Submitted:

14 December 2023

Posted:

14 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

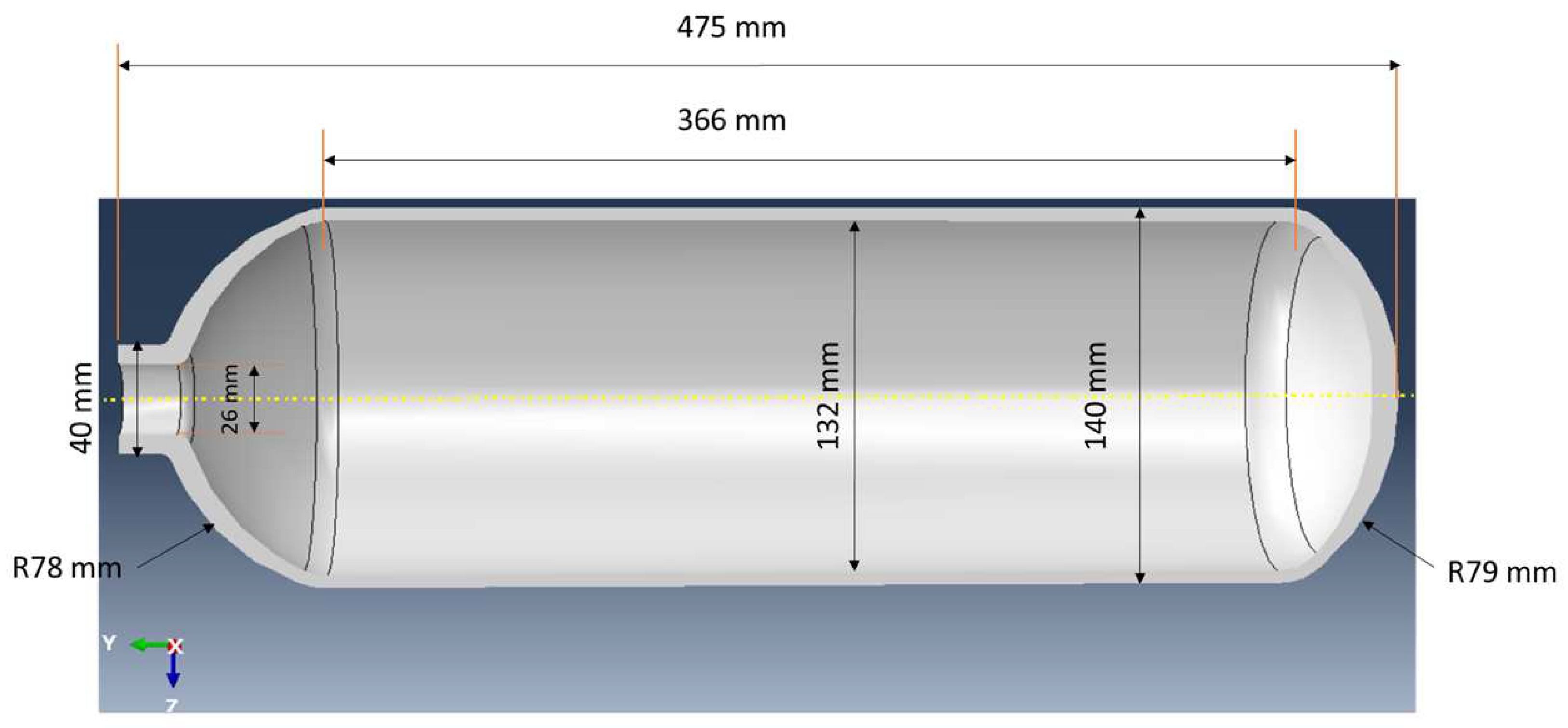

2.2. Manufacturing of COPVs Using Filament Winding

2.3. Modelling of COPVs Using Finite Element Method

2.4. Micro-Mechanics Models

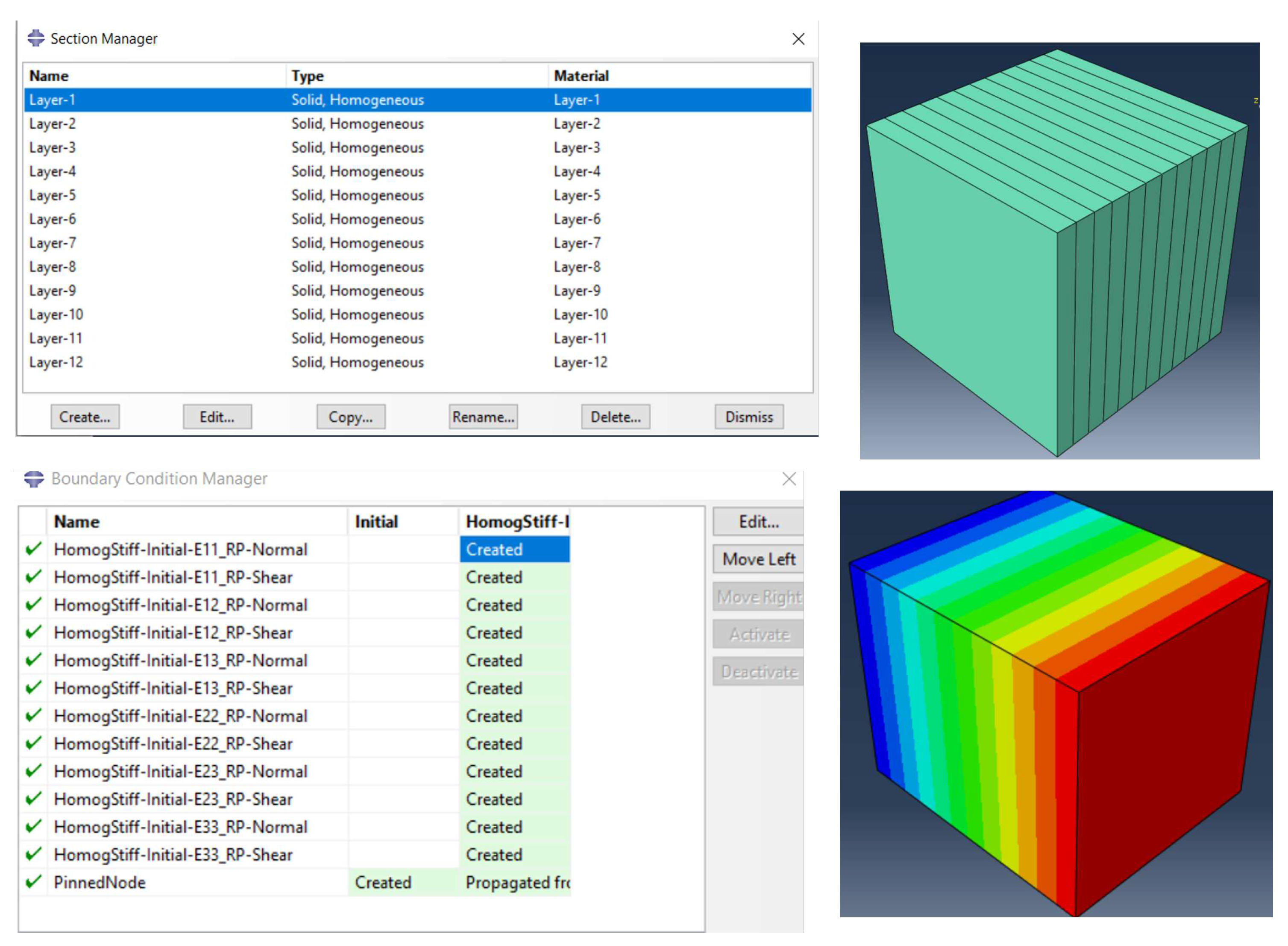

2.4.1. Micromechanics Plugin for Abaqus/CAE

2.4.2. Solid-To-Solid Mechanical Homogenization Scenario

2.4.3. Solid-To-Shell Homogenization Scenario

2.5. Constitutive Models for the Liner and the Overwrapped Composite Layers

- Fiber tension ():

3. Numerical Simulations

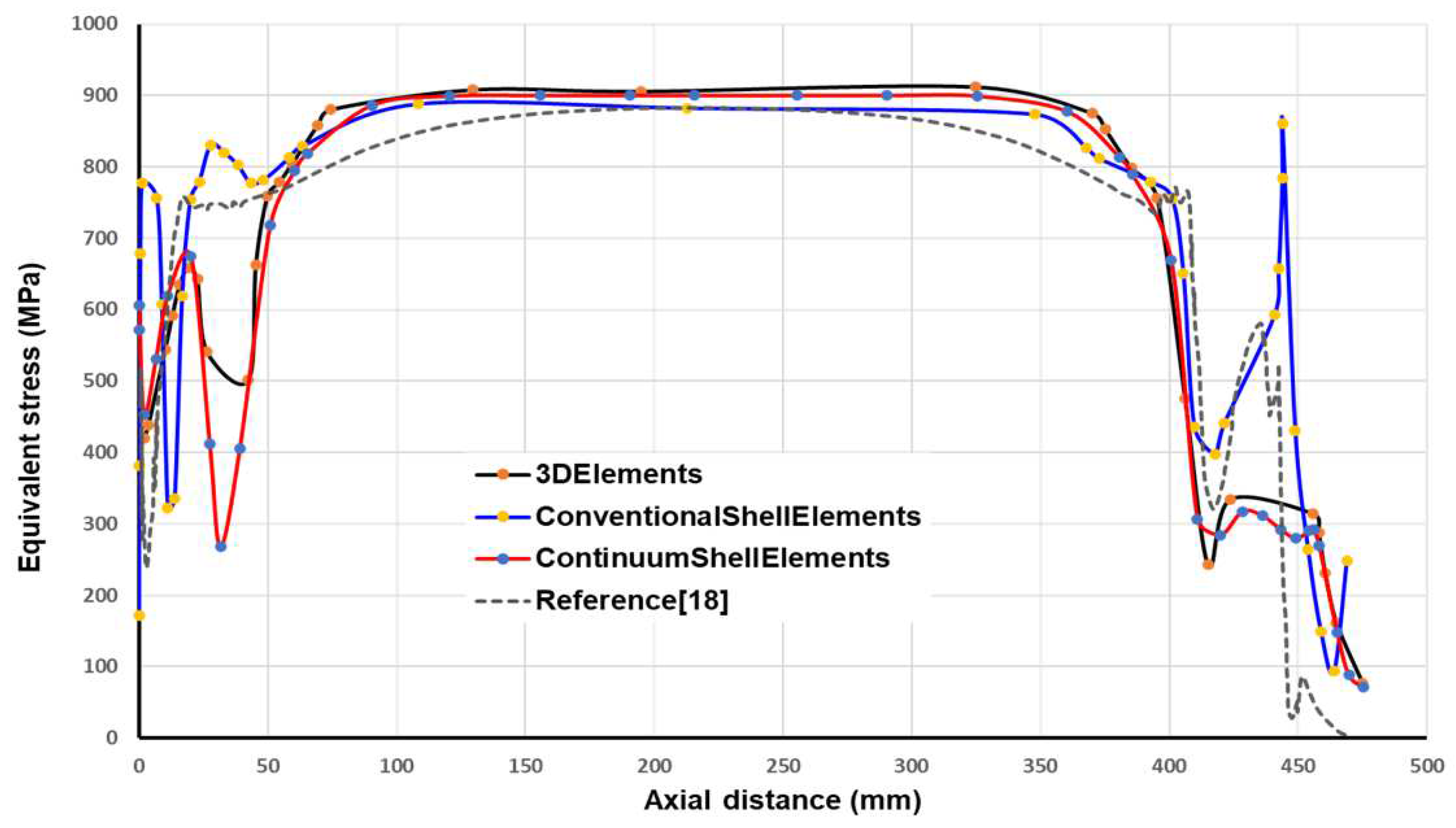

3.1. Simulation Using 3D Elements

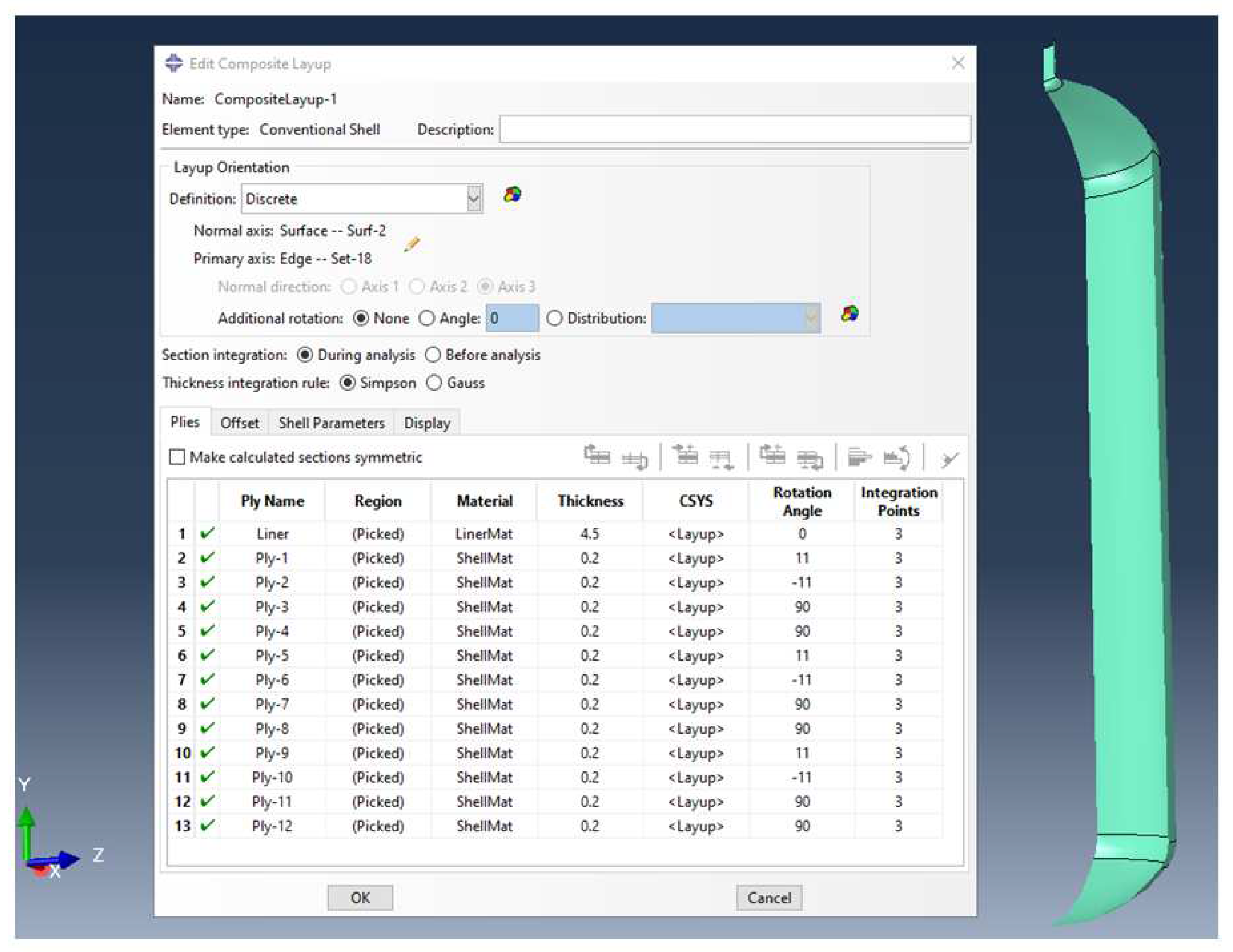

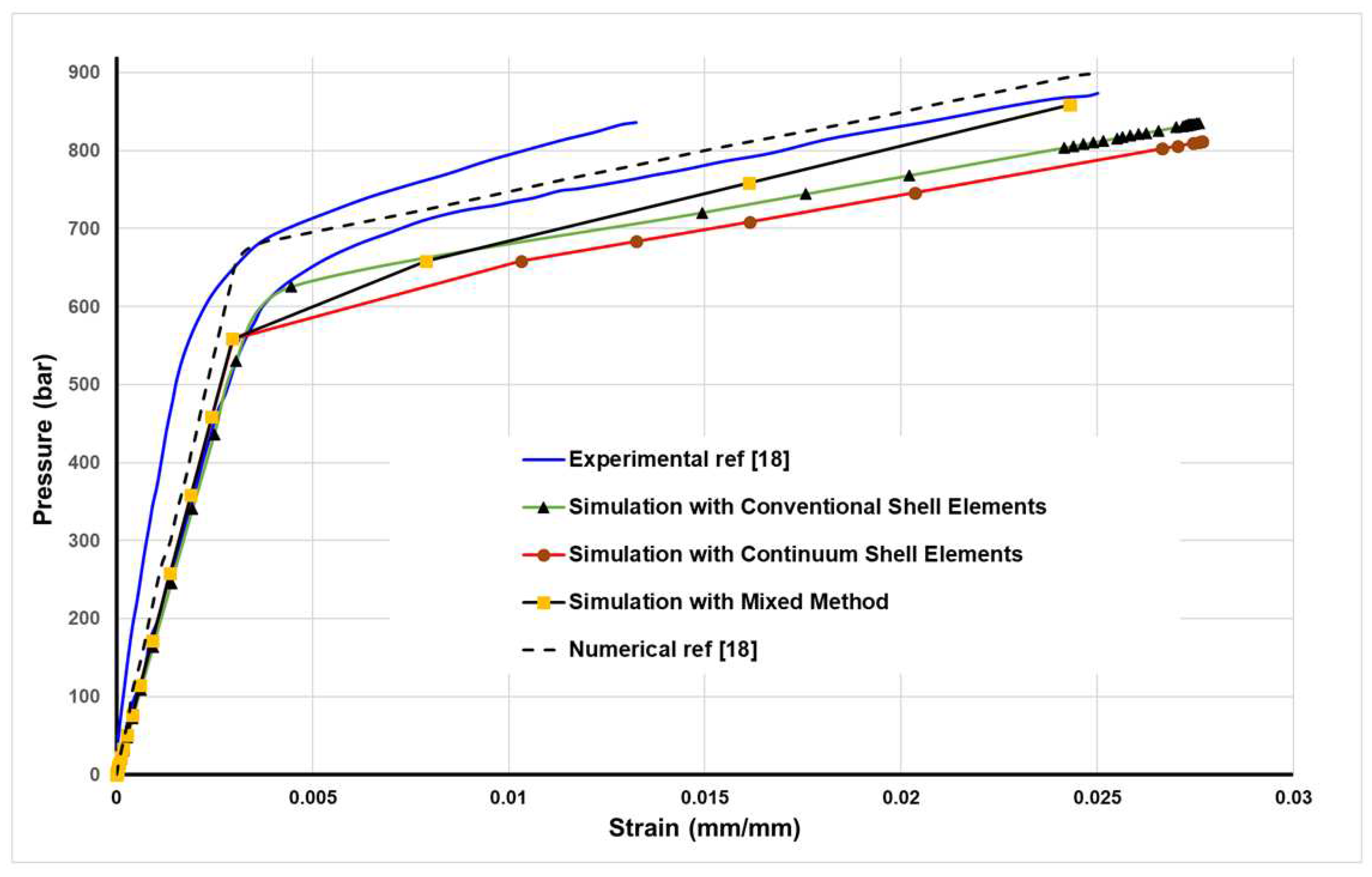

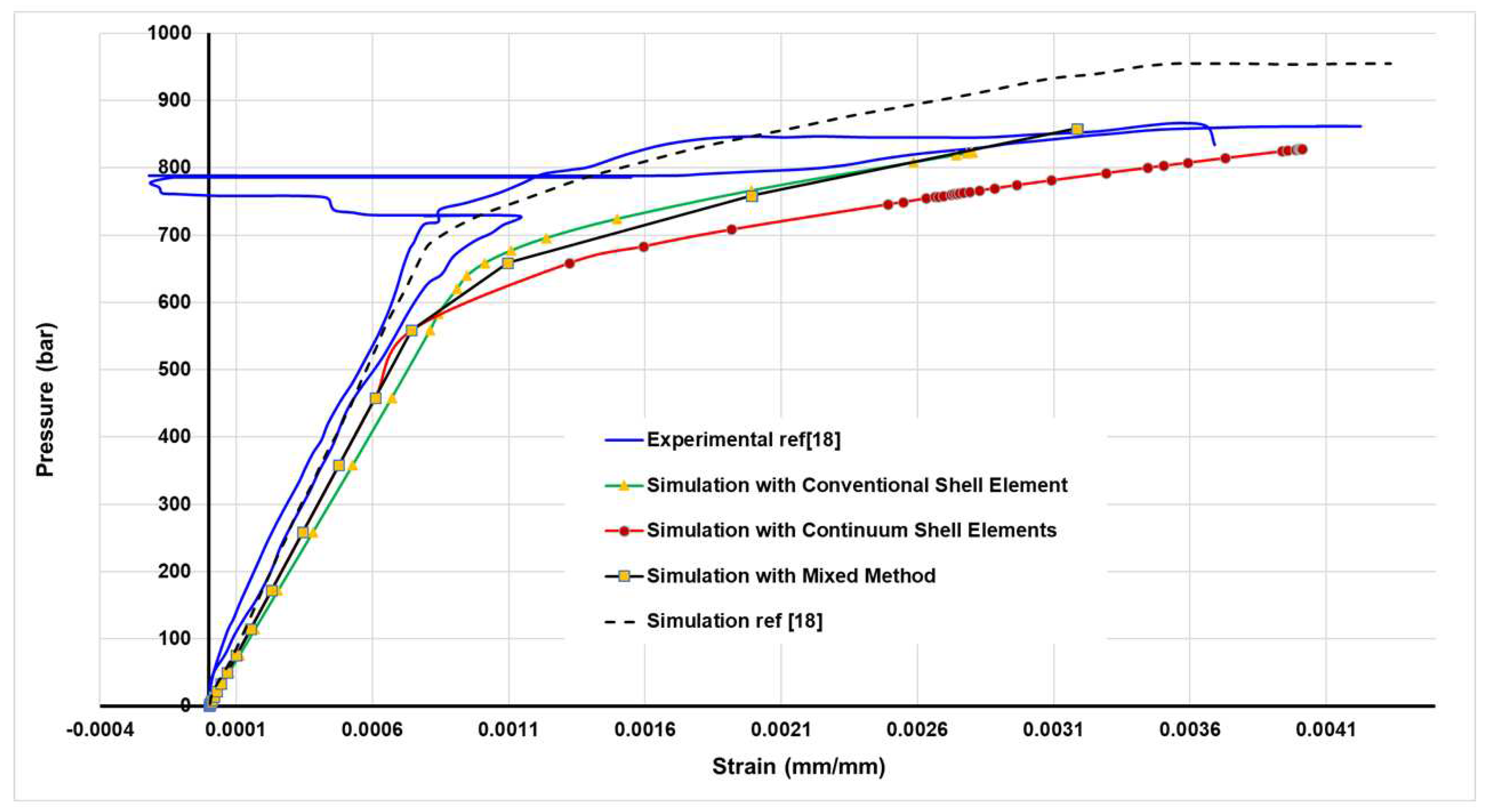

3.2. Simulation Using Conventional Shell Elements

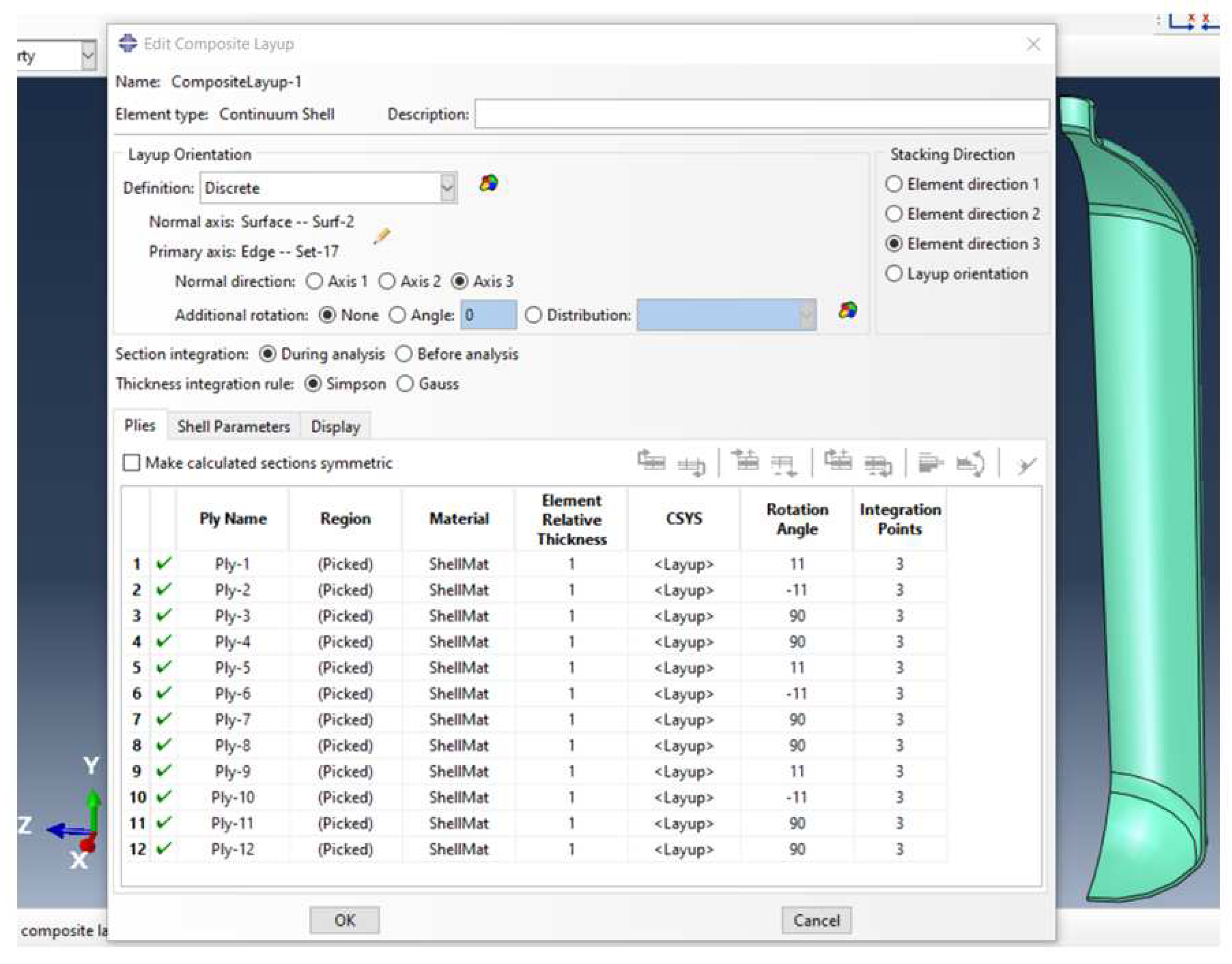

3.3. Simulation Using Continuum Shell Elements

3.4. Simulation Using Mixed Method

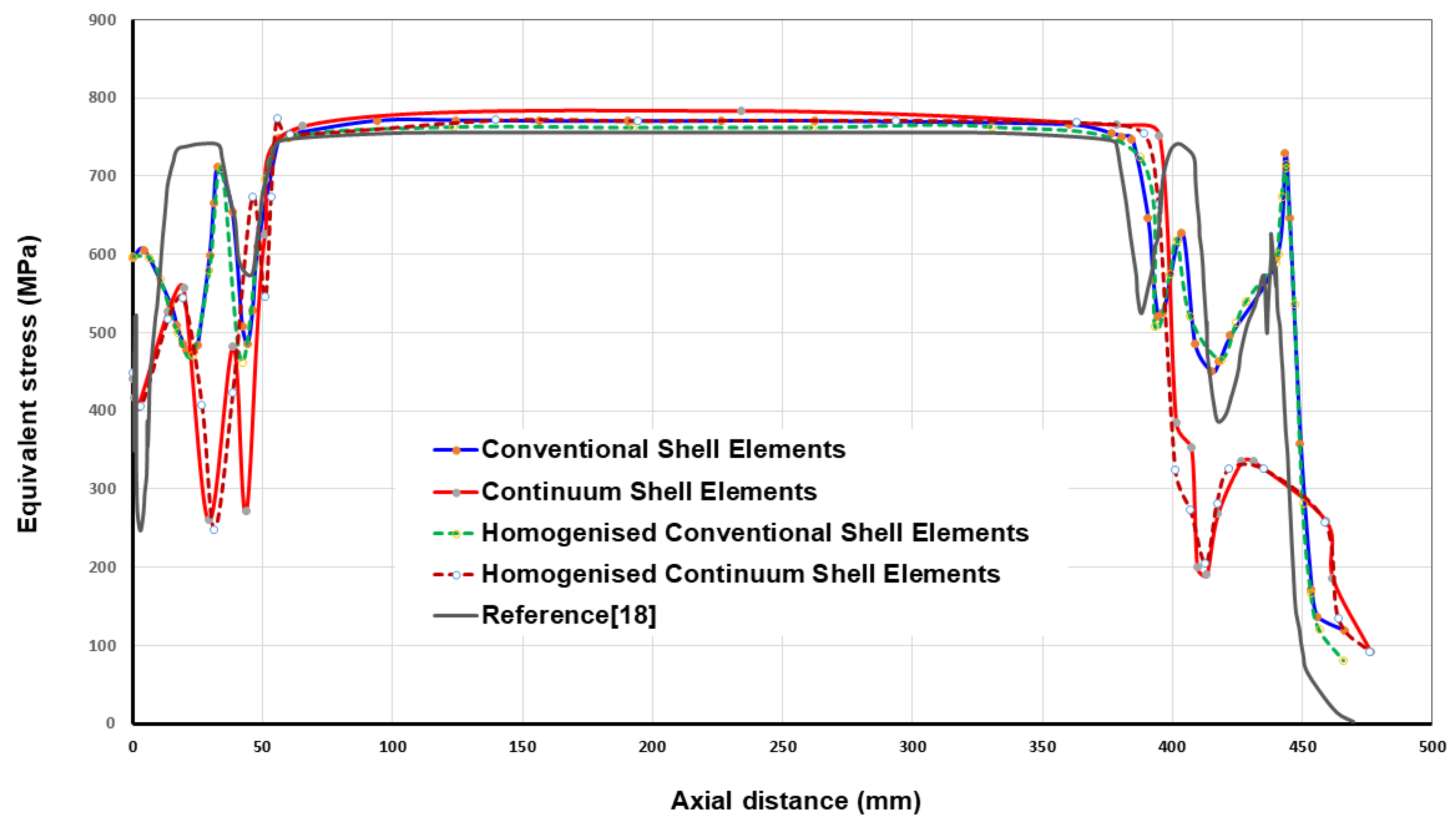

4. Comparison between Methods and Discussion

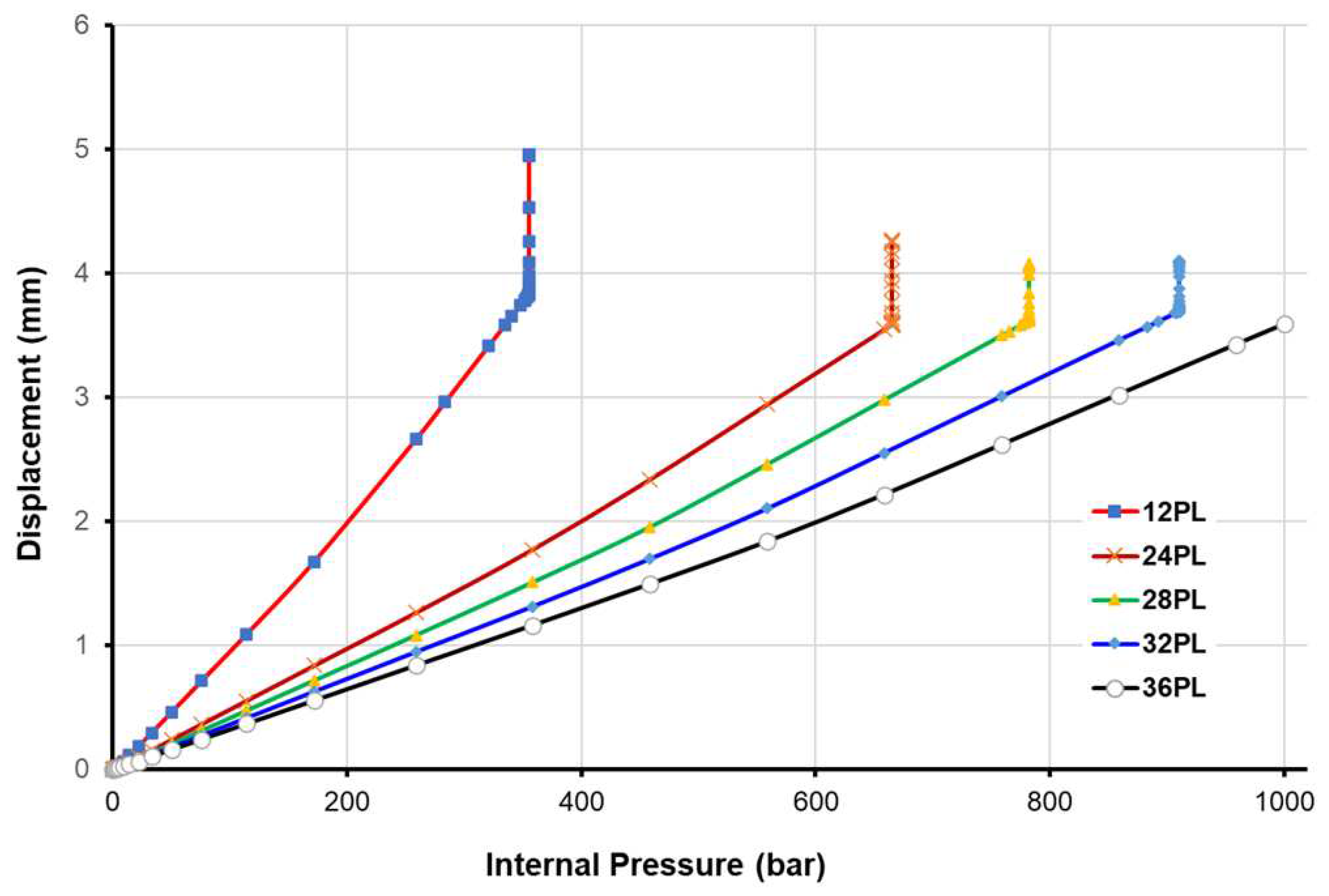

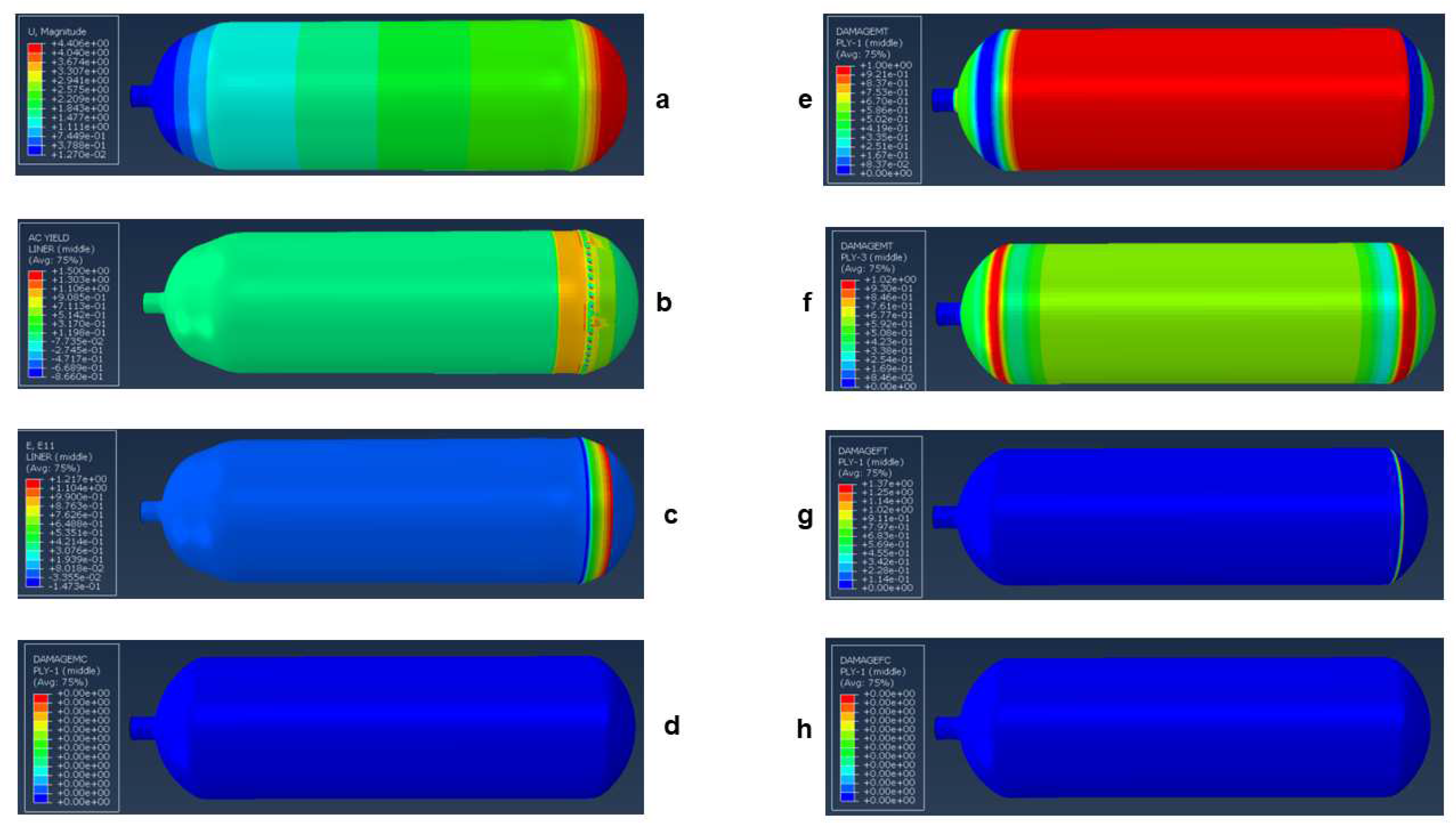

5. New Design of Type-IV Hydrogen Tank

6. Concluding Remarks

- In this study, we presented a comparative analysis of various numerical methods for modeling composite pressure vessels, aiming to provide a comprehensive understanding of their performance. The methods under scrutiny include finite element analysis in Abaqus with conventional shell elements, continuum shell elements, three-dimensional solid elements, and homogenization approaches for multilayered composite pressure vessels. Through a systematic comparison, this research offers insights into the strengths and limitations of each method.

- The findings of this study indicate that three-dimensional solid elements yield the highest accuracy in modeling composite pressure vessels. However, their practicality diminishes as the number of layers in the composite increases. Following closely are the continuum shell elements, which strike a balance between accuracy and computational efficiency due to their intermediate nature, combining features of both 3D and conventional shell elements. Meanwhile, the method relying solely on conventional shell elements proves accurate for specific applications but lacks universality.

- Moreover, this research underscores the significance of the homogenization technique, particularly for damage-free applications, as it consistently delivers highly accurate results.

- In the second part of the paper, a new design dedicated to type-IV hydrogen tank, composed of carbon fibers, epoxy resin, and a high-density polyethylene (HDPE) liner, is proposed. The study concentrates on predicting damage onset and behavior within the tank and burst pressure prediction. With this new design, we demonstrated that the tank can endure a pressure of 1000 bar when using 36 plies, resulting in a composite shell thickness of 7.2 mm.

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- J. Humberto, J. Almeida, L. St-Pierre, Z. Wang, M. L. Ribeiro, V. Tita, S. C. A. f, S. G. Castro, Design, modelling, optimization, manufacturing, and testing of variable-angle filament-wound cylinders, Composites Part B 225 (2021) 109224.

- Y. Regassa, J. Gari, H. G. Lemu, Composite overwrapped pressure vessel design optimization using numerical method, J. Compos. Sci. 6 (2022) 229. [CrossRef]

- Q. Zhanga, H. Xua, X. Jiab, L. Zua, S. Chenga, H. Wanga, Design of a 70 mpa type iv hydrogen storage vessel using accurate modelling techniques for dome thickness prediction, Composite Structures 236 (2020) 111915.

- K. C. Jois, M. Welsh, T. Gries, J. Sackmann, Numerical analysis of filament wound cylindrical composite pressure vessels accounting for variable dome contour, J. Compos. Sci. 5 (2021) 56. [CrossRef]

- N. Zhang, S. Gao, M. Song, Y. Chen, X. Zhao, J. Liang, J. Feng, A multiscale study of cfrp based on asymptotic homogenization with application to mechanical analysis of composite pressure vessels, Polymers 14 (2022) 2817. [CrossRef]

- H. Kang, P. He, C. Zhang, Y. Dai, H. Lv, M. Zhang, D. Yang, Stress–strain and burst failure analysis of fibre wound composite material high-pressure vessel, Polymers and Polymer Composites 29(8) (2021) 1291–1303.

- H. Wang, S. Fu, Y. Chen, L. Hua, Thickness-prediction method involving tow redistribution for the dome of composite hydrogen storage vessels, Polymers 14 (2021) 902. [CrossRef]

- S. Sapre, K. Pareek, M. Vyas, Investigation of structural stability of type iv compressed hydrogen storage tank during refueling of fuel cell vehicle, Energy Storage 2 (2020) 150. [CrossRef]

- A. V. Daniele Landi, S. Borriello, M. Scafà, M. Germani, A methodological approach for the design of composite tanks produced by filament winding, Computer-Aided Design and Applications 17 (6) (2020) 1229–1240. [CrossRef]

- M. A. Jebeli, M. Heidari-Rarani, Development of abaqus wcm plugin for progressive failure analysis of type iv composite pressure vessels based on puck failure criterion, Engineering Failure Analysis 131 (2022) 105851. [CrossRef]

- J. H. S. A. Jr., L. St-Pierre, Z. Wang, M. L. Ribeiro, V. Tita, S. C. Amico, S. G. Castro, Design, modelling, optimization, manufacturing and testing of variable-angle filament-wound cylinders, Composites Part B 225 (2021) 109224.

- O. Kartav, S. Kangal, K. Yücetürk, M. Tanoglu, E. Aktas, H. S. Artem, Development and analysis of composite overwrapped pressure vessels for hydrogen storage, Journal of Composite Materials 0 (2021) 1–15. [CrossRef]

- M. Zhang, H. Lv, H. Kang, W. Zhou, C. Zhang, A literature review of failure prediction and analysis methods for composite high-pressure hydrogen storage tanks, International Journal of Hydrogen Energy 44 (2019) 25777–25799. [CrossRef]

- B. N. Nguyen, H. S. Roh, D. R. Merkel, K. L. Simmons, A predictive modelling tool for damage analysis and design of hydrogen storage composite pressure vessels, International Journal of Hydrogen Energy 46 (2021) 20573–20585. [CrossRef]

- R. Moradi, K. M. Growth, Hydrogen storage and delivery: Review of the state-of-the-art technologies and risk and reliability analysis, International Journal of Hydrogen Energy 44 (2019) 12254–12269.

- A. J. Modesto, R. Birgul, R. J. Werlink, F. N. Catbas, Damage detection of composite overwrapped pressure vessels using arx models, International Journal of Pressure Vessels and Piping 192 (2021) 104410. [CrossRef]

- L. W. Kaite Guo, J. Xiao, M. Lei, S. Wang, C. Zhang, X. Hou, Design of winding pattern of filament wound composite pressure vessel with unequal openings based on non-geodesics, Journal of Engineered Fibers and Fabrics 15 (2020) 1–17. [CrossRef]

- S. Kangal, O. Kartav, M. Tanoglu, E. Aktas, H. S. Artem, Investigation of interlayer hybridization effect on burst pressure performance of composite overwrapped pressure vessels with load-sharing metallic liner, Journal of Composite Materials 54 (7) (2020) 961–980. [CrossRef]

- A. Rohatgi, Webplotdigitizer: Version 4.6 (2022).URL https://automeris.

- L. Bouhala, A. Makradi, S. Belouettar, H. Kiefer-Kamal, P. Fréres, Modelling of failure in long fibres reinforced composites by xfem and cohesive zone model, Composites: Part B 55 (2013) 352–361.

- L. Bouhala, Q. Shao, Y. Koutsawa, A. Younes, P. Núnez, A. Makradi, S. Belouettar, An xfem crack-tip enrichment for a crack terminating at a bi-material interface, Engineering Fracture Mechanics 102 (2013) 51–64. [CrossRef]

- Dassault Systèmes, Micromechanics Plugin for Abaqus/CAE, Version 1.18, Dassault Systèmes Simulia Corp., United States, 2022. [CrossRef]

- W. L. Azoti, A. Tchalla, Y. Koutsawa, A. Makradi, G. Rauchs, S. Belouettar, H. Zahrouni, Mean-field constitutive modeling of elasto-plastic composites using two (2) incremental formulations, Composite Structures 105 (2013) 256–262. [CrossRef]

- L. Bouhala, Y. Koutsawa, A. Makradi, S. Belouettar, An advanced numerical method for predicting effective elastic properties of heterogeneous composite materials, Composite Structures 117 (1) (2014) 114–123. [CrossRef]

- Dassault Systèmes, User’s Manual, Version 2022, Dassault Systèmes Simulia Corp., United States, 2022.

- I. Lapczyk, J. A. Hurtado, Progressive damage modeling in fiber-reinforced materials, Composites Part A: Applied Science and Manufacturing 38 (11) (2007) 2333–2341. [CrossRef]

| Symbol | Description | Unit | Value |

| Glass fiber/epoxy composite | |||

| Longitudinal (fiber dominated) modulus | MPa | 38,500 | |

| Transverse (matrix dominated) modulus | MPa | 16,500 | |

| Poisson’s ratio in-plane) | - | 0.27 | |

| Poisson’s ratio (planes 2-3) | - | 0.28 | |

| In-plane shear modulus | MPa | 4700 | |

| Shear modulus (planes 2-3) | MPa | 5000 | |

| Longitudinal (fiber dominated) Tensile strength | MPa | 1250 | |

| Longitudinal (fiber dominated) Compressive strength | MPa | -650 | |

| Transverse (matrix dominated) Tensile strength | MPa | 36 | |

| Transverse (matrix dominated) Compressive strength | MPa | -165 | |

| In-plane shear strength | MPa | 86 | |

| Fracture energy of the fiber | N/mm | 12.5 | |

| Fracture energy of the matrix | N/mm | 1 | |

| Steel liner (SL) | |||

| ESL | Young’s modulus | MPa | 205,000 |

| Poisson’s ratio | - | 0.3 | |

| Yield strength | MPa | 743 | |

| Bilinear isotropic hardening tangent modulus | MPa | 2600 | |

| E1 (MPa) | E2 (MPa) | E3 (MPa) | (-) | (-) | (-) | G12 (MPa) | G13 (MPa) | G23 (MPa) |

| 26548.24 | 27347.34 | 17343.40 | 0.180 | 0.344 | 0.339 | 5204.77 | 4700 | 4700 |

| Symbol | Description | Unit | Value | ||||

| Carbon fiber/epoxy composite | |||||||

| Longitudinal (fiber dominated) modulus | MPa | 141,000 | |||||

| Transverse (matrix dominated) modulus | MPa | 11,400 | |||||

| Poisson’s ratio in-plane) | - | 0.28 | |||||

| Poisson’s ratio (planes 2-3) | - | 0.40 | |||||

| In-plane shear modulus | MPa | 5000 | |||||

| Shear modulus (planes 2-3) | MPa | 3080 | |||||

| Longitudinal (fiber dominated) Tensile strength | MPa | 2080 | |||||

| Longitudinal (fiber dominated) Compressive strength | MPa | -1250 | |||||

| Transverse (matrix dominated) Tensile strength | MPa | 60 | |||||

| Transverse (matrix dominated) Compressive strength | MPa | -290 | |||||

| In-plane shear strength | MPa | 110 | |||||

| Fracture energy of the fiber | N/mm | 78 | |||||

| Fracture energy of the matrix | N/mm | 1 | |||||

| Isotropic elastic properties for the high-density polyethylene liner (HDPE) [25] | |||||||

| Young’s modulus | MPa | 903.114 | |||||

| Poisson’s ratio | - | 0.39 | |||||

| Isotropic plastic hardening data for the HDPE liner material [25] | |||||||

| Yield stress (MPa ) | 8.618 | 13.064 | 16.787 | 18.476 | 20.337 | 24.543 | 26.887 |

| Plastic strain (-) | 0 | 0.007 | 0.025 | 0.044 | 0.081 | 0.28 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).