Submitted:

12 June 2024

Posted:

13 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiment

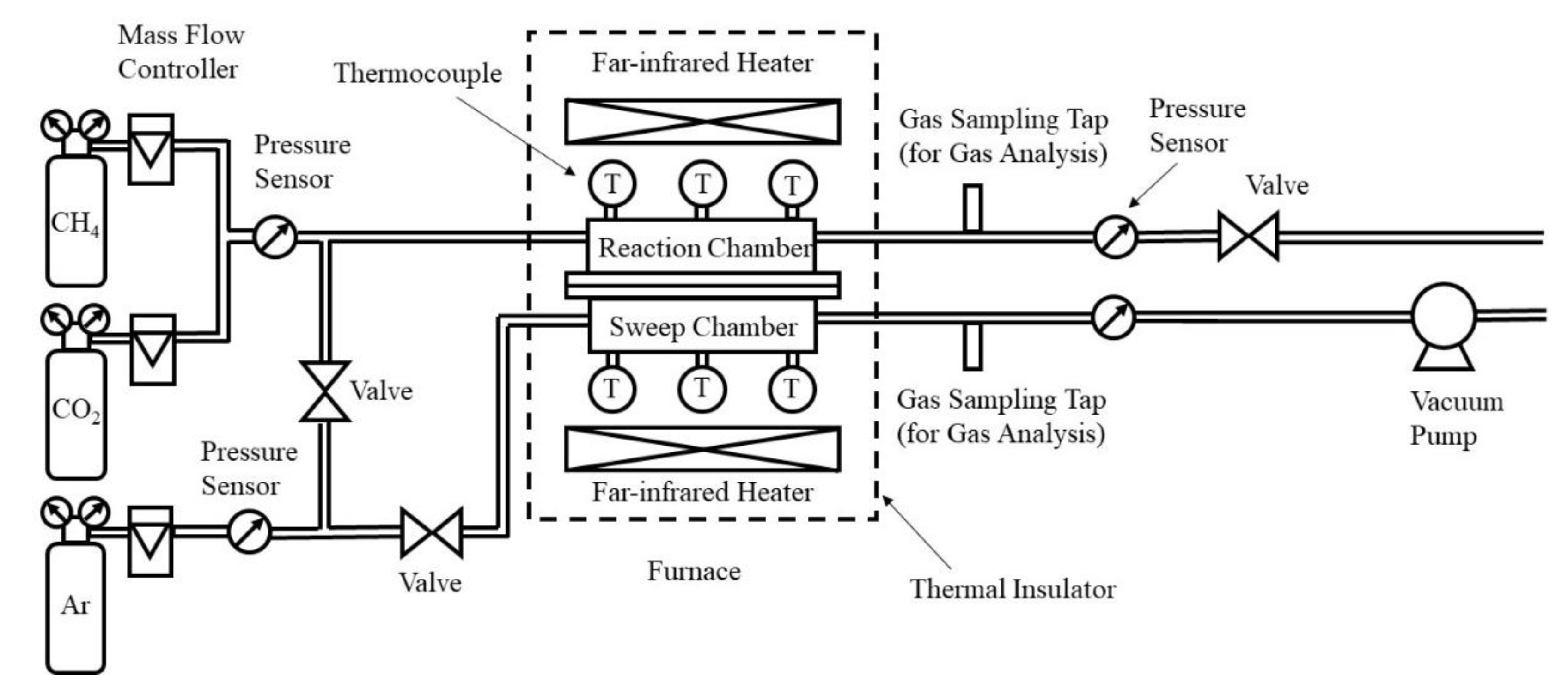

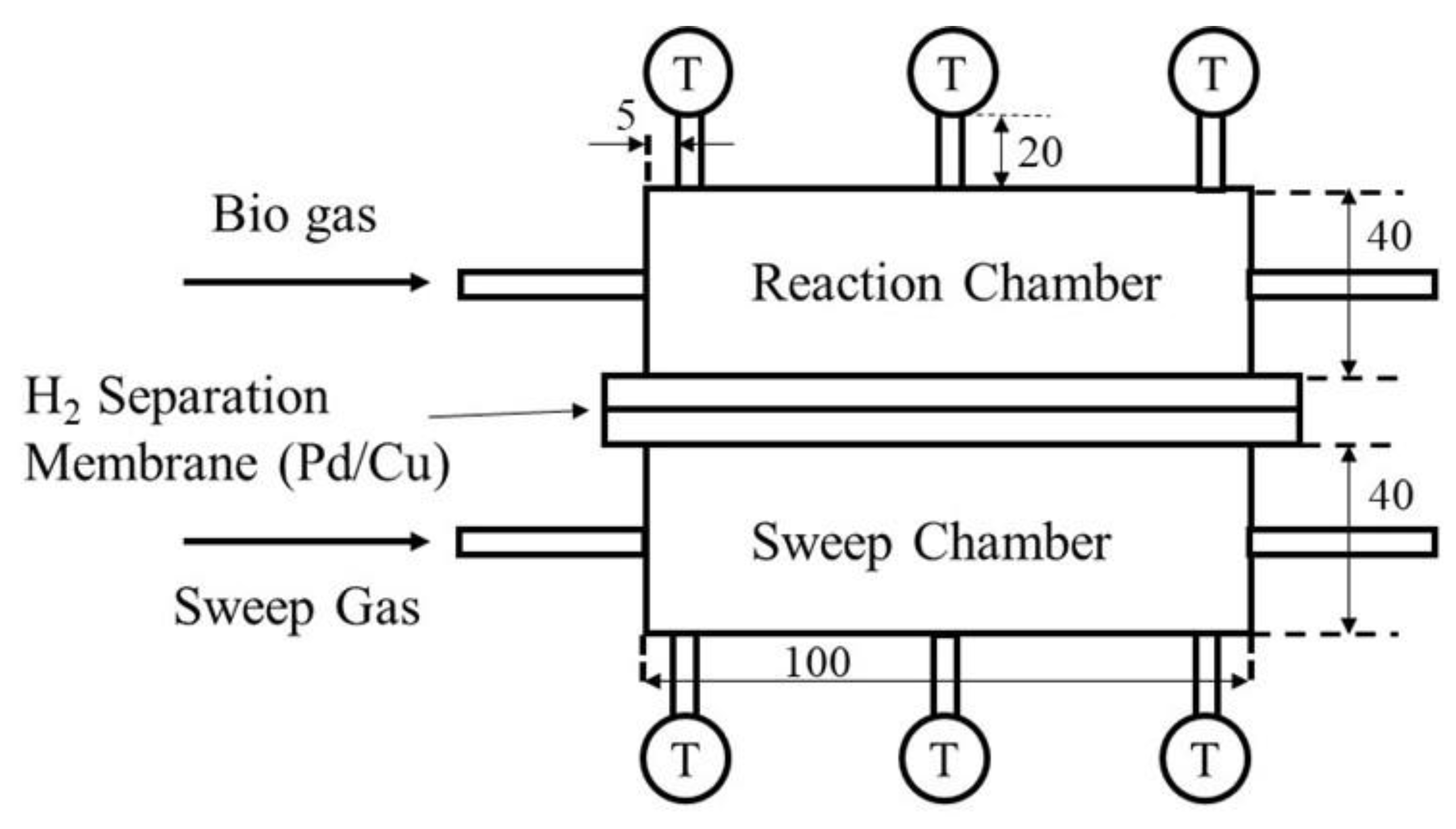

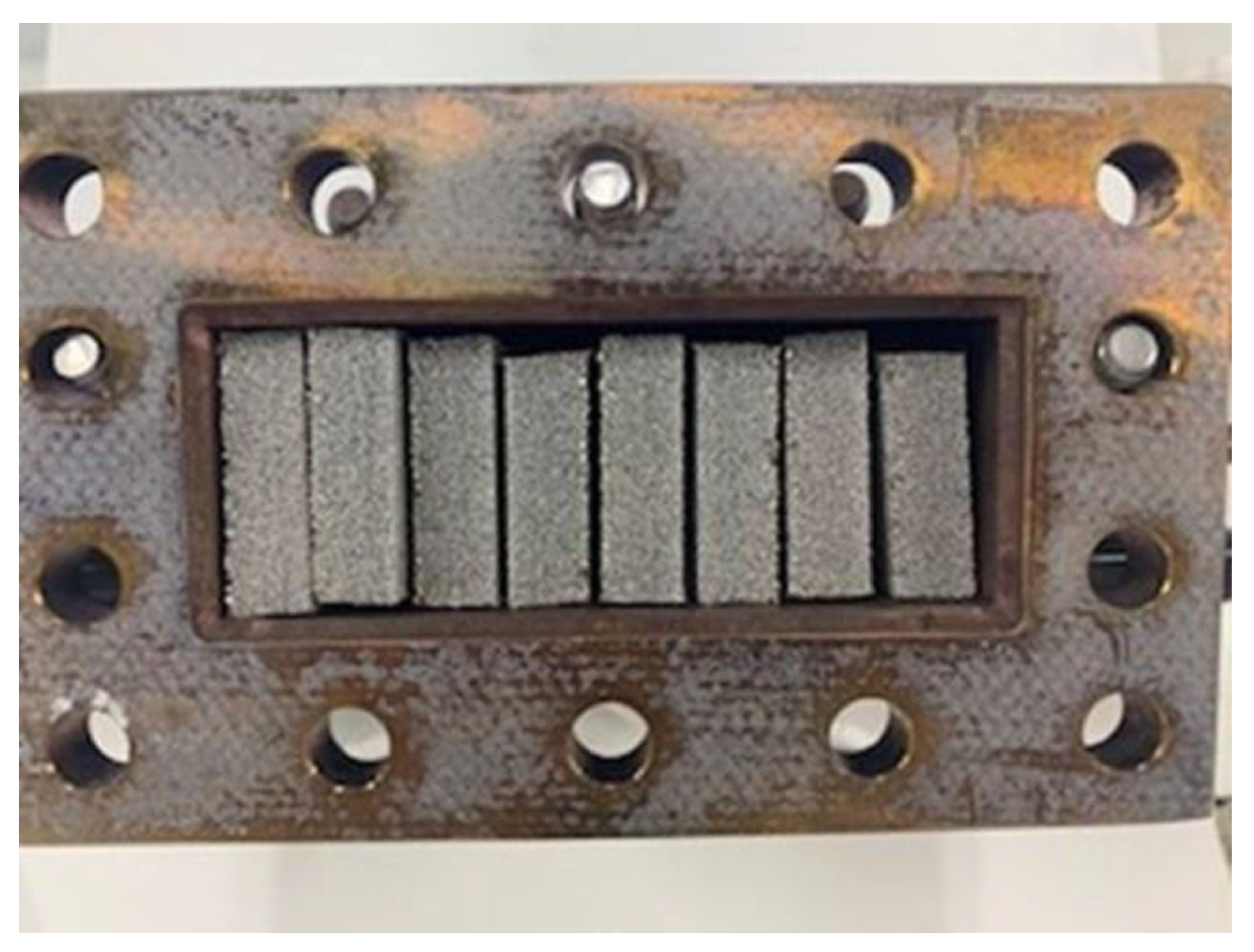

2.1. Experimental Apparatus

2.2. Assessment Factor to Evaluate the Performance of Membrane Reactor

3. Results and Discussion

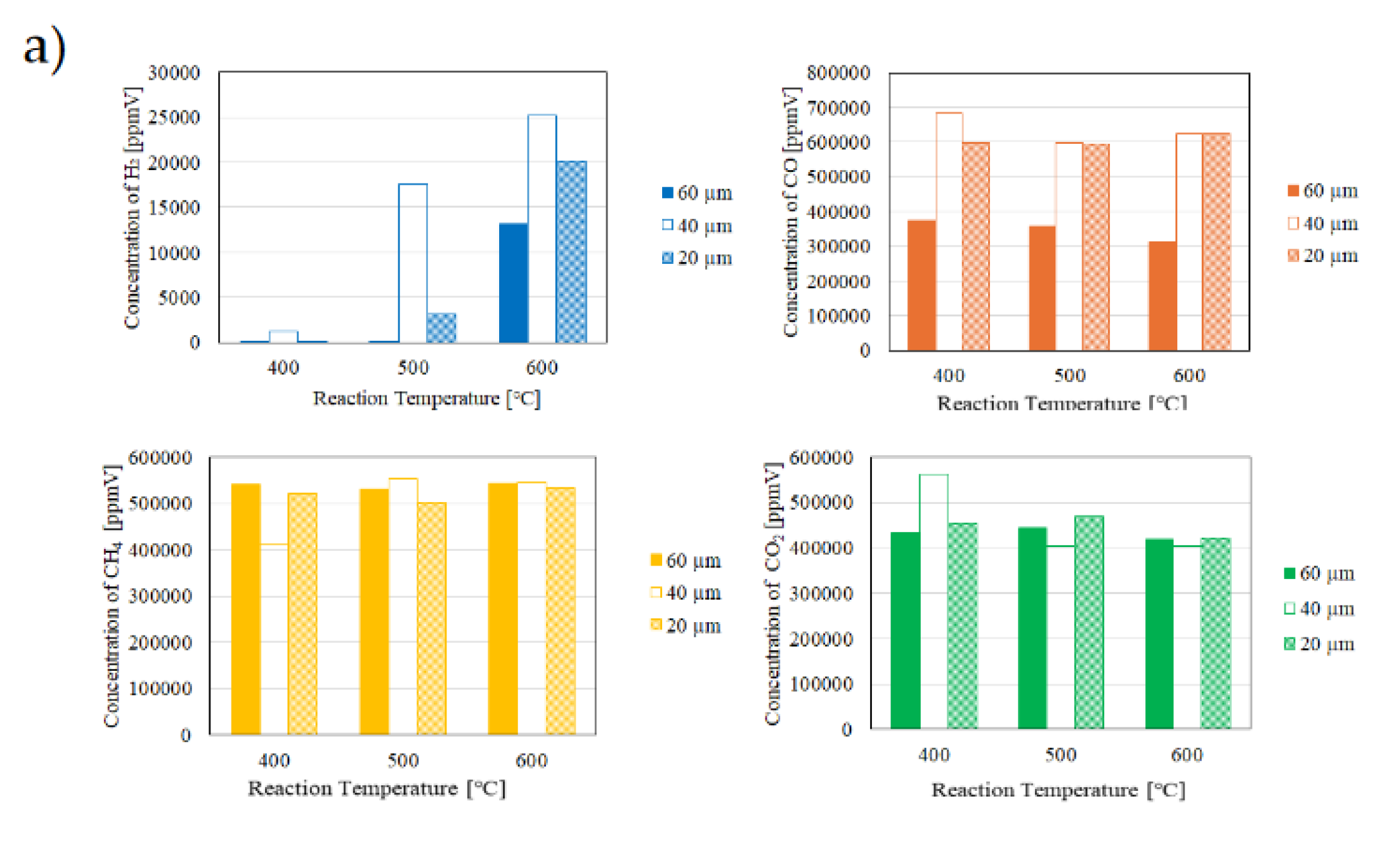

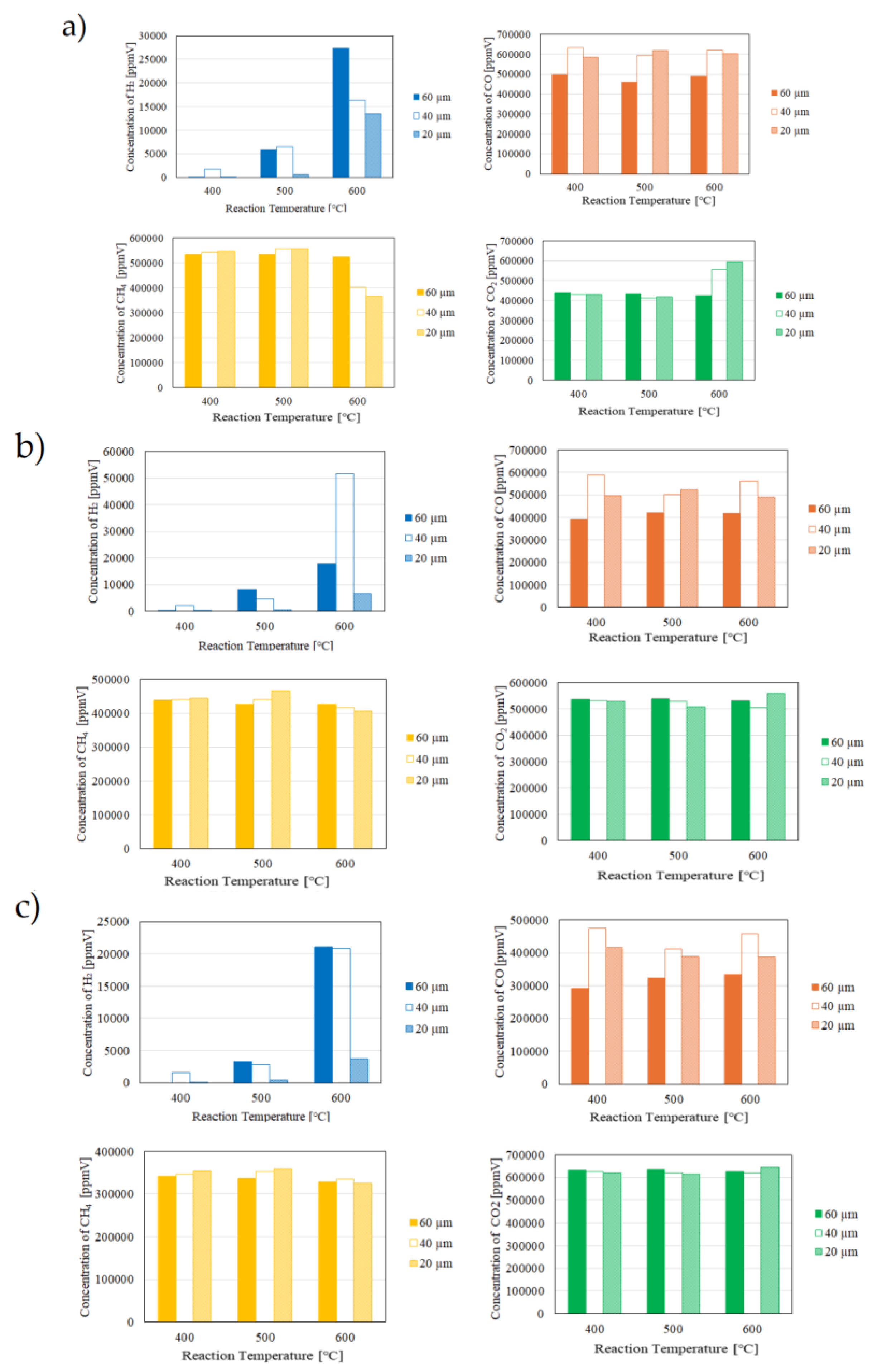

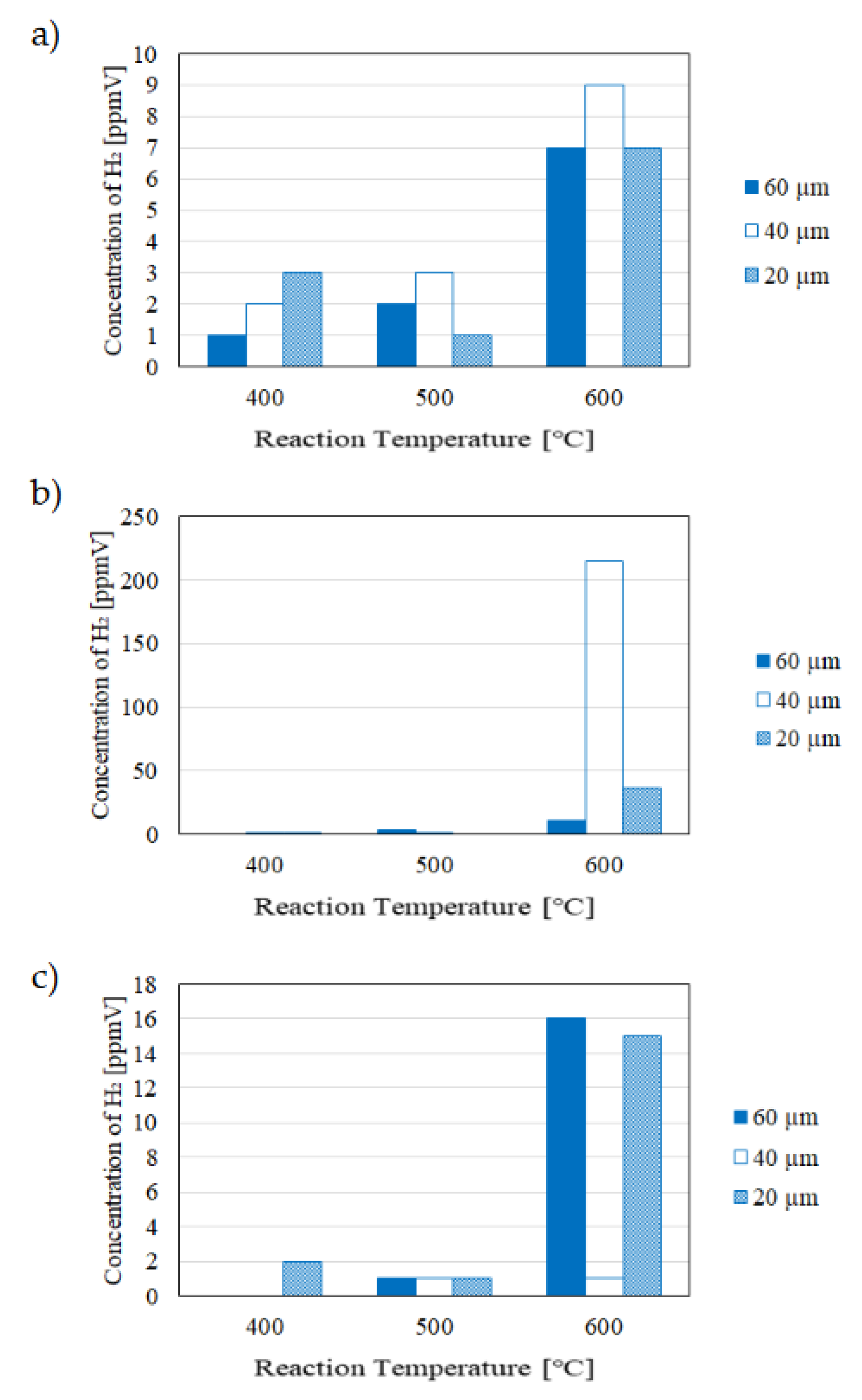

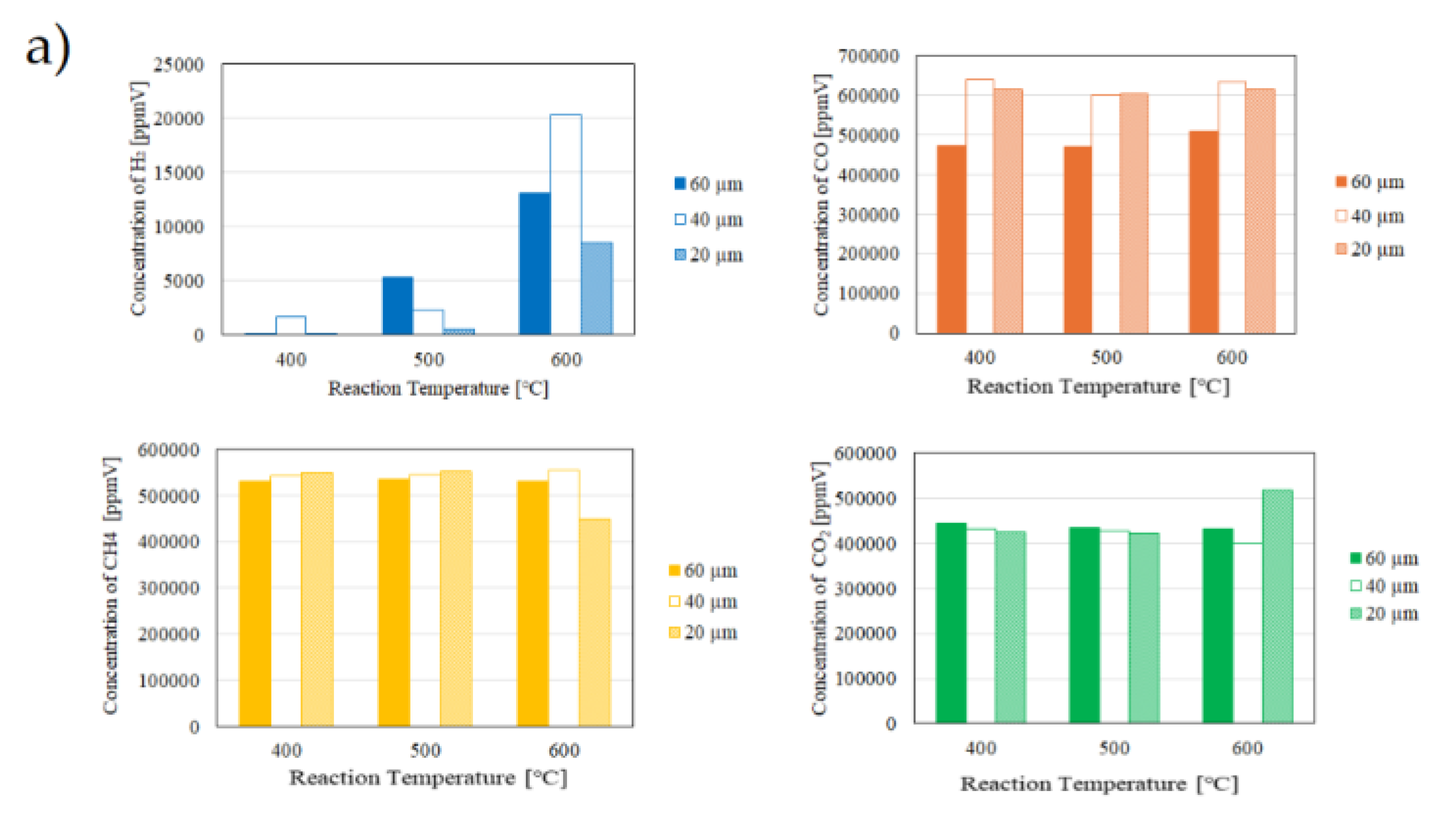

3.1. Impact of Initial Reaction Tempreature and Molar Ratio of CH4:CO2

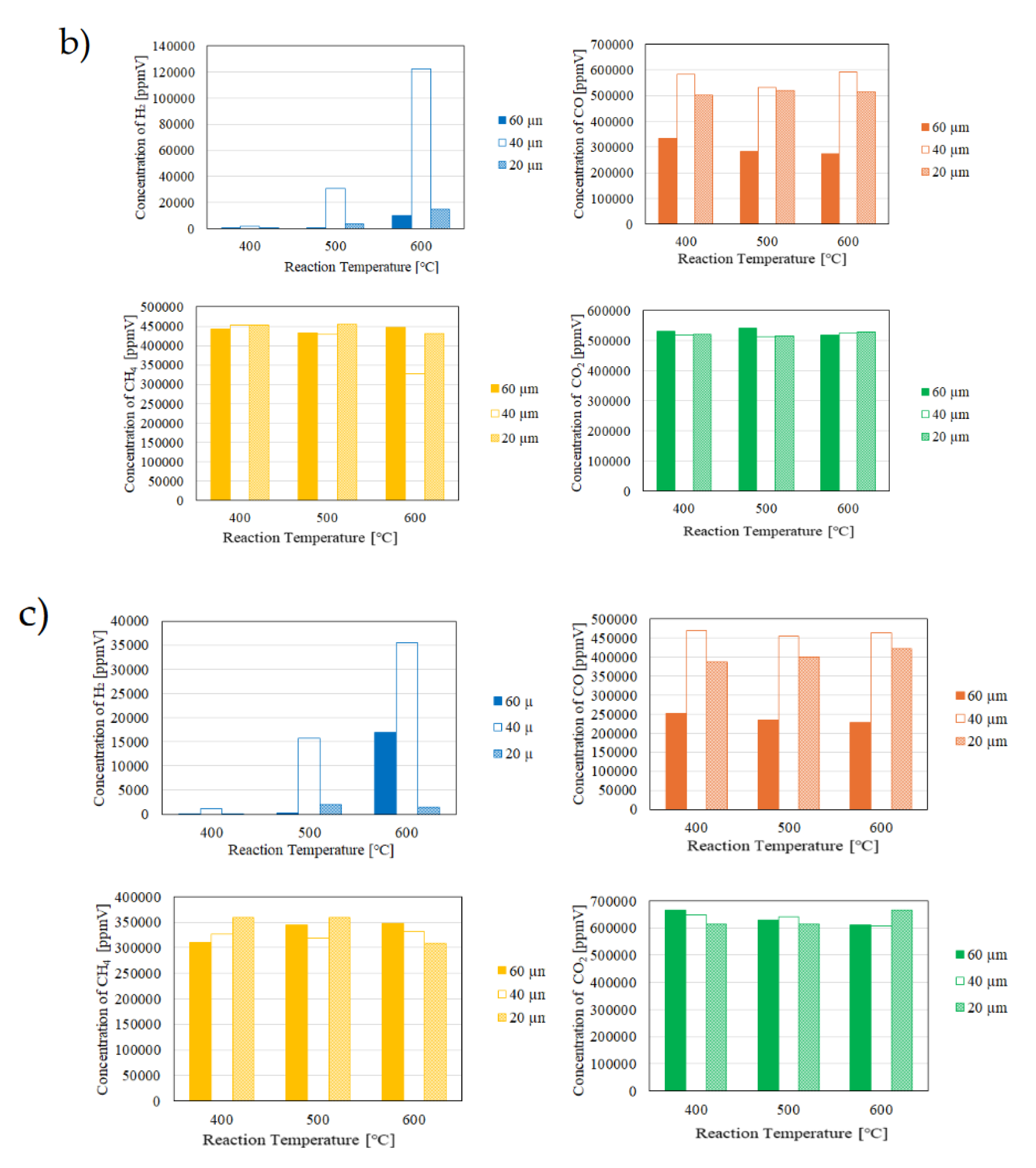

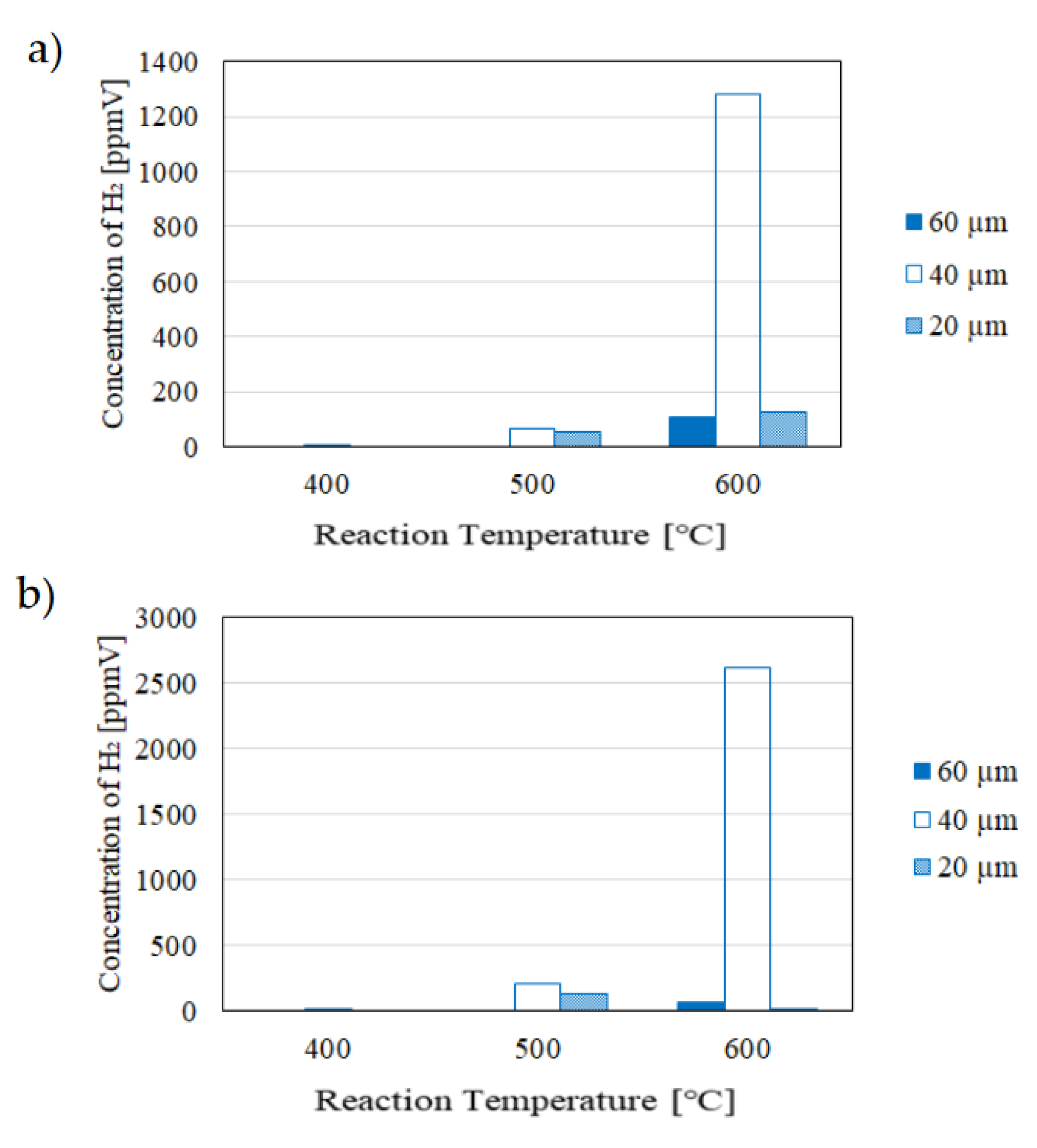

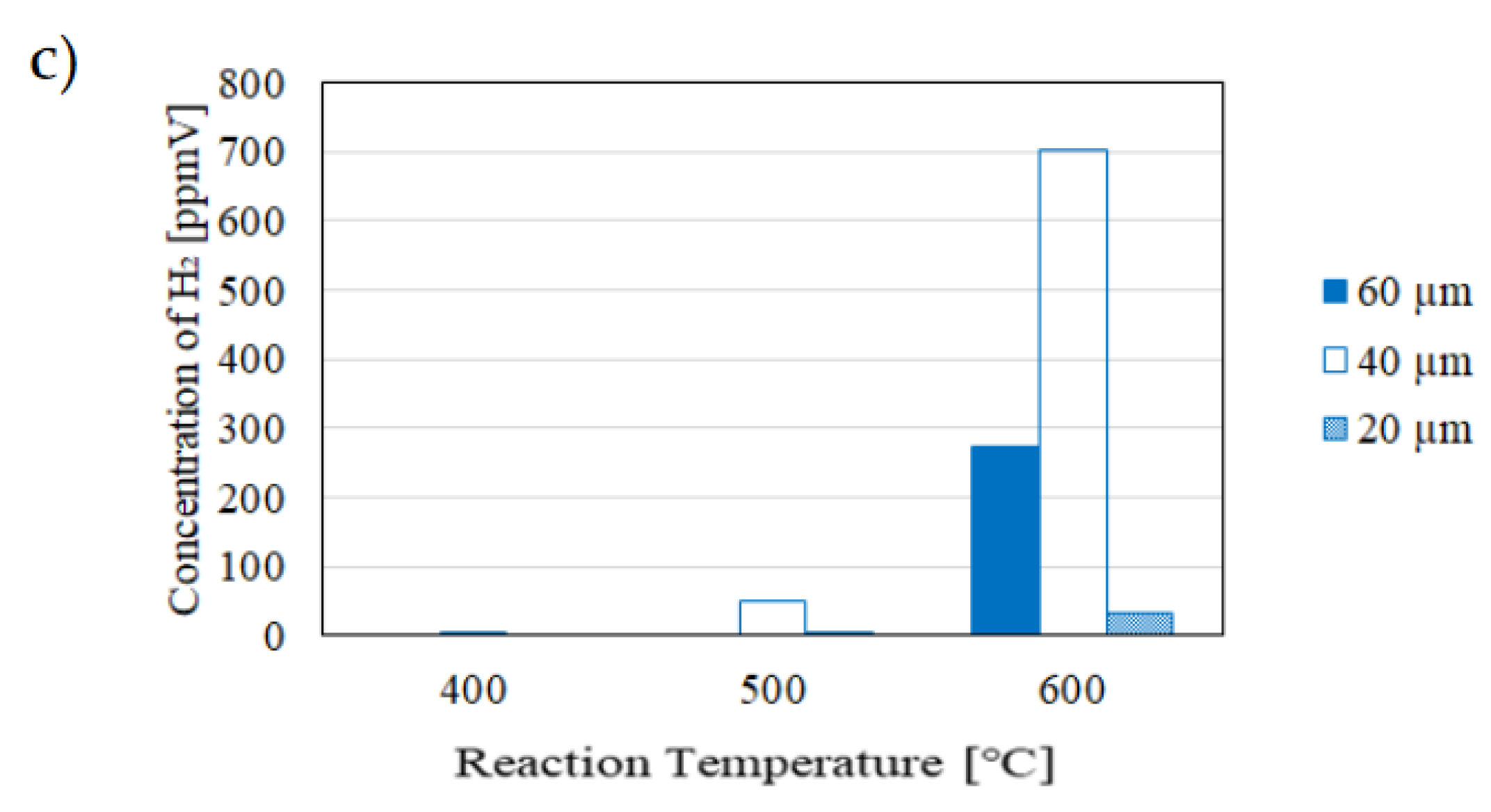

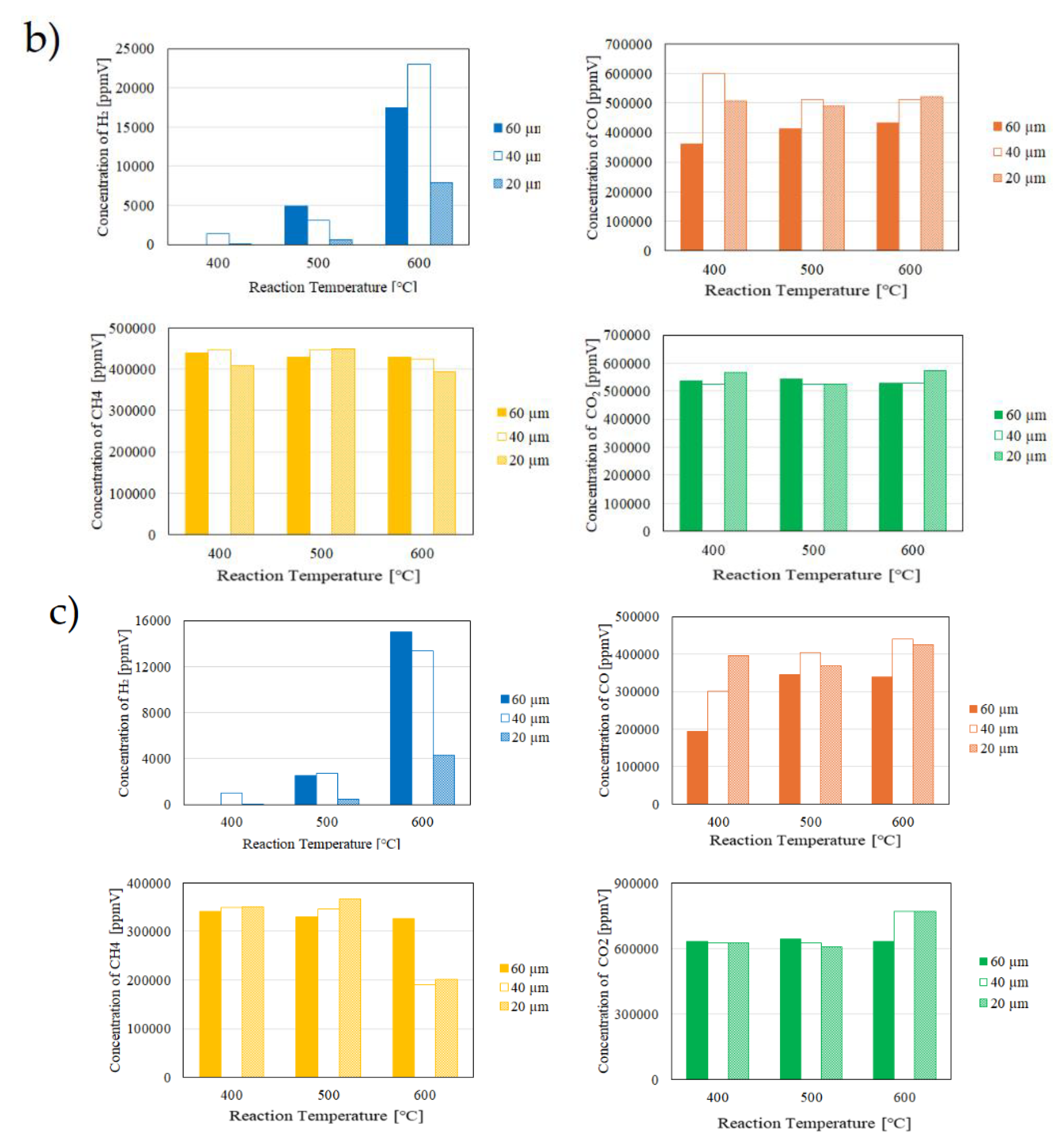

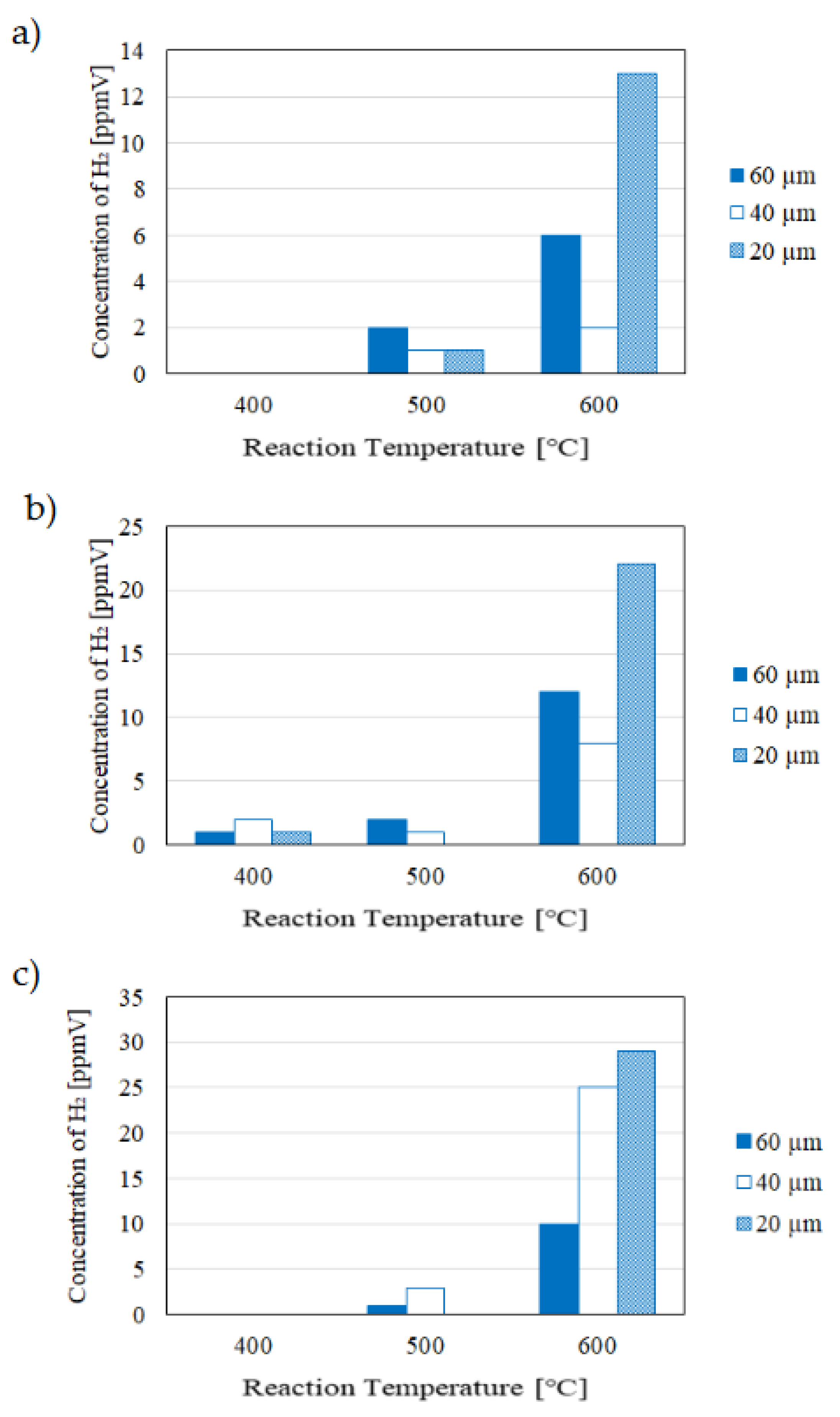

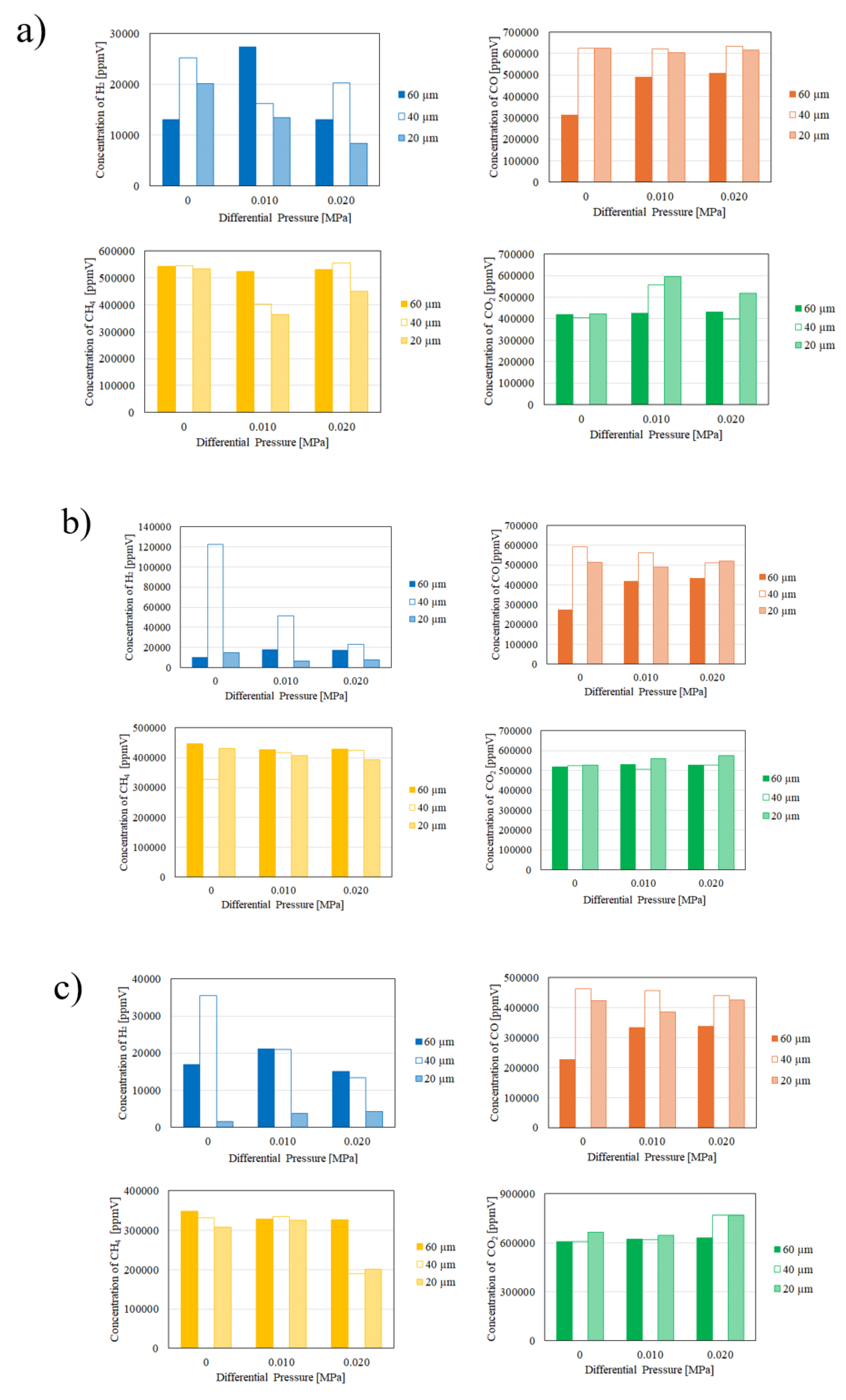

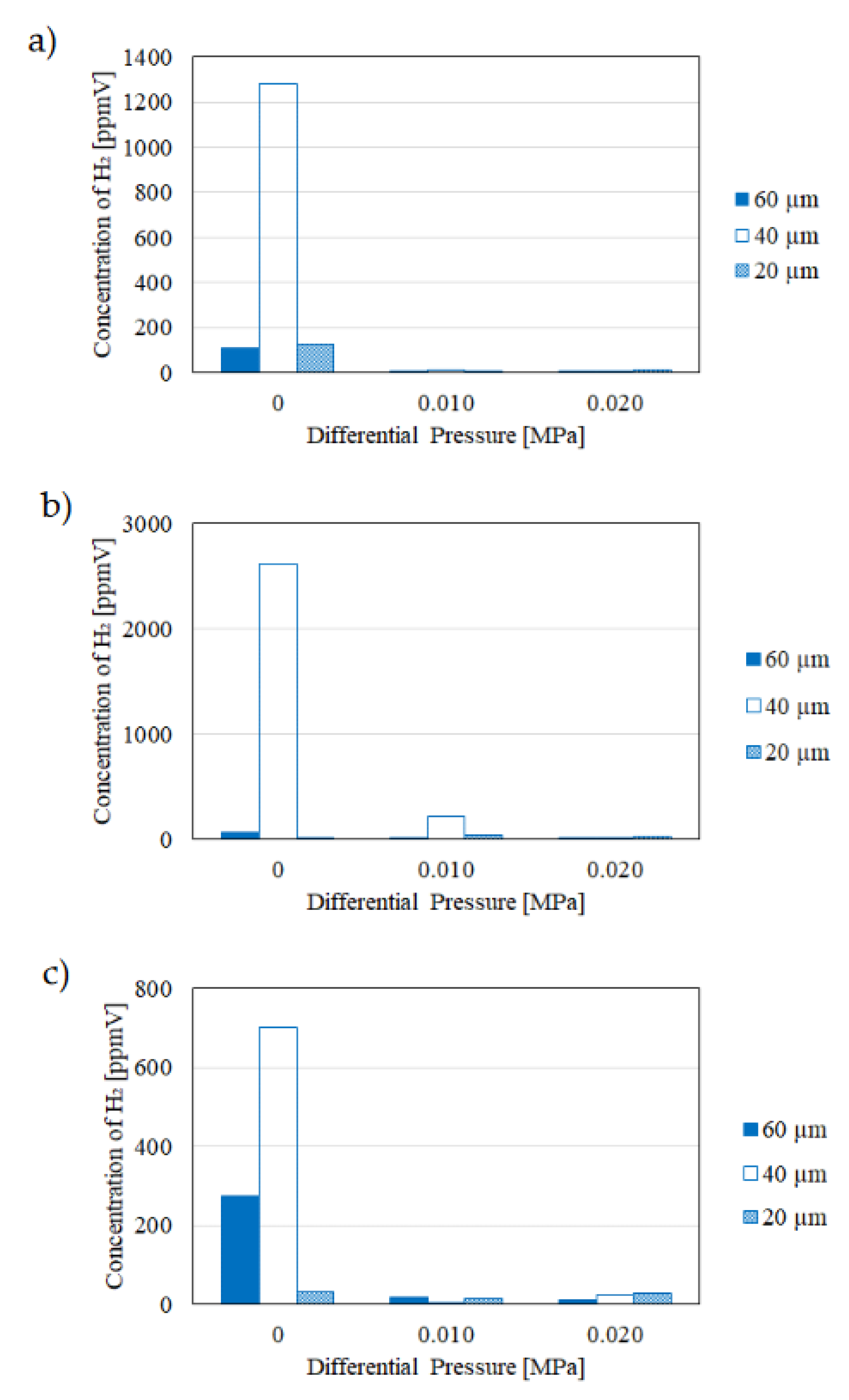

3.2. Impact of Differential Pressure between the Reaction Chamber and the Sweep Chamber

3.3. Comparison of Assessment Factor among the Investigated Experimental Conditions

- (i)

- H2 is produced by Equation (1) or Equation (5).

- (ii)

- CO is produced after consuming H2 via Equation (2).

- (iii)

- Carbon and CO2 are produced after consuming a part of CO via Equation (6).

4. Conclusions

- (1)

- The concentration of H2 at the outlet of reaction chamber increases with the increase in the reaction temperature irrespective of the molar ratio of CH4:CO2, the thickness of Pd/Cu membrane and the differential pressure between the reaction chamber and the sweep chamber. In addition, the concentration of H2 at the outlet of the sweep chamber also increases with the increase in the reaction temperature.

- (2)

- At the differential pressure of 0 MPa, the highest concentration of H2 in the reaction chamber as well as the sweep chamber is obtained for the thickness of 40 m irrespective of molar ratio of CH4:CO2. At the differential pressure of 0.020 MPa, the concentration of H2 in the sweep chamber for the thickness of 20 m is the highest among the investigated thicknesses, while the concentration of H2 at the outlet of the reaction chamber for the thickness of 20 m is the lowest among the investigated thicknesses irrespective of the molar ratio of CH4:CO2. On the other hand, at the differential pressure of 0.010 MPa, the optimum thickness of Pd/Cu membrane obtaining the highest concentration of H2 in the reaction chamber as well as that in the sweep chamber is not clear.

- (3)

- The concentration of H2 at the outlet of the reaction chamber and the sweep chamber increases with the decrease in the differential pressure between the reaction chamber and the sweep chamber relatively irrespective of the molar ratio of CH4:CO2, respectively.

- (4)

- The reaction performed in this study can be proposed as follows: (i) H2 is produced by Equation (1) or Equation (5). (ii) CO is produced after consuming H2 via Equation (2). (iii) Carbon and CO2 are produced after consuming a part of CO via Equation (6).

- (5)

- The highest concentration of H2 is 122711 ppmV which is obtained in case of CH4:CO2 =1:1 at the reaction temperature of 600 ℃ and the differential pressure of 0 MPa using the Pd/Cu membrane whose thickness of 40 m. Under this condition, the kinetic rate is 0.86 mol/(m3・s) and the permeation flux is 0 mol/(m2・s). In addition, CH4 conversion, CO2 conversion, H2 yield, H2 selectivity, CO selectivity, H2 permeability and thermal efficiency is 13.7 %, -5.73 %, 1.51 %, 2.84 %, 97.2 %, 1.06×10-1 % and 11.0 %, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalai, D. Y.; Stangeland, K.; Jin, Y.; Tucho, W. M.; Yu, Z. Biogas dry reforming for syngas production on La promoted hydrotalcite-derived Ni catalyst. International Journal of Hydrogen Energy 2018, 43, 19438–19450. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics. Available online: https://worldbioenergy.org./global-bioenergy-statistics (accessed on 2 June 2024).

- The Japan Gas Association. Available online: https://www.gas.or.jp/gas-life/biogas/ (accessed on 2 June 2024).

- Nishimura, A.; Takada, T.; Ohata, S.; Kolhe, M. L. Biogas dry reforming for hydrogen through membrane reactor utilizing negative pressure. fuels 2021, 2. [Google Scholar]

- Nishimura, A.; Hayashi, Y.; Ito, S.; Kolhe, M. L. Performance analysis of hydrogen production for a solid oxide fuel cell system using a biogas dry reforming membrane reactor with Ni and Ni/Cr catalysts. fuels 2023, 4. [Google Scholar] [CrossRef]

- Nishimura, A.; Sato, R.; Hu, E. An energy production system powered by solar heat with biogas dry reforming reactor and solid oxide fuel cell. Smart Grid and Renewable Energy 2023, 14, 85–106. [Google Scholar] [CrossRef]

- Miao, C.; Chen, S.; Shang, K.; Liang, L.; Ouyang, J. Highly active Ni-Ru bimetallic catalyst integrated with MFI zeolite loaded cerium zirconium oxide for dry reforming of methane. ACS Applied Materials & Interfaces 2022, 14, 47616–47632. [Google Scholar]

- Schaffner, R. A.; Schwengber, C. A.; Kowalski, R. L.; Assis, N. S. G.; Domingues, R. C. P. R.; Yamamoto, C. I. , Alves, H. J. Dry reforming of methane: effect of different calcination temperatures of Al2O3 and Mg-Al2O3 supports on Ni catalysts. The Canadian Journal of Chemical Engineering 2021, 100, 3345–3356. [Google Scholar] [CrossRef]

- Kaviani, M.; Rezaei, M.; Alavi, S. M.; Akbari, E. High coke resistance Ni-SiO2@SiO2 core-shell catalyst for biogas dry reforming: effects of Ni loading and calcination temperature. Fuel 2022, 330. [Google Scholar] [CrossRef]

- Ha, Q. L. M.; Atia, H.; Kreyenschulte, C.; Lund, H.; Bartling, S.; Lisak, G.; Wohlrab, S.; Armbruster, U. Effects of modifier (Gd, Sc, La) addition on the stability of low Ni content catalyst for dry reforming of model biogas. Fuel 2022, 312. [Google Scholar]

- Hajizadeh, A.; Mohamadi-Baghmolaei, M.; Saady, N. M. C.; Zendehboudi, S. Hydrogen production from biomass through integration of anaerobic digestion and biogas dry reforming. Applied Energy 2022, 309. [Google Scholar] [CrossRef]

- Calgaro, C. O.; Lima, D. S.; Tonetto, R.; Perez-Lopez; O. W. Biogas dry reforming over Ni-Mg-La-Al catalysts: influence of La/Mg ratio. Catalysis Letters 2021, 151, 267–280. [Google Scholar] [CrossRef]

- Nishimura, A.; Ohata, S.; Okukura, K.; Hu, E. The impact of operating conditions on the performance of a CH4 dry reforming membrane reactor for H2 production. Journal of Energy Power Technologies 2020, 2. [Google Scholar] [CrossRef]

- Cherbanski, R.; Kotkowski, T.; Molga, E. Thermogravimetric analysis of coking during dry reforming of methane. International Journal of Hydrogen Energy 2023, 48, 7346–7360. [Google Scholar] [CrossRef]

- Pakhare, D.; Spivey, J. A review of dry (CO2) reforming of methane over noble metal catalyst. The Royal Society of Chemistry 2014, 43, 7813–7837. [Google Scholar] [CrossRef] [PubMed]

- Fontana, A. D.; Faroldi, B.; Cornaglia, L. M.; Tarditi, A. M. Development of catalytic membranes over PdAu selective films for hydrogen production through the dry reforming of methane. Molecular Catalysis 2020, 481. [Google Scholar] [CrossRef]

- Brunetti, A.; Fontananova, E. CO2 conversion by methane reactors. Journal of Nanoscience and Nanotechnology 2019, 19, 3124–3134. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Information |

| Initial reaction temperature (Pre-set reaction temperature) [℃] | 400, 500, 600 |

| Pressure of supply gas [MPa] | 0.10 |

| Differential pressure between the reaction chamber and the sweep chamber [MPa] | 0, 0.010 and 0.020 |

| Molar ratio of provided CH4 : CO2 (Flow rate of provided CH4 : CO2 [NL/min]) | 1.5:1, 1:1 and 1:1.5 (1.088:0.725, 0.725:0.725, 0.725:1.088) |

| Feed ratio of sweep gas to supply gas [-] | 1.0 |

| (a) | |||||||

| CH4 conversion [%] | CO2 conversion [%] | H2 yield [%] | H2 selectivity [%] | CO selectivity [%] | H2 permeability [%] | Permeation flux [mol/(m2・s)] | Thermal efficiency [%] |

| 400 ℃ | |||||||

| 0 MPa | |||||||

| 12.9 | -13.1 | 1.00×10-3 | 2.02×10-3 | 100 | 0 | 0 | 1.36×10-2 |

| 0.010 MPa | |||||||

| 9.14 | -7.46 | 4.28×10-4 | 8.77×10-4 | 100 | 58.5 | 5.00×10-3 | 2.40×10-3 |

| 0.020 MPa | |||||||

| 8.30 | -6.19 | 1.78×10-4 | 3.47×10-4 | 100 | 0 | 7.07×10-3 | 2.40×10-3 |

| 500 ℃ | |||||||

| 0 MPa | |||||||

| 16.2 | -17.3 | 2.62×10-1 | 5.24×10-1 | 99.5 | 1.62 | 0 | 2.74 |

| 0.010 MPa | |||||||

| 7.44 | -4.76 | 5.06×10-2 | 9.48×10-2 | 99.9 | 1.65×10-1 | 2.50×10-3 | 5.39×10-1 |

| 0.020 MPa | |||||||

| 8.05 | -5.69 | 4.34×10-2 | 8.65×10-2 | 99.9 | 1.92×10-1 | 3.54×10-3 | 4.62×10-1 |

| 600 ℃ | |||||||

| 0 MPa | |||||||

| 11.1 | -5.40 | 1.69 | 3.15 | 96.9 | 6.22×10-1 | 0 | 14.8 |

| 0.010 MPa | |||||||

| 39.2 | -49.1 | 1.12 | 2.19 | 97.8 | 5.19×10-2 | 5.00×10-4 | 9.90 |

| 0.020 MPa | |||||||

| 25.1 | -29.3 | 7.04×10-1 | 1.33 | 98.7 | 1.54×10-1 | 7.07×10-4 | 6.20 |

| (b) | |||||||

| 400 ℃ | |||||||

| 0 MPa | |||||||

| 9.37 | -4.37 | 1.51×10-3 | 3.03×10-3 | 100 | 0 | 0 | 1.70×10-2 |

| 0.010 MPa | |||||||

| 11.0 | -6.02 | 2.07×10-4 | 4.19×10-4 | 100 | 48.3 | 5.00×10-3 | 1.20×10-3 |

| 0.020 MPa | |||||||

| 18.2 | -13.2 | 3.49×10-4 | 6.90×10-4 | 100 | 28.6 | 7.07×10-3 | 2.80×10-3 |

| 500 ℃ | |||||||

| 0 MPa | |||||||

| 9.09 | -3.33 | 3.93×10-1 | 7.51×10-1 | 99.2 | 3.38 | 0 | 3.37 |

| 0.010 MPa | |||||||

| 6.73 | -1.60 | 6.26×10-2 | 1.20×10-1 | 99.9 | 0 | 2.50×10-3 | 5.54×10-1 |

| 0.020 MPa | |||||||

| 10.0 | -4.92 | 5.41×10-2 | 1.10×10-1 | 99.9 | 0 | 3.54×10-3 | 4.79×10-1 |

| 600 ℃ | |||||||

| 0 MPa | |||||||

| 13.7 | -5.73 | 1.51 | 2.84 | 97.2 | 1.06×10-1 | 0 | 11.0 |

| 0.010 MPa | |||||||

| 18.4 | -12.1 | 6.56×10-1 | 1.32 | 98.7 | 5.49×10-1 | 5.00×10-4 | 4.78 |

| 0.020 MPa | |||||||

| 21.4 | -14.8 | 7.97×10-1 | 1.51 | 98.5 | 2.76×10-1 | 7.07×10-4 | 5.82 |

| (c) | |||||||

| 400 ℃ | |||||||

| 0 MPa | |||||||

| 10.0 | -2.50 | 1.34×10-4 | 2.76×10-4 | 100 | 0 | 0 | 1.20×10-3 |

| 0.010 MPa | |||||||

| 11.4 | -3.40 | 5.15×10-4 | 9.89×10-4 | 100 | 48.6 | 5.00×10-3 | 2.37×10-3 |

| 0.020 MPa | |||||||

| 12.3 | -4.03 | 2.75×10-4 | 5.56×10-4 | 100 | 0 | 7.07×10-3 | 2.47×10-3 |

| 500 ℃ | |||||||

| 0 MPa | |||||||

| 10.1 | -2.20 | 2.57×10-1 | 5.11×10-1 | 99.5 | 1.46×10-1 | 0 | 1.82 |

| 0.010 MPa | |||||||

| 10.0 | -2.43 | 5.15×10-2 | 1.06×10-1 | 99.9 | 2.43×10-1 | 2.50×10-3 | 3.64×10-1 |

| 0.020 MPa | |||||||

| 8.21 | -1.23 | 5.87×10-2 | 1.27×10-1 | 99.9 | 0 | 3.54×10-3 | 4.16×10-1 |

| 600 ℃ | |||||||

| 0 MPa | |||||||

| 22.9 | -10.9 | 1.95×10-1 | 3.68×10-1 | 99.6 | 2.05 | 0 | 1.12 |

| 0.010 MPa | |||||||

| 18.7 | -7.66 | 4.60×10-1 | 9.44×10-1 | 99.1 | 4.07×10-1 | 5.00×10-4 | 2.68 |

| 0.020 MPa | |||||||

| 49.5 | -28.1 | 5.38×10-1 | 1.00 | 99.0 | 6.74×10-4 | 7.07×10-4 | 3.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).