Submitted:

19 October 2023

Posted:

23 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Mine model

2.1. Optimization problem

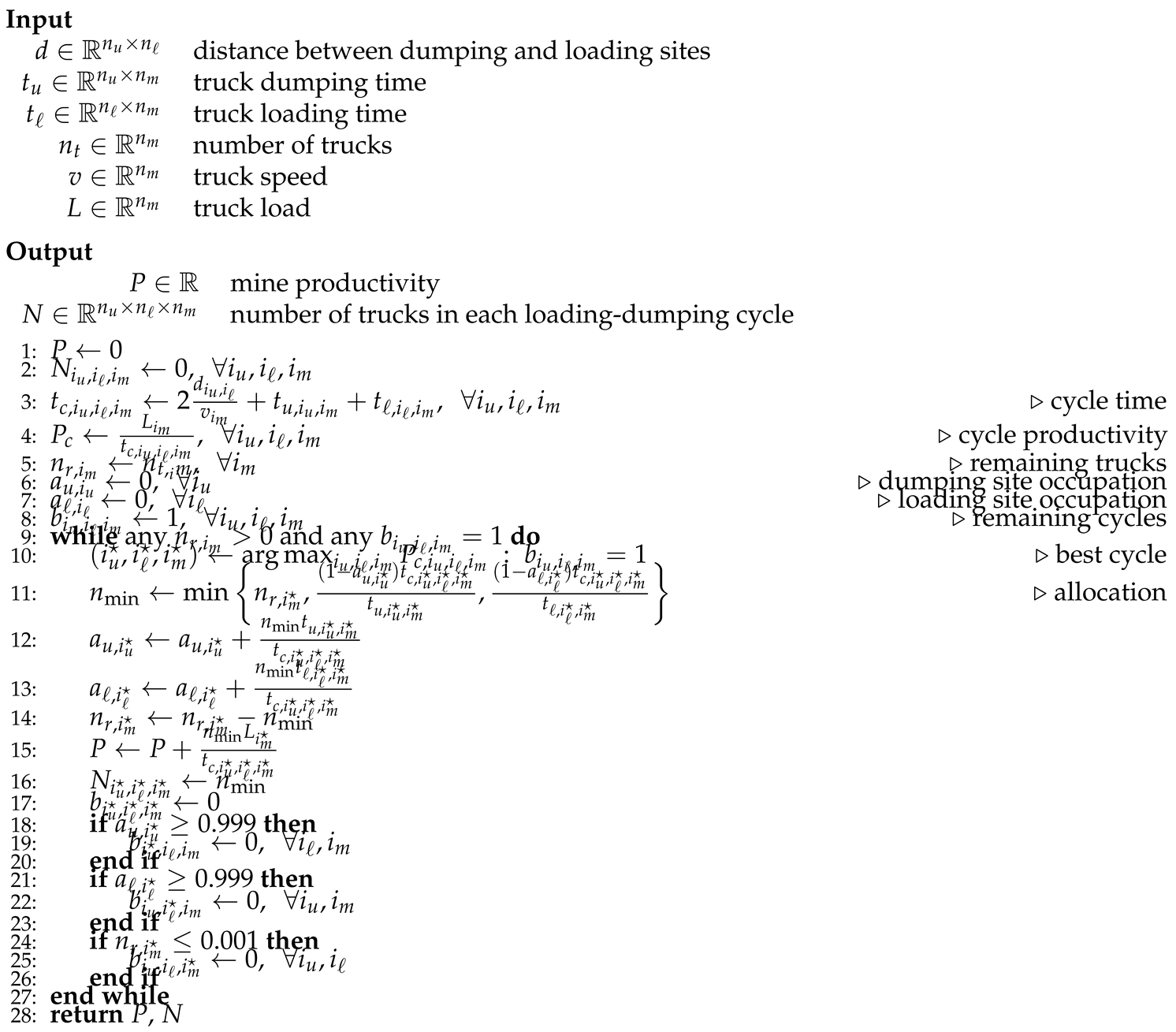

2.1.1. Greedy search

| Algorithm 1 Greedy search for mine productivity. |

|

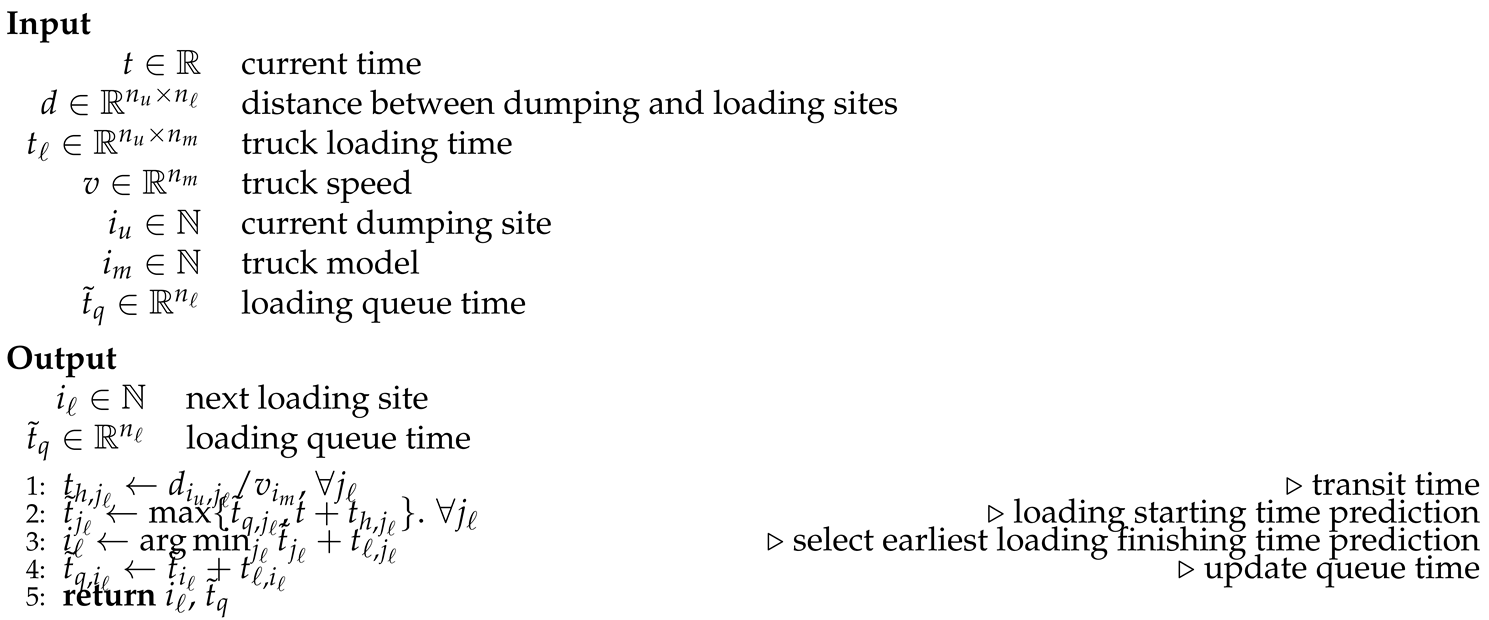

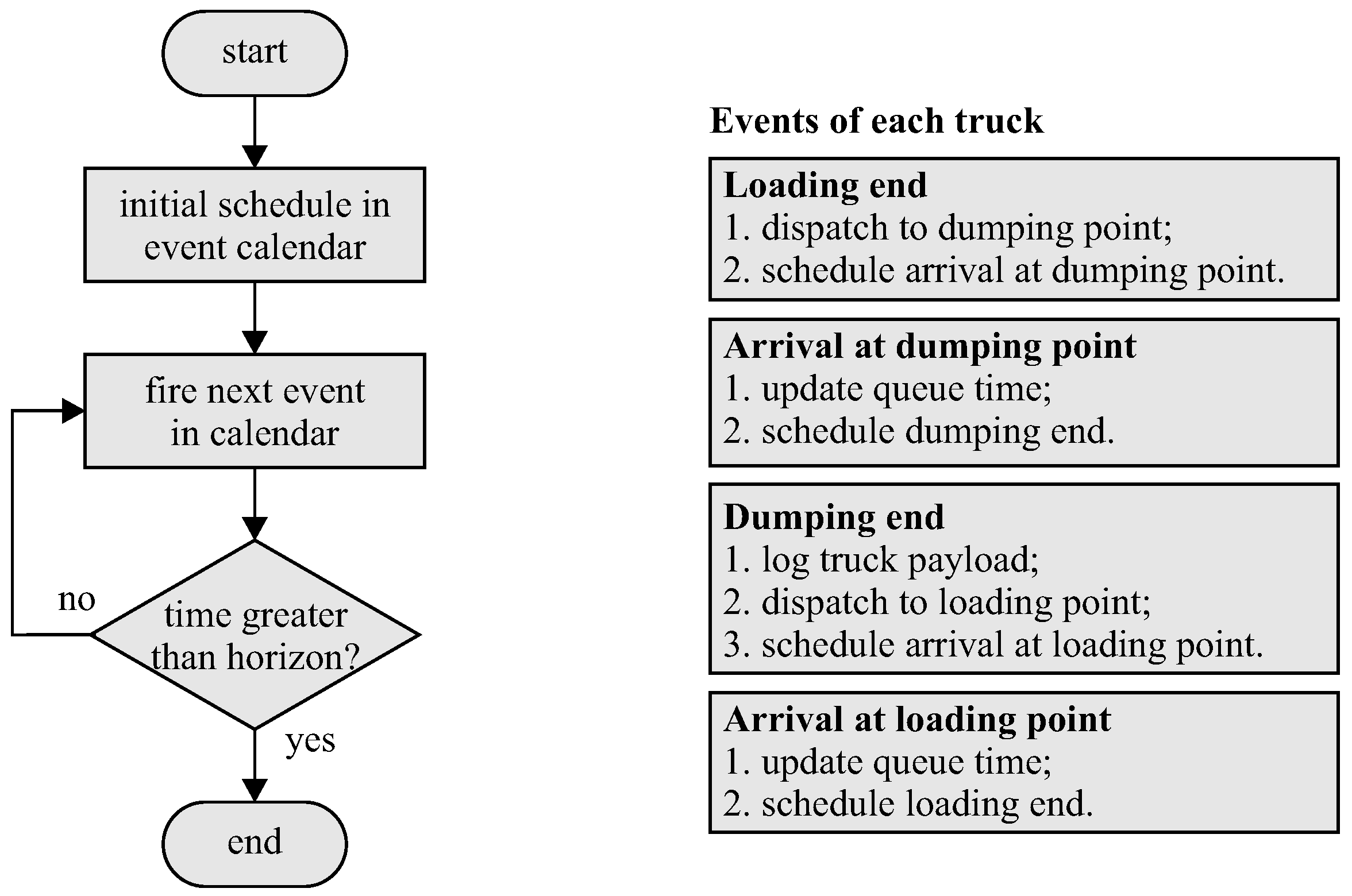

2.2. Simulation

| Algorithm 2 Dispatch rule to a loading site. |

|

3. Results

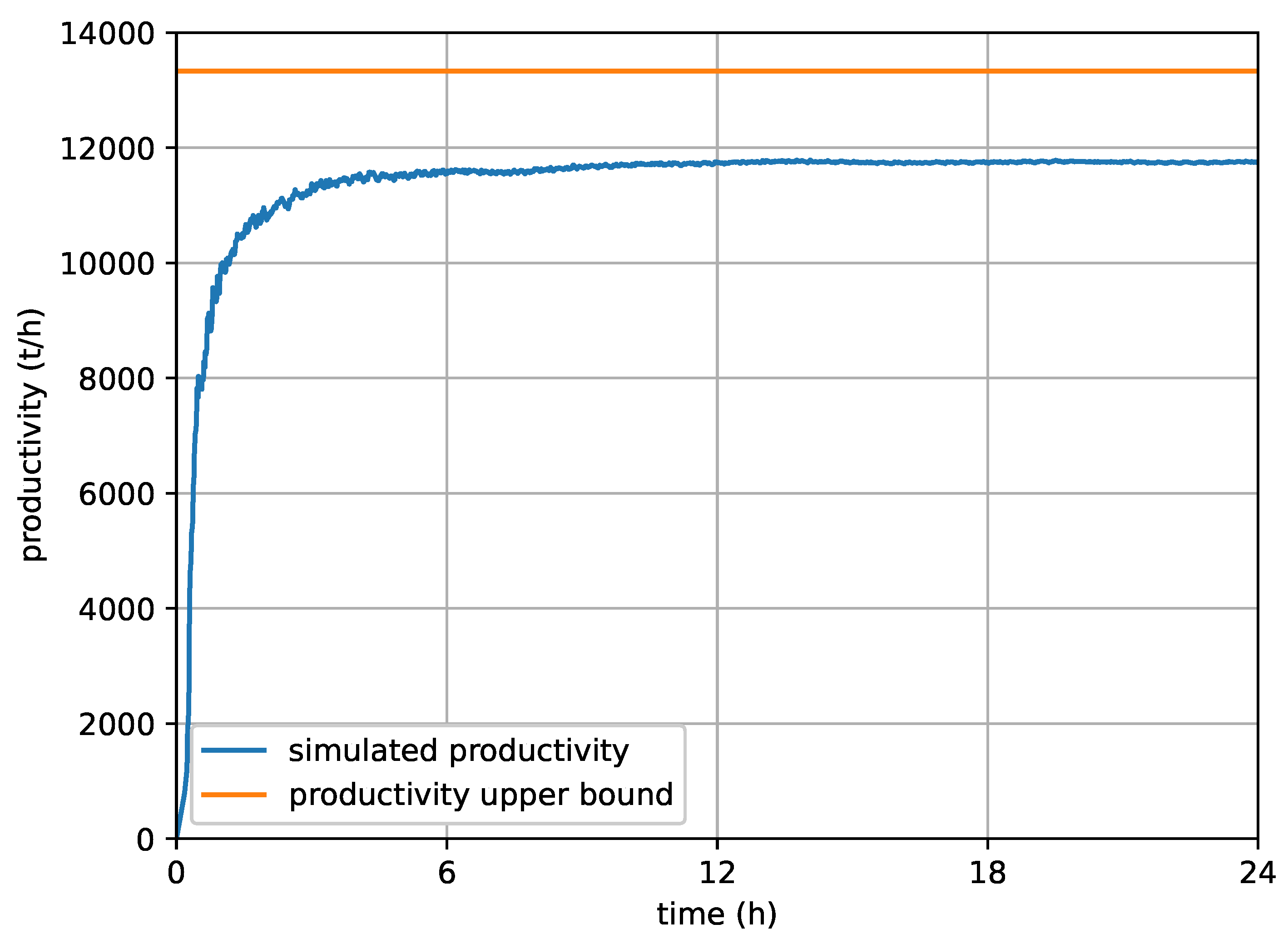

3.1. Simulated productivity convergence and its upper bound

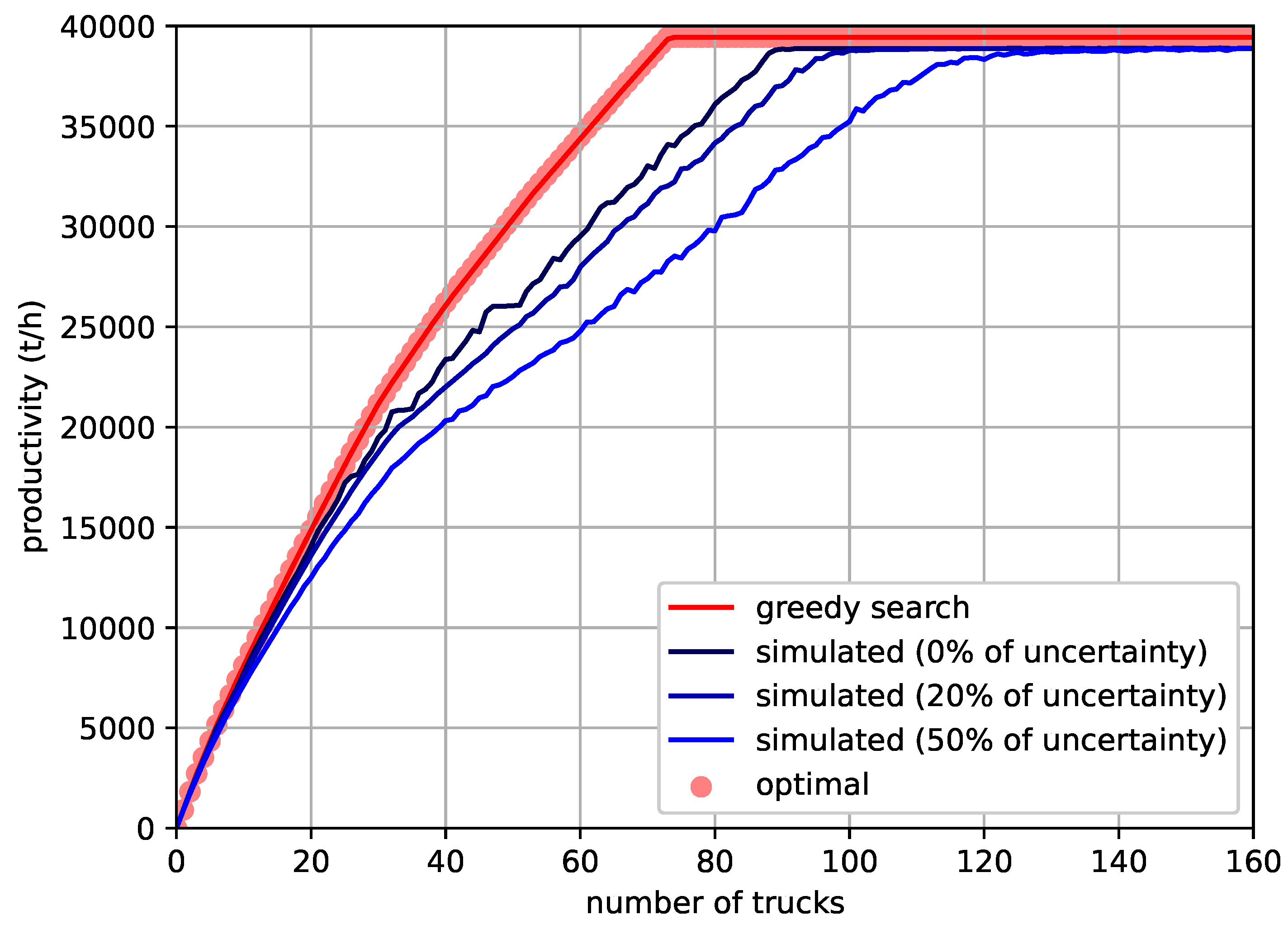

3.2. Fleet sizing

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Humphreys, D. The mining industry after the boom. Mineral Economics 2019, 32, 145–151. [Google Scholar] [CrossRef]

- Alarie, S.; Gamache, M. Overview of solution strategies used in truck dispatching systems for open pit mines. International Journal of Surface Mining, Reclamation and Environment 2002, 16, 59–76. [Google Scholar] [CrossRef]

- Hauck, R.F. A real-time dispatching algorithm for maximizing open-pit mine production under processing and blending requirements. Seminar on Scheduling in Mining, Smelting and Metallurgy 1973, pp. 1–10.

- Hauck, R.F. Computer-controlled truck dispatching in open-pit mines. Computer Methods for the 80’s in the Mineral Industry 1979, pp. 735–742.

- Li, Z. A methodology for the optimum control of shovel and truck operations in open-pit mining. Mining Science and Technology 1990, 10, 337–340. [Google Scholar] [CrossRef]

- Subtil, R.F.; Silva, D.M.; Alves, J.C. A practical approach to truck dispatch for open pit mines. 35Th APCOM Symposium, 2011.

- Moradi Afrapoli, A.; Askari-Nasab, H. Mining fleet management systems: a review of models and algorithms. International Journal of Mining, Reclamation and Environment 2019, 33, 42–60. [Google Scholar] [CrossRef]

- Lizotte, Y.; Bonates, E. Truck and shovel dispatching rules assessment using simulation. Mining Science and Technology 1987, 5, 45–58. [Google Scholar] [CrossRef]

- Temeng, V.A.; Otuonye, F.O.; Frendewey Jr, J.O. Real-time truck dispatching using a transportation algorithm. International Journal of Surface Mining, Reclamation and Environment 1997, 11, 203–207. [Google Scholar] [CrossRef]

- Afrapoli, A.M.; Tabesh, M.; Askari-Nasab, H. A multiple objective transportation problem approach to dynamic truck dispatching in surface mines. European Journal of Operational Research 2019, 276, 331–342. [Google Scholar] [CrossRef]

- Afrapoli, A.M.; Tabesh, M.; Askari-Nasab, H. A transportation problem-based stochastic integer programming model to dispatch surface mining trucks under uncertainty. Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection-MPES 2018. Springer, 2019, pp. 255–264. [CrossRef]

- Maran, J. Study of truck allocation and truck dispatching problems in open pit mines. Master’s thesis, Virginia Tech, 1987.

- Burt, C.N.; Caccetta, L. Match factor for heterogeneous truck and loader fleets. International Journal of Mining, Reclamation and Environment 2007, 21, 262–270. [Google Scholar] [CrossRef]

- Dabbagh, A.; Bagherpour, R. Development of a match factor and comparison of its applicability with ant-colony algorithm in a heterogeneous transportation fleet in an open-pit mine. Journal of Mining Science 2019, 55, 45–56. [Google Scholar] [CrossRef]

- Mohtasham, M.; Mirzaei-Nasirabad, H.; Askari-Nasab, H.; Alizadeh, B. Truck fleet size selection in open-pit mines based on the match factor using a MINLP model. Mining Technology, 2021; 1–17. [Google Scholar] [CrossRef]

- Ercelebi, S.G.; Bascetin, A. Optimization of shovel-truck system for surface mining. Journal of the Southern African Institute of Mining and Metallurgy 2009, 109, 433–439. [Google Scholar]

- Ganguli, R.; Bandopadhyay, S. Expert system for equipment selection. International Journal of Surface Mining, Reclamation and Environment 2002, 16, 163–170. [Google Scholar] [CrossRef]

- Lashgari, A.; Yazdani-Chamzini, A.; Fouladgar, M.M.; Zavadskas, E.K.; Shafiee, S.; Abbate, N. Equipment selection using fuzzy multi criteria decision making model: key study of Gole Gohar iron min. Engineering Economics 2012, 23, 125–136. [Google Scholar] [CrossRef]

- Edwards, D.J.; Malekzadeh, H.; Yisa, S.B. A linear programming decision tool for selecting the optimum excavator. Structural Survey 2001. [Google Scholar] [CrossRef]

- Fu, Z.; Topal, E.; Erten, O. Optimisation of a mixed truck fleet schedule through a mathematical model considering a new truck-purchase option. Mining Technology 2014, 123, 30–35. [Google Scholar] [CrossRef]

- Samanta, B.; Sarkar, B.; Mukherjee, S. Selection of opencast mining equipment by a multi-criteria decision-making process. Mining Technology 2002, 111, 136–142. [Google Scholar] [CrossRef]

- Markeset, T.; Kumar, U. Application of LCC techniques in selection of mining equipment and technology. In Mine Planning and Equipment Selection 2000; Routledge, 2018; pp. 635–640.

- Que, S.; Anani, A.; Awuah-Offei, K. Effect of ignoring input correlation on truck–shovel simulation. International Journal of Mining, Reclamation and Environment 2016, 30, 405–421. [Google Scholar] [CrossRef]

- Chaowasakoo, P.; Seppälä, H.; Koivo, H.; Zhou, Q. Digitalization of mine operations: Scenarios to benefit in real-time truck dispatching. International Journal of Mining Science and Technology 2017, 27, 229–236. [Google Scholar] [CrossRef]

- Chaowasakoo, P.; Seppälä, H.; Koivo, H.; Zhou, Q. Improving fleet management in mines: The benefit of heterogeneous match factor. European Journal of Operational Research 2017, 261, 1052–1065. [Google Scholar] [CrossRef]

- Mirzaei-Nasirabad, H.; Mohtasham, M.; Askari-Nasab, H.; Alizadeh, B. An optimization model for the real-time truck dispatching problem in open-pit mining operations. Optimization and Engineering 2023. [Google Scholar] [CrossRef]

- Yao, J.; Wang, Z.; Chen, H.; Hou, W.; Zhang, X.; Li, X.; Yuan, W. Open-Pit Mine Truck Dispatching System Based on Dynamic Ore Blending Decisions. Sustainability 2023, 15, 3399. [Google Scholar] [CrossRef]

- Arelovich, A.; Masson, F.; Agamennoni, O.; Worrall, S.; Nebot, E. Heuristic rule for truck dispatching in open-pit mines with local information-based decisions. 13th International IEEE Conference on Intelligent Transportation Systems 2010, pp. 1408–1414. [CrossRef]

- Forsman, B.; Rönnkvist, E.; Vagenas, N. Truck dispatch computer simulation in Aitik open pit mine. International Journal of Surface Mining 1993, 7, 117–120. [Google Scholar] [CrossRef]

- de Carvalho, J.P.; Dimitrakopoulos, R. Integrating Production Planning with Truck-Dispatching Decisions through Reinforcement Learning While Managing Uncertainty. Minerals 2021, 11, 1–17. [Google Scholar] [CrossRef]

| Truck model | Minimum a (s) | Maximum b (s) | Mode c (s) |

| 1 | 23 | 47 | 35 |

| 2 | 30 | 54 | 42 |

| Truck model | Minimum a (s) | Maximum b (s) | Mode c (s) |

| 1 | 146 | 298 | 222 |

| 2 | 185 | 349 | 267 |

| Truck model | Minimum a (km/h) | Maximum b (km/h) | Mode c (km/h) |

| 1 | 15 | 31 | 23 |

| 2 | 17 | 33 | 25 |

| Truck model | Minimum a (t) | Maximum b (t) | Mode c (t) |

| 1 | 138 | 148 | 143 |

| 2 | 189 | 201 | 195 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).