1. Introduction

Global energy consumption has increased significantly, mainly using fossil energy. The primary energy consumption has shared by oil, natural gas, coal, nuclear energy, renewable energies and electricity 31.2 %, 24.7%, 27.2%, 6.7%, 5.7 % and 4.3% of overall energy in the world in 2020, respectively [

1]. More or less, 80% of the world’s main energy use is provided by fossil fuels in 2020 [

2]. Most countries, particularly developing countries, face energy crunches owing to over-dependence on fossil fuels [

3]. The energy carters of all nations are environmental safety, energy protection, and economic development. The fossil fuels meet the risk of imminent reduction whereas non-oil producing nations meets energy security problems as a result of over dependence on fossil fuels whose distribution is mainly influenced by external factors [

4]. Adding to the energy crisis, climate changes due to greenhouse gas emissions, the Kyoto Protocol recommends that all countries switch to renewable energy to reduce the energy crisis. Rather than that, according to the world energy council, landfill waste is rapidly increasing and a projection of more than six million tons of waste will be produced every day by 2025 worldwide [

5].

Biogas technology is the best strategy for managing landfill waste as raw material to produce energy. Biogas has proven to be multi-purpose solution technology that can provide an efficient strategy for producing clean energy while at the same time conserving the environment. Biogas production through an anaerobic digestion (AD) process led to the generation of approximately 40-70% methane (CH

2) and traces of impurities which include carbon dioxide (CO

2), nitrogen (N2), hydrogen sulfide (H

2S), hydrogen (H

2), ammonia (NH

3), oxygen (O

2), carbon monoxide (CO), water (H

2O), dust particles, siloxanes, aromatic and halogenated compounds [

6].

Anaerobic digestion is the breakdown of organic material (biomass) by microorganisms in absence of oxygen. AD process consists of three stages which include hydrolysis, fermentation (acidogenesis and acetogenesis), and methane fermentation [

7]. Hydrolysis is a process where larger and insoluble organic materials are broken down into soluble compounds such as sugar, amino acid, and fatty acids by different microorganisms which include Streptococci, Bactericides, Clostridia, etc. In the second stage of anaerobic digestion (acidogenesis and acetogenesis), soluble organic compounds from the hydrolysis process are broken down by various microorganisms such as methanothrix, methanococcus, and methanobacterium into different compounds which include acetic acid, carbon dioxide, and hydrogen. Methane fermentation is the last stage of anaerobic digestion where compounds are broken down into methane and other gases such as carbon dioxide.

The gas produced from the above processes can be used for various purposes as a source of energy, for example, heating, fuel for electricity production, and fuel cells substrate to replace natural gas [

8]. Although anaerobic digestion is an appropriate technology widely established around the world, system instability and lower efficiency than other energy sources are commonly faced problems throughout the running of biogas [

9]. By controlling thermo physical parameters like temperature, pH, HRT, C/N ratio, solid concentration, moisture, OLR, nitrogen content, stirring/mixing, seeding of biogas plants, particle size, nutrient concentration and pre-treatment, the efficiency of the biogas power plants can be improved [

10,

11,

12,

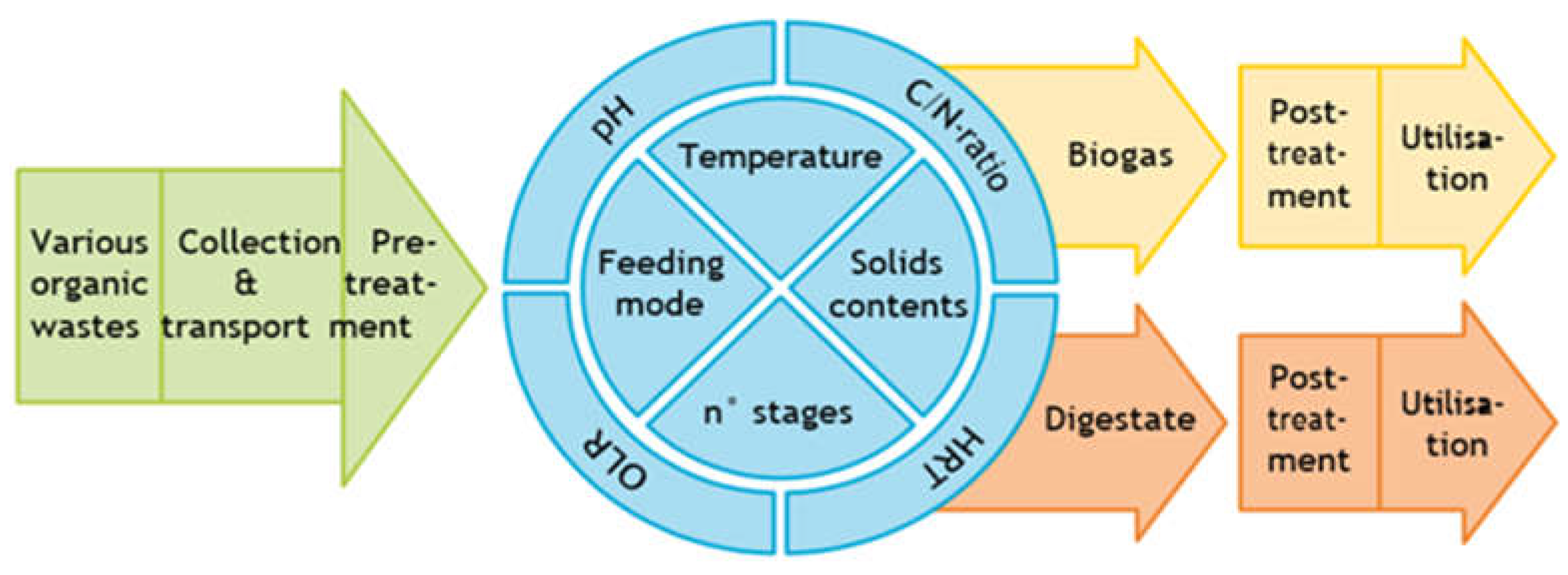

13]. The various stages of the biogas production process are shown in

Figure 1. Many researchers have studied the effects of various parameters on biogas production. However, optimizing parameters using some experimental design methods is of great significance for improving the efficiency of biogas power plants.

The objectives of this study include: (1) To analyze the effects of temperature, pretreatment, pH value and retention ratio on biogas production during anaerobic digestion of cow manure. (2) Analyze the methanogenic performance of microorganisms at high temperatures (3) Compare the effects of different pretreatments on biogas production (4) Optimize the parameters to achieve the highest biogas yield during anaerobic co-digestion of cow manure and food waste using Taguchi Design of Experiments.

2. Factors Affecting on Anaerobic Digestion

Anaerobic decomposition depends on various thermo physical parameters for efficient operation. For obtaining efficient operation of bio gas power plants several operational parameters have to be considered into account rather than its design criteria. These operational parameters are to be controlled to avoid the problems that lead to inhibition of bio gas production. The different parameters selected for the present study are detailed below.

2.1. Temperature

The anaerobic digestion system significantly depends on the inside digester temperature. Many researchers have observed that the physical and physio-chemical properties of compounds, microbial species, kinetic and thermodynamic properties of biological processes, stability and methane yield are significantly affected by temperature [

14]. There are different temperature extents that can be applied during anaerobic decomposition: Psychrophilic, Mesophilic and thermophilic of < 30℃, 30–40℃ and 50–60℃, respectively. In most cases, AD processes are preferred under mesophilic conditions [

15]. Because it requires minimal energy consumption under medium temperature conditions and is more stable during operation. Due to lower temperatures in the digestive system microbial growth, feedstock degradation rates, and biogas yield are reduced [

16,

17]. As well, cellular energy depletion and intracellular material leakage may also be affected by low temperatures [

18]. On the other hand, volatile CH

4 gases are produced at high temperatures, inhibiting methanogenesis activities and leading to a decrease in biogas production [

19].Briški et al., [

20] stated that temperature should maintained below 65℃, since the enzyme will denature during digestion above 65°C. Anyhow, faster digestion of organic matter, higher methane production, lower waste water viscosity, and higher annihilation of pathogen growth are possible under high temperature conditions [

20].

Owing to uphold the optimal temperature within the digester, some factors can be considered when setting up the digester and coated with thermal insulation materials within an appropriate [

22]. By coating charcoal around the digester floor, gas production in a biogas plant increased by 7-15% [

23]. If the internal temperature of the digester is maintained at 40°C, the HRT can be decreased by more than 40 % [

24]. Hot water can also be used during raw material preparation, which helps improve production performance. The operating temperature for the anaerobic digestion process goes up to approximately 60 0C. Thermophilic bacteria are active at (50 -60 °C). Mesophilic bacteria are active in a temperature range of (30 to 40 °C) and psychrophilic bacteria in less than 30°C.

2.2. Pre-Treatment

Pre-treatment of substrates aids bio-digestion and maximizes the efficiency of biogas power plants. Since there are multiple pre-treatment methods, one method effective for one type of substrate may not be suitable for another. Therefore, it is important to analyse the change of other process parameters during pre-treatment. Hren et al. [

25] examined two different pre-treatment technologies, thermal and biological, during the fermentation of sewage sludge and riverbank grass. Thermal treatments were carried out at lower temperature (38.6 °C) and higher temperature (80 °C). Biological treatment was performed by mixing the substrate with cattle rumen fluid. The results showed that pre-treatment helps to effectively change operating parameters, while low-temperature biological and thermal treatment improve biogas production. Hamdi [

26] found that pre-treatment of olive mill waste by fermentation with Aspergillus Niger reduced the toxicity of methanogens and improved the AD process. Lin et al.,[

30] showed that alkali pre-treatment with various proportions of sodium hydroxide solutions prior to AD of pulp and paper sludge (PPS) can increase methane production.

2.3. pH

The growth of microorganisms during AD process is significantly influenced by pH. Many researchers have been reported neutral pH is optimal for high methane yield. Because, most of the microorganisms, which produce methane cultivates at the pH range of 6.7 - 7.5 [

28]. During digestion, hydrolysis and acidogenesis processes happens at acidic pH ranges of 5.5 – 6.5 while methanogenic stage happens at pH of 6.5 to 8.2 [

29]. Nearly 3000 mg/L of alkalinity concentration must be maintained for the appropriate buffering capability of the bio digester. Ward et al.,[

30] reported an optimal pH level of 6.8-7.2 can enhance the AD process. Lee et al., [

31] concluded that methanogenesis phase can be completed successfully at pH levels of 6.5-8.2.

2.4. Mixing Ratio

Anaerobic digestion of waste materials often suffers the carbon deficiency, for this reason the biogas production rate becomes slower than the expected rate. The agricultural wastes are known as the most potential biomass for anaerobic digestion, but the single digestion of agricultural waste provides the insufficiency of carbon. [

32]. As well, the animal manure is now being used as a potential source of biogas, but the moisture content in the animal manure causes the dilution in the anaerobic digestion [

33]. Agricultural residues and cattle manure are both very promising substrates for the extraction of biogas via anaerobic digestion with very low capital costs. However, the above-mentioned shortcomings have hindered the productivity of biogas. To overcome these obstacles, anaerobic co-digestion can be used instead of single and separate anaerobic digestion [

34]. The above researches reveal that, the co-digestion of chicken waste with food wastes or cattle manure provides better nutrients to the digestion system and thus enhance the biogas production process than the single anaerobic digestion of the above-mentioned wastes. Though there are many advantages of anaerobic co-digestion, but the use of different types of organic wastes has made this technique more sophisticate. In particular, the wrong choice of organic substrate can easily damage the system. In addition, in anaerobic co-digestion, the mixing ratio between waste raw materials plays a very important and influential role. Unconventional mixing ratios can easily disrupt the biogas production process, while appropriate mixing ratios can produce more biogas with higher methane concentrations [

35].

3. Materials and Methods

Anaerobic decomposition depends on various thermo physical parameters for efficient operation. For obtaining efficient operation of bio gas power plants several operational parameters have to be considered into account rather than its design criteria. These operational parameters are to be controlled to avoid the problems that lead to inhibition of bio gas production. The different parameters selected for the present study are detailed below.

This study focused on analyzing the effect of temperature, pre-treatment, retention time and mixing ratio of the biogas production and to optimize the parameters based on highest biogas production using Taguchi Design of Experiments.

3.1. Experimental Set Up

This study analysed the effect of the temperature pH and mixing ratio during the anaerobic digestion of cow manure alone and co digestion of cow manure (CM) and food waste (FW). Cow dung was collected and treated at Kumamoto University. A clean container with a lid was used for obtaining the cow manure. The sample obtained was dried for five days and then using a mortar and a pestle it was pulverized in a 2000 ml pot. After pulverization, the cow dung waste was filtered and dried for two more days. 100g of the dried and screened cow dung was weighed and added into a 2000 ml pot and then stirred with 300 cm

3 of distilled water, in the ratio of 1:3. The blend was thoroughly mixed using a stir to ensure homogeneity solution was achieved. The substrate preparation is shown in

Figure 2.

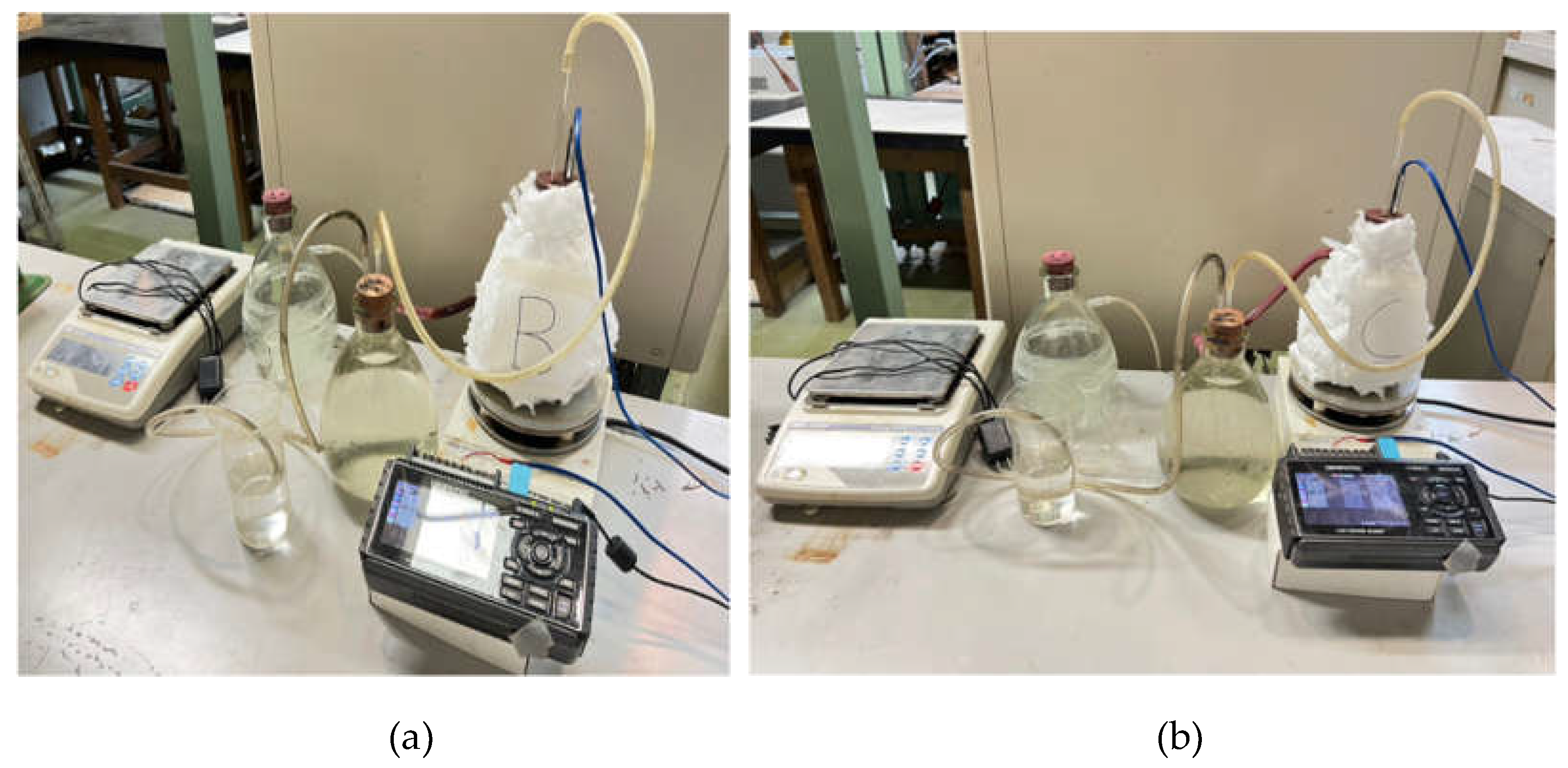

Three sets of reactors (A, B and C) were used for experimental studies. These reactors were connected with water displacement method for gas volume measurement. The reactor A was maintained at context temperature (28 °C) and gas was obtained over water. The reactor B was maintained at an optimal temperature of (35 °C) and gas was obtained over water. The reactor C was kept at 50 °C and gas was collected over water. The experimental test set up of reactor A, reactor B and reactor C are shown in

Figure 3,

Figure 4 (a) and

Figure 4 (b), respectively. Each set of experimental tests set up contained a 500 ml reactor and a 1000 ml collection flask. The 2000 ml pot was used for pulverization. The ends of all delivery tubes were well sealed to ensure there was no leakage. The prepared substrates were fed into the reactors and left to undergo anaerobic digestion for four weeks of retention time frame, the gas yields were measured on weekly basis. Food waste is collected from the canteen of Kumamoto university and blended with a kitchen blender and used for the digestion.

3.2. Analysis of Methanogenic Performance

For analyzing the activity microorganisms at higher temperature, a characterization study is carried out with the analysis of acetate, propionate, butyrate, hydrogen, glucose, and formate. The 2 ml slurry is added in a 60 ml bottles, which contains 48 mM sodium acetate, 24 mM butyrate, 1.8 g/l glucose, 24 mM formate, 24 mM sodium propionate and 101 kPa H2/CO2 (80%: 20%) overpressure. The bottle is then placed in an incubator maintained at 55 and 65°C in stirred water.

3.3. Pre-Treatment Methods Used

The gas volume production from three different types of pre-treated substrates (ultrasonication, autoclaved and microwave) were subjected to the analysis and the comparison with untreated substrate. The ultrasonic testing tool used in this study was the Vibra Cell ultrasonic processor. The device uses a titanium alloy capsule tube probe with an operating frequency of 20kHz and an output power of 130W. The sample was thereby sonicated for 30 minutes. Heat treatment of autoclave thermal systems with the assistance of Zipper clave (Autoclave French). Temperature control is accomplished using PID controller. Cow dung is pre-treated in the autoclave maintained at pressure 10 bar and temperature 120 °C for 30 min. The Microwave pre-treatment was carried out by using a microwave oven equipped with a rotating arm. The treatment of the cow dung prior to hydrothermal carbonization was done inside a 2 L polypropylene pot. The rotating tray changes the way the container rotates, this way allowing each part to have more than a modest viewpoint. The samples of cow dung were injected at ambient temperature and kept at 20 °C prior to feeding

3.3. Taguchi Design of Experiments

Taguchi Design of Experiments helps to optimize the factors which affect the anaerobic digestion with minimum number of experiments [

36,

37]. The selection of process parameters, and their values depends on the earlier studies on literature. Signal-to-Noise ratio is utilized in Taguchi Design of Experiments to evaluate an output of the provided group in input variables. Three different terms in S/N ratios are: ‘‘smaller the better”, ‘‘nominal the better” and ‘‘larger the better,”,” reliant on output variables. The Signal/Noise ratios determine from the response and then the optimal condition is calculated from each of the responses.

The formulas utilized to calculate the S/N ratios are given below:

For larger the better instant.

For smaller the better instant

In the present analysis there are three control factors which affects anaerobic co-digestion of food waste and cow manure viz. temperature, pH and mixing ratio that vary in three levels as shown in

Table 1. While considering the control parameters and their levels, the number of analyses required for the optimization study is very high. It is highly complicated and time consuming.

3.3. Analysis of Variance (ANOVA)

Analysis of Variance (ANOVA) is used for studying the influence of considered parameters (temperature, pH and mixing ratio) on the biogas production. ANOVA spans deviation of output (biogas production) between the considered parameters. This analysis helps to find the factors that influence the biogas production for a wide variation. It is used for analyzing the variations on the output responses and also can find the contribution of each parameters on the selected parameters. It also helps to identify the contribution of each parameters on the result variables.

3. Results and Discussions

3.1. Effect of Temperature

The biogas levels and pH from the anerobic digestion of the 3 sets of reactors were recorded. Reactor B is maintained at 35°C showed the highest biogas production of 156 mL. While the reactor A which is maintained at lower temperature (28°C) produced the lower volume of biogas (48 mL). The results from

Table 2, it is seen that the higher quantity of biogas yield reported at 28th day (week 4). The quantity of biogas increased with the increase in retention time amongst reactors A, B, and C. The amount of biogas produced is low in the first few weeks because the cow manure has not yet completely decomposed, so the growth rate of the methanogens is quite low and they are unable to produce biogas. This response due to the reason that cattle dung is mainly contains fibrous materials, and it take a long time to completely degrade. This is why the highest biogas production was recorded in the fourth week. Retention time will be based on different operating parameters of the anaerobic reactor, which include pH level, feed rate, temperature, particle size, total solids, alkalinity, and carbon to nitrogen ratio.

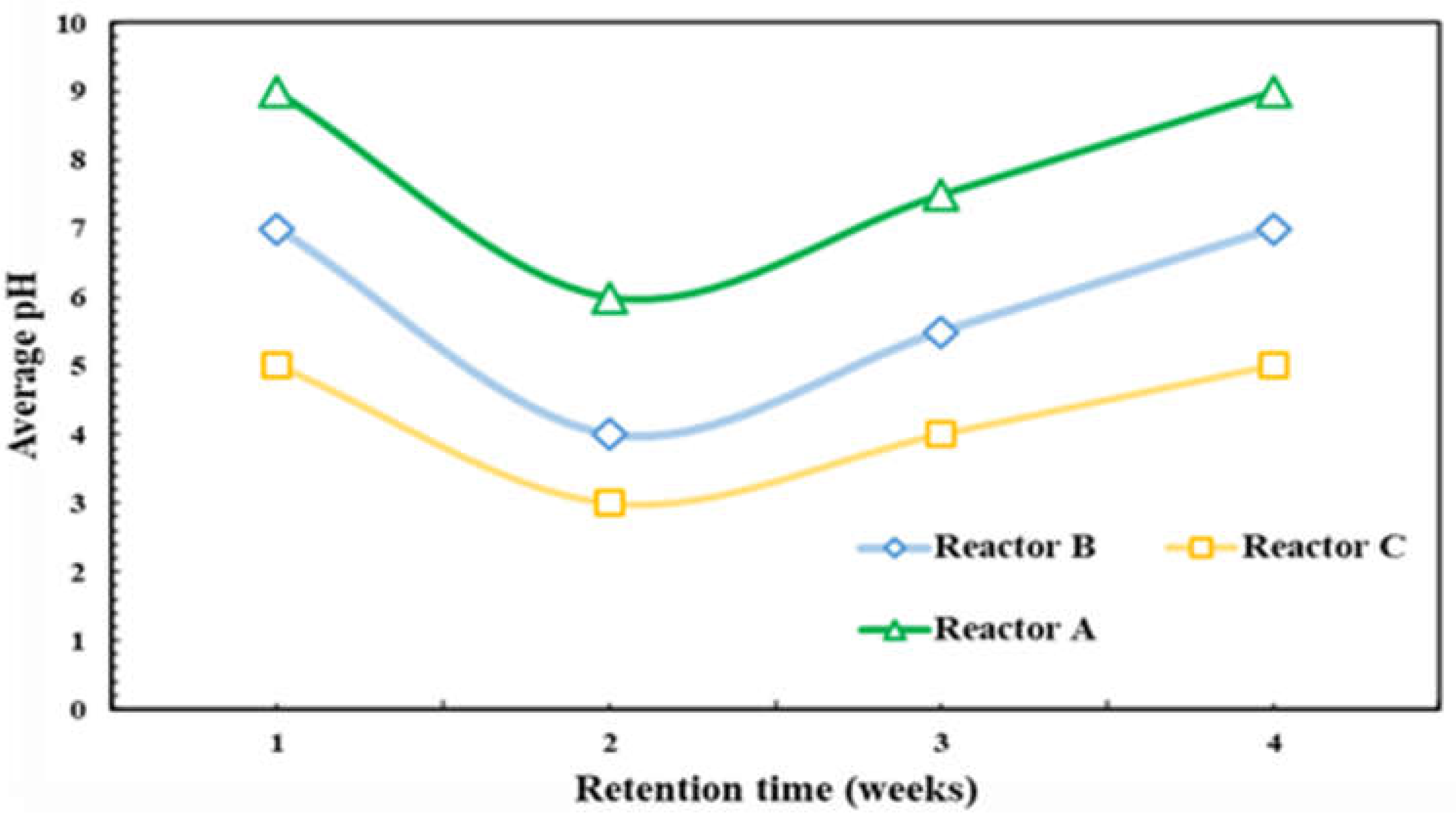

From day 7 to day 14, the pH of the substrate was observed to be between 9 and 3, and from day 14 to the remainder of the retention period, a slow increase in substrate pH was observed, as shown in

Figure 5. The Reactor A maintained at 28°C shows pH between 6 and 9. Reactor B maintained at 35°C shows pH between 4 and 7. Reactor C maintained at 50°C shows pH between 3 and 5. In all cases, the pH values recorded during the initial week were high. However, as time increases, the pH value first decreases and then increases. According to analysis, the drop in pH was due to the presence of highly volatile fatty acids. The sudden decrease in pH illustrates a sudden transition in the various steps of biogas production, whereby the mixture becomes acidic and thus produces the substrate that will produce biogas, from the hydrolysis stage to the acidogenesis stage.

Experimental results show that when the temperature increases from 28°C to 35°C, the biogas production increases by 69.23% and the pH value decreases by 22.22%. The further increase is due to the presence of abundant easily biodegradable materials in the matrix. When the temperature increased from 35°C to 50 °C, the biogas production decreased by 64.1% and the pH value decreased by 28.57%. This output shows that the methanogenic bacteria cannot grow effectively under high temperature conditions of 50°C than under medium temperature conditions. The results exhibit that pH also influences biogas yield, as it controls the activity of microorganisms included in bio digestion especially with methanogenic bacteria.

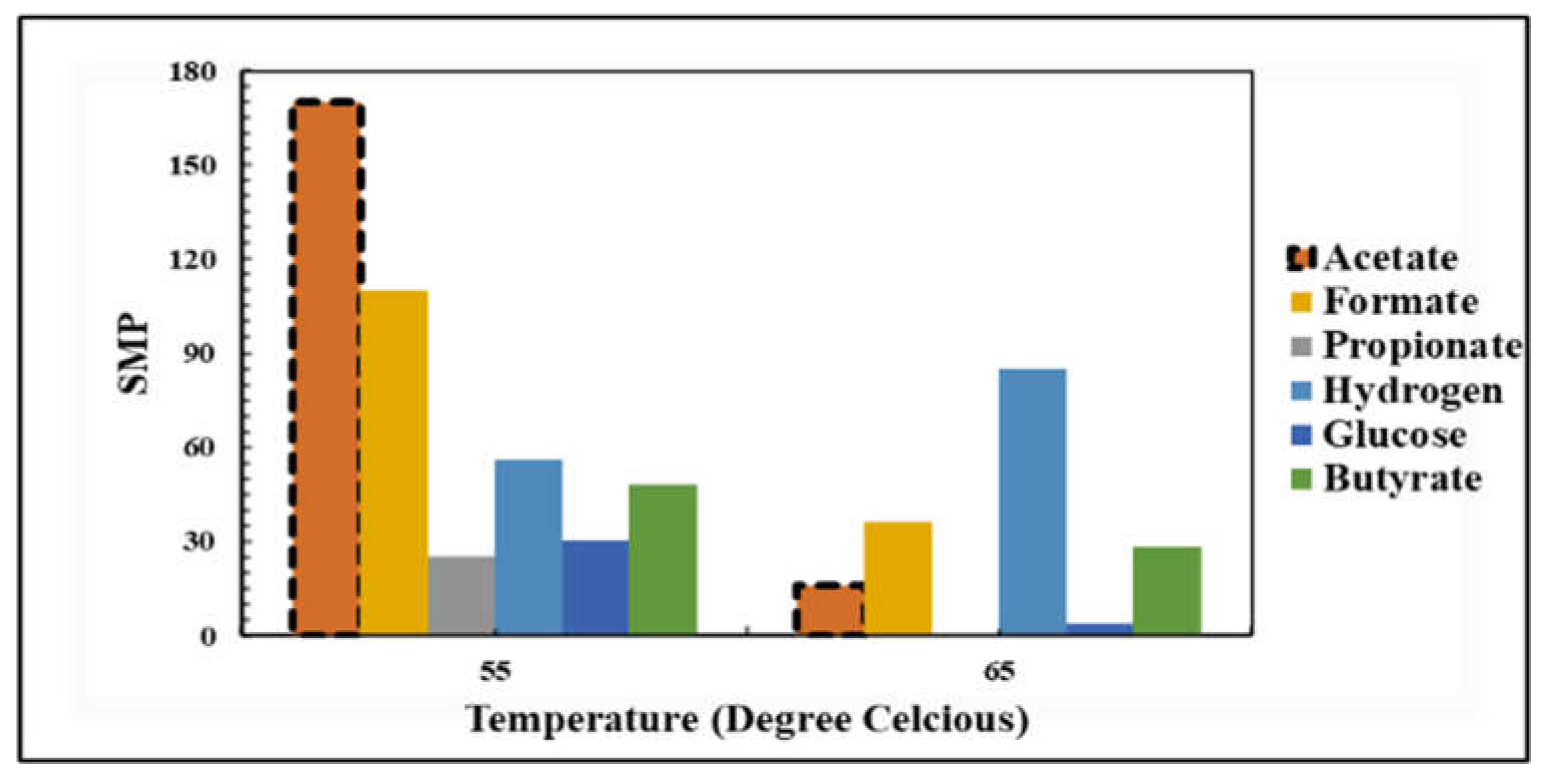

3.2. Effect of Microorganisms at Thermophilic Condition

The analysis of the SMP (µmol CH

4/g VS/h) showed that when the temperature increased from 55 °C to 60 °C the activities of methanogens, which utilize the formate, acetate, glucose, and butyrate has decreased. But the activity of hydrogen-using methanogens increased.

Figure 6 showed specific methanogenic performance at d operating temperatures 55 °C and 65 °C. The substrate in the reactor maintained at 65°C did not show any microbial activity with propionate.

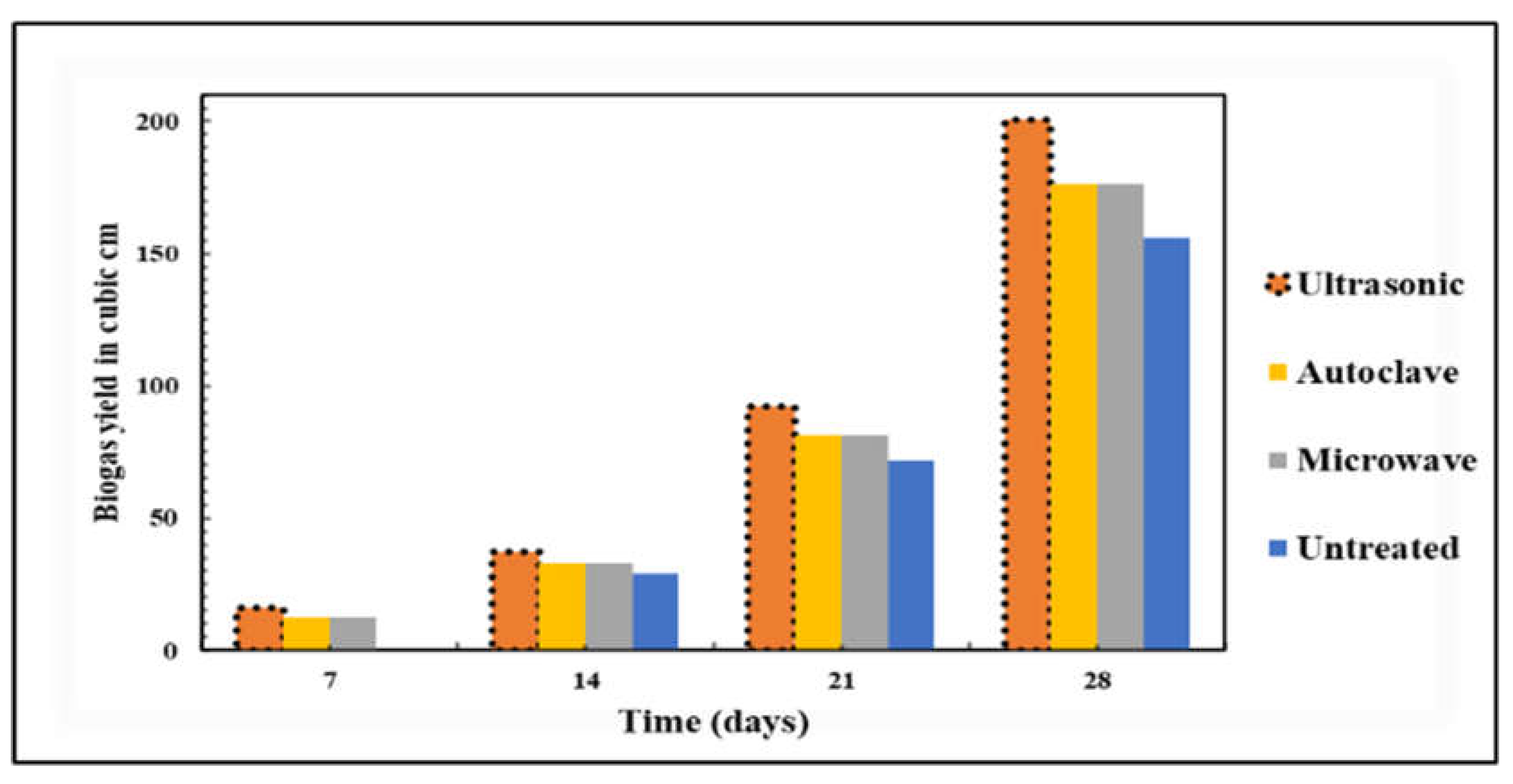

3.3. Effect of Pretreatment on Biogas Production

The comparison of the biogas production rates from substrates which have undergone different pretreatment methods, shown in

Figure 7. Biogas production increased by 28.1%, 20.23%, and 13.27 % for ultrasonic treatment, autoclave, and microwave treatment, respectively, compared to the untreated substrate. Comparison of biogas levels obtained from substrates undergone different pre-treatments is shown in

Figure 7.

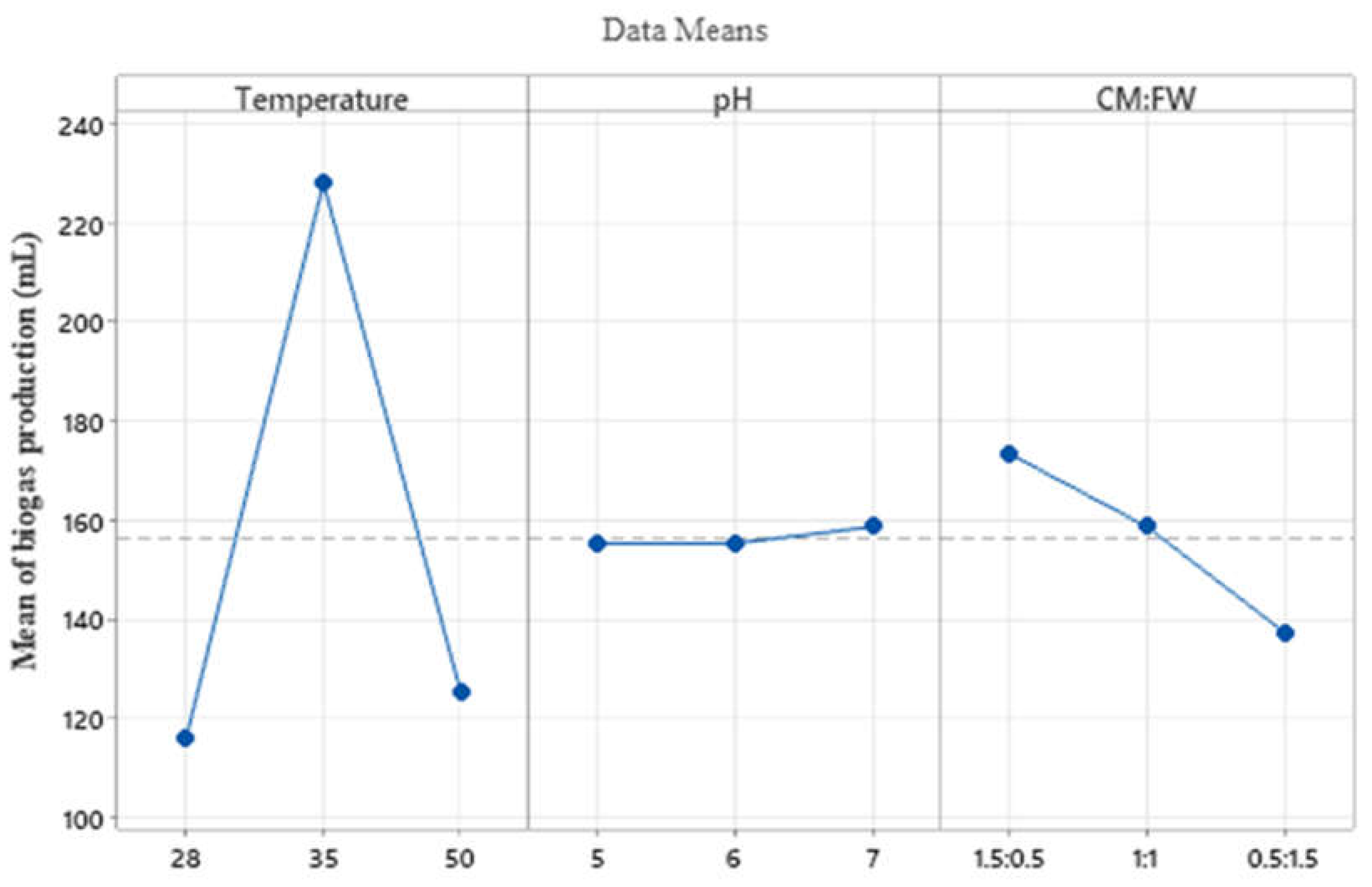

3.4. Optimization of the Parameters Using Taguchi Design of Experiments

Experimental tests were carried out at different temperature mixing ratio and pH as per the analysis is planned as per Taguchi L9 orthogonal array design as shown in

Table 3. The biogas produced in each level of experiment is shown in

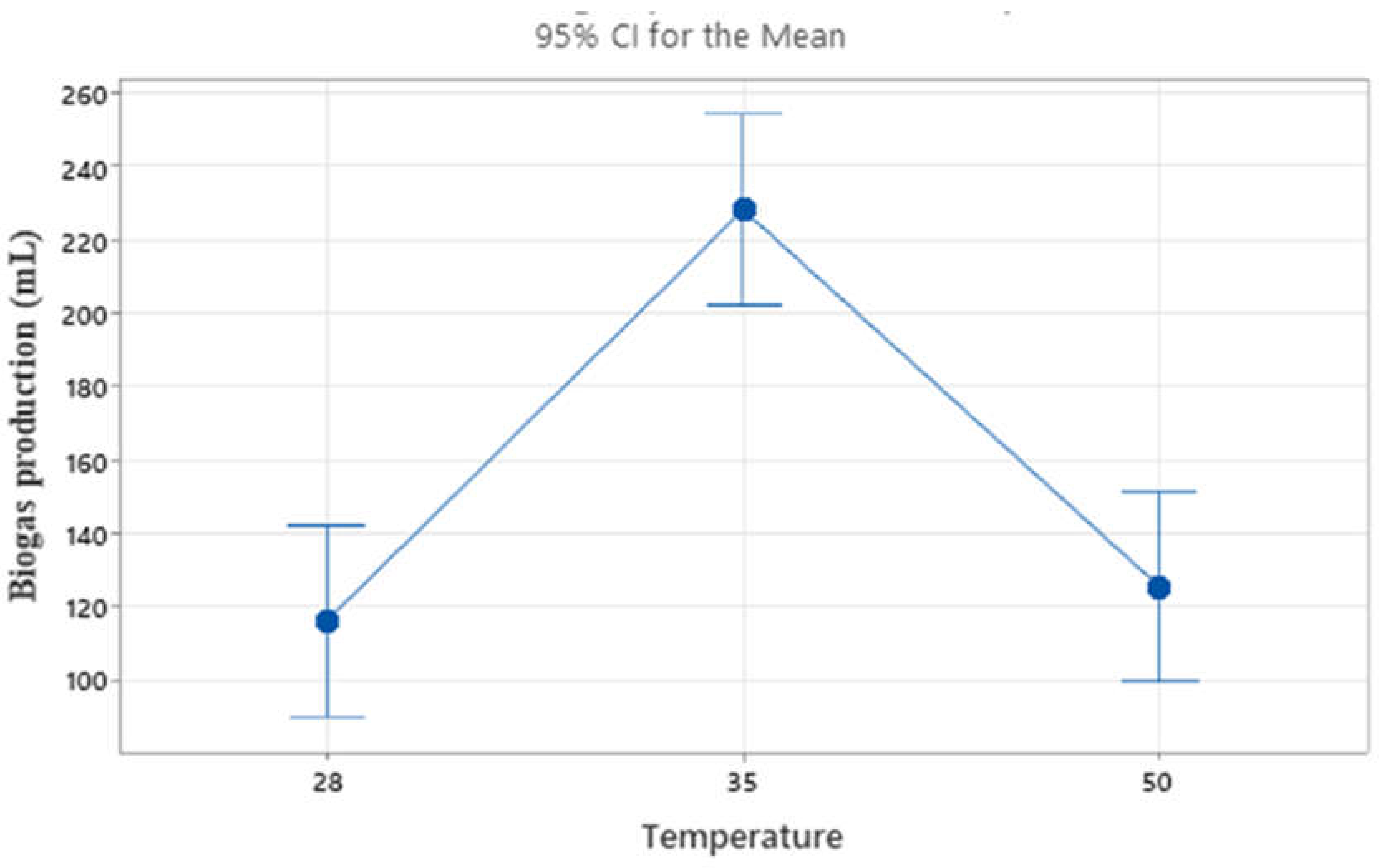

Table 3. The S/N ratio for biogas production is determined with equation (1). The output of the experimental test showed that when the temperature increased from Observations made from the experimental results show that when the temperature increased from 28 °C to 35 °C, average biogas yield increased by 49.1%. When the temperature increased from 35 °C to 50 °C, an average decrease of 45% biogas yield observed, as shown in

Table 4 and

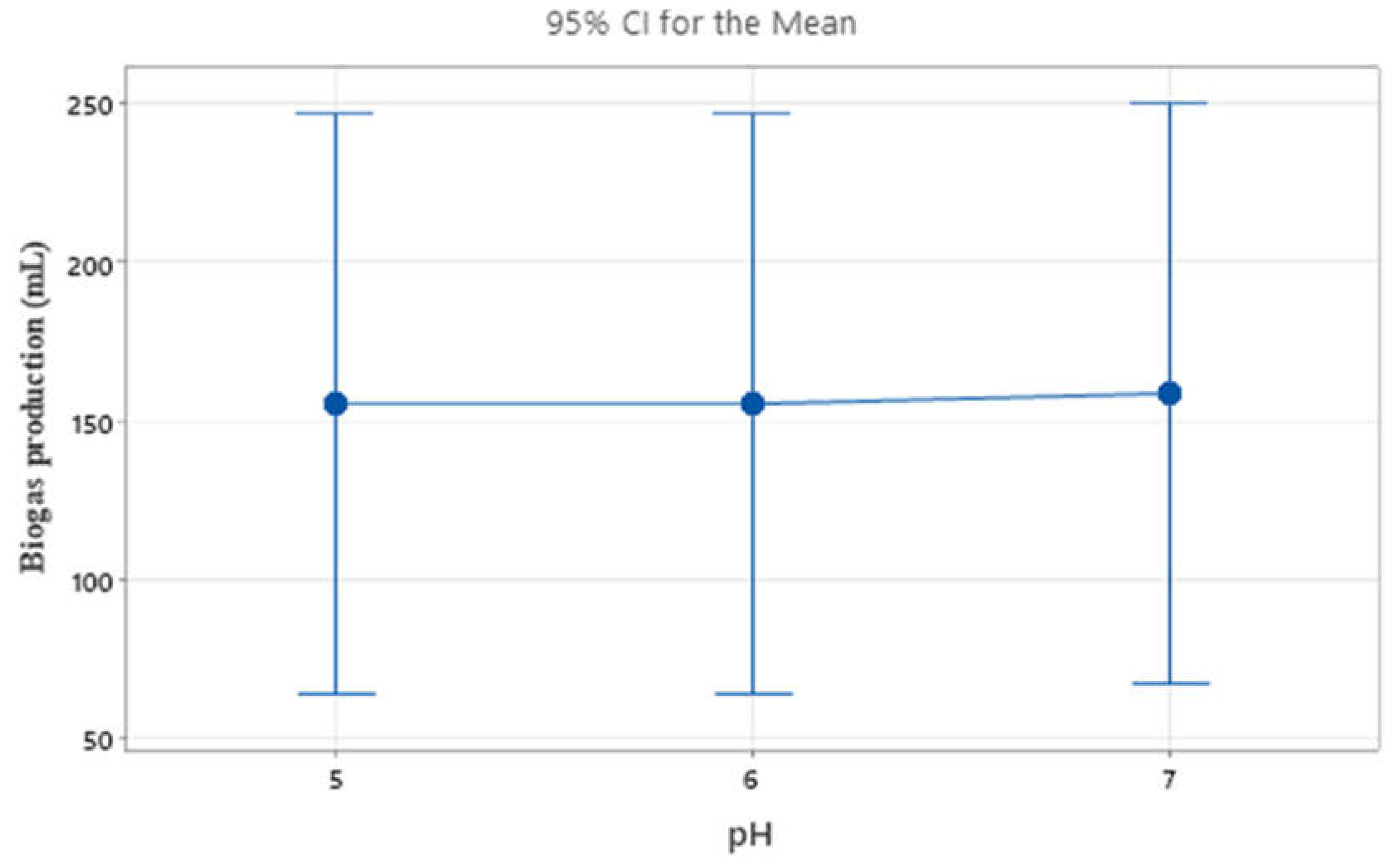

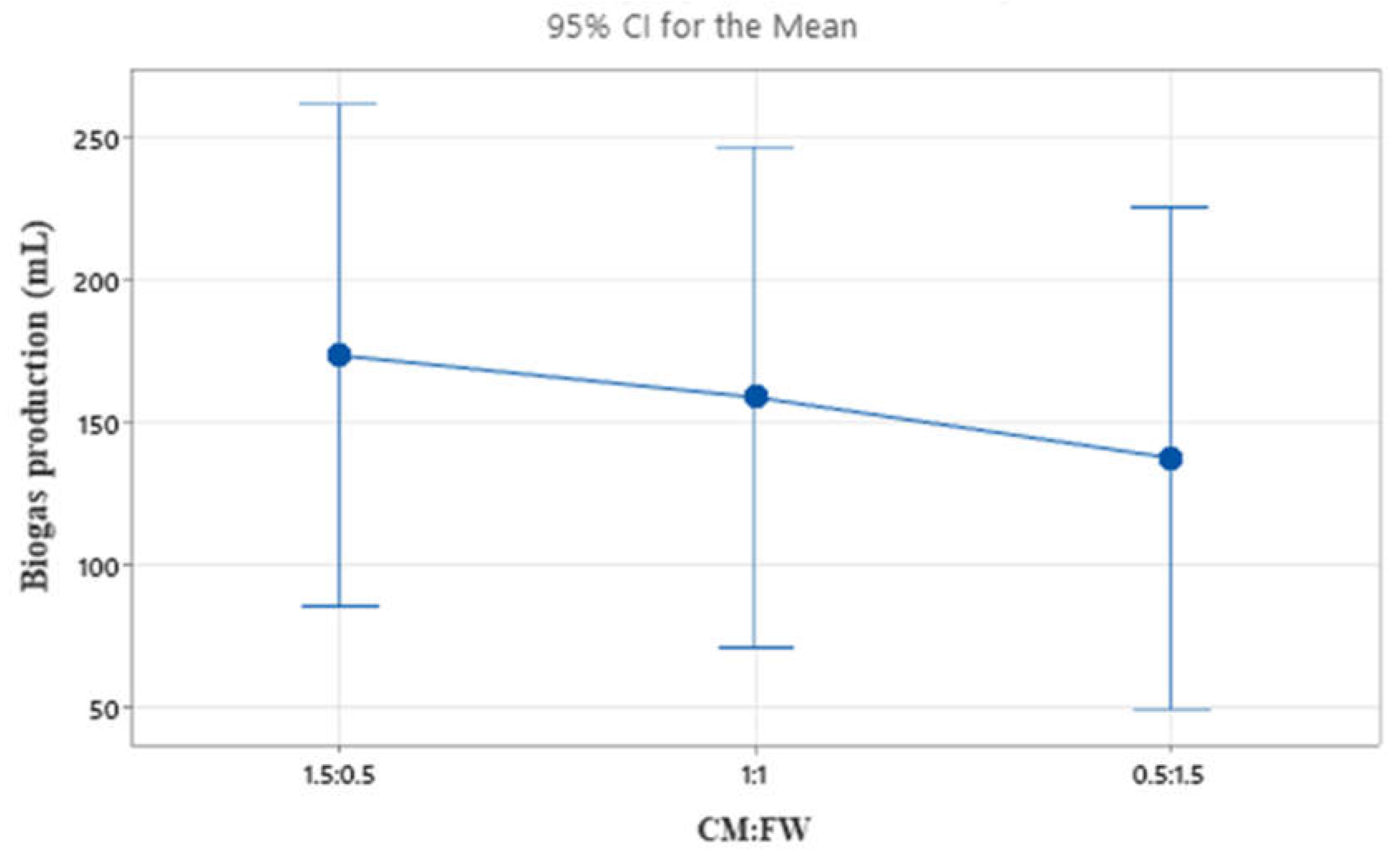

Figure 8. When the pH of the substrate changed from 5 to 6, there is no change in biogas production observed while pH changed from 6 to 7, a small variation of biogas production observed. When food waste increases, biogas production decreases. The mixing ratio, which contains 75% cow manure and 25% food waste showed the highest biogas production, as shown in

Table 4 and

Figure 8. From the results in

Table 3, It can see that the parameters kept the condition of temperature 35 °C, pH of 7 and CW:FW ratio of 1.5:0.5 showed the highest biogas production of 250 mL.

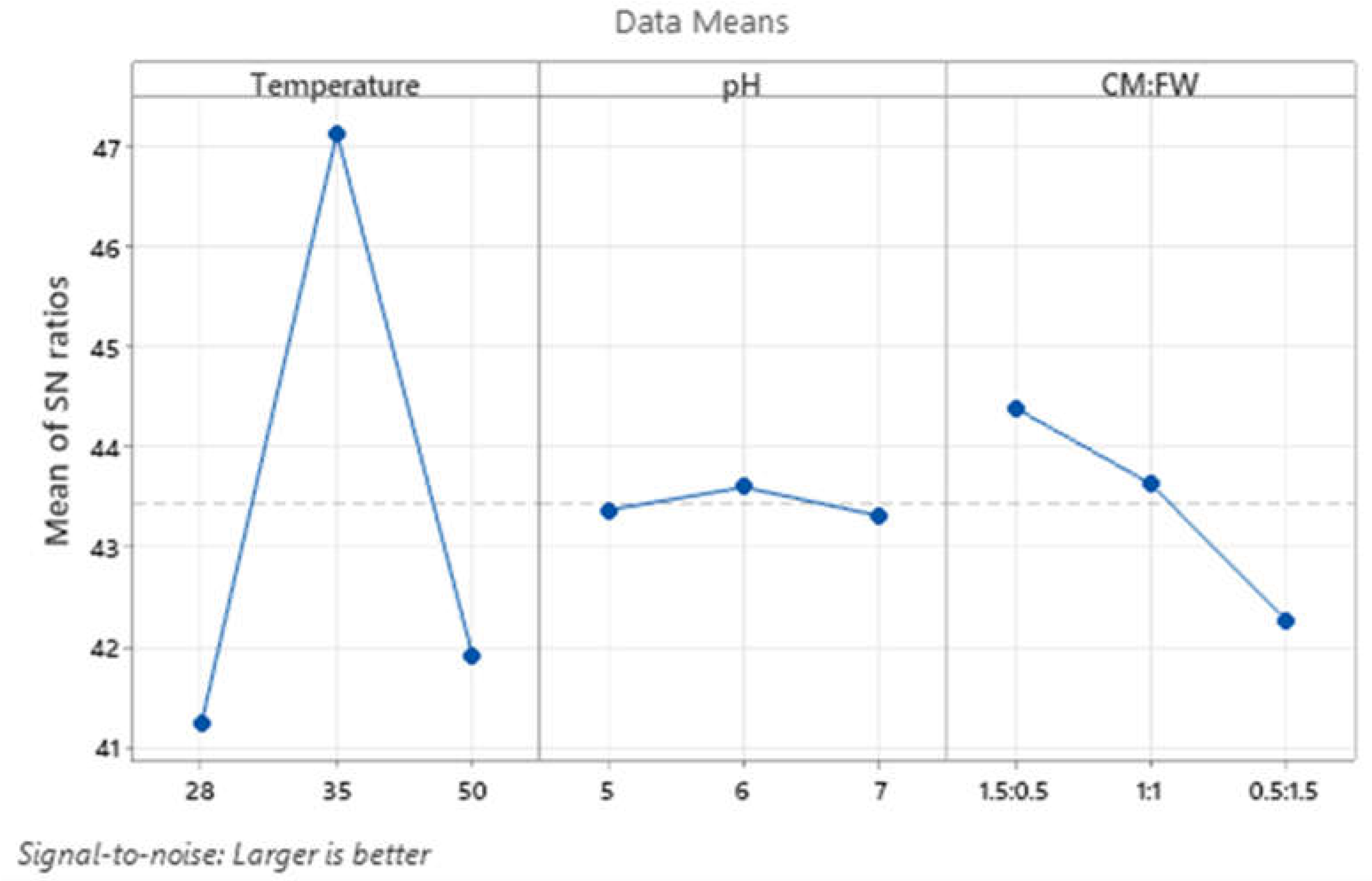

The S/N ratio curve (

Figure 9) and

Table 5 show that the most important influencing parameter controlling biogas production is temperature. The optimum temperature for achieving maximum biogas production is 35 °C. Mixing ratio is the second influencing parameter, when 75% cow dung co-digested with 25% food waste produced the higher biogas. pH is the parameter with the least influence on biogas production.

The ANOVA in

Table 6 shows that temperature is the most influential factor due to its high contribution among the process parameters, followed by mixing ratio. The selected pH values varied slightly (5, 6, and 7) and are an unimportant parameter for biogas production. The significance of each parameter ie, Temperature, pH and mixing ratio and its values are shown in

Figure 10,

Figure 11 and

Figure 12, respectively.

5. Conclusions

The analysis concluded that the reactor operating at 35°C provided higher biogas production during the 28-day digestion period. The biogas production rate decreases when temperature varies from 35℃ to 50℃. A change in digestion temperature from mesophilic to thermophilic caused a sudden decrease in biogas production due to the decrease in growth of sufficient number of microbial populations. The analysis of the specific methanogenic performance (SMP) showed that when the temperature increased from 55°C to 65°C the activities of methanogens, which utilize the formate, acetate, glucose, and butyrate has decreased. Therefore, in cold climate areas, the temperature inside the digester must be maintained at around 35°C. The highest biogas production reported when the operating pH for the anaerobic digestion process ranges between 5 to 7. Levels of volatile fatty acids and carbon dioxide can change pH. To control the changing pH, acid or alkali can be added to the feedstock in the digester. The results also concluded that the substrates, which had undergone ultrasonic pre-treatment showed higher biogas output compared untreated, autoclave treated and microwave treated substrates. The optimized condition for the highest biogas production during anaerobic co digestion of food waste and cow manure is temperature of 50 °C, pH of 7 and mixing ratio (CM: FW=1.5:0.5). ANOVA showed that temperature is the most important input parameter affecting biogas production, followed by mixing ratio.

Author Contributions

The formal analysis, investigation, resources, data curation, writing—original draft preparation, writing—review and editing, and visualization were conducted by S.S.H and K.M.S; supervision by S.T. and A.C.A All authors have read and agreed to the published version of the manuscript.

Funding

The authors are very thankful for providing funding by Kumamoto University, Japan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The research data can be provided on request.

Acknowledgments

The authors are thankful for the staff of the Department of Mechanical Engineering, Kumamoto University, Japan, for their technical support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of Biogas Production from Farm Animal Waste in Malaysia. Renewable and Sustainable Energy Reviews 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Mohammad, N.; Mohamad Ishak, W.W.; Mustapa, S.I.; Ayodele, B.V. Natural Gas as a Key Alternative Energy Source in Sustainable Renewable Energy Transition: A Mini Review. Frontiers in Energy Research 2021, 9. [Google Scholar] [CrossRef]

- Gürsan, C.; de Gooyert, V. The Systemic Impact of a Transition Fuel: Does Natural Gas Help or Hinder the Energy Transition? Renewable and Sustainable Energy Reviews 2021, 138, 110552. [Google Scholar] [CrossRef]

- Kabeyi, M.J.; Olanrewaju, O.A. Sustainable Energy Transition for Renewable and Low Carbon Grid Electricity Generation and Supply. Frontiers in Energy Research 2022, 9. [Google Scholar] [CrossRef]

- Habib, S.S.; Torii, S. Biogas as Alternative to Liquefied Petroleum Gas in Mauritania: An Integrated Future Approach for Energy Sustainability and Socio-Economic Development, Clean Technologies. 2024, 6, 453–470.

- Abbasi, T.; Tauseef, S.M.; Abbasi, S.A. Biogas and Biogas Energy: An Introduction. Biogas Energy 2011, 1–10. [Google Scholar]

- Xu, W.; Long, F.; Zhao, H.; Zhang, Y.; Liang, D.; Wang, L.; Lesnik, K.L.; Cao, H.; Zhang, Y.; Liu, H. Performance Prediction of Zvi-Based Anaerobic Digestion Reactor Using Machine Learning Algorithms. Waste Management 2021, 121, 59–66. [Google Scholar] [CrossRef]

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of Trends in Biogas Upgradation Technologies and Future Perspectives. Bioresource Technology Reports 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Ma, C.; Liu, J.; Ye, M.; Zou, L.; Qian, G.; Li, Y.-Y. Towards Utmost Bioenergy Conversion Efficiency of Food Waste: Pretreatment, Co-Digestion, and Reactor Type. Renewable and Sustainable Energy Reviews 2018, 90, 700–709. [Google Scholar] [CrossRef]

- Aboudi, K.; Álvarez-Gallego, C.J.; Romero-García, L.I. Semi-Continuous Anaerobic Co-Digestion of Sugar Beet Byproduct and Pig Manure: Effect of the Organic Loading Rate (OLR) on Process Performance. Bioresource Technology 2015, 194, 283–290. [Google Scholar] [CrossRef]

- Dhar, H.; Kumar, P.; Kumar, S.; Mukherjee, S.; Vaidya, A.N. Effect of Organic Loading Rate during Anaerobic Digestion of Municipal Solid Waste. Bioresource Technology 2016, 217, 56–61. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Effect of Substrate Pretreatment on Biogas Production through Anaerobic Digestion of Food Waste. International Journal of Hydrogen Energy 2017, 42, 26522–26528. [Google Scholar] [CrossRef]

- Ajiboye, O.K.; Ochiegbu, C.V.; Ofosu, E.A.; Gyamfi, S. A Review of Hybrid Renewable Energies Optimisation: Design, Methodologies, and Criteria. International Journal of Sustainable Energy 2023, 42, 648–684. [Google Scholar] [CrossRef]

- Demollari, E. Temperature and Stirring Effect of Biogas Production from Two Different Systems. American Journal of Energy Engineering 2017, 5, 6. [Google Scholar] [CrossRef]

- El-Mashad, H.M.; van Loon, W.K.P.; Zeeman, G. A Model of Solar Energy Utilisation in the Anaerobic Digestion of Cattle Manure. Biosystems Engineering 2003, 84, 231–238. [Google Scholar] [CrossRef]

- Trzcinski, A.P.; Stuckey, D.C. Treatment of Municipal Solid Waste Leachate Using a Submerged Anaerobic Membrane Bioreactor at Mesophilic and Psychrophilic Temperatures: Analysis of Recalcitrants in the Permeate Using GC-MS. Water Research 2010, 44, 671–680. [Google Scholar] [CrossRef]

- Kim, J.K.; Oh, B.R.; Chun, Y.N.; Kim, S.W. Effects of Temperature and Hydraulic Retention Time on Anaerobic Digestion of Food Waste. Journal of Bioscience and Bioengineering 2006, 102, 328–332. [Google Scholar] [CrossRef]

- Kashyap, D.R.; Dadhich, K.S.; Sharma, S.K. Biomethanation under Psychrophilic Conditions: A Review. Bioresource Technology 2003, 87, 147–153. [Google Scholar] [CrossRef]

- Fezzani, B.; Ben Cheikh, R. Two-Phase Anaerobic Co-Digestion of Olive Mill Wastes in Semi-Continuous Digesters at Mesophilic Temperature. Bioresource Technology 2010, 101, 1628–1634. [Google Scholar] [CrossRef]

- Briški, F.; Vuković, M.; Papa, K.; Gomzi, Z.; Domanovac, T. Modelling of Composting of Food Waste in a Column Reactor. Chemical Papers 2007, 61. [Google Scholar] [CrossRef]

- Zhu, B.; Gikas, P.; Zhang, R.; Lord, J.; Jenkins, B.; Li, X. Characteristics and Biogas Production Potential of Municipal Solid Wastes Pretreated with a Rotary Drum Reactor. Bioresource Technology 2009, 100, 1122–1129. [Google Scholar] [CrossRef]

- Molnar, L.; Bartha, I. High Solids Anaerobic Fermentation for Biogas and Compost Production. Biomass 1988, 16, 173–182. [Google Scholar] [CrossRef]

- Anand, R.C.; Singh, R. A Simple Technique, Charcoal Coating around the Digester, Improves Biogas Production in Winter. Bioresource Technology 1993, 45, 151–152. [Google Scholar] [CrossRef]

- Desai, M.; Madamwar, D. Anaerobic Digestion of a Mixture of Cheese Whey, Poultry Waste and Cattle Dung: A Study of the Use of Adsorbents to Improve Digester Performance. Environmental Pollution 1994, 86, 337–340. [Google Scholar] [CrossRef] [PubMed]

- Hren, R.; Petrovič, A.; Čuček, L.; Simonič, M. Determination of Various Parameters during Thermal and Biological Pretreatment of Waste Materials. Energies 2020, 13, 2262. [Google Scholar] [CrossRef]

- Hamdi, M. Effects of Agitation and Pretreatment on the Batch Anaerobic Digestion of Olive Mil. Bioresource Technology 1991, 36, 173–178. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, D.; Wu, S.; Wang, C. Alkali Pretreatment Enhances Biogas Production in the Anaerobic Digestion of Pulp and Paper Sludge. Journal of Hazardous Materials 2009, 170, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic Digestion of Organic Solid Wastes. an Overview of Research Achievements and Perspectives. Bioresource Technology 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The Anaerobic Digestion of Solid Organic Waste. Waste Management 2011, 31, 1737–1744. [Google Scholar] [CrossRef] [PubMed]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresource Technology 2008, 99, 7928–7940. [Google Scholar] [CrossRef]

- Lee, D.H.; Behera, S.K.; Kim, J.W.; Park, H.-S. Methane Production Potential of Leachate Generated from Korean Food Waste Recycling Facilities: A Lab-Scale Study. Waste Management 2009, 29, 876–882. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Bai, X.; Zhou, X.; Cheng, S.; Gao, R.; Sun, J. Study on Improving Anaerobic Co-Digestion of Cow Manure and Corn Straw by Fruit and Vegetable Waste: Methane Production and Microbial Community in CSTR Process. Bioresource Technology 2018, 249, 290–297. [Google Scholar] [CrossRef] [PubMed]

- Hills, D.J. Effects of Carbon: Nitrogen Ratio on Anaerobic Digestion of Dairy Manure. Agricultural Wastes 1979, 1, 267–278. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Bai, X.; Zhou, X.; Cheng, S.; Gao, R.; Sun, J. Study on Improving Anaerobic Co-Digestion of Cow Manure and Corn Straw by Fruit and Vegetable Waste: Methane Production and Microbial Community in CSTR Process. Bioresource Technology 2018, 249, 290–297. [Google Scholar] [CrossRef] [PubMed]

- Stroot, P.G.; McMohan, K.D.; Mackie, R.I.; Raskin, L. Anaerobic co-digestion of solid wastes and biosolids under various mixing conditions. Water Research 2001, 35, 1804–1816. [Google Scholar] [CrossRef] [PubMed]

- Mol, S.K.; Sadiq, A. Material Parametric Optimisation of Wing Leading Edge Profile against Soft Body Impact. International Journal of Crashworthiness 2020, 27, 677–687. [Google Scholar] [CrossRef]

- Salem. , K.M.; Salem, S.C.; Sadiq, A. Crashworthiness Enhancement of Aluminum Alloy Used for Leading Edges of Wing and Empennage Structures. Journal of Aerospace Engineering 2022, 35. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).