2. Experimental Section

2.1. Materials and Measurements

Zirconium(IV) n-propoxide (70% in 1-propanol, Aldrich), Zirconium(IV) n-butoxide (80% in 1-butanol, Aldrich), salicylic acid (SAH, 98%, Aldrich), 3-methylsalicylic acid (3-Me-SAH, 97%, Aldrich), 4-methylsalicylic acid (4-Me-SAH, 99%, Aldrich), 3,5-di-tert-butylsalicylic acid (3,5-tBu2-SAH, 99%, Aldrich), Ɛ-caprolactone (Ɛ-CL, 99%, Alfa Aesar), and tetrahydrofuran (THF, 99.9%, Merck) were used as received. 1-Propanol (99%, Merck) and 1-butanol (99%, Merck) were dried over activated 4A° molecular sieves. All syntheses without polymers were carried out in closed vessels under ambient atmosphere.

1H and 13C{1H}NMR samples were measured by a Bruker 400 MHz spectrometers.

Infrared spectra of zirconium complexes (C1-C8) were carried out with a Brucker Tensor 27 Fourier-transform infrared spectrophotometer (FTIR) equipped with single reflection ATR using diamond crystal in wavenumber from 400 to 4000 cm−1 at a resolution of 4 cm−1. The elemental analyses were performed on a LECO CHNS-932 elemental analyzer. Mass spectrometry (Waters SYNAPT, HRMS) was employed to measure the molecular masses of zirconium complexes (C1-C8) using with electrospray ionization (ESI ±) method. Thermogravimetric analysis was carried out with a Perkin Elmer Pyris 1 TGA. All samples (C1-C8) were heated between 25 oC and 790 oC at heating rate of 10 oC/min in synthetic air flow. Colorimetric measurements for PCL were performed by differential scanning calorimetry (PerkinElmer DSC 8000). The PCL sample was heated in N2 atmosphere from -80 oC to +80 oC at a heating rate of 10 oC per minute and thus measurements were performed. Gel permeation chromatographic (GPC) analysis was performed on a Shimadzu prominence GPC system equipped with a refractive index detector (RID-10A), a solvent delivery unit (LC-20AD), a column oven (CTO-10AS), and a set of two columns, PSS SDV 5µL 1000 A° and PSS SDV 5 µL 50 A°. THF (99.9%) was used as the mobile phase at 1.0 mL/min. PCL concentration and the injection volume were ~2 mg/mL and 50µL, respectively. The calibration curve was plotted with several polystyrene standards including the molecular weight range 162 to 67000 Da.

2.2. Preparation of [(SA-OH)2(SA)Zr2(OnPr)2O] (C1)

Salicylic acid (1.05 g, 7.60 mmol) was added to the solution of zirconium n-propoxide (1.78 g, 3.81 mmol) in 30 mL n-propanol. The reaction mixture was stirred at room temperature (RT) for 3 hours. Then, the volatiles were removed from the solution by vacuum evaporator at 50 oC for 3 hours. The resulting white solid product was then washed three times with hexane and dried in an evaporator under reduced pressure. Elemental analysis (EA) (C27H28O12Zr2, (SA-OH)2(SA)Zr2(OnPr)2O, Mw = 726.95 g/mol): Calc. C 44.61, H 3.88%. Found: C 42.84, H 3.16%. MS: C27H28O12Zr2 = 723.97, C27H28O12Zr2 = 713.42 Da. 1H NMR (CDCl3) δ/ppm: 0.91 (t, 6H, J=7.4 Hz, CH3, OnPr), 1.61 (sext, 4H, J=7.4 Hz, CH2, OnPr), 3.35 (t, 4H, J=6.6 Hz, OCH2, OnPr), 7.03 (brd, 2H, H-3, ph), 7.06 (t, 2H, J=5.6 Hz, H-5, ph), 7.33 (brd, 2H, H-4, ph), 7.90 (d, 2H, J=6.32 Hz, H-6, ph), 10.5 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 10.35 (CH3, OnPr), 25.57 (CH2, OnPr), 62.43 (OCH2, OnPr), 111.7 (C-1, ph), 117.6 (C-3, ph), 119.5 (C-5, ph), 130.78 (C-6, ph), 162.1 (C-2, ph), 173.28 (COO). FTIR (cm-1): 3238 (OH), 3057 (Csp2-H), 2958 (Csp3-H), 1580 (COO, asym), 1523, 1463, 1399 (COO, sym), 1241 (Csp2-O), 1147, 1101, 1031 (Csp3-O), 954, 888, 864, 806, 755.

2.3. Preparation of [(3-Me-SA-OH)2(3-Me-SA)Zr2(OnPr)2O] (C2)

The reaction of 3-methylsalicylic acid (1.22 g, 8.27 mmol) with zirconium n-propoxide (1.82 g, 3.90 mmol) in 30 mL n-propanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded an orange solid product. EA (C30H34O12Zr2, (3-Me-SA-OH)2(3-Me-SA)Zr2(OnPr)2O, Mw = 769.03 g/mol): Calc. C 46.85, H 4.46%. Found: C 45.58, H 3.64%. TGA: % loss= 69.51%. 1H NMR (CDCl3) δ/ppm: 0.84 (t, 6H, J=7.4 Hz, CH3, OnPr), 1.42 (sext, 4H, J=7.4 Hz, CH2, OnPr), 2.28 (s, CH3, 3-Me-SA), 3.35 (t, 4H, J=6.6 Hz, OCH2, OnPr), 6.81 (t, 2H, J=7.65 Hz, H-5, ph), 7.36 (d, 2H, J=7.22 Hz, H-4, ph), 7.75 (d, 2H, J=7.94 Hz, H-6, ph), 10.5 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 10.35 (CH3, OnPr), 15.8 (CH3, 3-Me-SA), 25.3 (CH2, OnPr), 62.4 (OCH2, OnPr), 113.9 (C-1, ph), 118.6 (C-5, ph), 126.5 (C-3, ph), 128.5 (C-6, ph), 136.8 (C-4, ph), 163.4 (C-2, ph), 174.0 (COO). FTIR (cm-1): 3290 (OH), 3018 (Csp2-H), 2957 (Csp3-H), 2916, 2875, 1601 (COO, asym), 1537, 1460, 1429 (CH3 bending), 1394 (COO, sym), 1239 (Csp2-O), 1191, 1157, 1081, 1005 (Csp3-O), 874, 754, 658.

2.4. Preparation of [(4-Me-SA-OH)2(4-Me-SA)Zr2(OnPr)2O] (C3)

The reaction of 4-methylsalicylic acid (1.22 g, 8.10 mmol) with zirconium n-propoxide (1.86 g, 3.98 mmol) in 30 mL n-propanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded an orange solid product. EA (C30H34O12Zr2, (4-Me-SA-OH)2(4-Me-SA)Zr2(OnPr)2O, Mw = 769.03 g/mol): Calc. C 46.85, H 4.46%. Found: C 45.13, H 3.63%. MS, Calc.: 766.01 Da for C30H34O12Zr2, Found: 764.54 Da for C30H34O12Zr2H+. 1H NMR (CDCl3) δ/ppm: 0.84 (t, 6H, J=7.4 Hz, CH3, OnPr), 1.49 (sext, 4H, J=7.4 Hz, CH2, OnPr), 2.48 (s, 6H, CH3, 3-Me-SA), 3.60 (t, 4H, J=6.6 Hz, OCH2, OnPr), 6.90 (t, 2H, J=7.65 Hz, H-5, ph), 7.28 (d, 2H, J=7.22 Hz, H-4, ph), 7.75 (d, 2H, J=7.94 Hz, H-6, ph), 10.5 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 10.35 (CH3, OnPr), 21.8 (CH3, 4-Me-SA), 25.5 (CH2, OnPr), 66.8 (OCH2, OnPr), 110.9 (C-1, ph), 117.6 (C-5, ph), 120.5 (C-3, ph), 130.9 (C-6, ph), 146.8 (C-4, ph), 161.1 (C-2, ph), 173.0 (COO). FTIR (cm-1): 3262 (OH), 3018 (Csp2-H), 2961 (Csp3-H), 2922, 2876, 1614 (COO, asym), 1577, 1494, 1437 (CH3 bending and COO, sym), 1382, 1249 (Csp2-O), 1167, 1111, 1038, 1010 (Csp3-O), 957, 866, 781, 754, 704, 619, 527.

2.5. Preparation of [(3,5-But2-SA-OH)2(3,5-But2-SA)Zr2(OnPr)2O] (C4)

The reaction of 3,5-di-tertbutylsalicylic acid (0.5 g, 2.1 mmol) with zirconium n-propoxide (0.45 g, 0.96 mmol) in 30 mL n-propanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded a white solid product. EA (C51H76O12Zr2, (3,5-But2-SA-OH)2(3,5-But2-SA)Zr2(OnPr)2O, Mw = 1063.60 g/mol): Calc. C 57.59, H 7.20%. Found: C 56.65, H 7.53%. Mass Spectra (MS), Calc.: 1060.34 Da for C51H76O12Zr2, Found: 1060.33 Da for C51H76O12Zr2. 1H NMR (CDCl3) δ/ppm: 0.85 (t, 6H, J=7.4 Hz, CH3, OnPr), 1.42 (sext, 4H, J=7.4 Hz, CH2, OnPr), 1.48-1.60 (a few singlets, 36H, tertbutyl), 3.64 (t, 4H, J=6.6 Hz, OCH2, OnPr), 6.90 (t, 2H, J=7.65 Hz, H-5, ph), 7.28 (d, 2H, J=7.22 Hz, H-4, ph), 7.40 (d, 2H, J=9.07 Hz, ph), 11.0 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 10.4 (CH3, OnPr), 25.6 (CH2, OnPr), 25.8-31.3 (3,5-But2), 64.8 (OCH2, OnPr), 84.0, 86.1, 108.5, 123.4, 130.7, 140.1, 148.7, 165.6 (C-2, ph), 176.0 (COO). FTIR (cm-1): 3203 (OH), 2956 (Csp3-H), 2908, 2871, 1613 (COO, asym), 1534, 1445 (CH3 bending), 1389 (COO, sym), 1361, 1281, 1243 (Csp2-O), 1199, 1148, 1024, 1045, 1006 (Csp3-O), 959, 896, 851, 809, 752, 723, 677, 641, 541.

2.6. Preparation of [(SA-OH)2(SA)Zr2(OnBu)2O] (C5)

Salicylic acid (0.70 g, 5.07 mmol) was added to the solution of zirconium n-butoxide (1.20 g, 2.51 mmol) in 30 mL n-butanol. The reaction mixture was stirred at RT for 3 hours. Then, the volatiles were removed from the solution by vacuum evaporator at 50 oC for 3 hours. The resulting white solid product was then washed three times with hexane and dried in an evaporator under reduced pressure. EA (C29H32O12Zr2, (SA-OH)2(SA)Zr2(OnBu)2O, Mw = 755.01 g/mol): Calc. C 46.13, H 4.27%. Found: C 45.18, H 3.57%. 1H NMR (CDCl3) δ/ppm: 0.93 (t, 6H, J=7.4 Hz, CH3, OnBu), 1.25-1.60 (m, 4H, J=7.4 Hz, CH2, OnBu), 3.70 (t, 4H, J=6.6 Hz, OCH2, OnBu), 6.91 (brd, 2H, H-3, ph), 6.99 (t, 2H, J=5.6 Hz, H-5, ph), 7.57 (brd, 2H, H-4, ph), 7.99 (d, 2H, J=6.32 Hz, H-6, ph), 10.5 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 13.8 (CH3, OnBu), 18.8 (CH2, OnBu), 34.70 (CH2, OnBu), 62.9 (OCH2, OnBu), 111.7 (C-1, ph), 117.6 (C-3, ph), 119.3 (C-5, ph), 130.8 (C-6, ph), 136.4 (C-4, ph), 162.1 (C-2, ph), 173.28 (COO). FTIR (cm-1): 3238 (OH), 3057 (Csp2-H), 2958 (Csp3-H), 1580 (COO, asym), 1523, 1463, 1399 (COO, sym), 1241 (Csp2-O), 1147, 1101, 1031 (Csp3-O), 954, 888, 864, 806, 755.

2.7. Preparation of [(3-Me-SA-OH)2(3-Me-SA)Zr2(OnBu)2O] (C6)

The reaction of 3-methylsalicylic acid (0.81 g, 5.49 mmol) with zirconium n-butoxide (1.22 g, 2.55 mmol) in 30 mL n-butanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded a white solid product. EA (C32H38O12Zr2, (3-Me-SA-OH)2(3-Me-SA)Zr2(OnBu)2O, Mw = 797.09 g/mol): Calc. C 48.22, H 4.81%. Found: C 46.50, H 4.15%. MS, Calc.: 833.01, 835.01, 837.01 for C32H38O12Zr2+K, Found: 834.65 for C32H38O12Zr2+K. 1H NMR (CDCl3) δ/ppm: 0.91 (t, 6H, J=7.4 Hz, CH3, OnBu), 1.32-1.54 (m, CH2, OnBu), 2.28 (s, CH3, 3-Me-SA), 3.60 (t, 4H, J=6.6 Hz, OCH2, OnBu), 6.81 (t, 2H, J=7.65 Hz, H-5, ph), 7.36 (d, 2H, J=7.22 Hz, H-4, ph), 7.82 (d, 2H, J=7.94 Hz, H-6, ph), 10.7 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 13.6 (CH3, OnBu), 15.8 (CH3, 3-Me-SA), 18.44 (CH2, OnBu), 34.3 (CH2, OnBu), 63.2 (OCH2, OnBu), 110.6 (C-1, ph), 118.6 (C-5, ph), 126.7 (C-3, ph), 128.5 (C-6, ph), 137.3 (C-4, ph), 163.4 (C-2, ph), 174.3 (COO). FTIR (cm-1): 2955 (Csp3-H), 2918, 2868, 1661 (COO, asym), 1328, 1238 (Csp2-O), 1155, 1081, 1005 (Csp3-O), 872, 752, 656, 526.

2.8. Preparation of [(4-Me-SA-OH)2(4-Me-SA)Zr2(OnBu)2O] (C7)

The reaction of 4-methylsalicylic acid (0.78 g, 5.18 mmol) with zirconium n-butoxide (1.21 g, 2.52 mmol) in 30 mL n-propanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded a white solid product. EA (C32H38O12Zr2, (4-Me-SA-OH)2(4-Me-SA)Zr2(OnBu)2O, Mw = 797.09 g/mol): Calc. C 48.22, H 4.81%. Found: C 46.49, H 4.12%. MS: Calc. C32H38O12Zr2+K=833.01, 835.01, 837.01, Found: 834.65. 1H NMR (CDCl3) δ/ppm: 0.83 (t, 6H, J=7.4 Hz, CH3, OnBu), 1.03-1.37 (m, CH2, OnBu), 2.36 (s, CH3, 3-Me-SA), 3.49 (t, 4H, J=6.6 Hz, OCH2, OnBu), 6.75 (t, 2H, J=7.65 Hz, H-5, ph), 7.46 (d, 2H, J=7.22 Hz, H-4, ph), 7.71 (d, 2H, J=7.94 Hz, H-6, ph), 10.5 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 12.3 (CH3, OnBu), 19.7 (CH2, OnBu), 21.8 (CH3, 3-Me-SA), 35.7 (CH2, OnBu), 63.0 (OCH2, OnBu), 111.4 (C-1, ph), 117.6 (C-5, ph), 130.5 (C-3, ph), 131.6 (C-6, ph), 146.4 (C-4, ph), 161.3 (C-2, ph), 173.0 (COO). FTIR (cm-1): 3246 (OH), 2957 (Csp3-H), 2927, 2869, 1577 (COO, asym), 1496, 1438, 1381 (COO, asym), 1250 (Csp2-O), 1166, 1108, 1067, 1031 (Csp3-O), 953, 856, 828, 780, 754, 647, 618, 500.

2.9. Preparation of [(3,5-But2-SA-OH)2(3,5-But2-SA)Zr2(OnBu)2O] (C8)

The reaction of 3,5-di-tertbutylsalicylic acid (0.5 g, 2.1 mmol) with zirconium n-butoxide (0.46 g, 0.96 mmol) in 30 mL n-butanol was performed under the same experimental conditions as in the previous reaction. The reaction yielded a yellow solid product. EA (C53H80O12Zr2, (3,5-But2-SA-OH)2(3,5-But2-SA)Zr2(OnBu)2O, Mw = 1091.66 g/mol): Calc. C 58.31, H 7.39%. Found: C 58.26, H 7.56%. TGA: % loss= 83.37%. 1H NMR (CDCl3) δ/ppm: 0.91 (t, 6H, J=7.4 Hz, CH3, OnBu), 1.32-1.59 (a few singlets, 36H, tertbutyl), 3.60 (t, 4H, J=6.6 Hz, terminal-OCH2, OnBu), 3.80 (t, 4H, J=6.6 Hz, bridge-OCH2, OnBu), 7.84-7.28 (d, 6H, J=9.07 Hz, ph), 11.2 (s, 2H, 2OH). 13CNMR (CDCl3) δ/ppm: 10.1 (CH3, OnBu), 19.7 (CH2, OnBu), 34.3 (CH2, OnBu), 29.5-35.1 (3,5-But2), 62.8 (OCH2, OnBu), 84.0, 86.1, 111.0, 124.5, 131.2, 137.3, 140.6, 159.6 (C-2, ph), 176.1 (COO). FTIR (cm-1): 3176 (OH), 2955 (Csp3-H), 2909, 2870, 1653 (COO, asym), 1613, 1551, 1441 (CH3 bending), 1389 (COO, sym), 1361, 1280, 1241 (Csp2-O), 1198, 1150, 1021, 1067, 1026 (Csp3-O), 940, 851, 807, 721, 670, 640, 541, 514, 478, 431.

2.10. ROP of Ɛ-caprolactone with the catalyst [(4-Me-SA-OH)2(4-Me-SA)Zr2(OnBu)2O]

Catalyst

C7 (20 mg) was mixed with Ɛ-caprolactone (1.2 mL) in a small flask under N

2 gas. The solvent-free or bulk mixture was stirred in a hot plate stirrer at 90-110

oC for 8-24 hours as shown in

Table 1.

1H NMR (CDCl

3, ppm), δ: 4.06 (t,

J=6.64 Hz,

εCH

2-O), 2.31 (t,

J=7.46 Hz,

αCH

2-C=O), 1.65 (m,

J=7.34 Hz,

β,δCH

2), 1.40 (m,

J=7.25 Hz, γCH

2).

13C NMR (CDCl

3), δ/ppm: 176 (C=O), 68.2 (

εCH

2O), 34.8 (

αCH

2), 30.1 (

γCH

2), 29.2 (

δCH

2), 23.7 (

βCH

2), [O=C-

αCH

2βCH

2γCH

2δCH

2εCH

2O-]. The ROP reactions of Ɛ-caprolactone with all new catalysts (

C1-C6, C8) were performed as described above and under the same experimental conditions.

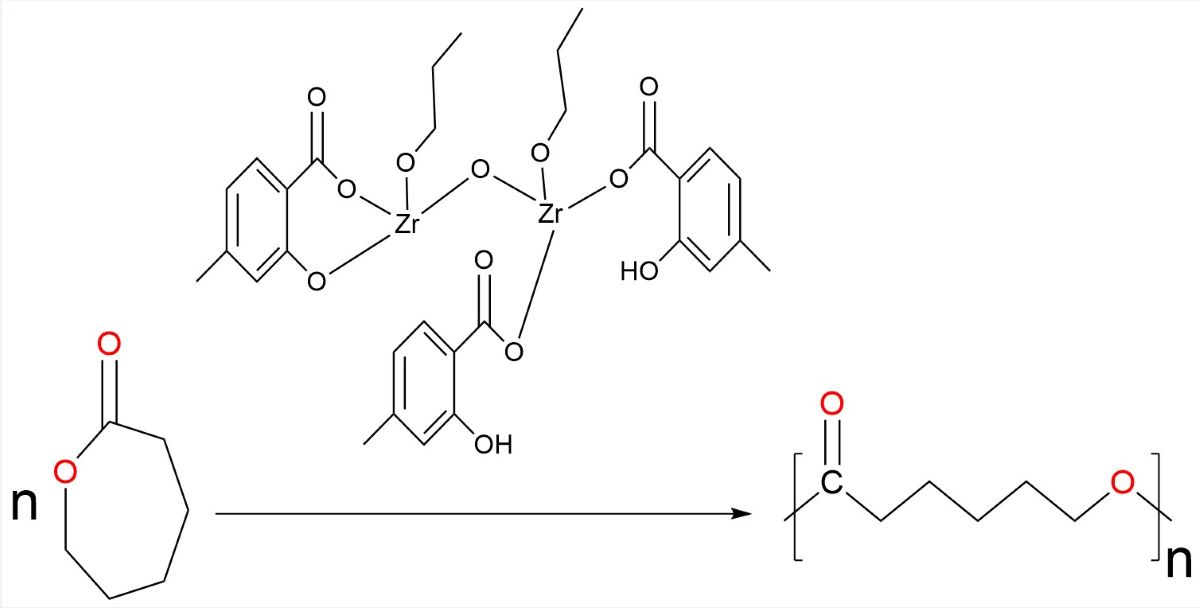

3. Results and Discussion

Reactions of Zr(O

nPr)

4 and Zr(O

nBu)

4 with salicylate derivatives in 1:2 mole ratios in propanol/butanol at RT produced the products of [(SA-OH)

2(SA)Zr

2(O

nPr)

2O], [(3-Me-SA-OH)

2(3-Me-SA)Zr

2(O

nPr)

2O], [(4-Me-SA-OH)

2(4-Me-SA-OH)Zr

2(O

nPr)

2O], [(3,5-Bu

t2-SA-OH)

2(3,5-Bu

t2-SA)Zr

2(O

nPr)

2O], [(SA-OH)

2(SA)Zr

2(O

nBu)

2O], [(3-Me-SA-OH)

2(3-Me-SA)Zr

2(O

nBu)

2O], [(4-Me-SA-OH)

2(4-Me-SA)Zr

2(O

nBu)

2O], and [(3,5-Bu

t2-SA-OH)

2(3,5-Bu

t2-SA)Zr

2(O

nBu)

2O]. These complexes were coded from

C1 to

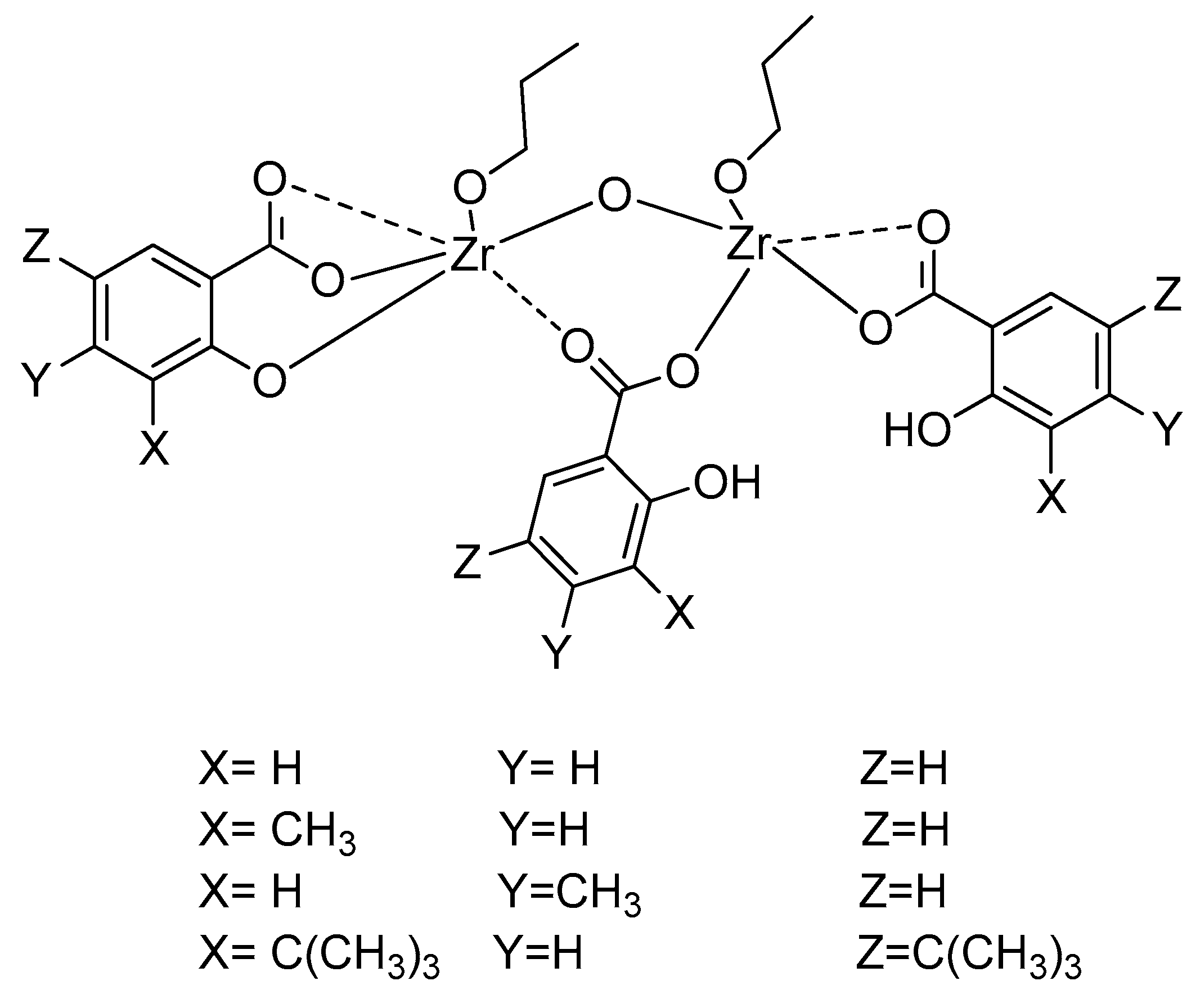

C8, respectively. The formulations of the

C1-C8 complexes were based on

1H-,

13C-NMR, FTIR, mass (MS), and TGA measurements as well as the results of elemental analysis. When salicylic acid derivatives were added to the starting zirconium alkoxide solutions, some of the propoxy or butoxy groups in the starting zirconium-based precursors were replaced by salicylate groups and some of them were condensed to form oxo groups depending on the reaction time and environment. The presence and number of oxo groups were determined by mass measurements, elemental and thermogravimetric analysis.

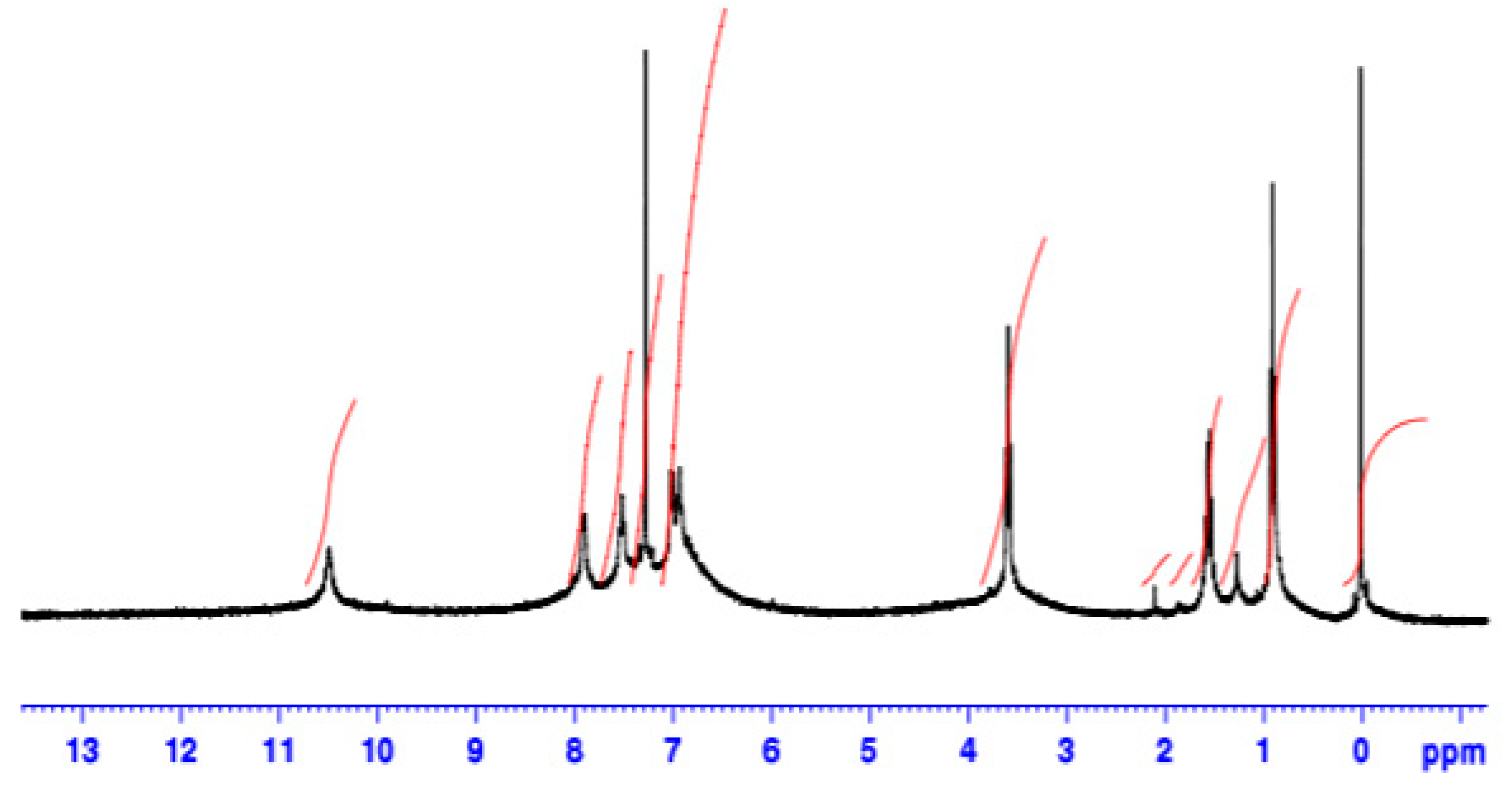

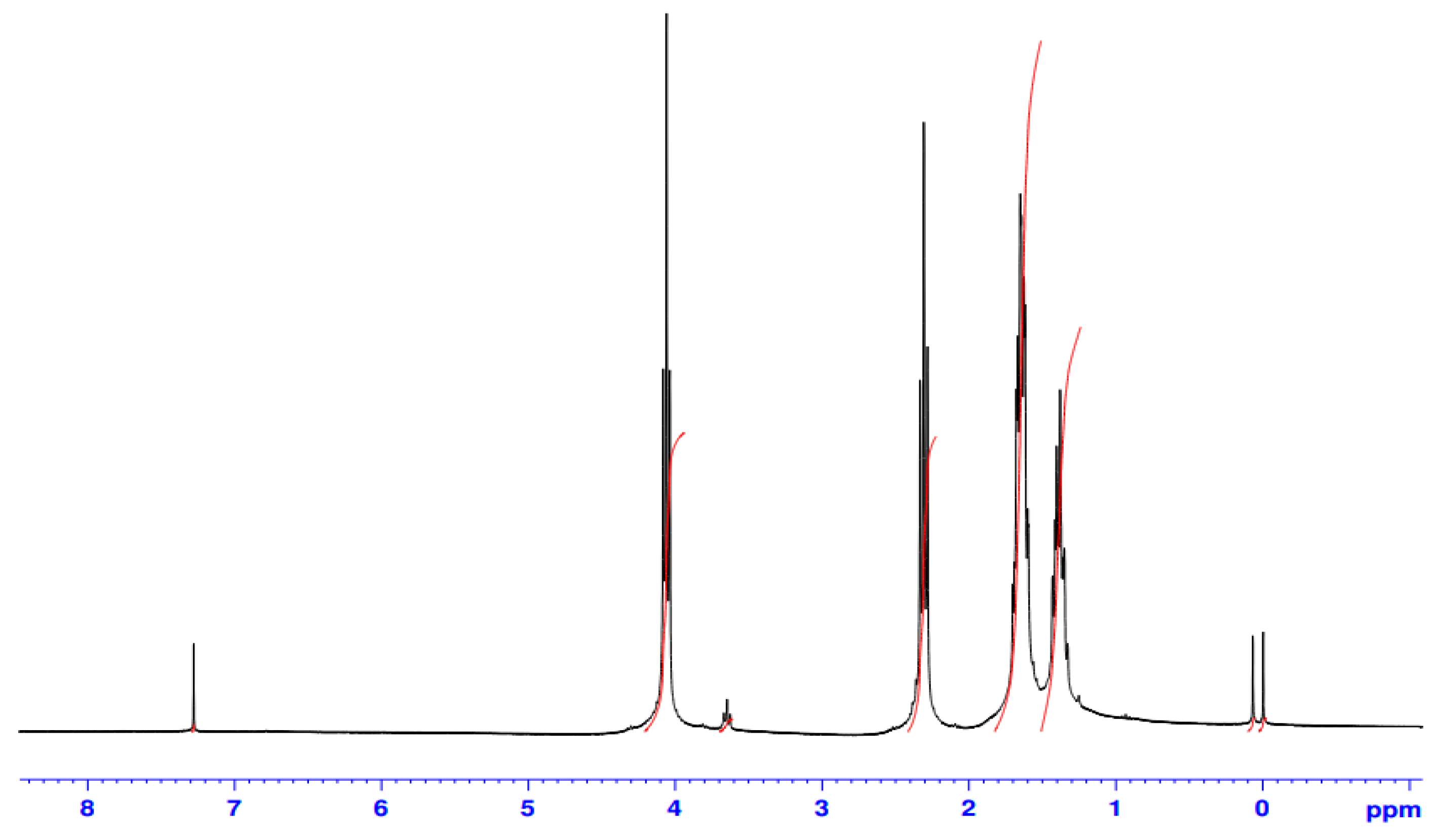

1H NMR spectra of salicylate zirconium compounds confirmed the expected peaks, peak areas, and peak multiplicities for the organic groups as suggested in the formulation. For instance,

1H NMR spectrum of [(SA-OH)

2(SA)Zr

2(O

nPr)

2O] (

C1) demonstrated triplets at 0.91 ppm for CH

3 (J=7.4 Hz) protons, sextet at 1.61 ppm for CH

2 protons, triplet at 3.35 ppm for OCH

2 of O

nPr, doublets or triplets at 6.32-7.90 ppm for salicylate protons, and around at 10.5 ppm for non-bonded OH proton (

Figure 1). The fact that salicylic acid, which gives a carboxyl (COOH) peak at ~11 ppm before coordinating to zirconium, does not give a peak at ~11 ppm after coordinating specifies that the salicylate is fully bonded to zirconium via the carboxyl group. However, the appearance of two proton peaks belonging to OH peaks at around 10.5 indicated that only one unit of salicylate was connected from both carboxyl and OH. The other two were bonded only through COO groups. Substituted phenyl protons were also present in the

1H-NMR spectrum as given above.

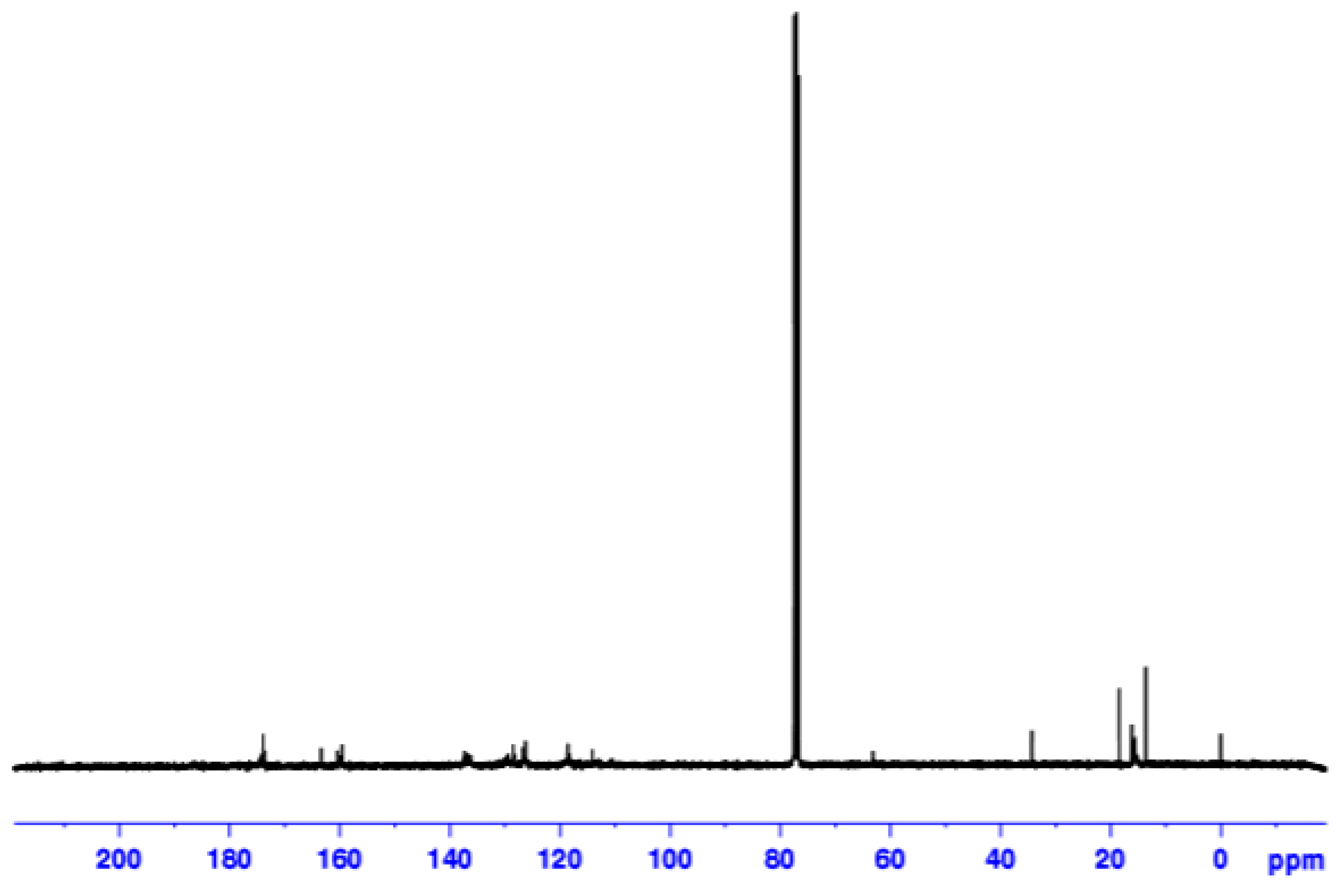

The

13C NMR spectra of the zirconium compounds showed some shifts compared to those of the free salicylate derivatives. These shifts were more predominant at the carboxyl carbons (COO) and at the carbons containing the OH group (C-OH) bound to zirconium. For example,

13C NMR spectrum of [(3-Me-SA-OH)

2(3-Me-SA)Zr

2(O

nBu)

2O] gave peaks at 173.3 ppm for C=O and 162.1 ppm for C-O (3-Me-C

5H

3-C-OH) as seen in

Figure 2. These peak values were different from the free ligand values. The chemical shift values (

δ) and coupling constants (

J) reported in the experimental part are in agreement with published literature values for similar carboxylate or salicylate compounds [

19].

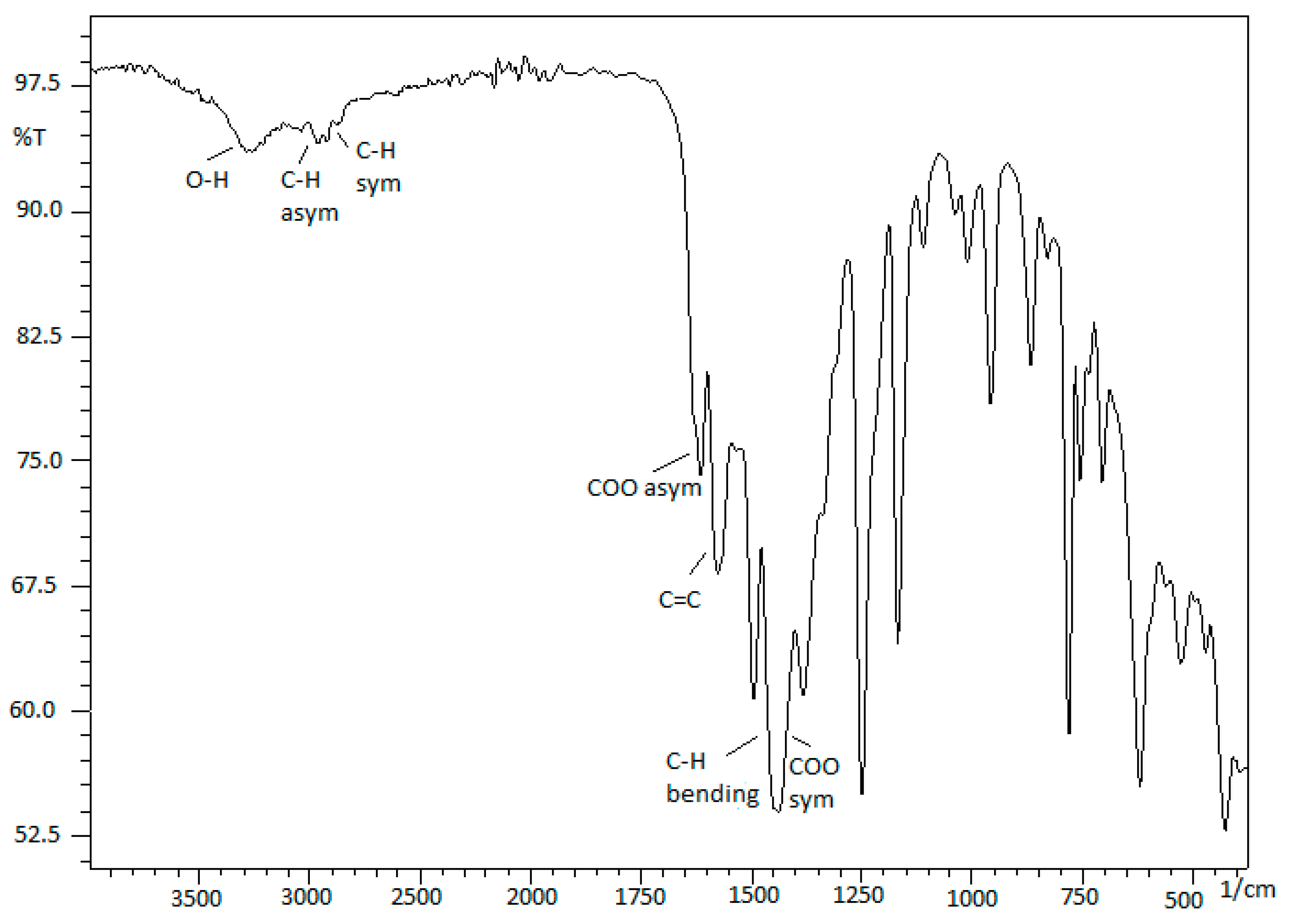

As shown in

Scheme 1, the binding of carboxylate groups as chelate and bidentate was inferred from the FTIR measurements of the

C1-C8 compounds. FTIR spectra of free salicylic acid and its derivatives show characteristic intense bands at ~1670 and 1440 cm

-1 corresponding to asymmetric and symmetric stretching vibrations of carboxyl groups.

After the reaction of salicylate derivatives with zirconium alkoxides, the asymmetric COO vibration band at ~1670 cm

-1 appears in the ~1570-1620 cm

-1 region, i.e. at lower wave number or energy (

Figure 3). For instance, the coordinated carboxylate bands for

C3 appeared at ~1614 cm

-1 for νCOO

asym and ~1437 cm

-1 for νCOO

sym. The Δυ

asym-sym value (177 cm

-1) was smaller than 220 cm

-1, indicating that zirconium atoms and the carboxylate group of salicylate were bonded in the bidentate and chelate coordinate mode, i.e. not mono dentate [

20]. The IR spectra of catalysts

C1-C8 also showed a broad peak at ~3175-3300 cm

-1 because of the O-H stretching, indicating the presence of hydroxide group on the salicylate ligand which was not linked to the zirconium atom. All these values are in agreement with those given for a number of transition metal-carboxylate complexes in the literature [

21].

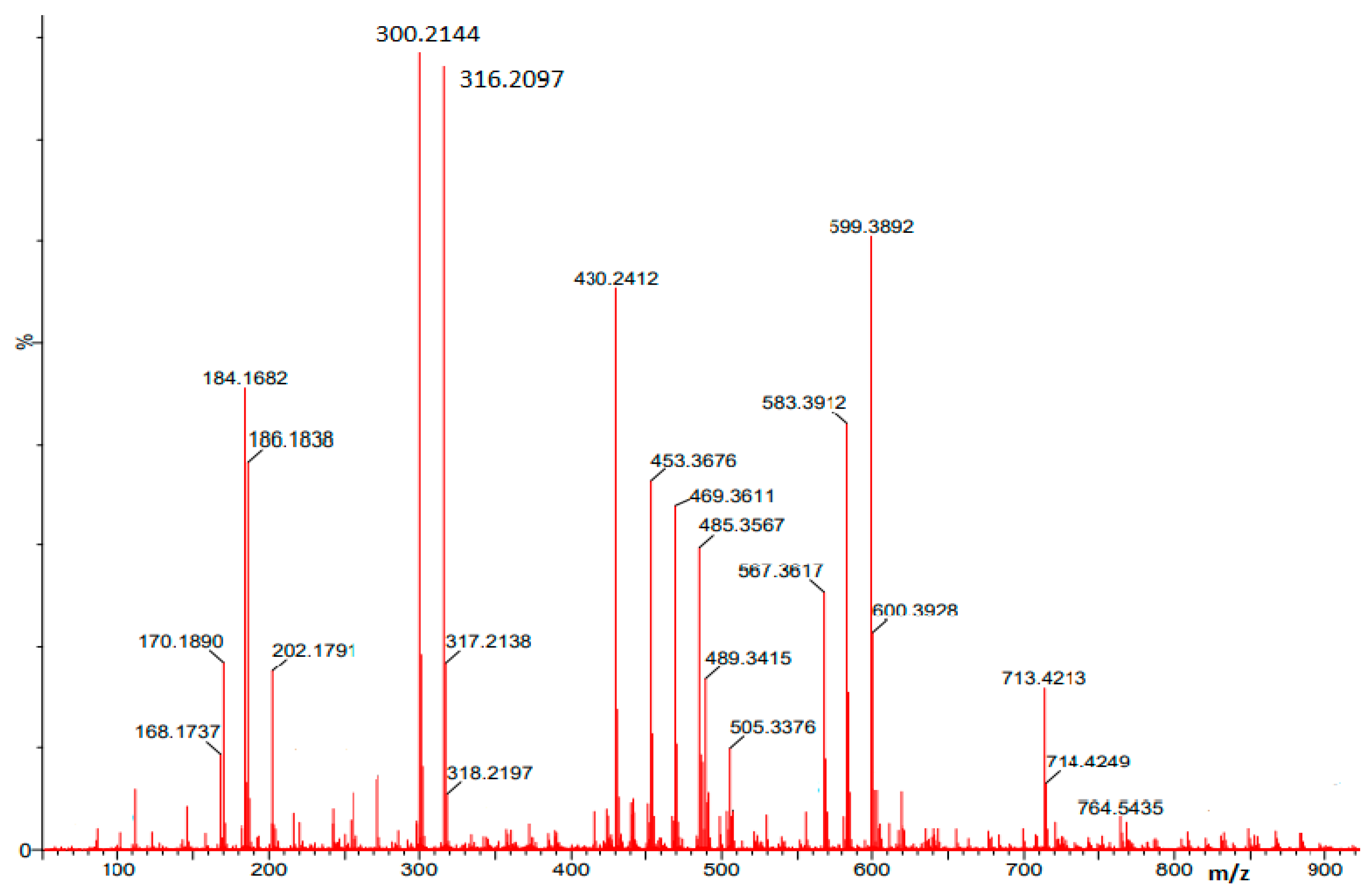

The masses of salicylate or substituted salicylate zirconium complexes analyzed under positive ionization conditions were determined using high resolution mass spectrometry (HRMS). The m/z spectrum of [(SA-OH)

2(SA)Zr

2(O

nPr)

2O] complex gave molecular ion at m/z 713.42 and 714.42 Da which was 12 Da lower than the predicted protonated ion, (SA-OH)

2(SA)Zr

2(O

nPr)

2O+H]

+ or [C

27H

28O

12Zr

2+H]

+ (

Figure 4). At this stage, the formula to be proposed for this complex is the dimeric compound of [C

27H

28O

12Zr

294+H]

+. This proposed dimeric formula was also supported by the percentages of carbon and hydrogen found by elemental analysis and the ratios of hydrogen areas found by

1H-NMR results. However, the reaction of zirconium propoxide with salicylate under different experimental conditions was formulated as Zr

10O

6(OH)

4(OOC-C

6H

4OH)

8(OOC-C

6H

4O)

8.6PrOH by U. Schubert and co-workers [

22]. Different formulations of salicylate zirconium complexes depend on several experimental parameters like carboxylate/zirconium alkoxy ratio, reaction times, hydrolysis, crystallization conditions, solvent volatilization conditions and solvents used. The parameters of the experiments influence which types of clusters are formed. Changing this parameter allows the synthesis of cluster-type compounds of different sizes and shapes.

Based on mass spectroscopy measurements it was suggested to be a dimer, but the difference of about 12-16 Da in the measurement results is perhaps evidence that these compounds may be tetramers or even hexamers. A similar result was observed in other mass measurements (

Figure S1). So it is an indication that it has broken over the oxygen bridge. Since it is very difficult to prepare single crystals, the simplest unit was estimated from mass measurements.

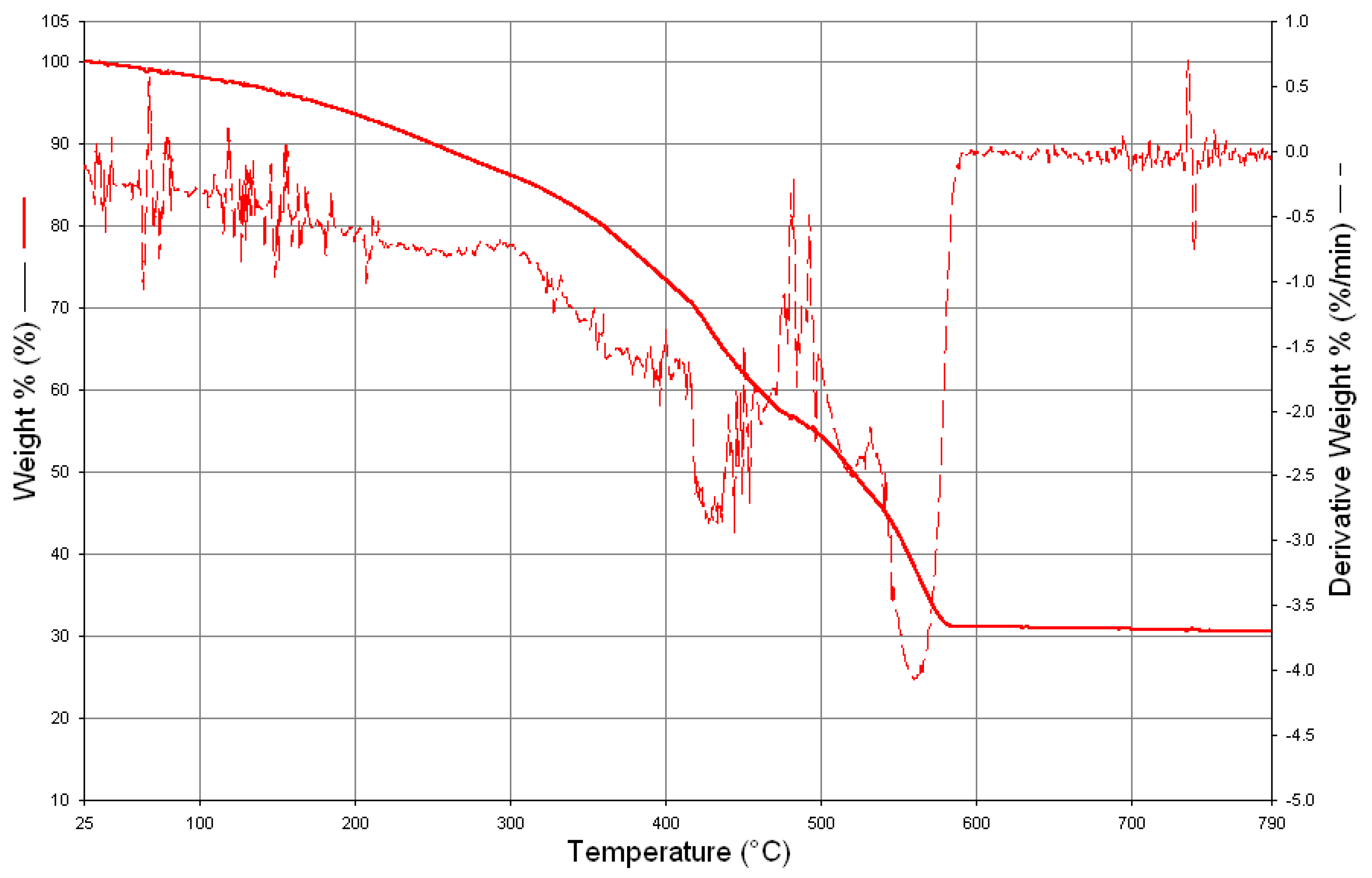

Thermogravimetric measurements of the compounds were also taken and interpreted to support or confirm the proposed

C1-C8 formulas by elemental analysis, H-NMR, and mass measurements. For instance, the thermal decomposition graph of compound-

2 (

C2), TGA of which was taken under artificial air flow, showed that it was stable up to 250

oC, with only a 10% weight loss up to this temperature. This may be a result of the removal of moisture and solvent impurities. Thermogravimetric analysis (TGA) of compound-

2 showed that the weight loss was considerable up to 580

oC, with a small amount from 580

oC to 700

oC. Another way of putting it, the complete degradation of compound-

2 to ZrO

2 continued until about 700

oC (calc. ZrO

2 weight was 32.05%). As seen in

Figure 5, the total weight loss up to 790

oC was found to be 69.51% by TGA (weight loss calculated from the proposed formula was 67.95%).

The difference between the calculated and measured weight loss based on the proposed formula (69.51-67.95=1.56%) also supported the proposed formula of compound-2.

All new compounds were characterized and formulated similar to the above zirconium compounds. After all these characterizations, the structures of compounds (

C1-C4) can be drawn as seen in

Scheme 1. The open structure of

C5-C8 is the same as

C1-C4, except that butoxide groups are present instead of propoxide groups.

These zirconium compounds (

C1-C8) were utilized as catalysts to initiate the ring-opening polymerization (ROP) of Ɛ-CL under different experimental conditions. In ROP reactions using single-ended metal alkoxide compounds as catalysts, alkoxide groups are the active groups initiating the polymerization. In methy/

tbutyl-salicylate zirconium compounds, the polymerization of Ɛ-caprolactone by n-propoxide or n-butoxide group was also initiated. The chemical and physical properties of PCL polymers obtained from ROP of Ɛ-CL were determined by

1H,

13C NMR, FTIR, and GPC measurements. In the

1H NMR spectra of polycaprolactone (PCL), peaks were assigned as follows: δ 4.07 ppm (H

ε), δ 2.31 ppm (H

α) δ 1.39 (H

γ) and 1.66 ppm (H

β+δ), characterizing the polymer chain (

Figure 6). (Pure Ɛ-caprolactone:

1H NMR (CDCl

3) δ: 4.23 (m, ε-CH

2), 2.64 (m, α-CH

2), 1.86 (m, δ-CH

2), 1.77 (m, β-CH

2 + γ-CH

2)). In the

13C NMR spectrum of PCL, peaks were assigned as follows: 173.79 (C=O), 64.38 (

εCH

2O), 34.34 (

αCH

2), 28.57 (

δCH

2), 25.75 (

βCH

2), 24.80 (

γCH

2). [O=C-

αCH

2βCH

2γCH

2δCH

2εCH

2O-]. These values are consistent with those in the literatures [

23,

24].

The improvement of “single-site” metal alkoxide catalysts has been an important target to understand the mechanism of ring opening polymerization (ROP) and to produce polymers with controllable molecular weights and polydispersities [

25,

26]. Single-site metal alkoxide compounds containing different auxiliary ligands were synthesized and used as efficient initiators with high catalytic activities for the controlled polymerization of Ɛ-CL [

26,

27]. Considering the catalytic advantages of single-site metal alkoxy complexes, new catalysts have been synthesized between salicylate ligands containing electron donating groups and zirconium alkoxides. Since

C1-C8 compounds have active alkoxide group (one alkoxide for every Zr atom), these complexes as catalysts were utilized for activity towards ROP of Ɛ-CL.

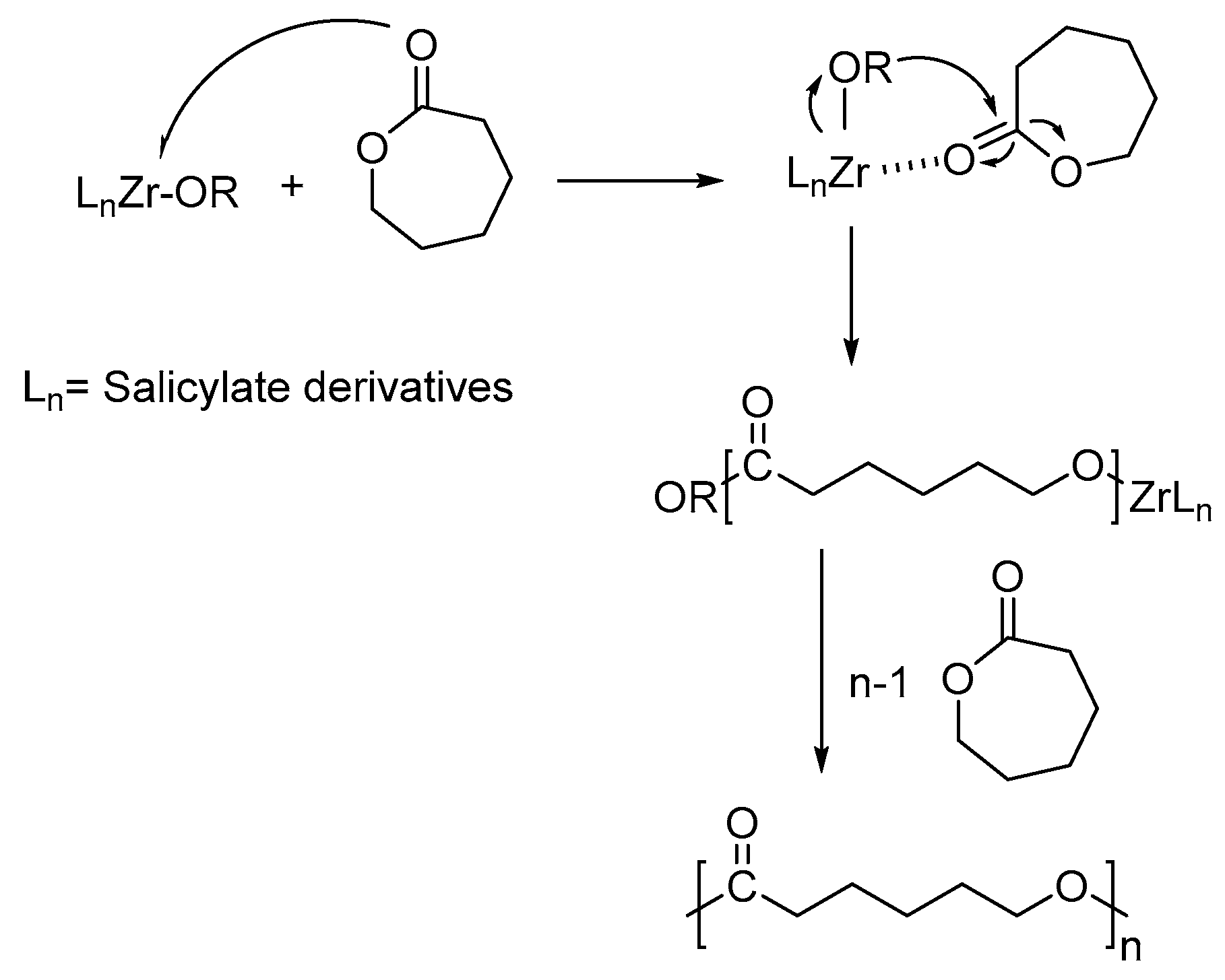

The reaction mechanism starting from Ɛ-caprolactone and continuing until PCL formation is shown in

Scheme 2. Zirconium complexes bearing salicylate ligands (

C1-C8) performed ROP of Ɛ-caprolactone through a coordination-insertion mechanism. Interpretation of the results obtained from spectroscopic measurements shows that Ɛ-CL first attacks the zirconium atom and then the nucleophile O

nPr

- or O

nBu

- ion attacks the O-C=O carbon atom in Ɛ-CL and the reaction proceeds in this way

8.

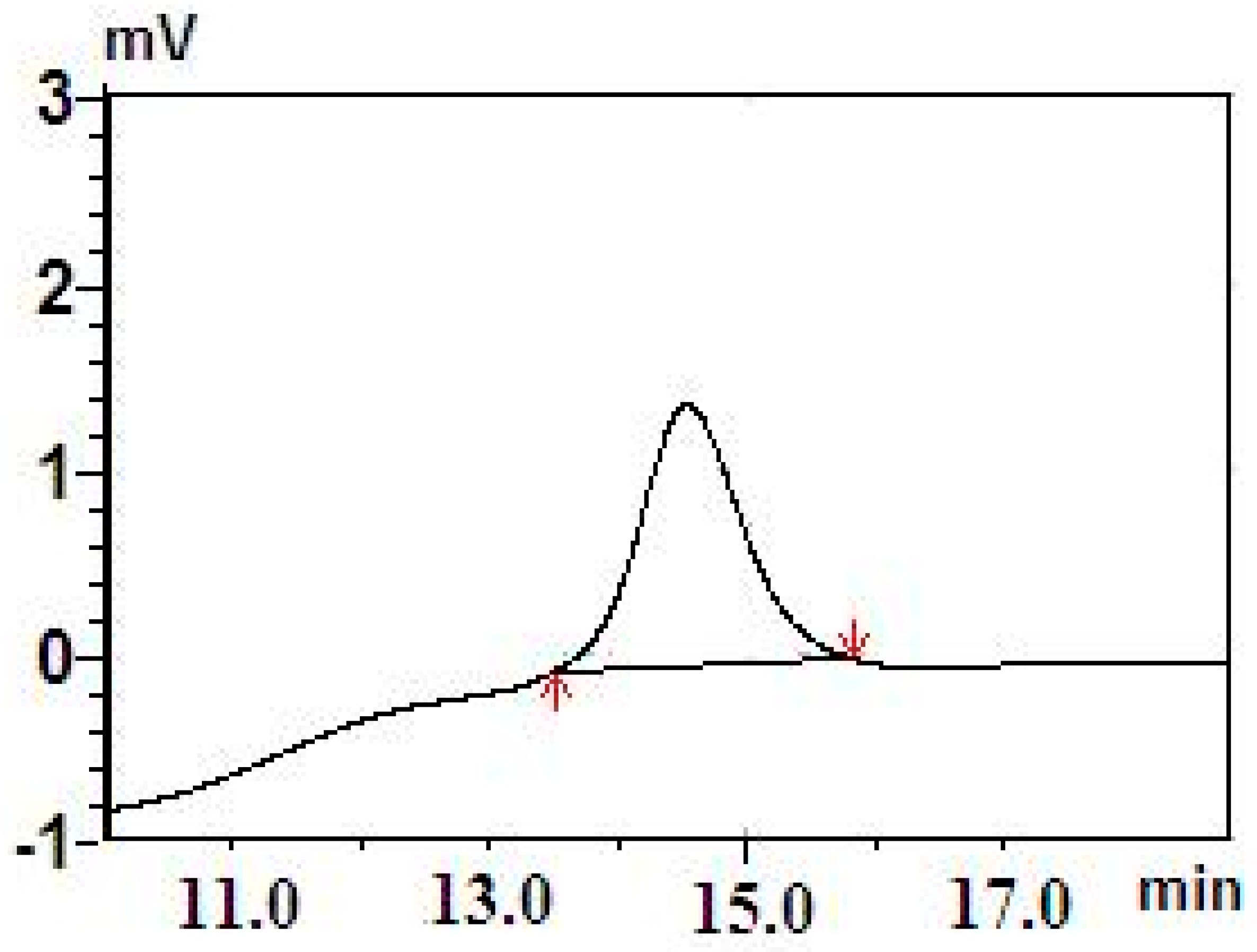

GPC was used to determine the percentage conversion of Ɛ-CL monomers to PCL, whether the polymer formed was viable, whether it contained different phases, the molecular weight (

Mw) and molecular weight distribution index (PDI:

Mw/Mn) of PCL. The PCL with different average

Mw or number average

Mn were obtained at 90-110

oC for different hours stirring (

Table 1 and

Table 2). For PCL prepared by stirring with catalyst

C7 at 110

oC for 24 hours, the main peak appeared at 18905 Da for weight average molecular weight (

Mw) and at 14617 Da for number average molecular weight (

Mn). The ratio of the

Mw/Mn was 1.29 (

Figure 6). As can be seen from

Table 1 and

Table 2, in addition to temperatures and times, the molecular weights of PCL also changed due to the change in the position and composition of the electron-donating groups on the salicylate derivatives connected to zirconium. In conclusion, both the electron donating power and resonance effects of functional organic groups (Me,

tBu, OH, and COO) on salicylate parts were important for the activity of the alkoxy group attached to the central zirconium atom. Due to the electron donating groups, electrons increase on both the salicylate ligand and zirconium center. As the electron donating tendency of the substituent (Me and

tBu) on the salicylate ligand increases, the Lewis acidity of the zirconium center will decrease. Hence, Ɛ-CL monomers will be somewhat slower to readily attack the zirconium center to initiate ring opening polymerization of Ɛ-CL compared to those containing electron-withdrawing groups. But the easiest and most controlled way to synthesize a ~30000 Da PCL is to work with electron server groups. The steric effect may be the reason why the catalysts (

C4 and C8) containing

tertbutyl group are weaker in polymerization. Due to the large steric effect, the Ɛ-CL monomer has difficulty in binding to the zirconium center. When the substituted groups on the salicylate and other experimental parameters are the same, if there is a difference in activity in the catalyst reaction, it is due to the difference in alkoxy groups attached to the zirconium. For example, the

C2 catalyst formed a PCL of 9150 Da in 24 hours at 110

oC, while the

C6 catalyst formed a PCL of 5110 Da under the same conditions. The only reason for this difference was the different alkoxy groups attached to zirconium. Zirconium compounds (

C1-C8) containing salicylate ligands with electron donating groups on them were effective catalysts for the synthesis of PCL from ε-caprolactone by ring-opening polymerization with average size compared with known metal alkoxy catalysts. PCLs with an average size of 10000-30000 Da are used in important areas such as drug release because they dissolve more easily compared to large-molecule PCLs [

1,

28]. Zirconium compounds of salicylate ligands containing electron donating groups formed polymers with lower molecular weight and lower poly dispersity indices than Zirconium compounds of salicylate ligands containing electron withdrawing groups in Ɛ-caprolactone polymerization [

19].

C7, (24 h, 110 oC).

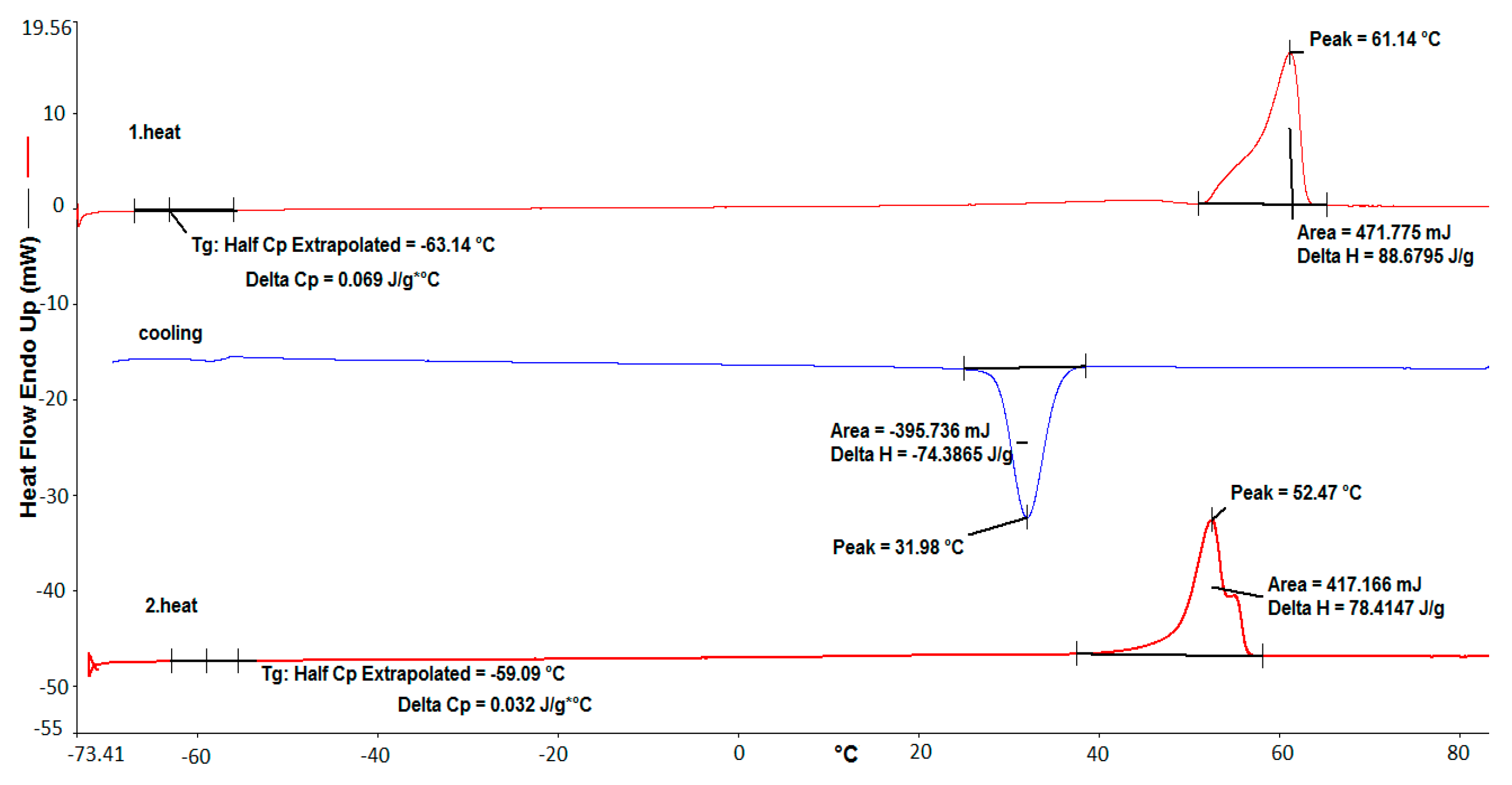

DSC analysis was performed to determine the melting point and degree of crystallinity of PCL prepared with

C7 (

Figure 7). As seen in the

Figure 7, PCL had a melting temperature at 61.14

oC, an enthalpy of melting at 88.68 j/g and a glass transition temperature at -63.14

oC.

In the DSC curve, the initial temperature of crystallization was evident at approximately 37 °C. The crystallization exotherm peak with a maximum appeared at 31.98 °C. The TGA measurement of

C8, which exhibits similar behavior, is given in

Figure S2. These DSC data are in agreement with published papers on the physical properties of polycaprolactone

29.