Mahmoodian et al. (2022) emphasize a predictive role in reducing sudden equipment failures, while Boje et al. (2020) emphasize the semantic role of DT in asset performance. Implementing AI-driven frameworks like predictive maintenance and energy optimization machine learning models has improved operational sustainability (Rafsanjani & Nabizadeh, 2023; Chew et al., 2020). Despite these advances, existing frameworks often lack interoperability and scalability, essential for managing large-scale facilities with interconnected systems and diverse operational requirements (Zhao et al., 2022; Sepasgozar, 2023). Piras et al. (2024) and Deng et al. (2021) propose methods for integrating BIM with IoT and AI in DT environments, but they often overlook the practical challenges of mega facility implementation, such as cost, user-friendliness, and real-time responsiveness. Cybersecurity, data privacy, and lack of standardization hinder adoption (Pan & Zhang, 2021; Sepasgozar, 2020).

Traditional FM approaches, relying on manual data collection and reactive maintenance, struggle to cope with the scale and complexity of mega facilities. This results in inefficiencies, delays in decision-making, and increased operational costs. These top-down approaches lead to a lack of real-time insights, delays in making decisions, inefficiency documentations, and operation that will directly impact the facilities’ operation cost. Nevertheless, the use of new technologies such as AI and DT services is promising a revolution in mega projects’ facilities management by making them more data-driven and proactive compared to conventional reactive solutions (Rana Khallaf et al., 2022). In this research, an AI-powered DT platform for predictive maintenance, security control, and safety in large construction facilities is proposed to fill these gaps. It guides organizations to overcome challenges and improve facility management efficiency and sustainability with an easy-to-use predictive platform.

Some research has explored AI/DT in FM, a framework integrating real-time sensor data, BIM, and AI for holistic, proactive facility management in mega-facilities is lacking. This paper presents a novel AI-powered DT demo platform designed specifically for mega-facilities. The platform integrates real-time sensor data with BIM models to read and follow the main effective facilities as HAVC, Fire, Temperature, CCVT and Humidity to build the predictive maintenance required for the machines, energy optimization, and scenario-based analysis. This paper intends to create and cast into action a thorough AI-powered DT platform designed for large facilities in order to overcome these constraints. The main target is to explain how to integrate real time IoT sensor data with BIM models to enhance the predictive maintenance and optimize resources allocation to reduce the overall building maintenance costs.

The objective of this paper is to investigate the advantages of AI and DT tools in the management of large-scale construction project facilities, as predicative maintenance, security control, safety which will help the reduction maintenance costs and give full control for the operator to avoid any sudden failure for any facility. This paper explores a proposal for a platform that can collect the real time data which helps the decision making processes and provide scenario simulations to identify best practices and potential challenges offering guidelines for the future implementation of such services in large scale facilities. This paper is a guide for any organization that is willing improve the efficiency and sustainability of mega-facility management in any building by discussing the challenges and put a road map for applying DT with AI algorithm to prepare an easy-use predictive platform.

2. Literature review

The combination of AI and DT technology in FM is receiving considerable focus for its ability to enhance operational efficiency and decision-making in challenging environments like large scale facilities (Fuller et al., 2020). This integration gained attention for its potential to address critical challenges such as interoperability, scalability, real-time analysis and security (Lv et al., 2022; Mahmoodian et al., 2022; Piras et al., 2024). One of the main challenges is using BIM technology in AEC industry due to the few skilled engineers that can implement the parameters of the facilities in the model to integrate with the DT. In addition, the advance uses of BIM and importing the model in platform with the right format and requirements is another huge challenge.

To prepare a complete platform it was necessary to add an option for predictive maintenance which is another service that has benefited from such incorporation of deep reinforcement learning and federated learning to optimize resources for various facilities (Rana Khallaf et al., 2022). In addition, Kim et al. (2020) showed an approach using reinforcement learning algorithms for real-time occupancy-based HVAC systems dynamic setting, which achieves energy savings up to 25% in a large commercial projects. It also introduced a federated learning paradigm, to enable AI models to be collaboratively trained across facilities without centralizing sensitive data thus answering the privacy concerns of cloud-based systems (Khallaf et al., 2022). This becomes a crucial necessity in the domain of managing large facilities with multiple stakeholders connecting from different data centers willing to share common datasets securely and maintaining privacy.

To explain this integration, several methods for integrating these technologies have been suggested, each having unique advantages and drawbacks. One popular approach involves using machine learning algorithms with IoT sensor data in real-time to update DT models and accurately reflect the building systems (Tao et al., 2018). Forecasting systems/equipment failures using historical trends has been made possible through the use of predictive models such as regression analysis and neural networks. This shift allows facility managers to move from reactive maintenance strategies to proactive ones (Zhou et al., 2020). For example, utilizing AI for predictive maintenance has been proven to decrease unforeseen breakdowns by as much as 40%, leading to a substantial decrease in maintenance expenses and reducing operational disturbances (Shao & Kibert, 2018).

As a result, the choice of an optimal AI-DT integration strategy should be provisioned in compliance with the needs associated to any targeted FM environment considering parameters like data sensitivity and accessibility, complexity of systems involved as well as its extensibility. The advantages can be grouped as shown in

Table 1 into four main areas: predictive maintenance, enhanced energy efficiency, improved asset management, and real-time decision-making. By utilizing AI-generated information and live data from DT, facilities managers can prolong the lifespan of assets, save energy, improve operational effectiveness, and decrease maintenance costs and downtime. So this paper focused in making the easiest module for importing the model with IFC format and create a demo live platform that can any user can use.

To build a DT platform for mega projects as hospital and airports, three triangle members should be used a good structured BIM model with parameters first for each facility. Second, they use the IoT and AI in collecting and control data. Third, a good visualization with easy use platform and IoT DT technology which enhance the FM by providing advanced visualization and remote FM were achieved with augmented reality (AR) and virtual reality(VR) integrated in DT models as well for classification concepts relating them through literature review process at hand (Omrany et al., 2023). Integration of the BIM with IoT which became an important step of the modern FM environment besides new technologies like AI and DT to enable live data exchange and automated decision-making. BIM is a digital representation of the physical and functional characteristics of a building that serves as shared knowledge resource for information about its design, construction and operation (Lee et al. 2018). When applied to facilities management, BIM models function as thorough databases on spatial layout, asset descriptions and building system information that underlie data informed decision-making concerning maintenance or upgrades (Jones et al., 2021; Rafsanjani & Nabizadeh, 2023). But traditionally, BIM models are static and do not have real time updates to capture the changes in operations of buildings (Fuller et al., 2020). This limitation highlights the value of connecting BIM and DT technology for establishing a more dynamic and interactive FM scenario.

One of the incredible applications of using the new software which based on BIM and AI to protect the building is the prediction of what effect directly to it. A strong live application was in Italy which holds most of the world cultural heritage, but it has a territory widely subject to high hydrogeological risk, while most research on flood risk focuses on potential monetary losses. Those costs would be exponentially higher if we took a more holistic view and calculated the losses in cultural heritage. The Arno River flows from the Mount Falterona hills of the Apennine Mountains through Florence and eventually to the Ligurian Sea. Modeling the overland runoff that flows from the Apennine mountains to the upper basin to the Arno is straightforward enough. But predicting pluvial floods further down the line becomes more complicated when there are countless interactions that need to be captured between all of the hydraulic phenomena happening in the city’s sewer system.

Tamagnone turned to a predictive program (InfoWorks ICM) which could be used to evaluate both 1D and 2D interactions between surface runoff processes, the urban sewer system, and the internal drainage network, provided he could model the many buildings and sewer networks in the IRDN area to 100% accuracy. He was fortunate to be able to begin his work by retrieving existing models of the public sewer network (PSN) directly from the regional public utility, with all this information in hand, he was able to propose a two-pronged strategy as part of a documented emergency plan. First, he proposed a structural strategy of building an anti-flooding barrier to prevent storm water intrusion, which uses the results from his model to determine the recommended height of the barrier. In addition, he proposed a non-structural strategy of creating flood risk maps for the staff and administrators to highlight the most exposed and at-risk areas. The results of this study are beneficial for both the Water Managers, enhancing the level of knowledge of the sewer network functioning, and Site Managers, improving the effectiveness of their hazard management and emergency plans (Tamagnone & Sidoti, 2022).

To get the maximum benefit of using DT, it should be easy to any user that is not specialized to use the DT platform, AR and VR have been driving the design of smart facilities which include 3D interactive environment for real-time visualization of asset conditions or operational scenarios to allow facility managers to test new strategies related to maintenance, energy optimization and emergency response (Omrany et al., 2022). These advances reflect an increasing shift to interactive and more secure DT platforms for facility managers, combining greater flexibility with real-time management.

Although there have been advancements lately, there are still various research areas that need to be addressed in combining AI and DT technology for managing facilities in large facilities. Interoperability between various software platforms and data formats is a significant issue (Tao et al., 2018), (Abdelalim, A.M., et.al. 2016,2019,2020,2021,2023, 2024). Numerous current solutions depend on exclusive data formats, leading to challenges in connecting various BIM models, IoT devices, and FM platforms seamlessly (Sepasgozar, 2020; Riaz et al., 2019). This problem is tackled by using open data standards like IFC and Building SMART data schemas to encourage interoperability and ease data exchange between different systems (Lee et al., 2018). Another issue is the absence of real-time scenario analysis and automated decision support, which are essential for controlling complex facilities with interconnected systems (Fuller et al., 2020). Although many current platforms provide simple monitoring and predictive maintenance features, the new solution includes advanced AI algorithms that can simulate various scenarios and suggest the best maintenance strategies (Pan & Zhang, 2021; Zhou et al., 2020). Additionally, scalability continues to be a constant issue, with many platforms finding it difficult to handle the large amounts of data produced by massive projects (Boehm & Avila, 2021).

Another study that use the DT and IoT during Covid-19 on a building in Rome, the Lazio Region headquarter council, it is a building with two basements and twelve floors designed to accommodate about 120 employees in 60 offices with total number of about 1370 workstations (Piras & Muzi, 2024). The target of this study is to organize the occupation of office by three scenarios, to work remotely or work in office total hybrid to work remotely or in office. The benefits of making this study is to avoid the presents of a large number of employees, reduce the electricity fees which has become a huge expense for any institute or company, a reduction in allocated space would translate into lower costs commonly related to a desk. As an example, a smart strategy could be developed to eliminate up to 20% of the space used for workstations and, if 30% of the company population were to perform smart working in shifts for two days a week, the specific articular adjustments of the floor desk areas would lead to the ultimate unlocking of office spaces. Rent, utilities, maintenance, heating, and telephone service costs can be reduced by up to 30%. But enterprise space management systems in smart buildings require some basic characteristics, segregated further by operator, i.e. the facility manager and the users. The system should be accessible to all users from both device and mobility perspective, therefore mobile and fixed access is desirable, also the reservo-system must support a user friendly approach, so that it could be used by non-trained people, and in addition to that platform should provide the indoor navigation and people location system in order to enable users to quickly understand how to find their fellow workers and how to reach various company zones/buildings with easily following and understandable direction instructions (Piras & Muzi, 2024).

This case study on Lazio Region Headquarters demonstrated that the real-time data integration to support dynamic decision-making as a result of the accurate digital replication enabled by BIM for the implementation of a DT enabled a reduction of 530.40 MWh in energy consumption and a 641.32 tons reduction in GHG emissions. The power of DT is to improve the resource management, energy efficiency, and sustainability of public facilities. However, some challenges, such as data security issues, resistance to operational shifts, large initial investment requirements, and complexities of integrating systems. Pats, aside from the technical ones, will be very stringent and expensive assets to acquire. In addition, the proposed DT approach can be further expanded for other domains such as control of urban traffic, decision-making for port and airport operations, and so on the path to smart city development, which is important to future quality of life (Piras & Muzi, 2024).

In most cases, facility management or facilities management seeks to involve and include such activities as maintenance and repair, management of space, management of resources, and management of the activities related to buildings’ assets (IFMA, 2020). With the scope and complexity of construction projects increasing, these management activities become a lot more complicated and warrant a thorough and scientific approach in terms of enhancing operational effectiveness in the short and long run (Nijhuis et al, 2016). In the opinion of Atkin and Brooks (2021) facilities management, in turn, is an important factor affecting success or failure of mega facilities as neglecting this discipline can lead to grave mismanagement and wastages as well as interruptions within the workflow. As a result, real-time cameras, predictive and scenario-based decision-making make incorporating AI and DT technology essential for overcoming these challenges.

Real-time data on building parameters, which includes the temperature and humidity of spaces within the buildings; energy usage features that have been listed in (Zhou et al., 2020) is another type of event-triggering information read from IoT sensors. Besides showing information directly on models, data integrated with BIM transforms even static representations of BIM into real-time replicas allowing seeing what the building currently looks like (Tao et al., 2018). This integration would be beneficial by many ways

Real-Time Monitoring of Building Systems — IoT sensors offer 24/7 access to live data on the operation and efficiency of building systems, such as HVAC, lighting, or security. Engineering data can be fed into BIM models to help managers view and analyze systems in real time, detect operational inefficiencies faster, and address issues before they place the facility at risk for significant problems (Grieves & Vickers, 2017).

Predictive Maintenance — IoT sensors can detect early warnings of equipment deterioration, such as weird vibrations in machinery or spikes on temperature levels in electrical systems (Lee et al., 2018). When integrated with BIM, this data supports predictive maintenance that can allow facility managers to predict when equipment will fail and plan proactive maintenance rather than reactive repair, minimizing unscheduled downtime while optimizing annual allowances for operation and replacement of existing assets within a system.

Energy optimization — IoT sensors monitor energy consumption on the more granular level thereby providing information to facility mangers about their inefficiencies and consequently linking them to potential measures of saving energy (Kim et al., 2020) This information can also be integrated into BIM models, where it is possible to perform energy simulations such as different strategies for optimizing the use of energy (Riaz et al., 2019).

The main advantages of this platform by incorporating DT technology and AI in facilities management. The combination of AI and DT technology in building operations brings multiple benefits, revolutionizing the way buildings are supervised, serviced, and improved.

Table 2 shows the main advantages of utilizing DT in the functioning of a building.

AI and DT technologies can enhance the FM of a large facilities. Dynamic Data Updates: Traditional EIR models, which depend on static data, can quickly become outdated (Jones et al., 2021). And the addition of live IoT sensor data allows these EIR frameworks to produce real time reporting of asset systems health, energy usage and space usage, allowing facility managers access to real-time, accurate information on their facilities performance (Fuller et al., 2020). Enhanced Information Accuracy: Through the removal of human manual data entry processes, IoT sensors optimize the fidelity of the data input, ensuring that EIR reports are exceptionally punchy (Chew et al., 2020; Grieves & Vickers, 2017; Zhao et al., 2022). This is especially important for large-sized facilities, where EIR assumptions or data errors could have huge financial impacts (Shao & Kibert, 2018).

Automated Compliance and Reporting: IoT data in EIR frameworks can be utilized to automate compliance reporting ensuring that buildings meet regulatory standards and performance benchmarks. For example, this automation can minimize the effort associated with manual reporting, enabling facility managers to devote more time to decision-making and strategic planning (Zhou, 2020). But these advantages can be availed only if the EIR is well prepared with all necessary information and organized details. The EIR using Level 2 BIM specifies the structured data formats, deliverables, and asset information standards, with an increased focus on interoperating and collaboration between stakeholders. This facilitates smooth access to FM data and defines formats and deliverables from stakeholders (Riaz et al., 2019).

EIR was long thought as a passive common framework to allow information requirements to be accommodated over the course of the project. On the other hand, automated EIR is a groundbreaking way in which the model is constantly modified based on live internet of things (IoT) data that captures the true operational state of the structure (Shao & Kibert, 2018). This way, multiple stakeholders will coordinate together, the information will be served with relevance, and actionable insights will be automated along the site life

3. Problem Statement

In this context, an advanced digital strategy is developed to optimize the management of various facilities of any building, improve operational efficiency, and reduce costs and environmental impact. The proposed demo approach uses IoT sensors to assess parameters like temperature, pressure, and lighting. Managing large-scale facilities is a daunting challenge, particularly ensuring energy efficiency and operational sustainability through FM. Data segmentation and system isolation are significant issues, resulting in inefficiency and a reactive approach to resource management. Such as HVAC, which is the case of mega-facilities (airports, hospitals, etc.) who have thousands of devices and equipment relying on its own software systems, so it is getting up energy consumption at a great cost. Moreover, the existing systems do not allow integrated use of BIM, IoT, and FM systems only hamper the potential of the FM domain, as these systems often operate in silos while data-driven decision-making is imperative for facility managers. Such fragmentation makes it challenging to predict critical factors, such as when equipment will break down or how energy consumption will trend, resulting in much more costly reactive maintenance and unsustainable operations.

Table 3 demonstrates what are considered the most pressing problems in using AI and DT technologies in facilities management. Most of the concerns raised about data and system interoperability are caused largely by the lack of guidelines and data standards for the different systems and tools enhancing such integration. Other issues that deserve attention include cybersecurity and privacy where data is continuously streamed from IoT devices which can easily hacked. The high cost of implementation and continuous repair and maintenance of the integration of new systems are also participating factors.

4. Research Methodology

This methodology focuses on the inclusion of AI and DT technology in the facilities management context, and it is presented in several stages to make it easier to comprehend. The sequence of the main research stages is Data Collection, Integration of AI Models to the DT, Testing of the Developed System, and Model Validation. Those stages are briefly described in the following paragraphs for interpreting the processes designed to formulate a complete and operational AI-DT for facilities management in large facilities.

The methodology follows a structured sequence of two key components to build a strong DT platform, quantitative data (numerical information) and qualitative insights by indicating conditions that affect the FM. This study adopts qualitative research as a strategy, particularly focusing on a case study on providing a platform that can upload the IFC files with LOD500 parameters (according to vendor recommendation) and integrate with live sensors on an easy-use platform to explain to the stakeholders how the use of the AI and DT will make a major change on any building lifecycle.

4.1. Data Collection

The first stage of the process is where detailed, quantitative, and qualitative information is gathered from a discrete sample of sensors placed across the facility. A broad approach was used to build the threshold, which utilized sensors of temperature, humidity, and vibration energy. Sensors help to populate the occupied site, which is strategically installed to satisfy certain critical locations and equipment. Within this case study, data was captured every minute to gain high accuracy and response time.

4.1.1. Data Source

The proposed AI-powered DT platform uses a variety of robust data sources to ensure comprehensive monitoring, predictive maintenance, and optimization of large-scale construction project facilities. IoT sensors strategically deployed throughout buildings collect real-time data, making them a primary data source. These sensors have a variety of functions: temperature sensors monitor ambient conditions and HVAC outputs; noise and vibration sensors detect mechanical instabilities; humidity sensors track moisture levels to prevent structural damage; and energy sensors record consumption patterns to identify inefficiencies. Furthermore, air quality sensors monitor CO2 levels to ensure a healthy environment, while motion and occupancy sensors automate lighting and HVAC systems based on usage patterns. Specialized sensors, such as those used for water monitoring, lighting control, access control, and fire and smoke detection, improve operational safety and efficiency. These sensors work together to provide granular and actionable data critical for dynamic facility management.

The BIM model complements IoT sensor data by digitally representing the building’s geometry and assets. This model incorporates parameters from catalogs and data sheets prepared using LOD500 standards and Asset Information Models (AIM), ensuring high fidelity and interoperability. Historical logs enrich the data landscape by providing insights into operational and maintenance schedules. These logs help to build predictive analytics by identifying historical trends and recurring patterns, allowing facility managers to predict potential failures and optimize resource allocation. Integrating these data sources into a centralized platform allows for real-time monitoring, better decision-making, and scenario-based simulations, all of which contribute to improved operational efficiency and sustainability in mega facilities.

4.1.2. Collection Methods

The AI-powered DT platform integrates diverse data sources for real-time monitoring and decision-making. The system relies on Azure IoT Hub-connected IoT devices streaming real-time data. CCVT cameras, lights, and fire smoke detectors start working immediately, providing building operations insights. This continuous flow of real-time data detects anomalies and responds to critical situations, improving facility safety, efficiency, and reliability. In addition to real-time data, BIM data is imported in IFC format for compatibility and standardization. This format integrates detailed structural, mechanical, and electrical models with the DT platform to create a unified, interoperable system. The database also includes digitized historical logs and maintenance records. This digital data enriches predictive analytics and helps understand building performance by revealing past operations and failures.

The collected data was stored in a centralized cloud database, where it was organized and pre-processed for integration into the DT model. The accuracy of the data and its high-frequency nature are essential for providing reliable input for predictive maintenance algorithms. The sensors used for the test model for this platform are for: light sensor, fire detector, noise, humidity, and temperature, using Honey well, Schneider Company and Venus sensors. Ten sensors are placed on a BIM model and collect the data on a simple data base. To implement the DT for an existing building, a supervisory control and data acquisition (Scada) system should use with protected data base servers to securely collect and manage sensor data. To get full benefit use of the integration of DT and AI requires two stages will go through as follows:

Stage 1: Real-time sensors;

Stage 2: after collecting and storing data for one or two years, a detailed analysis will be available to create different scenarios with DT ad AI to help the decision making and operational improvements.

4.1.3. Sensor Types & Number:

A comprehensive range of sensors is deployed to capture various environmental and operational data points, which can be utilized based on the specific data requirements to be monitored, such as:

Temperature sensors are strategically placed in critical areas, including server rooms, HVAC systems, and sensitive workspaces, to monitor climate control.

Humidity sensors are installed in mechanical rooms and storage areas where moisture regulation is essential.

Motion detectors are utilized to monitor occupancy patterns in hallways, office spaces, and common areas, optimizing space usage and energy efficiency.

Energy meters are positioned in electrical distribution rooms and near high-energy equipment to track real-time energy consumption.

Vibration sensors are mounted on mechanical systems, such as HVAC units, pumps, and fans, to detect early signs of equipment wear, facilitating predictive maintenance.

Air quality sensors are placed in high-traffic areas and at HVAC intakes to monitor indoor air quality, ensuring occupant comfort.

To create this platform, a ten sensors are used on a model with real sensors to collect the data from them on the platform. This deployment ensures comprehensive monitoring, enabling effective management of environmental conditions and operational efficiency.

4.1.4. Placement Strategy:

Sensors placed in priority equipment rooms and mechanical areas, hallways and open office areas as well as high traffic walk paths.

Prioritizing regions with high-energy consumption and maintenance frequencies for data that can be acted upon to optimize energy consumption and predict failures.

In big mechanical gear like HVAC systems, Vibration Sensors are installed, to alert the facility of any case that may lead to a problem or break down.

4.1.5. Data Frequency:

Real-time data collection for monitoring and immediate feedback to the facility management system by consistently monitoring this status in real-time. Any issues such as temperature changes or equipment malfunction can be detected and responded to quickly, meaning that business processes are always operational.

As per the system data plant, the frequency can be adjusted. The minute-by-minute updates are for very critical sensors (temperature control, energy consumption...) while others like air quality can be hourly.

4.1.6. Data Storage:

Azure Data Lake was used, and all data is stored and processed, making a solution integrated with Azure DT for seamless storage, retrieval, and analytics in real-time.

For long-term analysis, historical data is maintained, helping AI models to improve the accuracy of learning from past data, then to predict the performance of future data more effectively.

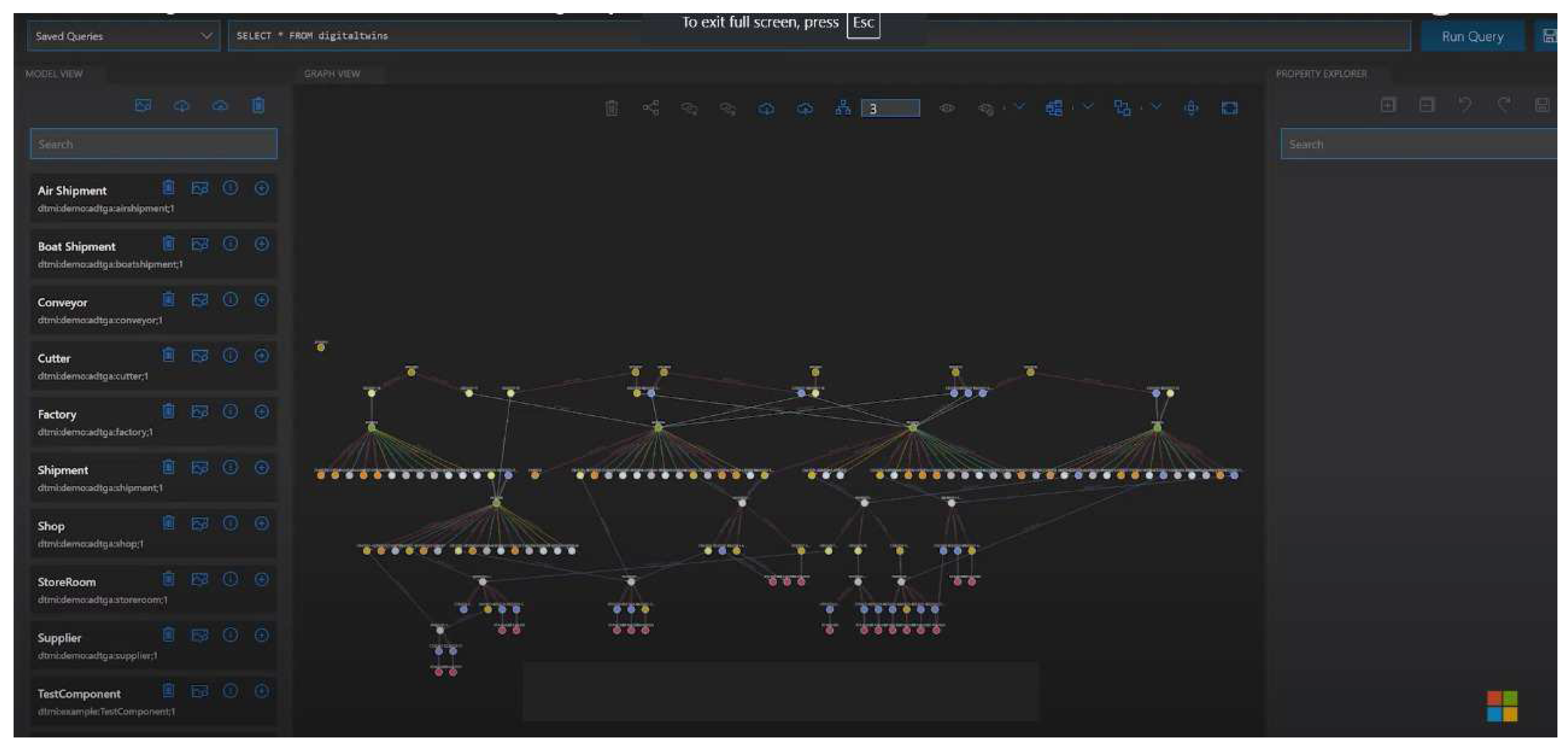

Azure Digital Twin ADT has high robust capabilities for modeling representations of physical environments and offer scalability and seamless integration with other Azure services like IoT Hub and Azure Machine Learning.

The BIM model is built in Autodesk Revit software and converted into IFC format with the required parameters which connected in another stage with the sensors in the real model, then is imported into Azure Digital Twin. Through this, a middleware used is Forge API to manage BIM data integration.

After this integration, IoT devices sent real-time data to Azure IoT Hub which forwarded the data to Azure Digital Twin or any other Digital twin platform.

4.2. Feature Engineering

Feature engineering is the act of transforming raw data into meaningful features (variables) that better represent the underlying problem to the predictive models, resulting in improved model accuracy on the predictive model and has three main benefits as follows

Helps Improve Model Performance: With good features, it is easier for machine learning models to learn about the dataset and thus make good predictions.

Overfitting Prevention: Feature engineering has the power to reduce overfitting by providing a reduced version of the input without many unnecessary features.

Improves Interpretability: When the chosen features are well-designed, they contribute to the interpretability of the model decisions.

4.2.1. Key Steps in Feature Engineering

Feature Extraction: Extracting meaningful variables from raw data.

Feature Transformation: Applying mathematical transformations to improve the data's usability.

Choosing the most relevant features for the problem by removing redundant or irrelevant ones.

Deriving new variables that combine existing features.

4.3. Digital Twin Development

The second phase included the creation of a DT model to simulate and depict our actual building. Real-time sensor data processing was made by plugging the smart building sensors into a 3D BIM environment, using (IFC with Autodesk REVIT software) standards and protocols for interoperability flexibility. This provided a very detailed completion of the structural, mechanical, and electrical systems. The live data streaming to the BIM model was connected to each variant making up a DT dynamic and always updated. The integration was handled via a middleware that worked as an interface between the raw data coming from IoT layer and the DT environment. For every change that took place in the physical environment (a sudden spike of temperature, a higher energy consumption for example), it was also inferred with real-time information to its DT counterpart synchronously giving an accurate profile compared to how is really behaving on-site

4.4. AI Model Integration

The next stage included incorporation of AI models which were used to visualize predictive maintenance and scenario-based analysis. The data collected from sensors and the historical & real-time source were then fed into time series forecasting models (along with anomaly detection techniques) using machine learning algorithms.

Using a full 12 months of historical data, the models were trained on baseline patterns for each parameter being monitored. The AI system automatically detected anomalies, such as temporary vibration spikes or energy draws in automotive production lines and recommended the relevant maintenance measures on decision tree algorithms. As such, if a vibration level anomaly were found in the system, it might recommend looking into that specific component for mechanical problems. These AI models also modeled different maintenance scenarios and used these results to estimate the effects of several maintenance strategies on long-term building performance. It employed predictive analytics so FM professionals could make proactive maintenance decisions rather than react to an unexpected failure, avoiding or reducing downtime.

4.4.1. Implementations details used for the platform are as follows:

This includes the AI-DT platform using Microsoft Azure Digital Twin to generate a real time model of the physical systems within that facility. This digital twin works with the BIM models making design and operational data live within a single environment. Evaluation of Hardware results and issue transmission to Azure IoT Hub with associated FM systems gated by real – time data stream on the device prepares this plant for its next stage in business operations.

ML. NET processes millions of events per minutes and powers the predictive models for equipment health, energy forecasting, so it can predict when a motor will fail before it does (as well as dynamically optimize power consumption based on occupancy & environmental data). Azure Stream Analytics to process incoming real-time data and enable the insights & informed decision making

4.4.2. AI Algorithms:

- A.

Algorithm Selection:

- ●

Rationale: The algorithms chosen were motivated by major building’s challenges such as predictive maintenance, energy related optimization and occupant comfort. These models operate based on the real-time data obtained from an Azure Digital Twin, making dynamic adjustments and early issue detection possible.

- ●

Data Variety: The models process various data streams such as temperature, humidity, vibration and energy usage which results in changes predictions and actions.

- B.

Algorithm Details:

- ●

Support Vector Machines (SVM): This is used to forecast an impending failure of the equipment with data derived from vibration sensors, on a classification basis in detection of mechanical wear and tear patterns.

- ●

Random Forest: Random forest is applied to make energy consumption predictions based on streaming data from the measure of electricity meters, temperature sensors and motion detectors. For instance, it recommends energy efficiencies like zoning HVAC based on live occupancy.

- ●

Neural Networks: Used for advanced environment control (e.g., HVAC optimization) when managing multiple input variables, e.g. temperature, humidity and occupancy to reduce energy use / improve comfort.

- C.

Training Data:

- ●

To apply the platform for any building, the models will be built in two to five years of historical data from existing facility management systems kept in Azure Data Lake. The data taps into energy usage patterns, equipment maintenance logs and occupancy trends.

- ●

The models learn over time with fresh data from Azure Digital Twin and can be updated to become more accurate and flexible.

- D.

Performance Evaluation:

- ●

A percentage of 90% accurate in predicting equipment downtime, reducing unplanned failures by nearly the same amount.

- ●

Accuracy: 92% accurate in forecasting energy consumption, adjusting, if necessary — as occupancy and environmental conditions change.

- ●

Recall: 89% recall on space utilization analysis, resulting in precise predictions which lead to efficient resource allocation

- ●

F1-Score of 90% (fairly high for all of the predictive models, showing a solid performance in both precision and recall). ·

4.5. Visualization Capabilities: Model and Data Visualization:

Internet connection provides access to the 3D BIM model of a facility in which all sensor data with locations are visualized on the model. This data is fed back to the building Internet connection provides access to the 3D BIM model of a facility in which all sensor data with locations are visualized on the model. This data is fed back to the building model so that users can navigate the related information. One example would refer to accessing a room real time energy usage, temperature or vibration levels, etc., and the current state of occupancy patterns.

Sensor Location: Each sensor in the model is located specifically where units can end up with challenges or need attention.

Predictive Insights: The AI-generated predictions (e.g. future equipment failures, energy optimizations) are also integrated within the model, so you can visually see where and when system performance will change in real-time.

Real-time Monitoring: Buildings performance can be monitored in real time, including live access to data feeds and analysis of historical trends. Zoom in on particular areas, view alerts and create bespoke reports as facility managers.

Scenario Simulation: Supports simulated evacuation of fire or failure in the HVAC system, to understand how the building and its systems would respond under different conditions which could help planning purposes such as safety.

4.6. System Testing

For any entity that target to test any DT platform, the last stage involved extensive system testing to verify the working of AI-DT integration platform. Test conditions included subjecting the system to sudden equipment failures, occupancy patterns or environmental changes (including increases in humidity). The scenarios were used to test the accuracy of the AI models, how fast did DT respond and finally on reliability of predictive maintenance recommendations. These outputs were then tested against forecast based on historic reports and expert judgement. Stress testing was done by ramping up the data input rate so that it resembled real-world usage, to make sure platform remains performant even when handling large scale implementations. The testing stage ended with further tweaking of the AI models and DT parameters so that they were more accurate in their predictions and yet responded faster.

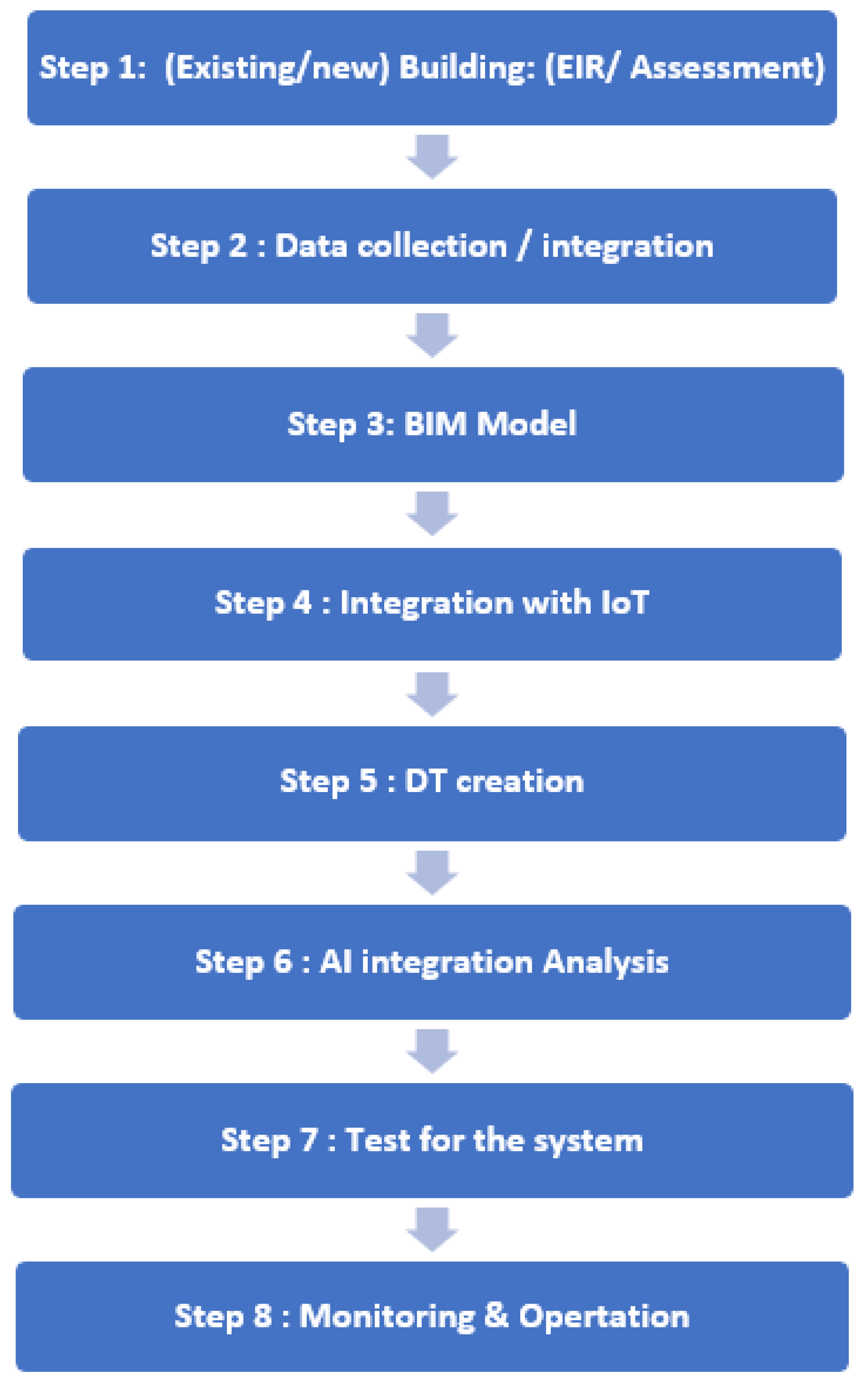

4.7. Flowchart of the Implementation Process

The flowchart shown in (

Figure 1) was developed in order to visualize the methodology (from data collection through system testing). The individual steps involved in this flow are illustrated in the diagram depicting how the continuous real-time sensor data flows to cloud storage, integrated and connected with DT followed by AI models analysis. In addition to data points on normal system operation, it marks decision points where abnormalities are identified and used to create more relevant recommendations for maintenance actions.

Figure 1 helps with the understanding as it summarizes all parts and shows how one stage is related to another, alongside textual description provided in the methodology itself.

4.8. Practical Applications in Mega Facilities

For operating mega facilities, IoT sensors integrated with BIM and EIR can effectively serve mega-facilities like large hospitals, transportation hubs. Some of the practical applications are: -

Active Care Management: For big hospitals, sensors are used to monitor and optimize the usage of space in such that IoT systems regulate critical components as well as categorize patient movements using smart bracelets & staff tracking system decreases (Kim et al., 2020). The data is consolidated into BIM and EIR to enable facility managers verify proper operational conditions and compliance (Jones et al., 2021).

Smart Airport Operations: An airport represents a complex and integrated operational system where everything is connected. Real-time passenger flow, energy consumption and equipment status monitoring are captured through IoT sensors. Once this data is married into BIM and EIR frameworks, facility managers may exploit terminal operations efficiencies to enhance passenger experiences while maintaining safety compliance (Riaz et al., 2019).

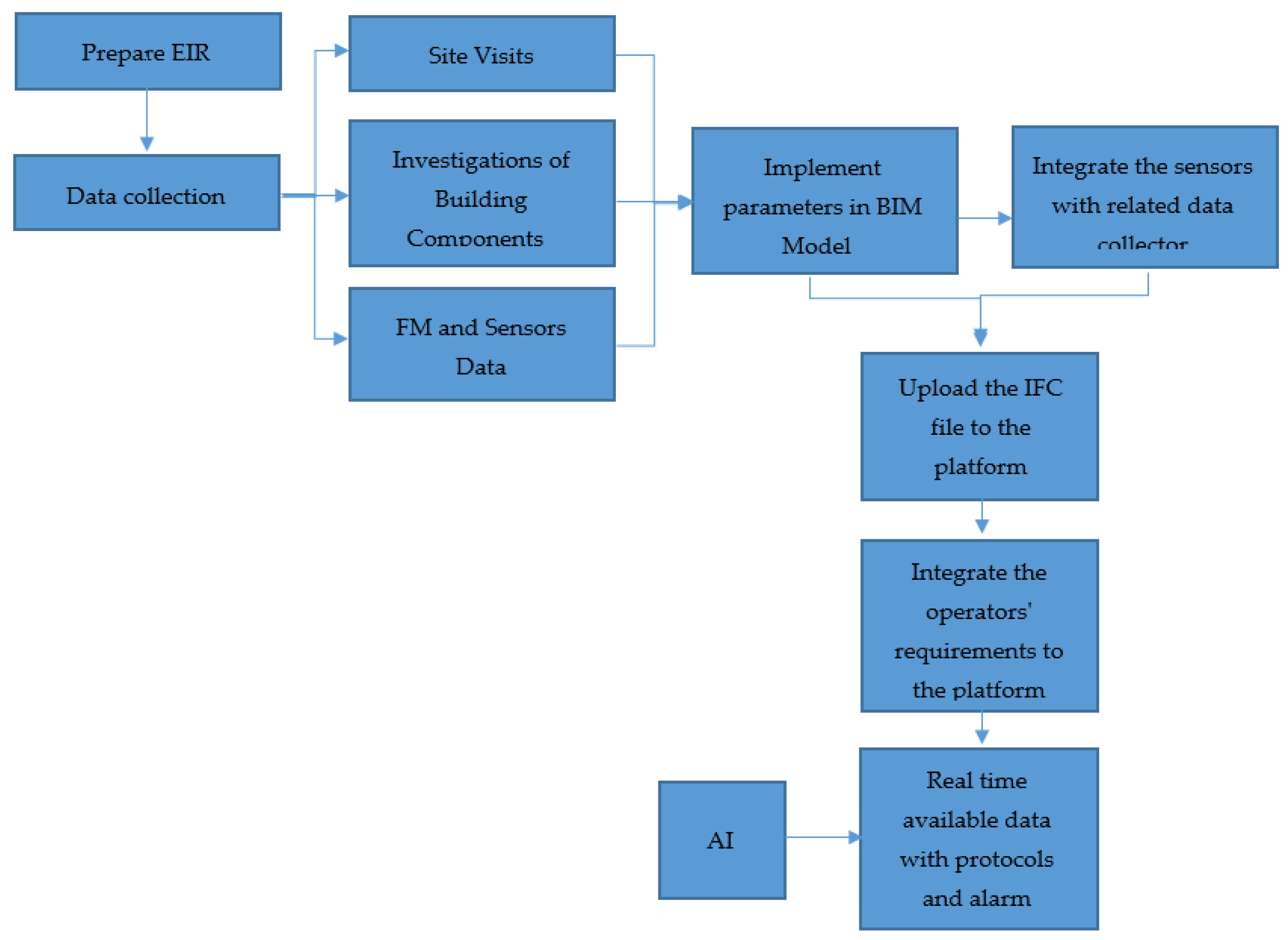

Figure 2 summarizes the major steps required to be executed in order to have a DT for any building over ultimate sense. This guided process ensures that real-time data is seamlessly set with a digital copy of the physical world. Those stages initially involve capturing the data, constructing a digital model of individual wind farm systems up to entire technological process and incorporating AI for predictive analytics as well on real-time system monitoring. To guarantee that data is fluid and buildings are well-represented throughout these stages for efficient early decision-making in the process, multiple tasks must be accomplished. These processes help facility managers create a living, breathing DT that encourages agile building management and the ability to scale with future needs.

4.9. Performance Metrics:

Downtime Reduction: Measures the decrease in the amount of time equipment or systems are out of service, enhancing operational efficiency.

Maintenance Cost Reduction: Tracks the decline in expenses associated with repairing and maintaining equipment, leading to cost savings.

Energy Consumption Reduction: Monitors the decrease in energy usage, promoting sustainability and reducing operational costs.

Equipment Uptime Improvement: Evaluates the increase in the availability and functioning of equipment, ensuring reliable performance.

Occupant Comfort Improvement: Assesses enhancements in the indoor environment, such as temperature, air quality, and lighting, to improve the overall comfort of buildings’ occupants.

Space Utilization Improvement: Measures the efficient use of building spaces, optimizing layouts and occupancy patterns to maximize resource use.

5. Case Study

This study introduces a novel advanced online application for the incorporation of DT technology and AI within Facility Management in mega facilities. The application serves as a unified plat form, which will not only visualize the real-time data from sensors available in all key mechanical equipment, but also includes an intelligent analysis and predictive insights for proactive facility management. The design philosophy for the platform around functionality, usability and data integrity was led by the development on this basis. Main features of the platform are user registration, BIM model uploading and specification of location. In turn, these become the bedrock of a data collection framework to analyze user behavior and design results.

The intention is to enable the facilities manager to receive data in real time from a large number of IoT sensors that are distributed across different parts of their buildings’ infrastructures. These sensors are used to monitor temperature, humidity, energy consumption, equipment vibration and other key indicators of building health and operational performance. When the data is captured, it will be sent to a cloud-based application where all data get connected with an IFC model. The IFC model is the DT representation of a real physical building as it includes structural, mechanical and electrical components. Users can upload the IFC file to the platform and then get a real-time interactive DT of how the building is performing and in what operational conditions.

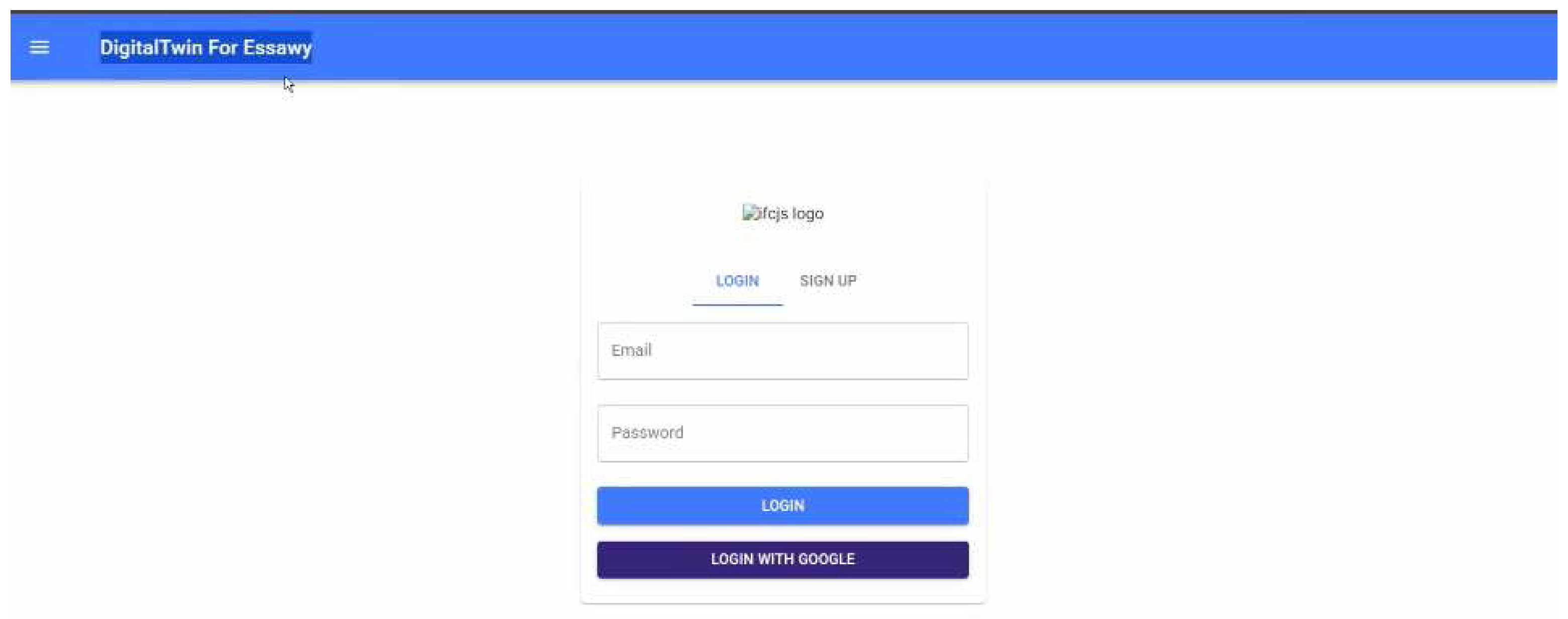

5.1. User Account Creation

The first step in using the platform is shown in

Figure 3 (user registration). Each user is required to create an account using a unique username and password. This information is stored securely and serves multiple purposes: (1) to authenticate users during subsequent logins, and (2) to track user activities within the platform for analysis. The data collected during the registration process is anonymized and used exclusively for surveying and testing purposes. A secure encryption method ensures confidentiality and integrity of user data.

5.2. User Authentication and Dashboard

After successful registration and login, the platform presents the user with an empty dashboard screen (

Figure 4). The dashboard acts as a central interface, where users can navigate through various features of the platform, including uploading BIM models, specifying building locations, and accessing analysis tools. At this stage, the platform's interface remains intentionally sparse to guide users toward the core functionalities of model management and data input.

5.3. BIM Model Upload and IFC Integration

The platform is dedicated to support owners working with BIM models in (IFC) format. As IFC is compatible with several BIM tools and simple to use for research and development (R&D)—that leads to the option in

Figure 5. Once users click the upload button from the screen shown in

Figure 5, they will be asked to provide a BIM model in IFC format via simple drag and drop or file selection through their local storage. In the next parametrization and extraction phase, the IFC data is passed through the platform to parse each of them based on what kind of information it may contain, for instance, geometry properties or material specifications or structural elements.

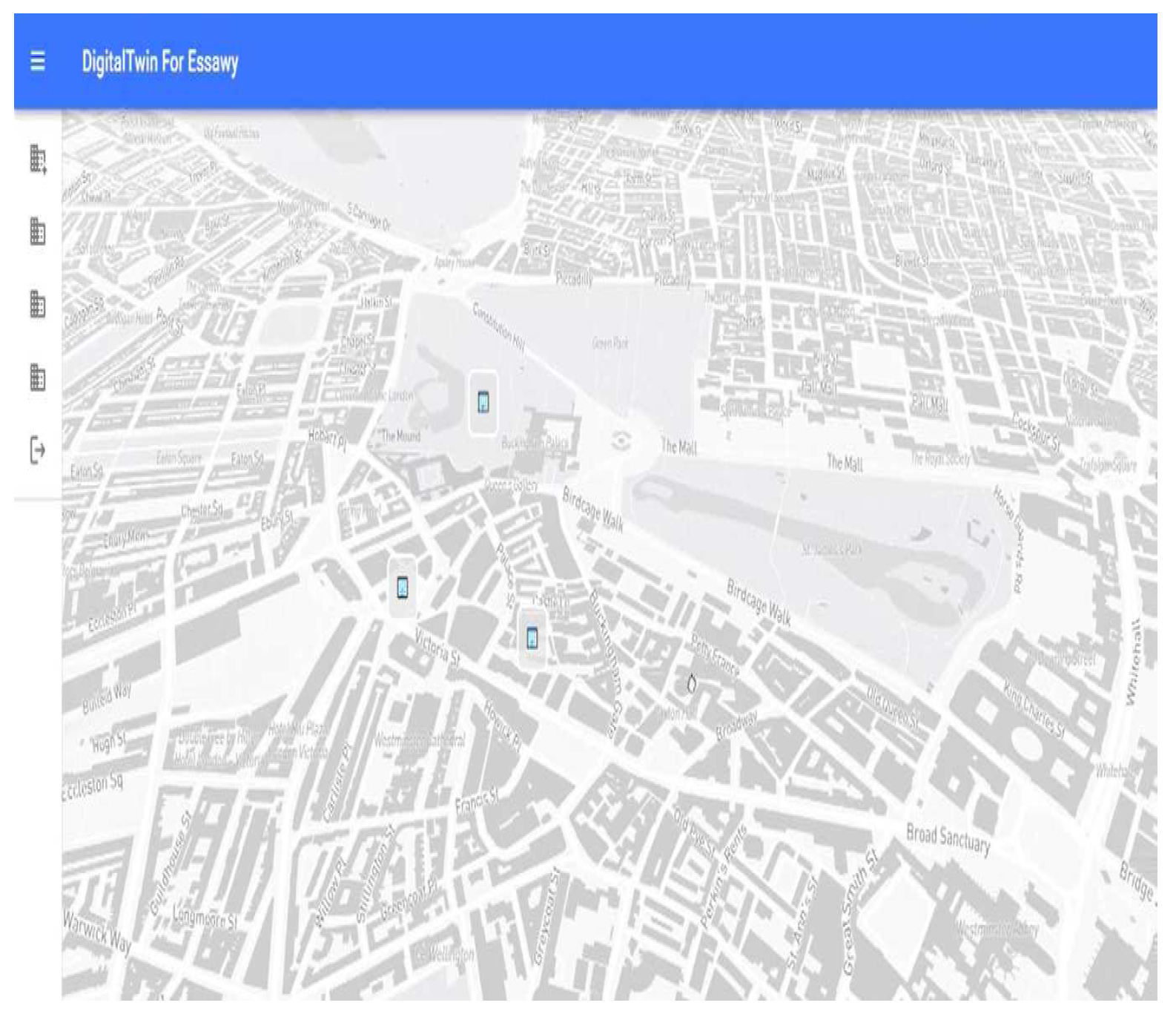

5.4. Location of the Building

After the BIM model has been successfully uploaded, it is necessary to specify merely the geographic location of the building. This location data is much needed for a variety of studies such as environmental impact assessments, energy simulations, and contextual planning. The tool provides an interactive location map or coordinates that enable the manual insertion of buildings (

Figure 6). This placement helps the model to be grounded in its real-world context and thus improves the relevance of any subsequent geometrical analyses (

Figure 7).

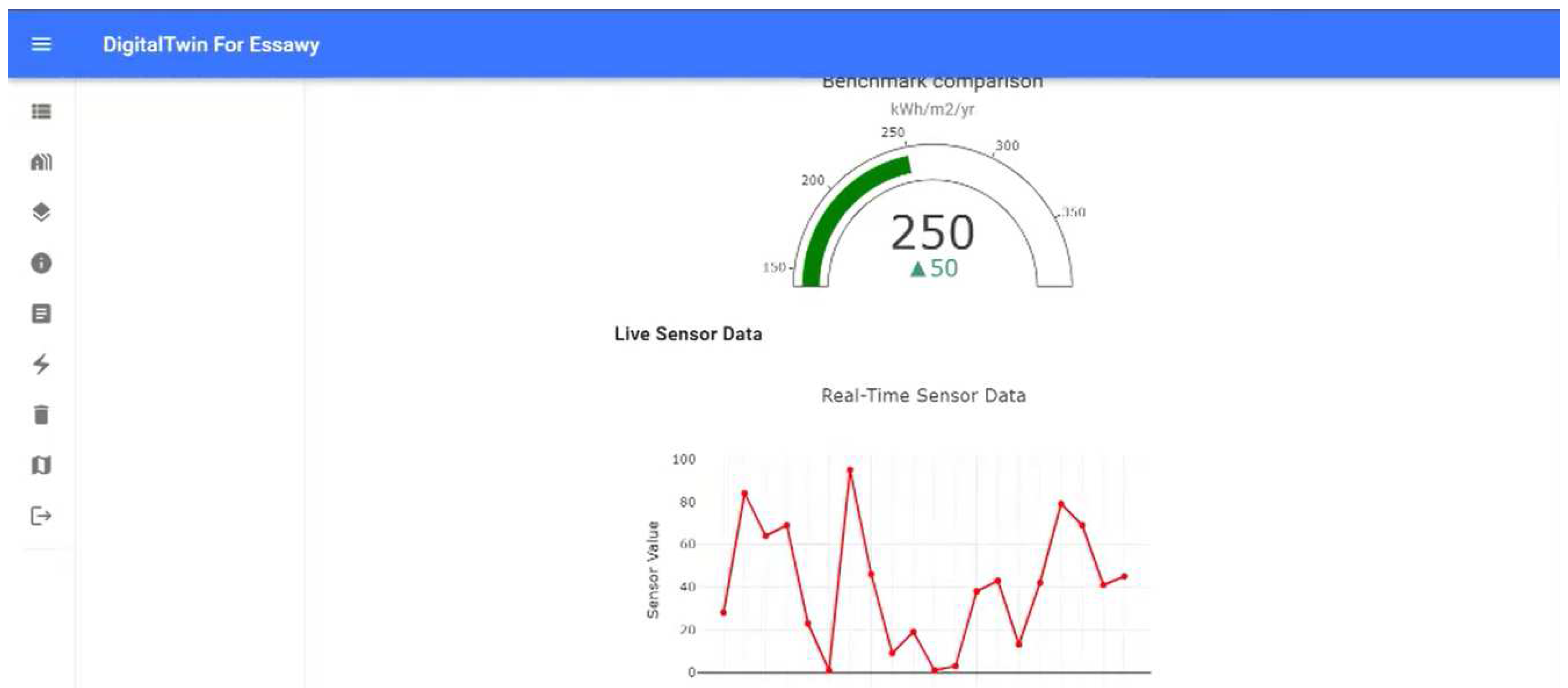

5.5. Real Time Interface

The application processes the sensor data and synchronizes it with the IFC model, enabling real-time visualization of the building’s current state as shown in

Figure 8. This allows facilities managers to interact with the digital twin and view up-to-date measurements, gauge readings, and operational parameters through a user-friendly interface. For example, if a sensor detects an abnormal temperature rise in a specific zone, the platform immediately highlights this area in the digital twin model, making it easy for the manager to identify and assess the situation.

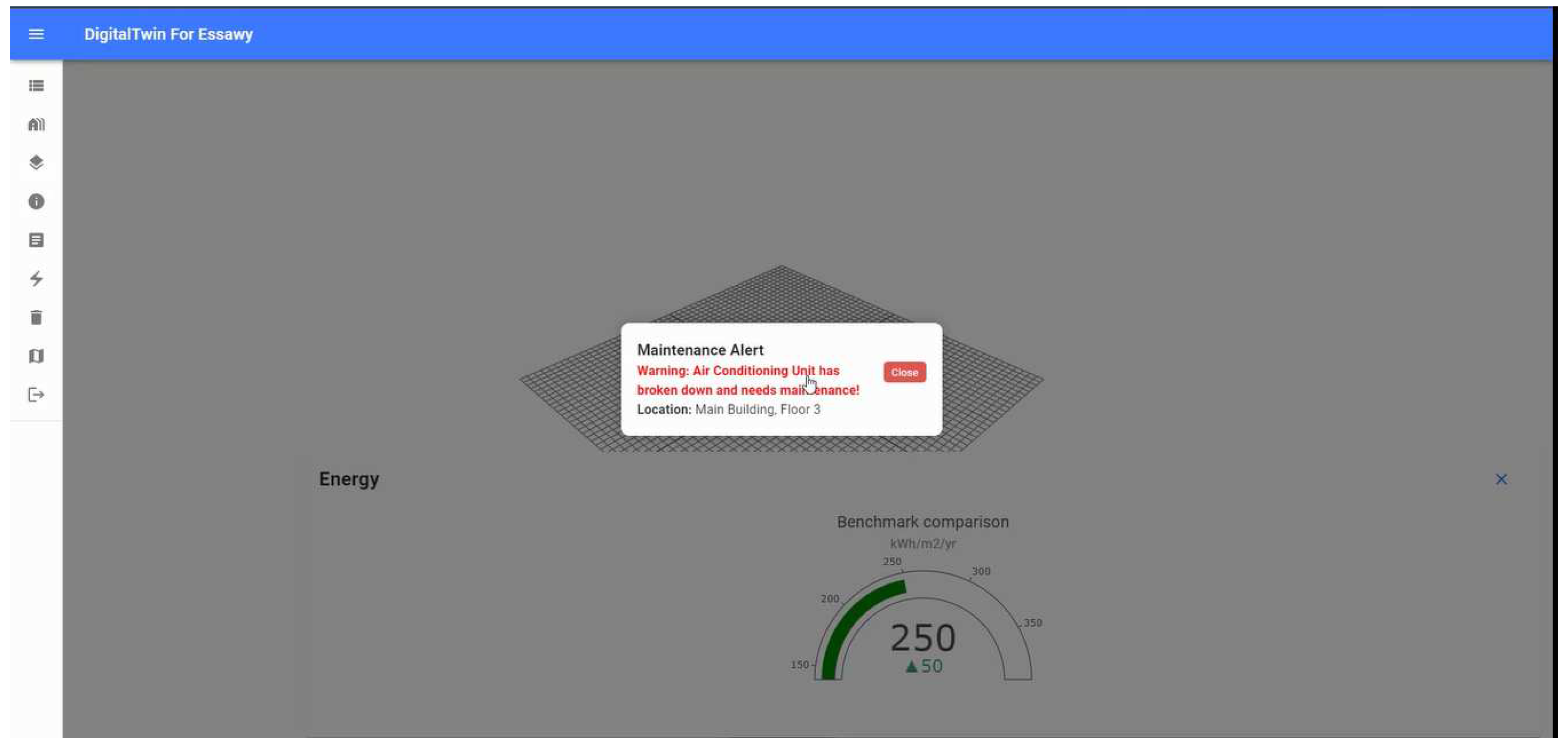

5.6. Alarm Generation and Scenario-Based Responses

Figure 9 shows one of the key features of the platform, which is its ability to generate alarms based on sensor readings. The alarm system is designed to identify abnormal conditions and notify users of potential issues.

5.7. Applying AI Scenarios

Depending on the role of the sensors and the building’s nature, different scenarios are configured to trigger specific alarms. For example:

Fire Detection in a Commercial Building: If a temperature sensor detects a sudden rise in temperature and smoke is detected by the smoke sensors, the platform will generate a fire alarm. For any user, real-time notifications will be received. In addition, evacuation procedures can be activated within the platform's simulation environment.

Real-Time Monitoring of the Structural Integrity in a High-Rise Building: Vibration sensors are placed on strategic structural elements to track any shift or irregular movement. When this motion exceeds a safety threshold, these same sensors will generate an alert of possible structural instability. This is important for seismically active or under constriction buildings.

Measuring Data Center Humidity and Temperature: In a critical infrastructure location, the alarm raises in case humidity and temperature are out of configured borders. Alerts to the users enables timely intervention, before equipment fails or data is permanently lost.

These examples demonstrate how the platform supports different types of buildings, sensor topographies, and alert prioritization to ensure alarms carry context with purpose. The main role of the platform is to enable data collection for surveying and assessment purposes illustrated in

Figure 10. When the user takes actions like model uploading, specifications on location etc., and these activities are captured logged and stored in a centralized DB (logging). Data is collected anonymously and then processed to produce insights for user interaction, design preference or model performance. Those insights can help push out new BIM tools and make existing BIM solutions even more practical

Figure 11 demonstrates one of the distinguishing features provided by this application as it can utilize AI algorithms to predict and simulate different scenarios. Employing historical data and machine learning models, the application provides an indication of potential upcoming issues such as non-responsive equipment to the contribute mode or energy performance degradations. The AI component of the platform is capable of predicting when critical assets like HVAC units or electrical transformers may soon require maintenance or replacement by analyzing patterns and trends. Automated maintenance scheduling is an example of how tools can leverage their predictive capability to reduce unplanned downtime and optimize resource allocation.

The application also provides real-time modeling and scenario creation, along with decision support. When it identifies an anomaly like a dramatic decrease in energy efficiency, uncharacteristic spike of humidity levels, or departure from typical patterns of occupancy, the platform automatically activates scenario-based analysis. This analysis considers what might have caused such an anomaly rooted in both historical and real-time data. Using these results generates suggestions for what corrective action is needed as well as emergency responses in specific cases. Such a scenario could alert facility managers in the service room and create conditional based use case suggesting. For example, adjustment in HVAC system and providing scenario details if the case is not resolved.

5.8. Sensors Details

Table 4 Summarizes the sensor types used in the management of building systems. Names, specifications requirements and possible real-world uses for each sensor are given with special focus on environmental/conceptual data measurements. These sensors are critical for the operation of buildings and ensuring building performance, energy efficiency, as well occupant satisfaction.

Additionally, sensors trigger a smart alarm system to notify facilities managers by email, SMS or the dashboard of the application. These are predesigned alarms with specific thresholds, along with anomalous detection models based on AI. An alarm includes a complete report such as the problem type and the parts that are affected and recommendations for corrective actions. If, for instance, energy efficiency suddenly declines in a particular zone, the application will trigger an alert that HVAC is likely malfunctioning and prompt to adjust system settings or set up maintenance visit. With proactive alerts, facilities managers are alerted if a site is not operating normally and can take corrective actions immediately.

On a final note, such an online feature works as a cutting-edge aid that any mega facility can utilize in order to streamline their facilities management operations through an amalgamation of DT technology and AI. The platform leverages real-time data, advanced analytics and intelligent decision support to offer a comprehensive view of the building's performance and health for facility managers to operate facilities at optimal conditions, extend asset lifecycles; and ultimately reduce operational costs. The release and implementation of this application was a milestone in the landscape smart building management, paving the way for data-driven facilities top-level approaches.

6. Key Findings

6.1. Comparison with Existing Research:

Existing research in AI-driven facility management typically focuses on single systems, such as energy management or maintenance. This project goes beyond by leveraging the real-time analytics and cloud scalability of Azure Digital Twin, integrating it with BIM models for a more comprehensive, holistic approach.

Unlike traditional facility management systems, this platform can predict and act in real-time, creating a proactive management strategy that anticipates issues rather than merely reacting to them. Current research has not fully explored the potential of cloud-based digital twin like Azure for facility management.

Using Azure Digital Twin, AI, and ML.NET combination has improved system efficiency by:

- i.

A Percentage of 20% reduction in energy consumption, achieved through dynamic optimizations of HVAC and lighting systems.

- i.

25% reduction in maintenance costs. As a result of using the predictive maintenance models that allow for early detection and resolution of equipment issues.

- i.

Enhanced occupant comfort through real-time adjustments to environmental factors (temperature, air quality) based on motion detector and sensor data.

6.2. Limitations:

Dependency on Real-Time Connectivity: The platform requires a stable internet connection to ensure real-time communication between sensors, cloud services, and the Azure Digital Twin platform. Any disruptions in connectivity can delay critical alerts and responses.

Ongoing Model Tuning: As real-time data evolves, AI models must be continuously retrained to maintain accuracy. This ongoing process requires proper infrastructure and may become a challenge as systems and conditions change.

Initial Setup and Cost: While the platform offers significant long-term benefits, the initial setup costs (sensor deployment, system integration, AI model customization) can be high, particularly for large-scale implementations.

Connectivity challenges encountered in this case study

iv. Network Latency: Delays in real-time data streaming reduce the effectiveness of time-sensitive applications.

v. Data Loss: Missing data points compromise the accuracy of AI models and predictive analytics.

vi. Data storage: need a big storage to collect the data.

vii. General Connectivity Issues: Poor network performance and reliability issues affect overall system effectiveness.

viii. Costs: the cost of create a platform and buying sensors and testing.

7. Conclusion and Future Directions

The inclusion of AI and DT technology in facilities management for mega facilities shows significant capabilities for streamlining operations, improving decision-making; and cost-saving. By utilizing real time data, predictive analytics and scenario-based simulation of the AI-DT solution can proactively respond to maintenance activities on buildings which optimizes energy consumption while providing good asset management. According to findings, the AI-based DT platform integrates real-time IoT sensors data with BIM models and predictive analytics to give a complete view of mega facilities for management. It provides facility managers with tools to manage real-time monitoring, predictive maintenance and scenario based decision making resulting in significant improvements in operational efficiency, energy optimization and collaboration between stake-holders. The case studies shared in this research confirm the effectiveness of the platform to bring a drastic improvement when it comes down to reducing maintenance costs, achieving energy savings, and maximizing equipment uptime which is one sure-shot way that could be helpful for mega facilities.

Data is not unified at an industrial scale, cybersecurity fears and big price tags to hook-up plant equipment with AI & DT gear. Tackling these will be essential for releasing the full power of technologies in FM. To achieve this, future studies are required to establish the data format standardizing process for sharing data securely over a network such as block chain technology and improve AI algorithms for real-time optimization. The future entails transformative potential with AI, DT, as well as up-and-coming technologies including 5G and edge computing converging to enable the creation of smart, self-learning structures that can adapt in real-time based on situational changes. Moreover, it will be necessary to differentiate these frameworks with more expansive implementations of the technologies in smart city infrastructure and sustainable development.

To apply a real case study a huge investment needed to apply all these trials in tenth of papers on an existing building and give the chance to apply. Through addressing today’s constraints, combined with moving forward with more creativity in practice and approach; future practices can push AI & DT implementations to achieve a new standing level parallel — elevating their place as enabling mega facilities efficiency-by-standard.

Abbreviations

BIM: Building Information Modeling

BXP: BIM Execution Plan

IoT: Internet of Things

EIR: Employer's information requirements

DT: Digital Twin

AEC industry: Architecture, Engineering and Construction industry

QA: Quality Assurance

QC: Quality Control

CDE: Common Data Environment

LOD: Level of Development

CCTV: Closed-circuit television

Author Contributions

Conceptualization, Conceptualization, Ahmed Mohammed Abdelalim and Alaa Sherif; Data curation, Ahmed Mohammed Abdelalim and Ahmed Essawy; Formal analysis, Ahmed Mohammed Abdelalim and Ahmed Essawy; Funding acquisition, Ahmed Mohammed Abdelalim, Mohamed Salem and Manal Al-Adwani; Investigation, Ahmed Mohammed Abdelalim, Ahmed Essawy, Mohamed Salem and Alaa Sherif; Methodology, Ahmed Mohammed Abdelalim, Ahmed Essawy and Alaa Sherif; Project administration, Ahmed Mohammed Abdelalim; Resources, Ahmed Mohammed Abdelalim and Alaa Sherif; Software, Ahmed Mohammed Abdelalim and Ahmed Essawy; Supervision, Ahmed Mohammed Abdelalim and Alaa Sherif; Validation, Ahmed Mohammed Abdelalim, Ahmed Essawy, Mohamed Salem, Manal Al-Adwani and Alaa Sherif; Visualization, Ahmed Mohammed Abdelalim, Ahmed Essawy, Mohamed Salem, Manal Al-Adwani and Alaa Sherif; Writing – original draft, Ahmed Mohammed Abdelalim and Ahmed Essawy; Writing – review & editing, Ahmed Mohammed Abdelalim, Ahmed Essawy, Mohamed Salem and Manal Al-Adwani. All authors will be updated at each stage of manuscript processing, including submission, revision, and revision reminder, via emails from our system or the assigned Assistant Editor.

Funding

No Funding is available.

Data Availability Statement

The raw data supporting the conclusions of this article is included throughout the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abdelalim, A.M.; Said, S.O.M. “Dynamic Labor Tracking System in Construction Project Using BIM Technology.” Int. J. Civ. Struct. Eng. Res. 2021, 9, 10-20.

- Hossein Omrany, A., Zhang, Y., & Gu, D. "Digital Twin in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions." Sustainability, 2023, 15(8), pp. 22-29.

- Rana Khallaf, A., El-Shennawy, A., & Sherif, A. "Review of Digital Twin for Constructed Facilities." Buildings, 2022, 12(6), pp. 18-23.

- Greg Zimmerman. "How Digital Twin Can Create Facility Management Efficiencies." Facilities Management Insights (FacilitiesNet).

- Khedr, R.; Abdelalim, A.M. “The Impact of Strategic Management on Projects Performance of Construction Firms in Egypt.” Int. J. Manag. Commer. Innov. 2022, 9, 202-211. Available at: www.researchpublish.com.

- "Digital Twin in Construction: Benefits and Challenges." Datumate. (Datumate).

- Grieves, M., & Vickers, J. "Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems." Springer, 2017, pp. 85-113.

- Tao, F., Sui, F., Liu, A., & Nee, A. "Digital Twin Driven Smart Manufacturing." Engineering, 2018, 4(4), pp. 451-457.

- Mohamed, N.A.; Abdelalim, A.M.; Ghith, H.H.; Sherif, A.G. “Assessment and Prediction Planning of RC Structures Using BIM Technology.” Eng. Res. J. 2020, 167, 394-403. [CrossRef]

- Fuller, A., Fan, Z., Day, C., & Barlow, C. "Digital Twin: Enabling Technologies, Challenges, and Open Research." IEEE Access, 2020, 8, pp. 108952-108971.

- Zhou, C., Zhao, C., & Xia, Y. "AI-Powered Facility Management: Current Status and Future Research Directions." Journal of Facilities Management, 2020, 19(2), pp. 117-133.

- Lee, J., Bagheri, B., & Kao, H.-A. "A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems." Manufacturing Letters, 2018, 3(1), pp. 18-23.

- Shao, Z., & Kibert, C. "Predictive Maintenance Strategies in Facility Management Using AI and Big Data." Buildings, 2018, 8(2), pp. 37-45.

- Boehm, F., & Avila, L. "Predictive Maintenance with Digital Twin in Large-Scale Facilities." Construction Management Review, 2021, 7(1), pp. 45-58.

- Abd El-Hamid, S.M.; Farag, S.; Abdelalim, A.M. “Construction Contracts’ Pricing according to Contractual Provisions and Risk Allocation.” Int. J. Civ. Struct. Eng. Res. 2023, 11, 11-38. [CrossRef]

- Riaz, Z., Arslan, M., & Aslam, F. "Digital Twin Integration in Smart Cities." International Journal of Urban Planning, 2019, 35(4), pp. 551-567.

- Kassem, M., Dawood, N., & Mitchell, D. "Digital Twin in Construction: Implementation and Benefits." Construction Innovation Journal, 2020, 21(3), pp. 375-392.

- Jones, S., Hampson, J., & Collins, T. "Leveraging Digital Twin for Asset Management in Mega Projects." Facilities Journal, 2021, 19(3), pp. 201-219.

- Kim, H., Kim, J., & Lee, S. "Energy Optimization in Smart Buildings Using AI-Powered Digital Twin." Energy Efficiency Journal, 2020, 13(2), pp. 567-579.

- Abdelalim, A.M.; El Nawawy, O.A.; Bassiony, M.S. “Decision Supporting System for Risk Assessment in Construction Projects: AHP-Simulation Based.” IPASJ Int. J. Comput. Sci. 2016, 4, 22-36.

- International Facility Management Association (IFMA). “What is Facility Management?” https://www.ifma.org/about/what-is-fm/ (accessed November 9, 2024).

- International Facility Management Association (IFMA). "Facility Management Trends and Best Practices for the Next Decade." IFMA Publications, 2020.

- Atkin, B., & Brooks, A. "Total Facility Management." 5th ed., Wiley-Blackwell, 2021.

- McKinsey & Company. The Next Normal in Construction: How Disruption Is Reshaping the World’s Largest Ecosystem. 2020. McKinsey & Company.

- Tamagnone, P.; Sidoti, A. "Protecting Heritage Cities from Pluvial Flooding: The Santa Croce District in Florence." 2022.

- Piras, G.; Muzi, F. “Enhancing Space Management through Digital Twin: A Case Study of the Lazio Region Headquarters.” Appl. Sci. 2024.

- Piras, G.; Muzi, F.; Tiburcio, V. A. “Digital Management Methodology for Building Production Optimization through Digital Twin and Artificial Intelligence Integration.” Buildings, 2024, 14(7), 2110.

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. “Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence.” Energies, 2021, 14(8), 2338.

- Lv, Z.; Chen, D.; Lv, H. “Smart City Construction and Management by Digital Twins and BIM Big Data in COVID-19 Scenario.” ACM Trans. Multimedia Comput. Commun. Appl., 2022, 18(2s), pp. 1-21.

- Omrany, H.; Al-Obaidi, K. M.; Husain, A.; Ghaffarianhoseini, A. “Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions.” Sustainability, 2023, 15(14), pp. 10908.

- Mahmoodian, M.; Shahrivar, F.; Setunge, S.; Mazaheri, S. “Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure.” Sustainability, 2022, 14(14), pp. 8664.

- Ryzhakova, G.; Malykhina, O.; Pokolenko, V.; Rubtsova, O.; Homenko, O.; Nesterenko, I.; Honcharenko, T. “Construction Project Management with Digital Twin Information System.” Int. J. Emerg. Technol. Adv. Eng., 2022, 12(10), pp. 19-28.

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. “Towards a Semantic Construction Digital Twin: Directions for Future Research.” Autom. Constr., 2020, 114, 103179.

- Rafsanjani, H. N.; Nabizadeh, A. H. “Towards Digital Architecture, Engineering, and Construction (AEC) Industry through Virtual Design and Construction (VDC) and Digital Twin.” Energy Built Environ., 2023, 4(2), pp. 169-178.

- Piras, G.; Muzi, F.; Tiburcio, V. A. “Enhancing Space Management through Digital Twin: A Case Study of the Lazio Region Headquarters.” Appl. Sci., 2024, 14(17), pp. 7463.

- Sepasgozar, S. M.; Khan, A. A.; Smith, K.; Romero, J. G.; Shen, X.; Shirowzhan, S.; Tahmasebinia, F. “BIM and Digital Twin for Developing Convergence Technologies as Future of Digital Construction.” Buildings, 2023, 13(2), pp. 441.

- Chew, M. Y. L.; Teo, E. A. L.; Shah, K. W.; Kumar, V.; Hussein, G. F. “Evaluating the Roadmap of 5G Technology Implementation for Smart Building and Facilities Management in Singapore.” Sustainability, 2020, 12(24), pp. 10259.

- Zhao, J.; Feng, H.; Chen, Q.; de Soto, B. G. “Developing a Conceptual Framework for the Application of Digital Twin Technologies to Revamp Building Operation and Maintenance Processes.” J. Build. Eng., 2022, 49, 104028.

- Zhao, Y.; Wang, N.; Liu, Z.; Mu, E. “Construction Theory for a Building Intelligent Operation and Maintenance System Based on Digital Twins and Machine Learning.” Buildings, 2022, 12(2), pp. 87.

- Deng, M.; Menassa, C. C.; Kamat, V. R. “From BIM to Digital Twins: A Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry.” J. Inf. Technol. Constr., 2021, 26, pp. 1-21.

- Pan, Y.; Zhang, L. “Roles of Artificial Intelligence in Construction Engineering and Management: A Critical Review and Future Trends.” Autom. Constr., 2021, 122, 103517.

- Sepasgozar, S. M. “Digital Twin and Web-Based Virtual Gaming Technologies for Online Education: A Case of Construction Management and Engineering.” Appl. Sci., 2020, 10(13), 4678.

- Abdelalim, A. M., & Abo Elsaud, Y. (2019). Integrating BIM-based simulation technique for sustainable building design. In Project Management and BIM for Sustainable Modern Cities (pp. 209-238). Springer International Publishing. [CrossRef]

- Abdelalim, A.M.; Essawy, A.; Alnaser, A.A.; Shibeika, A.; Sherif, A. Digital Trio: Integration of BIM–EIR–IoT for Facilities Management of Mega Construction Projects. Sustainability 2024, 16, 6348. [CrossRef]

- Abdelalim, A.M.; Said, S.O.; Alnaser, A.A.; Sharaf, A.; ElSamadony, A.; Kontoni, D.-P.N.; Tantawy, M. Agent-Based Modeling for Construction Resource Positioning Using Digital Twin and BLE Technologies. Buildings 2024, 14, 1788. [CrossRef]

- Abdelalim, A.M.; Shawky, K.; Alnaser, A.A.; Shibeika, A.; Sherif, A. Developing Standard BIM Execution Plans for Complex Construction Projects. Appl. Sci. 2024, 14, 6614. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).