Submitted:

25 May 2024

Posted:

27 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

3. Problem Statement

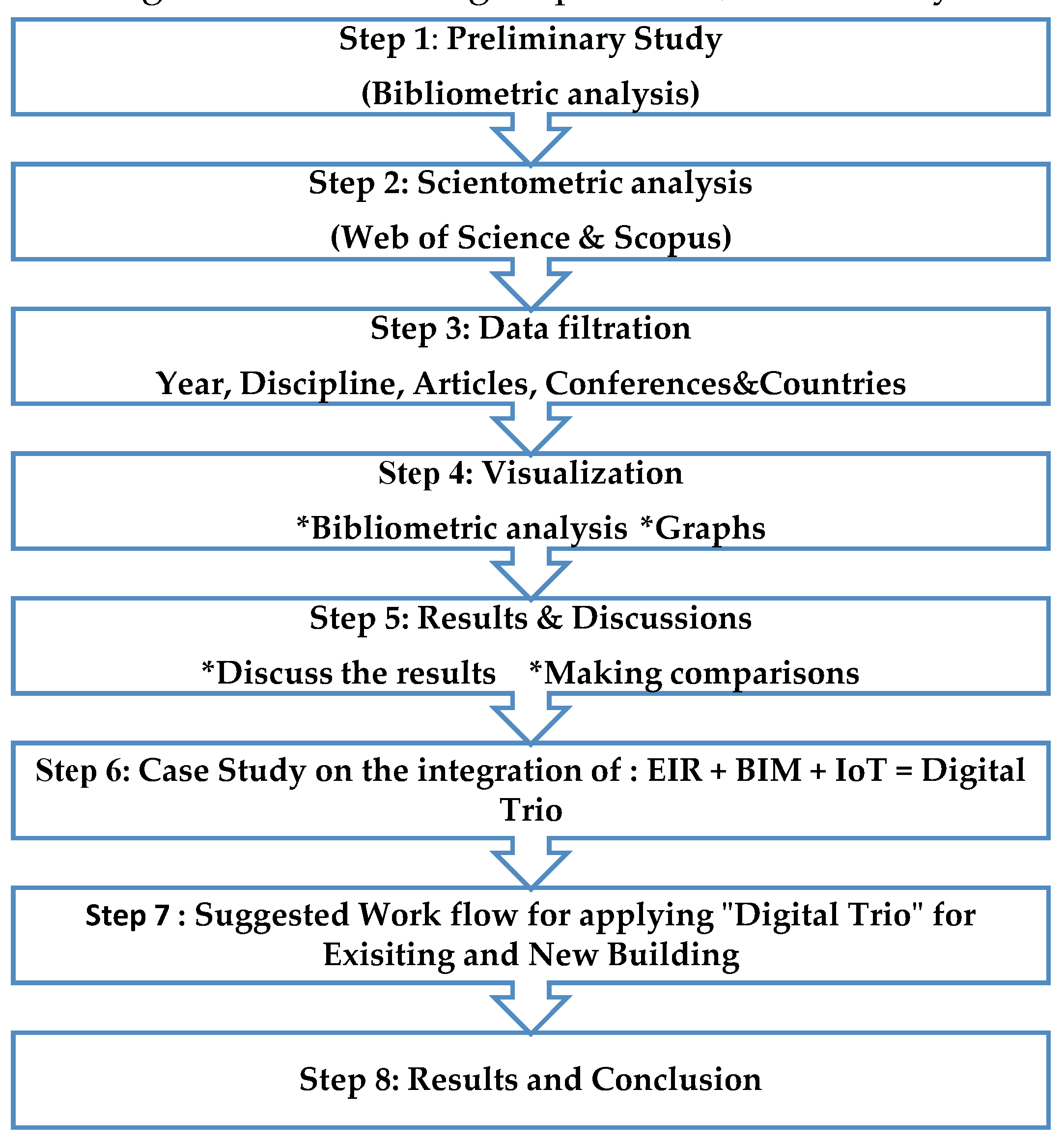

4. Research Methodology

- We conducted an in-depth review of current research to identify the challenges organizations encounter when implementing Building Information Modeling (BIM) to optimize Facility Management (FM) processes and maximize benefits.

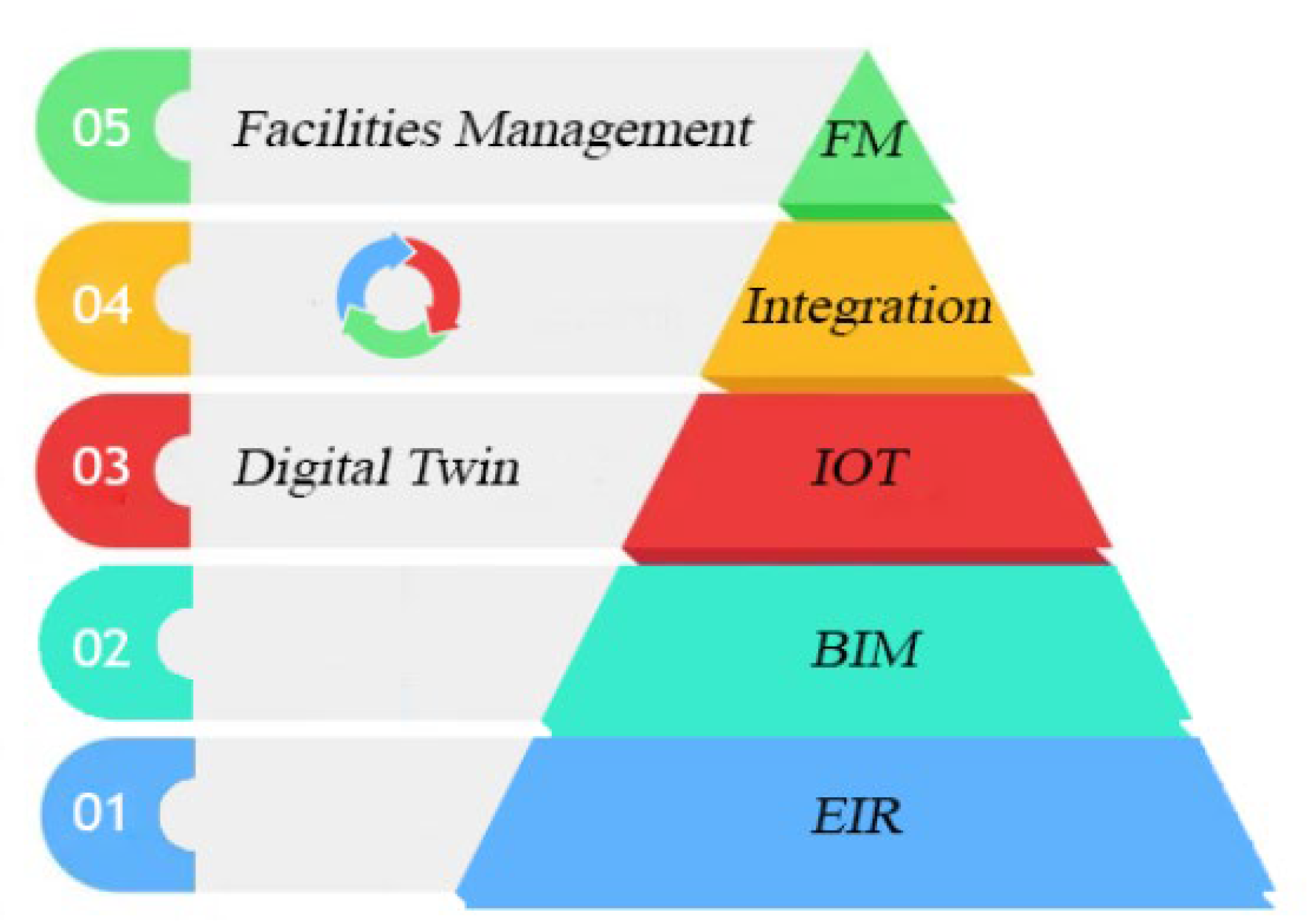

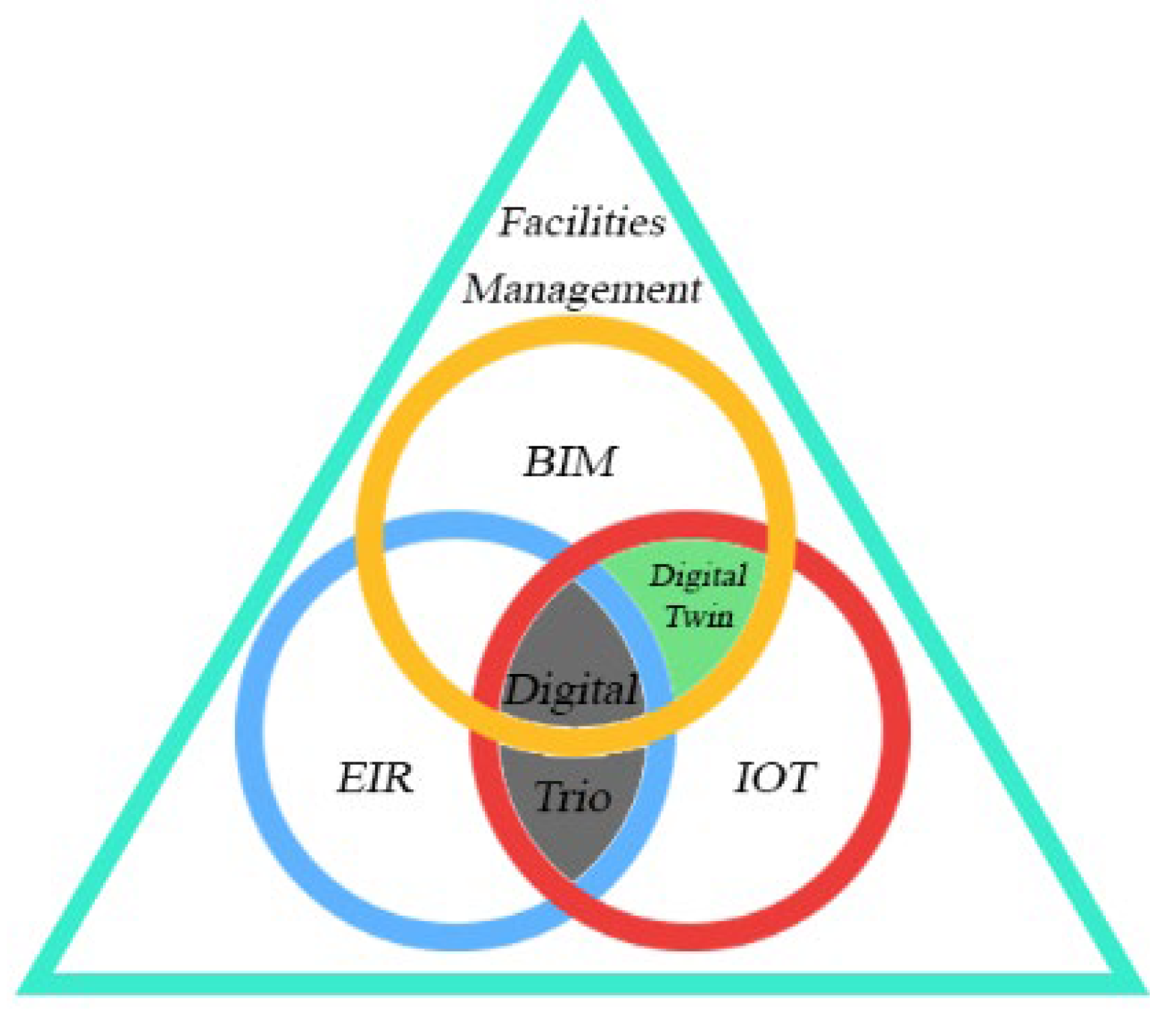

- The concept of the "Digital Trio is defined within the context of the role of Facility Managers (FMs) in the BIM process. Explore how this framework can enhance organizational workflow and improve efficiency.

- Develop an intuitive Digital Twin Platform that seamlessly integrates BIM and IoT technologies to facilitate FM applications in buildings. Users can easily upload BIM models to foster the implementation of FM practices.

- Design a user-friendly interface for a Digital Twin Platform accessible to engineers and specialists. Provide scenario-based tools to address potentially critical situations encountered in various building environments.

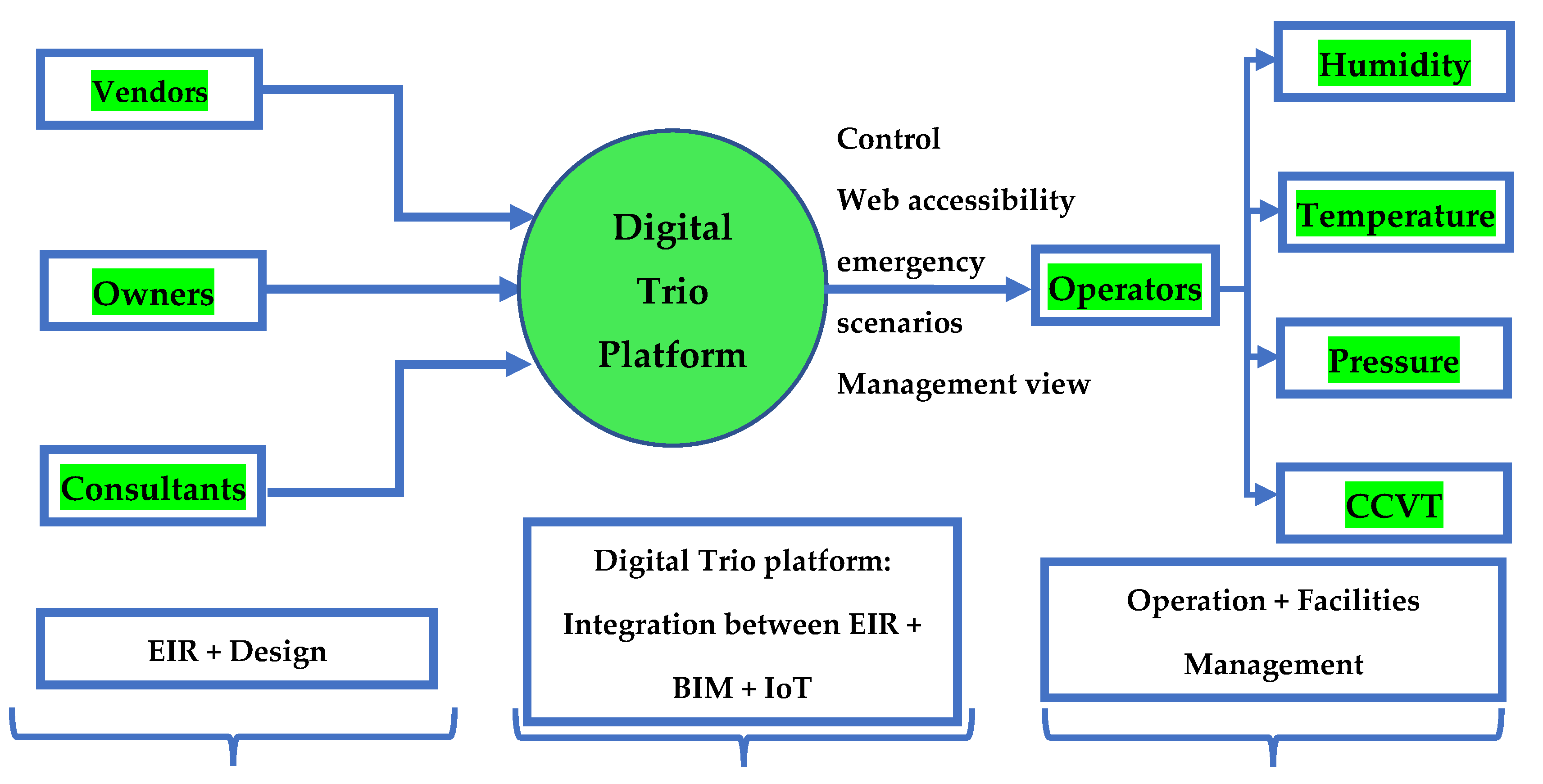

- Advocate the early involvement of owners, operators, and vendors in projects using the Digital Trio framework. Emphasize collaborative creation of Employer Information Requirements (EIR) to preemptively mitigate challenges during the construction and operation phases.

- Validate the Digital Twin Platform with BIM/FM experts to refine and ensure its effectiveness.

4.1. BIM Process

4.1.1. Vendors Input in EIR

- Suboptimal Tool Selection: Optimal selection of tools and software might not be made without vendor involvement. Vendors who are capable of advising on the most suitable solutions that can efficiently meet the demands of a project might offer more effective or economical alternatives.

- Misalignment with Software Capabilities: Critical insights into the alignment between tool capabilities and the requirements might be missing if vendors are excluded. Such exclusion can lead to misalignment, causing delays and increased costs owing to necessary adjustments or changes in tools during the project.

- Inefficient Workflows: Without vendor guidance during EIR preparation, workflows might be designed that are not optimized for the tools being used, leading to reduced efficiency and possibly affecting the quality of the project.

- Increased risk of noncompliance: The risk that specified standards and practices may not be fully supported by the software increases if vendors are not involved in drafting the EIR. Compliance issues may arise, particularly if the software does not support certain standards or data formats.

4.1.2. The Use of FM for the AEC and Owners

- Design firms often perceive BIM as a tool for issuing schematics and drawing detailed designs. This limited perspective results in the minimal use of BIM technology post-construction during the operational stage, often without coordination. During the design process, equipment data are unavailable until the project is awarded to a contractor, preventing designers from applying real dimensions or tagging the final information on all elements.

- In most construction companies and projects, BIM is utilized only when mandated by the owner owing to insufficient awareness of BIM among the team or management. Furthermore, a well-prepared BIM model is required before construction work commences, necessitating considerable time investment, particularly at the outset of the project. Project managers often resort to using 2D tools to accelerate site progress during critical phases; however, this leads to numerous coordination issues, resulting in wasted time and increased costs.

- Owners play a critical role in implementing BIM in projects and should envision its use during the operation phase. However, many projects lack the preparation of the employer’s Information Requirements (EIR) before initiation, leading to a misalignment of the vision for using BIM in facility management. Often, owners assign project managers who lack experience and understanding BIM, causing the project to lose its full benefits.

- Operators responsible for asset usage have a significant influence on a project's alignment with their requirements. Frequently, owners negotiate with operators during the construction phase, missing the benefits that could be gained if the operator's requirements and vision are incorporated from the beginning.

4.1.3. Using FM in Operation and Maintenance

4.1.4. Quality of BIM Models

4.1.5. Contractual Framework between Stakeholders

4.1.6. Cost

4.1.7. Economic Situation

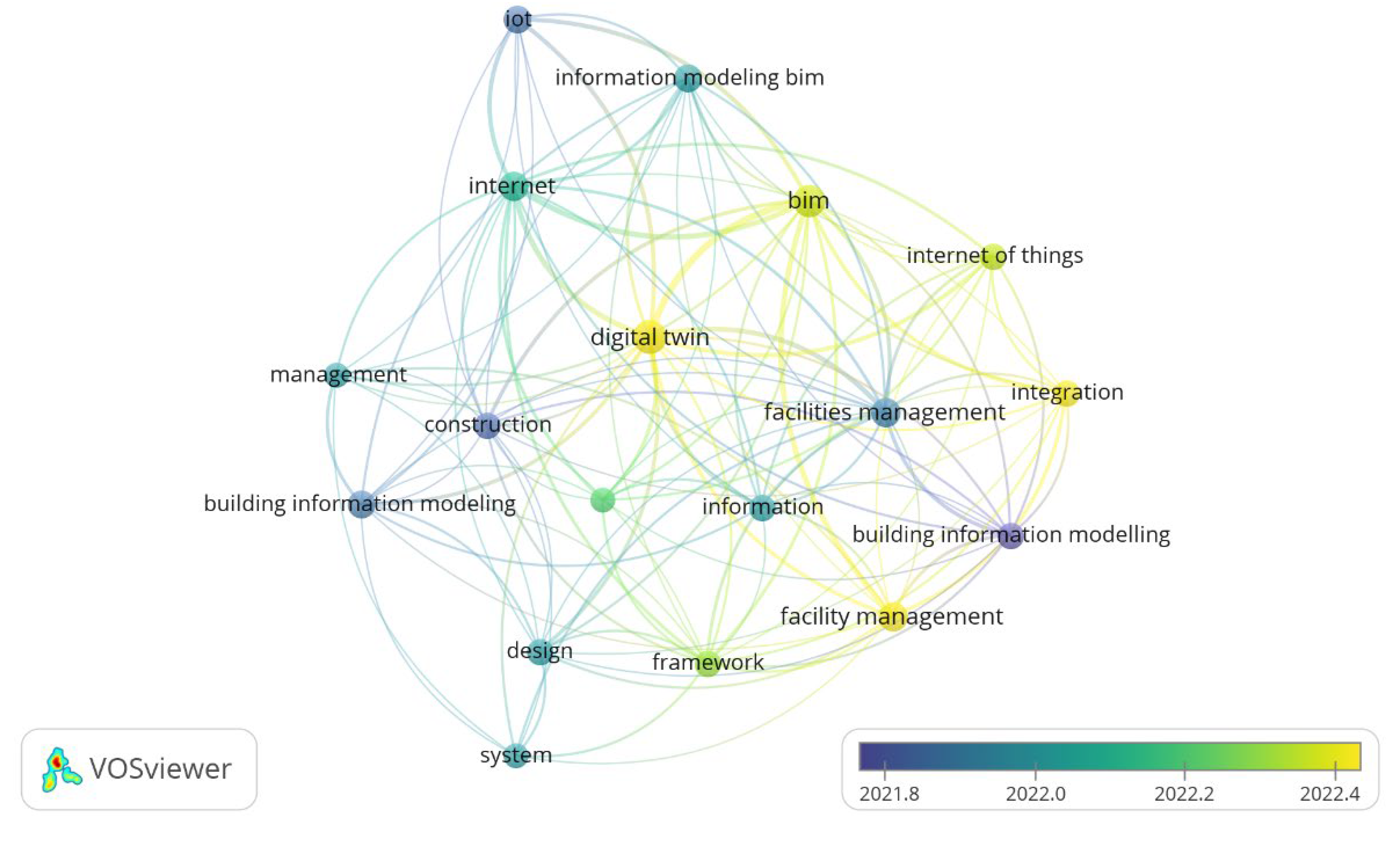

5. Bibliometric Review of Research

6. Case Study

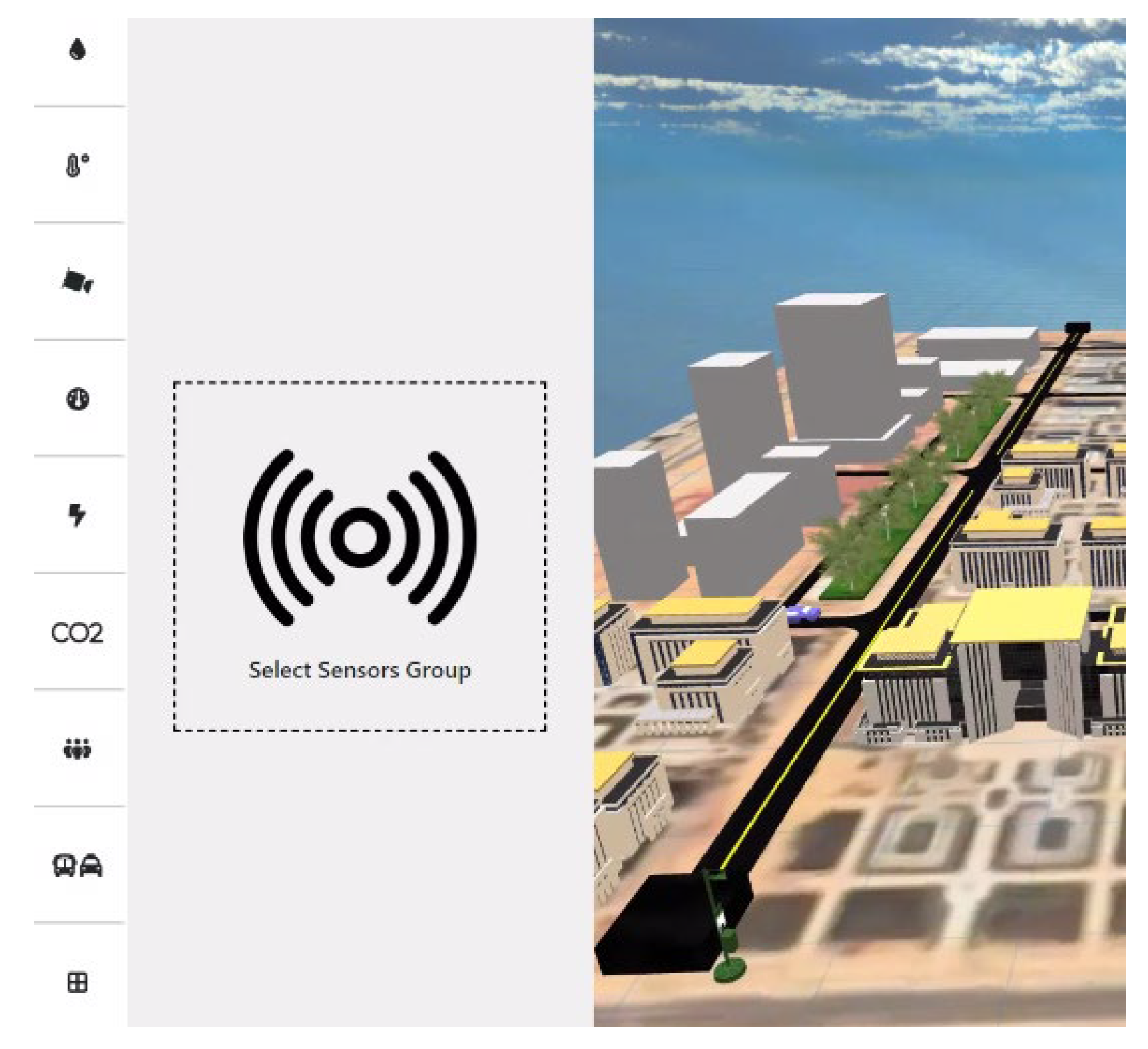

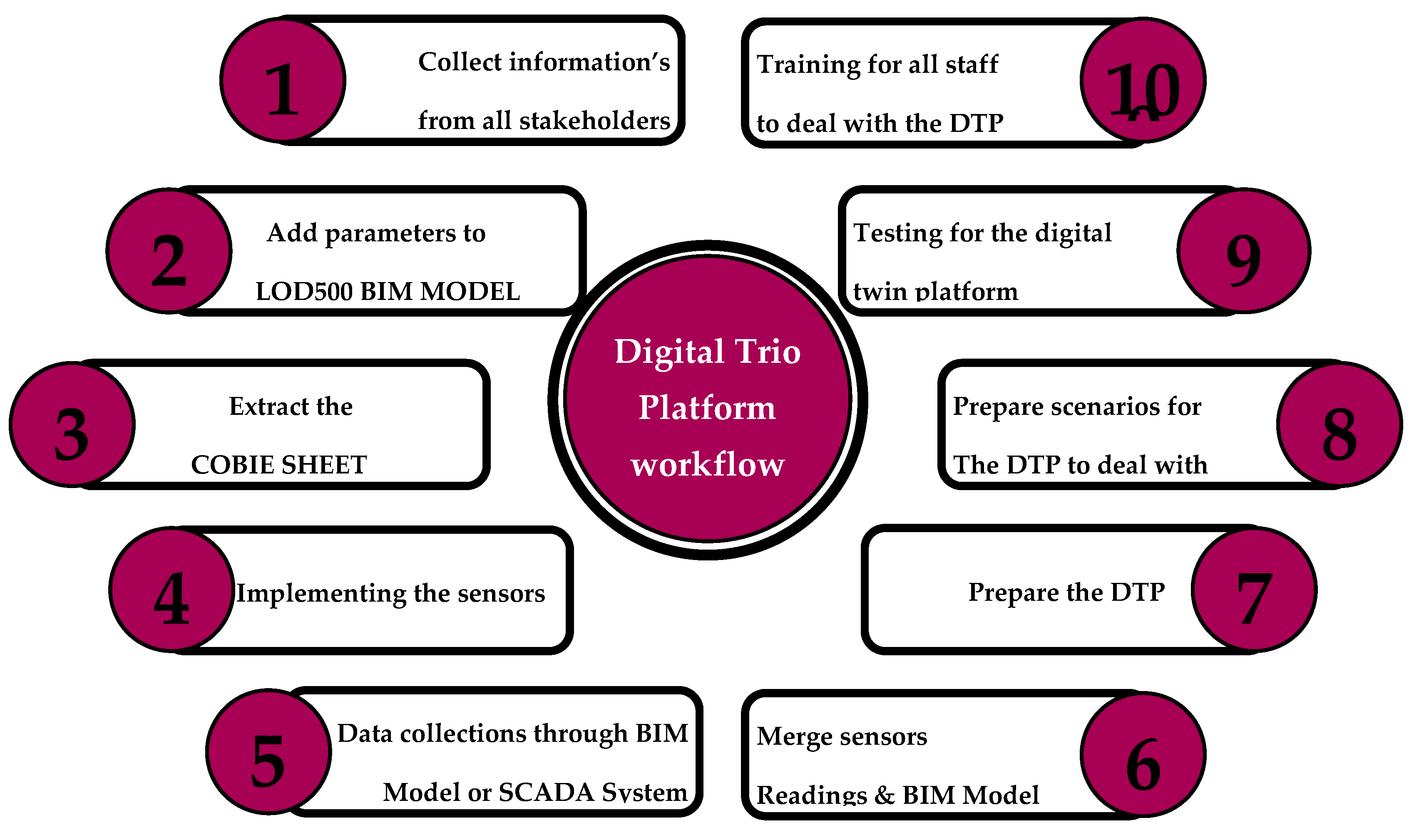

6.1. Digital Trio Platform

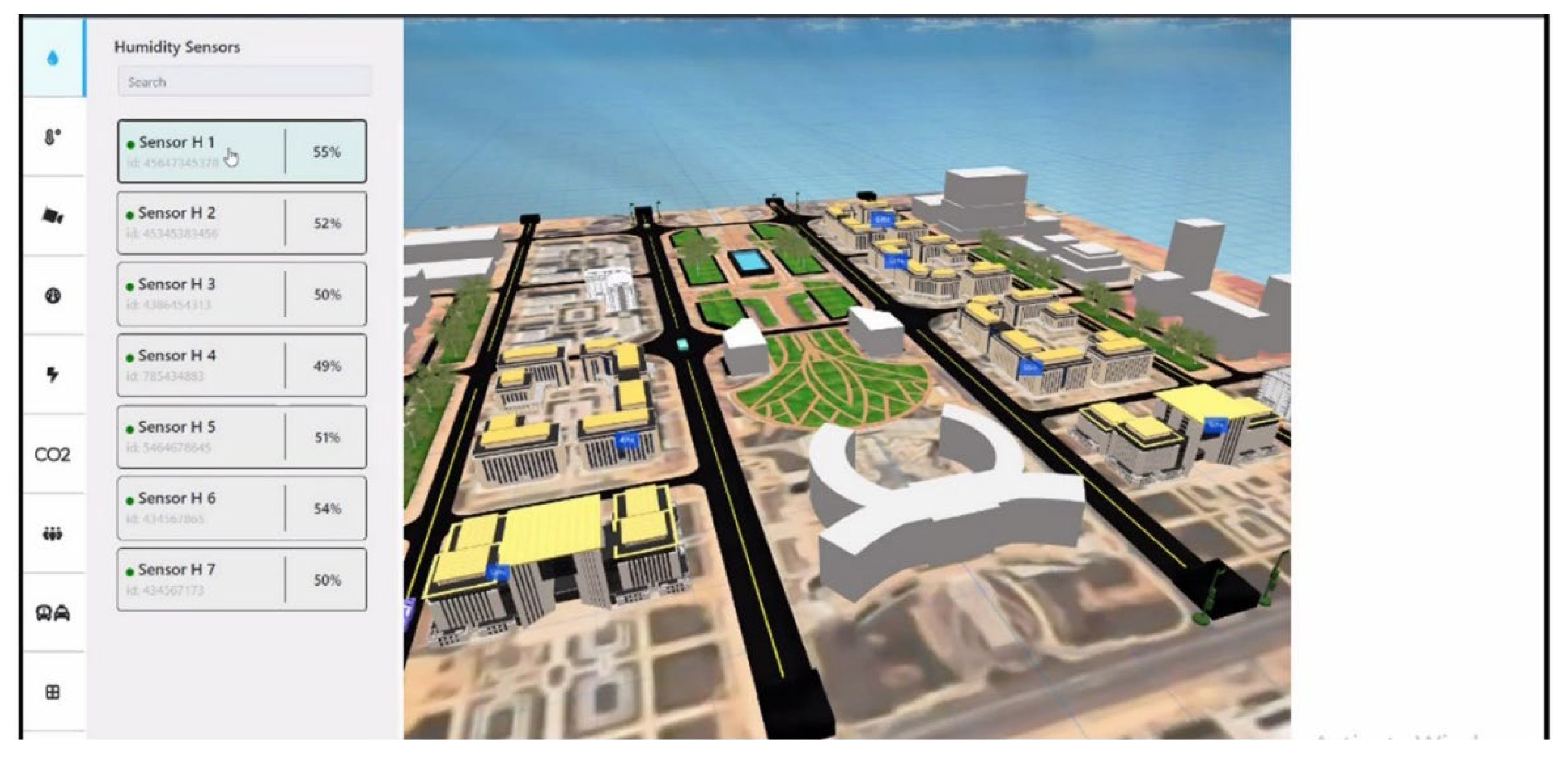

6.2. Humidity

- Indoor Air Quality (IAQ): Proper humidity control is crucial for maintaining good indoor air quality. It helps prevent conditions that can lead to health issues, such as mold growth and proliferation of allergens.

- Comfort and Occupant Well-being: Maintaining optimal humidity levels enhances occupant comfort and well-being. Appropriate humidity levels can prevent respiratory issues, skin irritation, and other health problems caused by excessively dry or humid conditions.

- Energy Efficiency: Humidity control can improve the efficiency of HVAC systems. HVAC systems can operate more effectively by maintaining appropriate humidity levels, leading to energy savings and lower operational costs.

- Quality Preservation of Stored Products: For moisture-sensitive products, such as food and beverages, pharmaceuticals, and electronics, monitoring humidity levels is essential to prevent degradation and ensure quality preservation.

- System Performance and Maintenance: Continuous humidity monitoring helps identify potential issues with HVAC and other environmental control systems. The early detection of abnormal humidity levels can prompt timely maintenance, prevent significant problems, and extend the lifespan of equipment.

- Regulatory Compliance: In specific environments such as healthcare facilities, laboratories, and food storage areas, humidity control is necessary to meet regulatory standards. Proper monitoring ensures compliance and protects the integrity of the stored goods and processes.

- Data-Driven Decision Making: Collecting and analyzing humidity data provides valuable insights into environmental conditions, helping building managers make informed decisions about system adjustments, maintenance schedules, and potential building modifications.

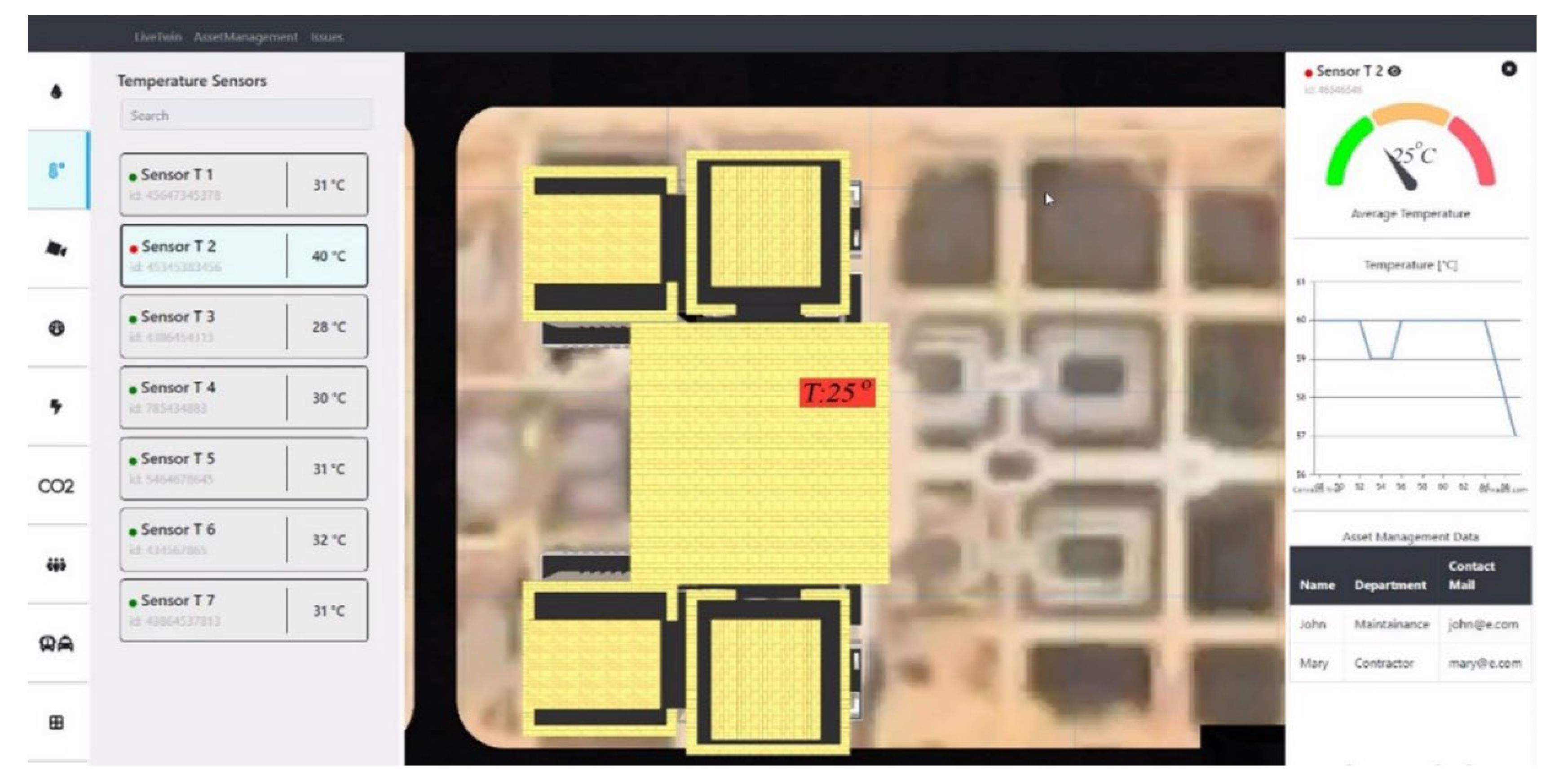

6.3. Temperature

- Comfort and Occupant Well-being: Monitoring indoor temperature ensures comfortable environments for occupants and enhances their well-being.

- Energy Efficiency: Temperature measurements are vital for energy conservation. Analyzing temperature data helps identify HVAC inefficiencies, optimize settings, and implement energy-saving strategies, resulting in cost savings and environmental benefits.

- HVAC System Performance: Monitoring temperature variations allows for early detection of HVAC issues, such as inadequate airflow or equipment malfunctions, enabling timely maintenance and improving system performance and equipment lifespan.

- Indoor Air Quality (IAQ) Management: Temperature control affects humidity levels and indoor air quality, helping to prevent condensation and mold growth.

- Data-Driven Optimization: Analyzing temperature data over time reveals patterns and trends, enabling energy savings, optimizing equipment schedules, and assessing building modifications.

- Regulatory Compliance: In regulated environments such as healthcare facilities and laboratories, temperature monitoring ensures compliance with standards, safeguarding stored goods, and sensitive processes.

6.4. Pressure

- System Performance: Pressure measurement helps assess the efficiency and functionality of fluid or gas flow in infrastructure systems.

- Safety: Monitoring pressure levels helps to prevent equipment failures, leaks, bursts, and other hazardous situations.

- Compliance: Pressure measurement ensures adherence to regulatory standards and requirements.

- Leakage Detection: Monitoring pressure drops helps detect and locate leaks, conserve resources, and reduce the environmental impact.

- System Balancing: Pressure measurement allows for optimal pressure levels across different zones, improving the system performance and energy efficiency.

- Equipment Maintenance: Pressure monitoring helps identify abnormal variations, enabling timely maintenance and preventing equipment failure.

- System Design: Accurate pressure measurements can inform infrastructure design and planning for effective system operation and reliability.

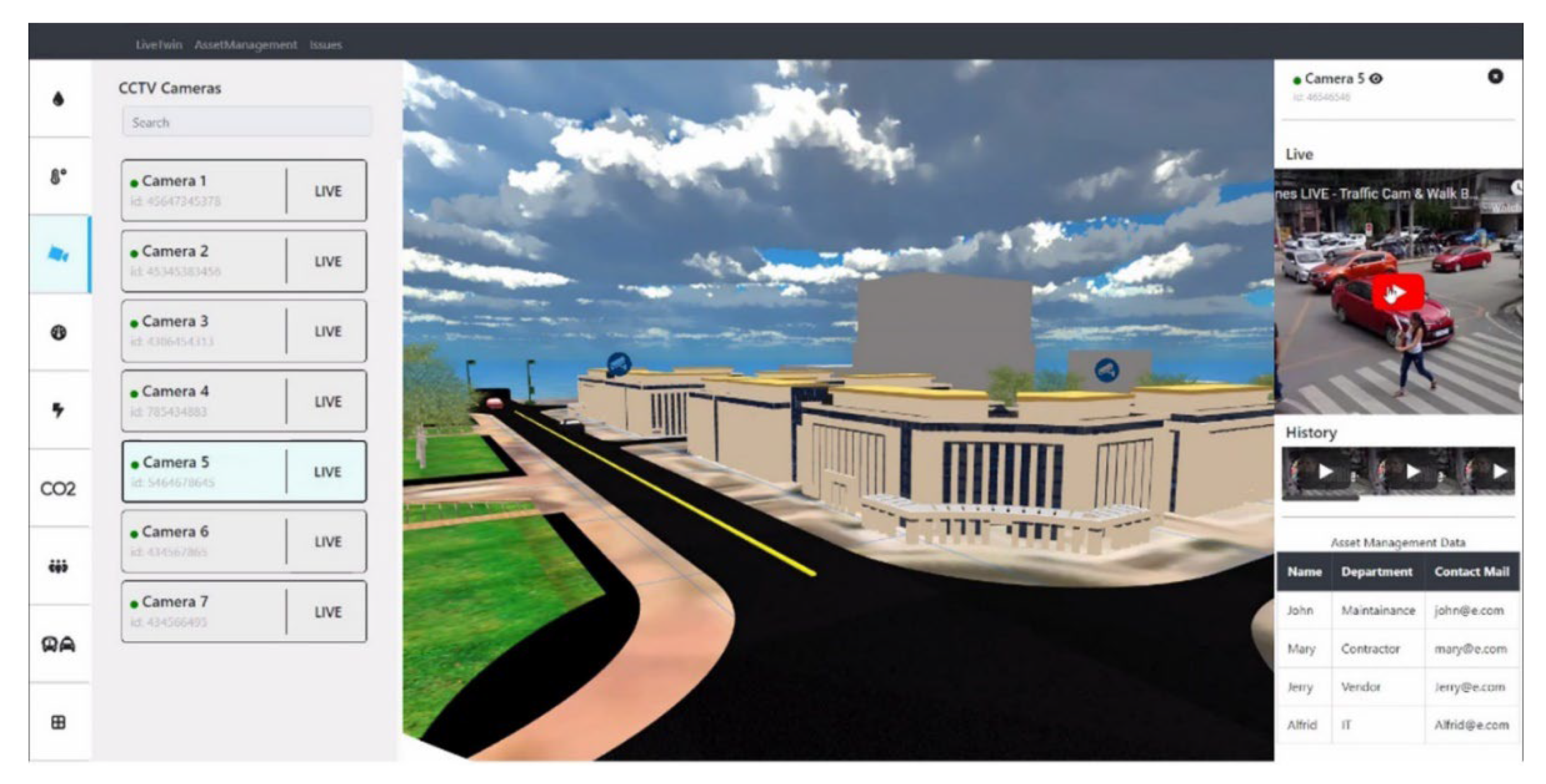

6.5. CCTV

- Crime Deterrence and Prevention: The installation of visible CCTV cameras acts as a deterrent for potential offenders, thereby decreasing the incidence of theft, vandalism, and unauthorized entry.

- Incident Detection and Response: CCTV cameras provide continuous real-time surveillance, enabling immediate identification of security breaches or safety hazards.

- Evidence Collection and Investigation: Recorded CCTV footage is crucial for investigating incidents or criminal activities, assisting in the identification of involved individuals, reconstructing the sequence of events, and supporting law enforcement and security teams.

- Safety and Emergency Management: CCTV systems monitor areas susceptible to accidents or safety risks, such as fire-prone zones or overcrowded spaces, aiding in timely responses, efficient crowd management during emergencies, and safe evacuation of occupants.

- Operational Monitoring and Efficiency: CCTV cameras can observe operational processes, allowing the identification of areas requiring improvement. By analyzing traffic patterns and observing key locations, building managers can optimize staffing, streamline operations, and improve customer service.

- Remote Monitoring and Control: Many CCTV systems offer remote access capabilities, facilitating surveillance and control from a central location or via mobile devices. This enhances proactive surveillance, enables rapid response, and allows for the simultaneous monitoring of multiple sites, thereby improving security management.

- Loss Prevention and Asset Protection: CCTV surveillance is instrumental in protecting valuable assets, equipment, and inventory by monitoring sensitive areas to detect and deter theft, unauthorized access, or tampering, thereby reducing financial losses and ensuring asset security.

- Liability and Risk Management: CCTV footage provides objective evidence in liability disputes or potential legal claims, helping to establish the sequence of events, providing accurate information, and safeguarding the interests of the building management and occupants involved.

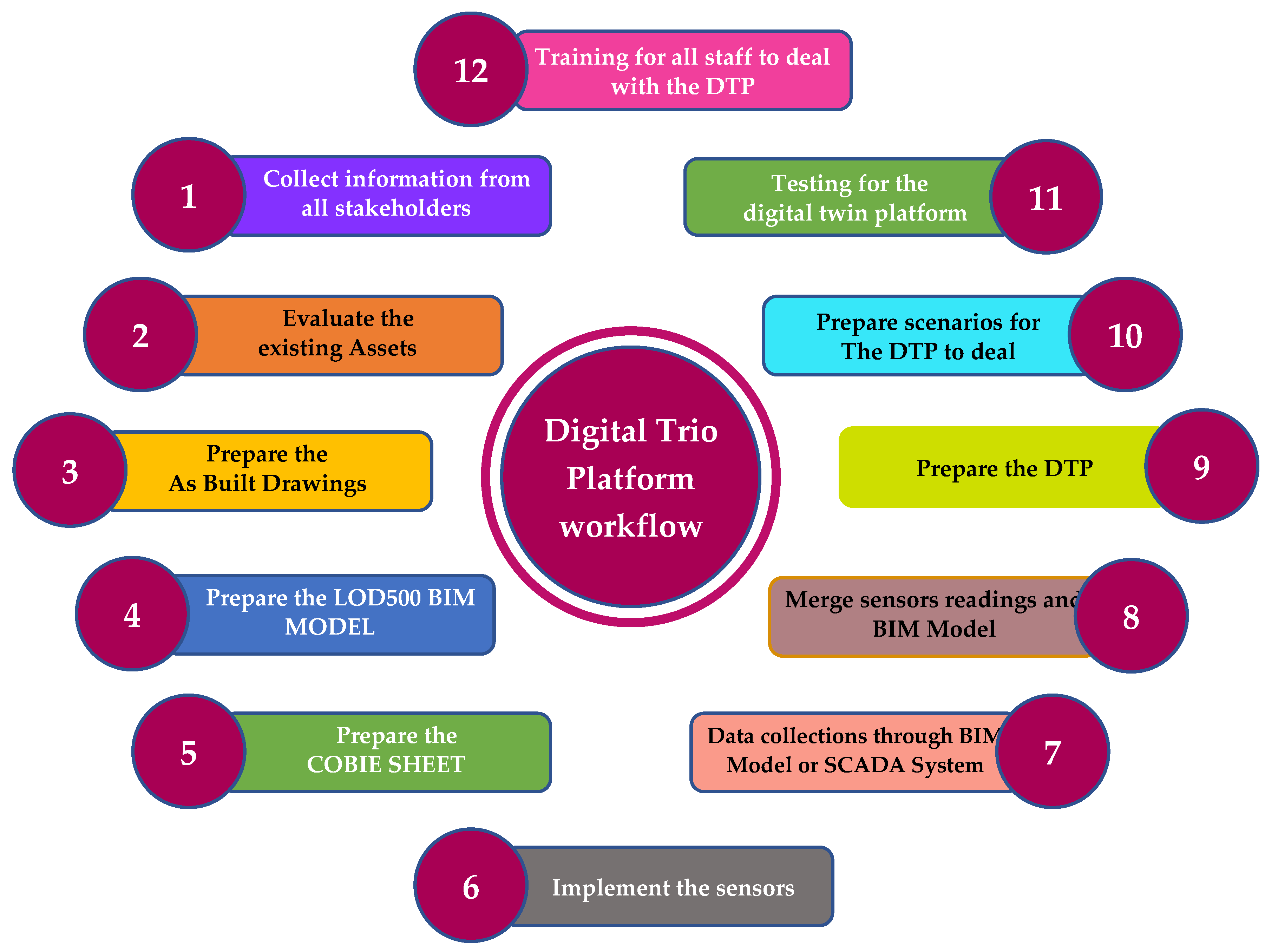

7. Proposed Framework of Integration of IoT, FM and BIM

7.1. A Road Map to Apply Digital Twin in Existing or New Building

7.1.1. Methodology for Preparing Digital Twin Platform for Existing (Governmental) Building

- Data Acquisition: Data Sources: Identify the various data sources that will be used to create the digital trio platform. These include sensors, IoT devices, historical data, building information Modeling (BIM) data, and Geographic Information System (GIS) data.

- Sensor Deployment: Sensors and data collection devices are installed in the building to gather real-time data. These sensors include temperature sensors, humidity sensors, occupancy sensors, and security cameras.

- Data Quality: Ensure data quality by regularly calibrating and maintaining the sensors. Inaccurate or inconsistent data can lead to errors in the digital trio platforms.

- Data Types: Collect data on various aspects of the building, such as temperature, humidity, energy consumption, occupancy, structural data, and security data.

- Data Security and Privacy:

- Address data security and privacy concerns by implementing encryption, access control, and compliance with relevant regulations.

- Data Modeling: Building Information Modeling (BIM): If available, incorporate BIM data, which provide a detailed 3D model of the building's architecture, infrastructure, and systems. This can serve as a foundational element of digital trio platforms.

- Semantic Modeling: Create a semantic model that represents the components, systems, and relationships within a building. This involves defining the ontology and taxonomy of the DT.

- Time Series Data: Handle time-series data for monitoring and predictive analytics. This includes historical data and real-time data streaming from sensors.

- Machine Learning and AI: Implementation of machine learning algorithms and artificial intelligence for data analysis and predictive capabilities. For example, predictive maintenance models can help anticipate when equipment fails.

- Visualization: Develop a user-friendly interface for visualizing the digital trio. This may include 3D models, dashboards, and data visualizations.

7.1.2. Methodology for Preparing Digital Twin Platform for New Building

- Design Integration: New buildings are often designed using digital tools that can be easily integrated with a digital trio platform. This means that the digital trio can be developed alongside the building using the same models and data used for construction.

- Sensor Integration: In a new building, the sensors and IoT devices necessary for a digital trio can be included in the design and built into the structure. This seamless integration ensured comprehensive data collection from the start.

- Data Availability: For digital trio to be effective, it requires data. New buildings can be designed to collect and feed data into twins from day one

- Technological Compatibility: New buildings can be constructed using the latest technology to ensure compatibility with modern digital trio platforms.

- Planning and Budgeting: When a digital trio is part of the original plan for a new building, it can be budgeted and implemented in the most efficient way.

- Customization and Optimization: With new construction, the digital trio can be customized and optimized during the design phase, ensuring that it meets all the specific needs of the building.

- Regulatory Compliance: New buildings will be designed to comply with current regulations, including those that may relate to digital systems and data handling.

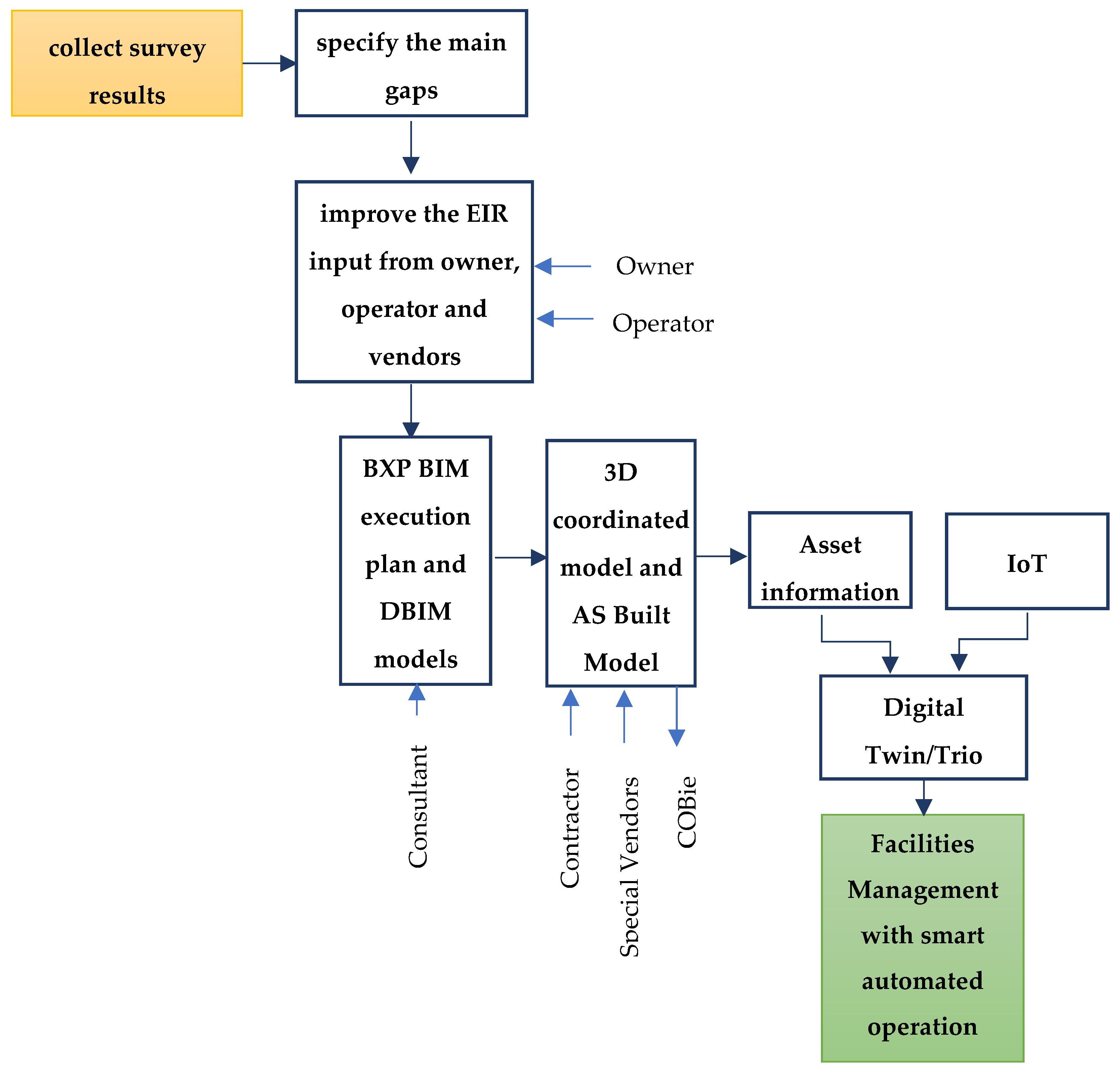

7.2. Framework for Establishing DT

- Owner/Operator: This is where the process starts, likely with the building's owner or operator identifying the need for a digital twin and initiating the process.

- Collect Survey Results: The first action is to collect survey results, which could refer to the collection of data about the current state of the building or facility.

- Specify the Main Gaps: Based on the survey results, the main gaps in information or performance are identified. This is a critical step in understanding what needs to be addressed using the digital twin.

- EIR (Exchange Information Requirements): As a result of identifying gaps, improvements are made to the Exchange Information Requirements, which dictate what information needs to be collected and exchanged throughout the process.

- BXP BIM Execution Plan and DBIM Models: The consultant then developed a BIM Execution Plan (BXP) and Detailed BIM (DBIM) models. This involves planning how the BIM process will unfold and create detailed building models.

- 3D Coordinated Model and AS Built Model: The contractor, possibly with the help of specialized subcontractors, uses the execution plan and models to create a 3D coordinated model of the building as it is to be built (or as it exists, in the case of an existing building).

- AIM (Asset Information Model): The Asset Information Model (AIM) is developed, which contains detailed information about the assets within the building, crucial for the management of the facility.

- IoT (Internet of Things): IoT plays a role in this workflow by providing a network of sensors and devices that collect real-time data from the building.

- Digital Twin: This is the culmination of the previous steps, where AIM and IoT come together to form the digital twin, a virtual representation of the physical building that is dynamic and data-rich.

- Facilities Management with Smart Automated Operation: Finally, the digital twin is used for advanced facilities management, enabling smart, automated operations of the building systems, likely aimed at improving efficiency, reducing costs, and enhancing user experience within the building.

8. Results

9. Conclusions

- Education and Awareness: Raising awareness and educating stakeholders about the benefits of these technologies through training programs for architects, engineers, and construction professionals as well as workshops and seminars for government officials and developers.

- Development of Standards and Guidelines: Establishing standards and guidelines for data exchange and interoperability tailored to the Egyptian market in collaboration with international organizations and experts.

- Encouragement of Collaboration and Partnerships: Promote collaboration among stakeholders, including government agencies, private sector developers, and academic institutions, to facilitate successful implementation.

- Implementation of Pilot Projects: Demonstrating the benefits of BIM, IoT, and EIR through pilot projects in various sectors such as infrastructure, industrial, commercial, and residential projects to gather data and feedback for future implementation efforts.

- Establishment of a Legal Framework: Creating a legal framework to regulate data collection, sharing, and usage, ensuring the protection of data and the rights of stakeholders.

- Encouragement of Innovation and Research: Promoting innovation and research in BIM, IoT, and EIR to stay updated with the latest developments, potentially through funding initiatives.

Declarations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BIM | Building Information Modeling |

| BXP | BIM Execution Plan |

| IoT | Internet of Things |

| EIR | Employer's information requirements |

| DT | Digital Twin |

| AEC industry | Architecture, Engineering and Construction industry |

| QA/ QC | Quality Assurance/ Quality Control |

| CDE | Common Data Environment |

| LOD | Level of Development |

| CCTV | Closed-circuit television |

References

- Abd El-Hamid, S.M.; Farag, S.; Abdelalim, A.M. , Construction Contracts’ Pricing according to Contractual Provisions and Risk Allocation. Int. J. Civ. Struct. Eng. Res. 2023, 11, 11–38. [Google Scholar] [CrossRef]

- Abd El-Karim, M.S.B.A.; Mosa El Nawawy, O.A.; Abdelalim, A.M. Identification and Assessment of Risk Factors Affecting Construction Projects. HBRC J. 2017, 13, 202–216. [Google Scholar] [CrossRef]

- Abdelalim, A.M. Risks Affecting the Delivery of Construction Projects in Egypt: Identifying, Assessing and Response. In Project Management and BIM for Sustainable Modern Cities; Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer International Publishing: Cham, Switzerland, 2019; pp. 125–154. [Google Scholar] [CrossRef]

- Abdelalim, A.M.; Abo. Elsaud, Y. Integrating BIM-Based Simulation Technique for Sustainable Building Design. In Project Management and BIM for Sustainable Modern Cities; Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer International Publishing: Cham, Switzerland, 2019; pp. 209-238. [CrossRef]

- Abdelalim, A.M.; El Nawawy, O.A.; Bassiony, M.S. Decision Supporting System for Risk Assessment in Construction Projects: AHP-Simulation Based. IPASJ Int. J. Comput. Sci. 2016, 4, 22–36. [Google Scholar]

- Abdelalim, A.M.; Elbeltagi, E.; Mekky, A.A. Factors Affecting Productivity and Improvement in Building Construction Sites. Int. J. Prod. Qual. Manag. 2019, 27, 464–494. [Google Scholar] [CrossRef]

- Abdelalim, A.M.; Said, S.O.M. Dynamic Labor Tracking System in Construction Project Using BIM Technology. Int. J. Civ. Struct. Eng. Res. 2021, 9, 10–20. [Google Scholar]

- Abd-Elhamed, A.; Amin, H.E.; Abdelalim, A.M. Integration of Design Optimality and Design Quality of RC Buildings from the Perspective of Value Engineering. Int. J. Civ. Struct. Eng. Res. 2020, 8, 105–116. [Google Scholar]

- Afifi, A.; Elsamadony, A.; Abdelalim, A. M, A Proposed Methodology for Managing Risks in Construction Industry in Egypt. Int. J. Civ. Struct. Eng. Res. 2020, 8, 63–78. [Google Scholar]

- Afifi, A.; Elsamadony, A.; Abdelalim, A.M. , Risk Response Planning for Top Risks Affecting Schedule and Cost of Mega Construction Projects in Egypt. Int. J. Civ. Struct. Eng. Res. 2020, 8, 79–93. [Google Scholar]

- Akinshipe, O.; Aigbavboa, C.; Anumba, C. The Future of Facility Management: A Case for Digital Twin. 2022.

- Ashworth, S.J. The Evolution of Facility Management (FM) in the Building Information Modelling (BIM). 2020.

- Beadle, S. Employer’s Information Requirements (EIR): An Overview of Facilities Management Requirements. 2017.

- Bhaskar, K. Requirements of Construction Scheduling for the BIM Execution Plan: A Literature Review. 2023.

- CIC BIM Standards. Hong Kong, 2021.

- Codinhoto, R.; Campos Fialho, B. BIM and IoT for Facilities Management: Understanding Key Maintenance Issues. 2023.

- Dawood, N.; Kassem, M. BIM for Facilities Management: A Framework and a Common Data Environment Using Open Standards. 2020.

- El Dean, S.M.; Abdelalim, A.M. A Proposed System for Prequalification of Construction Companies & Subcontractors for Projects in Egypt. Int. J. Manag. Commer. Innov. 2021, 9, 290–304. [Google Scholar]

- Elhosin, Y.; El Badawy Sayed, A.; Farag, M.A.M.; Abdelalim, A.M. Risk Identification of Building Construction Projects in Egypt. Buildings 2023, 13, 1084. [Google Scholar] [CrossRef]

- El-Kholy, A.M.; Abdelalim, A.M. A Comparative Study for Fuzzy Ranking Methods in Determining Economic Life of Equipment. Int. J. Constr. Eng. Manag. 2016, 5, 42–54. [Google Scholar]

- El-Samadony, A.A.; Abdelalim, A.M.; Elharony, A.A. Quantitative Risk Assessment and Mitigation for Construction Projects in Egypt. Proceedings of the International Conference of Sustainable Construction and Project Management, ICSCPM-16, 29-31 March 2016, Aswan, Egypt.

- Harode, A.; Thabet, W.; Dongre, P. A Tool-Based System Architecture for a Digital Twin: A Case Study in a Healthcare Facility. 2023.

- Hassanen, M.A.H.; Abdelalim, A.M. A Proposed Approach for a Balanced Construction Contract for Mega Industrial Projects in Egypt. Int. J. Manag. Commer. Innov. 2022, 10, 217–229. [Google Scholar] [CrossRef]

- Hassanen, M.A.H.; Abdelalim, A.M. Risk Identification and Assessment of Mega Industrial Projects in Egypt. Int. J. Manag. Commer. Innov. 2022, 10, 187–199. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Imran, A.; Cardenas-Cartagena, J.; Svennevig, P.R. A Review of the Digital Twin Technology in the AEC-FM Industry. 2022.

- Hosamo, H.H.; Nielsen, H.K.; Kraniotis, D.; Svennevig, P.R.; Svidt, K. Energy and Buildings. Energy Build. 2023, 288, 112992. [Google Scholar] [CrossRef]

- Hu, W.; Lim, K.Y.H.; Cai, Y. Digital Twin and Industry 4. 0 Enablers in Building and Construction. 2022.

- Khedr, R.; Abdelalim, A.M. The Impact of Strategic Management on Projects Performance of Construction Firms in Egypt. Int. J. Manag. Commer. Innov. 2022, 9, 202–211. [Google Scholar]

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building Information Modelling and Internet of Things Integration for Facility Management—Literature Review and Future Needs. Appl. Sci. 2021. [CrossRef]

- Medhat, W.; Abdelkhalek, H.; Abdelalim, A.M., A Comparative Study of the International Construction Contract (FIDIC Red Book 1999) and the Domestic Contract in Egypt (the Administrative Law 182 for the Year 2018). 2023. [CrossRef]

- Mohamed, N.A.; Abdelalim, A.M.; Ghith, H.H.; Sherif, A.G. Assessment and Prediction Planning of RC Structures Using BIM Technology. Eng. Res. J. 2020, 167, 394–403. [Google Scholar] [CrossRef]

- Moreno, C.; Olbina, S.; Issa, R.R. BIM Use by Architecture, Engineering, and Construction (AEC) Industry in Educational Facility Projects. Adv. Civ. Eng. 2019. [CrossRef]

- Nashwan Dawood, Mohamad Kassem, BIM for facilities management: A framework and a common data environment using open standards. 2020.

- Parsanezhad, P. Towards a BIM-Enabled Facility Management: Promises, Obstacles and Requirements. Doctoral Thesis, Stockholm, Sweden, 2019. [Google Scholar]

- Rizk Elimam, A.Y.; Abdelkhalek, H.A.; Abdelalim, A.M. Project Risk Management during Construction Stage According to International Contract (FIDIC). Int. J. Civ. Struct. Eng. Res. 2022, 10, 76–93. [Google Scholar] [CrossRef]

- Saback, V.; Popescu, C.; Blanksvärd, T. Framework for Facility Management of Bridge Structures Using Digital Twins. 2022.

- Said, S.O.M.; Abdelalim, A.M. Theoretical Understanding of Indoor/Outdoor Tracking Systems in the Construction Industry. Int. J. Civ. Struct. Eng. Res. 2021, 9, 30–36. [Google Scholar]

- Shawky, K.A.; Abdelalim, A.M.; Sherif, A.G. Standardization of BIM Execution Plans (BEP’s) for Mega Construction Projects: A Comparative and Scientometric Study. Telematics Comput. Sci. 2024. [CrossRef]

- Sherif, A.; Abdelalim, A.M. Delay Analysis Techniques and Claim Assessment in Construction Projects. Int. J. Eng. Manag. Humanit. 2023, 10, 316–325. [Google Scholar] [CrossRef]

- Siccardi, S.; Villa, V. Trends in Adopting BIM, IoT and DT for Facility Management: A Scientometric Analysis and Keyword Co-Occurrence Network Review. 2022.

- Stephen Beadle, Matthew Tucker, Imon Ashworth, Employer’s information requirements (EIR) An overview of facilities management requirements, 2017.

- United Nations. Building Information Modelling (BIM) for Road Infrastructure. 2021.

| Title | Traditional Approach | Using BIM and Digital Twin |

|---|---|---|

| Information Accessibility |

Description: Relied on scattered and paper-based documentation, making it challenging to access comprehensive and up-to-date information about the building. | Description: BIM and Digital Twins provide a centralized repository of comprehensive and real-time information, improving accessibility for facility managers, maintenance teams, and stakeholders. |

| Challenges: Limited accessibility, and potential for outdated information | Advantages: Enhanced access, and real-time data updates. | |

| Data Entry and Updates | Description: Facility management involved manual data entry and updates, leading to errors, inconsistencies, and delays in reflecting changes in building configurations. | Description: Automation in BIM and Digital Twins ensures that changes in the building are automatically updated, reducing manual data entry errors and ensuring data accuracy. |

| Challenges: Data inaccuracies, and time-consuming processes. | Advantages: Increased efficiency, and reduced errors. | |

| Collaboration and Communication |

Description: isolated information and lack of collaboration between design, construction, and facility management teams. | Description: BIM fosters collaboration by providing a common platform for stakeholders to access and update information throughout the building's lifecycle. |

| Challenges: Inefficiencies, miscommunication, difficulty in sharing information. | Advantages: Improved communication, and efficient collaboration | |

| Maintenance Practices | Description: Facility managers struggled with inefficient maintenance practices due to a lack of detailed and real-time information about the building's components. | Description: BIM and Digital Twins enable proactive and efficient maintenance practices by providing detailed information on the condition of building components. |

| Challenges: Reactive maintenance, and increased downtime. | Advantages: Predictive maintenance, and reduced downtime. | |

| Analytical Capabilities |

Description: the traditional way of analysis required a lot of effort and documents with the risk of human mistakes to conclude a result | Description: BIM and Digital Twins enable advanced analytics, allowing facility managers to simulate, analyze, and optimize building performance. |

| Challenges: hard to make a decision | Advantages: Improved decision-making, and optimization. | |

| Lifecycle Management | Description: Lack of sufficient information in all stages of the project on one software. | Description: BIM and Digital Twins support the entire lifecycle of a building, from design and construction to operation and decommissioning. |

| Challenges: Ensuring a seamless flow of information across different phases can be challenging due to diverse data sources and formats. | Advantages: Comprehensive lifecycle management, and historical data access. | |

| Cost Savings and Efficiency | Description: Managing costs efficiently throughout the lifecycle is challenging due to varying human manpower and documentation methods among stakeholders. | Description: The use of BIM and Digital Twins contributes to cost savings through improved operational efficiency, reduced downtime, and better-informed decision-making. |

| Challenges: limited ability to adapt to dynamic project conditions. | Advantages: Increased cost-effectiveness, and operational efficiency. | |

|

User Experience |

Description: it is always hard to give all stakeholders a complete vision for the project in all stages | Description: Digital Twins can enhance the overall user experience by personalizing building environments based on occupant preferences. |

| Challenges: big effort with less satisfaction | Advantages: Increased satisfaction, and improved productivity. |

| Title | Technical Requirements in EIR | Consequences if Not Applied |

Effect |

|---|---|---|---|

| Technical Documentation and Specifications | Prepare detailed technical documentation including specifications, installation guides, user manuals, and maintenance instructions. | Misunderstandings, incorrect installations, improper use of systems. | Increased errors, higher maintenance costs, extended project timelines, reduced overall project quality. |

| BIM Compliance and Standards | Ensure all deliverables comply with relevant BIM standards such as ISO 19650. Develop BIM models that meet the specified Level of Detail (LOD) and Level of Information (LOI). | Inconsistent and incompatible data, coordination issues. | Project delays, cost overruns, potential rework due to misaligned models and information. |

| Data Management and Exchange | Establish protocols for data management, including naming conventions, file formats (e.g., IFC, COBie), and data exchange procedures. Set up a Common Data Environment (CDE) for collaboration and data sharing. | Data loss, inconsistencies, difficulty in data retrieval. | Inefficient project execution, miscommunication among stakeholders, potential legal disputes over data discrepancies. |

| Quality Assurance and Control | Implement a quality assurance plan with procedures for verifying the accuracy and completeness of deliverables. Conduct model-checking and clash detection processes to ensure data integrity. | Defects and errors can go unnoticed until late stages of the project. | Increased rework, compromised project integrity, higher costs, diminished client satisfaction. |

| Security and Data Protection | Implement measures for data security, including encryption, access control, and secure data transfer methods. Ensure compliance with data protection regulations | Data breaches and unauthorized access to sensitive information. | Legal penalties, loss of client trust, financial losses, potential project termination. |

| Software and Tools | Confirm the availability and compatibility of all software tools and platforms to be used. Ensure team proficiency with the required software | Incompatible or outdated software can hinder collaboration and data exchange. | Reduced productivity, increased likelihood of errors, project delays. |

| Integration and Interoperability | Prepare for integration with existing systems and infrastructure. Ensure interoperability of software and hardware components through standardized interfaces and protocols. | Siloed systems and data fragmentation | Inefficient workflows, increased manual intervention, higher operational costs |

| Training and Competency | Conduct training programs for team members to ensure proficiency in required tools and methodologies. Prepare training materials and schedules for project stakeholders. | Improper use of tools and technologies, reducing overall project efficiency. | Increased error rates, lower productivity, potential safety hazards. |

| Project Planning and Scheduling | Develop a detailed project plan including timelines, milestones, and resource allocation. Use project management tools to track progress and manage tasks. | Unrealistic timelines, resource conflicts, missed deadlines. |

Project delays, cost overruns, diminished project quality and stakeholder satisfaction. |

| Communication and Collaboration | Set up communication channels and collaboration platforms for efficient coordination with stakeholders. Define roles and responsibilities and establish protocols for issue resolution and decision-making. | Misunderstandings and misalignment among project stakeholders. | Increased conflicts, duplicated efforts, inefficient project execution |

| Hardware and Infrastructure | Ensure the availability of necessary hardware such as workstations, servers, and networking equipment. Verify hardware performance requirements for software and tasks. | Performance bottlenecks and inability to run necessary software | Reduced efficiency, increased downtime, potential project delays. |

| Regulatory Compliance | Ensure all deliverables and processes comply with relevant industry standards, codes, and regulations. Obtain necessary certifications and approvals before starting the project. |

Legal issues and project halts. | Legal penalties, increased costs for modifications, damage to reputation. |

| Risk Management | Identify potential risks and develop mitigation plans. Continuously monitor and manage risks throughout the project lifecycle. | Unforeseen issues and crises during the project. | Project delays, cost overruns, potential project failure. |

| Support and Maintenance |

Establish a plan for ongoing technical support and maintenance services. Ensure availability of support staff and resources for issue resolution. | Unresolved technical issues and system downtimes. | Increased operational disruptions, higher maintenance costs, decreased system reliability |

| Environmental and Sustainability Considerations | Implement practices supporting environmental sustainability, such as waste reduction and energy efficiency. Prepare documentation to support environmental assessments and compliance with sustainability | Environmental damage and non-compliance with regulations. | Legal penalties, increased operational costs, negative impact on the company’s reputation and social responsibility goals |

| No | Challenge | Description |

|---|---|---|

| 1 | Old Buildings. | Many of the governmental buildings are established in old buildings that were used for another purpose, which means that there is no available full data like plans, equipment catalog and information for any asset.. |

| 2 | Data Integration | Inefficient project execution, miscommunication among stakeholders, potential legal disputes over data discrepancies. |

| 3 |

Data Integration. |

Governmental buildings often have various systems and equipment from different manufacturers and vendors. Integrating all data from different sources into one digital twin platform can be very hard and require standardized data formats and protocols |

| 4 | Accuracy and Quality of Data | The accuracy of the digital twin model depends on the quality of the data input. Inaccurate or outdated data can lead to build a wrong vision and decisions. Ensuring data accuracy and arranging documents is a challenge, especially when dealing with legacy systems |

| 5 | Initial Setup and Cost | Creating a comprehensive digital twin model requires significant huge investment in terms of technology, sensors, data collection infrastructure, and software development. Governmental budgets and procurement processes might pose challenges in acquiring the necessary resources |

| 6 | Technical Expertise | Developing and maintaining a digital twin platform requires expertise in fields such as IoT, data analytics, software development, and building systems. Government agencies might face challenges in recruiting or training staff with the required skills. |

| 7 | Data Privacy and Security | Government buildings often house sensitive information, and ensuring data privacy and security in the digital twin environment is crucial. Implementing robust cybersecurity measures to protect both the physical and virtual aspects of the building is challenging |

| 8 | Interoperability. | Digital twins may need to interact with other systems and databases within the governmental organization. Ensuring that the digital twin platform is compatible and can seamlessly integrate with existing systems can be challenging due to differing technologies and protocols. |

| 9 | Scalability | Governmental organizations often manage multiple buildings across various locations. Scaling a digital twin platform to cover a wide range of buildings while maintaining consistency and efficiency can be challenging. |

| 10 | Change Management. | Implementing a digital twin platform requires a shift in workflows and processes. Employees may resist change or require training to adapt to the new technology, which can pose challenges to adoption. |

| 11 | Regulatory Compliance | Government buildings must adhere to various regulations and standards. Integrating these compliance requirements into the digital twin model and ensuring ongoing compliance monitoring can be complex |

| 12 | Maintenance and Updates | Digital twin platforms require ongoing maintenance and updates to ensure they remain accurate and aligned with real-world changes. Ensuring regular updates without disrupting operations can be challenging |

| 13 | Vendor Lock-In | Depending on third-party vendors for digital twin solutions can lead to vendor lock-in, limiting flexibility and potentially increasing costs in the long run. |

| 14 | Return on Investment (ROI) Demonstrations | Establishing a clear ROI for digital twin implementations can be challenging, especially when the benefits may be realized over the long term or are difficult to quantify directly. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).