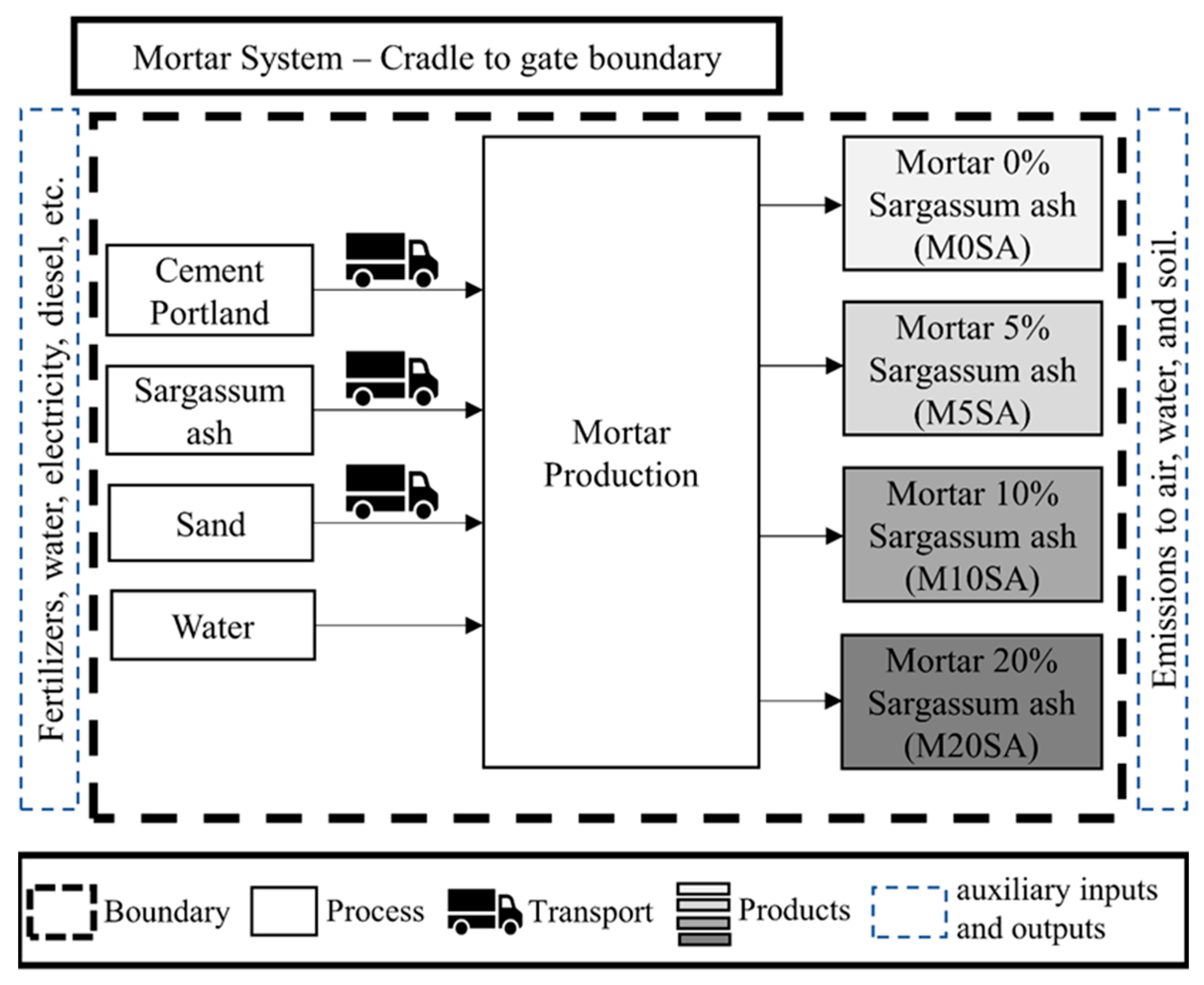

3.3. Life Cycle Assessment (LCA)

The LCIA methodology used in this ReCiPe 2016 study contains 19 impact categories.

Table 7 presents the categories and their respective acronyms.

This item presents the comparative LCA of the four different mortars: M0SA, M5SA, M10SA, and M20SA.

Mitigations from the use of sargassum were not taken into account when analyzing the contribution of each process except in the comparison stages of scenarios 2 and 3. This allows us to analyze which stage presents the most significant negative environmental impacts while suggesting solutions to mitigate them.

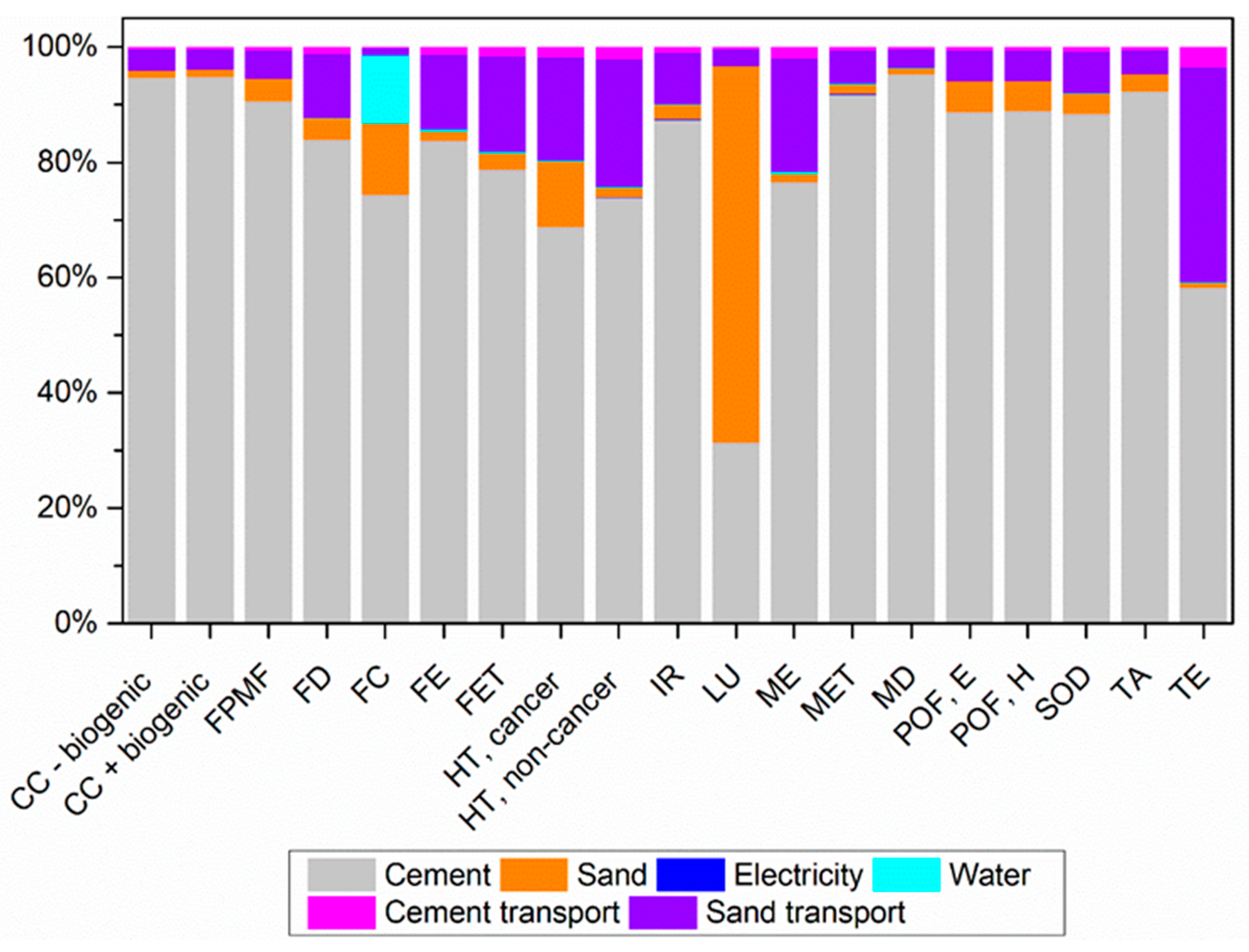

Figure 10 depicts the environmental impact contributions from mortar production without the substitution of sand with sargassum ashes (M0SA).

Cement production is the stage with the greatest contribution to 18 impact categories among a total of 19. The majority of cement emissions occur due to the production of clinker, where raw materials are heated to approximately 1450 °C in rotary kilns using non-renewable fuels such as oil and coal. Additionally, there are considerable emissions from the transportation used throughout the production chain.

Climate change categories are among the most affected by cement production; it is estimated that for every 1 kg of cement, approximately 0.9 kg of CO2 is emitted due to the limestone calcination process.

For the terrestrial ecotoxicity category, the transport process brings a significant contribution, especially sand due to the use of fossil fuels such as diesel, ranking as the second-largest contribution.

In the Land Use category, sand extraction is the process that contributes the most due to the transformation, occupation, and clearing of the soil that occurs in extensive areas. Following that, cement production causes soil transformation due to the extraction of natural raw materials such as clay and lime.

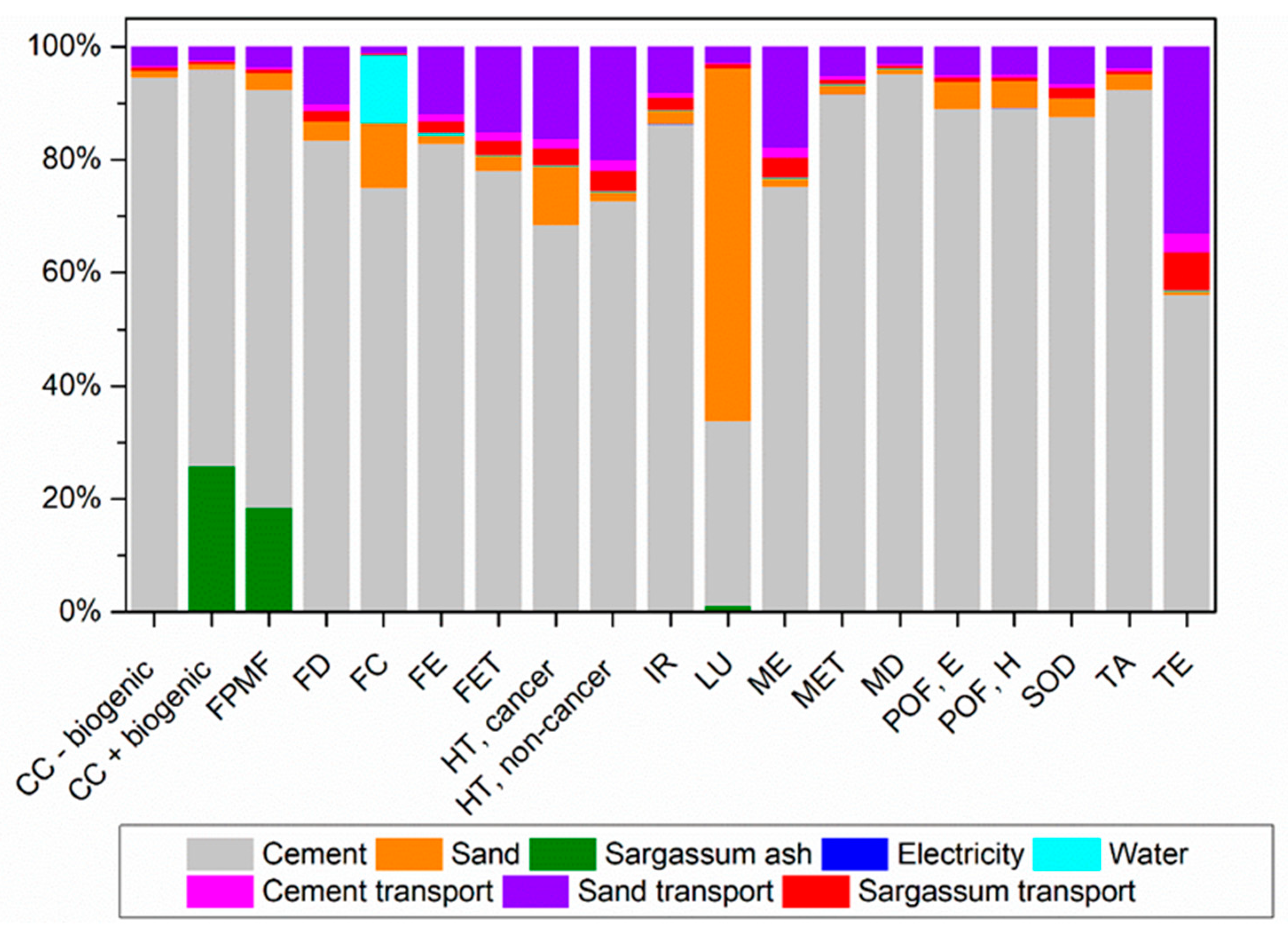

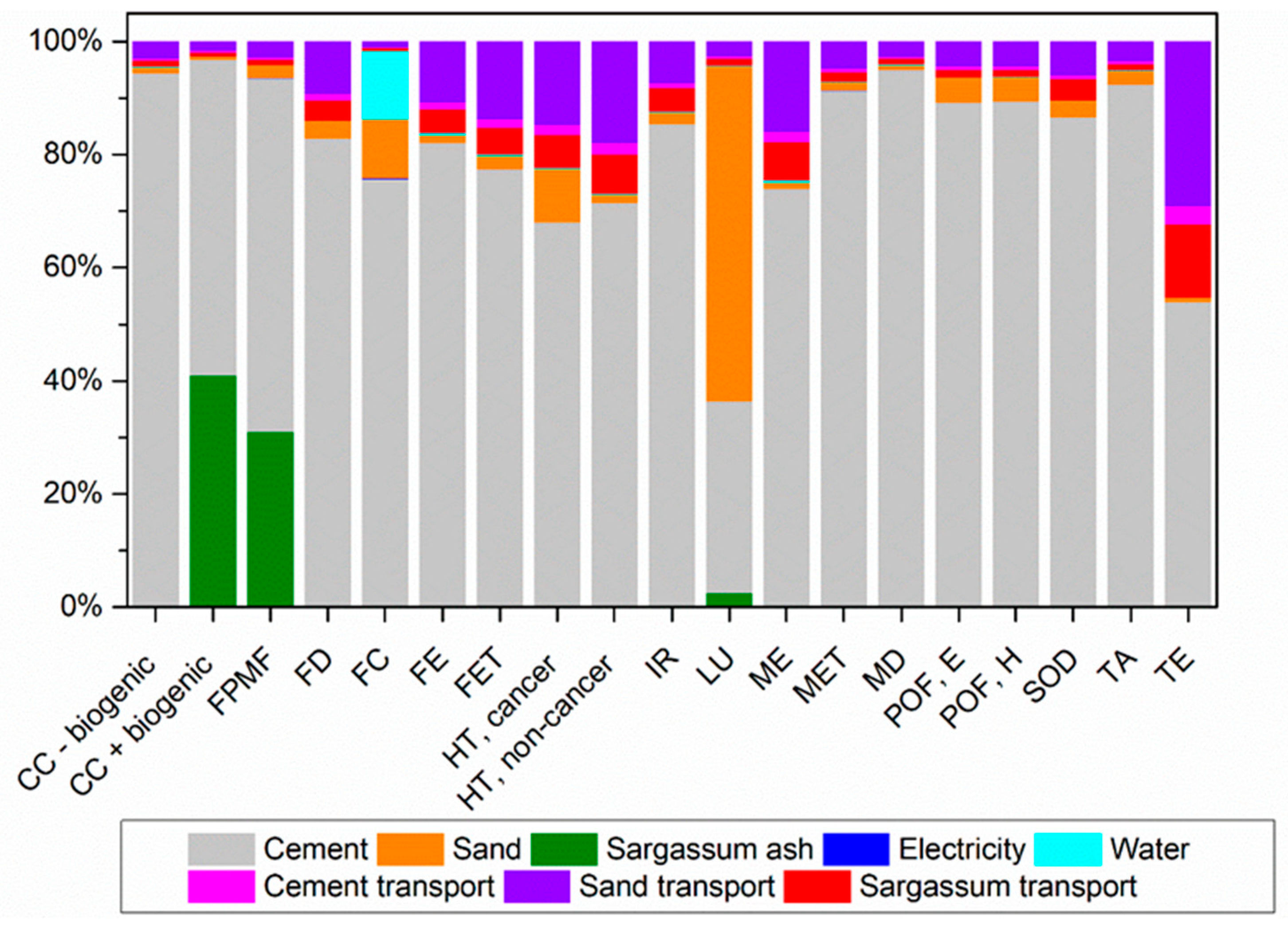

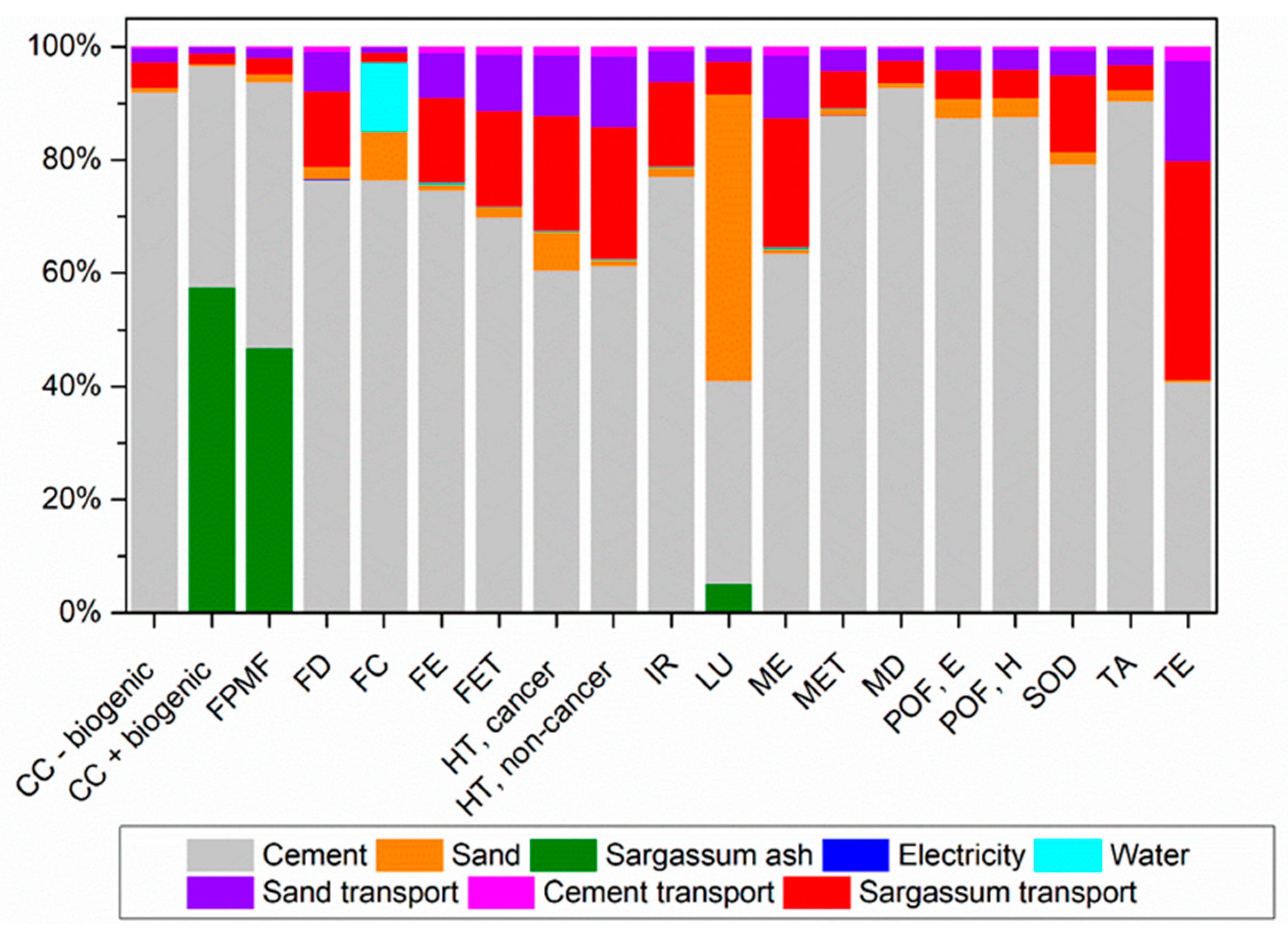

Figure 11,

Figure 12 and

Figure 13 illustrate the contribution of each unit process to the potential environmental impacts of mortars with sand replaced with sargassum ash at 5%, 10%, and 20%, respectively.

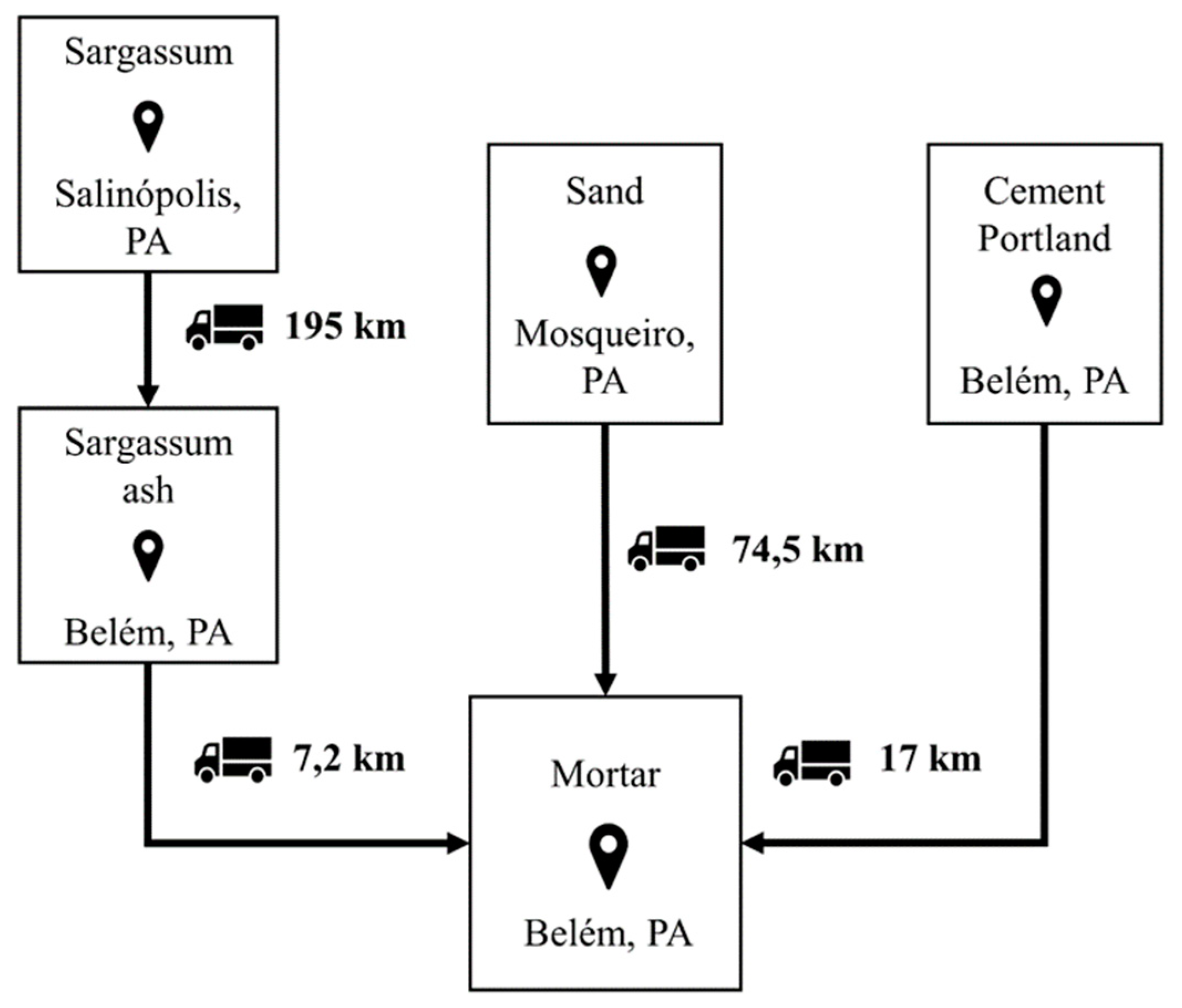

There are no change in the major processes contributing to impact categories when partially replacing sand with sargassum ash at 5% and 10%. Nevertheless, there is a decrease in the contribution to some of these categories due to emissions from the transportation and burning of sargassum.

Three impact categories differ when comparing the former to the results for mortars with a 20% substitution. For the CC+ biogenic and FPMF categories, the production of sargassum ash is the process contributing the most due to the generation of gases and particle formation from burning.

For the terrestrial ecotoxicity category, transportation becomes the stage with the greatest contribution, surpassing cement. This shift is attributed to the greater contribution of sargassum transportation, which covers the longest distance when compared to other raw materials. This represent approximately 59% of emissions for this category, considering all transport.

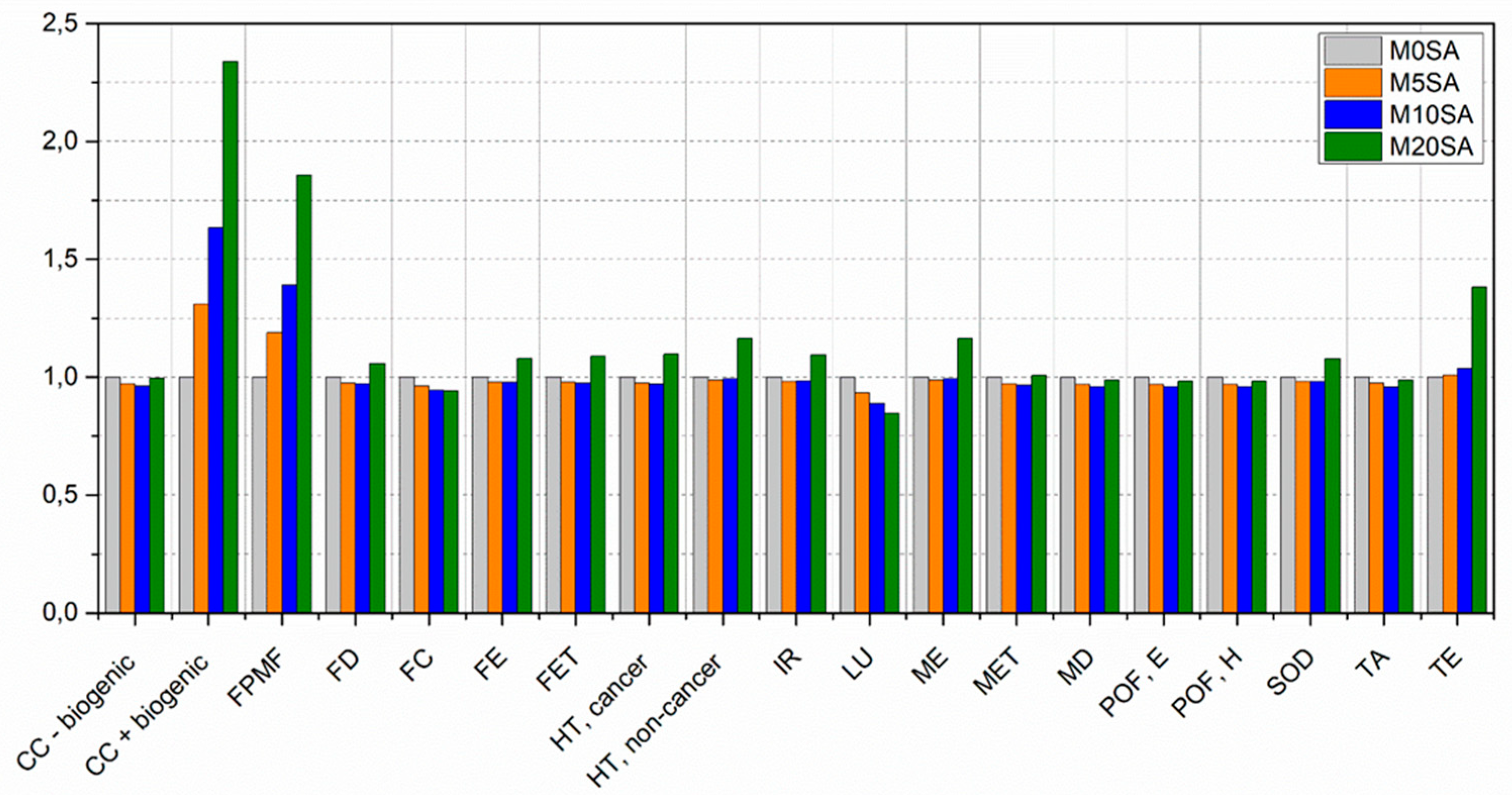

Figure 14 presents a comparison between the different mortar formulations with partial replacement of sand by sargassum ash taking all process emissions without mitigation from the implementation of sargassum ash into account.

Mortar with 20% sargassum ash presented the worst performance for 12 of the 19 categories, while mortar without substitution did for seven. The categories most affected by sargassum addition are CC + biogenic and FPMF, especially due to the process of sargassum. The other categories in which sargassum present the worst environmental performance, and are mainly affected by transported distance.

The best environmental performance results were mostly attributed to the use of sargassum ash. Of the 19 categories evaluated, replacing sand with sargassum showed the best performance for 16, five categories at a 5% substitution, nine categories at a 10% substitution, and one for 20%. The mortar without sargassum ash showed the best results for three categories.

The implementation of sargassum ash at 10% did best, having presented positive results for 9 categories and better results for 7 categories in relation to mortar without sargassum ash.

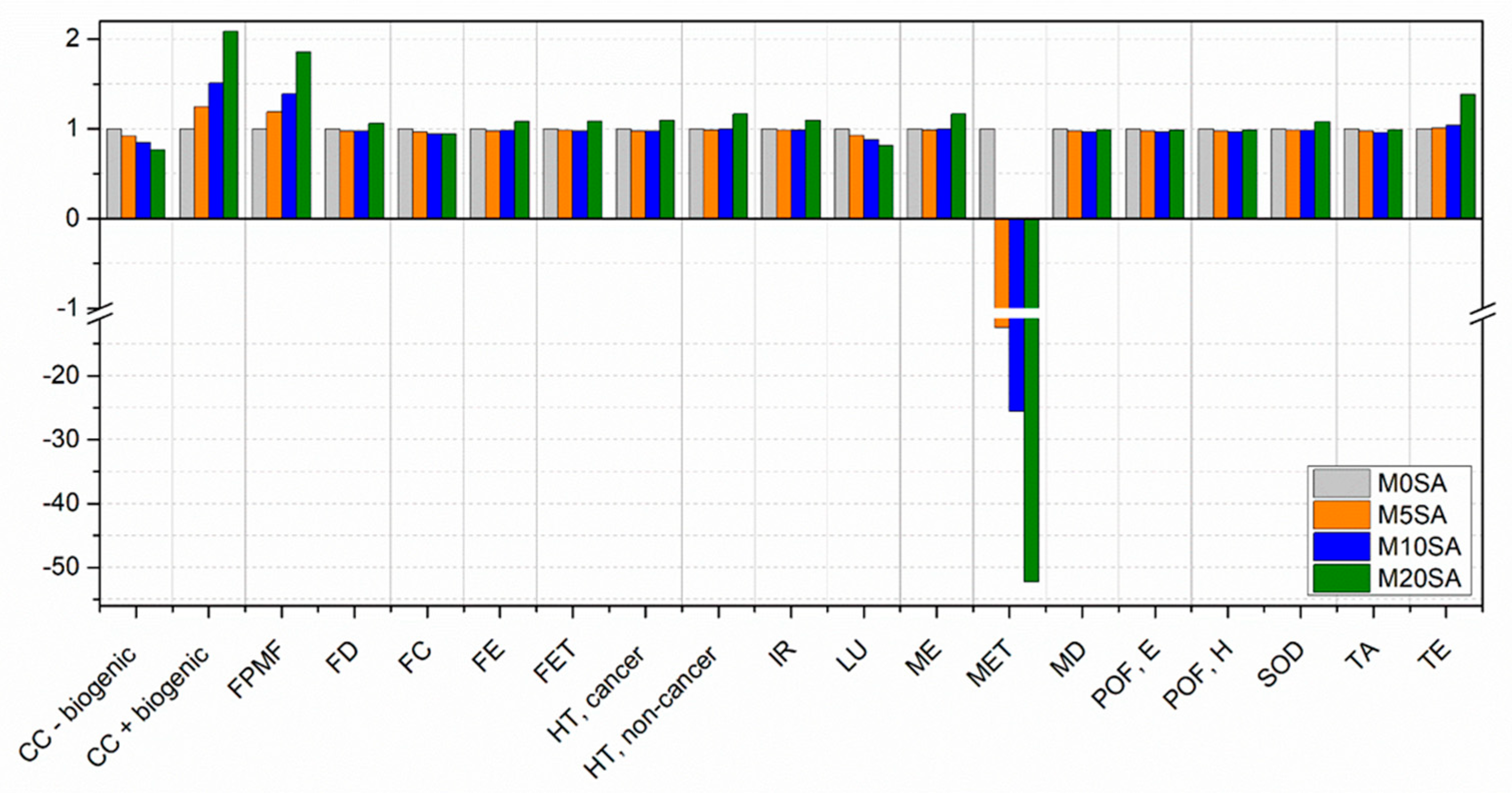

Figure 15 presents a comparison between the different formulations with partial replacement of sand by sargassum ash while taking into account the mitigation of gases not emitted from decomposition on beaches.

The worst environmental performances are observed for the same formulations when mitigations are not considered, except for the marine eutrophication impact category. When taking the mitigation from avoiding its decomposition on beaches into account, mortar without sargassum ash presents a worst performance.

The best results undergo changes in three categories. Nevertheless, the use of sargassum ash still presents the best results for 16 categories, 5 categories for mortar with 5% replacement, seven categories for mortar with 10% replacement, and four categories for a 20% replacement.

The main change occurred for the marine eutrophication category and has a positive environmental impact when sargassum ash is used (as demonstrated in the graph in the negative results on the y-axis). The decomposition of sargassum on beaches increases nutrient levels in the sea, promoting its proliferation and affecting aquatic life. As such, high positive impacts are observed for this category when this process is avoided.

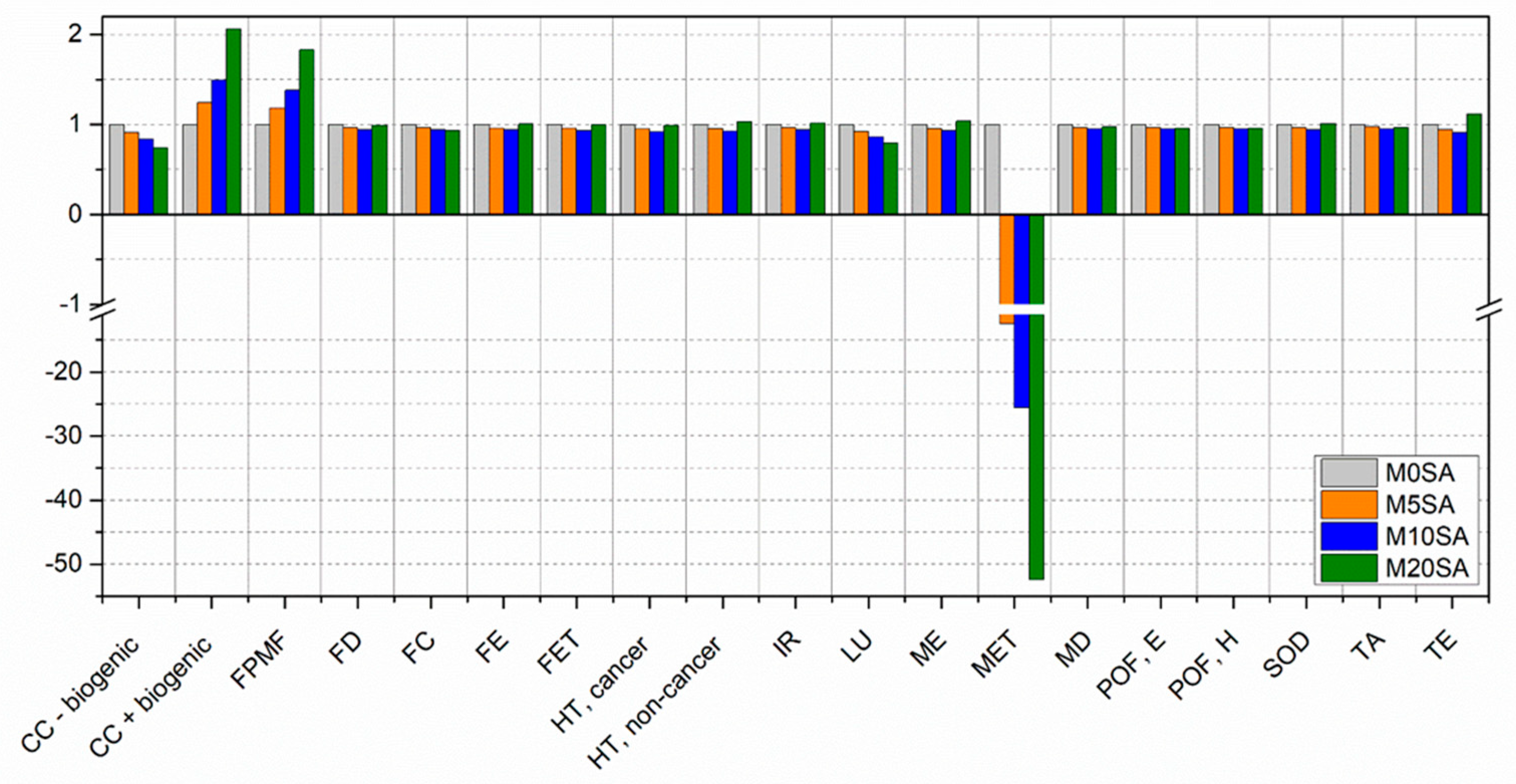

Figure 16 presents a comparison between the different mortar formulations taking the mitigation of gases emitted from decomposition in landfills into account. This is a suitable assumption, as sargassum is typically removed from beaches and then taken to landfills in attempts to minimize its impact on tourism and maritime activities.

The decomposition of sargassum in landfills is the scenario that most closely resembles reality, as sargassum is currently removed from the coasts and sent to landfills due to its negative effects on local tourism.

When considering the mitigation of emissions from sargassum decomposition in landfills from the 19 categories, a 20% sargassum ash addition provided the worst environmental performances for eight categories. For the other categories, mortars without sargassum ash presented the worst results.

The use of this ash in mortars showed better environmental performance for 17 categories, 13 for mortars with 10% replacement, and four for a 20% replacement. Only CC + biogenic and FPMF presented the best results for mortar without the use of sargassum from these categories. This is because the burning of sargassum generates gases and fine particles, which affect these two categories.

Among the categories, those that showed the most significant variations were climate change (including biogenic carbon), fine particulate matter formation, and marine eutrophication. Marine eutrophication, as in the previous case, presents positive environmental impacts when sargassum ash is used.

Based on the results obtained for the different possibilities, it is possible to verify the importance of providing an adequate destination for sargassum, especially when taking mitigation from avoiding decomposition on beaches into account.

Therefore, the use of sargassum ash in mortars is a viable alternative, presenting better environmental performance results in addition to reducing the consumption of finite raw materials such as sand. As such, this destination for sargassum contributes to economic, social, and environmental aspects.