Submitted:

20 September 2024

Posted:

20 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Banana Pseudo-Stem

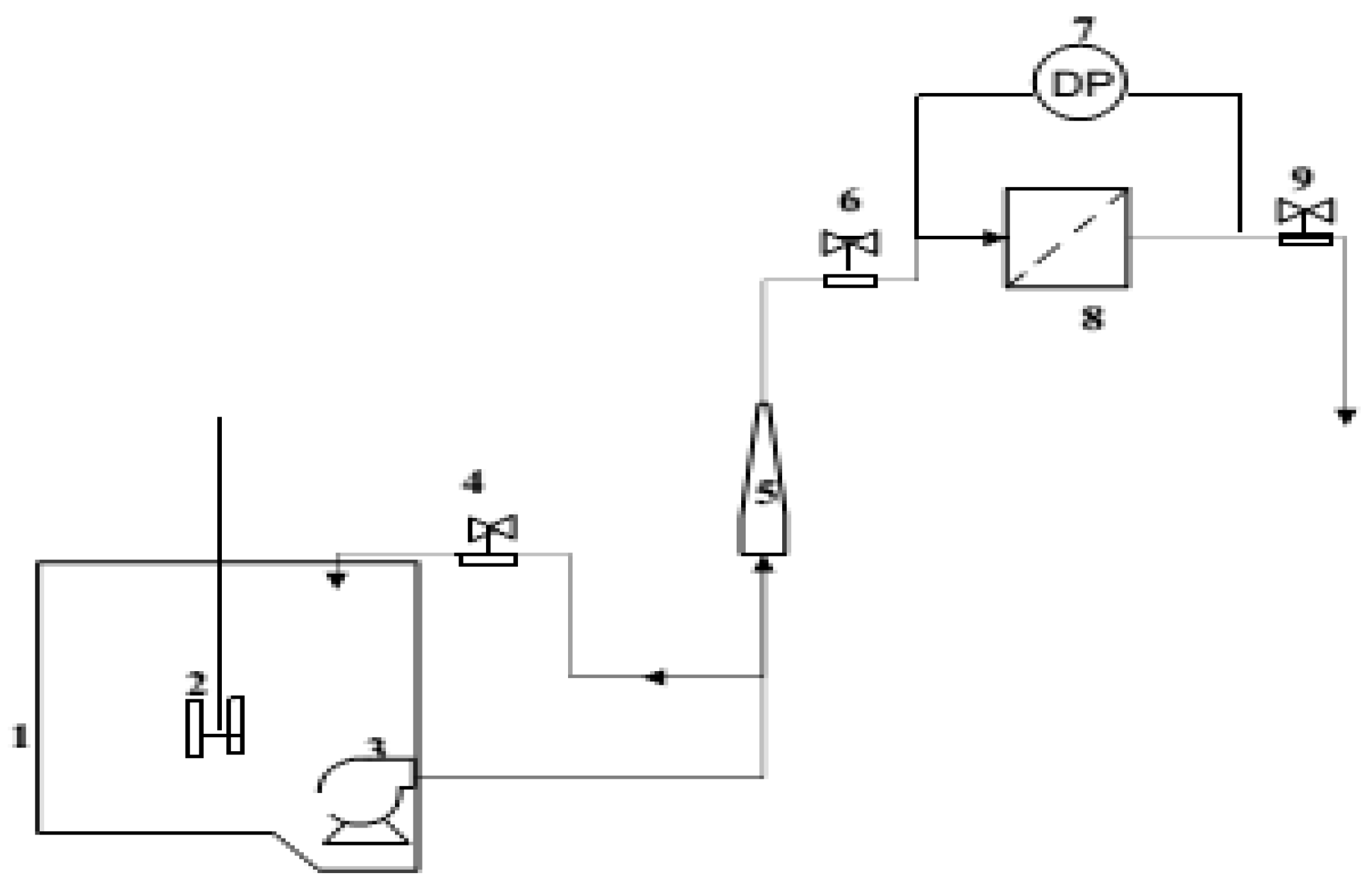

2.2. Filtration Pilot

2.3. Preparation of the Concentration Suspension

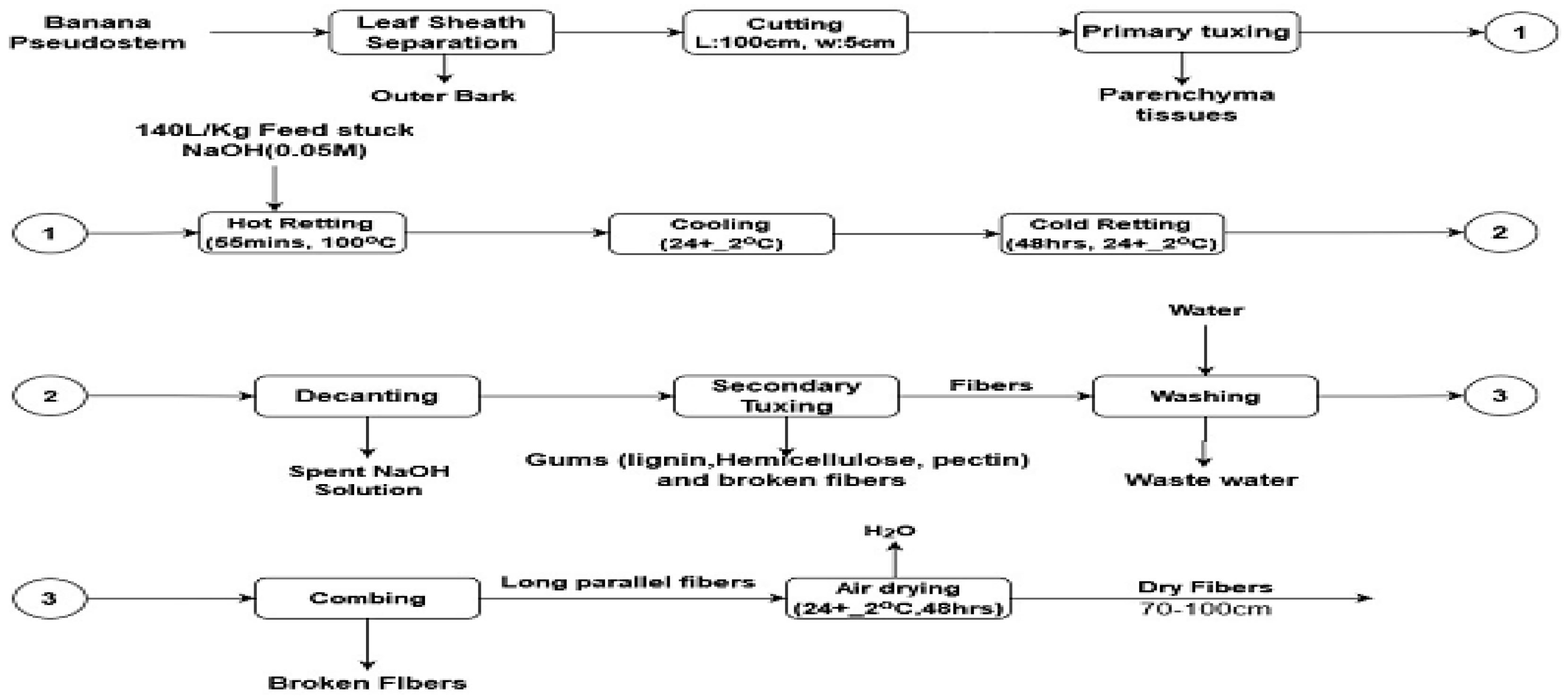

2.4. Extraction of Banana Fibers

2.5. Characterisation (Density, Cellulose Content and Breaking Strength) of Untreated and Treated Fibers

2.6. Banana Fiber Yarn Production and Characterisation

2.6.1. Fineness

2.6.2. Porosity

2.7. Manufacture and Characterisation of the Membrane

2.7.1. Surface Density of the Membrane

2.7.2. Membrane Porosity

2.7.3. Experimental Determination of Membrane Permeability and Resistance

2.8. Conducting Pilot Tests

2.9. Particle Size Distribution of Sludge (Cut-off Threshold)

2.10. Clogging Power Evaluation Parameter

3. Results and Discussion

3.1. Fibers Characteristics

| Characteristics | Valors |  |

| Extraction yield (%) | 5,90 | |

| Water content (%) | 17.76 | |

| Fiber length (cm) | 85.45 | |

| Swelling (%) | 81,51 |

3.2. Wire Characteristics

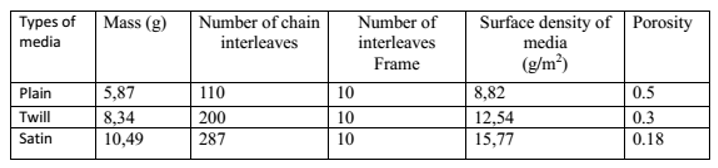

3.3. Characteristics of the Filter Media

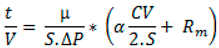

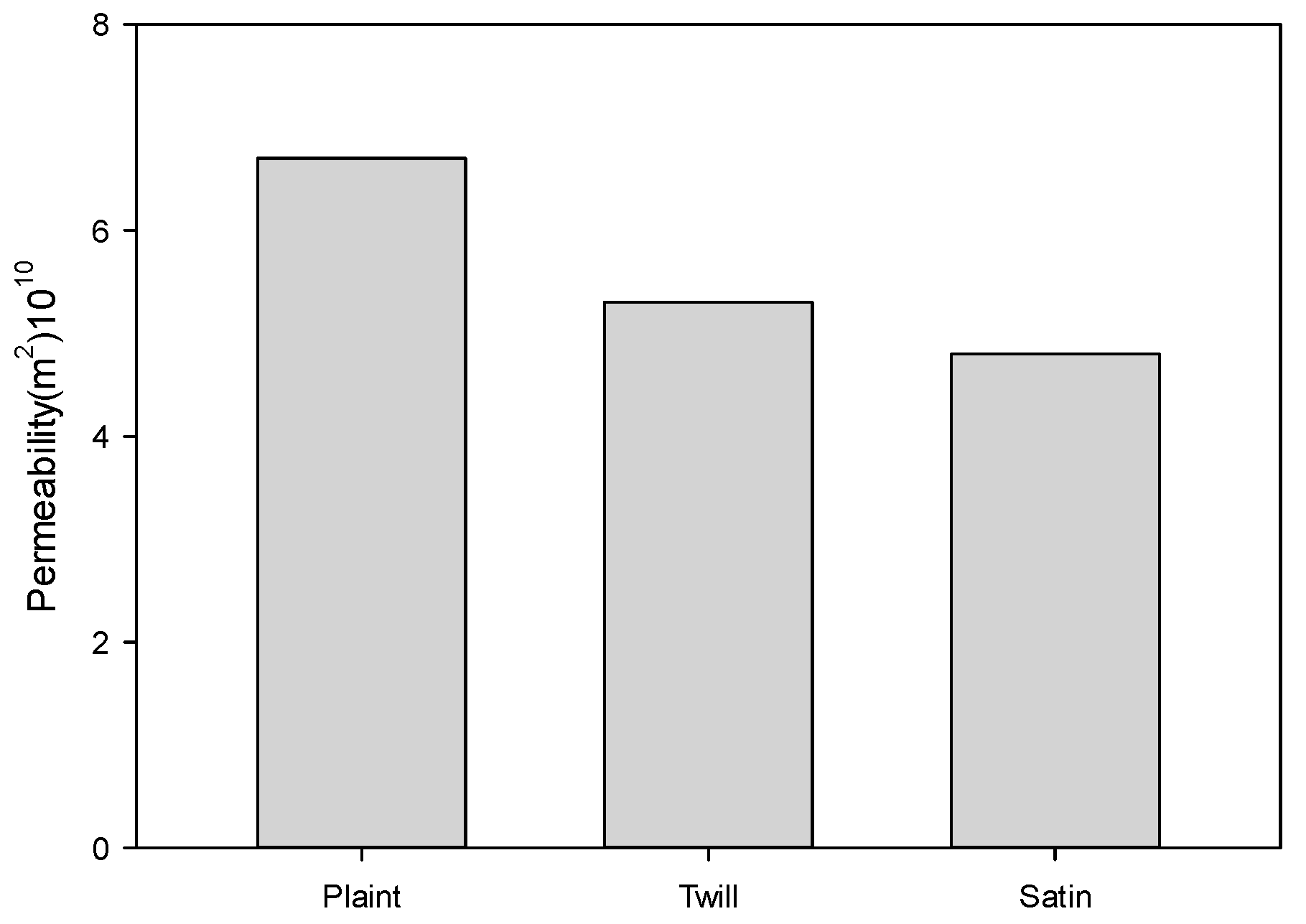

3.4. Membrane Permeability and Resistance

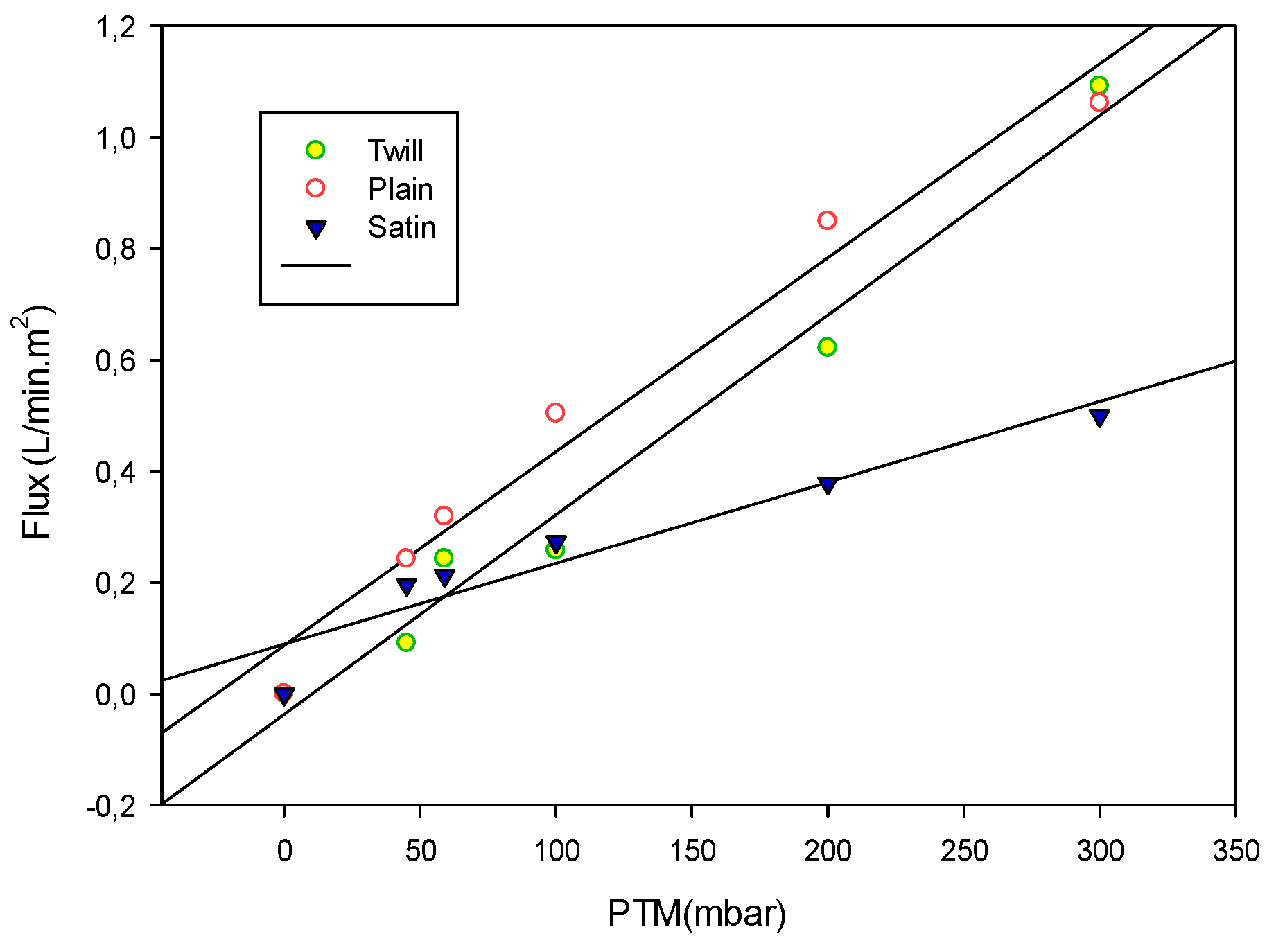

3.5. Evaluation of the Flow Generated as a Function of the Pressure Drop

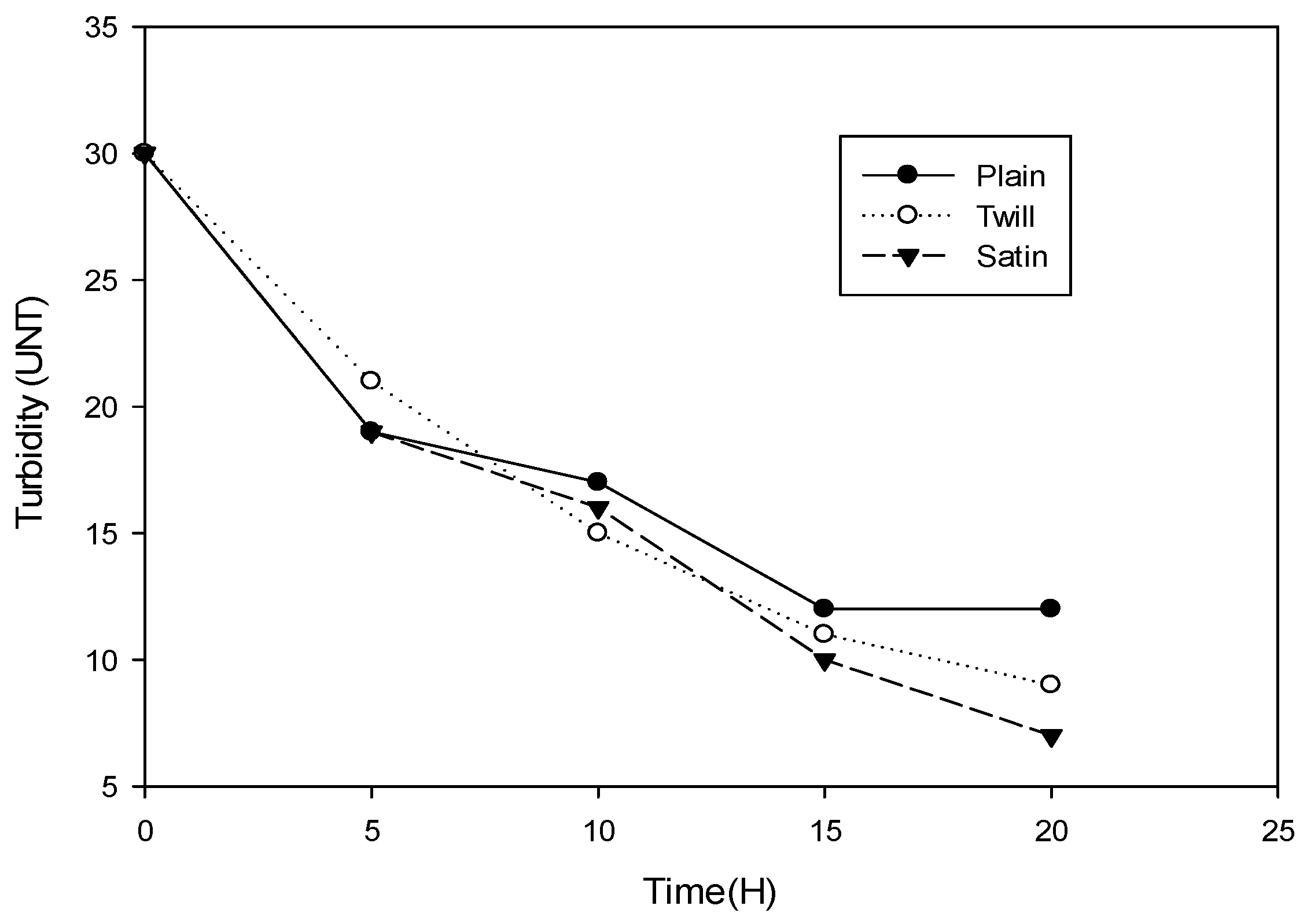

3.6. Effect of Weaving Method on Turbidity

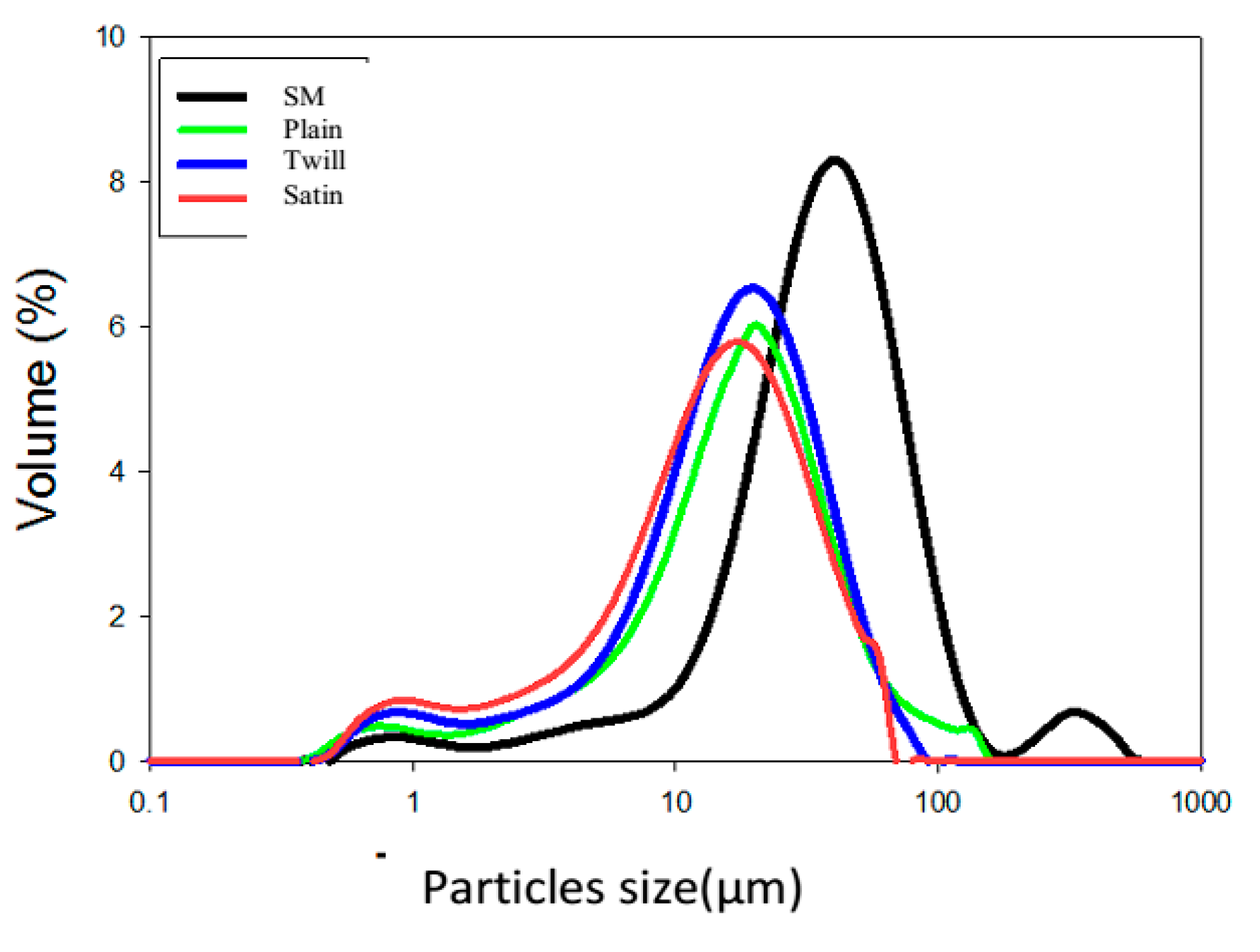

3.7. Cut-off Threshold for Different Membranes

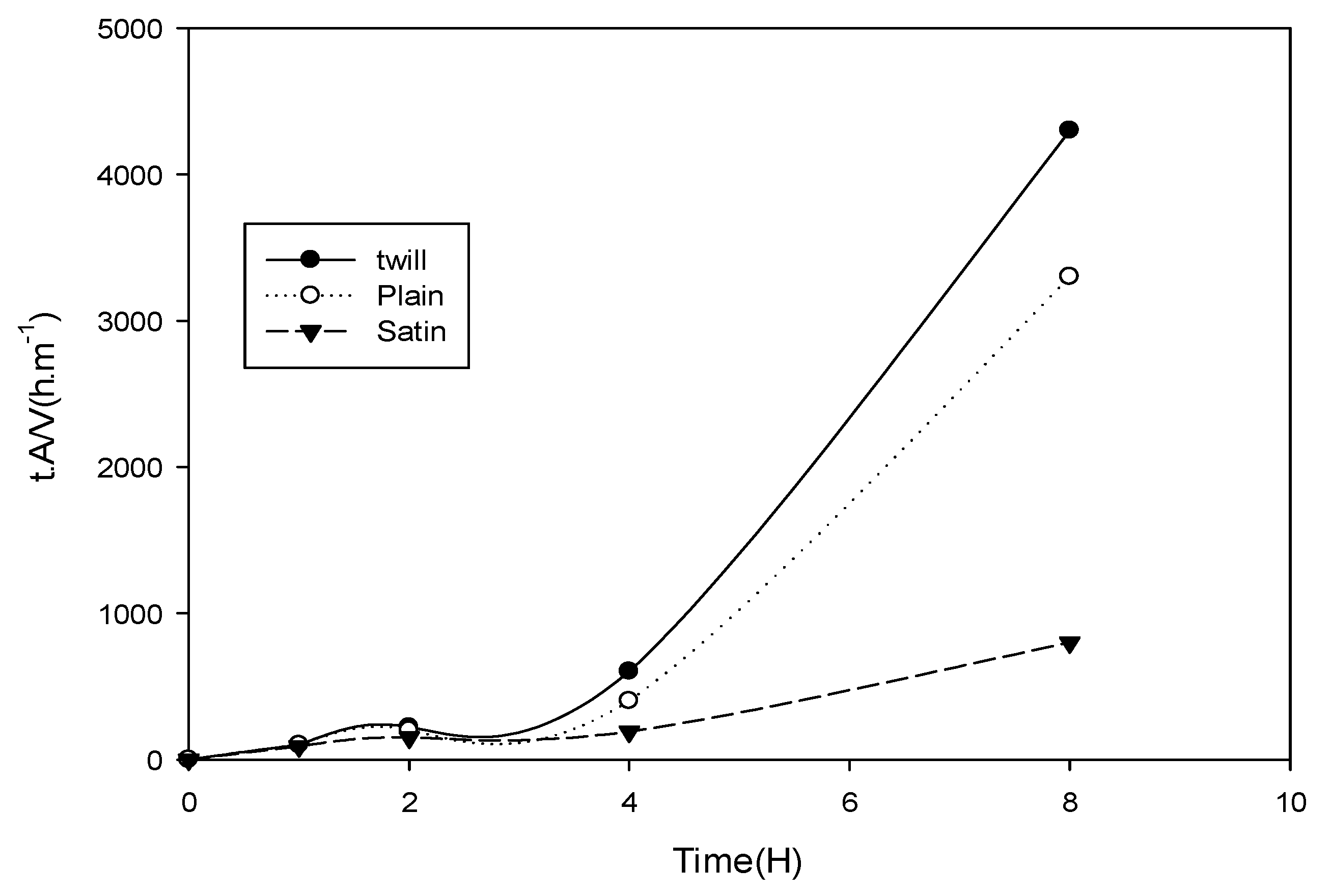

3.8. Effect of the Weaving Method on the Clogging Mechanism

3.9. Characteristics of Membranes after Filtration

| Types of Weave | Thickness of Filter Element(s) (m) |

Porosity (ε) | Effective Resistance of the Filter Element (Rm) (m-2) |

Cake Resistance (Rg) (m-2) |

Compressibility Index | Cake Mass (W) g/m2 |

|---|---|---|---|---|---|---|

| Plain | 0 ,001 | 0,5 | 2,57.109 | 1,76 .1011 | 0,81 | 26 ,34 |

| Twill | 0,004 | 0,3 | 2,76.109 | 3,01.1011 | 1 | 35,11 |

| Satin | 0,006 | 0,18 | 2,86.109 | 3,38.1011 | 1,1 | 43,23 |

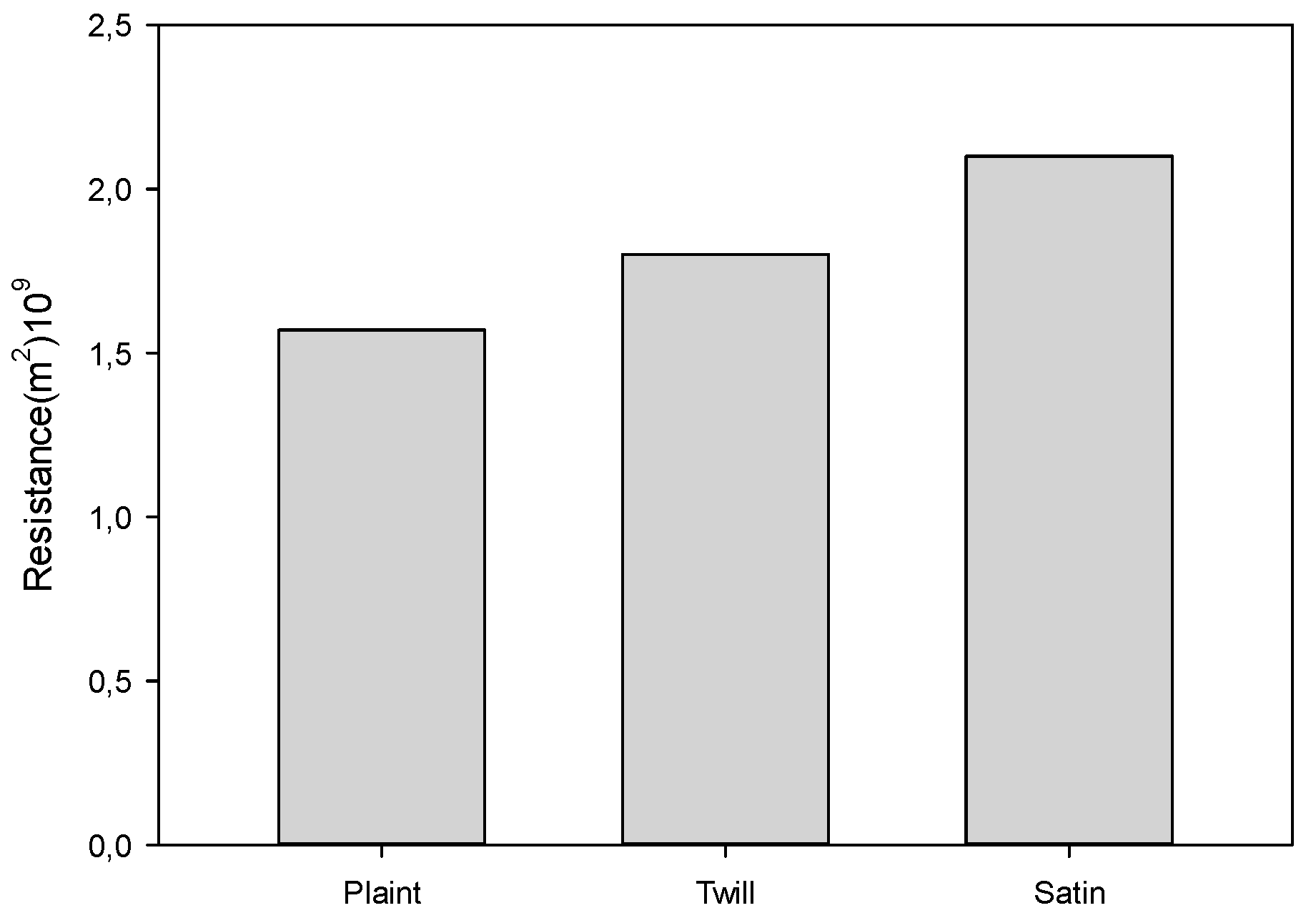

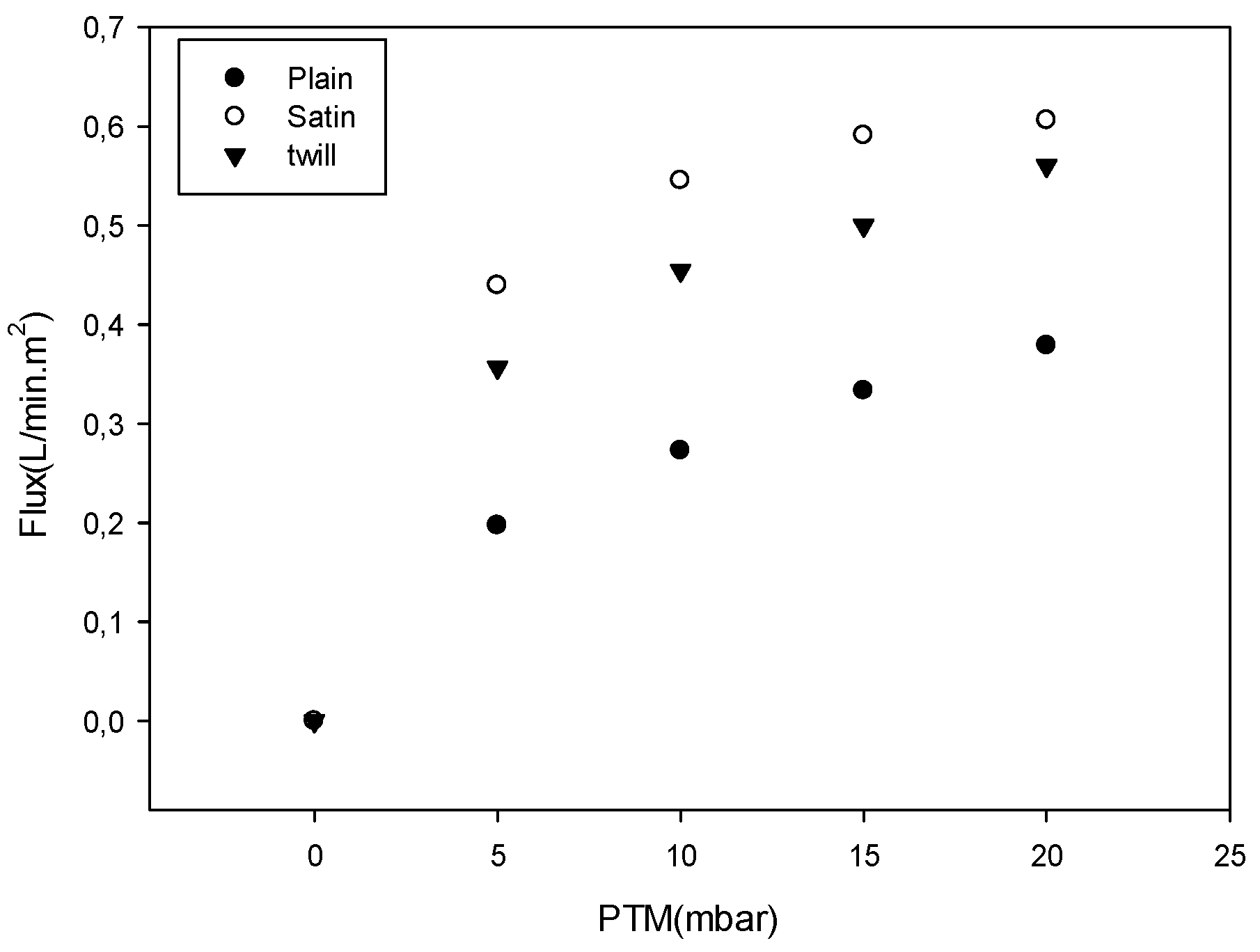

3.10. Influence of Weaving Type on Flow during Filtration

4. Conclusion

References

- Begum Melike Tanis-Kanbura, René I. Peinadord , José I. Calvo, Antonio Hernández , JiaWei Chewa. 2021.Porosimetric membrane characterization techniques: a review. Journal of Membrane Science 619(3):118750. [CrossRef]

- Sulastri A. et Rahimidar L., 2016. Fabrication de biomembrane à partir de tige de banane pour l'élimination du plomb. Journal indonésien des sciences et technologies. 1(1): 115 - 131.

- Kozlowski.R . M, Mackiewicz-Talarczyk . M, and Barriga-Bedoya. J, (2010). “Natural Fibers Production, Processing, and Application: Inventory and Future Prospects,” in Contemporary Science of Polymeric Materials , vol. 1061, American Chemical Society, pp. 3–41.

- Gregory M.R, (2009). Environmental implications of plastic debris in marine settingsentanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions.Philosophical Transactions of the Royal Society B: Biological Sciences, 364 pp. 2013-2025.

- Alimba CG and Faggio C (2019). Microplastics in the marine environment: Current trends in environmental pollution and mechanisms of toxicological profile. Environ. Toxicol. Pharmacol., 68, pp 1-164.

- Wilcox C et al. (2018). A quantitative analysis linking sea turtle mortality and plastic debris ingestion. Scient. Reports 8:12536 |. [CrossRef]

- Tserki, V., Zafeiropoulos, N.E., Simon, F., Panayiotou, C. (2005). A study of the effect of acetylation and propionylation surface treatments on natural fibres. Composites Part A:Applied Science and Manufacturing, 36(8), 1110-1118.

- Wafiroh S., Abdulloh A., Widati AA, 2021. Fibres creuses d'acétate de cellulose revêtues de Ti2O pour la dégradation des déchets de teinture textile. Technologie chimique. 15 (2): 291 -298. [CrossRef]

- Ortega, E., et al. (2014) Urban Fragmentation Map of the Chamberí District in Madrid. Journal of Maps, 1-10.

- Rajendran, K.V., Shivam, Saloni, Ezhil Praveena, P., Joseph Sahaya Rajan, J., Sathish Kumar, T., Avunje, Satheesha, Jagadeesan, V., Prasad Babu, S.V.A.N.V., Pande, Ashish, Navaneeth Krishnan, A., Alavandi, S.V., Vijayan, K.K., Emergence of Enterocytozoon hepatopenaei (EHP) in farmed Penaeus (Litopenaeus) vannamei in India, Aquaculture (2016). [CrossRef]

- Baghel S. Ravir, Poornima Suthar , Tejal K. Gajaria , Sourish Bhattacharya, Annamma Anil , C.R.K. Reddy.(2020). Seaweed biorefinery: A sustainable process for valorising the biomass of brown seaweed.Journal of Cleaner Production 263(21):121359. [CrossRef]

- Gao, J., An, Z., & Bai, X. (2019). A new representation method for probability distributions of multimodal and irregular data based on uniform mixture model. Annals of Operations Research. [CrossRef]

- Behera . B. K, and Hari . P. K, (2010). Woven textile structure: Theory and applications.

- Duroudier J.-P. , 1.7 Les supports filtrants, in Pratique de la filtration, HERMES Science Publications: Paris, (1999).

- Daufin, G., René, F., and Aimar, P. (1998). Les séparations par membrane dans les procédés de l’industrie alimentaire.

- Espinasse, B., Bacchin, P., and Aimar, P. (2008). Filtration method characterizing the reversibility of colloidal fouling layers at a membrane surface: Analysis through critical flux and osmotic pressure. J. Colloid Interface Sci. 320, 483–490.

- Bessière, Y. (2005). Filtration frontale sur membrane : mise en évidence du volume filtré critique pour l’anticipation et le contrôle du colmatage. Université Paul Sabatier.

- Chanlong, (2011). .M,Effect of fabric constructionon water permeability rate of woven filter cloth.Easten Liaoning University,325 Wenhua roat,Dandong, Liaoning,118003,China ddcd@126.com. Advanced material Research, vol 331 ,PP 48-51.doi : 10.4028 /AMR 331.48.

- Kameni. N. M. Bernard, N. K. Sylvere, K. G. Patrice, and K. G. Joseph, “Coagulation and sedimentation of concentrated laterite sus- pensions: comparison of hydrolysing salts in presence of Grewia spp. biopolymer,” Journal of Chemistry, vol. 2019, Article ID 1431694, 9 pages, 2019.

- Pratikhya Badanayak, Seiko Jose & Gautam Bose (2023) Banana pseudo stem fiber: A critical review on fiber extraction, characterization, and surface modification, Journal of Natural Fibers, 20:1.

- Sutherland and Derek. (2000). Handbook of filter media. Elsevier.

- Kanade, P. Role of Spinning Machine Process Variables on Porosity of DREF Spun Yarn. Fibers Polym 24, 2521–2527 (2023). [CrossRef]

- Abdul Cader Salahudeen Izzathul Mumthas, Ganemulle Lekamalage Dharmasri Wickramasinghe and Ujithe SW Gunasekera Effect of physical, chemical and biological extraction methods on the physical behaviour of banana pseudo-stem fibres: Based on fibres extracted from five common Sri Lankan cultivars Journal of Engineered Fibers and Fabrics.Volume 14, January-December 2019. [CrossRef]

- Turan R., Befru, et O. Ayse, "Prediction of the in-plane et through-plane fluid flow behavior of woven fabrics." Textile Research Journal (2013): 700-717.

- Hanafi Y., K.Baddari, A.Szymczyk, F.Zibouche. Caractérisation de la densité de charge de surface de membranes nanoporeuses Journal of Materials, Processes and Environment 1 (01) (2013).

- Nsoe M.N. , E.V. Amba, N.M. Kameni, G.P. Kofa, K.S. Ndi, M. Heran and G.J. Kayem.(2023). Biodegradation of Natural Rubber Wastewater in the Submerged Membrane Bioreactor by Pichia Guilliermondii and Yarrowia Lipolytica. International Journal of Membrane Science and Technology, 2023, 10, 38-46.

- Kouakou E., Salmon T., Marchot P., Crine M.,(2006b). Influence of operating parameters on nitrite accumulation in a nitrifying submerged MBR. Proc. Int. Symp. Environ. Biotechnol.Liepzig, Germany, 9th to 13th September 2006. 5pp.

- Contreras, A.E., Kim, A., Li, Q., 2009. Combined fouling of nanofiltration membranes: Mechanisms and effect of organic matter. Journal of Membrane Science 327, 87–95.

- Marie Grégoire. Extraction des fibres de chanvre pour des composites structuraux – Optimisation du potentiel mécanique des fibres pour des applications concernant des matériaux composites 100% bio-sourcés. Matériaux et structures en mécanique [physics.class-ph]. Institut National Polytechniquede Toulouse - INPT, 2021. Français. NNT : 2021INPT0002ff. tel-04165247ff.

- Athijayamani A, Thiruchitrambalam M, Natarajan U, Pazhanivel B. Influence of alkalitreated fibers on the mechanical properties and machinability of roselle and sisal fiber hybrid polyester composite. Polymer Composites 2010; 31:723–31.

- Mbouyap Chengoué A, T. Tchotang, C. Bopda Fokam, B. Kenmeugne. 2020.Influence of extractions techniques on the physico-mechanical properties of banana pseudo- stem fibers J. Mater. Environ. Sci. 11(7), pp. 1121-1128.

- Venkataravanappa, R.Y.; Lakshmikanthan, A.; Kapilan, N.; Chandrashekarappa, M.P.G.; Der, O.;Ercetin, A. Physico-Mechanical Property Evaluation and Morphology Study of Moisture-Treated Hemp–Banana Natural-Fiber- Reinforced Green Composites. J. Compos. Sci. 2023, 7, 266. [CrossRef]

- Lerch T. P.; Determination of surface density of nonporous membranes with air-coupled ultrasound. AIP Conf. Proc. 31 March 2015; 1650 (1): 1292–1298. [CrossRef]

- Sumesh, K. R., V. Kavimani, G. Rajeshkumar, S. Indran, and A. Khan. 2022. Mechanical, water absorption and wear characteristics of novel polymeric composites: Impact of hybrid natural fibers and oil cake filler addition. Journal of Industrial Textiles 51 (4):5910S–37.

- Jermann, D., Pronk, W., Kägi, R., Halbeisen, M., Boller, M., 2008. Influence of interactions between NOM and particles on UF fouling mechanisms. Water Research 42, 3870–3878.

| Characteristics | Valors |  |

| Types | S | |

| Number of twists | 10 | |

| Tex | 168 | |

| Wire diameter (mm) | 0,75 | |

| Porosity | 0,5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).