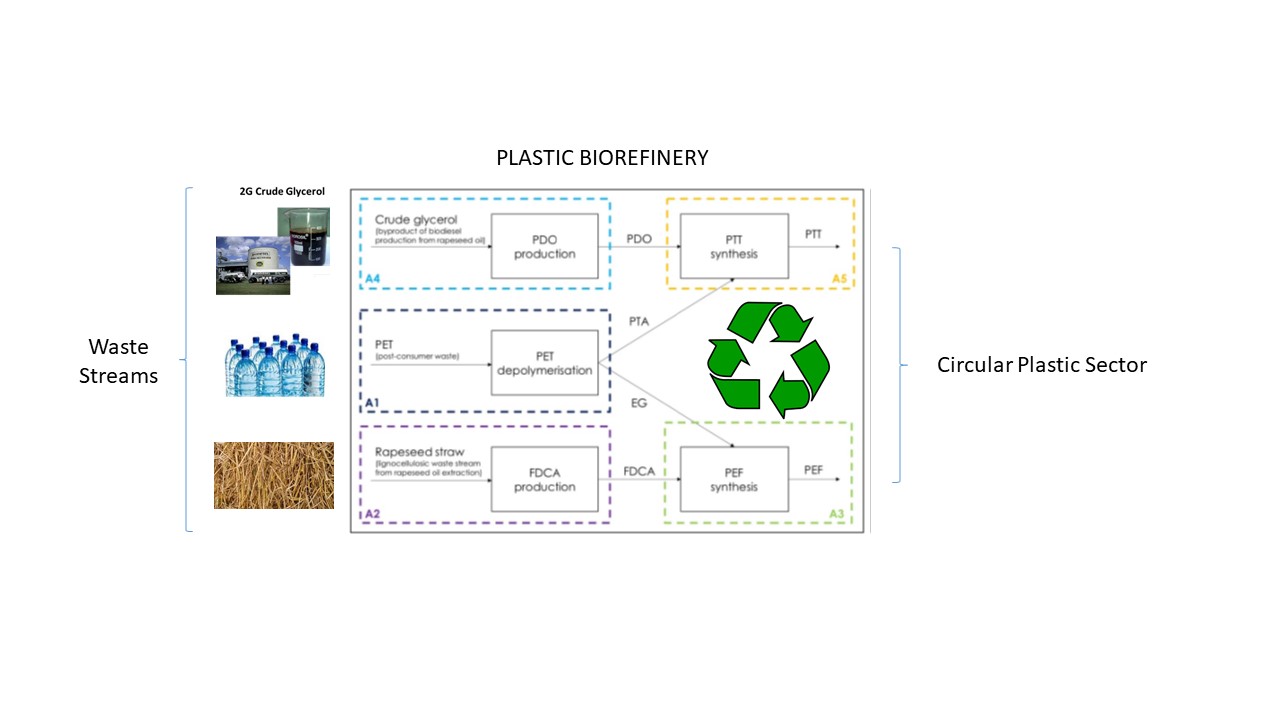

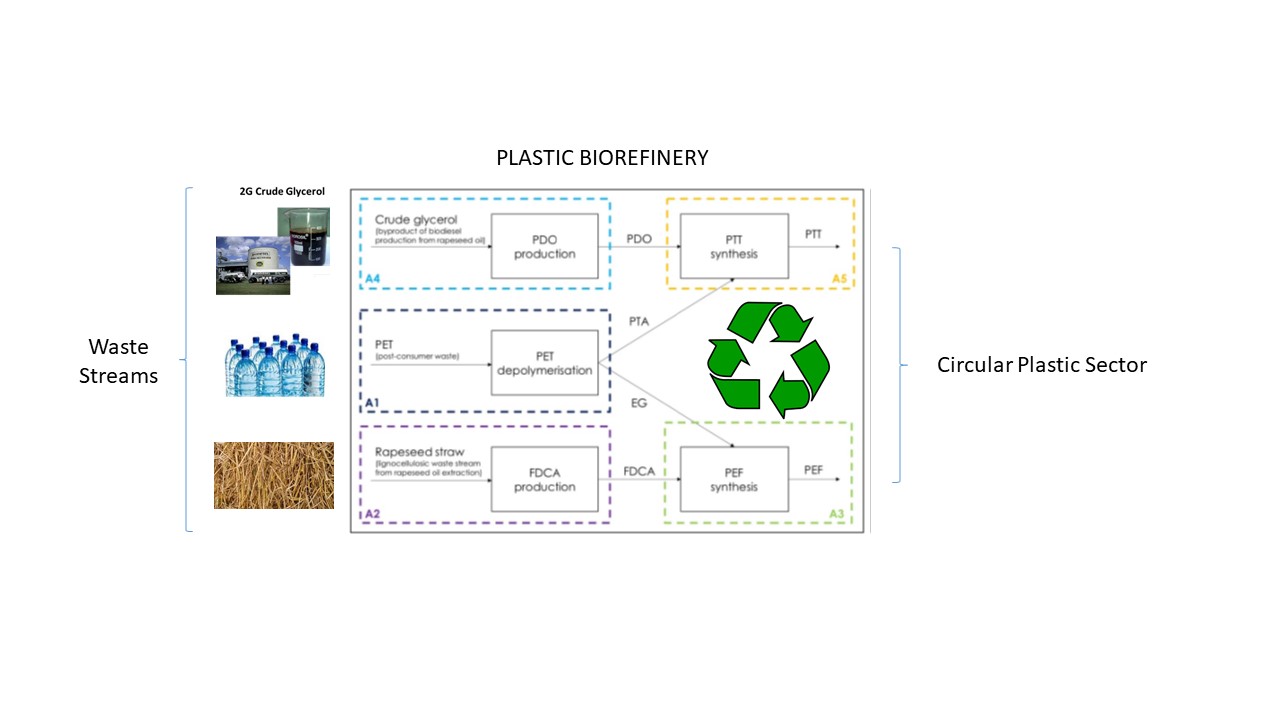

It is widely accepted that plastic waste is one of our most urgent environmental concerns the world is currently facing. Plastic has contributed greatly to innovation in all fields, but the raw material for its production (fossil fuels), as well as the linear economy in which it is currently produced and used, makes the material problematic from a sustainability and human health perspectives. The emergence of bio-based plastics provides an opportunity to reduce dependency on fossil fuels and transition to a more circular plastics economy. For polyethylene terephthalate (PET), one of the most prevalent plastics in packaging and textiles, there exist two bio-based alternatives that are similar or superior in material property and recyclability. These are polyethylene furanoate (PEF) and polytrimethylene terephthalate (PTT). The overarching aim of this study was to examine the transition from fossil-based to renewable plastics, through the lens of PET upcycling into PEF and PTT. The process for the production of PEF and PTT from three feed streams (post-consumer PET waste, lignocellulosic biomass-derived cellulose and biodiesel-derived crude glycerol) was developed in the software SuperPro Designer and the economic viability assessed via a discounted cumulative cash flow (DCCF) analysis. This study represents a conceptual case study of the valorisation of existing plastic waste into new, recyclable bio-based plastics, for a more sustainable plastics production. A techno-economic analysis of the designed process revealed that the minimum selling price (MSP) of second generation-derived PEF and PTT is 3.13 USD/kg, and that utilities and the feedstock used for the production of 2,5-furandicarboxylic acid (FDCA) needed in PEF synthesis contributed the most to the process operating costs. The effect of recycling PEF and PTT through the process at three recycling rates (42%, 50% and 55%) was investigated and revealed that increased recycling could reduce the MSP of the 2G bio-plastics (by 48.5%) to 1.61 USD/kg. This demonstrates that increasing recycling rates would have a beneficial effect on the economic viability of the plastic biorefinery.