1. Introduction

Rammed earth construction is used for building walls using natural raw materials such as earth, chalk, lime, or gravel. The more the construction society pursue sustainable natural building materials and economical construction methods, the more intensive the interest to use rammed earth construction in recent years. Indeed, rammed earth construction provides an easily accessible method to construct noncombustible, strong, and durable walls with excellent thermal properties [

1].

However, the method encounters eroding issues when the air contact surface areas of rammed earth walls are frequently exposed to weather elements (i.e., rain, snow, fog, dew, and sleet, etc.) which continuously alternate wetting and drying. The issue causes the earth particles to retain a high amount of moisture, hence, leading to destructive effects [

2]. The vapor diffusion properties and humidity control ability of rammed earth, which is commendable for the wall building materials, may be earned only when the permeability and hydrophilic properties of the rammed earth materials are controlled appropriately because moisture particles can easily penetrate through the walls [

2]. Indeed, the porous structure of the rammed earth wall causes high sensitivity to moisture absorption through capillary tubes in the wall. For sure, controlling moisture absorption is an important contributor to the reduction of various water-induced damages such as stains, scaling attributed to freeze thaw cycles, chemical attacks, and corrosion to reinforcing steel [

3].

Since moisture penetration is the major contributor that influences the durability of the rammed earth wall, a recent series of methods focus on improving the durability of rammed earth structures using stabilizers such as cement. Soil stabilization binds soil particles together, improves soil strength, and increases softening resistance to water by means of waterproofing [

4]. Noteworthy is that cement neither does lend itself to water penetration, because it is also a hydrophilic material, nor to solve eco-friendliness because it allows damage to the insulation of the rammed earth buildings.

The recent representative methods, which improve the durability of rammed earth buildings against natural weathering, are twofold, internal admixtures treatment and post-surface treatment [

5]. The ones, internal admixture treatments using mainly a silicone water repellent, minimize effectively the movement of moisture in the capillaries in the first step of rammed earth construction. The others, post-surface treatments, block the inlets of capillaries on the surface of the rammed earth wall after when the wall is built and cured. Silicone-based repellents are useful for rammed earth constructions against existing post-surface treatments, because the sealer penetrates the capillary system and reacts with the substrate via strong bonding, hence providing long-term protection against natural weathering. The post-surface treatment using water repellents has been well accepted as a reliable long-lasting solution to minimize water penetration within inorganic construction materials [

5]. In the last decades, silane, siloxane, or silicone resin-based emulsions or powders of have been used as water repellents in mortar and concrete. Indeed, the treatment using these compounds is now an established technology with well-accepted benefits [

6,

7]. However, these compounds have been rarely used for rammed earth walls.

Siloxane polymer-based repellents offer permanent water-repellent layers on various types of construction materials composed of soil, aggregate, and inorganic [

7,

8]. The reaction leads to the monolayer of the surfaces by converting the water-like silanol groups to water-repellent siloxane bonds. These siloxane polymers react with soil particles, hence, forming hydrophobic layers on the surface of the soil particles.

Most siloxane-based polymer water repellents consist of alkyl groups such as octyl or dodecyl groups. Siloxane polymers substituted with these long-chain alkyls have a good water repellency effect. However, fluoroalkyls outperform in hydrophobicity rather than alkyl groups. Note that few studies on siloxane polymer water repellents are made of fluoroalkyl, and only a few studies report on water-repellent properties according to the composition and type of fluoroalkyl as well.

This study develops a water repellent, which may increase the durability of rammed earth walls, by copolymerizing various siloxane monomers. The water repellent is produced by performing the hydrolysis and condensation copolymerization of alkyl groups or fluoroalkyl groups that are substituted by trialkoxysilane and tetraethoxysilane compounds. The performance of repellent is investigated according to polymerization conditions, composition ratios, and solution concentrations.

A siloxane copolymer with a low molecular weight is prepared for post-surface treatment using spray surface coatings. The water-repellent characteristics are identified by the contact angle depending on the composition ratio of the copolymer. In addition, the moisture content and the compressive strength obtained after immersing a specimen in water are measured to confirm the durability of the rammed earth wall against moisture penetration.

3. Results and Discussions

Soils become solidified when they are dry but lose their strength completely when they are wet. To complement this issue, the surface treatments are used to improve the weather resistance, hence, acquiring the long-term performance of the rammed earth materials. The quality requirements for the surface treatment performance include allowing vapor transmission, controlling carbonation, reducing moisture penetration, and improving sufficient drywall, etc. Silane-based hydrophobic admixtures obtained by mixing with concrete and water repellents have been used to protect the surface of the concrete [

13]. However, the surface coating method of rammed earth walls, which makes use of a spray, is more favorable than the mixing with soils and water repellents. It facilitates enclosing only the surfaces of the rammed earth walls, which are vulnerable areas to weather erosion, by applying water-repellents after completing the rammed earth walls. Siloxane polymers consist of hydrophilic and hydrophobic groups. The active group Si-OH, which is a hydrophilic group, easily reacts with the surface of the rammed earth walls, hence, forming a chemically bonded layer. The outside of such a coat is composed of a water-repellent group, which consists of alkyl groups. This study synthesizes siloxane copolymers, which is specialized to coat the surface of rammed earth walls. A silane with an octyl group that is commonly used as a water repellent and a silane monomer in which a perfluorodecyl group and a trifluoro propyl group are substituted are copolymerized. The copolymerization outputs obtained by performing the hydrolysis and condensation [

14] of four types of monomers: OTES, PFTES, TFTMS, and TEOS are shown in

Table 1.

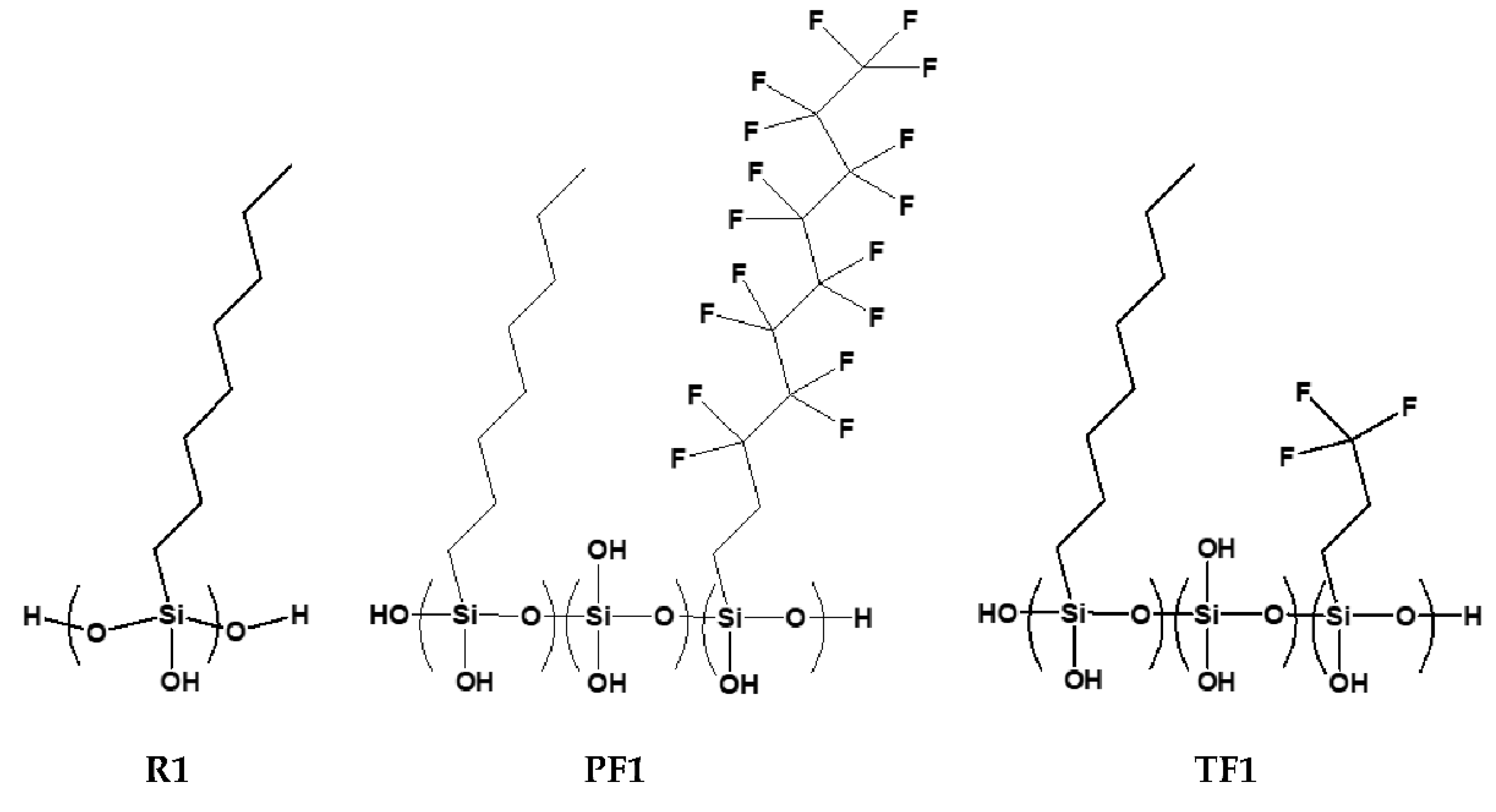

The molecular weight of OTES homopolymer (R1) is the highest among other copolymers (i.e., PF1 and TF1), given the monomer feed ratios of 8,000 g/mol. Those of PF1 and TF1 using PFTES and TFTMS substituted with fluorine, respectively, are relatively lower than R1, given the monomer feed ratio of 5,000 g/mol and that of 4,000 g/mol. It is confirmed that PF1 and TF1 are the most favorable for spray-coated water repellents because of their low molecular weights.

The water-repellent performance is evaluated by drying the rammed earth specimen followed by spray the siloxane copolymer solution to coat the surface of the rammed earth specimen followed by drying the coat, and followed by measuring the water contact angle. Water droplet is performed to measure each of which of the contact angle of a specimen which is coated with the siloxane copolymer PF1 and that which is not coated with it as shown in

Figure 2.

The shape of the droplet on the surface of PF1 remains intact even 5 minutes time lapse passes after dropping the droplet as shown in (a) of

Figure 2. However, that on the surface of the specimen, which is not coated, disappears completely within 10 seconds, hence, being unable to measure even a minimal contact angle. It is confirmed that the siloxane copolymer with an alkyl group and a fluoroalkyl group is promising for the water-repellent of rammed earth walls. The surface properties of the coated layer are generally dictated by the functional groups and are affected by the variations in the chain flexibility as well [

15]. A silane monomer having an octyl group and a perfluoro decyl group as a substituent is used because the hydrophobicity of C-F is much higher than that of C-H is. In addition, the copolymer is prepared using a monomer with a perfluoro decyl group and a trifluoro propyl group to examine the effect of the chain length, chain flexibility, and amount of fluorine. The contact angles of water droplets on the surface of rammed earth specimens, which are coated by the spray with siloxane copolymer of FP1, siloxane copolymer of TF1, commercial repellent, and commercial epoxy resin, are measured after natural drying as shown in (a), (b), (c), and (e) of

Figure 3, respectively.

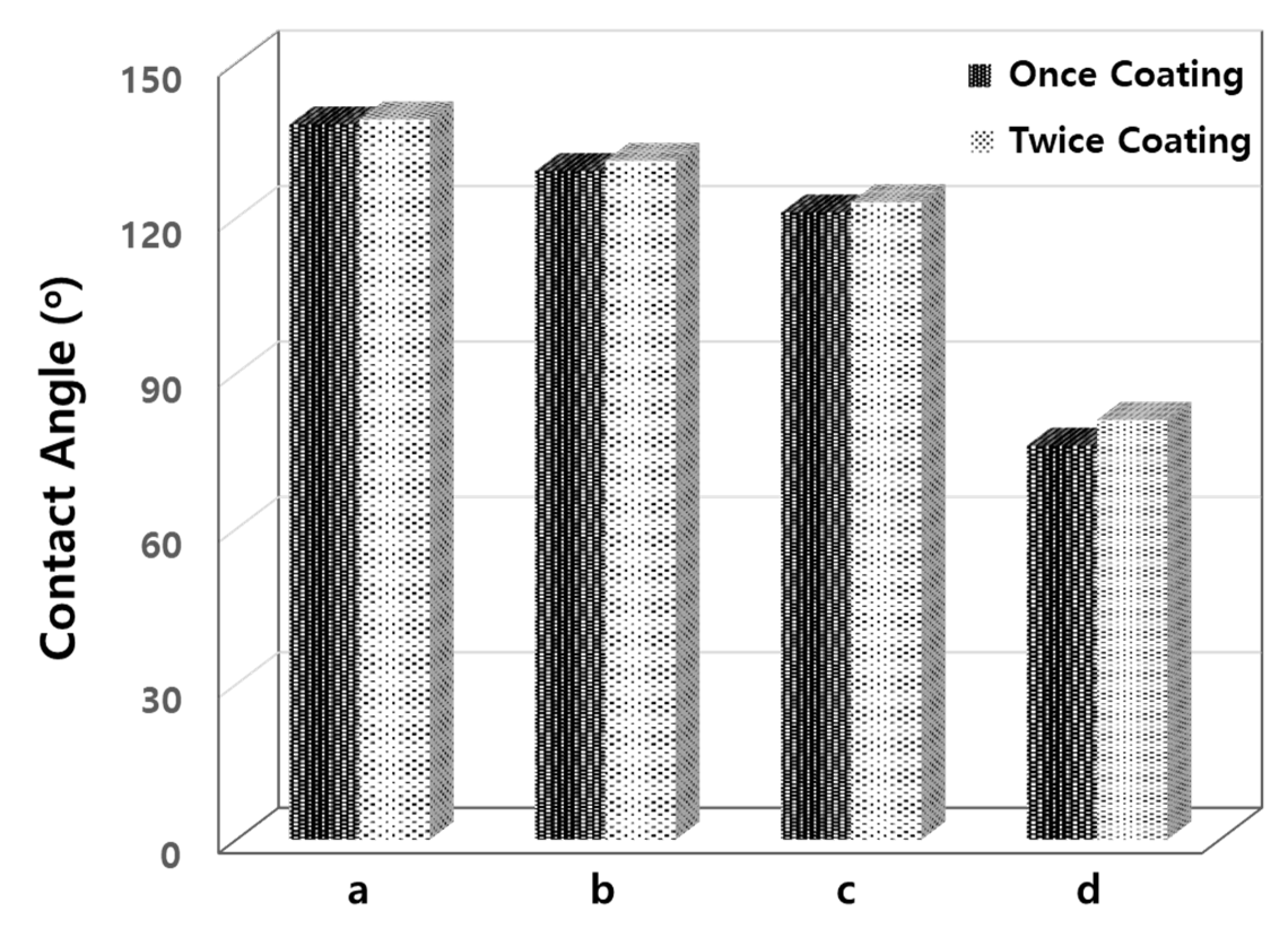

The contact angle of the water repellent using the siloxane copolymer containing a fluorine group outperforms that of the commercial water repellent. The contact angle of PF1 having a high fluorine content outperforms that of TF1 having a low fluorine content in proportion to the hydrophobicity. In addition, the contact angle of the specimen coated twice is approximately 2 to 3 degrees higher than that of the specimen coated once.

Impregnation is widely used to treat masonry materials to make them water-repellent [

16]. After immersing the rammed earth specimens that are coated with siloxane copolymers and those that are not coated with them into water, the water absorption amount is measured to evaluate the water resistance and the water-repellent performance. After elapsing the predefined time, the specimens emerge from the water followed by removing the surface moisture quickly with a towel and followed by weighing the specimens. The weight increase is indicated by the wt.% of water absorption against to the initial dry weight. The increase of water absorption obtained by the specimens as the function of immersion time in water is shown in

Figure 4.

The specimen that is not coated with the copolymer absorbs about 18 wt.% of water after immersing into water for 1 hour. The water absorption becomes almost constant at about 20 wt.% after immersing in water for 3 hours. The surface of the specimen swells, hence, detaching soil particles on the edge part after immersing the specimens into water for 5 hours. The specimen swells in water but does not completely release the soil particles because the stabilizers bind the soil particles strongly, hence, increasing the apparent density as confirmed by existing study [

1]. The specimen that is not coated with the copolymer absorbs about 18 wt.% of water after immersing in water for 1 hour. The water absorption becomes almost constant at about 20 wt.% after immersing in water for 3 hours. The surface of the specimen swells, hence, detaching soil particles on the edge part after immersing the specimens into water for 5 hours. The specimen swells in water but does not completely release the soil particles because the stabilizers bind the soil particles strongly, hence, increasing the apparent density as confirmed by existing study [

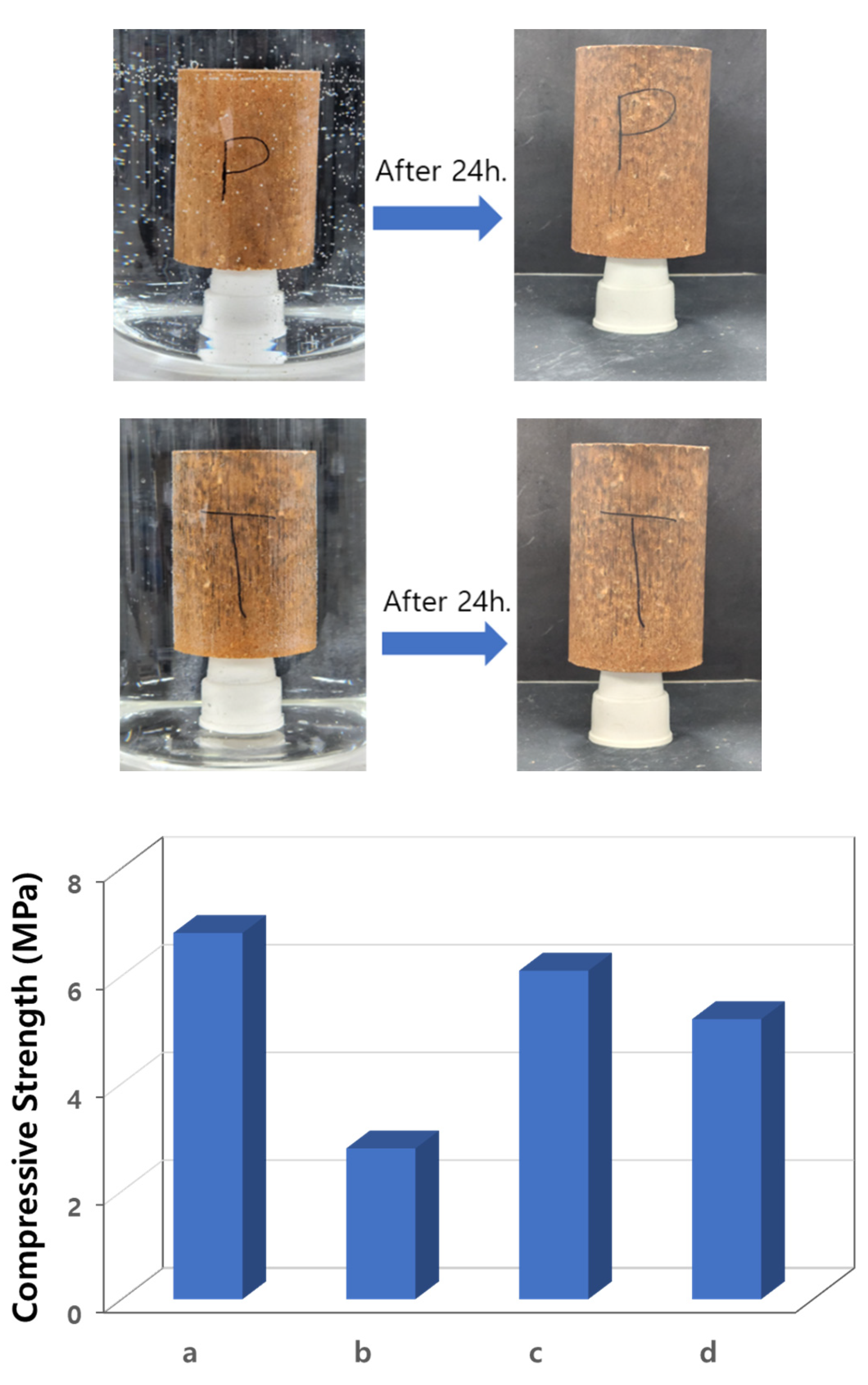

1]. However, the specimen coated with the copolymer PF1 of which the contact angle is the highest absorbs 3.5 wt.% or less even after 24 hours of immersion time, hence, hardly water absorption. In addition, the specimen coated with the copolymer TF1 of which the contact angle is lower than that with PF1 absorbs 14 wt.% or less after 5 hours of immersion time, hence, occurring at a higher absorption rate rather than PF1 does. The outputs of the contact angle and the water absorption rate over time lapse provide admissible that the siloxane copolymer invented in the study has excellent characteristics as a water-repellent.

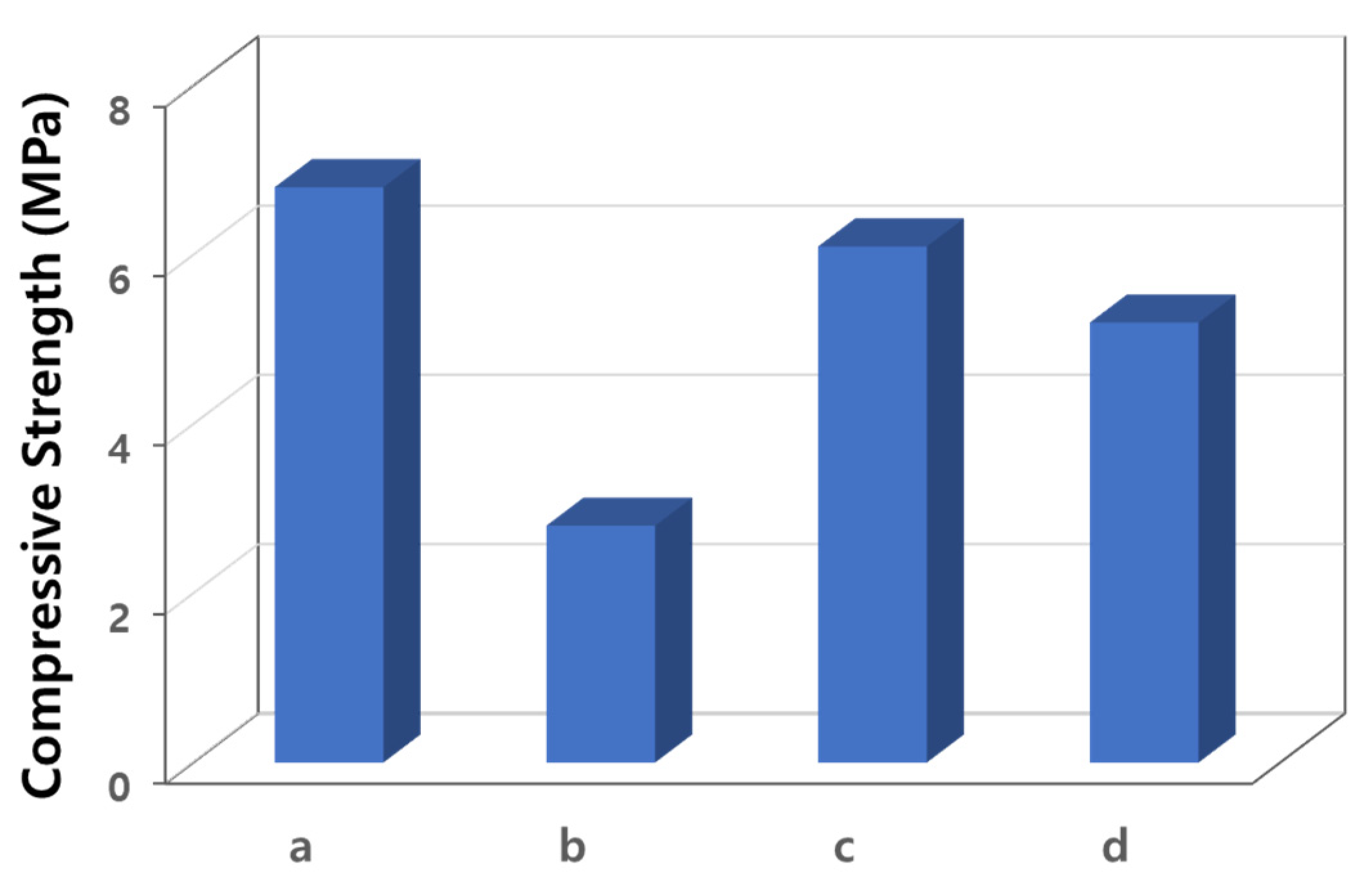

The compressive strength of the specimens used for the water absorption experiment, which are coated with the water-repellent developed to complement the vulnerable hydrophilic of rammed earth walls exposed to rainfall in this study, are shown in

Figure 5.

Being immersed in water for 24 hours the specimens coated with the siloxane copolymer, the water absorption values of PF1 and that of TF1 are 3.5 wt.% and 17 wt.%, respectively. However, their shape and appearance before immersion in water remain intact. The compressive strength of the specimen PF1 absorbing a little moisture and that of the specimen that does not immerse in water are 6.1 MPa and 6.7 MPa, respectively, hence, reducing the strength by about 10%. However, the strength of the specimen PF1 remains sufficient enough for use in rammed earth walls. The compressive strength of the specimens TF1 absorbing more moisture than PF1 is 5.1 MPa, hence, reducing the strength by more than 25%. It confirms that the rammed earth walls coated with TF1 are more vulnerable to moisture attributed climates because it absorbs 17 wt.% of water more rather than PF1 does. The compressive strength of the specimen being not coated with siloxane copolymers absorbs 20 wt.% of water, hence, decreasing the strength rapidly by more than 60% to 2.5 MPa. For sure, the compressive strength of it does not meet the intended use of a rammed earth wall, because it is too low. The series of experiments provide a piece of admissible evidence that the developed siloxane-based copolymer containing fluorine has a sufficient effect as a water repellent along with and contributes to keeping intact the durability of the rammed earth wall.

The price competitiveness of either PF1 or TF1 is unfavorable to that of a water-repellent made of silane composed of conventional alkyl groups, even if only 10 mol% of the siloxane monomer with a high-price fluorine group is used. That is why, the water-repellent effect depending on the solution concentration of siloxane copolymers is investigated. PF1 and TF1, which are siloxane copolymers containing 10 mol% fluorosiloxane monomers, are mixed in ethanol/water at 50, 25, 10, and 5 vol.%. The contact angle of water droplets on the rammed earth specimens each of which is coated with different concentrations of siloxane copolymers by spray coating is measured. The variation of contact angles attributed to the concentration of siloxane copolymer is shown in

Figure 6.

The contact angle keeps intact above 130 o regardless of the type and concentration of the siloxane copolymer. Indeed, the contact angle of the rammed earth specimen that is coated by the siloxane copolymer solution diluted to 10 vol.% concentration keeps intact almost to that coated by it having 50 vol.% concentration. It is found that the water-repellent effect is sufficient, even if the siloxane copolymer containing the fluorine group is used in the amount of 10 vol.% or less, hence, being favorable to the price competitiveness, even when the fluorine group is used.