Submitted:

25 July 2023

Posted:

26 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

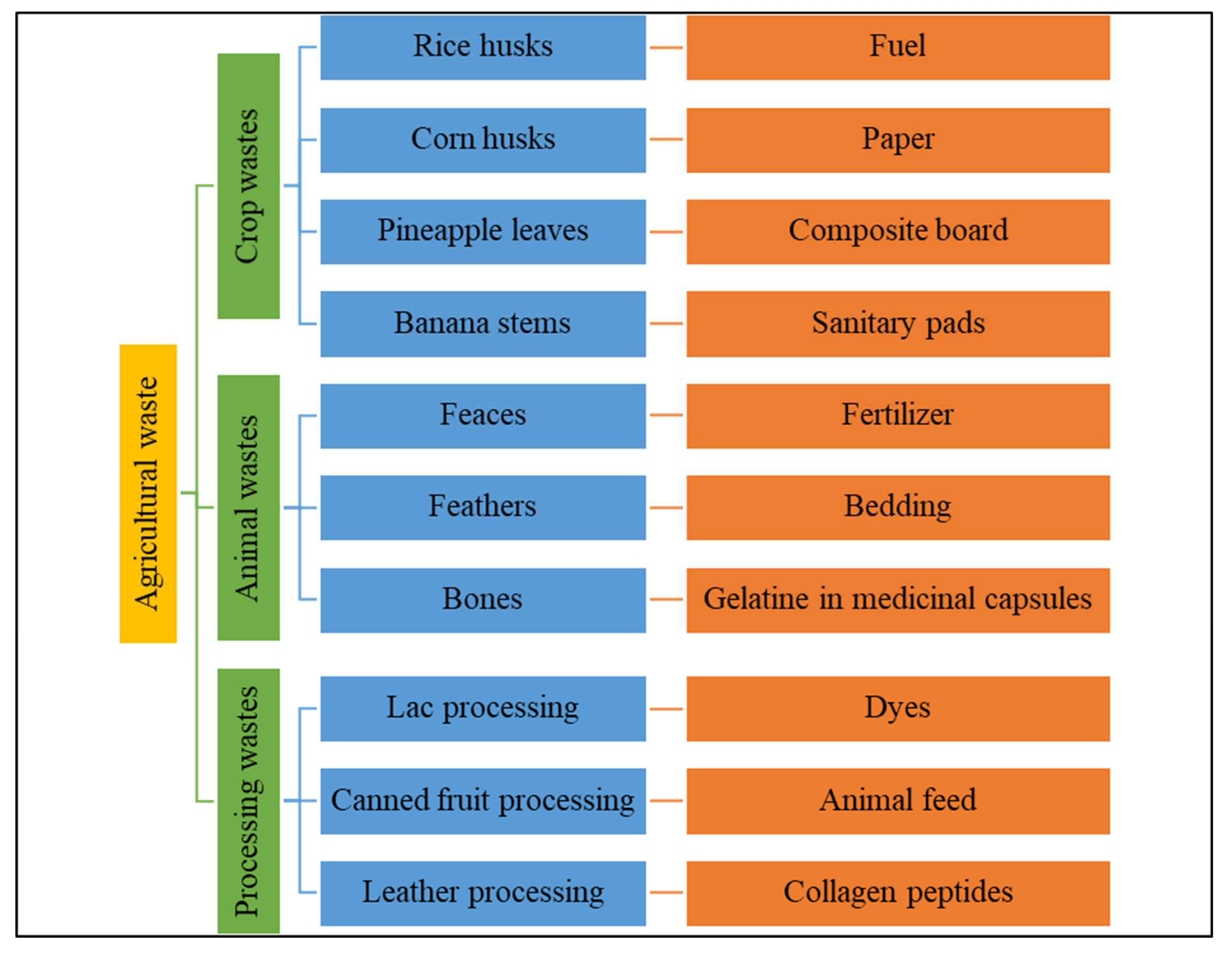

2. Converting agricultural waste to wealth

2.1. Crop waste

2.2. Animal waste

2.3. Processing waste

3. Agricultural waste as fiber polymer-reinforced material

3.1. Physical and mechanical properties of fibers

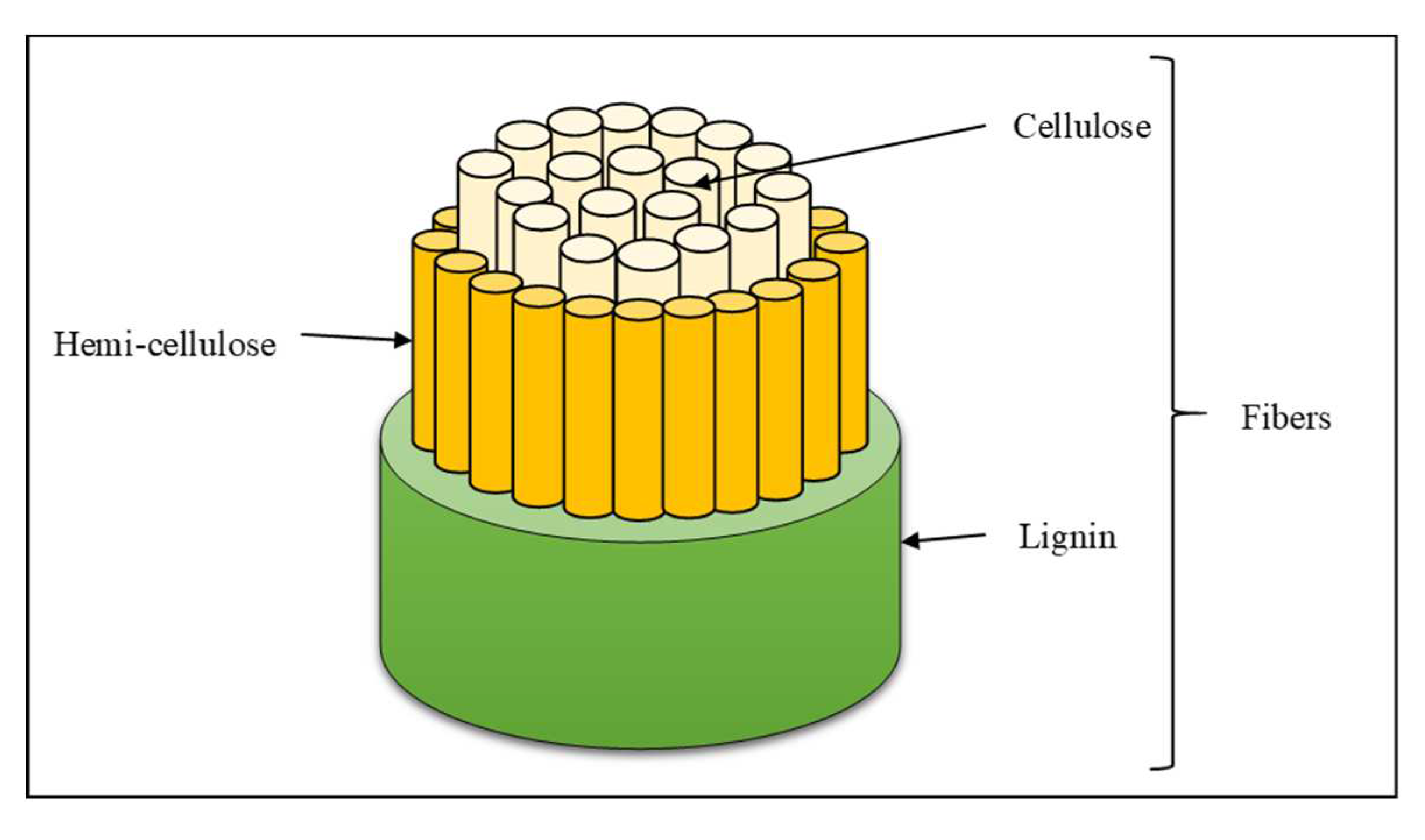

3.2. Chemical properties of fibers

4. Reinforced Pineapple Leaf Fiber in UAV Construction

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Isaac Oluseun A, Olufemi Adebukola A. Agricultural Solid Wastes: Causes, Effects, and Effective Management. Strateg. Sustain. Solid Waste Manag., 2021, p. 134–253.

- Ahmed OH, Husni MHA, Awang Noor AG. The Removal and Burning of Pineapple Residue in Pineapple Cultivation on Tropical Peat: An Economic Viability Comparison. PertanikaJ Trop Agric Sci 2002;25:47–51.

- Alzate Acevedo S, Díaz Carrillo ÁJ, Flórez-López E, Grande-Tovar CD. Recovery of Banana Waste-Loss from Production and Processing: A Contribution to a Circular Economy. Molecules 2021;26. [CrossRef]

- Malomo GA, Madugu AS, Bolu SA. Sustainable Animal Manure Management Strategies and Practices. Agric Waste Residues 2018. [CrossRef]

- Fela K, Wieczorek-Ciurowa K, Konopka M, Woźny Z. Present and prospective leather industry waste disposal. Polish J Chem Technol 2011;13:53–5. [CrossRef]

- Singh SP, Jawaid M, Chandrasekar M, Senthilkumar K, Yadav B, Saba N, et al. Sugarcane wastes into commercial products: Processing methods, production optimization and challenges. J Clean Prod 2021;328. [CrossRef]

- Širá E, Kravčáková Vozárová I, Kotulič R, Dubravská M. EU27 Countries’ Sustainable Agricultural Development toward the 2030 Agenda: The Circular Economy and Waste Management. Agronomy 2022;12. [CrossRef]

- Peng X, Jiang Y, Chen Z, Osman AI, Farghali M, Rooney DW, et al. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: a review. Environ Chem Lett 2023. [CrossRef]

- The World Bank. Agriculture and Food 2022. https://www.worldbank.org/en/topic/agriculture/overview#:~:text=Growth in the agriculture sector,more than 25%25 of GDP.

- Ferronato N, Torretta V. Waste mismanagement in developing countries: A review of global issues. Int J Environ Res Public Health 2019;16. [CrossRef]

- Felgueiras C, Azoia NG, Gonçalves C, Gama M, Dourado F. Trends on the Cellulose-Based Textiles: Raw Materials and Technologies. Front Bioeng Biotechnol 2021;9. [CrossRef]

- Sahin HT, Arslan MB. A study on physical and chemical properties of cellulose paper immersed in various solvent mixtures. Int J Mol Sci 2008;9:78–88. [CrossRef]

- Hosny KM, Alkhalidi HM, Alharbi WS, Md S, Sindi AM, Ali SA, et al. Recent Trends in Assessment of Cellulose Derivatives in Designing Novel and Nanoparticulate-Based Drug Delivery Systems for Improvement of Oral Health. Polymers (Basel) 2022;14. [CrossRef]

- Scheller HV, Ulvskov P. Hemicelluloses. Annu Rev Plant Biol 2010;61:263–89. [CrossRef]

- Sutay Kocabaş D, Köle M, Yağcı S. Development and optimization of hemicellulose extraction bioprocess from poppy (Papaver somniferum L.) stalks assisted by instant controlled pressure drop (DIC) pretreatment. Biocatal Agric Biotechnol 2020;29. [CrossRef]

- Ma C, Kim TH, Liu K, Ma MG, Choi SE, Si C. Multifunctional Lignin-Based Composite Materials for Emerging Applications. Front Bioeng Biotechnol 2021;9. [CrossRef]

- Wu X, Jiang J, Wang C, Liu J, Pu Y, Ragauskas A, et al. Lignin-derived electrochemical energy materials and systems. Biofuels, Bioprod Biorefining 2020;14:650–72. [CrossRef]

- Zhang Y, Jiang M, Zhang Y, Cao Q, Wang X, Han Y, et al. Novel lignin–chitosan–PVA composite hydrogel for wound dressing. Mater Sci Eng C 2019;104. [CrossRef]

- Ebers LS, Arya A, Bowland CC, Glasser WG, Chmely SC, Naskar AK, et al. 3D printing of lignin: Challenges, opportunities and roads onward. Biopolymers 2021;112. [CrossRef]

- Yuliah Y, Kartawidjaja M, Suryaningsih S, Ulfi K. Fabrication and characterization of rice husk and coconut shell charcoal based bio-briquettes as alternative energy source. IOP Conf. Ser. Earth Environ. Sci., vol. 65, 2017. [CrossRef]

- Liu C, Luan P, Li Q, Cheng Z, Sun X, Cao D, et al. Biodegradable, Hygienic, and Compostable Tableware from Hybrid Sugarcane and Bamboo Fibers as Plastic Alternative. Matter 2020;3:2066–79. [CrossRef]

- Kabeyi MJB, Olanrewaju OA. Biogas Production and Applications in the Sustainable Energy Transition. J Energy 2022;2022:1–43. [CrossRef]

- Zheng M, Zhang K, Zhang J, Zhu LL, Du G, Zheng R. Cheap, high yield, and strong corn husk-based textile bio-fibers with low carbon footprint via green alkali retting-splicing-twisting strategy. Ind Crops Prod 2022;188. [CrossRef]

- Achuthan K, Muthupalani S, Kolil VK, Bist A, Sreesuthan K, Sreedevi A. A novel banana fiber pad for menstrual hygiene in India: a feasibility and acceptability study. BMC Womens Health 2021;21. [CrossRef]

- Merino D, Bertolacci L, Paul UC, Simonutti R, Athanassiou A. Avocado Peels and Seeds: Processing Strategies for the Development of Highly Antioxidant Bioplastic Films. ACS Appl Mater Interfaces 2021;13:38688–99. [CrossRef]

- Raghuram, N. Raghuram N. Recycling crop and animal waste is a win for green farming. Nat India 2022. [CrossRef]

- Abed AM, Lafta HA, Alayi R, Tamim H, Sharifpur M, Khalilpoor N, et al. Utilization of Animal Solid Waste for Electricity Generation in the Northwest of Iran 3E Analysis for One-Year Simulation. Int J Chem Eng 2022;2022. [CrossRef]

- Arshad M, Ansari AR, Qadir R, Tahir MH, Nadeem A, Mehmood T, et al. Green electricity generation from biogas of cattle manure: An assessment of potential and feasibility in Pakistan. Front Energy Res 2022;10. [CrossRef]

- Oladele, I. Oladele I., Omotoyimbo JA, Ayemidejor SH. Mechanical Properties of Chicken Feather and Cow Hair Fibre Reinforced High Density Polyethylene Composites. Int J Sci Technol 2014;3:66–72.

- Patil K, Wang X, Lin T. Electrostatic coating of cashmere guard hair powder to fabrics: Silver ion loading and antibacterial properties. Powder Technol 2013;245:40–7. [CrossRef]

- Siddiqua A, Hahladakis JN, Al-Attiya WAKA. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ Sci Pollut Res 2022;29:58514–36. [CrossRef]

- Tushar Uddin M, Abdur Razzaq M, Hai Quadery A, Jaman Chowdhury M, Al-Mizan, Moshrur Raihan M, et al. Extraction of Dye from Natural Source (LAC) & its Application on Leather. Am Sci Res J Eng 2017;34:1–7.

- Park JS, Kim SH, Kim YS, Kwon E, Lim HJ, Han KM, et al. Nonclinical safety evaluation of food colorant lac dye via systematic toxicity profiling with assessment of in vivo antigenic potential. Front Pharmacol 2022;13. [CrossRef]

- Singh AK, Ghosal S, Sinha NK, Kumar N. Utilization of Lac Factory Waste for Integrated Nutrient Management in Brinjal and Its Effect on Soil Fertility. Multilogic Sci 2018;8:246–9. [CrossRef]

- Kimothi SP, Panwar S, Khulbe A. Creating wealth from agricultural waste. 2020.

- Fazliyana A, Hamzah A, Hamzah MH, Man HC, Jamali NS, Siajam SI, et al. Recent Updates on the Conversion of Pineapple Waste ( Ananas comosus ) to Value-Added Products , Future Perspectives and Challenges. Agronomy 2021.

- Su C, Gong JS, Qin J, He JM, Zhou ZC, Jiang M, et al. Glutathione enables full utilization of wool wastes for keratin production and wastewater decolorization. J Clean Prod 2020;270. [CrossRef]

- The Council of Fashion Designers of America. FIBER GUIDE: SILK. CfdaCom 2021. https://cfda.com/resources-tools/materials-hub/article/fiber-guide-silk#:~:text=Silk Noils%3A Also known as,lower quality than filament silk. (accessed March 21, 2023).

- Jain J, Sinha S. Potential of Pineapple Leaf Fibers and Their Modifications for Development of Tile Composites. J Nat Fibers 2022;19:4822–34. [CrossRef]

- Khan GMA, Sarkar MA, Islam MM, Alam MS. Wet processing of agro-residual fibres for potential application in fancy décor items. Adv Mater Process Technol 2022;8:3215–30. [CrossRef]

- Yves OR, Christian FB, Akum OB, Theodore T, Bienvenu K. Physical and mechanical properties of pineapple fibers (leaves, stems and roots) from awae Cameroon for the improvement of composite materials. J Fiber Sci Technol 2018;76:378–86. [CrossRef]

- Thilagavathi G, Muthukumar N, Neela Krishnanan S, Senthilram T. Development and Characterization of Pineapple Fibre Nonwovens for Thermal and Sound Insulation Applications. J Nat Fibers 2020;17:1391–400. [CrossRef]

- Patel BY, Patel HK. Retting of banana pseudostem fibre using Bacillus strains to get excellent mechanical properties as biomaterial in textile & fiber industry. Heliyon 2022;8. [CrossRef]

- Silva FS, Ribeiro CEG, Demartini TJ da C, Rodríguez RJS. Physical, Chemical, Mechanical, and Microstructural Characterization of Banana Pseudostem Fibers from Musa Sapientum. Macromol Symp 2020;394. [CrossRef]

- Pandit, P. Pandit P. Characteristics & Properties of Banana Fibers. Text Value Chain 2020:4. https://textilevaluechain.in/news-insights/characteristics-properties-of-banana-fibers/#:~:text=The chemical composition of banana,upon the extraction %26 spinning process.

- Xu S, Xiong C, Tan W, Zhang Y. Microstructural, thermal, and tensile characterization of banana pseudo-stem fibers obtained with mechanical, chemical, and enzyme extraction. BioResources 2015;10:3724–35. [CrossRef]

- Rini DS, Ishiguri F, Nezu I, Ngadianto A, Irawati D, Otani N, et al. Geographic and longitudinal variations of anatomical characteristics and mechanical properties in three bamboo species naturally grown in Lombok Island, Indonesia. Sci Rep 2023;13:2265. [CrossRef]

- Nirmal Kumar K, Dinesh Babu P, Surakasi R, Kumar PM, Ashokkumar P, Khan R, et al. Mechanical and Thermal Properties of Bamboo Fiber-Reinforced PLA Polymer Composites: A Critical Study. Genet Res (Camb) 2022;2022. [CrossRef]

- Dessalegn Y, Singh B, Vuure AW va., Badruddin IA, Beri H, Hussien M, et al. Investigation of Bamboo Fibrous Tensile Strength Using Modified Weibull Distribution. Materials (Basel) 2022;15. [CrossRef]

- Gao X, Zhu D, Fan S, Rahman MZ, Guo S, Chen F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: a review. J Mater Res Technol 2022;19:1162–90. [CrossRef]

- Ibrahim MIJ, Sapuan SM, Zainudin ES, Zuhri MYM. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J Mater Res Technol 2020;9:200–11. [CrossRef]

- De Carvalho Mendes CA, De Oliveira Adnet FA, Leite MCAM, Furtado CRG, De Sousa AMF. Chemical, physical, mechanical, thermal and morphological characterization of corn husk residue. Cellul Chem Technol 2015;49:727–35.

- Sari NH, Wardana ING, Irawan YS, Siswanto E. Physical and Acoustical Properties of Corn Husk Fiber Panels. Adv Acoust Vib 2016;2016. [CrossRef]

- Jayamaui E, Rahman MR, Benhur DA, Bakri MK Bin, Kakair A, Khan A. Comparative study of fly ash/sugarcane fiber reinforced polymer composites properties. BioResources 2020;15:5514–31. [CrossRef]

- Bhatnagar R, Gourav G, Sachin Y. A Review on Composition and Properties of Bagasse Fibers. Int J Sci Eng Res 2015;5.

- Anwar, SI. Anwar SI. Determination of moisture content of bagasse of jaggery unit using microwave oven. J Eng Sci Technol 2010;5:472–8.

- Fematt-flores GE, Aguiló-aguayo I, Marcos B, Camargo-olivas BA, Sánchez-vega R, Soto-caballero MC, et al. Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties. Coatings 2022;12. [CrossRef]

- Yang Y, Reddy N. Properties and potential medical applications of regenerated casein fibers crosslinked with citric acid. Int J Biol Macromol 2012;51:37–44. [CrossRef]

- Thill S, Schmidt T, Wöll D, Gebhardt R. A regenerated fiber from rennet-treated casein micelles. Colloid Polym Sci 2021;299:909–14. [CrossRef]

- Zhan M, Wool RP. Mechanical properties of chicken feather fibers. Polym Compos 2011;32:937–44. [CrossRef]

- Reddy N, Yang Y. Structure and properties of chicken feather barbs as natural protein fibers. J Polym Environ 2007;15:81–7. [CrossRef]

- CHOUDARY RB, PRASAD AS, BHARGAVA NRMR. Feather fiber reinforced polyester composites. Mater Sci Res India 2007;4:487–92. [CrossRef]

- Tesfaye T, Sithole B, Ramjugernath D, Chunilall V. Valorisation of chicken feathers: Characterisation of chemical properties. Waste Manag 2017;68:626–35. [CrossRef]

- Mann GS, Azum N, Khan A, Rub MA, Hassan MI, Fatima K, et al. Green Composites Based on Animal Fiber and Their Applications for a Sustainable Future. Polymers (Basel) 2023;15:601. [CrossRef]

- Chaochai T, Imai Y, Furuike T, Tamura H. Preparation and properties of gelatin fibers fabricated by dry spinning. Fibers 2016;4. [CrossRef]

- Fukae R, Midorikawa T. Preparation of gelatin fiber by gel spinning and its mechanical properties. J Appl Polym Sci 2008;110:4011–5. [CrossRef]

- Chong EJ, Phan TT, Lim IJ, Zhang YZ, Bay BH, Ramakrishna S, et al. Evaluation of electrospun PCL/gelatin nanofibrous scaffold for wound healing and layered dermal reconstitution. Acta Biomater 2007;3:321–30. [CrossRef]

- Khan RA, Khan MA, Sarker B, Saha S, Das AK, Noor N, et al. Fabrication and characterization of gelatin fiber-based linear low-density polyethylene foamed composite. J Reinf Plast Compos 2010;29:2438–49. [CrossRef]

- Czaplicki, Z. Czaplicki Z. Properties and structure of polish alpaca wool. Fibres Text East Eur 2012;90:8–12.

- Jankowska D, Wyrostek A, Patkowska–Sokoła B, Czyż K. Comparison of Physico-mechanical Properties of Fibre and Yarn Made of Alpaca, Sheep, and Goat Wool. J Nat Fibers 2019. [CrossRef]

- Cheung HY, Lau KT, Ho MP, Mosallam A. Study on the mechanical properties of different silkworm silk fibers. J Compos Mater 2009;43:2521–31. [CrossRef]

- Asim M, Abdan K, Jawaid M, Nasir M, Dashtizadeh Z, Ishak MR, et al. A review on pineapple leaves fibre and its composites. Int J Polym Sci 2015;2015:6. [CrossRef]

- Chokshi S, Parmar V, Gohil P, Chaudhary V. Chemical Composition and Mechanical Properties of Natural Fibers. J Nat Fibers 2022;19:3942–53. [CrossRef]

- Adeoye MD, Lawal AT, Jimoh AO, Adelani AK, Ojo OO, Ndukwe NA, et al. Fascinating physical-chemical properties and fiber morphology of selected waste plant leaves as potential pulp and paper making agents. Biomass Convers Biorefinery 2021;11:3061–70. [CrossRef]

- Zhang M, Liu Q, Twebaze CB, Zhuang X, Kimani M, Zheng G, et al. The Effect of Activated Water Degumming Technique on Alkali-pretreated Banana Fiber. BioResources 2022;17:6775–88. [CrossRef]

- Martijanti M, Juwono AL, Sutarno S. Investigation of characteristics of bamboo fiber for composite structures. IOP Conf. Ser. Mater. Sci. Eng., vol. 850, 2020. [CrossRef]

- Bourmaud A, Beaugrand J, Shah DU, Placet V, Baley C. Towards the design of high-performance plant fibre composites. Prog Mater Sci 2018;97:347–408. [CrossRef]

- Aziz AA, Ismail S, Mahayuddin SA. a Review of the Factors Affecting the Properties of Bamboo Fiber Bio-Composite Materials. Malaysian J Sustain Environ 2023;10:275–98. [CrossRef]

- Duong NT, Satomi T, Takahashi H. Potential of corn husk fiber for reinforcing cemented soil with high water content. Constr Build Mater 2021;271. [CrossRef]

- Prasad L, Kumar S, Patel RV, Yadav A, Kumar V, Winczek J. Physical and mechanical behaviour of sugarcane bagasse fibre-reinforced epoxy bio-composites. Materials (Basel) 2020;13:1–13. [CrossRef]

- Pavan M, Samant L. Regenerated Milk Fiber: An Approach towards Green Textiles. Just Agric e-Newsletter 2022;3:6.

- Mwanza EP, van der Westhuizen WA, Boucher CE, Charimba G, Hugo C. Heterologous expression and characterisation of a keratinase produced by Chryseobacterium carnipullorum. Protein Expr Purif 2021;186. [CrossRef]

- Li Z, Reimer C, Picard M, Mohanty AK, Misra M. Characterization of Chicken Feather Biocarbon for Use in Sustainable Biocomposites. Front Mater 2020;7. [CrossRef]

- Roy AN, Samanta KK, Patra K. Physico-chemical properties of black yak fibre and its modification for blending with jute fibre. J Nat Fibers 2019;16:225–36. [CrossRef]

- Atav R, Ergünay U, Gürkan Ünal P. Determining the Effect of Pigmentation on Some Physical and Mechanical Properties of Yak and Cashmere Down Fibers. J Nat Fibers 2022. [CrossRef]

- GMIA. Gelatin Handbook. 2012.

- Hegazy EM, El-Sayed Khamis NH. Effect of fresh garlic and ginger on the shelf-life of Gelatin waste used for improvement of plant growth. World Appl Sci J 2014;30:83–8.

- Ulfa M, Trisunaryanti W, Falah II, Kartini I, Sutarno S. Synthesis of mesoporous carbon using gelatin as source of carbon by hard template technique and its characterizations. IOSR J Appl Chem 2014;7:01–7. [CrossRef]

- Kiron, MI. Kiron MI. Chemical Composition of Natural Fibers (Cotton, Jute, Flax, Hemp, Ramie, Sisal, Coir, Wool and Silk). Testile Learn 2022. https://textilelearner.net/chemical-composition-of-natural-fibers/.

- Parlato MCM, Valenti F, Midolo G, Porto SMC. Livestock Wastes Sustainable Use and Management: Assessment of Raw Sheep Wool Reuse and Valorization. Energies 2022;15. [CrossRef]

- Prof. Robert J. Lancashire. Unit - Chemistry of Garments: Animal Fibres. Chem Mona 2016.

- Kumar P, Sai Ram C, Srivastava JP, Behura AK, Kumar A. Synthesis of Cotton Fiber and Its Structure. Nat. Synth. Fiber Reinf. Compos., 2022, p. 17–36. [CrossRef]

- Łukaszewicz, A. Łukaszewicz A. Modelling of solid part using multibody techniques in parametric CAD systems. Solid State Phenomena 2009;147-149:924 9.

- Grzejda, R. Grzejda R. New method of modelling nonlinear multi-bolted systems, in: Advances in Mechanics: Theoretical, Computational and Interdisciplinary Issues, Proc. of the 3rd Polish Congress of Mechanics (PCM) and 21st International Conference on Computer Methods in Mechanics (CMM), Leiden, CRC Press 2016, p. 213–6.

- Grzejda, R. Grzejda R. Modelling nonlinear multi-bolted connections: A case of the assembly condition. In Proceedings of the 15th International Scientific Conference 'Engineering for Rural Development 2016', Jelgava, Latvia, 25-27 May 2016, p. 329–35.

- Grzejda, R. Grzejda R. Modelling nonlinear multi-bolted connections: A case of operational condition. In Proceedings of the 15th International Scientific Conference 'Engineering for Rural Development 2016', Jelgava, Latvia, 25-27 May 2016 p. 336–41.

- Grodzki W, Łukaszewicz A. Design and manufacture of unmanned aerial vehicles (UAV) wing structure using composite materials, Materialwissenschaft und Werkstofftechnik 2015;46(3):269–78.

- Mikołajczyk T, Mikołajewski D, Kłodowski A, Łukaszewicz A, Mikołajewska E, Paczkowski T, Macko M, Skornia M. Energy sources of mobile robot power systems: A systematic review and comparison of efficiency. Appl Sci 2023;13:7547.

- Šančić T, Brčić M, Kotarski D, Łukaszewicz A. Experimental characterization of composite-printed materials for the production of multirotor UAV airframe parts. Materials 2023;16:5060.

- Sayeed MMA, Sayem ASM, Haider J, Akter S, Habib MM, Rahman H, et al. Assessing Mechanical Properties of Jute, Kenaf, and Pineapple Leaf Fiber-Reinforced Polypropylene Composites: Experiment and Modelling. Polymers (Basel) 2023;15. [CrossRef]

- Afkari AS, Pratama RA, Juwono AL, Roseno S. Mechanical Properties of Pineapple Leaf Fiber/Epoxy Composites with 0°/0°/0°/0° and 0°/90°/0°/90° Fiber Orientations. J SAINS Mater Indones 2022;23:83–9.

- Jose S, Shanumon PS, Paul A, Mathew J, Thomas S. Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber. Polymers (Basel) 2022;14. [CrossRef]

- Suteja J, Firmanto H, Soesanti A, Christian C. Properties investigation of 3D printed continuous pineapple leaf fiber-reinforced PLA composite. J Thermoplast Compos Mater 2022;35:2052–61. [CrossRef]

- Anand PB, Lakshmikanthan A, Chandrashekarappa MPG, Selvan CP, Pimenov DY, Giasin K. Experimental Investigation of Effect of Fiber Length on Mechanical, Wear, and Morphological Behavior of Silane-Treated Pineapple Leaf Fiber Reinforced Polymer Composites. Fibers 2022;10. [CrossRef]

- Galatas A, Hassanin H, Zweiri Y, Seneviratne L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers (Basel) 2018;10. [CrossRef]

| Agricultural activity | Wastes produced | Disposal method | Ref |

|---|---|---|---|

| Pineapple production | Leaves, crown, core, peels, stems | Dumping, burning, burying, decomposing | [2] |

| Banana production | Peels, stems, trunks | Dumping, burning, burying, decomposing | [3] |

| Animal production | Left-over feed, wastewater, hatchery wastes, manure, carcasses | Dumping, burning, buried | [4] |

| Leather tanning | Hair, bristle, flesh side, splits, trimmings, fleshing, splits trimmings, shavings, sludge | Dumping | [5] |

| Sugar processing | Bagasse, cane trash, press mud, molasses | Dumping, burning, buried | [6] |

| Types | Materials | Density (g/cm3) |

Tensile strength (MPa) |

Young’s Modulus (GPa) |

Ref |

|---|---|---|---|---|---|

| Crop waste | Pineapple leaf fiber | 0.95 – 1.53 | 460.00 – 1244.30 | 4.4 – 43 | [39,40,41,42] |

| Banana stem fiber | 0.22 – 0.96 | 210 – 914 | 16.36 – 32 | [43,44,45,46] | |

| Bamboo fiber | 0.6 – 1.4 | 206.5 – 630 | 17 – 36 | [47,48,49,50] | |

| Corn husk fiber | 1.16 –1.49 | 180 – 256 | 4.57 – 15.87 | [51,52,53] | |

| Sugarcane bagasse fiber | 0.88 – 1.2 | 20 – 290 | 3 – 27.1 | [54,55,56] | |

| Animal waste | Milk protein/casein fiber | 1.30 | 37 – 116 | 2.08 – 7.4 | [57,58,59] |

| Chicken feather fiber | 0.78 – 0.90 | 130 – 220 | 3.0 – 4.5 | [60,61,62,63] | |

| Yak fiber | 1.32 – 3.41 | 270.05 | 45.09 | [64] | |

| Gelatin fiber | 1.2 – 1.58 | 91 – 170 | 2.0 – 3.1 | [65,66,67,68] | |

| Processing waste | Wool waste fiber | 1.29 – 1.31 | 130 – 210 | 2.6 – 3.6 | [61,69,70] |

| Silk waste fiber | 1.32 – 1.33 | 165.27 – 248.77 | 3.82 – 6.10 | [71] | |

| Recycled cotton fiber | 1.5 – 1.6 | 287 – 597 | 5.5–12.6 | [72] |

| Types | Materials | Chemical Properties (%) | Ref |

| Crop waste | Pineapple leaf fiber | Cellulose: 64.4 – 72.14 Hemicellulose: 4.86 – 21.73 Lignin: 4.28 –13.55 Pectin: 1.3 – 1.6 Ash: 0.8 – 5.01 |

[3,39,40,42,74] |

| Banana stem fiber | Cellulose: 39.2 – 64 Hemicellulose: 10.2 – 27.8 Lignin: 11.40 – 27.77 Pectin: 2.1 – 2.78 Ash: 3.88 |

[43,44,45,46,75] | |

| Bamboo fiber | Cellulose: 36.1 – 55.68 Hemicellulose: 11.4 – 19.15 Lignin: 16.93 – 28.5 Pectin: <1 |

[76,77,78] | |

| Corn husk fiber | Cellulose: 43 – 45.7 Hemicellulose: 31 – 40 Lignin: 2 – 22 Ash: 0.36 – 6.4 |

[51,52,79] | |

| Sugarcane bagasse fiber | Cellulose: 30 – 55 Hemicellulose: 20 – 28.25 Lignin:18 – 26 Pectin: 0.6 – 0.8 Ash: 3 – 10 |

[55,80] | |

| Animal waste | Milk protein/casein fiber | Carbon: 53.0 Hydrogen: 7.50 Oxygen: 23.0 Nitrogen: 15.0 Sulfur: 0.70 Phosphorous: 0.80 |

[81] |

| Chicken feather fiber | Protein: 82 – 91 Carbon: 64.47 Nitrogen: 10.41 Oxygen: 22.34 Sulfur: 2.64 |

[63,82,83] | |

| Yak fiber | Protein: 65–95 Carbon: 51.09 – 58.3 Nitrogen: 13.47 – 18.2 Oxygen: 20.7 – 32.06 Sulfur: 2.09 – 2.3 |

[84,85] | |

| Gelatin/protein fiber | Protein: 98 – 99 Carbon: 47.98 – 50.5 Nitrogen: 14.42 – 17 Oxygen: 25.2 – 29.44 |

[86,87,88] | |

| Processing waste | Wool waste fiber | Protein: 33 Carbon: 50 Nitrogen: 14 – 25 Oxygen: 10 Sulfur: 0.1 – 0.2 |

[89,90] |

| Silk waste fiber | Protein: 78 – 95 Nitrogen: 16.35 Sulfur: 3.65 |

[89,91] | |

| Recycled cotton fiber | Cellulose: 90 – 94 Moisture: 6 – 7 Protein: 1 – 1.5 Pectin: 0.9 Ash: 1.2 |

[92] |

| Fiber | Matrix | Fiber treatment | Composition of fiber | Density | Tensile strength | Young’s Modulus | Ref |

|---|---|---|---|---|---|---|---|

| (%) | (g/cm3) | (MPa) | (GPa) | ||||

| Pineapple leaf fiber | Polypropylene | None | 40 | - | 58 | 1.67 | [100] |

| Pineapple leaf fiber | Epoxy | Alkaline (NaOH) treatment | 40 | 1.18 | 93.82 | 4.24 | [101] |

| Pineapple leaf fiber | Natural rubber | None | 25 | 1.09 | 11.14 | 0.33 | [102] |

| Pineapple leaf fiber | Polylactic acid | None | 25 | - | 96.78 | - | [103] |

| Pineapple leaf fiber | Polyester | Silane treatment | - | - | 55 | 2.3 | [104] |

| None | Polylactic acid | None | 0 | 1.27 | 56 | 3.37 | [105] |

| None | Acrylonitrile-Butadiene-Styrene | None | 0 | 1.05 | 26-31 | 2.18 –2.23 | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).