Submitted:

07 June 2024

Posted:

11 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

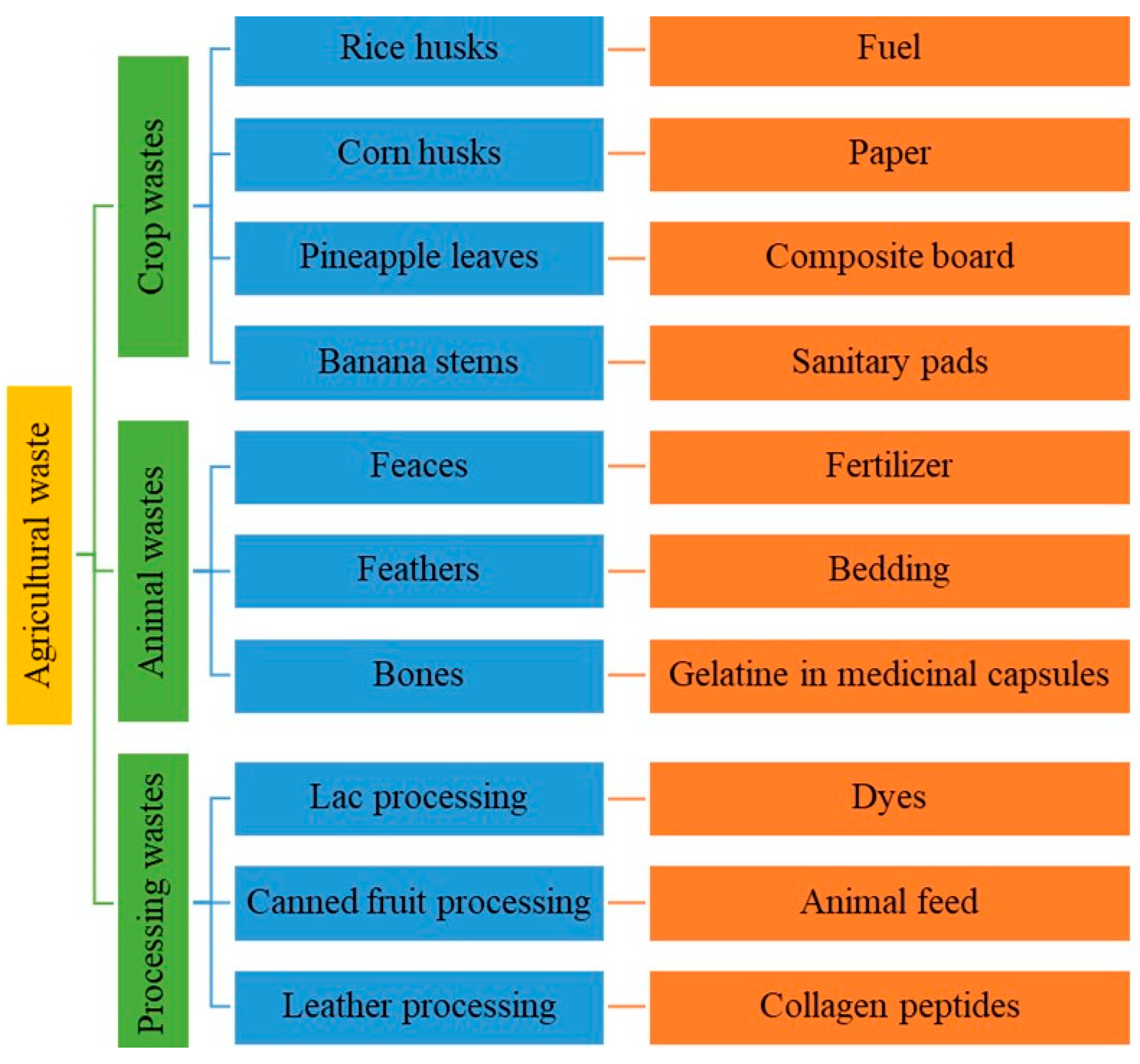

2. Converting Agricultural Waste to Wealth

2.1. Crop Waste

2.2. Animal Waste

2.3. Processing Waste

3. Agricultural Waste as Fiber Polymer-Reinforced Material

3.1. Physical and Mechanical Properties of Fibers

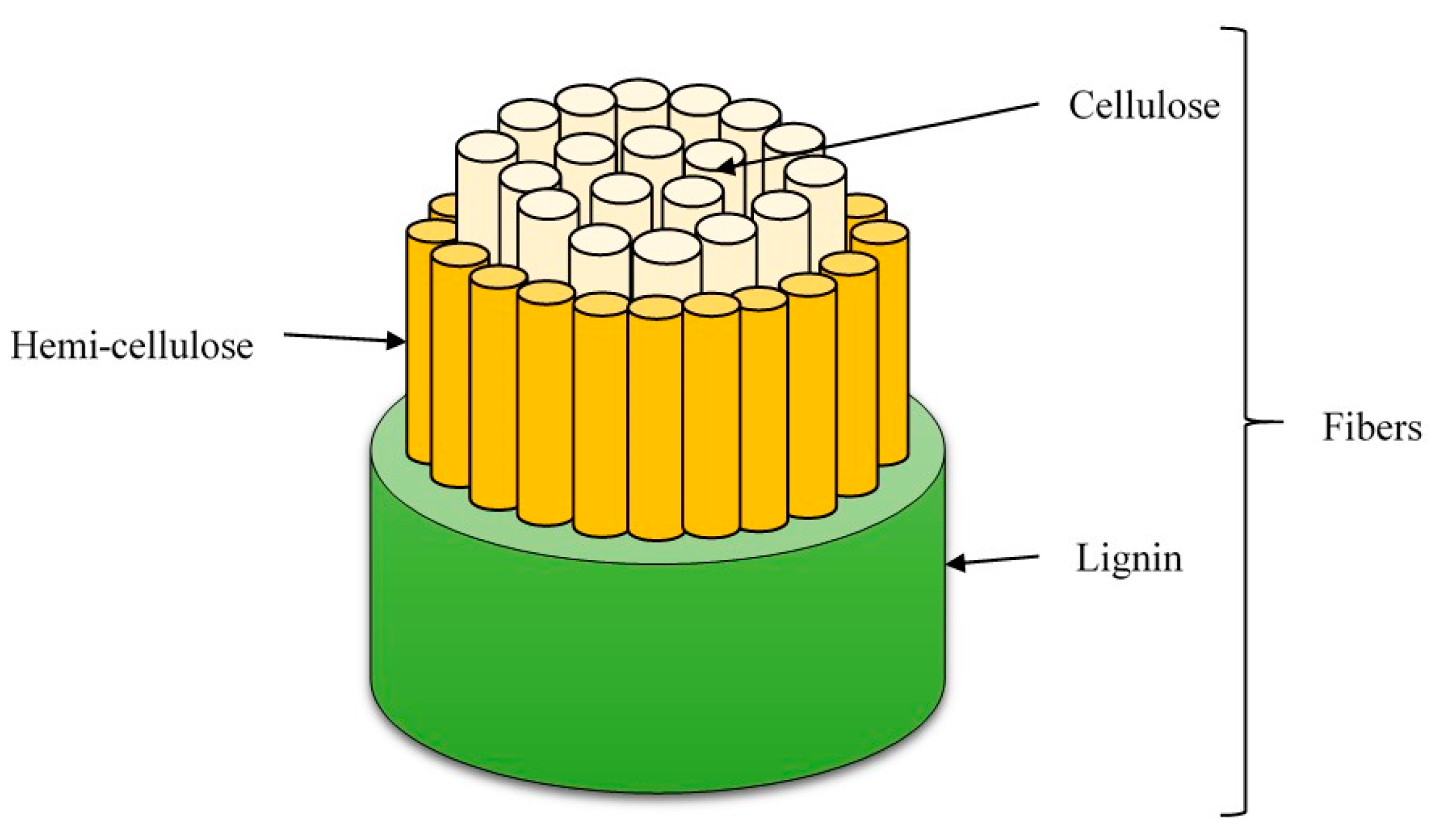

3.2. Chemical Properties of Fibers

4. Plant Fiber Composites for Structural Components

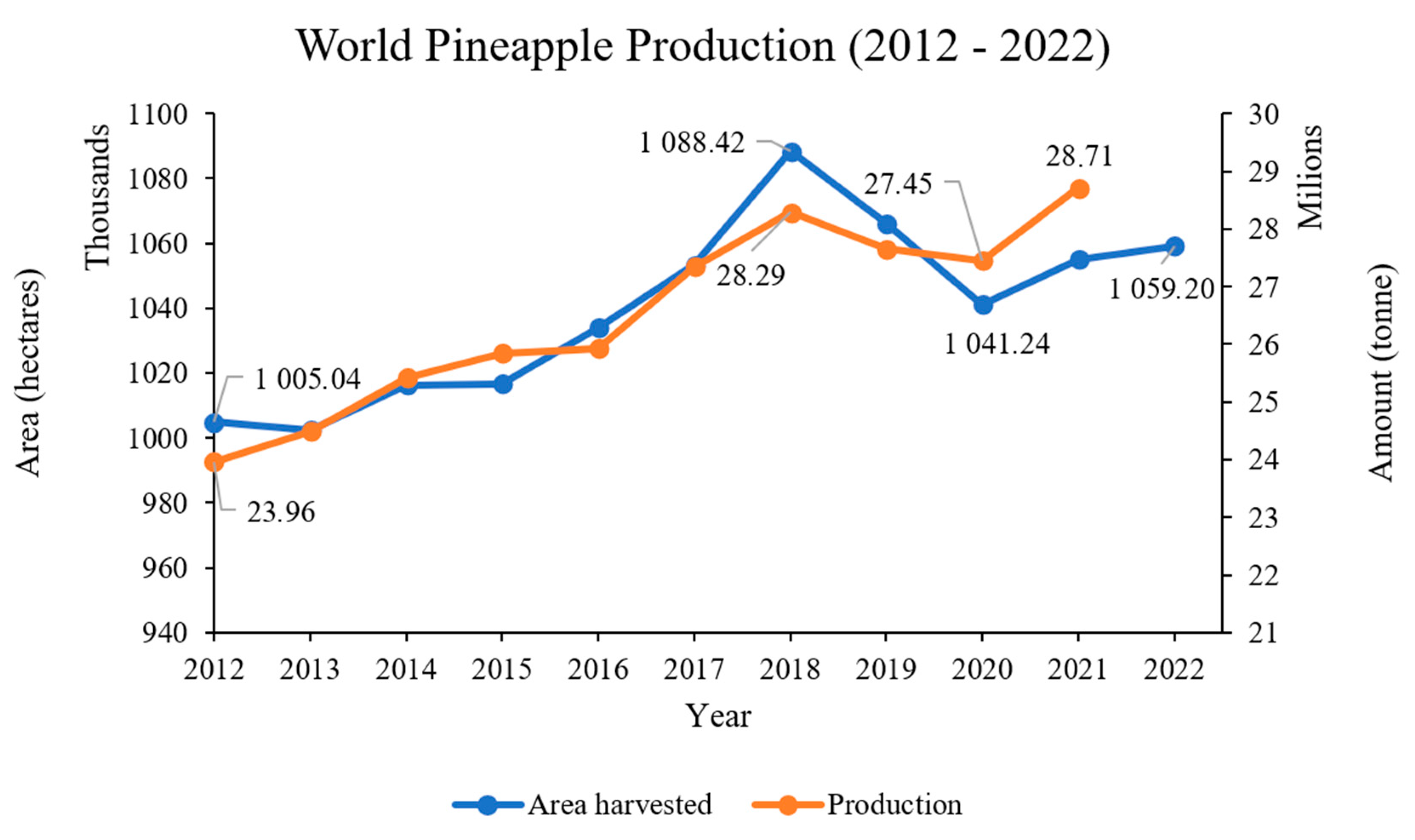

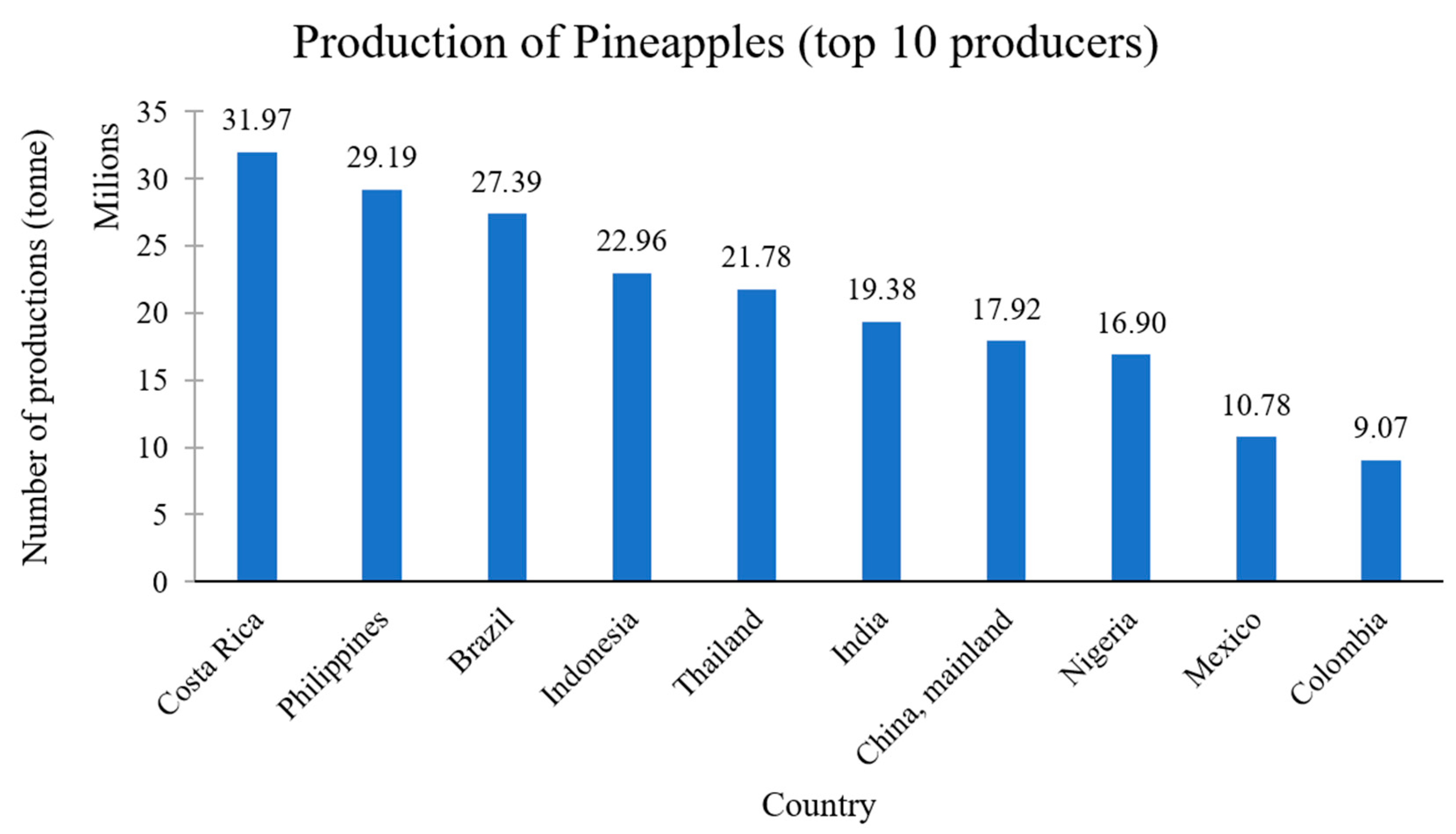

5. Possibility of Pineapple Leaf Fiber-Reinforced Composite as an Alternative in UAV Construction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adejumo, I.O.; Adebiyi, O.A. Agricultural Solid Wastes: Causes, Effects, and Effective Management. In Strategies of Sustainable Solid Waste Management; Saleh, H.M., Ed.; IntechOpen: London, UK, 2021; pp. 134–253. [Google Scholar]

- Ahmed, O.H.; Husni, M.H.A.; Awang Noor, A.G. The removal and burning of pineapple residue in pineapple cultivation on tropical peat: An economic viability comparison. PertanikaJ. Trop. Agric. Sci. 2002, 25, 47–51. [Google Scholar]

- Alzate Acevedo, S.; Díaz Carrillo, Á.J.; Flórez-López, E.; Grande-Tovar, C.D. Recovery of banana waste-loss from production and processing: A contribution to a circular economy. Molecules 2021, 26, 5282. [Google Scholar] [CrossRef] [PubMed]

- Malomo, G.A.; Madugu, A.S.; Bolu, S.A. Sustainable Animal Manure Management Strategies and Practices. In Agricultural Waste and Residues; Aladjadjiyan, A., Ed.; IntechOpen: London, UK, 2018; pp. 119–137. [Google Scholar]

- Fela, K.; Wieczorek-Ciurowa, K.; Konopka, M.; Woźny, Z. Present and prospective leather industry waste disposal. Polish J. Chem. Technol. 2011, 13, 53–55. [Google Scholar] [CrossRef]

- Singh, S.P.; Jawaid, M.; Chandrasekar, M.; Senthilkumar, K.; Yadav, B.; Saba, N.; Siengchin, S. Sugarcane wastes into commercial products: Processing methods, production optimization and challenges. J. Clean. Prod. 2021, 328, 129453. [Google Scholar] [CrossRef]

- Širá, E.; Kravčáková Vozárová, I.; Kotulič, R.; Dubravská, M. EU27 countries’ sustainable agricultural development toward the 2030 Agenda: The circular economy and waste management. Agronomy 2022, 12, 2270. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- The World Bank, Agriculture and Food. Available online: https://www.worldbank.org/en/topic/agriculture/overview#:~:text=Growth in the agriculture sector,more than 25%25 of GDP (accessed on 6 June 2024).

- Ferronato, N.; Torretta, V. Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Felgueiras, C.; Azoia, N.G.; Gonçalves, C.; Gama, M.; Dourado, F. Trends on the cellulose-based textiles: Raw materials and technologies. Front. Bioeng. Biotechnol. 2021, 9, 608826. [Google Scholar] [CrossRef] [PubMed]

- Sahin, H.T.; Arslan, M.B. A study on physical and chemical properties of cellulose paper immersed in various solvent mixtures. Int. J. Mol. Sci. 2008, 9, 78–88. [Google Scholar] [CrossRef]

- Hosny, K.M.; Alkhalidi, H.M.; Alharbi, W.S.; Md, S.; Sindi, A.M.; Ali, S.A.; Bakhaidar, R.B.; Almehmady, A.M.; Alfayez, E.; Kurakula, M. Recent trends in assessment of cellulose derivatives in designing novel and nanoparticulate-based drug delivery systems for improvement of oral health. Polymers 2022, 14, 92. [Google Scholar] [CrossRef]

- Scheller, H.V.; Ulvskov, P. Hemicelluloses. Annu. Rev. Plant Biol. 2010, 61, 263–289. [Google Scholar] [CrossRef] [PubMed]

- Sutay Kocabaş, D.; Köle, M.; Yağcı, S. Development and optimization of hemicellulose extraction bioprocess from poppy (Papaver somniferum L.) stalks assisted by instant controlled pressure drop (DIC) pretreatment. Biocatal. Agric. Biotechnol. 2020, 29, 101793. [Google Scholar] [CrossRef]

- Ma, C.; Kim, T.H.; Liu, K.; Ma, M.G.; Choi, S.E.; Si, C. Multifunctional lignin-based composite materials for emerging applications. Front. Bioeng. Biotechnol. 2021, 9, 708976. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Jiang, J.; Wang, C.; Liu, J.; Pu, Y.; Ragauskas, A.; Li, S.; Yang, B. Lignin-derived electrochemical energy materials and systems. Biofuels, Bioprod. Biorefining 2020, 14, 650–672. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, M.; Zhang, Y.; Cao, Q.; Wang, X.; Han, Y.; Sun, G.; Li, Y.; Zhou, J. Novel lignin–chitosan–PVA composite hydrogel for wound dressing. Mater. Sci. Eng. C 2019, 104, 110002. [Google Scholar] [CrossRef] [PubMed]

- Ebers, L.S.; Arya, A.; Bowland, C.C.; Glasser, W.G.; Chmely, S.C.; Naskar, A.K.; Laborie, M.P. 3D printing of lignin: Challenges, opportunities and roads onward. Biopolymers 2021, 112, e23431. [Google Scholar] [CrossRef] [PubMed]

- Yuliah, Y.; Kartawidjaja, M.; Suryaningsih, S.; Ulfi, K. Fabrication and characterization of rice husk and coconut shell charcoal based bio-briquettes as alternative energy source. Proc. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012021. [Google Scholar] [CrossRef]

- Liu, C.; Luan, P.; Li, Q.; Cheng, Z.; Sun, X.; Cao, D.; Zhu, H. Biodegradable, hygienic, and compostable tableware from hybrid sugarcane and bamboo fibers as plastic alternative. Matter 2020, 3, 2066–2079. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas production and applications in the sustainable energy transition. J. Energy 2022, 2022, 8750221. [Google Scholar] [CrossRef]

- Zheng, M.; Zhang, K.; Zhang, J.; Zhu, L.L.; Du, G.; Zheng, R. Cheap, high yield, and strong corn husk-based textile bio-fibers with low carbon footprint via green alkali retting-splicing-twisting strategy. Ind. Crops Prod. 2022, 188, 115699. [Google Scholar] [CrossRef]

- Achuthan, K.; Muthupalani, S.; Kolil, V.K.; Bist, A.; Sreesuthan, K.; Sreedevi, A. A novel banana fiber pad for menstrual hygiene in India: A feasibility and acceptability study. BMC Women’s Health 2021, 21, 129. [Google Scholar] [CrossRef] [PubMed]

- Merino, D.; Bertolacci, L.; Paul, U.C.; Simonutti, R.; Athanassiou, A. Avocado peels and seeds: Processing strategies for the development of highly antioxidant bioplastic films. ACS Appl. Mater. Interfaces 2021, 13, 38688–38699. [Google Scholar] [CrossRef]

- Raghuram, N. Recycling crop and animal waste is a win for green farming. Nature India 2022, Available online:. Available online: https://www.nature.com/articles/d44151-022-00121-6 (accessed on 6 June 2024).

- Abed, A.M.; Lafta, H.A.; Alayi, R.; Tamim, H.; Sharifpur, M.; Khalilpoor, N.; Bagheri, B. Utilization of animal solid waste for electricity generation in the Northwest of Iran 3E analysis for one-year simulation. Int. J. Chem. Eng. 2022, 2022, 4228483. [Google Scholar] [CrossRef]

- Arshad, M.; Ansari, A.R.; Qadir, R.; Tahir, M.H.; Nadeem, A.; Mehmood, T.; Alhumade, H.; Khan, N. Green electricity generation from biogas of cattle manure: An assessment of potential and feasibility in Pakistan. Front. Energy Res. 2022, 10, 911485. [Google Scholar] [CrossRef]

- Oladele, I. .; Omotoyimbo, J.A.; Ayemidejor, S.H. Mechanical properties of chicken feather and cow hair fibre reinforced high density polyethylene composites. Int. J. Sci. Technol. 2014, 3, 66–72. [Google Scholar]

- Patil, K.; Wang, X.; Lin, T. Electrostatic coating of cashmere guard hair powder to fabrics: Silver ion loading and antibacterial properties. Powder Technol. 2013, 245, 40–47. [Google Scholar] [CrossRef]

- Siddiqua, A.; Hahladakis, J.N.; Al-Attiya, W.A.K.A. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef] [PubMed]

- Tushar Uddin, M.; Abdur Razzaq, M.; Hai Quadery, A.; Jaman Chowdhury, M.; Al-Mizan; Moshrur Raihan, M. ; Ahmad, F. Extraction of dye from natural source (LAC) & its application on leather. Am. Sci. Res. J. Eng. Technol. Sci. 2017, 34, 1–7. [Google Scholar]

- Park, J.S.; Kim, S.H.; Kim, Y.S.; Kwon, E.; Lim, H.J.; Han, K.M.; Choi, Y.K.; Jung, C.W.; Kang, B.C. Nonclinical safety evaluation of food colorant lac dye via systematic toxicity profiling with assessment of in vivo antigenic potential. Front. Pharmacol. 2022, 13, 1020379. [Google Scholar] [CrossRef]

- Singh, A.K.; Ghosal, S.; Sinha, N.K.; Kumar, N. Utilization of lac factory waste for integrated nutrient management in brinjal and its effect on soil fertility. Multilogic Sci. 2018, 8, 246–249. [Google Scholar]

- Kimothi, S.P.; Panwar, S.; Khulbe, A. Creating Wealth from Agricultural Waste; Indian Council of Agricultural Research: New Delhi, India, 2020. [Google Scholar]

- Fazliyana, A.; Hamzah, A.; Hamzah, M.H.; Man, H.C.; Jamali, N.S.; Siajam, S.I.; Ismail, M.H. Recent updates on the conversion of pineapple waste (Ananas comosus) to value-added products, future perspectives and challenges. Agronomy 2021, 11, 2221. [Google Scholar] [CrossRef]

- Su, C.; Gong, J.S.; Qin, J.; He, J.M.; Zhou, Z.C.; Jiang, M.; Xu, Z.H.; Shi, J.S. Glutathione enables full utilization of wool wastes for keratin production and wastewater decolorization. J. Clean. Prod. 2020, 270, 122092. [Google Scholar] [CrossRef]

- The Council of Fashion Designers of America, Fiber Guide: Silk. Available online: https://cfda.com/resources-tools/materials-hub/article/fiber-guide-silk (accessed on 6 June 2024).

- Yves, O.R.; Christian, F.B.; Akum, O.B.; Theodore, T.; Bienvenu, K. Physical and mechanical properties of pineapple fibers (leaves, stems and roots) from awae Cameroon for the improvement of composite materials. J. Fiber Sci. Technol. 2018, 76, 378–386. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Muthukumar, N.; Neela Krishnanan, S.; Senthilram, T. Development and characterization of pineapple fibre nonwovens for thermal and sound insulation applications. J. Nat. Fibers 2020, 17, 1391–1400. [Google Scholar] [CrossRef]

- Jain, J.; Sinha, S. Potential of pineapple leaf fibers and their modifications for development of tile composites. J. Nat. Fibers 2022, 19, 4822–4834. [Google Scholar] [CrossRef]

- Khan, G.M.A.; Sarkar, M.A.; Islam, M.M.; Alam, M.S. Wet processing of agro-residual fibres for potential application in fancy décor items. Adv. Mater. Process. Technol. 2022, 8, 3215–3230. [Google Scholar] [CrossRef]

- Xu, S.; Xiong, C.; Tan, W.; Zhang, Y. Microstructural, thermal, and tensile characterization of banana pseudo-stem fibers obtained with mechanical, chemical, and enzyme extraction. BioResources 2015, 10, 3724–3735. [Google Scholar] [CrossRef]

- Silva, F.S.; Ribeiro, C.E.G.; Demartini, T.J. da C.; Rodríguez, R.J.S. Physical, chemical, mechanical, and microstructural characterization of banana pseudostem fibers from Musa Sapientum. Macromol. Symp. 2020, 394, 2000052. [Google Scholar] [CrossRef]

- Pandit, P. Characteristics & properties of banana fibers. Available online: https://textilevaluechain.in/news-insights/characteristics-properties-of-banana-fibers/#:~:text=The chemical composition of banana,upon the extraction %26 spinning process (accessed on 6 June 2024).

- Patel, B.Y.; Patel, H.K. Retting of banana pseudostem fibre using Bacillus strains to get excellent mechanical properties as biomaterial in textile & fiber industry. Heliyon 2022, 8, e10652. [Google Scholar]

- Dessalegn, Y.; Singh, B.; Vuure, A.W. va.; Badruddin, I.A.; Beri, H.; Hussien, M.; Ahmed, G.M.S.; Hossain, N. Investigation of bamboo fibrous tensile strength using modified Weibull distribution. Materials 2022, 15, 5016. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, D.; Fan, S.; Rahman, M.Z.; Guo, S.; Chen, F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: a review. J. Mater. Res. Technol. 2022, 19, 1162–1190. [Google Scholar] [CrossRef]

- Nirmal Kumar, K.; Dinesh Babu, P.; Surakasi, R.; Kumar, P.M.; Ashokkumar, P.; Khan, R.; Alfozan, A.; Gebreyohannes, D.T. Mechanical and thermal properties of bamboo fiber-reinforced PLA polymer composites: A critical study. Int. J. Polym. Sci. 2022, 2022, 1332157. [Google Scholar] [CrossRef]

- Rini, D.S.; Ishiguri, F.; Nezu, I.; Ngadianto, A.; Irawati, D.; Otani, N.; Ohshima, J.; Yokota, S. Geographic and longitudinal variations of anatomical characteristics and mechanical properties in three bamboo species naturally grown in Lombok Island, Indonesia. Sci. Rep. 2023, 13, 2265. [Google Scholar] [CrossRef] [PubMed]

- De Carvalho Mendes, C.A.; De Oliveira Adnet, F.A.; Leite, M.C.A.M.; Furtado, C.R.G.; De Sousa, A.M.F. Chemical, physical, mechanical, thermal and morphological characterization of corn husk residue. Cellul. Chem. Technol. 2015, 49, 727–735. [Google Scholar]

- Sari, N.H.; Wardana, I.N.G.; Irawan, Y.S.; Siswanto, E. Physical and acoustical properties of corn husk fiber panels. Adv. Acoust. Vib. 2016, 2016, 5971814. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Anwar, S.I. Determination of moisture content of bagasse of jaggery unit using microwave oven. J. Eng. Sci. Technol. 2010, 5, 472–478. [Google Scholar]

- Yadav, S.; Gupta, G.K.; Kumar, R. A review on composition and properties of bagasse fibers. Proc. Int. J. Sci. Eng. Res. 2015, 6, 143–148. [Google Scholar]

- Jayamaui, E.; Rahman, M.R.; Benhur, D.A.; Bakri, M.K. Bin; Kakair, A.; Khan, A. Comparative study of fly ash/sugarcane fiber reinforced polymer composites properties. BioResources 2020, 15, 5514–5531. [Google Scholar] [CrossRef]

- Yang, Y.; Reddy, N. Properties and potential medical applications of regenerated casein fibers crosslinked with citric acid. Int. J. Biol. Macromol. 2012, 51, 37–44. [Google Scholar] [CrossRef]

- Thill, S.; Schmidt, T.; Wöll, D.; Gebhardt, R. A regenerated fiber from rennet-treated casein micelles. Colloid Polym. Sci. 2021, 299, 909–914. [Google Scholar] [CrossRef]

- Fematt-Flores, G.E.; Aguiló-Aguayo, I.; Marcos, B.; Camargo-Olivas, B.A.; Sánchez-Vega, R.; Soto-Caballero, M.C.; Salas-Salazar, N.A.; Flores-Córdova, M.A.; Rodríguez-Roque, M.J. Milk protein-based edible films: Influence on mechanical, hydrodynamic, optical and antioxidant properties. Coatings 2022, 12, 196. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Structure and properties of chicken feather barbs as natural protein fibers. J. Polym. Environ. 2007, 15, 81–87. [Google Scholar] [CrossRef]

- Choudary, R.B.; Prasad, A.S.; Bhargava, N.R.M.R. Feather fiber reinforced polyester composites. Mater. Sci. Res. India 2007, 4, 487–492. [Google Scholar] [CrossRef]

- Zhan, M.; Wool, R.P. Mechanical properties of chicken feather fibers. Polym. Compos. 2011, 32, 937–944. [Google Scholar] [CrossRef]

- Tesfaye, T.; Sithole, B.; Ramjugernath, D.; Chunilall, V. Valorisation of chicken feathers: Characterisation of chemical properties. Waste Manag. 2017, 68, 626–635. [Google Scholar] [CrossRef] [PubMed]

- Mann, G.S.; Azum, N.; Khan, A.; Rub, M.A.; Hassan, M.I.; Fatima, K.; Asiri, A.M. Green composites based on animal fiber and their applications for a sustainable future. Polymers 2023, 15, 601. [Google Scholar] [CrossRef]

- Chong, E.J.; Phan, T.T.; Lim, I.J.; Zhang, Y.Z.; Bay, B.H.; Ramakrishna, S.; Lim, C.T. Evaluation of electrospun PCL/gelatin nanofibrous scaffold for wound healing and layered dermal reconstitution. Acta Biomater. 2007, 3, 321–330. [Google Scholar] [CrossRef] [PubMed]

- Fukae, R.; Midorikawa, T. Preparation of gelatin fiber by gel spinning and its mechanical properties. J. Appl. Polym. Sci. 2008, 110, 4011–4015. [Google Scholar] [CrossRef]

- Khan, R.A.; Khan, M.A.; Sarker, B.; Saha, S.; Das, A.K.; Noor, N.; Huq, T.; Khan, A.; Dey, K.; Saha, M. Fabrication and characterization of gelatin fiber-based linear low-density polyethylene foamed composite. J. Reinf. Plast. Compos. 2010, 29, 2438–2449. [Google Scholar] [CrossRef]

- Chaochai, T.; Imai, Y.; Furuike, T.; Tamura, H. Preparation and properties of gelatin fibers fabricated by dry spinning. Fibers 2016, 4, 2. [Google Scholar] [CrossRef]

- Czaplicki, Z. Properties and structure of polish alpaca wool. Fibres Text. East. Eur. 2012, 90, 8–12. [Google Scholar]

- Jankowska, D.; Wyrostek, A.; Patkowska–Sokoła, B.; Czyż, K. Comparison of physico-mechanical properties of fibre and yarn made of alpaca, sheep, and goat wool. J. Nat. Fibers 2019, 18, 1512–1517. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Lau, K.T.; Ho, M.P.; Mosallam, A. Study on the mechanical properties of different silkworm silk fibers. J. Compos. Mater. 2009, 43, 2521–2531. [Google Scholar] [CrossRef]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E.; Deng, Y. A review on pineapple leaves fibre and its composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical composition and mechanical properties of natural fibers. J. Nat. Fibers 2022, 19, 3942–3953. [Google Scholar] [CrossRef]

- Adeoye, M.D.; Lawal, A.T.; Jimoh, A.O.; Adelani, A.K.; Ojo, O.O.; Ndukwe, N.A.; Salaudeen, T.; Adewuyi, S. Fascinating physical-chemical properties and fiber morphology of selected waste plant leaves as potential pulp and paper making agents. Biomass Convers. Biorefinery 2021, 11, 3061–3070. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Q.; Twebaze, C.B.; Zhuang, X.; Kimani, M.; Zheng, G.; Wang, Z.; Zhao, J.; Zhu, R.; Wang, R. The effect of activated water degumming technique on alkali-pretreated banana fiber. BioResources 2022, 17, 6775–6788. [Google Scholar] [CrossRef]

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Martijanti, M.; Juwono, A.L.; Sutarno, S. Investigation of characteristics of bamboo fiber for composite structures. Proc. IOP Conf. Ser. Materials Science and Engineering, 0120. [Google Scholar]

- Aziz, A.A.; Ismail, S.; Mahayuddin, S.A. a Review of the Factors Affecting the Properties of Bamboo Fiber Bio-Composite Materials. Malaysian J. Sustain. Environ. 2023, 10, 275–298. [Google Scholar] [CrossRef]

- Duong, N.T.; Satomi, T.; Takahashi, H. Potential of corn husk fiber for reinforcing cemented soil with high water content. Constr. Build. Mater. 2021, 271, 121848. [Google Scholar] [CrossRef]

- Prasad, L.; Kumar, S.; Patel, R.V.; Yadav, A.; Kumar, V.; Winczek, J. Physical and mechanical behaviour of sugarcane bagasse fibre-reinforced epoxy bio-composites. Materials 2020, 13, 5387. [Google Scholar] [CrossRef] [PubMed]

- Pavan, M.; Samant, L. Regenerated milk fiber: An approach towards green textiles. Just Agric. e-Newsletter 2022, 3, 43. [Google Scholar]

- Li, Z.; Reimer, C.; Picard, M.; Mohanty, A.K.; Misra, M. Characterization of chicken feather biocarbon for use in sustainable biocomposites. Front. Mater. 2020, 7, 3. [Google Scholar] [CrossRef]

- Mwanza, E.P.; van der Westhuizen, W.A.; Boucher, C.E.; Charimba, G.; Hugo, C. Heterologous expression and characterisation of a keratinase produced by Chryseobacterium carnipullorum. Protein Expr. Purif. 2021, 186, 105926. [Google Scholar] [CrossRef]

- Roy, A.N.; Samanta, K.K.; Patra, K. Physico-chemical properties of black yak fibre and its modification for blending with jute fibre. J. Nat. Fibers 2019, 16, 225–236. [Google Scholar] [CrossRef]

- Atav, R.; Ergünay, U.; Gürkan Ünal, P. Determining the effect of pigmentation on some physical and mechanical properties of yak and cashmere down fibers. J. Nat. Fibers 2023, 20, 2149939. [Google Scholar] [CrossRef]

- Gelatin Handbook; Gelatin Manufacturers Institute of America: Muscatine, USA. Available online: https://nitta-gelatin.com/wp-content/uploads/2018/02/GMIA_Gelatin-Handbook.pdf (accessed on 6 June 2024).

- Hegazy, E.M.; El-Sayed Khamis, N.H. Effect of fresh garlic and ginger on the shelf-life of gelatin waste used for improvement of plant growth. World Appl. Sci. J. 2014, 30, 83–88. [Google Scholar]

- Ulfa, M.; Trisunaryanti, W.; Falah, I.I.; Kartini, I.; Sutarno, S. Synthesis of mesoporous carbon using gelatin as source of carbon by hard template technique and its characterizations. IOSR J. Appl. Chem. 2014, 7, 30107. [Google Scholar] [CrossRef]

- Kiron, M.I. Chemical composition of natural fibers (cotton, jute, flax, hemp, ramie, sisal, coir, wool and silk). Available online: https://textilelearner.net/chemical-composition-of-natural-fibers/ (accessed on 6 June 2024).

- Parlato, M.C.M.; Valenti, F.; Midolo, G.; Porto, S.M.C. Livestock wastes sustainable use and management: Assessment of raw sheep wool reuse and valorization. Energies 2022, 15, 3008. [Google Scholar] [CrossRef]

- Lancashire, R.J. Unit - chemistry of garments: Animal fibres. Available online: http://wwwchem.uwimona.edu.jm/courses/CHEM2402/Textiles/Animal_Fibres.html (accessed on 6 June 2024).

- Kumar, P.; Ram, C.S.; Srivastava, J.P.; Behura, A.K.; Kumar, A. Synthesis of cotton fiber and its structure. In Natural and Synthetic Fiber Reinforced Composites: Synthesis, Properties and Applications; Siengchin, S., Rangappa, S., Rajak, D.K., Eds.; Wiley Online Books, 2022; pp. 17–36.

- Jain, V.; Mittal, M.; Chaudhary, R. Design optimization and analysis of car bumper with the implementation of hybrid biocomposite material. IOP Conf. Ser. Mater. Sci. Eng. 2020, 804, 012004. [Google Scholar] [CrossRef]

- Sarmin, S.N.; Jawaid, M.; Mahmoud, M.H.; Saba, N.; Fouad, H.; Alothman, O.Y.; Santulli, C. Mechanical and physical properties analysis of olive biomass and bamboo reinforced epoxy-based hybrid composites. Biomass Convers. Biorefinery 2024, 14, 7959–7969. [Google Scholar] [CrossRef]

- Prakash, V.R.A.; Bourchak, M.; Alshahrani, H.; Juhany, K.A. Development of cashew nut shell lignin-acrylonitrile butadiene styrene 3D printed core and industrial hemp/aluminized glass fiber epoxy biocomposite for morphing wing and unmanned aerial vehicle applications. Int. J. Biol. Macromol. 2023, 253, 127068. [Google Scholar] [CrossRef] [PubMed]

- Ramadoss, P.K.; Mayakrishnan, M.; Arockiasamy, F.S. Discarded custard apple seed powder waste-based polymer composites: an experimental study on mechanical, acoustic, thermal and moisture properties. Iran. Polym. J. 2024, 33, 461–479. [Google Scholar] [CrossRef]

- Shivayogi, B.H.; Manjunatha, T.S.; Shivakumar Gouda, P.S.; Maruthi Prashanth, B.H.; Prashanth Pai, M. Influence of layering sequence on performance of jute/wool epoxy hybrid composites: a comparative study with automotive plastic. Eng. Res. Express 2024, 6, 015522. [Google Scholar]

- Madgule, M.; Deshmukh, P.; Perveen, K.; Qamar, M.O.; Razak, A.; Wodajo, A.W. Experimental investigation on mechanical properties of novel polymer hybrid composite with reinforcement of banana fiber and sugarcane bagasse powder. Adv. Mech. Eng. 2023, 15, 1–13. [Google Scholar] [CrossRef]

- Han, S.; Xiang Zhao; Xinpu Li; Hanzhou Ye; Wang, G. Synergistic in-situ reinforcement of lignin and adhesive for high-performance aligned bamboo fibers composites. J. Mater. Res. Technol. 2024, 28, 879–890. [Google Scholar] [CrossRef]

- Baigh, T.A.; Nanzeeba, F.; Hamim, H.R.; Habib, M.A. A comprehensive study on the effect of hybridization and stacking sequence in fabricating cotton-blended jute and pineapple leaf fibre biocomposites. Heliyon 2023, 9, e19792. [Google Scholar] [CrossRef] [PubMed]

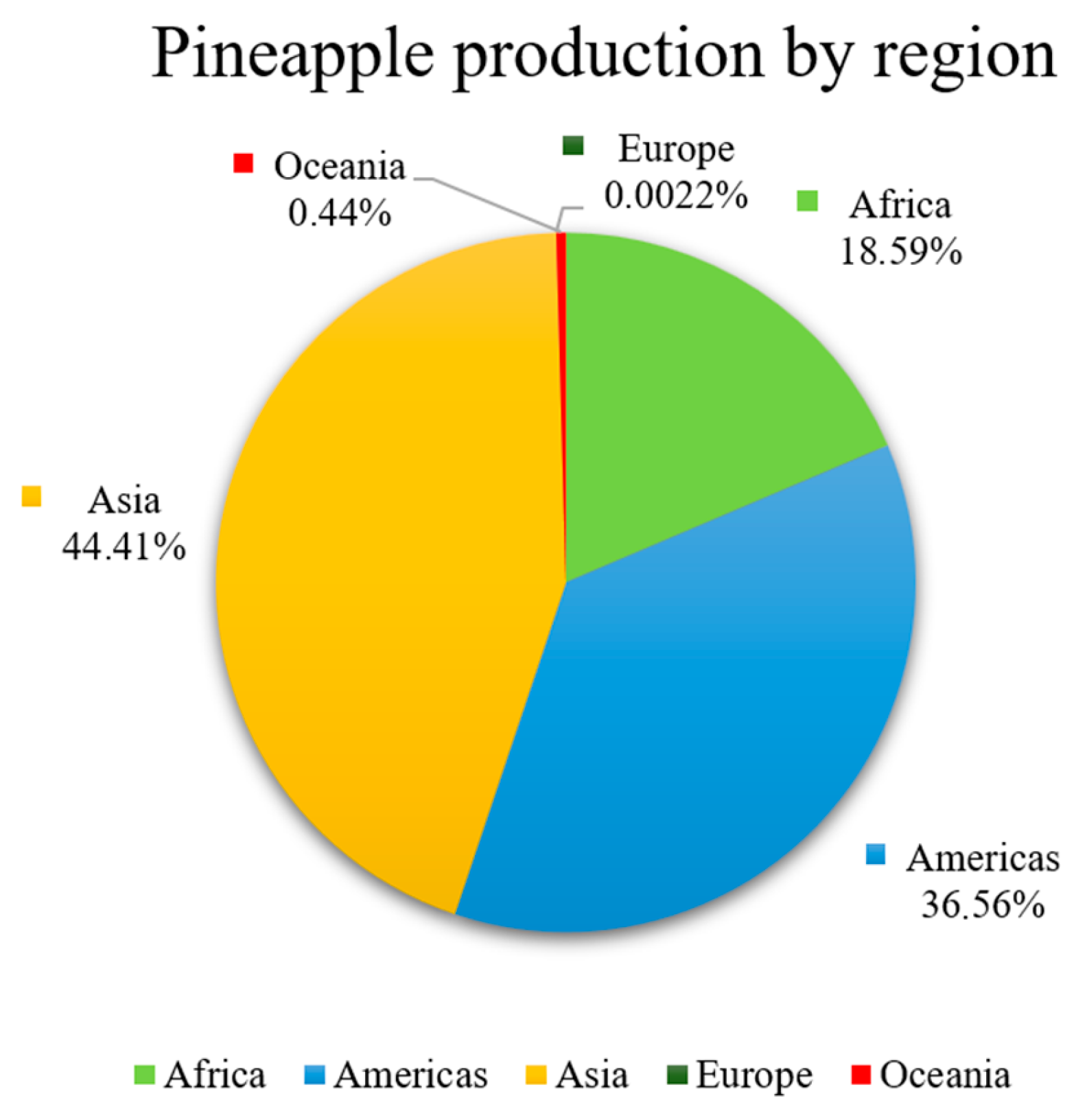

- Food and Agriculture Organization of the United Nations, Crops and livestock products. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 6 June 2024).

- Łukaszewicz, A. Modelling of solid part using multibody techniques in parametric CAD systems. Solid State Phenom. 2009, 147–149, 924–929. [Google Scholar] [CrossRef]

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of the Assembly Condition. In Proceedings of the 15th International Scientific Conference ‘Engineering for Rural Development 2016’, Jelgava, Latvia, 25–27 May 2016; pp. 329–335. [Google Scholar]

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of Operational Condition. In Proceedings of the 15th International Scientific Conference ‘Engineering for Rural Development 2016’, Jelgava, Latvia, 25–27 May 2016; pp. 336–341. [Google Scholar]

- Grzejda, R. New method of modelling nonlinear multi-bolted systems. In Advances in Mechanics: Theoretical, Computational and Interdisciplinary Issues; Kleiber, M., Burczyński, T., Wilde, K., Górski, J., Winkelmann, K., Smakosz, Ł., Eds.; CRC Press: Leiden, The Netherlands, 2016; pp. 213–216. [Google Scholar]

- Grodzki, W.; Łukaszewicz, A. Design and manufacture of umanned aerial vehicles (UAV) wing structure using composite materials. Materwiss. Werksttech. 2015, 46, 269–278. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Mikołajewski, D.; Kłodowski, A.; Łukaszewicz, A.; Mikołajewska, E.; Paczkowski, T.; Macko, M.; Skornia, M. Energy sources of mobile robot power systems: A systematic review and comparison of efficiency. Appl. Sci. 2023, 13, 7547. [Google Scholar] [CrossRef]

- Šančić, T.; Brčić, M.; Kotarski, D.; Łukaszewicz, A. Experimental characterization of composite-printed materials for the production of multirotor UAV airframe parts. Materials 2023, 16, 5060. [Google Scholar] [CrossRef] [PubMed]

- Sayeed, M.M.A.; Sayem, A.S.M.; Haider, J.; Akter, S.; Habib, M.M.; Rahman, H.; Shahinur, S. Assessing mechanical properties of jute, kenaf, and pineapple leaf fiber-reinforced polypropylene composites: Experiment and modelling. Polymers 2023, 15, 830. [Google Scholar] [CrossRef] [PubMed]

- Afkari, A.S. .; Pratama, R.A..; Juwono, A.L..; Roseno, S. Mechanical properties of pineapple leaf fiber/epoxy composites with 0°/0°/0°/0° and 0°/90°/0°/90° fiber orientations. Indones. J. Mater. Sci. 2022, 23, 83–89. [Google Scholar]

- Jose, S.; Shanumon, P.S.; Paul, A.; Mathew, J.; Thomas, S. Physico-mechanical, thermal, morphological, and aging characteristics of green hybrid composites prepared from wool-sisal and wool-palf with natural rubber. Polymers 2022, 14, 4882. [Google Scholar] [CrossRef] [PubMed]

- Suteja, J.; Firmanto, H.; Soesanti, A.; Christian, C. Properties investigation of 3D printed continuous pineapple leaf fiber-reinforced PLA composite. J. Thermoplast. Compos. Mater. 2022, 35, 2052–2061. [Google Scholar] [CrossRef]

- Anand, P.B.; Lakshmikanthan, A.; Chandrashekarappa, M.P.G.; Selvan, C.P.; Pimenov, D.Y.; Giasin, K. Experimental investigation of effect of fiber length on mechanical, wear, and morphological behavior of silane-treated pineapple leaf fiber reinforced polymer composites. Fibers 2022, 10, 56. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, T.S.; Sultan, M.T.H.; Shahar, F.S.; Basri, A.A.; Shah, A.U.M.; Sebaey, T.A.; Łukaszewicz, A.; Józwik, J.; Grzejda, R. Fatigue and impact properties of kenaf/glass-reinforced hybrid pultruded composites for structural applications. Materials 2024, 17, 302. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Das, S.; Rahman, M.; Hasan, M. Physico-mechanical properties of pineapple leaf and banana fiber reinforced hybrid polypropylene composites: Effect of fiber ratio and sodium hydroxide treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 438, 012027. [Google Scholar] [CrossRef]

| Agricultural activity | Wastes produced | Disposal method |

| Pineapple production [2] | Leaves, crown, core, peels, stems | Dumping, burning, burying, decomposing |

| Banana production [3] | Peels, stems, trunks | Dumping, burning, burying, decomposing |

| Animal production [4] | Left-over feed, wastewater, hatchery wastes, manure, carcasses | Dumping, burning, burying |

| Leather tanning [5] | Hair, bristle, flesh side, splits, trimmings, fleshing, splits trimmings, shavings, sludge | Dumping |

| Sugar processing [6] | Bagasse, cane trash, press mud, molasses | Dumping, burning, burying |

| Types | Materials | Density (g/cm3) | Tensile strength (MPa) | Young’s Modulus (GPa) |

| Crop waste | Pineapple leaf fiber [39,40,41,42] | 0.95 – 1.53 | 460 – 1244 | 4.4 – 43 |

| Banana stem fiber [43,44,45,46] | 0.22 – 0.96 | 210 – 914 | 16.4 – 32 | |

| Bamboo fiber [47,48,49,50] | 0.6 – 1.4 | 206.5 – 630 | 17 – 36 | |

| Corn husk fiber [51,52,53] | 1.16 –1.49 | 180 – 256 | 4.6 – 15.9 | |

| Sugarcane bagasse fiber [54,55,56] | 0.88 – 1.2 | 20 – 290 | 3 – 27.1 | |

| Animal waste | Milk protein/casein fiber [57,58,59] | 1.3 | 37 – 116 | 2.1 – 7.4 |

| Chicken feather fiber [60,61,62,63] | 0.78 – 0.90 | 130 – 220 | 3.0 – 4.5 | |

| Yak fiber [64] | 1.32 – 3.41 | 270.05 | 45.09 | |

| Gelatin fiber [65,66,67,68] | 1.2 – 1.58 | 91 – 170 | 2.0 – 3.1 | |

| Processing waste | Wool waste fiber [60,69,70] | 1.29 – 1.31 | 130 – 210 | 2.6 – 3.6 |

| Silk waste fiber [71] | 1.32 – 1.33 | 165.3 – 248.8 | 3.8 – 6.1 | |

| Recycled cotton fiber [72] | 1.5 – 1.6 | 287 – 597 | 5.5 – 12.6 |

| Types | Materials | Chemical properties (%) | ||

| Crop waste | Pineapple leaf fiber [3,39,41,42,74] | Cellulose: 64.4 – 72.1 Hemicellulose: 4.9 – 21.7 |

Lignin: 4.3 –13.6 Pectin: 1.3 – 1.6 |

Ash: 0.8 – 5.0 |

| Banana stem fiber [43,44,45,46,75] | Cellulose: 39.2 – 64 Hemicellulose: 10.2 – 27.8 |

Lignin: 11.4 – 27.8 Pectin: 2.1 – 2.8 |

Ash: 3.9 | |

| Bamboo fiber [76,77,78] | Cellulose: 36.1 – 55.7 Hemicellulose: 11.4 – 19.2 |

Lignin: 16.9 – 28.5 Pectin: <1 |

||

| Corn husk fiber [51,53,79] | Cellulose: 43 – 45.7 Hemicellulose: 31 – 40 |

Lignin: 2 – 22 | Ash: 0.4 – 6.4 | |

| Sugarcane bagasse fiber [55,80] | Cellulose: 30 – 55 Hemicellulose: 20 – 28.3 |

Lignin:18 – 26 Pectin: 0.6 – 0.8 |

Ash: 3 – 10 | |

| Animal waste | Milk protein/ casein fiber [81] |

Carbon: 53 Hydrogen: 7.5 |

Oxygen: 23 Nitrogen: 15 |

Sulfur: 0.7 Phosphorous: 0.8 |

| Chicken feather fiber [63,82,83] | Protein: 82 – 91 Carbon: 64.5 |

Nitrogen: 10.4 Oxygen: 22.3 |

Sulfur: 2.6 | |

| Yak fiber [84,85] | Protein: 65–95 Carbon: 51.1 – 58.3 |

Nitrogen: 13.5 – 18.2 Oxygen: 20.7 – 32.1 |

Sulfur: 2.1 – 2.3 | |

| Gelatin fiber [86,87,88] | Protein: 98 – 99 Carbon: 48 – 50.5 |

Nitrogen: 14.4 – 17 Oxygen: 25.2 – 29.4 |

||

| Processing waste | Wool waste fiber [89,90] | Protein: 33 Carbon: 50 |

Nitrogen: 14 – 25 Oxygen: 10 |

Sulfur: 0.1 – 0.2 |

| Silk waste fiber [89,91] | Protein: 78 – 95 | Nitrogen: 16.4 | Sulfur: 3.7 | |

| Recycled cotton fiber [92] | Cellulose: 90 – 94 Moisture: 6 – 7 |

Protein: 1 – 1.5 Pectin: 0.9 |

Ash: 1.2 | |

| Type of composites 1 | Density (g/cm3) |

Tensile strength (MPa) |

Young’s Modulus (GPa) |

Flexural strength (MPa) |

Flexural Modulus (GPa) |

Application | Results |

| PALF + GF + Epoxy | 1.142 | 49.28 | 1.57 | 152.21 | 6.86 | Car bumper | After optimizing the car bumper design, the deformation of the hybrid composites is less than that of steel and aluminum [93]. |

| Olive + BF + Epoxy | 1.200 | 31.28–37.09 | - | 56.70–65.64 | - | Floor panels, automotive interior | The hybrid composite shows better mechanical strength compared to the non-hybrid composite [94]. |

| Cashew nut shell + hemp + Epoxy | - | 136.00 | - | 168.00 | - | Morphing wing UAV | The mechanical properties of the composites were enhanced with the addition of cashew nut shells and hemp [95]. |

| JF + SG + KF + CASP + Epoxy | - | 60.43 | - | - | - | Theather interior | The sound absorption and mechanical properties were enhanced after CASP addition [96]. |

| JF + Wool + Epoxy | - | 40.00 | - | 99.00 | - | Automobile interior | Hybrid composites have better mechanical properties than automotive thermoplastics [97]. |

| Banana + SGB + Epoxy | - | 73.48 | - | 77.50 | - | Automobile, aircraft, building, sports, and household applications | The properties were enhanced after the addition of fibers [98]. |

| BF + Phenolic | 1.080 | 421.50 | - | 211.19 | - | Drone wings, wind turbine blades | The bamboo fiber composites exhibit superior mechanical properties compared to aluminum, steel, and titanium alloy [99]. |

| PALF + JF + Epoxy | 1.074 | 32.16 | 1.32 | - | - | Brake and accelerator pedals, | Hybrid composites show better mechanical properties compared to non-hybrid composites [100]. |

| Fiber | Matrix | Fiber treatment |

Composition of fiber (%) | Density (g/cm3) |

Tensile strength (MPa) | Young’s Modulus (GPa) |

| Pineapple leaf fiber | Polypropylene [109] | None | 40 | - | 58 | 1.7 |

| Epoxy [110] | Alkaline (NaOH) | 40 | 1.18 | 93.8 | 4.2 | |

| Natural rubber [111] | None | 25 | 1.09 | 11.1 | 0.3 | |

| Polylactic acid [112] | None | 25 | - | 96.8 | - | |

| Polyester [113] | Silane | - | - | 55 | 2.3 | |

| None | Polylactic acid [114] | None | 0 | 1.27 | 56 | 3.4 |

| Acrylonitrile-Butadiene-Styrene [114] | None | 0 | 1.05 | 26 – 31 | 2.18 – 2.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).