Submitted:

17 June 2024

Posted:

18 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

- User-Centric Design: The project follows a user-centered design (UCD) methodology, prioritizing the needs and expectations of warehouse personnel throughout the development process [23,24]. This approach involves close collaboration with stakeholders through interviews, workshops, and user acceptance testing to ensure that the final product aligns with their requirements and workflows. With the interview the warehouse processes, material flows, and data exchange procedures are mapped to identify pain points, inefficiencies, and opportunities for improvement. User stories were created based on the gathered requirements. These stories outlined the specific needs, goals, and expectations of different user groups within the warehouse environment.

- Data-Driven Approach: The project analysis the opportunity for the adoption of a data-driven approach to inform decision-making at every stage. This involves analyzing existing data sources [25,26] to support further evaluation different tracking technologies based on quantitative metrics [27], and using real-time data from IoT sensors to monitor and optimize warehouse processes [14]. Data sources and flows of use cases’ softwires are analyzed to identify relevant data points for integration into the DT.

- Digital Twin Framework: The development of the digital twin is based on the integration of data from Building Information Modeling, Internet of Things technologies, a well-established approach in the literature [28], and including manufacturing software’ data in Enterprise Resource Planning (ERP). The development of optimization algorithms in DT draws on research in operations research and artificial intelligence to find optimal solutions for complex problems in real-time.

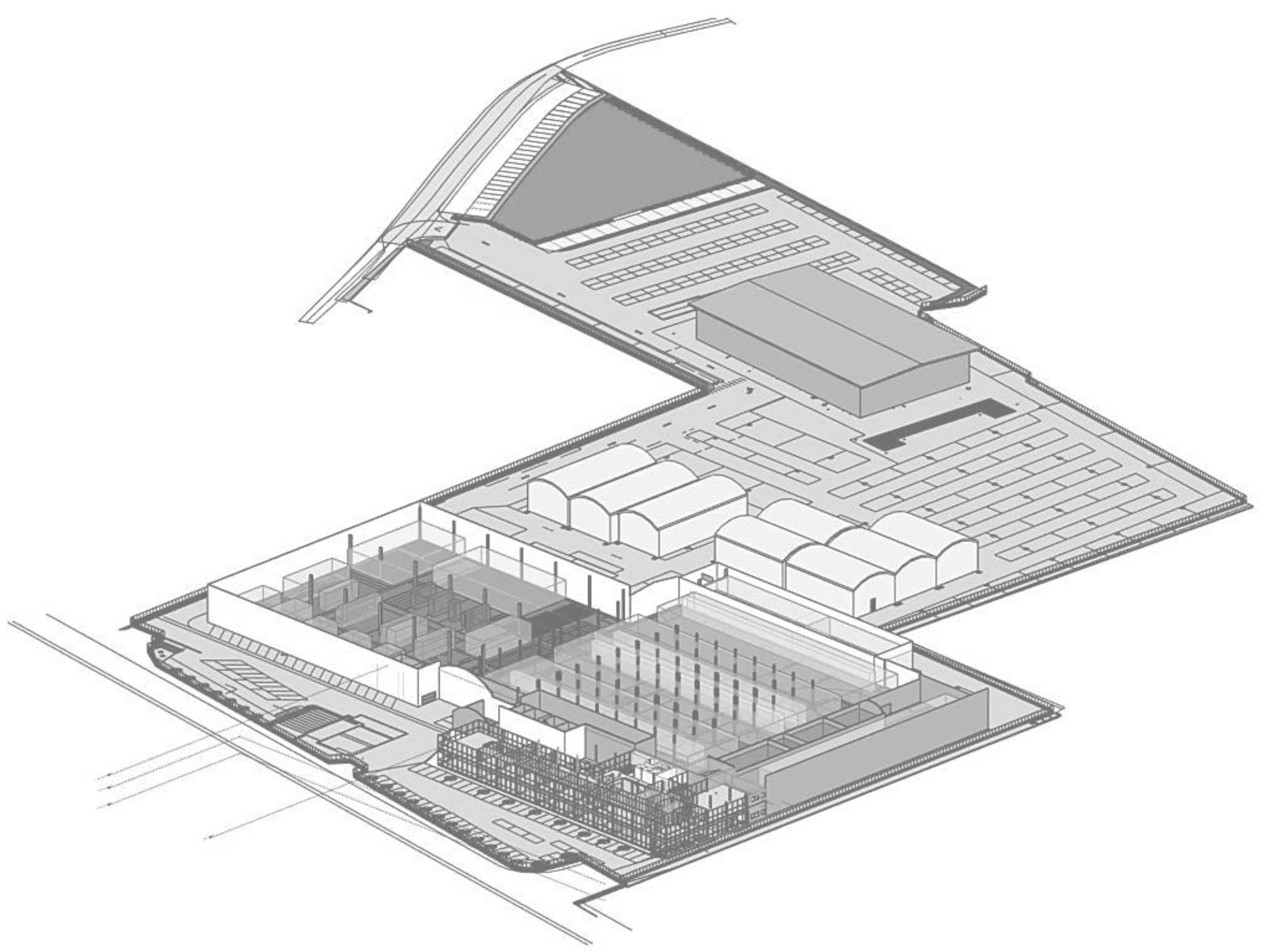

- Use case: Focchi S.p.A. manufacturing company of prefabricated building envelope is based in Poggio Torriana, Rimini (Italy) is adopted as use case. Focchi Spa is a family-owned company founded in 1914 and has established itself as a leading player in the construction industry, specializing in delivering high-tech architectural building envelopes for the construction industry based on an Engineer to Order model. Focchi's expertise lies in crafting bespoke façade solutions for unique buildings, blending craftsmanship with cutting-edge technology. Within the construction value chain, Focchi is engaged in the activities of engineering, manufacturing and installation of building envelopes with the purpose to oversee the stages from design concepts validation to final on-site installation.

-

Company assets: physical and digital assets are listed:

- ○

-

Physical assets: Three kinds of physical assets are evaluated in the Digital Twin design:

- ▪

- Built environment: the Focchi HQ premises is the physical space of the warehouse to be in DT. The research focuses on warehouse and external spaces used to store inbound materials and components and outbound prefabricated façade.

- ▪

- Means of transportation: bikes and forklifts used by warehouse operators will be in the DT.

- ▪

- Stillages for components storage: stillages, pallets, iron steels will be tracked in the DT.

- ○

-

Digital assets: Three kinds of digital assets are evaluated in the Digital Twin design for data-driven analysis:

- ▪

- ERP: This software centralizes and manages various business processes and data including inventory, and orders.

- ▪

- Production Planner: Integrated with the ERP and operations, this tool is used by operator to schedule production processes based on production loads and materials inventory analysis. The solution is manually handled.

- ▪

- BIM (Building Information Modeling): This model maintains a digital representation of the physical and functional characteristics of the Focchi facility and its warehouse.

3. Results

3.1. Warehouse Process Analysis and User Story Identification

-

Enhanced materials, components and stillages visibility and tracking:

- ○

- Real-time visibility of vehicle traffic, warehouse access points, inventory levels, package locations, and personnel/vehicle locations.

- ○

- Unique identification and tracking of materials, components and stillages.

-

Improved Efficiency and Optimization:

- ○

- Optimized route suggestions for material transport.

- ○

- Efficient packages search functionality.

- ○

- Streamlined check-in process and optimized storage locations.

- ○

- Faster and more productive work through better task assignments and organization.

- ○

- Real-time task status updates and efficient task allocation.

- ○

- Optimized warehouse layout and clear traffic routes.

- ○

- Real-time updates on production schedules and task prioritization.

-

Enhanced Safety:

- ○

- Real-time location tracking of personnel and vehicles for collision prevention.

- ○

- Improved visibility for pedestrians and bikers in warehouse areas.

-

Communication and Collaboration:

- ○

- Real-time communication platform for information sharing and collaboration.

- ○

- Clear communication of schedules and priorities.

-

Resource (personnel and space) Management:

- ○

- More available storage space for prepared materials and components.

- ○

- Effective management of outbound logistics without hindering inbound logistics.

- ○

- Planning of deliveries and arrivals of materials (including forecasting and reservations).

-

IoT technologies:

- ○

- Sensors for real-time tracking: These would be placed on pallets, forklifts, bicycles, and potentially on workers (privacy concerns to be addressed) to capture location data. These sensors should be supported by IoT antennas to connect the wireless device to communications networks.

- ○

- Proximity sensors: These could be used to detect proximity between objects or people, triggering alerts for potential collisions. This is particularly relevant in the case of promiscuity paths between forklifts and bicycles to reduce the risk of blind spots for the forklift operators.

-

AI algorithms:

- ○

- Search algorithms: To enable efficient search and location functionality for packages and materials.

- ○

- Routing algorithms: To optimize routes for forklifts and other vehicles, reducing travel time and improving efficiency.

- ○

- Workload balancing algorithms: To automate task allocation and ensure efficient distribution of work among warehouse operators.

- ○

- Data analysis and visualization tools: To process and display real-time data from IoT sensors in a meaningful way, allowing for quick decision-making.

-

Digital Twin platform:

- ○

- 3D layout visualization: To provide a visual representation of the warehouse layout, allowing for better spatial understanding and planning.

- ○

- Integration BIM data with IoT data: To overlay real-time data from IoT sensors onto the BIM model and geolocation, providing a comprehensive view of warehouse operations.

- ○

- Real-time location tracking display: To show the current location of pallets, vehicles, and personnel within the warehouse.

- ○

- Task management system: To assign, track, and prioritize tasks for warehouse operators. The solution should be supported for the production line as well as for the forklift utilization.

- ○

- Communication and collaboration tools: To enable real-time communication and information sharing between workers.

- ○

- Safety alerts and notifications: To provide audible alerts (and/or visual for forklift operator) for potential hazards, such as proximity to forklifts or unauthorized areas.

-

Digital Twin Business Intelligence:

- ○

- Dashboard visualizations: To display KPIs in an easy-to-understand format. Dashboards must be developed specifically for office users (desktop) and for warehouse workers (mobile and table) to support tasks and data deployments.

- ○

- Reporting tools: To generate reports on warehouse efficiency, safety, and other relevant metrics.

- ○

- Predictive analytics: To forecast future warehouse occupancy and potential issues in production based on real-time data and production planning.

-

Efficiency and Optimization KPIs:

- ○

- Vehicle turnaround time: The time it takes for a truck to enter the warehouse, unload/load, and exit.

- ○

- Warehouse utilization rate: The percentage and/or sqm of available warehouse space being effectively utilized.

- ○

- Production line downtime: The amount of time production lines is not productive due to lack of materials or components.

- ○

- Inventory accuracy: The degree to which the recorded inventory levels match the actual physical inventory.

- ○

- Non-Compliance Records (NCRs) due to loss: The number of incidents where materials or components are lost or misplaced.

- ○

- Picking time and cost: The time and resources required to locate and retrieve items from the warehouse.

- ○

- Task allocation and completion time: The time it takes to assign and complete various warehouse tasks.

- ○

- Operator efficiency: A measure of how effectively warehouse operators are performing their assigned tasks. The KPIs cannot include operator identification, but aggregated data for operators working in similar tasks.

- ○

- Overtime hours: The number of hours worked beyond regular shifts due to workload demands.

- ○

- Adherence to production schedule: The percentage of tasks completed on time according to the production schedule.

- ○

- Time spent on logistics tasks: The total time dedicated to logistics-related activities.

-

Safety KPIs:

- ○

- Incident rate related to stress: The number of incidents or near-misses attributed to worker stress or fatigue.

- ○

- Worker satisfaction surveys: Feedback from workers on their perception of safety and well-being in the warehouse.

- ○

- Incidents/near misses: The number of accidents, near misses, or unsafe situations occurring in the warehouse.

3.2. Data Flow and Source Analysis

3.3. Digital Twin Design and Development

- Pallet for location in the warehouse: IoT system aims at optimizing the warehouse involving geolocating pallets stored in the outdoor warehouse, enhancing tracking capabilities.

- Forklift and bicycles transport routes: The IoT system aims at enabling real-time monitoring of transport routes, encompassing forklifts and bicycles, to ensure efficient and safe movement within the factory.

- Verification of the use of means of transport in forklift and bicycles by authorized personnel: IoT system ensures that only authorized personnel use specific means of transport, such as forklifts and bicycles, to enhance safety and control.

- Warehouse tasks optimization: AI aims at using data to define most productive scenarios and tasks assignment.

- Real-time collision risk alerts: AI aims at supporting on-board real-time alarms on forklifts will alert drivers to potential collision risks with bicycles or unauthorized areas, thus acting as a preventative measure against possible incidents.

- Asynchronous feedback for safety management: AI aims at communicating with safety operators in the factory will receive asynchronous feedback to identify areas with the highest levels of criticality, enabling them to take proactive measures to enhance safety.

-

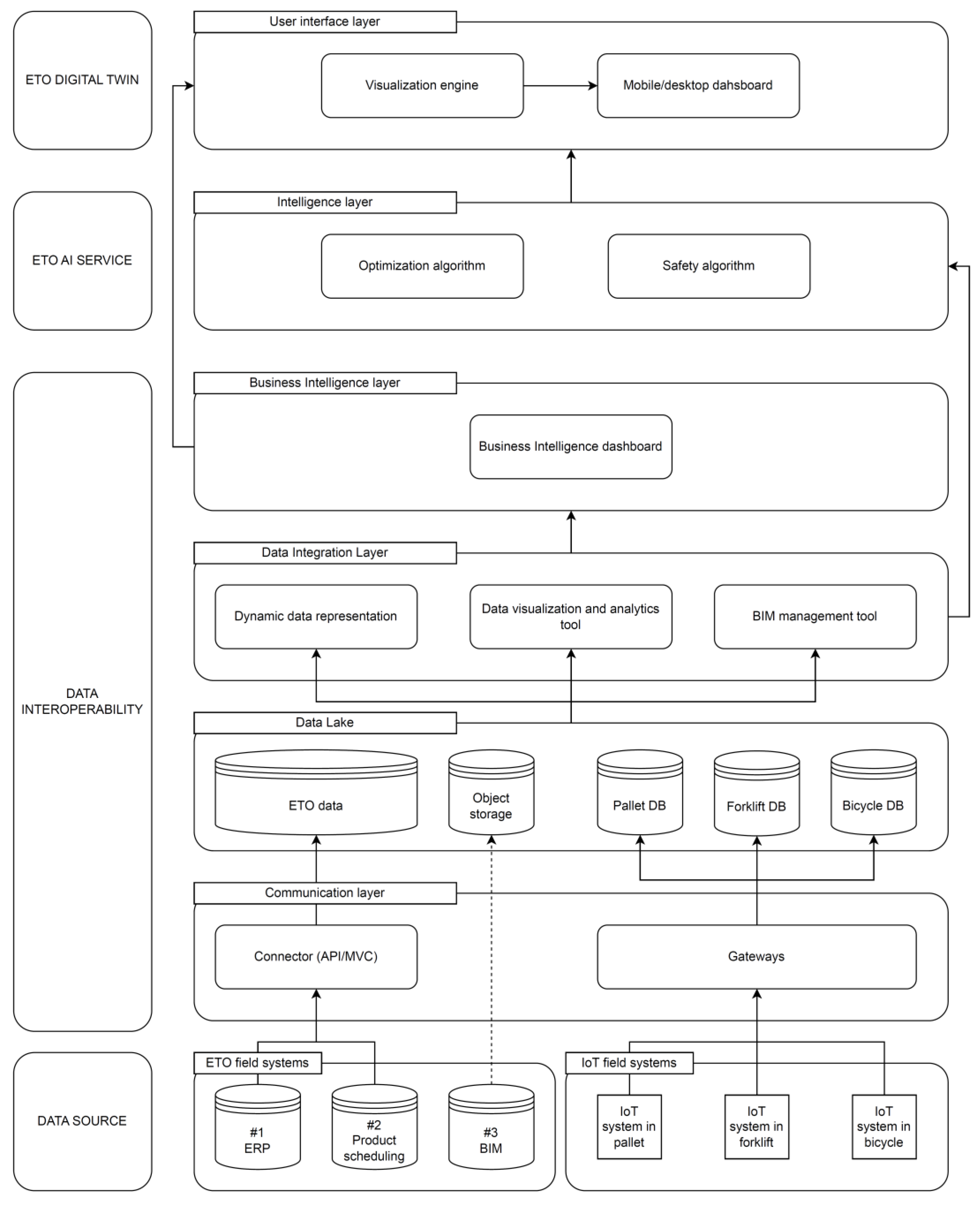

Data source:

- ○

- ETO field systems include existing dynamic data sources used by the company to support engineer-to-order processes such as ERP and product scheduling. BIM-Based 3D Model of the warehouse is used, providing a visual representation of the physical layout and enabling spatial analysis. The BIM includes a georeferencing of the facility as well as the definition of warehouse areas, locations and pedestrian paths.

- ○

- IoT field systems are designed to collect real-time data on pallet locations, forklift and bicycle movements.

-

Data interoperability:

- ○

- Communication layer to move from data sources to Data Lake using on-site gateways or connector with API or MVC solutions.

- ○

- Data Lake is with multiple Data Bases (DBs) related to data sources.

- ○

- Data integration layer connects data from DBs for dynamic data representation, data visualization and analytics tools and to manage BIM in DT.

- ○

- The Business Intelligence layer contains the dashboard for the business intelligence analysis of the data lake.

- ETO AI services with its intelligent layer deploys in the DT algorithms to meet user requirements for warehouse optimization and safety.

- ETO Digital Twin is the includes the front end with the user interface with the visualization engine and user interface for desktop and mobile.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| User unit | As a… <type of user> |

I want to… <perform a task> |

So that I can… <achieve this goal> |

User requirement | Technical requirement | KPI |

|---|---|---|---|---|---|---|

| O | Facility Manager | Monitor transit flows and times | Manage access for cleaning/services Optimize space |

Real-time visibility of truck traffic and warehouse access points | IoT sensors real-time data collection and analysis platform |

Truck turnaround time Service downtimeWarehouse utilization rate |

| O | Operations Manager | Support in searching packages | Reduce time and cost for picking | Efficient package search functionality | AI search algorithm Real-time location tracking |

Picking time Picking cost |

| O | Operations Manager | Optimize route routing | Reduce time and cost for picking | Optimized route suggestions | Routing algorithm real-time location data |

Picking time Picking cost |

| O | Operations Manager | Update package locations | Reduce time and cost for storing and picking | Real-time location updates for packages | IoT sensors real-time tracking |

Picking time Picking cost |

| O | Production Manager | Have more reactive production lines | Efficiently manage inventory emergencies | Real-time inventory visibility and alerts for low stock levels | IoT sensors Real-time inventory tracking AI automated alert system |

Production line downtime Inventory accuracy Emergency response time |

| O | Production Manager | Have unique locations for stillages | Decrease non-compliance records (NCRs) due to material loss | Unique identifier for each stillage, accurate tracking | RFID/barcode scanning Real-time location tracking system |

NCRs due to lossTime spent locating materials |

| O | Production Manager | Improve acceptance control and storage | Material doesn't stay in unload areas for long | Efficient check-in process, optimized storage locations | Digital checklists Real-time inventory updates AI optimized storage algorithm |

Material unloading time Storage utilization rate |

| O | Quality, H&S Manager | Increase visibility of pedestrians/bikers | Reduce the risk of collisions with vehicles | Real-time location of personnel and vehicles | IoT sensors Proximity detection Real-time alerts |

Near-miss incidents Accident rate |

| O | Safety Manager | Improve material positioning in the layout | Reduce time and cost for storing and picking | Optimized warehouse layout | 3D layout visualization AI simulation algorithm |

Trip/fall incidentsCollision incidents |

| O | Safety Manager | Improve traffic routes (pedestrians, vehicles, etc.) | Reduce risk of tripping and collisions | Clear traffic routes and signage | Digital twin visualization AI route optimization |

Trip/fall incidentsCollision incidents |

| W | Sequencer | Have a larger warehouse for prepared materials/components | Manage outbound logistics efficiently without hindering inbound logistics | More storage space for prepared materials/components | Warehouse expansion or reorganization | Outbound logistics processing time Number of outbound logistics delays |

| W | Sequencer | Share information in real-time with colleagues | Manage production line requests better | Real-time communication platform | Instant messaging Collaborative tools integrated in DT |

Production line response time Number of requests fulfilled on time |

| W | Sequencer | Share information in real-time with colleagues | Avoid wasting time | Real-time task status updates | Task management system Visual progress tracking |

Time spent on tasks Number of tasks completed on time |

| W | Sequencer | Share information in real-time with colleagues | Avoid unnecessary overtime | Efficient task allocation and prioritization | AI automated workload balancing Real-time task assignment |

Overtime hours Number of tasks completed within regular working hours |

| W | Sequencer | Share information in real-time with colleagues | Improve safety by reducing stress due to more efficient planning | Clear communication of schedules and priorities | Shared calendar Real-time updates on delays or changes |

Incident rate related to stress Worker satisfaction surveys |

| W | Sequencer | Automate the search for materials/components/stillages | Reduce time spent searching and placing items | Efficient search and location functionality | AI search algorithms Real-time location tracking Visual search tools in DT |

Time spent searching for items |

| W | Sequencer | Assign tasks to warehouse operators | Improve efficiency and reduce redundant interactions | Digital task assignment and tracking | Task management system in DT | Task completion time Operator efficiency |

| W | Sequencer | Have tools to support timely logistic operations | Perform tasks efficiently and align with production planning | Real-time updates on production schedules, task prioritization tools | Integration of production schedule data in DT AI task prioritization features |

Time spent on logistics tasks Adherence to production schedule |

| W | Sequencer | Have designated storage spaces for materials/components | Ensure materials don't remain in unload areas and are traceable | Organized storage with clear labels | Storage visualization in DT Inventory tracking |

Time spent locating materialsStorage utilization rate |

| W | Sequencer | Plan deliveries and arrivals of materials/components | Forecast arrivals/departures, improve safety, reduce congestion | Scheduling and reservation system | Appointment scheduling software Integration with DT |

Truck waiting time Congestion incidents |

| W | Worker in packages | Have better defined tasks and roles | Work faster and more productively | Clear task assignments and role descriptions | Workflow management system Task management system in DT |

Task completion time Productivity |

| W | Worker in reception | Have waterproof, high-visibility protective clothing | Improve visibility and protection | Provision of appropriate safety gear | IoT sensors Real-time tracking |

Incidents/near misses in loading/unloading areas |

| W | Worker in reception | Have a device to read QR/bar codes on supplier packing lists | Auto-fill outgoing packing lists | QR/bar code scanning and data extraction | Mobile device or tablet with QR code reader Integration with packing list system |

Time spent creating packing lists Packing list accuracy |

| W | Worker in reception | Share information in real-time with colleagues | Better manage production line requests and avoid wasting time | Real-time communication and information sharing platform | Instant messaging Collaborative tools integrated in DT |

Communication efficiency Time saved on communication |

| W | Worker in reception | Optimize traffic flows | Increase safety and speed | Real-time tracking of vehicles and personnel | IoT sensors Real-time location tracking DT visualization |

Incidents/near misses Time spent searching for materials |

| W | Worker in reception | Have well-signposted roads and clear signs | Improve safety and organization during loading/unloading | Clear signage and markings | DT visualization of signage Augmented reality navigation |

Incidents/near misses in loading/unloading areas |

References

- What Is Industry 4.0 and the Fourth Industrial Revolution? | McKinsey. Available online: https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolution-and-4ir (accessed on 28 May 2024).

- Industry 5.0 - European Commission. Available online: https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en (accessed on 28 May 2024).

- Wevolver Chapter 3: Industrial IoT and Manufacturing | Exploring the Dynamic World of Edge AI Applications Across Industries | 2024 State of Edge AI Report. Available online: https://www.wevolver.com/article/2024-state-of-edge-ai-report/industrial-iot-and-manufacturing (accessed on 28 May 2024).

- Vu, V.Q.; Tran, M.-Q.; Vu, L.T. Editorial: Applications of Artificial Intelligence and IoT Technologies in Smart Manufacturing. Front. Mech. Eng. 2023, 9. [Google Scholar] [CrossRef]

- Eurostat Digitalisation in Europe – 2023 Edition. Available online: https://ec.europa.eu/eurostat/cache/interactive-publications/digitalisation/2023/01/ (accessed on 28 May 2024).

- Amann, J. Industry 4.0 and Productivity.

- Facchini, F.; Digiesi, S.; Rodrigues Pinto, L.F. Implementation of I4.0 Technologies in Production Systems: Opportunities and Limits in the Digital Transformation. Procedia Comput. Sci. 2022, 200, 1705–1714. [Google Scholar] [CrossRef]

- Enrique, D.V.; Marodin, G.A.; Santos, F.B.C.; Frank, A.G. Implementing Industry 4.0 for Flexibility, Quality, and Productivity Improvement: Technology Arrangements for Different Purposes. Int. J. Prod. Res. 2023, 61, 7001–7026. [Google Scholar] [CrossRef]

- Kozlovska, M.; Klosova, D.; Strukova, Z. Impact of Industry 4.0 Platform on the Formation of Construction 4.0 Concept: A Literature Review. Sustainability 2021, 13, 2683. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating Major Challenges for Industry 4.0 Adoption among Construction Companies. Eng. Constr. Archit. Manag. 2021, 29, 1470–1503. [Google Scholar] [CrossRef]

- Bélanger, M.-J.; Pellerin, R.; Lamouri, S. A Literature Review on Digital Twins in Warehouses. Procedia Comput. Sci. 2023, 219, 370–377. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Stoidner, M.; Bründl, P.; Nguyen, H.G.; Baechler, A.; Franke, J. Towards the Digital Factory Twin in Engineer-to-Order Industries: A Focus on Control Cabinet Manufacturing. In Proceedings of the Advances in Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures; Alfnes, E., Romsdal, A., Strandhagen, J.O., von Cieminski, G., Romero, D., Eds.; Springer Nature Switzerland: Cham, 2023; pp. 80–95.

- Soori, M.; Arezoo, B.; Dastres, R. Digital Twin for Smart Manufacturing, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Wright, L.; Davidson, S. How to Tell the Difference between a Model and a Digital Twin. Adv. Model. Simul. Eng. Sci. 2020, 7, 13. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-Based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Y.; Huang, L.; Onstein, E.; Merschbrock, C. BIM and IoT Data Fusion: The Data Process Model Perspective. Autom. Constr. 2023, 149, 104792. [Google Scholar] [CrossRef]

- IRIS - Focchi. Available online: https://www.focchi.it/it/innovazione/iris (accessed on 28 May 2024).

- Home - Change2Twin Project. Available online: https://www.change2twin.eu/ (accessed on 28 May 2024).

- What Is Human-Centered Design? | HBS Online. Available online: https://online.hbs.edu/blog/post/what-is-human-centered-design (accessed on 28 May 2024).

- International Organization for Standardization ISO Central Secretariat ISO 9241-210:2019.

- Data-Driven Model. Wikipedia 2024.

- Waller, D. <italic>Harvard Business Review</italic>. 2020. [Google Scholar]

- Li, X.; Pang, H.; Li, G.; Jiang, J.; Zhang, H.; Gu, C.; Yuan, D. Wireless Positioning: Technologies, Applications, Challenges, and Future Development Trends. Comput. Model. Eng. Sci. 2024, 139, 1135–1166. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to Digital Twins: A Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry. J. Inf. Technol. Constr. ITcon 2021, 26, 58–83. [Google Scholar] [CrossRef]

- D1.5: DigiBUILD Architecture towards an Energy Efficient Building Data Space - Digibuild 2023.

| # | Stage | Tasks | Duration | Users (Warehouse Workers) |

Users (Office Employees) |

|---|---|---|---|---|---|

| 1 | Material Reception | Unload and inspect incoming materials, verify against BoM, create internal handling unit | 1/2 day | Worker in packages Worker in reception |

Operations Manager Quality, H&S Manager Safety Manager |

| 2 | Storage & Inventory | Store materials in warehouse, update inventory records | 1-5 days for inventory 3-25 days for storage |

Worker in packages Sequencer (Forklift operator) |

Operations Manager Facility Manager Q&H&S Manager Safety Manager |

| 3 | Production Planning | Create production schedules and orders based on site installation planning and material availability | daily updated | N/A | Production ManagerQ&H&S Manager |

| 4 | Material Picking | Pick materials from storage based on production orders | 1 day | Sequencer (Forklift operator) | Operations ManagerSequencer Q&H&S Manager |

| 5 | Production | Assemble components into finished products according to specifications and drawings | 1-2 days | Production line workers | Operations ManagerProduction ManagerProduction engineers, Q&H&S Manager |

| 6 | Packaging & Shipping | Pack finished products, create shipping labels, prepare for transport | 5 days | Worker in packages Forklift operator |

Operations ManagerShipping coordinators Q&H&S Manager |

| 7 | Delivery | Load products onto trucks for delivery to customers or construction sites | 1/2 day | Warehouse workers Forklift operator | Operations ManagerLogistics coordinators Q&H&S Manager |

| Dataset number | Dataset name | Data | Type of data | Data Origin | # Variables | Storage methodology | Sampling frequency | Storage format | Storage frequency | Read frequency | Update frequency |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Availabe quantity Description Handling Unit Item Item list Numer of production order Product ID Project Pallet ID Warehouse location (EMPTY) Work ID Working Center Year Year of production order |

Static | ERP | SQL in on premise server | 12 hours | xml | 2 times/day | 2 times/day | 2 times/day | ||

| 2 | End data of production Starting data of production Work ID |

Static | Production planning | SQL in on premise server | 12 hours | xml | 2 times/day | 2 times/day | 2 times/day | ||

| 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).