Submitted:

30 April 2024

Posted:

30 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiment

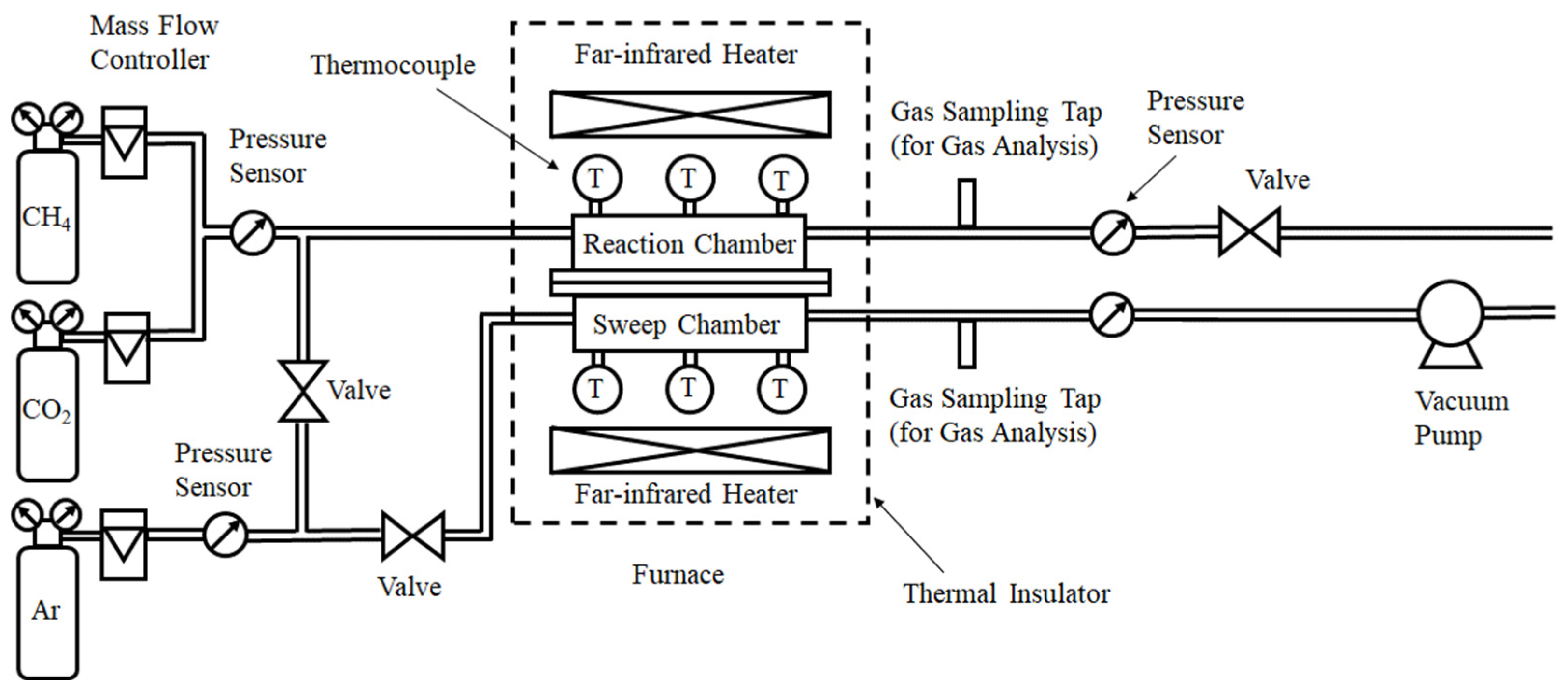

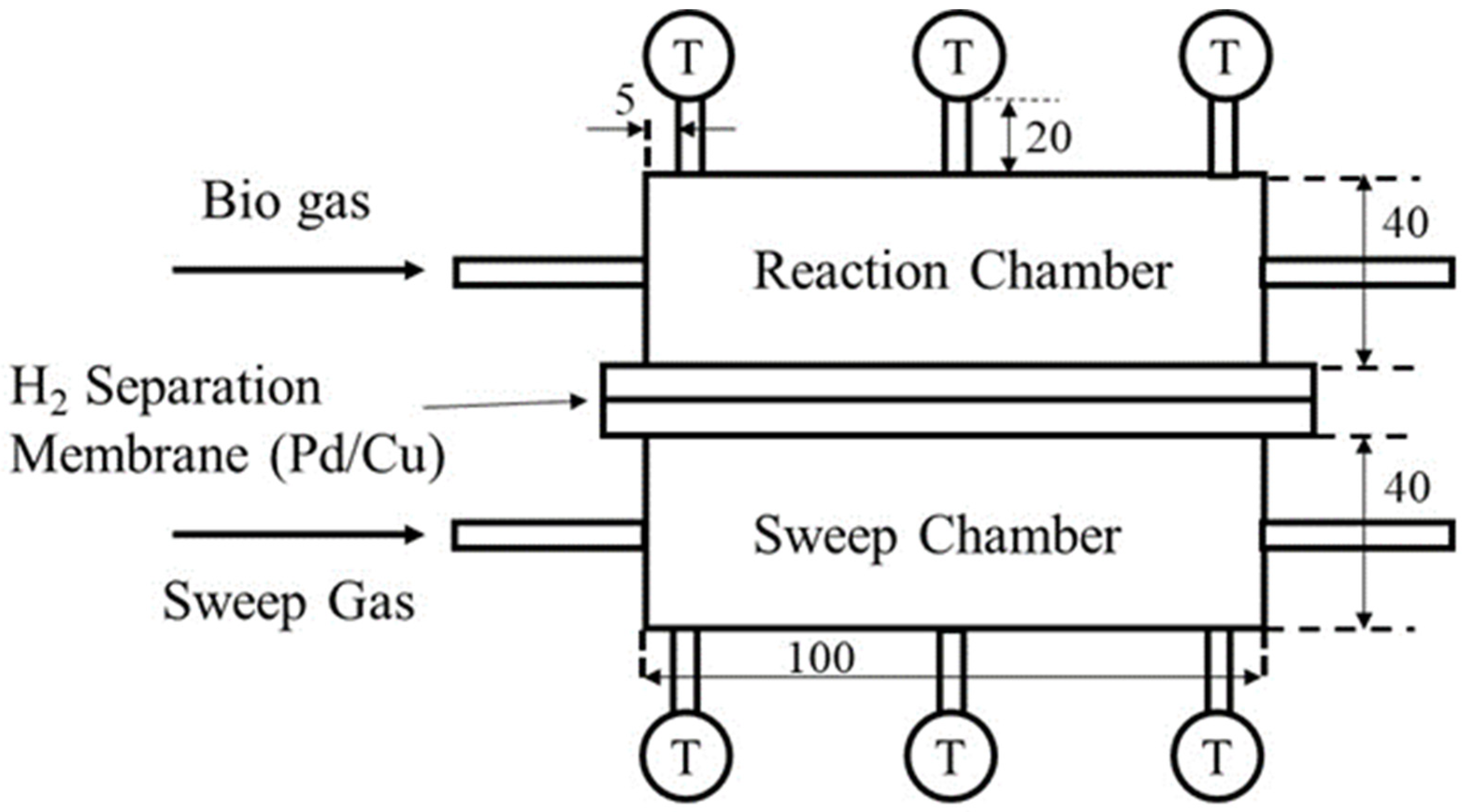

2.1. Experimental Apparatus

2.2. Assessment Factor to Evaluate the Performance of Membrane Reactor

3. Results and Discussion

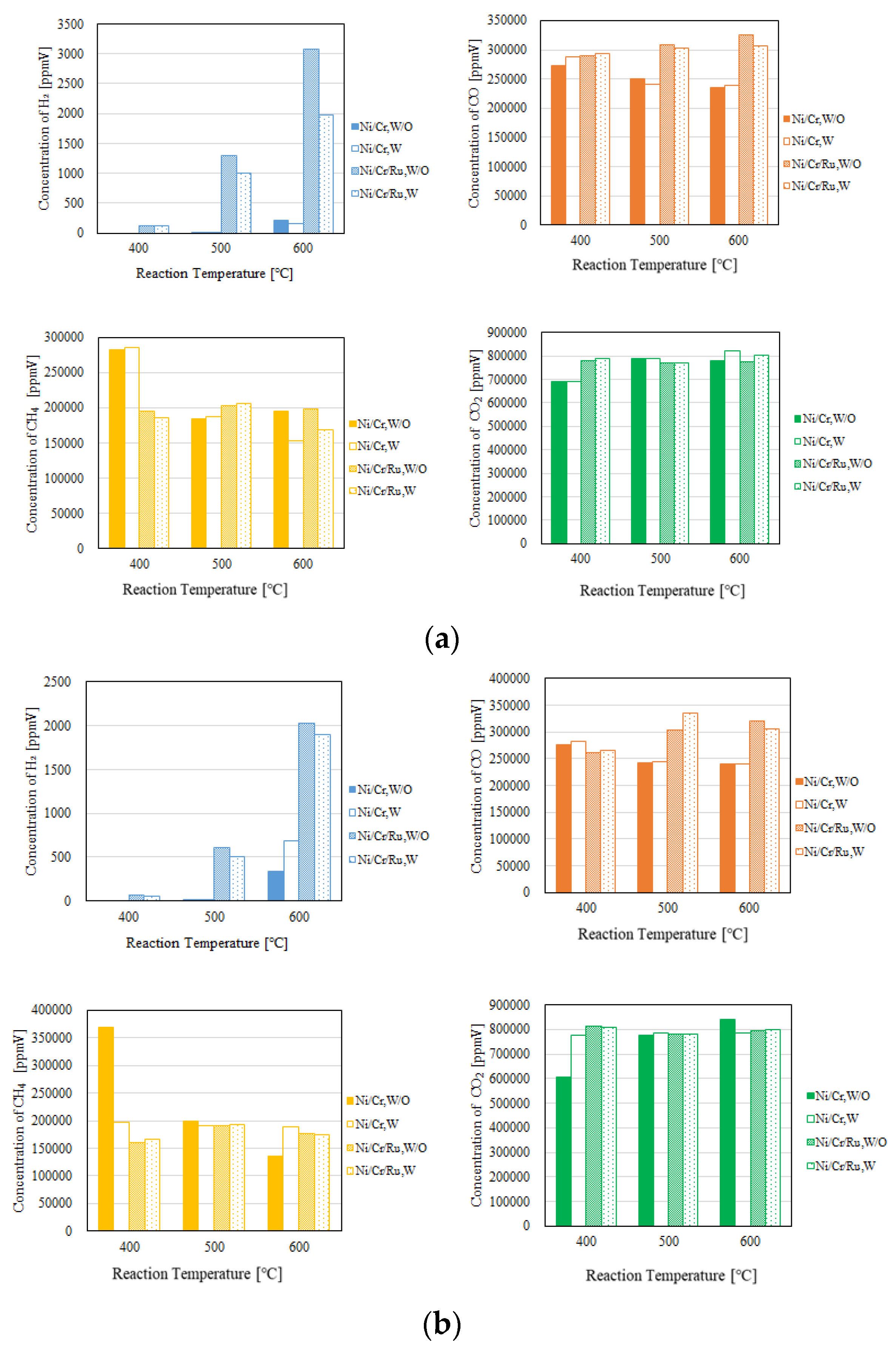

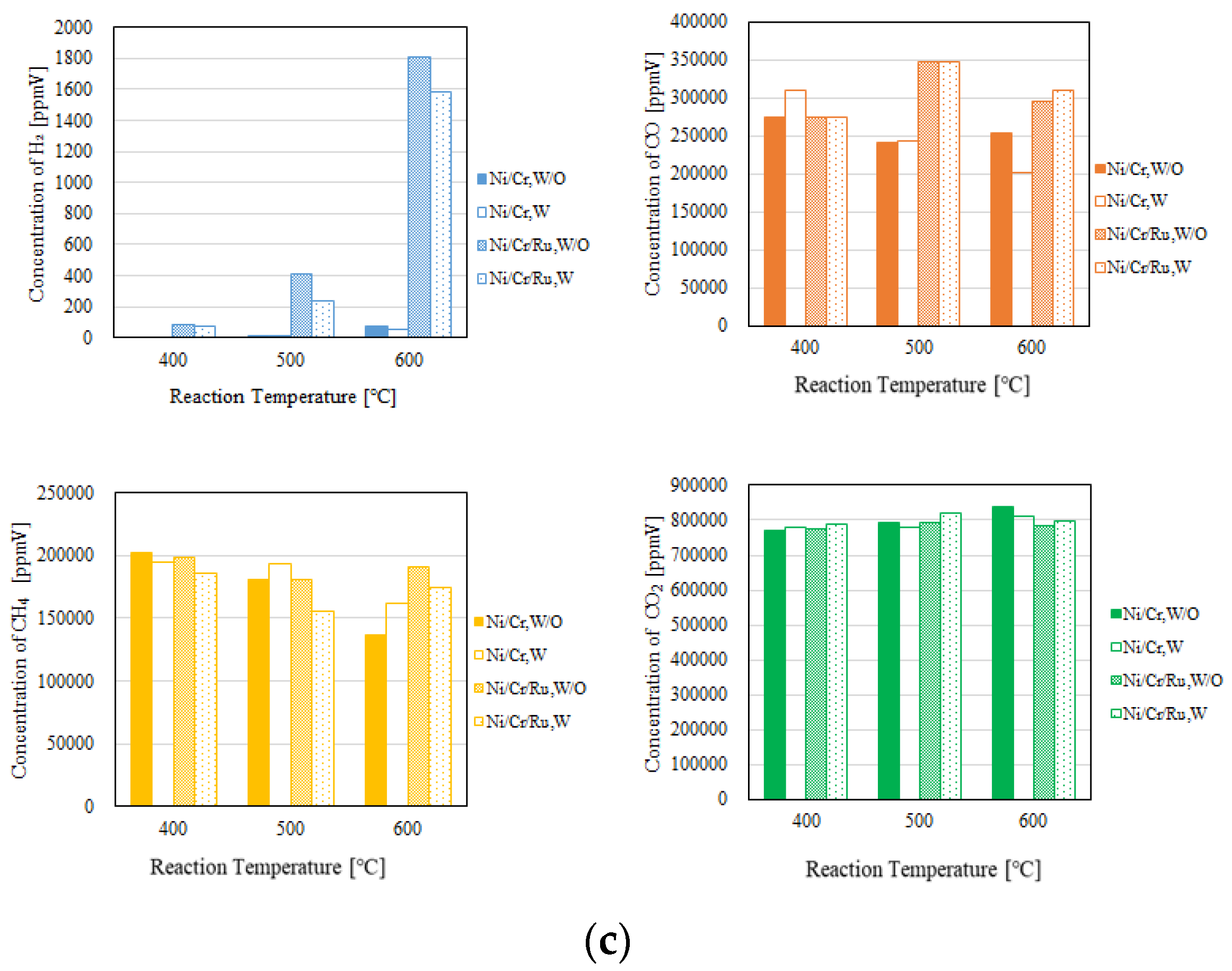

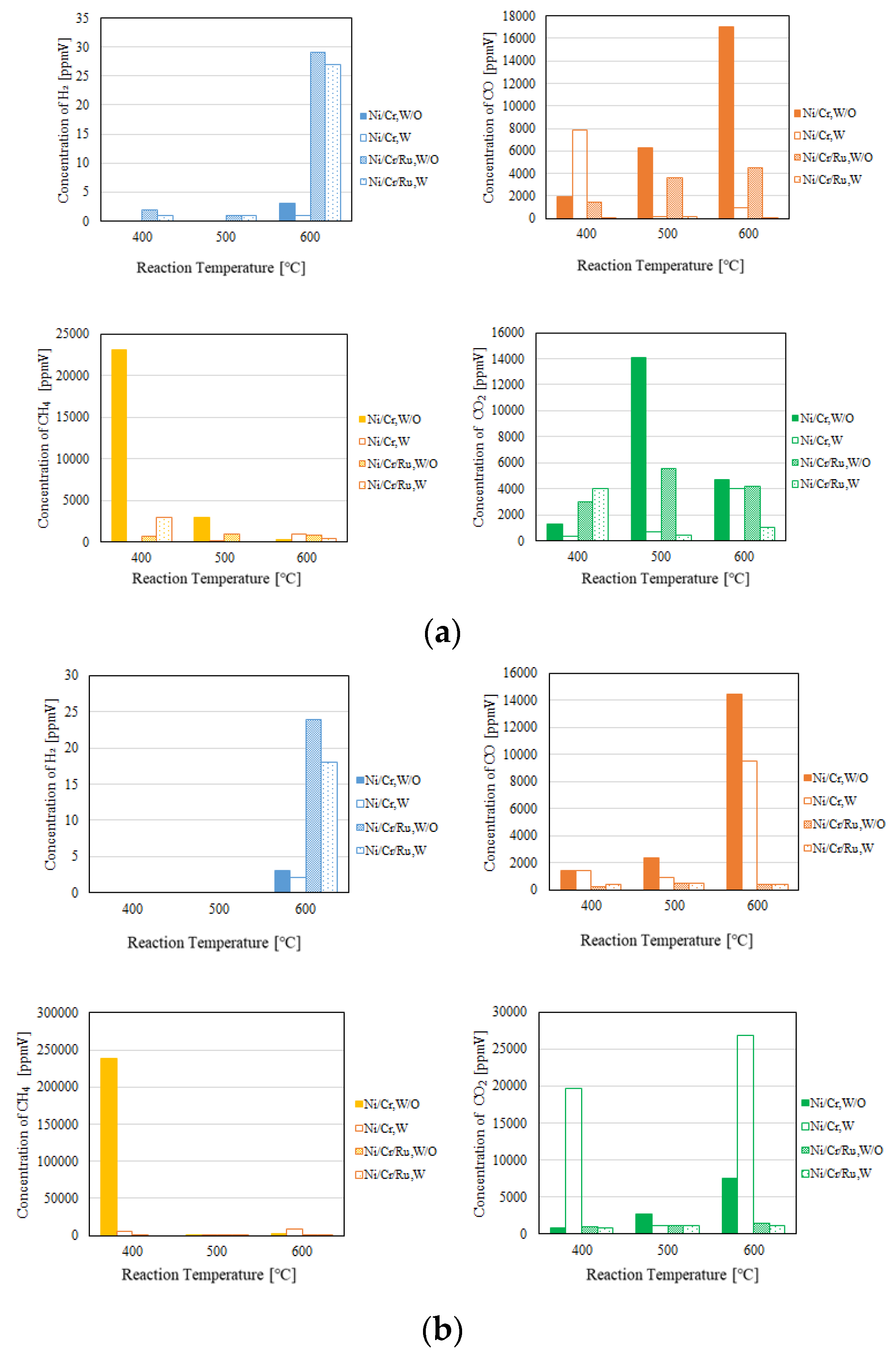

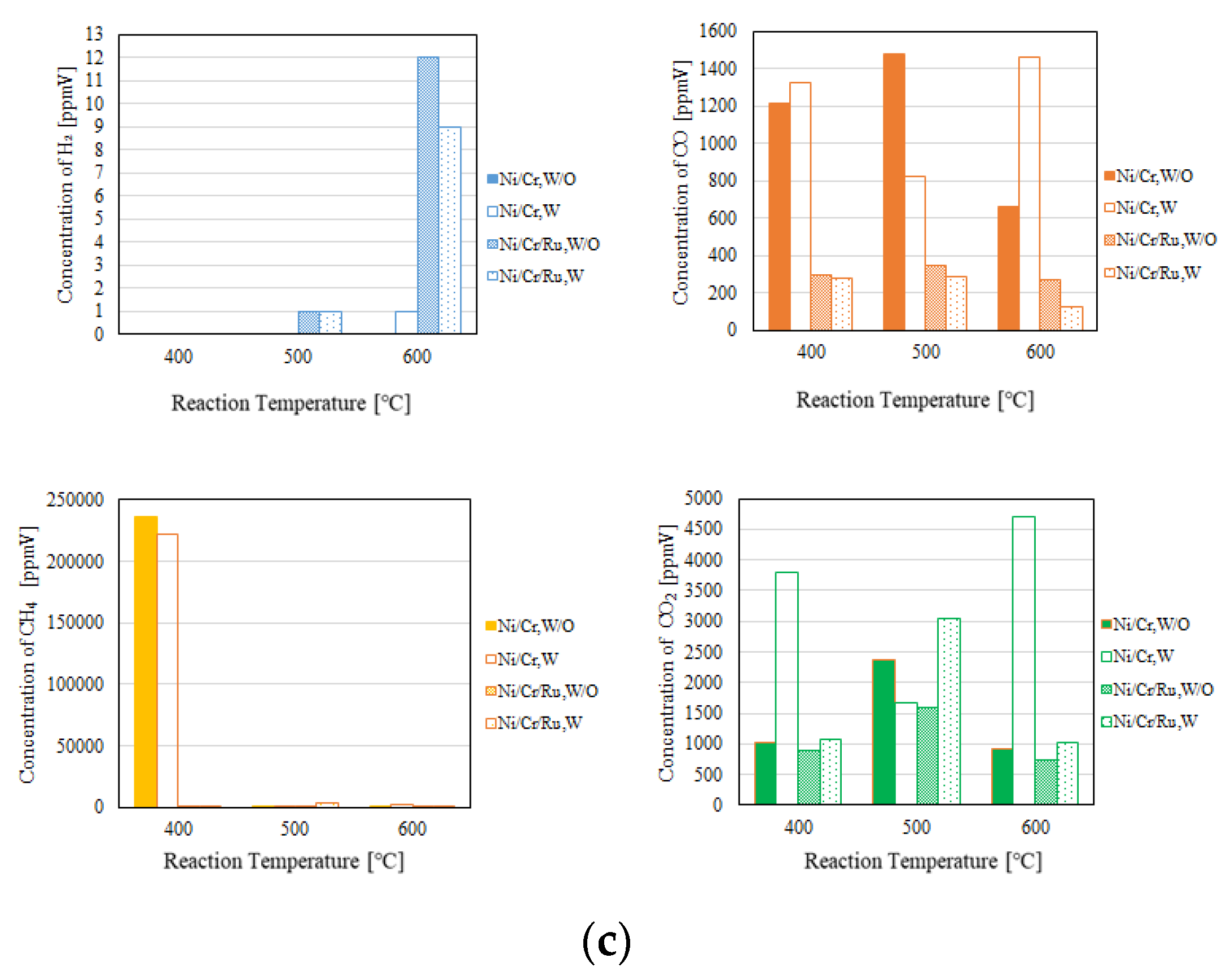

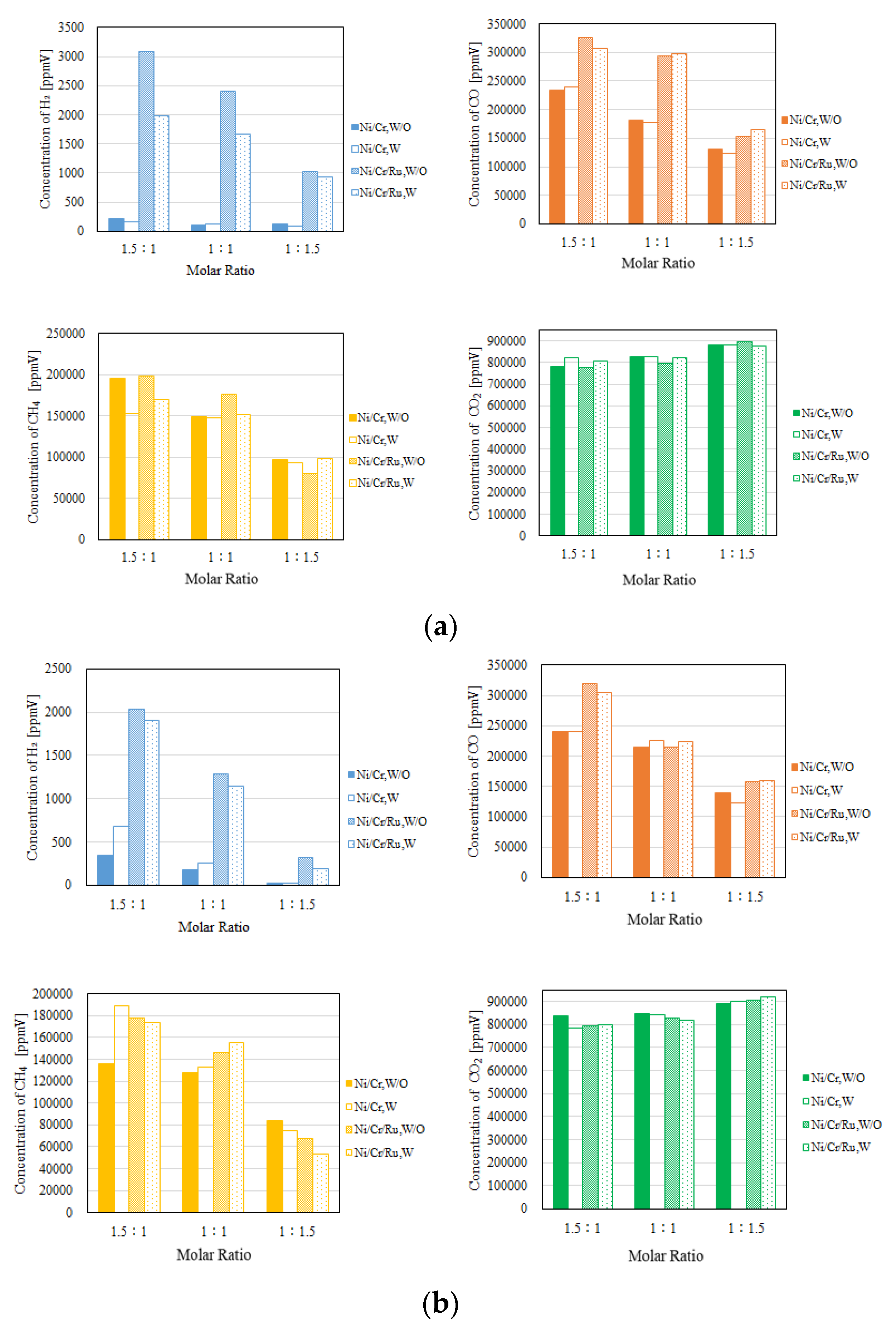

3.1. Comparison of Each Gas Concentration in Reaction Chabmber and Sweep Chamber Using Ni/Cr/Ru Catalyst with That Using Ni/Cr Catalyst Changing the Reaction Temperature and the Differential Pressure between the Reaction Chamber and The Sweep Chamber

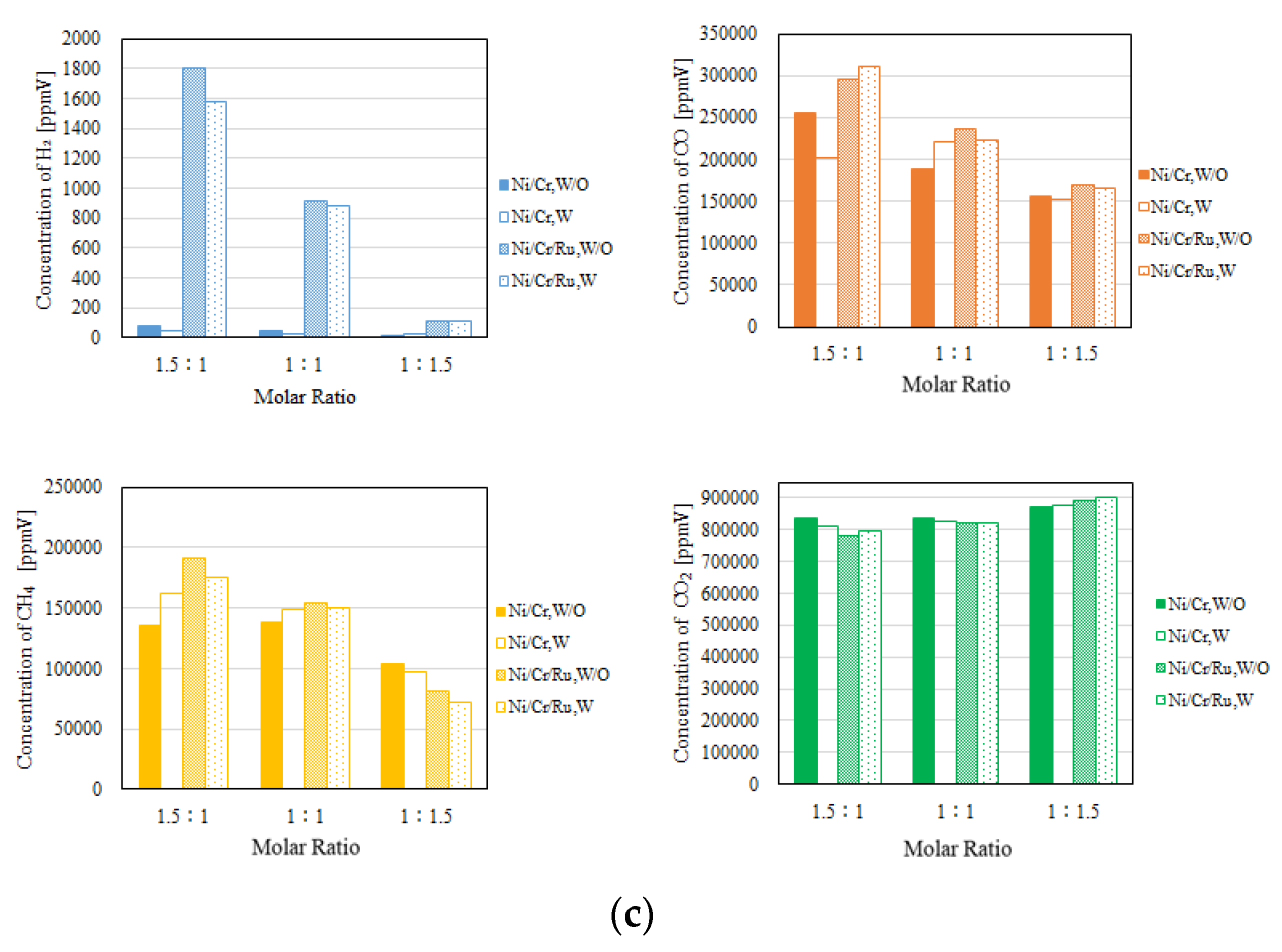

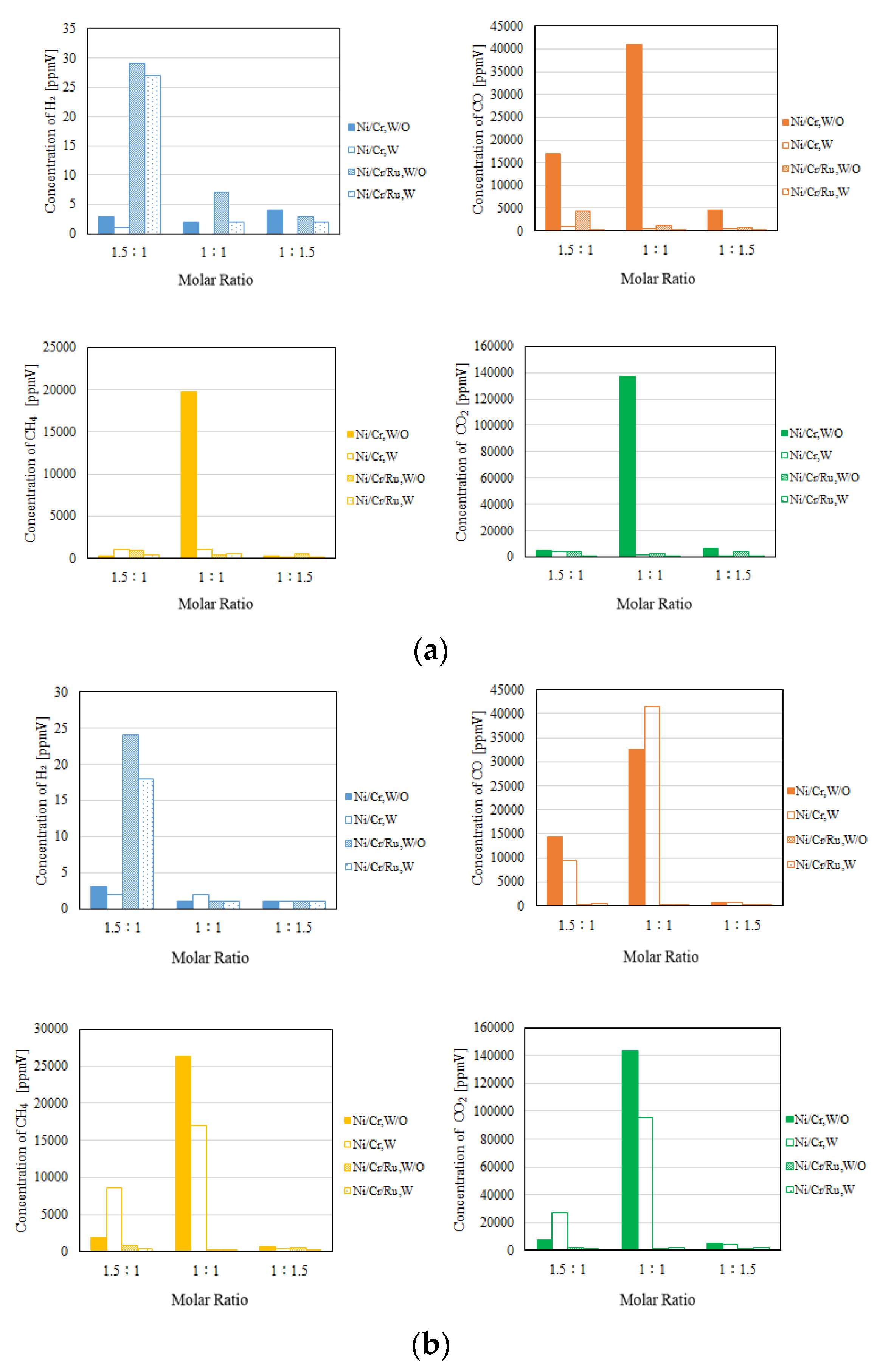

3.2. Comparison of each Gas Concentration in Reaction Chabmber and Sweep Chamber Using Ni/Cr/Ru Catalyst with That Using Ni/Cr Catalyst Changing The Molar Ratio and the Differential Pressure between the Reaction Chamber and the Sweep Chamber

3.3. Comparison of Assement Factor among the Investifated Experimental Conditions

4. Conclusions

- (i)

-

It is revealed that the concentration of H2 in the reaction chamber increases with theincrease in the reaction temperature. This tendency is confirmed irrespective of thecatalyst type as well as the differential pressure between the reaction chamber and thesweep chamber.

- (ii)

-

It is revealed that the concentration of H2 in the sweep chamber increases with theincrease in the reaction temperature. Since the concentration of H2 in the reactionchamber is higher at higher reaction temperature, the driving force to penetrate Pd/Cumembrane is larger due to the large H2 partial differential pressure between thereaction chamber and the sweep chamber. As a result, the higher concentration of H2in the sweep chamber is obtained.

- (iii)

-

It is revealed that the concentration of H2 in the reaction chamber and the sweepchamber is higher with the decrease in the differential pressure. As to the differentialpressure of 0.020 MPa, the differential pressure is too high, resulting that theseparation rate of H2 might be higher than the production rate of H2 in the reactionchamber. As a result, it is thought that the effective non-equilibrium state can not beobtained.

- (iv)

-

Regarding the effect of sweep gas, since the produced H2 is not high, the driving force,i.e. the difference in partial pressure of H2 between the reaction chamber and thesweep chamber is not high. As a result, it is thought that the improvement of H2separation is not obtained by the introduction of sweep gas.

- (v)

-

Comparing the performance of catalyst type, the concentration of H2 in the reactionchamber and that in the sweep chamber using Ni/Cr/Ru catalyst are much larger thanthose using Ni/Cr catalyst. This tendency is confirmed irrespective of the reactiontemperature and the differential pressure.

- (vi)

-

From the investigation by this study, the concentration of H2 using Ni/Cr/Ru catalystis larger than that using Ni/Cr catalyst by 2871 ppmV for the molar ratio of CH4 : CO2= 1.5 : 1 at the reaction temperature of 600 ℃ and the differential pressure of 0 MPawithout a sweep gas, especially. This study thinks that the synergy effect of them isobtained.

- (vii)

-

It is revealed that the highest concentration of H2 is obtained for the molar ratio ofCH4 : CO2 = 1.5 : 1 at 600 ℃ irrespective of the differential pressure and the catalysttype. The tendency that the highest concentration of H2 is obtained for the molar ratioof CH4 : CO2 = 1.5 : 1 among the investigated molar ratios matches with the authors’previous study investigating Ni and Ni/Cr catalyst.

- (viii)

-

According to the assessment evaluation, the CO2 conversion shows a negative valueand CO selectivity is much higher than H2 selectivity. The reaction mechanism can beexplained as follows: (i) H2 is produced by the reactions shown in Equation (1) and(5); (ii) the produced H2 is consumed by the reaction shown in Equation (2), resultingthat CO is produced; (iii) a part of CO produced by the reactions shown in Equations(1) and (2) is consumed during the reaction shown in Equation (6); (iv) H2O producedduring the reactions of Equations (2) and (3) are consumed by Equation (4).

- (ix)

-

From the investigation by this study, the highest concentration of H2 using Ni/Cr/Rucatalyst is obtained for the molar ratio of CH4 : CO2 = 1.5 : 1 at the reaction temperatureof 600 ℃ and the differential pressure of 0 MPa without a sweep gas, which is 3080ppmV. Under this condition, CH4 conversion, H2 yield and thermal efficiency are67.4 %, 1.77×10-2 % and 0.241 %, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalai, D.Y.; Stangeland, K.; Jin, Y.; Tucho, W.M.; Yu, Z. Biogas dry reforming for syngas production on La promoted hydrotalcitederived Ni catalyst. Int. J. Hydrog. Energy 2018, 43, 19438–19450. [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics. Available online: https://worldbioenergy.org./global-bioenergy-statistics (accessed on 2 April 2024).

- The Japan Gas Association. Available online: https://www.gas.or.jp/gas-life/biogas/ (accessed on 2 April 2024).

- Nishimura, A.; Takada, T.; Ohata, S.; Kolhe, M. L. Biogas dry reforming for hydrogen through membrane reactor utilizing negative pressure. fuels 2021, 2. [CrossRef]

- Nishimura, A.; Hayashi, Y.; Ito, S.; Kolhe, M. L. Performance analysis of hydrogen production for a solid oxide fuel cell system using a biogas dry reforming membrane reactor with Ni and Ni/Cr catalysts. fuels, 2023, 4. [CrossRef]

- Nishimura, A.; Sato, R.; Hu, E. An energy production system powered by solar heat with biogas dry reforming reactor and solar heat with biogas dry reforming reactor and solid oxide fuel cell. Smart Grid and Renewable Energy 2023, 14, 85-106. [CrossRef]

- Tang, L.; Huang, X.; Ran, J.; Guo, F.; Niu, J.; Qiu, H.; Ou, Z.; Yan, Y.; Yang, Z.; Qin, C. Density functional theory studies on direct and oxygen assisted activation of C-H bond for dry reforming of methane over Rh-Ni catalyst. International Journal of Hydrogen Energy 2022, 47, 30391-30403. [CrossRef]

- Rosset, M.; Feris, L. A.; Perez-Lopez, O. W. Biogas dry reforming using Ni-Al-LDH catalysts reconstructed with Mg and Zn. International Journal of Hydrogen Energy 2021, 46, 20359-20376. [CrossRef]

- Moreno, A. A.; Ramirez-Reina, T.; Ivanova, S.; Roger, A. C.; Centeno, M. A.; Odriozola, J. A. Bimetallic Ni-Ru and Ni-Re catalysts for dry reforming of methane: understanding the synergies of the selected promoters. Frontiers in Chemistry 2021, 9. [CrossRef]

- Shah, M.; Mondal, P. Optimization of CO2 reforming of methane process for the syngas production over Ni-Ce/TiO2-ZrO2 catalyst using the Taguchi method. International Journal of Hydrogen Energy 2021, 46, 22769-22812. [CrossRef]

- Sharma, H.; Dhir, A. Hydrogen augmentation of biogas through dry reforming over bimetallic nickel-cobalt catalysts supported on titania. Fuel 2020, 279. [CrossRef]

- Soria, M. A.; Mateos-Pedrero, C.; Guerrero-Ruiz, A.; Rodriguez-Ramos, I. Thermodynamic and experimental study of combined dry and steam reforming of methane on Ru/ZrO2-La2O3 catalyst at low temperature. International Journal of Hydrogen Energy 2011, 36, 15212-15220. [CrossRef]

- Andraos, S.; Abbas-Ghaleb, R.; Chlala, D.; Vita, A.; Italiano, C.; Lagana, M.; Pino, L.; Nakhl, M.; Specchia, S. Production of hydrogen by methane dry reforming over ruthenium-nickel based catalysts deposited on Al2O3 MgAl2O4 and YSZ. International Journal of Hydrogen Energy 2019, 44, 25706-25716. [CrossRef]

- Nishimura, A.; Ohata, S.; Okukura, K.; Hu, E. The impact of operating conditions on the performance of a CH4 dry reforming membrane reactor for H2 production. Journal of Energy and Power Technologies 2020, 2. [CrossRef]

- Cherbanski, R.; Kotkowski, T.; Molga, E. Thermogravimetric analysis of coking during dry reforming of methane. International Journal of Hydrogen Energy 2023, 48, 7346-7360. [CrossRef]

| Parameters | Information |

| Initial reaction temperature (Pre-set reaction temperature) [℃] | 400, 500, 600 |

| Pressure of supply gas [MPa] | 0.10 |

| Differential pressure between the reaction chamber and the sweep chamber [MPa] | 0, 0.010 and 0.020 |

| Molar ratio of provided CH4 : CO2 (Flow rate of provided CH4 : CO2 [NL/min]) | 1.5 : 1, 1 : 1 and 1 : 1.5 (1.088 : 0.725, 0.725 : 0.725, 0.725 : 1.088) |

| Feed ratio of sweep gas to supply gas [-] | 0 (W/O), 1.0 (W) |

| Reaction temperature [℃] | Catalyst | Sweep gas | CH4 conversion [%] | CO2 conversion [%] | H2 yield [%] | H2 selectivity [%] | CO selectivity [%] | H2 permeability [%] | Permeation flux [mol/(m2·s)] | Thermal efficiency [%] |

| (a) | ||||||||||

| 400 | Ni/Cr | W/O | 52.9 | -73.0 | 0 | 0 | 100 | 0 | 0 | 0 |

| W | 52.5 | -72.5 | 0 | 0 | 100 | 0 | 0 | 0 | ||

| Ni/Cr/Ru | W/O | 67.4 | -94.8 | 1.03×10-2 | 4.23×10-2 | 100 | 1.63 | 0 | 0.213 | |

| W | 69.0 | -97.2 | 1.05×10-2 | 4.29×10-2 | 100 | 0.794 | 0 | 0.141 | ||

| 500 | Ni/Cr | W/O | 69.3 | -97.7 | 0 | 2.34×10-3 | 100 | 0 | 0 | 8.36×10-3 |

| W | 68.9 | -97.0 | 0 | 1.66×10-3 | 100 | 0 | 0 | 3.55×10-3 | ||

| Ni/Cr/Ru | W/O | 66.2 | -92.7 | 0 | 2.34×10-3 | 100 | 0 | 0 | 8.36×10-3 | |

| W | 65.7 | -92.1 | 8.41×10-2 | 0.332 | 99.7 | 9.91×10-2 | 0 | 0.895 | ||

| 600 | Ni/Cr | W/O | 67.4 | -94.9 | 1.77×10-2 | 8.41×10-2 | 99.9 | 1.42 | 0 | 0.241 |

| W | 74.5 | -105 | 1.33×10-2 | 6.65×10-2 | 99.9 | 0.625 | 0 | 0.117 | ||

| Ni/Cr/Ru | W/O | 67.4 | -94.9 | 1.77×10-2 | 8.41×10-2 | 99.9 | 1.42 | 0 | 0.241 | |

| W | 71.8 | -101 | 0.167 | 0.649 | 99.4 | 1.34 | 0 | 1.46 | ||

| (b) | ||||||||||

| 400 | Ni/Cr | W/O | 55.0 | -50.0 | 0 | 0 | 100 | 0 | 0 | 0 |

| W | 63.7 | -58.7 | 0 | 0 | 100 | 0 | 0 | 0 | ||

| Ni/Cr/Ru | W/O | 66.9 | -61.9 | 9.40×10-3 | 4.26×10-2 | 100 | 1.06 | 0 | 0.164 | |

| W | 70.0 | -650. | 7.50×10-3 | 3.35×10-2 | 100 | 1.33 | 0 | 8.31×10-2 | ||

| 500 | Ni/Cr | W/O | 74.2 | -69.2 | 0 | 0 | 100 | 0 | 0 | 0 |

| W | 75.8 | -70.8 | 0 | 0 | 100 | 0 | 0 | 0 | ||

| Ni/Cr/Ru | W/O | 72.2 | -67.0 | 6.22×10-2 | 0.253 | 99.7 | 0.161 | 0 | 0.861 | |

| W | 72.7 | -67.6 | 4.08×10-2 | 0.171 | 99.8 | 0.245 | 0 | 0.360 | ||

| 600 | Ni/Cr | W/O | 70.3 | -65.3 | 1.15×10-2 | 5.17×10-2 | 99.9 | 1.74 | 0 | 0.130 |

| W | 69.8 | -64.5 | 0.167 | 0.557 | 99.4 | 0.120 | 0 | 9.01×10-2 | ||

| Ni/Cr/Ru | W/O | 64.9 | -59.4 | 0.241 | 0.812 | 99.2 | 0.290 | 0 | 2.76 | |

| W | 69.8 | -64.5 | 0.167 | 0.557 | 99.4 | 0.120 | 0 | 1.22 | ||

| (c) | ||||||||||

| 400 | Ni/Cr | W/O | 79.4 | -48.8 | 0 | 0 | 100 | 0 | 0 | 0 |

| W | 79.5 | -48.8 | 0 | 0 | 100 | 0 | 0 | 0 | ||

| Ni/Cr/Ru | W/O | 77.4 | -47.5 | 2.00×10-3 | 1.14×10-2 | 100 | 6.25 | 0 | 2.63×10-2 | |

| W | 77.5 | -47.5 | 2.38×10-3 | 1.48×10-2 | 100 | 0 | 0 | 2.13×10-2 | ||

| 500 | Ni/Cr | W/O | 74.1 | -45.2 | 0 | 0 | 100 | 0 | 0 | 0 |

| W | 74.4 | -45.4 | 0 | 0 | 100 | 0 | 0 | 0 | ||

| Ni/Cr/Ru | W/O | 76.8 | -47.0 | 2.06×10-2 | 8.86×10-2 | 99.9 | 0 | 0 | 0.229 | |

| W | 77.5 | -47.5 | 1.30×10-2 | 5.69×10-2 | 99.9 | 0 | 0 | 9.21×10-2 | ||

| 600 | Ni/Cr | W/O | 75.9 | -46.4 | 1.70×10-2 | 0.101 | 99.9 | 2.94 | 0 | 0.151 |

| W | 76.9 | -47.1 | 1.11×10-2 | 7.16×10-2 | 99.9 | 0 | 0 | 6.51×10-2 | ||

| Ni/Cr/Ru | W/O | 80.0 | -49.0 | 0.129 | 0.660 | 99.3 | 0.291 | 0 | 1.18 | |

| W | 75.5 | -46.0 | 0.116 | 0.561 | 99.4 | 0.216 | 0 | 0.677 | ||

| Reaction temperature [℃] | Catalyst | Sweep gas | CH4 conversion [%] | CO2 conversion [%] | H2 yield [%] | H2 selectivity [%] | CO selectivity [%] | H2 permeability [%] | Permeation flux [mol/(m2·s)] | Thermal efficiency [%] |

| (a) | ||||||||||

| 400 | Ni/Cr | W/O | 38.4 | -51.3 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 |

| W | 67.2 | -94.5 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 73.2 | -104 | 5.92×10-3 | 2.71×10-2 | 100 | 0 | 5.00×10-3 | 0.125 | |

| W | 72.2 | -102 | 4.08×10-3 | 1.84×10-2 | 100 | 0 | 5.00×10-3 | 5.51×10-2 | ||

| 500 | Ni/Cr | W/O | 67.0 | -94.2 | 0 | 1.23×10-3 | 100 | 0 | 5.00×10-3 | 4.18×10-3 |

| W | 68.2 | -96.0 | 0 | 2.45×10-3 | 100 | 0 | 5.00×10-3 | 5.33×10-3 | ||

| Ni/Cr/Ru | W/O | 68.1 | -95.7 | 5.12×10-2 | 0.201 | 99.8 | 0 | 5.00×10-3 | 0.856 | |

| W | 68.0 | -95.6 | 4.27×10-2 | 0.152 | 99.8 | 0 | 5.00×10-3 | 0.455 | ||

| 600 | Ni/Cr | W/O | 77.4 | -110 | 2.90×10-2 | 0.136 | 99.9 | 0 | 5.00×10-3 | 0.397 |

| W | 68.5 | -96.3 | 5.74×10-2 | 0.275 | 99.7 | 0 | 5.00×10-3 | 0.504 | ||

| Ni/Cr/Ru | W/O | 70.4 | -98.9 | 0.171 | 0.638 | 99.4 | 1.167 | 5.00×10-3 | 2.34 | |

| W | 71.0 | -99.8 | 0.160 | 0.624 | 99.4 | 0.938 | 5.00×10-3 | 1.40 | ||

| (b) | ||||||||||

| 400 | Ni/Cr | W/O | 47.4 | -42.4 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 |

| W | 26.8 | -21.8 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 69.7 | -64.7 | 7.80×10-3 | 3.86×10-2 | 100 | 0 | 5.00×10-3 | 0.137 | |

| W | 72.7 | -67.7 | 6.70×10-3 | 3.34×10-2 | 100 | 0 | 5.00×10-3 | 7.53×10-2 | ||

| 500 | Ni/Cr | W/O | 78.7 | -73.7 | 0 | 1.66×10-3 | 100 | 0 | 5.00×10-3 | 4.16×10-3 |

| W | 81.6 | -76.6 | 0 | 1.13×10-3 | 100 | 0 | 5.00×10-3 | 1.77×10-3 | ||

| Ni/Cr/Ru | W/O | 68.4 | -63.3 | 4.44×10-2 | 0.186 | 99.8 | 0 | 5.00×10-3 | 0.616 | |

| W | 74.2 | -69.1 | 3.68×10-2 | 0.126 | 99.9 | 0 | 5.00×10-3 | 0.326 | ||

| 600 | Ni/Cr | W/O | 74.5 | -69.5 | 1.83×10-2 | 7.41×10-2 | 99.9 | 0.546 | 5.00×10-3 | 0.209 |

| W | 73.5 | -68.4 | 2.60×10-2 | 9.70×10-2 | 99.9 | 0.769 | 5.00×10-3 | 0.189 | ||

| Ni/Cr/Ru | W/O | 70.8 | -65.6 | 0.128 | 0.595 | 99.4 | 7.80×10-2 | 5.00×10-3 | 1.47 | |

| W | 68.9 | -63.7 | 0.115 | 0.509 | 99.5 | 0.087 | 5.00×10-3 | 0.841 | ||

| (c) | ||||||||||

| 400 | Ni/Cr | W/O | 97.4 | -60.8 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 |

| W | 76.2 | -46.6 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 76.9 | -47.1 | 2.25×10-3 | 1.21×10-2 | 100 | 5.56 | 5.00×10-3 | 2.98×10-2 | |

| W | 74.3 | -45.3 | 2.25×10-3 | 1.22×10-2 | 100 | 0 | 5.00×10-3 | 2.02×10-2 | ||

| 500 | Ni/Cr | W/O | 76.2 | -46.6 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 |

| W | 77.0 | -47.2 | 0 | 0 | 100 | 0 | 5.00×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 72.7 | -44.3 | 1.46×10-2 | 6.48×10-2 | 99.9 | 0 | 5.00×10-3 | 0.162 | |

| W | 75.4 | -46.1 | 9.50×10-3 | 4.12×10-2 | 100 | 1.32 | 5.00×10-3 | 6.64×10-2 | ||

| 600 | Ni/Cr | W/O | 79.0 | -48.5 | 3.75×10-3 | 2.14×10-2 | 100 | 3.33 | 5.00×10-3 | 3.32×10-2 |

| W | 81.2 | -50.0 | 3.50×10-3 | 2.26×10-2 | 100 | 3.57 | 5.00×10-3 | 1.97×10-2 | ||

| Ni/Cr/Ru | W/O | 83.2 | -51.2 | 4.01×10-2 | 0.202 | 99.8 | 0.312 | 5.00×10-3 | 0.366 | |

| W | 86.7 | -53.6 | 2.34×10-2 | 0.117 | 99.9 | 0.535 | 5.00×10-3 | 0.136 | ||

| Reaction temperature [℃] | Catalyst | Sweep gas | CH4 conversion [%] | CO2 conversion [%] | H2 yield [%] | H2 selectivity [%] | CO selectivity [%] | H2 permeability [%] | Permeation flux [mol/(m2·s)] | Thermal efficiency [%] |

| (a) | ||||||||||

| 400 | Ni/Cr | W/O | 66.3 | -93.2 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 |

| W | 67.6 | -95.1 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 67.0 | -94.2 | 7.08×10-3 | 3.08×10-2 | 100 | 0 | 7.07×10-3 | 0.150 | |

| W | 68.9 | -97.1 | 6.00×10-3 | 2.63×10-2 | 100 | 0 | 7.07×10-3 | 8.08×10-2 | ||

| 500 | Ni/Cr | W/O | 69.9 | -98.6 | 0 | 1.64×10-3 | 100 | 0 | 7.07×10-3 | 5.57×10-3 |

| W | 67.7 | -95.3 | 0 | 2.45×10-3 | 100 | 0 | 7.07×10-3 | 5.33×10-3 | ||

| Ni/Cr/Ru | W/O | 69.9 | -98.5 | 3.40×10-2 | 0.117 | 99.9 | 0.245 | 7.07×10-3 | 0.567 | |

| W | 74.0 | -105 | 1.97×10-2 | 6.78×10-2 | 99.9 | 0.424 | 7.07×10-3 | 0.209 | ||

| 600 | Ni/Cr | W/O | 77.3 | -110 | 6.17×10-3 | 2.90×10-2 | 100 | 0 | 7.07×10-3 | 8.53×10-2 |

| W | 72.9 | -103 | 4.33×10-3 | 2.56×10-2 | 100 | 1.92 | 7.07×10-3 | 3.75×10-2 | ||

| Ni/Cr/Ru | W/O | 68.2 | -95.6 | 0.151 | 0.611 | 99.4 | 0.661 | 7.07×10-3 | 2.08 | |

| W | 70.8 | -99.6 | 0.132 | 0.508 | 99.5 | 0.567 | 7.07×10-3 | 1.16 | ||

| (b) | ||||||||||

| 400 | Ni/Cr | W/O | 67.2 | -62.2 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 |

| W | 25.5 | -20.5 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 72.9 | -67.8 | 4.80×10-3 | 2.37×10-2 | 100 | 0 | 7.07×10-3 | 8.46×10-2 | |

| W | 74.4 | -69.4 | 4.00×10-3 | 1.87×10-2 | 100 | 0 | 7.07×10-3 | 4.49×10-2 | ||

| 500 | Ni/Cr | W/O | 69.8 | -64.8 | 0 | 4.32×10-3 | 100 | 0 | 7.07×10-3 | 1.39×10-3 |

| W | 69.4 | -64.4 | 0 | 1.81×10-3 | 100 | 0 | 7.07×10-3 | 3.54×10-3 | ||

| Ni/Cr/Ru | W/O | 73.3 | -68.2 | 3.47×10-2 | 0.139 | 99.9 | 0 | 7.07×10-3 | 0.481 | |

| W | 71.5 | -66.4 | 2.79×10-2 | 0.113 | 99.9 | 0.358 | 7.07×10-3 | 0.246 | ||

| 600 | Ni/Cr | W/O | 72.3 | -67.3 | 5.00×10-3 | 2.59×10-2 | 100 | 2.00 | 7.07×10-3 | 5.63×10-2 |

| W | 70.1 | -65.1 | 2.20×10-3 | 9.92×10-3 | 100 | 4.55 | 7.07×10-3 | 1.54×10-2 | ||

| Ni/Cr/Ru | W/O | 69.1 | -63.9 | 9.12×10-2 | 0.384 | 99.6 | 0.110 | 7.07×10-3 | 1.05 | |

| W | 69.9 | -64.7 | 8.87×10-2 | 0.396 | 99.6 | 0.113 | 7.07×10-3 | 0.649 | ||

| (c) | ||||||||||

| 400 | Ni/Cr | W/O | 66.3 | -93.2 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 |

| W | 67.6 | -95.1 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 67.0 | -94.2 | 7.08×10-3 | 3.08×10-2 | 100 | 0 | 7.07×10-3 | 0.150 | |

| W | 68.9 | -97.1 | 6.00×10-3 | 2.63×10-2 | 100 | 0 | 7.07×10-3 | 8.09×10-2 | ||

| 500 | Ni/Cr | W/O | 78.7 | -48.3 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 |

| W | 81.1 | -49.9 | 0 | 0 | 100 | 0 | 7.07×10-3 | 0 | ||

| Ni/Cr/Ru | W/O | 76.6 | -46.9 | 1.19×10-2 | 5.35×10-2 | 99.9 | 1.05 | 7.07×10-3 | 0.130 | |

| W | 78.0 | -47.8 | 9.50×10-3 | 4.02×10-2 | 100 | 0 | 7.07×10-3 | 6.73×10-2 | ||

| 600 | Ni/Cr | W/O | 73.9 | -45.1 | 2.25×10-3 | 1.15×10-2 | 100 | 5.56 | 7.07×10-3 | 1.94×10-2 |

| W | 75.6 | -46.2 | 3.88×10-3 | 2.04×10-2 | 100 | 3.23 | 7.07×10-3 | 2.19×10-2 | ||

| Ni/Cr/Ru | W/O | 79.7 | -48.9 | 1.41×10-2 | 6.62×10-2 | 99.9 | 0.885 | 7.07×10-3 | 0.128 | |

| W | 81.8 | -50.4 | 1.35×10-2 | 6.51×10-2 | 99.9 | 0.926 | 7.07×10-3 | 7.82×10-2 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).