1. Introduction

Since the industrial revolution, society has been in a linear economy where the use of resources has been in danger because the energies used are conventional non-renewable energies such as fossil fuels. Natural resource depletion has been observed to be a serious issue, and currently natural resources are used at twice the rate used for production, and in the year 2050. It can be used at thrice the production rate [

1]. This growth in resource use is in sync with the growth of the world population which is estimated to touch 8 at some point in the future. Contributing to the estimated global population of 9.5 billion in 2030, the population increase consequently leads to the overexploitation of natural resources [

2]. Waste has become an international benchmark for the use and application of resources and clean low-impact energy, systems where the carbon and water footprint are minimal [

3]. But globally natural resource depletion together with the greenhouse gas emission rate has risen and is still rising. With this, it is believed that increasing attention to improving the circular economy could provide one of the most effective solutions for environmental harm reduction [

4]. The circular economy matches an economic and systemic model concerning the approach to production and consumption, resource management, maximizing resource use, and minimizing resource waste and the time environmental sustainability is advocated for. It is premised on the annulment of life cycles of products, materials, and resources with a view of reducing on the use of natural resources, recycling, and recovering products as well as different materials at the end of their useful life [

4].

In contrast to the prevalent conventional linear economy system, the circular economy is designed to be in a closed-loop system where resource value is circulating as long as possible. This comprises increasing the product life, supporting their easy repair and refurbishment, enabling reuse or exchange, and providing schemes for the recycling and recovery of the product's components for reprocessing and reintegration into the loop. The circular economy is not only a set of activities that take into account only the environment but also the economic and social advantages and gains [

5]

From the point of view of the economy, such approaches promote the completion of life cycles of products and materials thus catalyzing job creation, new technologies, optimization of cost, and fortification of economic stability. But the dependency on mining/yancing and other natural resources for production reduces hence; the bearing on the environment for production reduces as well and the bio-diversity is sustained. From the social perspective, the circular economy can contribute to social equity since it relies on business models that are more centralized on sharing within a community [

6]. It can also boost environmental literacy and thus ensure that communities become more responsible towards the environment. Therefore, in the year 2002, the concept of Cradle to Cradle was developed, abbreviated as C2C, where waste is utilized to create new products [

4]. Thus, the current system of generation and disposal of different materials has become unsustainable; one of the best examples relates to synthetic polymers, and although the world production of these materials has grown from 15 million tons in the sixties to 311 million tons in 2014, the expected increase in this value by the middle of the present century is threefold [

7]. Therefore, the world production of plastics apart from PET and PA fibers in 2019 was 51% in China, 19% in the United States, 16% in Europe, and 4% in Latin America [

4]. There are multiple advantages of sustainable polymers over regular petroleum-based plastics in terms of environmental impact. The first benefit is the ability of these cars to minimize emissions of carbon. This is because sustainable polymers use renewable feedstocks like plant-based materials or recycled plastics thus reducing the use of fossil fuels and hence reducing greenhouse gas emissions [

8].

In addition, these polymers use lesser amounts of resources as a whole such as fossil fuel, water, and energy in processing them. They also endorse recycling and biodegradability, that's is they do not favor landfill dumping so much. From the pollution point of view sustainable polymers are less hazardous to the environment as compared to conventional plastics. They employ environmentally less hazardous materials and uphold processes that follow the principles of a circular economy which help address problems such as microplastic pollution as well as the discharge of toxic substances to the environment [

9]. The benefits of sustainable polymers include the creation of employment, the establishment of new markets, cost efficiencies, and business promotion. The way sustainable polymers create new employment opportunities in areas like; renewable raw materials, polymer production, recycling, and disposal industries thus contributing to economic development and diversification [

10]. As consumers become conscious of sustainable products, there is a market for sustainable polymers and this becomes a novel market opportunity for businesses that put into practice these polymers [

11]. While the procurement costs of sustainable polymers are generally higher than those of conventional plastics, it is possible to cut expenses on energy consumption and waste disposal and extend the product's life cycle. Furthermore, the manufacturers who first adopt sustainable polymers for their products can gain a competitive edge and attract more customers since they're aware of a growing trend of sustainability. In general, the sustainable polymers concept does not hinder the environmental objectives but contributes to the multiple economic dimensions [

12].

1.1. Sustainable Polymers

Sustainable polymers are polymers that are derived from renewable, recyclable, or have a low carbon footprint in the feedstock or raw material further, these sustainable polymers are processed and used in an environmentally sound manner at the end of their life cycles (EoL) [

13]. Natural, modified, and synthetic polymers are employed in this approach to function throughout their scientifically-inspired life cycle while adhering to the concepts of circular economy [

14].

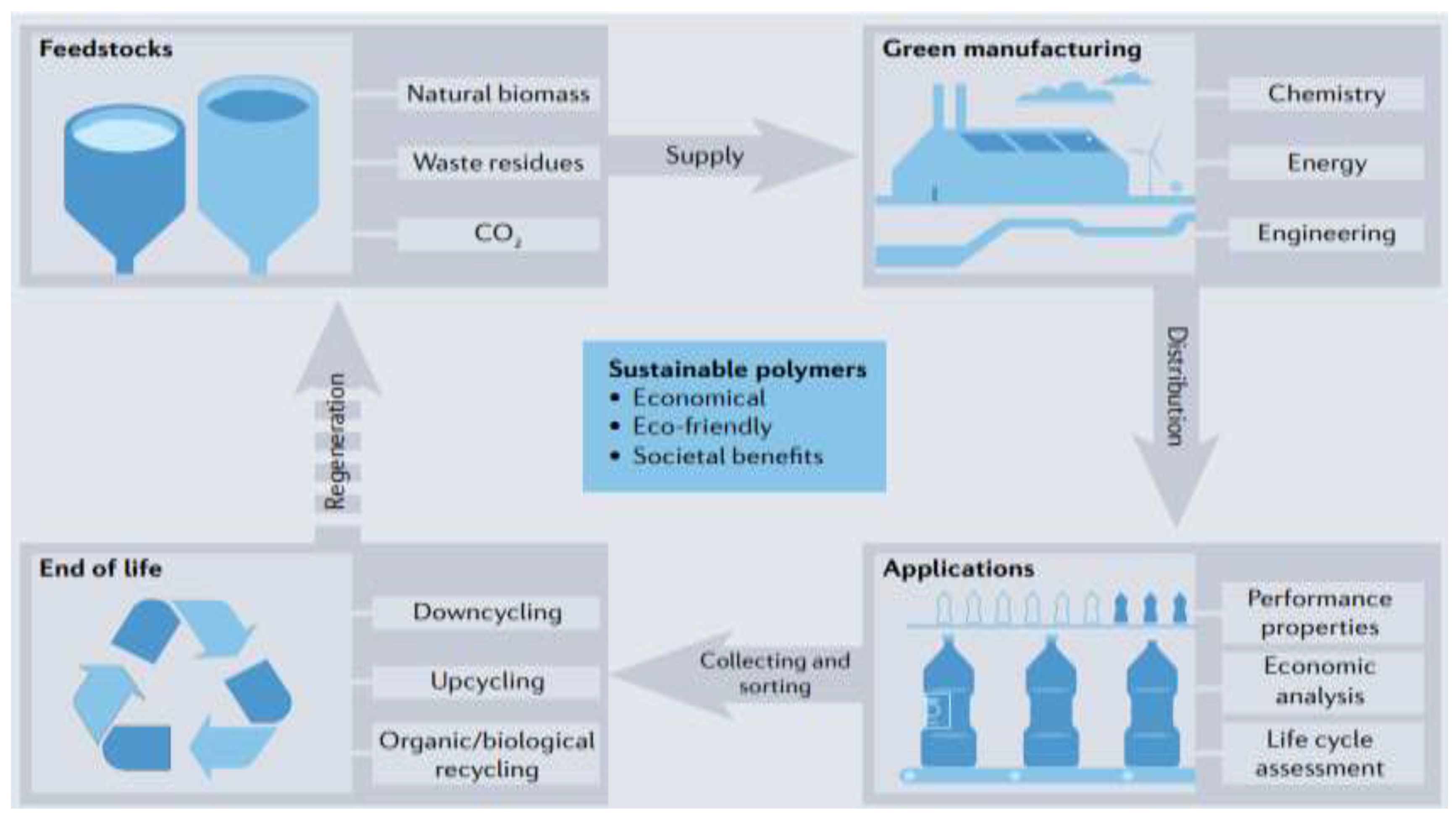

Figure 1 provides a graphical representation of sustainable polymer's life cycle from feedstock to regeneration. Emerging environmental problems, including the continued and increased presence of plastics on land and sea surfaces, have stimulated further development of new green polymers, as well as corresponding efforts to initiate global production processes of such materials, even though mankind had been employing such materials for extended periods [

14].

As for the key challenges of introducing sustainable polymers, these include supply chain sustainability and efficiency; achieving cost parity and polymer performance on a par with or better than conventional petrochemical polymers; and material design for reuse, reprocessing through mechanical recycling, and/or depolymerization recycling or biodegradation at end of life [

15]. Understanding sustainable polymers deals with the whole life cycle of the material, it involves a multidisciplinary research viewpoint, which includes the field of polymer science, engineering of the practical processing of polymers, biology, economics of cost and procurement, and ecology. Nature demonstrates key principles of biomimetic sustainable polymer science for enhancing the efficiency of chemistry and processes [

16]. By employing ordered structures and combinations of biological macromolecules for instance amino acids, saccharides, liposomes and ribonucleic acids’ complex life functions and composite materials can be developed. Such natural processes may be employed to learn from and then facilitate the design of sustainable polymers [

17]. There have been many review articles written on the topic of green polymers and their issues for development. These works have discussed the new feedstocks for polymeric products, their possible uses in the future, and the impact on people’s lives using waste carbon dioxide or different types of biomasses [

18]. Therefore, it is crucial to focus on the development of new environmentally friendly polymers that could potentially replace existing materials and that provide a wider range of EoL opportunities, including easier recyclability and biodegradation [

19]. From an elemental perspective, for polymers, a molecule needs to be chemically redesigned from the ground up to incorporate renewable feedstocks other than conventional fossil feedstocks in such a way that it can conserve energy and valuable resources in chain structures after use, the molecular structures of the polymers need to be disassembled and the properties of the polymers need to be regenerated after going through several recycling loops [

20]. It has been pointed out that one has been manufactured with characteristics similar to those of high-density polyethylene (HDPE) and it is capable of achieving all these. This makes the material derived from renewable plant-derived or microalgae-derived monomers and it can in turn be chemically depolymerized back to the monomers [

21]. This results in to need for the big platform of bio-based monomers to be handled by broad-based technologies starting with selective reactions, reversible processes, specific catalysts, and so on. This makes product and process sustainability analyses difficult hence making the price of the final product a critical success factor. To close the gap and align sustainability with market demands, pre-identifying useful polymers as well as specific monomers from which such polymers can be derived, assists in identifying areas that can benefit from limited research monies, minimizes risks as well as integrates the products to existing structures and equipment [

22]. The possibility of such an approach largely depends upon the research work being carried out for converting bio-based monomers into bio-based polymers and the final usability of such polymers for meeting technology requirements [

23]. The conversion of bio-based monomers to sustainable polymers is done by either chemical or microbial polymerizations. Several types of polymerizations including step-growth polymerization and chain-growth polymerization are the most common categories [

24].

1.2. Research Aim and Objectives

This research paper aims to provide a comprehensive analysis of the environmental and economic effects elicited by the use of sustainable polymers in managing carbon footprints and resource consumption. In this research, an effort is made to identify whether sustainable polymers can be useful in creation of a circular economy system and the role that they play in enabling the prevention of the degradation of the environment and at the same time promote economic growth.

Objectives are:

To evaluate the reduction in carbon emissions achieved by adopting sustainable polymers compared to conventional plastics.

To analyze the economic benefits of sustainable polymers, focusing on cost savings, job creation, and market opportunities.

To identify key challenges in scaling up sustainable polymers, such as cost competitiveness, supply chain efficiency, and material performance.

2. Material and Method

2.1. Research Design

This work employs the systematic review method in analyzing sustainable polymers' effects on carbon emission and resource consumption. The systematic review process is chosen because this approach enables a more structured and comprehensive analysis of the state of the current literature. It allows the selection of the studies that fit into some established criteria and also helps to systematically analyze the data to make valid conclusions [

25]. This research will aim to review previous literature on the topic with particular emphasis on literature that offers information on sustainable polymer technologies, the benefits of such technologies to the environment, and the profitability of the polymer technologies.

In order to sound the study methodologically, the Joanna Briggs Institute (JBI) approach to undertaking systematic reviews was considered for the current study [

26]. The presented approach makes the process of sourcing, selecting, and analyzing research studies a well-reproducible and accurate one. This specific systematic review also concerns compiling qualitative and quantitative evidence regarding the adoption and application of sustainable polymers for bringing efficient change in the circular economy and for lowering global warming potential and resource footprint.

2.2. Data sources and the Strategy

The literature search was made using relevant general and scientific databases and sources in order to collect substantial amount of information. These databases were Scopus, Web of Science, Google Scholar, ScienceDirect and PubMed databases [

27]. Both the databases were selected with respect to their scientific, economical and environmental importance of the study. Further, relevant articles and research papers available from government agencies and trade magazines were also consulted to get in-depth information about real-life application and difficulties of sustainable polymers [

27,

28].

Researcher used suitable keywords to search for the studies based on a given strategy. These keywords are the concept-oriented terms such as sustainable polymers, bio-degradable plastics, circular economy, bio-based monomers, carbon emission reduction, and resource efficiency; Boolean operators were employed in order to filter the articles and join the key terms, thus, only the articles that are most relevant and have immediate connection to the sustainable polymer technology and the environmental/economic effects of its implementation were selected [

29].

Specific criteria for inclusion of the studies were developed to increase the relevance and validity of the selected studies. Peer-reviewed publications were considered based on the year of publication with a specific focus on the review and advances and applications in sustainable polymers in the recent years from the period 2020 to 2024. In selecting the keywords, articles that presented only the environmental or the economic aspect on sustainable polymers were excluded; Instead, articles that made both the environmental and economic analysis were given preference in order of the following categories: Life Cycle Analysis (LCA), reduction on carbon footprint, recyclability and biodegradability of polymers. Also, articles had to have English translations and offer much information or insight. The excluded Articles were those that involved general plastics or non-polymeric materials, lacked quantification, and if the articles were not peer-reviewed.

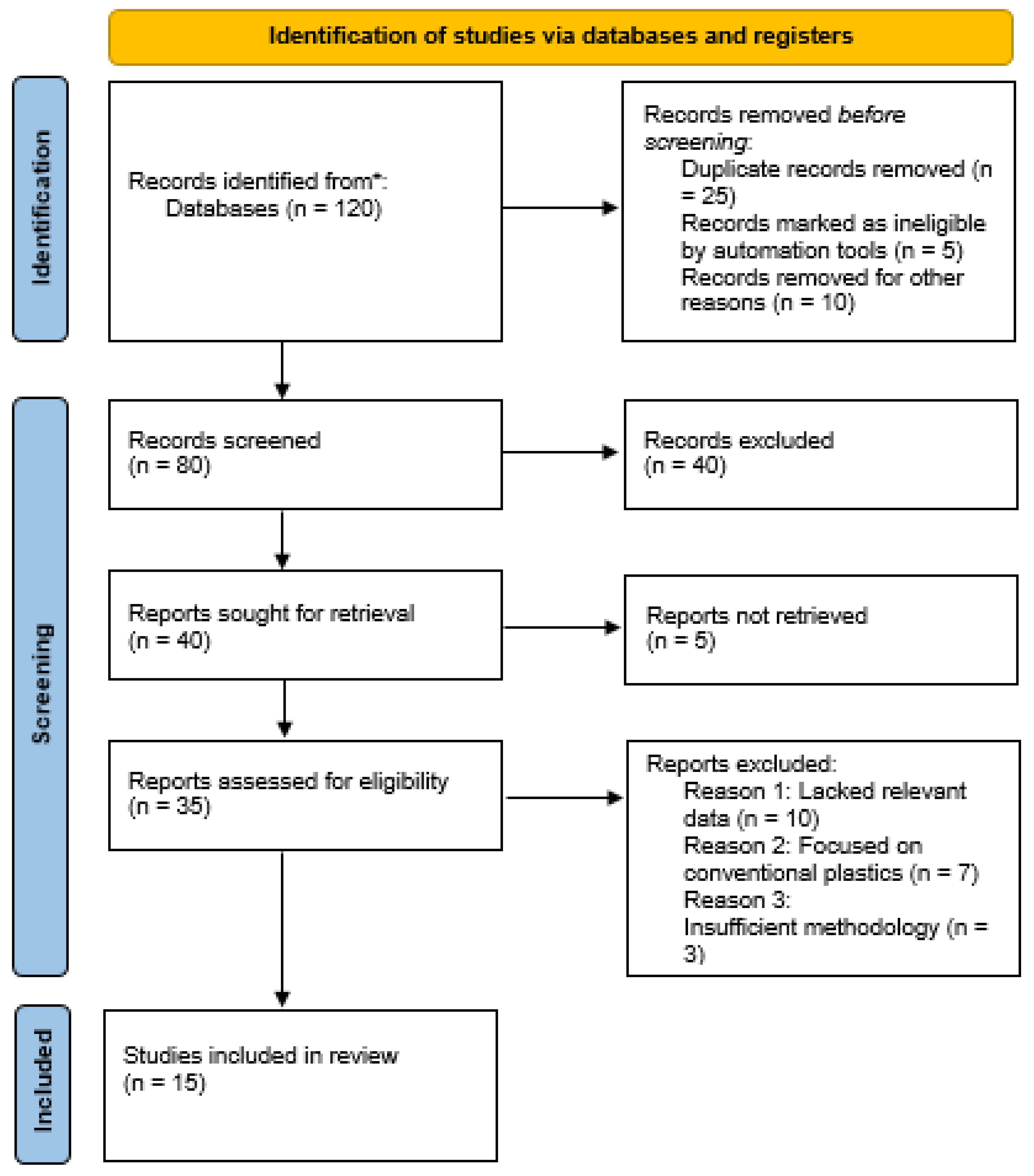

2.3. Study Selection Process

The steps employed in choosing research papers to be included in the synthesis included three broad sub-phases. The first stage was the titles and abstracts of the studies to look for directly related studies to the research goals. At this stage, the articles that were not somewhere related to sustainable polymers, circular economy, environment, or economy were removed. This step proved to be essential in filtering the outcome to only those studies that provided a vast emphasis on the utilization of sustainable polymers for environmental and economic improvement [

30].

The second step was scanning articles that passed the initial filtering for the presence of the full-text article in the databases. This stage was helpful in reviewing the studies towards the achievement of the inclusion criteria with much attention. At this stage, articles were screened based on methodological quality or soundness, the extent of their analysis, and their findings portrayment to address the identified research questions [

31]. The papers that did not state their methodological approach or offered little data were excluded at this point.

The last step of the systematic review was data extraction, whereby specific details from each of the selected papers were extracted [

32]. Other essential aspects gathered included the author of the article, the year in which the article was published, the type of study done, and the origin of the survey. In the data extraction process, more emphasis was given to the environmental consideration (as in carbon footprint and resource consumption) and economic value (cost savings and employment opportunities for the sustainable polymers. This way there is no question of bias creeping in while the two authors accomplished the data extraction process [

33].

Figure 2.

PRISMA Flow Chart.

Figure 2.

PRISMA Flow Chart.

2.4. Data Synthesis and Analysis

The process of synthesizing the data and comparing it with the results of the selected studies involved a thematic analysis. Thematic analysis was suggested since it enables the detection of common themes, patterns, and trends within the extant literature. This process was divided into two main areas of focus: impact evaluation into two categories that include the impact on the environment and the impact on the economy [

34].

From the environmental perspective, the assessment centered on the measurement of CO2 emissions saved through utilizing green polymers [

35]. As examined by the above-examined studies, the compared results highlighted the emissions of conventional petroleum-based plastics and sustainable plastics, including bio-based polymers and recycled plastics. This also focused on resource efficiency of sustainable polymers, particularly in the minimization of fossil fuel, water, and energy use during the manufacturing and use of the polymers. Particular emphasis was given to LCA, which assessed the impact of sustainable polymers right from the feedstock stages up to disposal or recycling.

The second topic of interest was the economic benefits of employing sustainable polymers. Indeed, the reviewed studies revealed many other economic gains, such as the development of new markets for bio-based materials and products, employment opportunities within renewable materials and recycling industries, cost savings from the decreased usage of energy and waste management. Some of them also touched on the benefits that accrue to companies that use sustainable polymers, such as larger market share due to consumers shifting towards green products [

36]. The assessment considered cost-effectiveness in the short-term and long-term, focusing more on the price range wherein sustainable polymers can effectively compete with traditional plastics.Data extraction was standardized and consistent across all identified studies to achieve high inter-observer reliability. The process involved reaching out for information such as study objectives, methodology, the findings of carbon emissions, resource consumption, and the economic effects of sustainable polymers. Some of the critical data points to be presented will be the LCA, the performance of the polymer material, the costs involved, and issues related to the supply chain. To improve the efficiency of the process, a data extraction form was used in all studies. Required fields included study type, type of polymer, environmental and economic consequences, and identified issues. This form also enforces the format for entering data in various studies and reduces the chances of omitting certain data. Regarding data management, reference management software like EndNote was used, and qualitative data management software, Excel, was used to code structure, sort, and categorize the extracted data in a thematic format.

2.5. Challenges and Limitations

Although the review established that sustainable polymers are feasible, the review also made several recommendations that need to be fulfilled for the large scale use of sustainable polymers. A key issue is to reduce the production cost down to the level of competing for generic petrochemical-based plastics [

37]. Recoverable polymers, especially those manufactured using bio-based feedstocks, can be relatively expensive since searching for renewable resources is not easy. In addition, efficient technologies are used to produce polymers. These costs can be costly, thus making it difficult for it to be adopted in industries that require large quantities of cheap plastic materials. The final and other enormous problem is the feasibility of the supply chain for sustainable polymers. The feedstock of bio-based materials must be renewable, and herein lies the problem, as factors such as climate change, inadequate agricultural production, and geopolitical instability might arise to hamper the availability of feedstock. Also, proper infrastructure to recycle or biodegrade sustainable polymers at the end of their life cycle still needs to be developed in most locations [

38]. To facilitate the recycling of sustainable polymers and their proper positioning in the circular economy, a lot of money has to be invested in overall recycling processes and equipment. Finally, the more sustainable polymers need to provide similar and better performance to make the conventional plastics popularise them. In many industries, including packaging, automobile, construction, and so on, specific attributes such as strength, endurance, or even resistance to some conditions are needed. Although remarkable progress has been achieved in enhancing sustainable polymers, there is still more ground to be covered to satisfy the needs of such industries. The method and material section describes the approach used in the systematic review to evaluate sustainable polymers' environmental and economic consequences. Utilizing a systematic and explicit research approach and thematic analysis offers a robust and well-founded approach to integrating the current literature on sustainable polymers [

39]. The discovered difficulties prove the need for further study and development to overcome the main obstacles within the polymer economy and the supply chain that can prevent sustainable polymers. Therefore, This review is useful for future research based on sustainable polymers and the chance they offer towards increased circularity of an economy [

40].

3. Results

Using sustainable polymers is gradually becoming a viable approach to addressing environmental concerns associated with conventional plastics. This chapter is devoted to evaluating sustainable polymers' environmental and economic potential, especially in reducing means of carbon emissions and material conservation. It also measures the efficiency gain from the product where the areas of cost advantages and employment generation potential are recognized vis-a-vis the difficulties involved in raising the scale of output. Sustainable polymers are biodegradable polymers, bio-based polymers, and recycled plastics. These materials include those obtained from renewable resources such as plants, wastes, or recycled plastics. They are used in packaging, automotive parts, medication applications, and textiles as reagents to the regular plastics market with principles such as reusability and low carbon footprints that congregate the circular economy.

Table 1.

Selected Studies and Their Relevance.

Table 1.

Selected Studies and Their Relevance.

| Author(s) |

Year |

Study Type |

Study Relevance |

| Objective: To evaluate the reduction in carbon emissions achieved by adopting sustainable polymers compared to conventional plastics |

|

|

|

| Mohanty et al., [41] |

2022 |

Review |

Assessed sustainable polymers' potential to reduce carbon emissions compared to conventional plastics, focusing on renewable resources. |

| Amulya et al., [42] |

2021 |

Experimental |

Explored the development of low-carbon biodegradable polymers and their contributions to reducing greenhouse gas emissions. |

| Hailemariam and Erdiaw-Kwasie MO [43] |

2023 |

Review |

Focused on circular economy strategies and the role of sustainable polymers in reducing emissions and improving environmental sustainability. |

| Pires da Mata Costa ; et al. [44] |

2021 |

Review |

Studied the capture and reuse of carbon dioxide for a circular plastics economy, contributing to lower carbon emissions. |

| Yang; et al. [45] |

2023 |

Review |

Analyzed circular economy strategies aimed at reducing environmental impacts, including carbon emission reductions via sustainable polymers. |

| Objective: To analyze the economic benefits of sustainable polymers, focusing on cost savings, job creation, and market opportunities |

|

|

|

| Sheldon and Norton [46] |

2020 |

Review |

Discussed the economic benefits of green chemistry in polymer production, including cost efficiencies, job creation, and market opportunities. |

| Das; et al. [47] |

2022 |

Review |

Examined the economic advantages of using natural and industrial waste for sustainable polymer composites, focusing on cost reductions and job creation. |

| Rosenboom et al., [48] |

2022 |

Review |

Explored economic opportunities associated with bioplastics, highlighting market expansion and cost savings in a circular economy. |

| Moshood; et al. [12] |

2022 |

Review |

Evaluated the economic potential of biodegradable plastics, focusing on market expansion, cost efficiencies, and their role in reducing plastic pollution. |

| Okogwu ; et al. [49] |

2023 |

Empirical |

Investigated the integration of sustainable materials in supply chain management, highlighting the economic benefits of sustainable polymers. |

| Objective: To identify key challenges in scaling up sustainable polymers, such as cost competitiveness, supply chain efficiency, and material performance |

|

|

|

| Shanmugam; et al. [50] |

2021 |

Review |

Addressed challenges in scaling biocomposites, focusing on cost competitiveness, supply chain sustainability, and material performance. |

| Carroccio; et al. [51] |

2022 |

Review |

Investigated the impact of nanoparticles on the sustainability of polymer nanocomposites, highlighting the challenges in production scalability and supply chain efficiency. |

| Di Bartolo et al., [52] |

2021 |

Review |

Discussed the adoption of bioplastics in the circular economy and the challenges associated with material performance and scaling. |

| Fagnani; et al. [53] |

2020 |

Viewpoint |

Examined the issues in scaling up sustainable polymers, particularly achieving cost parity and maintaining high material performance. |

| Farhana; et al. [54] |

2022 |

Review |

Focused on the challenges in adopting renewable energy in polymer production, addressing cost competitiveness and supply chain hurdles. |

The long-term use of sustainable polymers has been considered a potential approach to mitigating emissions and enhancing overall economic prosperity; however, there are several barriers to integrating sustainable polymers, including cost, efficiency of the supply chain, and material performance. Works such as Mohanty et al. (2022) and Amulya et al. (2021) argue that Polymers derived from renewable resources, for example, plant-based materials, will reduce greenhouse gas emissions compared to fossil-based plastics. Supporting these arguments, Hailemariam and Erdiaw-Kwasie (2023) comment on the prospects of sustainable polymers that invariably contribute to circular economy approaches that minimize the utilization of virgin fossil fuels and encourage recycling. It is compelling and unique that the work recommended by Pires da Mata Costa et al. (2021) was that carbon dioxide should be captured and utilized for polymer production to close the carbon cycle completely. Yang et al. (2023) argue for the potential for incorporating sustainable polymers in circular economy plans to contribute to decreasing environmental effects, such as in the case of packaging and manufacturing. From an economic point of view, commercially sustainable polymers have attractive advantages such as lower costs, new job opportunities, and market prospects. According to Sheldon and Norton (2020), the cost of sustainable polymers is slightly high at the beginning of procurement. Still, the cost of energy and disposal of wastes in the long run is relatively low. Also, Das et al. (2022) have established that these economic benefits are also realized since natural and industrial wastes, if used in the production of polymers, are cheaper than other raw products, and employment is created. Rosenboom et al. (2022) note that once consumers begin demanding greener products, those firms that venture into developing sustainable polymers stand to benefit from new market opportunities. Moshood et al. (2022) assess the cost advantage of Biodegradable Plastics by arguing that because they come at a higher cost than conventional plastics, their lasting Characteristics make them cheaper in the long run in terms of expenses towards waste disposal. From the channel perspective, Okogwu et al. (2023) demonstrate that sustainable polymers will no longer necessarily rely on fossil resources and that incorporating sustainable polymers can make the supply chain shorter in most cases. However, there are a few problems in utilizing large-scale sustainable polymers because of their high costs and poor performance. According to Shanmugam et al. (2021) and Fagnani et al. (2020), bio-based polymers are still more costly overall than traditional plastics, which is a crucial challenge, as discussed earlier.

Further, Carroccio et al. (2022) complete this list by pointing out that although polymer nanocomposites exhibit enhanced performance, they are expensive and problematic in manufacturing. Some factors that impact the ability to incorporate sustainable polymers include the performance of the material and factors such as durability and recyclability, which have also been highlighted by Di Bartolo et al. (2021). Farhana et al. (2022) state that high-energy consumption in producing Bio-based polymers makes the overall cost high, thus derogating their commercial prospect. However, the global utilization of sustainable polymers in decreasing carbon emissions and fueling economic prosperity is still promising; the next generation of technology and more policies to reach cost-competitive prices and improve the thermal and mechanical properties of polymers are required.

3.1. Control of Carbon Emission Through the Sustainable Polymers

An essential advantage of sustainable polymers is their lower carbon footprint than petroleum-based polymers, usually produced. The sustainability-focused research explored in the current review demonstrates how using sustainable polymers can help decrease the carbon impact of industries using plastics.

Available literature by Mohanty et al. (2022) gives an account of sustainable polymers and their effectiveness in reducing the emission intensity of greenhouse gases [

41]. This study stresses the need to embrace biomass, such as plant-derived sources, that help minimize the use of fossil fuels. Therefore, the synthesis of disposable polymers is considerably less emitting compared to the production of regular plastics. Mohanty et al. state that biopolymers specifically derived from renewable raw materials like corn and sugarcane yield lower carbon dioxide emissions throughout their lifecycle [

41].

Amulya et al. (2021) focused on synthesizing low-carbon biodegradable polymer matrices. Their study concentrated on the green benefits of biodegradable polymers due to their component in decreasing greenhouse gas emissions [

42]. It also revealed that these polymers, usually produced with low-energy processes, help lower total carbon emissions in industries where conventional plastics are substituted with biodegradable polymers [

42]. This goes alongside the idea that though such polymers are not the perfect solution to the plastic pollution crisis, green polymers are some of the best ways to cut down on the carbon footprint of the plastics industry [

42].

Pires da Mata Costa et al. (2021) considered the case of carbon capture and reuse in the production of polymers using carbon dioxide [

44]. Their research also pointed out how capturing carbon dioxide and then using it to produce sustainable plastics is likely to have a vast impact on eradicating emissions [

44]. The carbonization process is beneficial in minimizing carbon emissions into the atmosphere. Still, it also helps utilize waste carbon to produce valuable products with a closed-loop carbon cycle [

44].

In addition to arguing for the environmental advantages of sustainable polymers, Hailemariam and Erdiaw-Kwasie (2023) argued how such materials were best incorporated into circular economy paradigms [

43]. They established that green polymers contribute to lowering overall carbon footprints because they do not require virgin fossil fuels in their production and do not generate waste. Therefore, the study focused on the circular economy strategies that are considered instrumental in making sustainable polymers a realistic substitute for conventional plastics in various sectors [

43].

In the same way, Yang et al. (2023) reviewed circular economy initiatives that focused on mitigating environmental effects such as emissions [

45]. According to their study, circular practices, including recycling, reusing, and minimizing the use of plastics in industries, significantly decrease carbon emissions. Yang et al. revealed that sustainable polymers, when put into the circular economy, could help contribute a lot to climate goals, especially in industries that use plastics [

45].

3.2. Economical Advantages of Sustainable Polymers

Sustainable polymers present several economic benefits. These include cost-cutting, which has been seen to make a lot of sense financially, creating employment, and opening up new market prospects. Many studies reviewed here discuss the economic considerations to show that sustainable polymers spur development for business organizations or society.

Sheldon and Norton (2020) also highlighted cost savings as the benefit of using sustainable polymers. In their study, they noted that, even though procuring sustainable polymers may initially cost more than procuring conventional polymers, they entail lower energy consumption costs and minimal waste disposal expenses [

46]. The environmental liabilities are also smaller, as are the regulatory penalties, making sustainable polymers the best solution for companies looking to cut their costs [

46]. The authors also described methods of applying green chemistry for polymer production that would save energy and waste elimination costs [

46].

Das et al. (2022) discussed the utilization of natural and industrial waste towards developing renewable polymer composites [

47]. In their study, they also established that using waste materials in production not only aids in cutting the cost of acquiring raw materials but also generates employment for society through recycling and waste management companies. Polymer production is a perfect example of how waste can be recycled to help achieve environmental objectives while at the same time improving the advancement of the economy [

47]. Das et al. discovered that industries implementing these business models could obtain cost savings and access the emerging market for green products [

47].

Regarding the case of circular economy and bioplastics, Rosenboom et al. (2022) set their interest on the economic benefits [

48]. They insisted that in pursuing consumers’ awareness about environmental problems, the market for environmentally friendly products such as bioplastic is bound to grow [

48]. Therefore, early adopters of sustainable polymers can reach a more significant competitive advantage than their competitors simply because they have been more favorable to the environment [

48]. The paper also highlighted the effect of the change in trends towards green polymers in developing new market segments because consumers of different products prefer using environment-friendly products [

48].

Moshood et al. (2022) also investigated the costing analysis of biodegradable plastics, emphasizing their economic viability [

12]. Even though biodegradable plastics are costlier than regular plastics to some extent, the beneficial effects associated with their utilization, such as a reduction of the costs incurred during waste disposal and the expenses incurred in cleaning the environment, may outweigh some of these costs [

12]. Moshood et al. also pointed out the increase in demand for biodegradable plastics and their use in different sectors, which gives rise to new opportunities for companies [

12].

Okogwu et al. (2023) investigated the use of sustainable materials, including polymers, in supply chain management [

49]. According to their findings, integrating sustainable polymers will help cut supply chain lengths by decreasing dependence on fossil fuel-based feedstocks [

49]. Shifting the production line from a single country also minimizes supply chain risk through diversification of the materials sourced [

49]. Most supply chains tend to rely on renewable materials, which can help business entities reduce the risks related to price fluctuations and the availability of fossil fuels [

49].

3.3. Difficulties of Implementing Sustainable Polymers at Scale

There are several issues on how to effectively increase the use of sustainable polymers as disclosed below. Some of the leading issues affecting the market include cost control, supply chain management, and material characteristics.

The drawback that Shanmugam et al. (2021) discussed is the absence of cost-effectiveness, as SPs remain costlier to manufacture than traditional plastics [

50]. This is a significant concern, as proven by cost difference being a major factor hindering the manufacturing of these products from being widespread, especially in industries that incorporate cheap plastic material. Some of the suggestions that Shanmugam et al. put forward as ways to make more efficient and sustainable polymers include the development of new technologies to work towards cutting down on the cost of production [

50].

The study by Carroccio et al. (2022) established that although polymer nanocomposites outcompete conventional composites in regard to performance, their fabrication costs and logistical constraints hinder their large-scale use [

51]. Their studies revealed that the addition of sustainable polymers into current manufacturing systems demands heavy infrastructure, which a number of firms might be unwilling to incur [

51].

Di Bartolo et al. (2021) centered the impacts on material aspects, specifically durability and recyclability [

52]. They concluded that bioplastics and sustainable polymers lack performance, although better than conventional plastics [

52]. This makes them less ideal for applications like packaging and construction since strength and hardness are significant. Di Bartolo et al. also urged scientists to study the means to enhance the performance characteristics of sustainable polymers to make them more efficient than traditional plastics [

52].

Fagnani et al. (2020) well highlighted the concern of attaining cost-equalization with traditional plastics. In their study, the authors identified that while significant achievements have been made in sustainable polymer science, the costs remain prohibitive [

53]. Cost remains the most significant issue in sustainable polymers, and it may not immediately match the prices of the usual polymers used in industries unless there is a breakthrough in the polymerization processes and feedstock sourcing [

53].

Farhana et al. (2022), the authors also pointed out the difficulties concerning energy consumption in the sustainability of polymer production [

54]. Their work indicated that manufacturing bio-based polymers is energy-intensive, escalating the cost of the product. Farhana et al. argued that if the energy requirements of sustainable polymers’ production are to be cut down, then sustainable polymers will become more affordable [

54].

Table 2.

Key Findings.

| Author(s) |

Key Findings |

| Mohanty; et al. |

Sustainable polymers made from renewable feedstocks significantly reduce carbon emissions by minimizing fossil fuel use compared to conventional plastics. |

| Amulya; et al. |

Low-carbon biodegradable polymer matrices reduce greenhouse gas emissions due to low-energy production processes. |

| Pires da Mata Costa; et al. |

Carbon capture and reuse in sustainable polymer production reduces overall carbon emissions, creating a closed-loop system. |

| Hailemariam and Erdiaw-Kwasie MO |

Integrating sustainable polymers into a circular economy lowers carbon footprints by reducing reliance on virgin fossil fuels and minimizing waste generation. |

| Yang; et al. |

Circular economy strategies combined with sustainable polymers significantly reduce carbon emissions by promoting reuse and recycling. |

| Sheldon and Norton |

Sustainable polymers offer long-term cost savings by reducing energy consumption and waste disposal costs, while creating job opportunities in green industries. |

| Das; et al. |

Using natural and industrial waste as feedstocks reduces raw material costs and creates job opportunities in recycling and polymer production sectors. |

| Rosenboom et al., |

Bioplastics create new market opportunities and promote cost efficiencies within a circular economy framework. |

| Moshood; et al. |

Biodegradable plastics provide long-term savings through reduced waste management costs, despite higher initial procurement expenses. |

| Okogwu ; et al. |

Integrating sustainable polymers into supply chains reduces production costs and dependency on fossil fuels, offering economic benefits and new opportunities. |

| Shanmugam; et al. |

High production costs remain a significant barrier to the large-scale adoption of sustainable polymers, despite their environmental benefits. |

| Carroccio; et al. |

Challenges with integrating nanoparticles into polymer nanocomposites include high production costs and supply chain inefficiencies. |

| Di Bartolo; et al. |

Bioplastics face challenges in material performance, including durability and recyclability, which limit their suitability for industrial applications. |

| Fagnani; et al. |

Achieving cost parity with conventional plastics is difficult, slowing the adoption of sustainable polymers despite advances in polymer science. |

| Farhana; et al. |

Bio-based polymer production requires high energy inputs, increasing costs and reducing competitiveness with traditional plastics. |

4. Discussion

The results of the current study support the argument that sustainable polymers offer environmental and economic value including; Carbon capture, cost efficiencies as well as job opportunities. Nevertheless, the challenge is to scale up the process in terms of cost and performance. This section reviews these findings with respect to prior research and the working hypotheses to address their implications for practice and to outline avenues for future research.

The first conclusion that can be made from this review is that green polymers play a significant role in globally reducing carbon emissions than non-green plastics. By utilising renewable feedstocks from plants rather than the traditional, and by now, almost synonymous with carbon emission, use of fossil based feedstocks [

42,

45,

49]. This is in line with other studies which have indicated that biopolymers extracted from renewable resources were environmentally beneficiary. On this hypothesis suggesting the effect of sustainable polymers on decreasing carbon emissions, the data available in multiple sources support the hypothesis by stating repeatedly the use of renewable feedstocks in the production of polymers eventually reduces the greenhouse emissions [

50].

One of the methods embraced in this review that brings in a new dimension is the release and recapture of carbon dioxide in the creation of polymers for the green economy. It is a closed-loop method that can work in parallel for minimizing carbon emissions and at the same time using eco-friendly material. This discovery is relevant to prior literature in carbon capture and utilization technologies, which are widely used in the energy industry, but this is a relatively novel approach to extending their use to polymer synthesis [

55]. It is also worth mentioning that the integration of carbon capture in this context is presented as a promising direction for the further investigation in more details, including matters connected with its scalability and cost-effectiveness.

However, there are some issues when speaking about penetration of sustainable polymers on the base of circular economy [

56]. The global recycling initiatives, and managing the options for avoiding the virgin fossil fuels, reuse and recycle options are critical for reducing the carbon footprint. Although these strategies are gradually emerging in different industries, they presuppose significant changes to the orientations of production activities. These changes will not happen overnight, and established industries which have been using standard carbon-based plastics will find it quite challenging to adapt to circular system being based on sustainable polymers.

As it is highlighted, sustainable polymers bring the economic advantages where cost savings as well as development of new markets is an issue. Some of the conclusions establishing the monetary value of sustainable polymers include higher initial cost of production, lesser energy utilization in production, comparatively lower expenses on waste management, and regulation compliance, among others [

53,

57]. This supports the working hypothesis that the possession of sustainable polymers is also economically advantageous as it leads to the avoidance of such drawbacks as environmental penalties and fines, which are being enforced on industries that use renewable polymers.

Creating new jobs is another economic advantage of tourism that may be realized in the future. Using sustainable polymers leads to growth in sectors that include renewable, recycled, and polymer markets. This is in line with other studies conducted on the overall effect of the renewable energy sector, where employment generation is one of the primary forces behind this industry. This means that with the frequent use of sustainable polymers in the market, there will be a high demand for skilled workers in these fields that will, in turn, help the economy's development.

Sustainable polymers also spawn new market prospects, especially as buyers remain increasingly sensitive to environmental factors. Companies that use sustainable polymers can benefit from the market trend of increased consumer preference towards environmentally friendly products. This competitive advantage has already been noted in sectors like the packaging industry, where the firms that produce biodegradable or renewable plastic products are encroaching on the market share of their traditional counterparts. However, to achieve these market opportunities, challenges involving cost stations with conventional plastics create more problems that hinder their comprehensive implementation.

The properties of polymers have shown that both the sustainability of polymers and the cost associated with them are beneficial in terms of economic value. Nevertheless, polymers also present several challenges in terms of large-scale production [

52,

58,

59]. The costs of producing these polymers are relatively high, especially made from renewable resources, thus limiting their use. This has echoed previous studies where researchers have deemed it paramount to enhance technology to lower the cost of manufacturing bio-based plastics. This aspect forms a key goal for the industrialization of sustainable polymers so that more industries could adopt them since the profit margins are very narrow.

One of the significant challenges that arise with the use of e-commerce systems is performance-related problems. Polymers that are eco-friendly have been developed and are used to, but the actual problem is that these polymers lack the durability and recyclability of the common plastic. This is especially so in industries where material performance is critical, such as packaging, construction and automobile manufacturing. To nearly meet the specifications of traditional plastics and, more importantly, compete with them in the sectors above, there is still a need for more research on sustainable polymers, especially in mechanical properties, durability, and recyclability.

However, using new materials, including polymer nanocomposites, opens up fresh opportunities and risks for the industry [

60]. In general, nanocomposites provide better performance characteristics than conventional composites; however, it is challenging to mass produce them due to high cost and other related supply chain issues. This also shows that incorporating sustainable polymers into the existing supply chains is problematic since these chains are usually developed for the conventional plastics. Dealing with such current issues of supply chain will be crucial in achieving an increase in production and application of sustainable polymers.

Another challenge is the inability to reach cost equivalence with conventional plastics often presented as the main advantage of this type of material [

61]. Despite the enhancements of polymer science in the recent past, the synthesis of bio-based rats is comparatively expensive because of the relatively expensive raw materials, which are renewable and the high energy cost involved. From tangible evidence on the existing research work on sustainable polymers, it is rather challenging to foresee how sustainable polymers will be preferred over more traditional polymers based on plastics for several years. This underlines the need to further undertake more investigations on this area to enhance the usage of sustainable polymers as a viable option in the world. The publication of this review has revealed several significant research directions for the forthcoming investigations. First, correct implementation of carbon capture technologies within polymer production processes combined with further utilization of carbon dioxide for polymers synthesis can be recognized as a potential area that has a beneficial effect on both, minimizing the emission of carbon dioxide to the atmosphere and saving the material costs [

62]. The research in the field should continue and the emphasis should be made on developing these technologies further and analyzing how economically feasible they are in the long-run. This could include training chemists to come up with new ways of trapping co2 during the manufacturing process then incorporating these methods in the industrial polymer production.

Second, there is a distinct research opportunity namely focusing on enhancement of various parameters of sustainable polymers. Although improvements have been made, there is still considerable progress ‘to be made in the various areas in Bioplastic including improve the life span, recycling capability and other properties of the Bio-plastics material [

63]. This may entail searching for new ways of polymerization, employing superior materials such as nanoparticles or coming up with composite materials from the bioplastics and conventional plastics.

Finally, further studies have to build on extending existing research on cost and revenue considerations and other economic effects of adopting sustainable polymers. This requires more research to establish the ratios of the long-term economic gains in different industries and geographical areas so as to establish realistic evidence backing the expansion of sustainable polymers in industries.

5. Conclusions

The findings of this study reveal the importance of shifting to sustainable polymers from an environmental and economic standpoint. Due to lower carbon emissions and the development of a new economy, polymers provide innovation compared to regular plastics. However, problems of cost-effective competition, the performance of the materials used, and supply chain shortcomings have slowed mass adoption. However, further research is needed to enhance production cost and performance to bring the best out of sustainable polymers. Necessary measures should also be taken to shift to more sustainable plastic production: firstly, solutions based on the circular economy should be integrated; secondly, carbon capture technologies need to be further developed. In applying circular economy solutions and carbon capture technologies, the adoption of sustainable polymers need to act now. Short-term goals should consist in increasing recycling potential and using captured CO2 for polymer synthesis which is already successfully implemented by players like Covestro. Short-term strategies must look at increasing polymer performance through investigations on bio-sourced material while showing improvement in energy in the synthesis process. It is critical to bring down costs for industrial change that will suit industries to have competitive methods of mass production. In the future, the development of nanocomposites along with changes in feedstock choice might enhance the significance of sustainable polymers and correlate them with the ongoing modernization of the polymer market and consumers’ search for eco-friendly materials.

References

- Di Vaio, A.; Hasan, S.; Palladino, R.; Hassan, R. The transition towards circular economy and waste within accounting and accountability models: a systematic literature review and conceptual framework. Environment, Development and Sustainability 2022, 25. [Google Scholar] [CrossRef] [PubMed]

- Mies, A.; Gold, S. Mapping the social dimension of the circular economy. Journal of Cleaner Production 2021, 321, 128960. [Google Scholar] [CrossRef]

- Akhimien, N.G.; Latif, E.; Hou, S.S. Application of Circular Economy Principles in Buildings: A Systematic Review. Journal of Building Engineering 2020, 38, 102041. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2352710220336731?via%3Dihub. [CrossRef]

- Aranda, F.L.; Zúñiga, M.; Rivas, B.L.; Aranda, F.L.; Zúñiga, M.; Rivas, B.L. Polymers in Circular Economy: A Comprehensive Approach to Sustainability. An overview. Journal of the Chilean Chemical Society 2023, 68, 5950–5962. Available online: https://www.scielo.cl/scielo.php?script=sci_arttext&pid=S0717-97072023000305950&lng=es&nrm=iso#:~:text=In%20the%20traditional%20linear%20economy. [CrossRef]

- Roberta Braga, T.; Lucia, A.; Clara, M.; Vazquez-Brust, D.; Monteiro, M. How is the circular economy embracing social inclusion? 2023, 411, 137340. [Google Scholar]

- Luthin, A.; Traverso, M.; Crawford, R.H. Circular life cycle sustainability assessment: An integrated framework. Journal of industrial ecology. 2023, 28, 41–58. [Google Scholar] [CrossRef]

- Li, T.; Theodosopoulos, G.; Lovell, C.; Loukodimou, A.; Maniam, K.K.; Paul, S. Progress in Solvent-Based Recycling of Polymers from Multilayer Packaging. Polymers. 2024, 16, 1670–0. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Ogunseitan, O.A.; Wong, M.H.; Tang, Y. Sustainable materials alternative to petrochemical plastics pollution: A review analysis. Sustainable Horizons 2022, 2, 100016. [Google Scholar] [CrossRef]

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7. Available online: https://www.sciencedirect.com/science/article/pii/S2405844021020211. [CrossRef] [PubMed]

- Amarakoon, M.; Alenezi, H.; Homer-Vanniasinkam, S.; Edirisinghe, M. Environmental Impact of Polymer Fiber Manufacture. Macromolecular Materials and Engineering. 2022, 307, 2200356. [Google Scholar] [CrossRef]

- .Camilleri, M.A.; Cricelli, L.; Mauriello, R.; Strazzullo, S. Consumer Perceptions of Sustainable Products: A Systematic Literature Review. Sustainability 2023, 15, 8923, https://www.mdpi.com/2071-1050/15/11/8923. [Google Scholar] [CrossRef]

- . Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Current Research in Green and Sustainable Chemistry 2022, 5, 100273, https://www.sciencedirect.com/science/article/pii/S2666086522000157. [Google Scholar] [CrossRef]

- Schneiderman, D.K.; Hillmyer, M.A. 50th Anniversary Perspective: There Is a Great Future in Sustainable Polymers. Macromolecules. 2017, 50, 3733–3749. [Google Scholar] [CrossRef]

- Satchanska, G.; Slavena Davidova Petrov, P.D. Natural and Synthetic Polymers for Biomedical and Environmental Applications. Polymers 2024, 16, 1159–9, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC11055061/. [Google Scholar] [CrossRef] [PubMed]

- Beena Unni, A.; Muringayil Joseph, T. Enhancing Polymer Sustainability: Eco-Conscious Strategies. Polymers 2024, 16, 1769, https://www.mdpi.com/2073-4360/16/13/1769. [Google Scholar] [CrossRef]

- De Sousa, F.D.B. The role of plastic concerning the sustainable development goals: The literature point of view. Cleaner and Responsible Consumption. 2021, 3, 100020. [Google Scholar] [CrossRef]

- Bealer, E.J.; Onissema-Karimu, S.; Rivera-Galletti, A.; Francis, M.; Wilkowski, J.; Salas-de la Cruz, D.; et al. Protein–Polysaccharide Composite Materials: Fabrication and Applications. Polymers. 2020, 12, 464. [Google Scholar] [CrossRef]

- Velásquez-Hernández, M. de. J.; Linares-Moreau, M.; Astria, E.; Carraro, F.; Alyami, M.Z.; Khashab, N.M.; et al. Towards applications of bioentities@MOFs in biomedicine. Coordination Chemistry Reviews 2021, 429, 213651. Available online: https://www.sciencedirect.com/science/article/pii/S0010854520306469. [CrossRef]

- Jung, H.; Shin, G.; Kwak, H.; Hao, L.T.; Jegal, J.; Kim, H.J.; et al. Review of polymer technologies for improving the recycling and upcycling efficiency of plastic waste. Chemosphere. 2023, 320, 138089. [Google Scholar] [CrossRef]

- Sadeghi, K.; Jeon, Y.; Seo, J. Roadmap to the sustainable synthesis of polymers: From the perspective of CO2 upcycling. Progress in Materials Science. 2023, 135, 101103. [Google Scholar] [CrossRef]

- KIT. KIT - Meier Group - Institute of Organic Chemistry - Research - Sustainable Polymer Synthesis [Internet]. Kit.edu. Author; 2024 [cited 2024 Sep 2]. Available from: https://www.ioc.kit.edu/meier/182.php.

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and New Opportunities on Barrier Performance of Biodegradable Polymers for Sustainable Packaging. Progress in Polymer Science 2021, 117, 101395. Available online: https://www.sciencedirect.com/science/article/pii/S0079670021000423. [CrossRef]

- Picken, C.A.; Buensoz, O.; Price, P.D.; Fidge, C.; Points, L.; Shaver, M.P. Sustainable formulation polymers for home, beauty and personal care: challenges and opportunities. Chemical Science 2023, 14, 12926–12940. Available online: https://pubs.rsc.org/en/content/articlehtml/2023/sc/d3sc04488b. [CrossRef] [PubMed]

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable polymers from biomass: Bridging chemistry with materials and processing. Progress in Polymer Science 2020, 101, 101197. Available online: https://www.sciencedirect.com/science/article/pii/S0079670019302035. [CrossRef]

- Goodes, L.M.; Wong, E.V.; Alex, J.; Mofflin, L.; Toshniwal, P.; Brunner, M.; Solomons, T.; White, E.; Choudhury, O.; Seewoo, B.J.; Mulders, Y.R. A scoping review protocol on in vivo human plastic exposure and health impacts. Systematic Reviews. 2022, 11, 137, https://link.springer.com/content/pdf/10.1186/s13643-022-02010-6.pdf. [Google Scholar] [CrossRef]

- Neuvonen, R.; Huovinen, M.; Dorman, D.C.; Laitinen, H.; Sahlman, H. Phthalates and Polycystic Ovary Syndrome–Systematic Literature Review. Reproductive Toxicology 2023, 108473. Available online: https://www.sciencedirect.com/science/article/pii/S0890623823001478.

- O’Callaghan, L.; Olsen, M.; Tajouri, L.; Beaver, D.; Hudson, C.; Alghafri, R.; McKirdy, S.; Goldsworthy, A. Plastic induced urinary tract disease and dysfunction: a scoping review. Journal of Exposure Science & Environmental Epidemiology 2024, 1–5. Available online: https://www.nature.com/articles/s41370-024-00709-3.pdf.

- Mashallahi, A.; Ardalan, A.; Nejati, A.; Ostadtaghizadeh, A. Climate adaptive hospital: A systematic review of determinants and actions. Journal of Environmental Health Science and Engineering. 2022, 20, 983–1013, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9672300/. [Google Scholar] [CrossRef]

- Mlelwa, R.; Rother, H.A. Reviewing the current state of legacy POP-brominated flame retardants in plastic childcare products and toys: a scoping review protocol. Systematic Reviews. 2024, 13, 148, https://link.springer.com/content/pdf/10.1186/s13643-024-02524-1.pdf. [Google Scholar] [CrossRef]

- Wagner, T.; Ulrich, D. Increasing multidrug resistance in leech borne infections. Should we adjust antibiotic treatment regime in plastic surgery? A systematic review. European Journal of Plastic Surgery. 2024, 47, 16, https://link.springer.com/content/pdf/10.1007/s00238-023-02158-x.pdf. [Google Scholar] [CrossRef]

- Marin T, Pollock D, Aromataris E, Mulders Y, Dunlop S. UMBRELLA REVIEW: IMPACT OF PLASTIC-ASSOCIATED CHEMICAL EXPOSURE ON HUMAN HEALTH. https://cdn.minderoo.org/assets/new/documents/PHH-Umbrella-Review-Full-Report.pdf.

- Munn, Z.; Tufanaru, C.; Aromataris, E. JBI's systematic reviews: data extraction and synthesis. AJN The American Journal of Nursing. 2014, 114, 49–54, https://www.academia.edu/download/39809816/JBIs_Systematic_Reviews_Data_Extraction20151108-2886-16c8fs2.pdf. [Google Scholar] [CrossRef] [PubMed]

- Porritt, K.; Gomersall, J.; Lockwood, C. JBI's systematic reviews: study selection and critical appraisal. AJN The American Journal of Nursing. 2014, 114, 47–52, https://www.researchgate.net/profile/Kylie-Porritt/publication/295601491_Study_Selection_and_Critical_Appraisal/links/6357c6ef8d4484154a330526/Study-Selection-and-Critical-Appraisal.pdf. [Google Scholar] [CrossRef] [PubMed]

- Moola, S.; Munn, Z.; Sears, K.; Sfetcu, R.; Currie, M.; Lisy, K.; Tufanaru, C.; Qureshi, R.; Mattis, P.; Mu, P. Conducting systematic reviews of association (etiology): The Joanna Briggs Institute's approach. JBI Evidence Implementation. 2015, 13, 163–169, https://www.academia.edu/download/104775770/xeb.000000000000006420230805-1-oxqjw4.pdf. [Google Scholar] [CrossRef] [PubMed]

- Aromataris, E.; Fernandez, R.S.; Godfrey, C.; Holly, C.; Khalil, H.; Tungpunkom, P. Methodology for JBI umbrella reviews. https://ro.uow.edu.au/cgi/viewcontent.cgi?article=4367&context=smhpapers.

- Peters, M.D.; Godfrey, C.M.; Khalil, H.; McInerney, P.; Parker, D.; Soares, C.B. Guidance for conducting systematic scoping reviews. JBI Evidence Implementation. 2015, 13, 141–146, https://repositorio.usp.br/directbitstream/ce9c462e-396d-4e59-b6ee-6e807b67fcbc/SOARES%2C+C+B+doc+151.pdf. [Google Scholar] [CrossRef]

- Pearson, A.; Wiechula, R.; Lockwood, C. The JBI model of evidence-based healthcare. JBI Evidence Implementation. 2005, 3, 207–215, http://www.sgna.org/Portals/0/Education/DOC/JBICSR1213-0001-%20Reading01.pdf. [Google Scholar]

- Stern, C.; Lizarondo, L.; Carrier, J.; Godfrey, C.; Rieger, K.; Salmond, S.; Apostolo, J.; Kirkpatrick, P.; Loveday, H. Methodological guidance for the conduct of mixed methods systematic reviews. JBI evidence implementation. 2021, 19, 120–129, https://rgurepository.worktribe.com/preview/841862/STERN%202020%20Methodological%20guidance.pdf. [Google Scholar] [CrossRef]

- Robertson-Malt, S. JBI's systematic reviews: Presenting and interpreting findings. AJN The American Journal of Nursing. 2014, 114, 49–54, https://alliedhealth.ceconnection.com/files/PresentingandInterpretingFindings-1430416752788.pdf. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.; Bennett, M.; Godfrey, C.; McInerney, P.; Munn, Z.; Peters, M. Evaluation of the JBI scoping reviews methodology by current users. JBI Evidence Implementation. 2020, 18, 95–100, https://www.researchgate.net/profile/Hanan-Khalil/publication/335974715_Evaluation_of_the_JBI_scoping_reviews_methodology_by_current_users/links/61de545f4e4aff4a6435fbd6/Evaluation-of-the-JBI-scoping-reviews-methodology-by-currentusers.pdf. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Wu, F.; Mincheva, R.; Hakkarainen, M.; Raquez, J.M.; Mielewski, D.F.; Narayan, R.; Netravali, A.N.; Misra, M. Sustainable polymers. Nature Reviews Methods Primers. 2022, 2, 46, https://www.nature.com/articles/s41529-022-00262-0.pdf. [Google Scholar] [CrossRef]

- Amulya, K.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Low carbon biodegradable polymer matrices for sustainable future. Composites Part C: open access 2021, 4, 100111. Available online: https://www.sciencedirect.com/science/article/pii/S2666682021000062. [CrossRef]

- Hailemariam, A.; Erdiaw-Kwasie, M.O. Towards a circular economy: Implications for emission reduction and environmental sustainability. Business Strategy and the Environment. 2023, 32, 1951–1965, https://onlinelibrary.wiley.com/doi/pdf/10.1002/bse.3229. [Google Scholar] [CrossRef]

- Pires da Mata Costa, L.; Micheline Vaz de Miranda, D.; Couto de Oliveira, A.C.; Falcon, L.; Stella Silva Pimenta, M.; Guilherme Bessa, I.; Juarez Wouters, S.; Andrade, M.H.; Pinto, J.C. Capture and reuse of carbon dioxide (CO2) for a plastics circular economy: A review. Processes. 2021, 9, 759, https://www.mdpi.com/2227-9717/9/5/759/pdf. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.S. Circular economy strategies for combating climate change and other environmental issues. Environmental Chemistry Letters. 2023, 21, 55–80, https://link.springer.com/content/pdf/10.1007/s10311-022-01499-6.pdf. [Google Scholar] [CrossRef]

- Sheldon, R.A.; Norton, M. Green chemistry and the plastic pollution challenge: towards a circular economy. Green Chemistry. 2020, 22, 6310–6322, https://pure.tudelft.nl/ws/portalfiles/portal/84976681/GC_d0gc02630a_edit_report.pdf. [Google Scholar] [CrossRef]

- Das, O.; Babu, K.; Shanmugam, V.; Sykam, K.; Tebyetekerwa, M.; Neisiany, R.E.; Försth, M.; Sas, G.; Gonzalez-Libreros, J.; Capezza, A.J.; Hedenqvist, M.S. Natural and industrial wastes for sustainable and renewable polymer composites. Renewable and Sustainable Energy Reviews 2022, 158, 112054. Available online: https://www.sciencedirect.com/science/article/pii/S1364032121013162. [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nature Reviews Materials 2022, 7, 117–137. Available online: https://www.nature.com/articles/s41578-021-00407-8.pdf. [CrossRef] [PubMed]

- Okogwu, C.; Agho, M.O.; Adeyinka, M.A.; Odulaja, B.A.; Eyo-Udo, N.L.; Daraojimba, C.; Banso, A.A. Exploring the integration of sustainable materials in supply chain management for environmental impact. Engineering Science & Technology Journal. 2023, 4, 49–65, https://www.fepbl.com/index.php/estj/article/view/546/700. [Google Scholar]

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, Á.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; George, G. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Composites Part C: Open Access 2021, 5, 100138. Available online: https://www.sciencedirect.com/science/article/pii/S2666682021000335. [CrossRef]

- Carroccio, S.C.; Scarfato, P.; Bruno, E.; Aprea, P.; Dintcheva, N.T.; Filippone, G. Impact of nanoparticles on the environmental sustainability of polymer nanocomposites based on bioplastics or recycled plastics–A review of life-cycle assessment studies. Journal of Cleaner Production 2022, 335, 130322. Available online: https://www.sciencedirect.com/science/article/pii/S0959652621044863. [CrossRef]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. Polymers. 2021, 13, 1229, https://www.mdpi.com/2073-4360/13/8/1229/pdf. [Google Scholar] [CrossRef]

- Fagnani, D.E.; Tami, J.L.; Copley, G.; Clemons, M.N.; Getzler, Y.D.; McNeil, A.J. 100th anniversary of macromolecular science viewpoint: redefining sustainable polymers. ACS macro letters. 2020, 10, 41–53, https://pubs.acs.org/doi/pdf/10.1021/acsmacrolett.0c00789. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Mahamude, A.S.; Mica, M.T. Energy consumption, environmental impact, and implementation of renewable energy resources in global textile industries: an overview towards circularity and sustainability. Materials Circular Economy. 2022, 4, 15, https://www.researchgate.net/profile/Mushfika-Mica/publication/359574045_Energy_consumption_environmental_impact_and_implementation_of_renewable_energy_resources_in_global_textile_industries_an_overview_towards_circularity_and_sustainability/links/63f90e22b1704f343f7ca17f/Energy-consumption-environmental-impact-andimplementation-of-renewable-energy-resources-in-global-textile-industries-an-overview-towardscircularity-and-sustainability.pdf. [Google Scholar] [CrossRef]

- Zeng, X.; Zhang, Y.; Kwong, J.S.; Zhang, C.; Li, S.; Sun, F.; Niu, Y.; Du, L. The methodological quality assessment tools for preclinical and clinical studies, systematic review and meta-analysis, and clinical practice guideline: a systematic review. Journal of evidence-based medicine. 2015, 8, 2–10, https://www.researchgate.net/profile/Xian-Tao-Zeng/publication/270907782_The_methodological_quality_assessment_tools_for_preclinical_and_clinical_studies_systematic_review_and_metaanalysis_and_clinical_practice_guideline_A_systematic_review/links/5e2ff3dc4585152d156f7ae0/Themethodological-quality-assessment-tools-for-preclinical-and-clinical-studies-systematic-review-andmeta-analysis-and-clinical-practice-guideline-A-systematic-review.pdf. [Google Scholar] [CrossRef] [PubMed]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Sivakumar, N.; Lukk, T.; Pecoraro, L.; Thakur, V.K.; Roberts, D.; Newbold, J.; Gupta, V.K. Bioprocessing of waste biomass for sustainable product development and minimizing environmental impact. Bioresource Technology 2021, 322, 124548. Available online: https://www.academia.edu/download/66208204/Bioresource_Technology_2021.pdf. [CrossRef] [PubMed]

- Yang, M.; Chen, L.; Msigwa, G.; Tang, K.H.; Yap, P.S. Implications of COVID-19 on global environmental pollution and carbon emissions with strategies for sustainability in the COVID-19 era. Science of the Total Environment 2022, 809, 151657. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8592643/. [CrossRef] [PubMed]

- Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resources, Conservation and Recycling 2018, 133, 63–75. Available online: https://hal.science/hal-01977839/file/VoDong_21106.pdf. [CrossRef]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. Journal of Thermoplastic Composite Materials 2024, 08927057241254324. Available online: https://journals.sagepub.com/doi/pdf/10.1177/08927057241254324. [CrossRef]

- Fitzgerald, A.; Proud, W.; Kandemir, A.; Murphy, R.J.; Jesson, D.A.; Trask, R.S.; Hamerton, I.; Longana, M.L. A life cycle engineering perspective on biocomposites as a solution for a sustainable recovery. Sustainability. 2021, 13, 1160, https://www.mdpi.com/2071-1050/13/3/1160/pdf. [Google Scholar] [CrossRef]

- Worrell, E.; Allwood, J.; Gutowski, T. The role of material efficiency in environmental stewardship. Annual Review of Environment and Resources. 2016, 41, 575–598, http://web.mit.edu/ebm/www/Publications/Worrell-et-al-ARER-2016%20copy.pdf. [Google Scholar] [CrossRef]

- Lee, C.T.; Hashim, H.; Ho, C.S.; Van Fan, Y.; Klemeš, J.J. Sustaining the low-carbon emission development in Asia and beyond: Sustainable energy, water, transportation and low-carbon emission technology. Journal of cleaner production 2017, 146, 1–3. Available online: https://www.sciencedirect.com/science/article/am/pii/S0959652616320066. [CrossRef]

- Sharma, R. New Developments in Green Chemistry Renewable Polymer Sustainable Synthesis. http://www.ijcms2015.co/file/2020/vol-5-issue-2/aijra-vol-5-issue-2-30.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).