Submitted:

02 July 2023

Posted:

04 July 2023

You are already at the latest version

Abstract

Keywords:

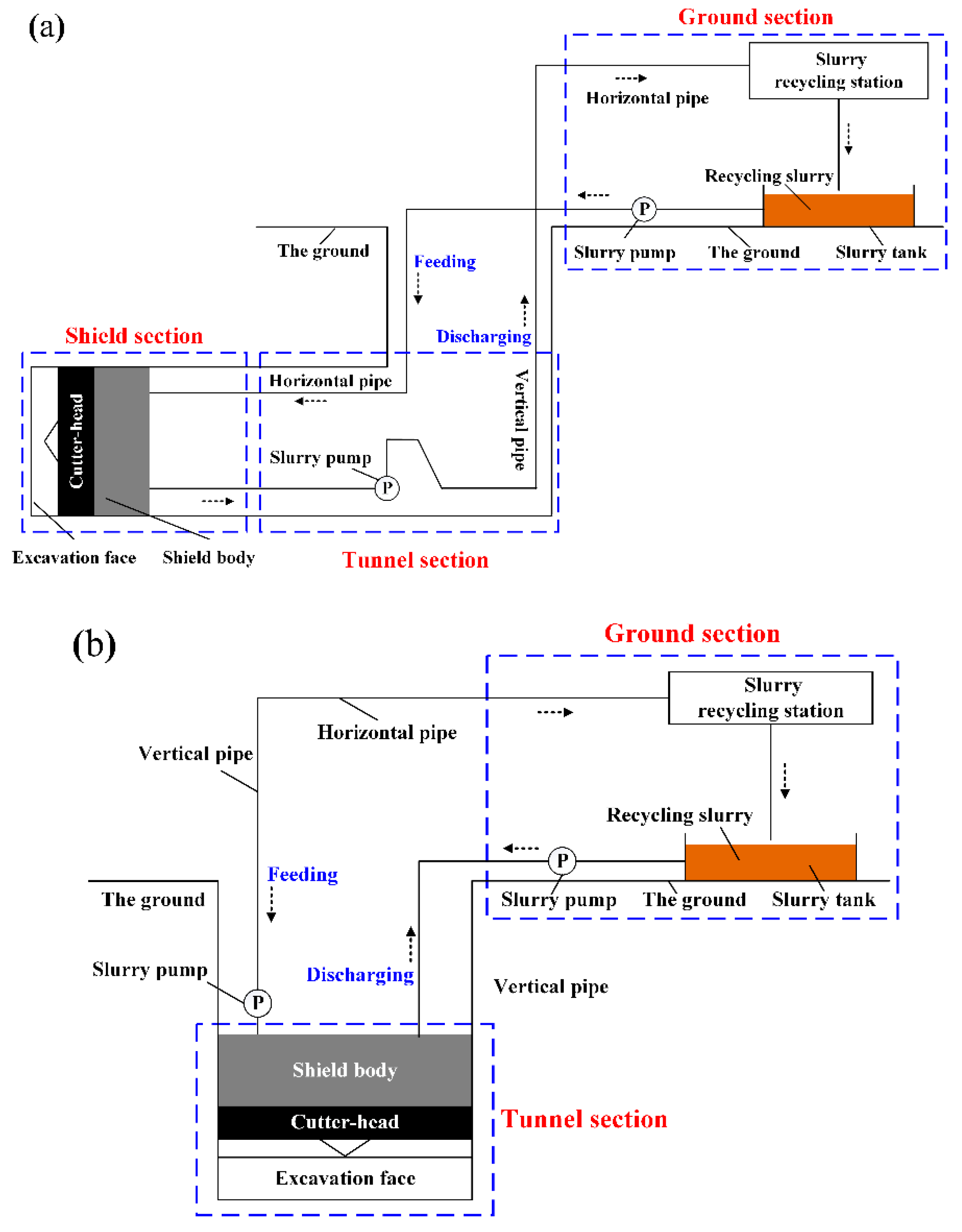

1. Introduction

2. Ballast pick-up velocity theoretical modelling

2.1. Ballast motion model

2.2. Slurry flow model

2.3. Slurry-ballast interaction

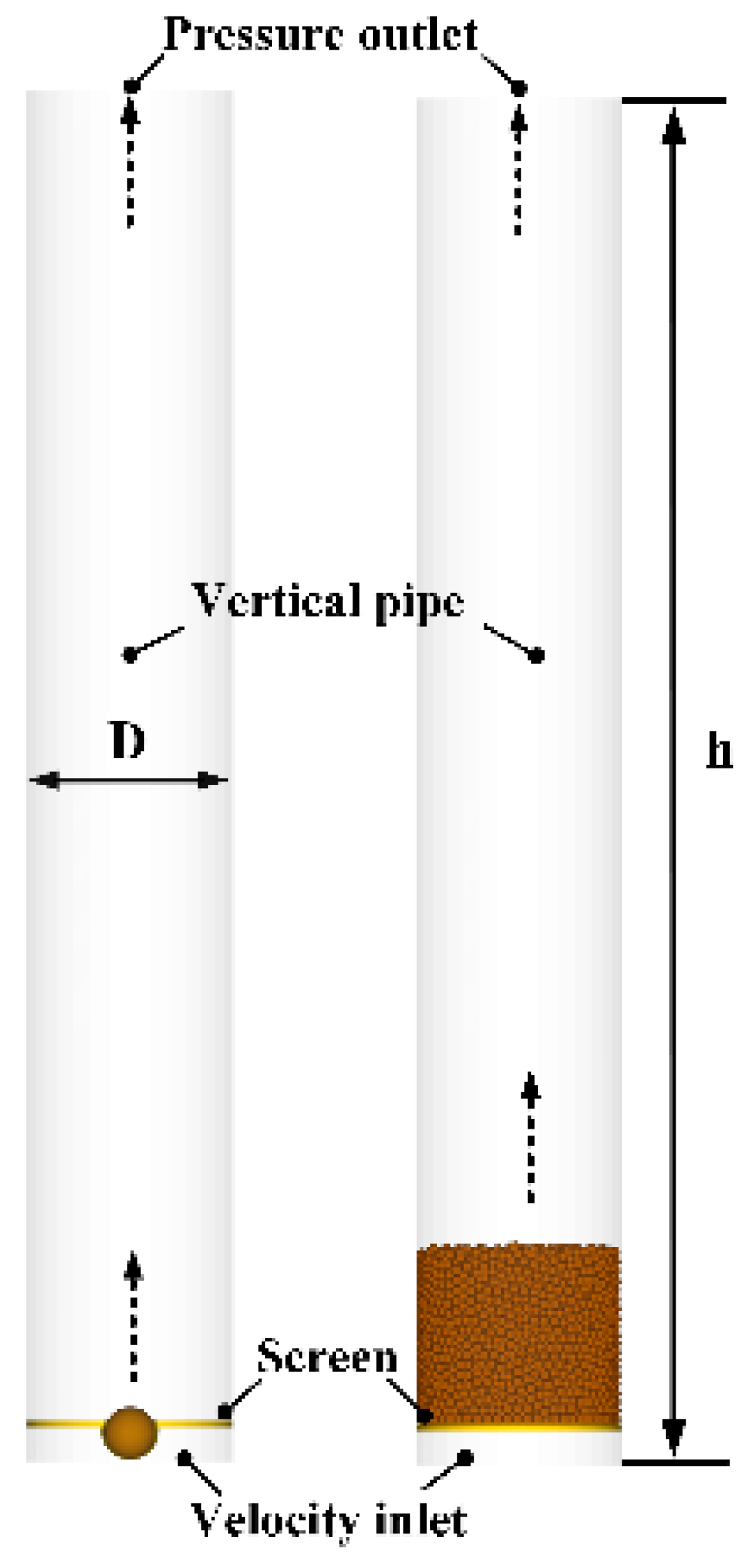

2.4. Simulation model and boundary conditions

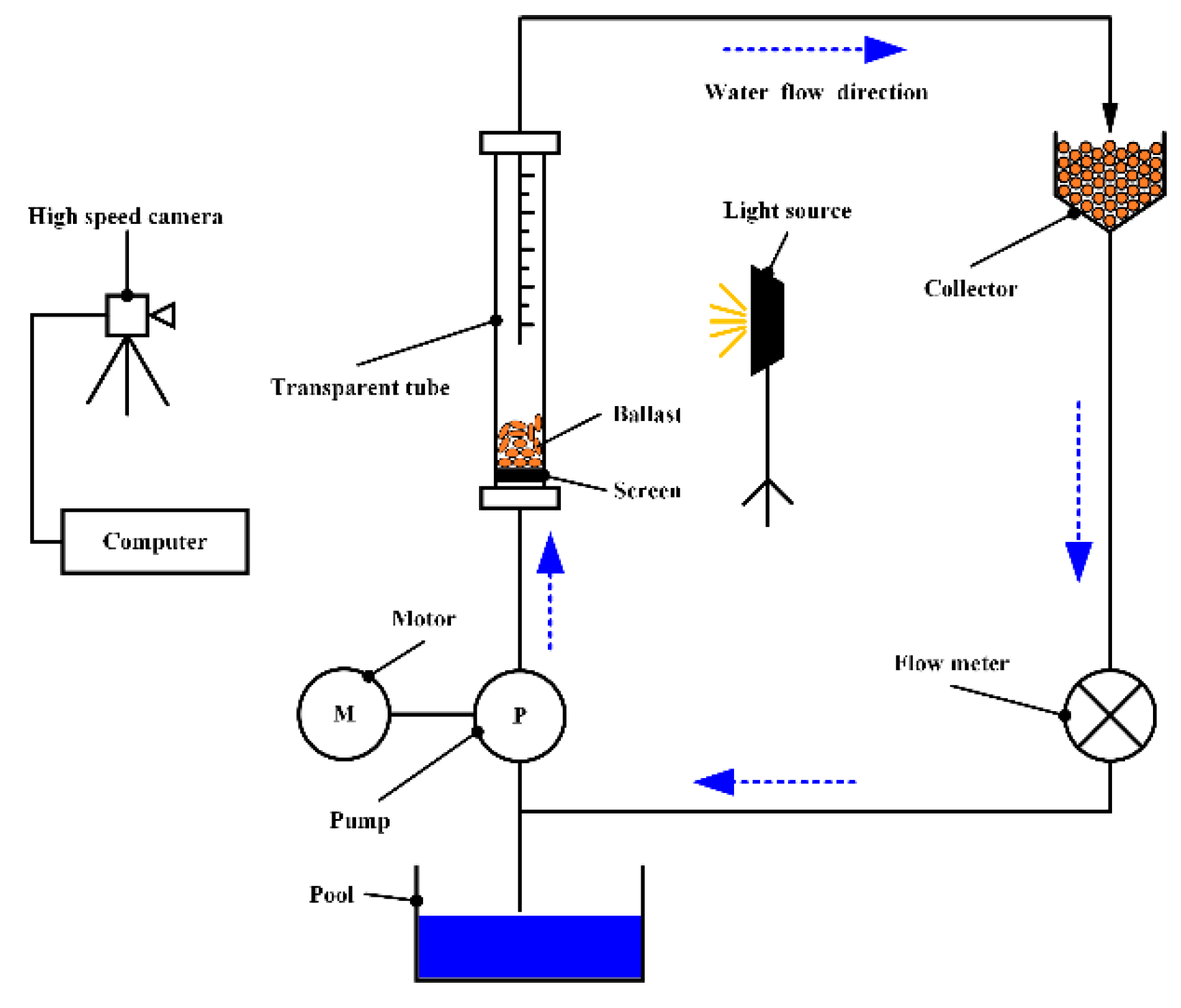

3. Model verification

3.1. Experimental scheme

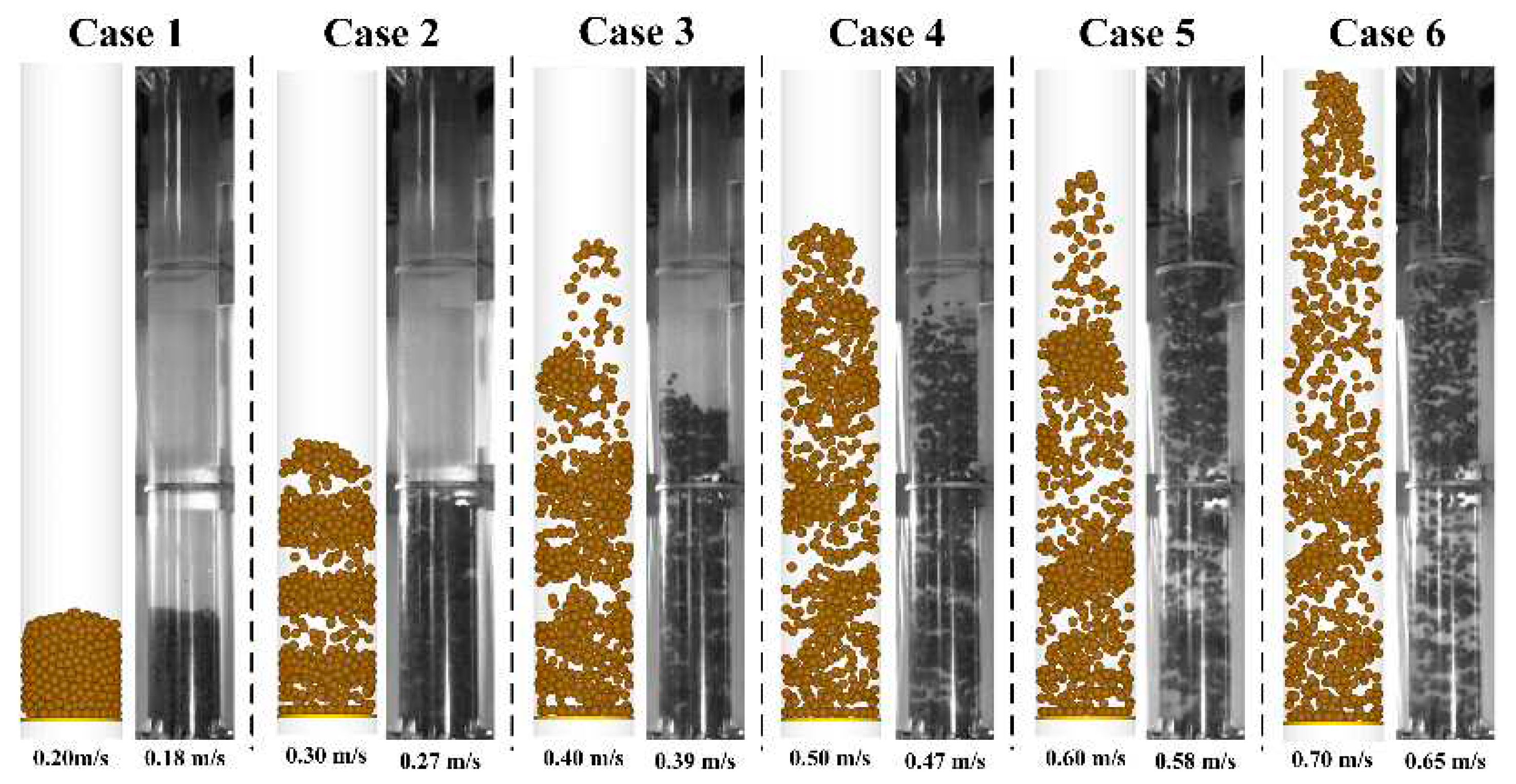

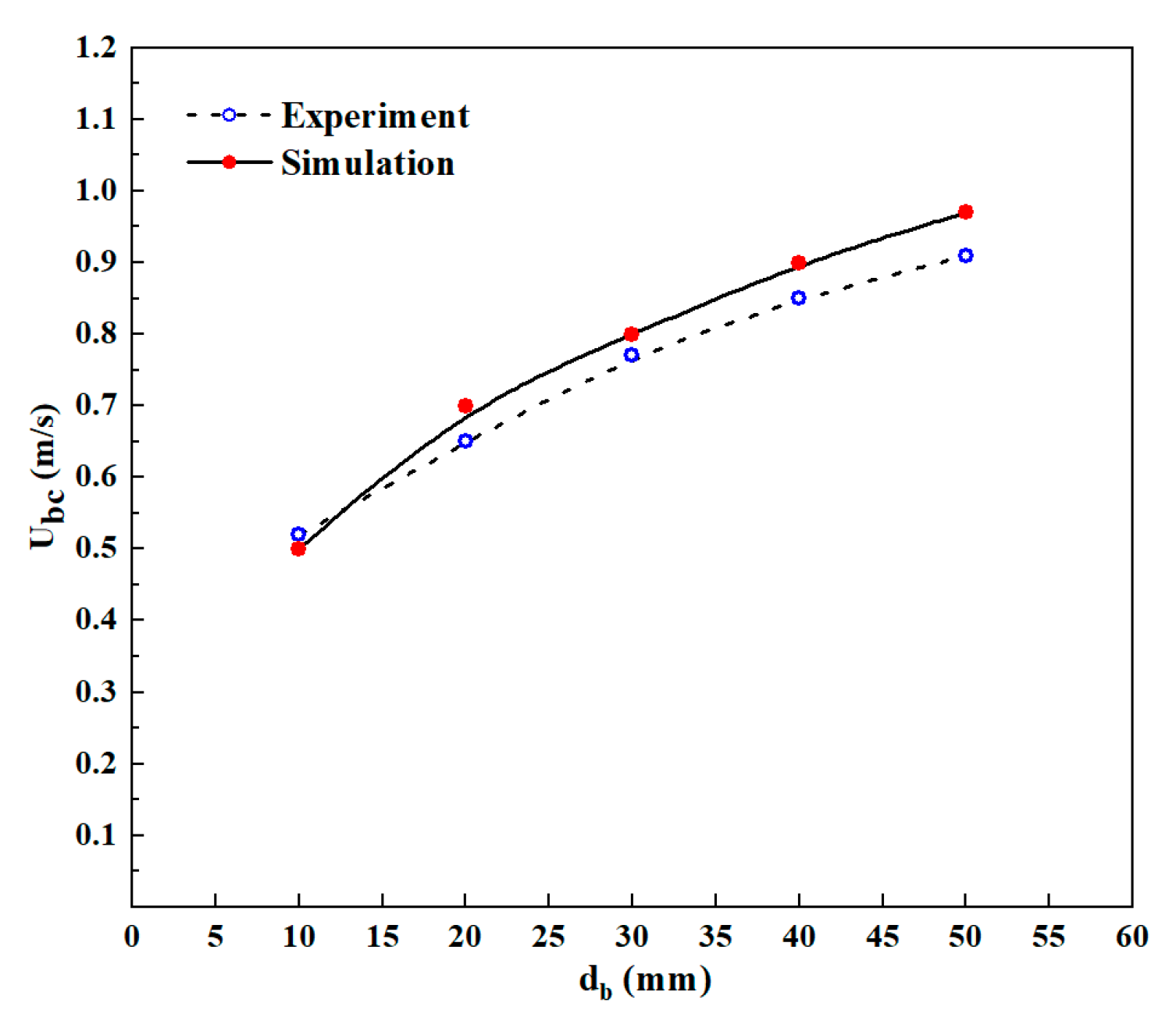

3.2. Ballast group verification

4. Ballast group flow characteristics

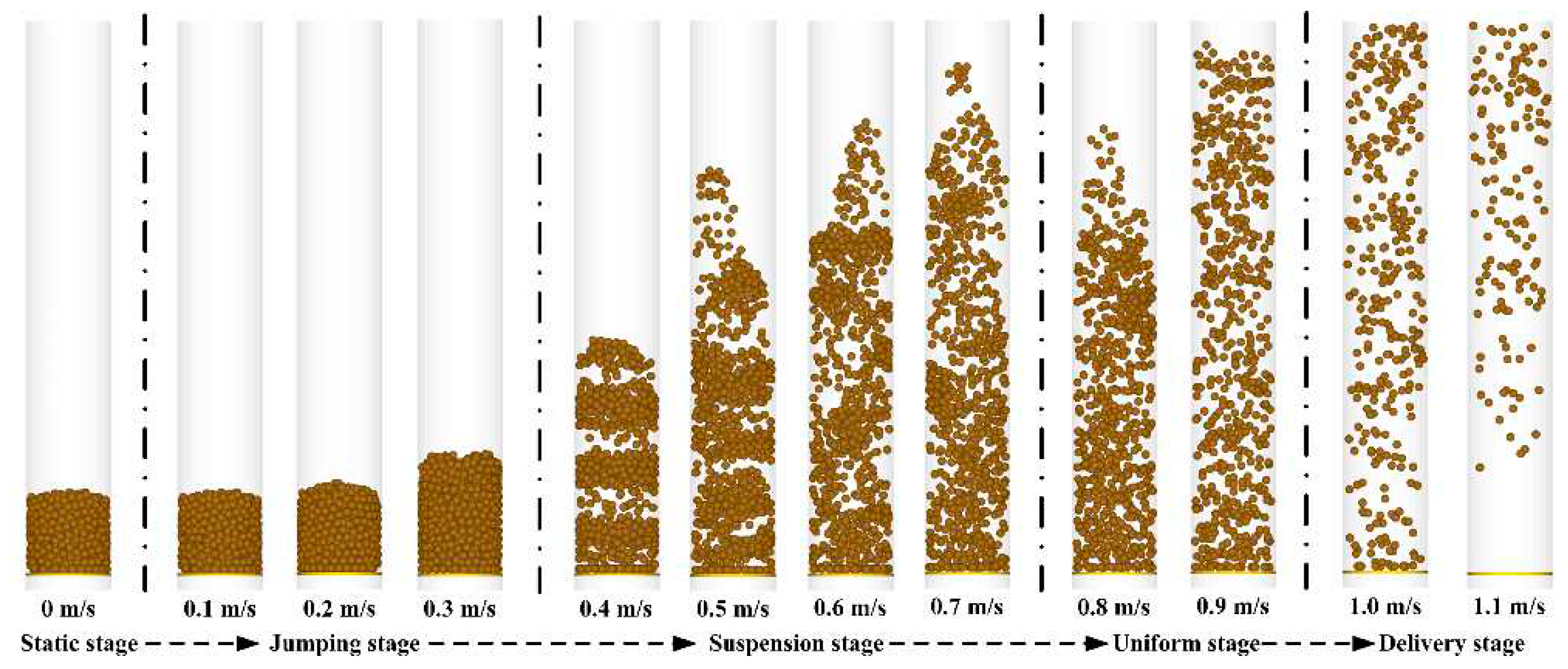

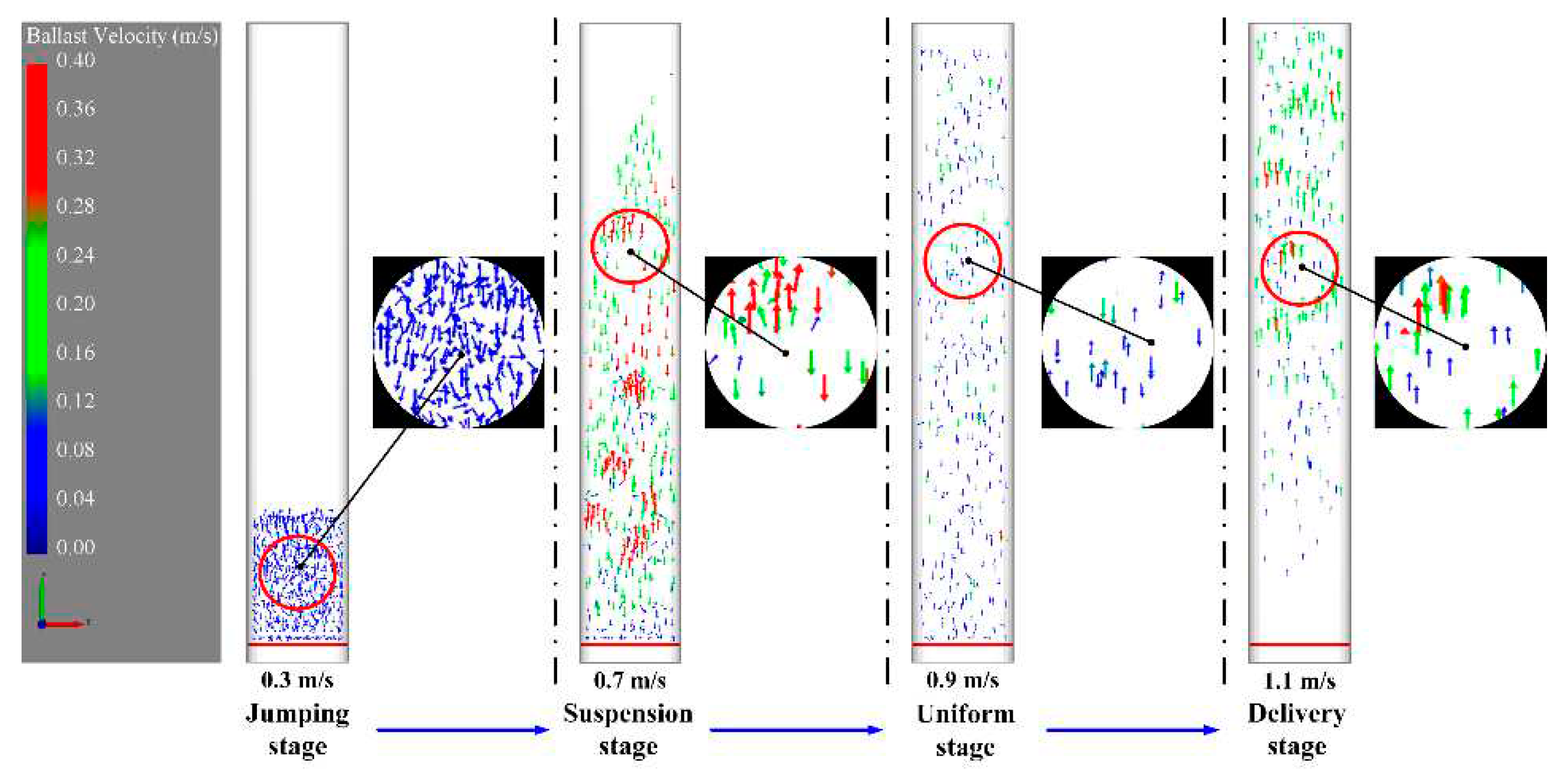

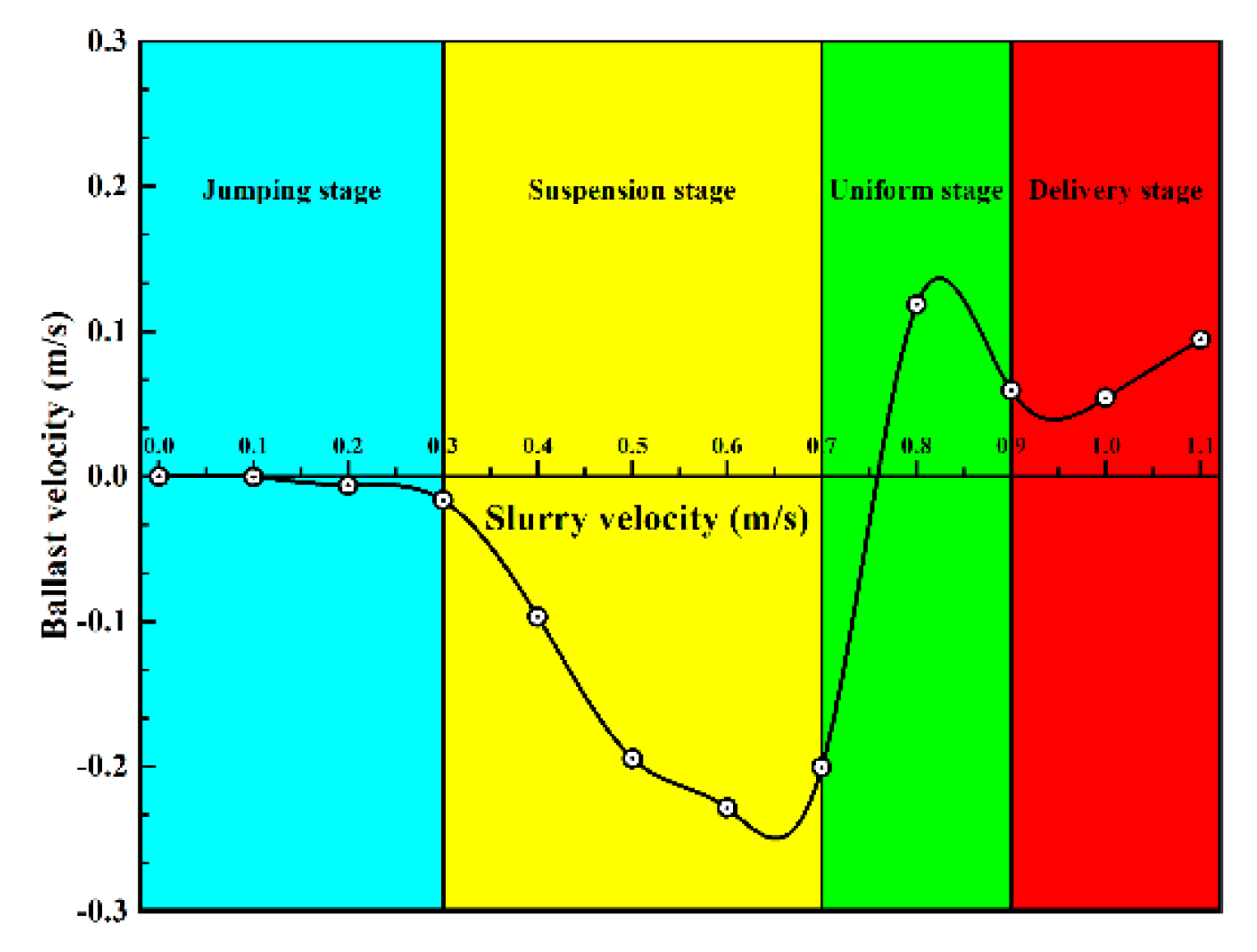

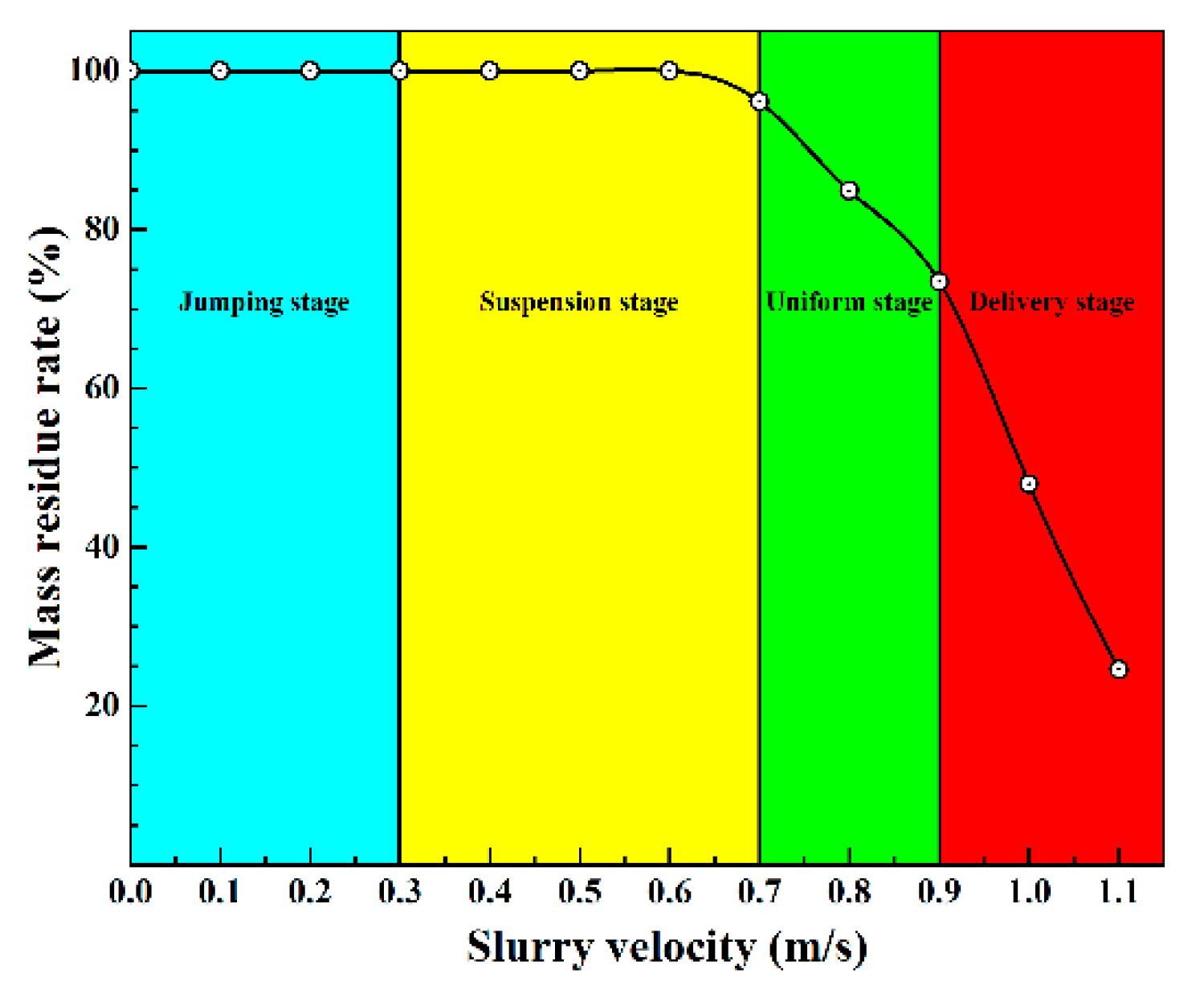

4.1. Ballast group initiation process in the vertical pipe

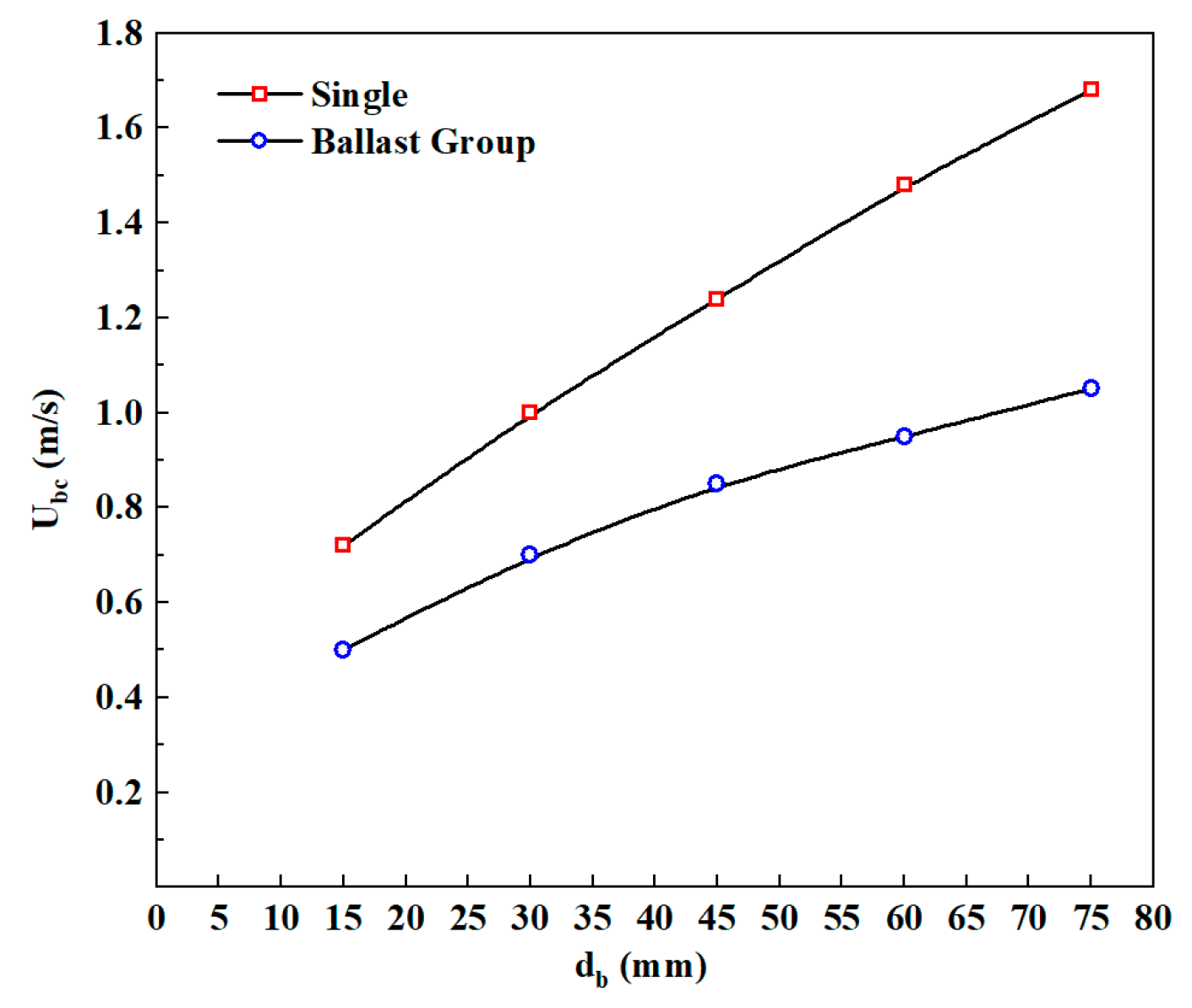

4.2. Effect of ballast size on pick-up velocity

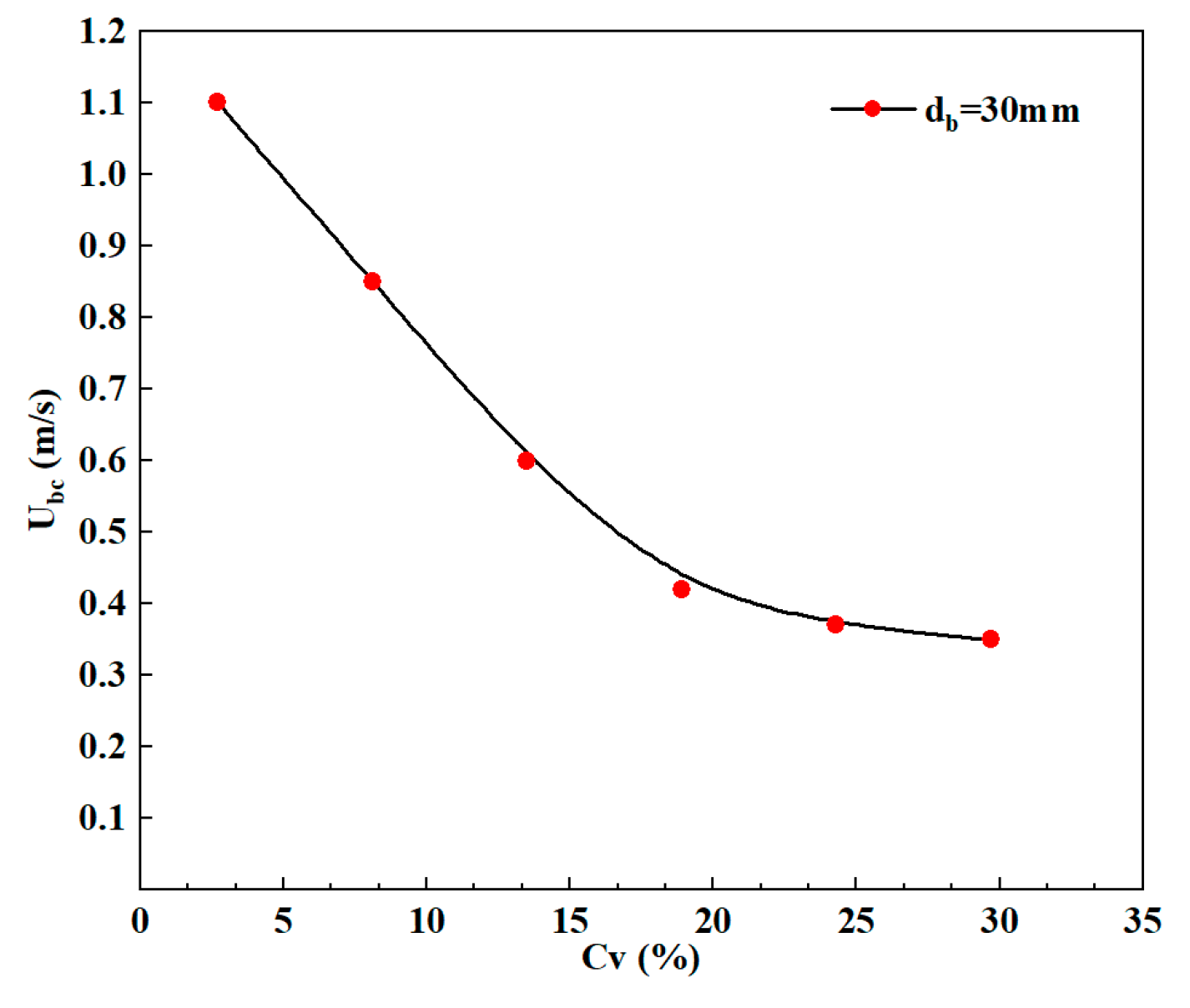

4.3. Effect of ballast concentration on pick-up velocity

5. Conclusion

Funding

Conflicts of Interest

Appendix

| Notation | Definition | Units |

| ub | ballast translational velocity | m/s |

| ωb,i | ballast angular velocity | rad/s |

| mb,i | ballast mass | kg |

| FC,ij | contact force | N |

| FD,i | fluid drag force | N |

| Fp,i | pressure gradient force | N |

| FM,i | Magnus lift force | N |

| FS,i | Saffman lift force | N |

| Fg,i | ballast gravity | N |

| Ib,i | ballast inertia moment | kg·m² |

| Mt,ij | tangential torque | N·m |

| Mr,ij | rolling friction torque | N·m |

| Cd | ballast drag coefficient | – |

| ρs | slurry density | kg/m3 |

| ubsrel | relative velocity | m/s |

| Re | Reynolds number | – |

| db | ballast size | mm |

| μs | slurry viscosity | Pa·s |

| εs | slurry volume fraction | – |

| us | slurry flow velocity | m/s |

| τs | slurry shear stress | Pa |

| p | slurry pressure | Pa |

| g | acceleration of gravity | m/s2 |

| S | momentum exchange term | kg/(m·s)2 |

| γ | slurry shear stress rate | s-1 |

| Fbs,i | interaction force | N |

| ∆V | calculated grid volume | m3 |

| t | simulation time | s |

| Cv | ballast concentration | % |

| mbg | ballast stacking quality | kg |

| ρb | ballast density | kg/m3 |

| h | pipe height | m |

| D | pipe diameter | mm |

| ubc | ballast pick-up velocity | m/s |

| API | Application Programming Interface |

References

- Van Wijk, JM, Talmon, AM, Van Rhee. C Stability of vertical hydraulic transport processes for deep ocean mining: An experimental study. Ocean Eng 2016; 125: 203-213.

- Zhang, H.; Liu, M.; Li, T.; Huang, Z.; Bo, H.; Dong, Y. Experimental study on plug formation characteristics of a novel draft tube type feeder for vertical pneumatic conveying of coarse particles. Powder Technol. 2016, 301, 730–736. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L. Numerical investigation on the pressure loss of coarse particles hydraulic lifting in the riser with the lateral vibration. Powder Technol. 2020, 367, 105–114. [Google Scholar] [CrossRef]

- Kalman, H.; Satran, A.; Meir, D.; Rabinovich, E. Pickup (critical) velocity of particles. Powder Technol. 2005, 160, 103–113. [Google Scholar] [CrossRef]

- Rabinovich, E.; Kalman, H. Pickup velocity from particle deposits. Powder Technol. 2009, 194, 51–57. [Google Scholar] [CrossRef]

- Gomes, L.; Mesquita, A.A. Effect of particle size and sphericity on the pickup velocity in horizontal pneumatic conveying. Chem. Eng. Sci. 2013, 104, 780–789. [Google Scholar] [CrossRef]

- Anantharaman, A.; Cahyadi, A.; Hadinoto, K.; Chew, J.W. Impact of particle diameter, density and sphericity on minimum pickup velocity of binary mixtures in gas-solid pneumatic conveying. Powder Technol. 2016, 297, 311–319. [Google Scholar] [CrossRef]

- Zhou, J.-W.; Xu, L.-G.; Du, C.-L. Prediction of lump coal particle pickup velocity in pneumatic conveying. Powder Technol. 2019, 343, 599–606. [Google Scholar] [CrossRef]

- Goy, S.P.; Chew, J.W.; Hadinoto, K. Effects of binary particle size distribution on minimum pick-up velocity in pneumatic conveying. Powder Technol. 2011, 208, 166–174. [Google Scholar] [CrossRef]

- Dasani, D.; Cyrus, C.; Scanlon, K.; Du, R.; Rupp, K.; Henthorn, K.H. Effect of particle and fluid properties on the pickup velocity of fine particles. Powder Technol. 2009, 196, 237–240. [Google Scholar] [CrossRef]

- Khan, T.S.; Dai, Y.; Alshehhi, M.S.; Khezzar, L. Experimental flow characterization of sand particles for pneumatic transport in horizontal circular pipes. Powder Technol. 2016, 292, 158–168. [Google Scholar] [CrossRef]

- Hayden, K.S.; Park, K.; Curtis, J.S. Effect of particle characteristics on particle pickup velocity. Powder Technol. 2003, 131, 7–14. [Google Scholar] [CrossRef]

- Soepyan FB, Cremaschi S, McLaury BS, et al. Pick-up velocity to initiate particle motion in horizontal and near-horizontal conduits. Powder Technol 2016; 292: 272-289.

- Dabirian R, Mohan R, Shoham O, et al. G Critical sand deposition velocity for gas-liquid stratified flow in horizontal pipes. J. Nat. Gas Sci Eng 2016; 33: 527-537.

- Rice, H.P.; Fairweather, M.; Peakall, J.; Hunter, T.N.; Mahmoud, B.; Biggs, S.R. Constraints on the functional form of the critical deposition velocity in solid–liquid pipe flow at low solid volume fractions. Chem. Eng. Sci. 2015, 126, 759–770. [Google Scholar] [CrossRef]

- Mansour, M.H.; A Zahran, A.; Rabie, L.H.; Shabaka, I.M. Experimental and numerical study of air-water flow characteristics in a horizontal duct. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2021, 235, 843–858. [Google Scholar] [CrossRef]

- Fatahi, M.; Farzanegan, A. An analysis of multiphase flow and solids separation inside Knelson Concentrator based on four-way coupling of CFD and DEM simulation methods. Miner. Eng. 2018, 126, 130–144. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, S.; Kuang, S.; Luo, K.; Fan, J.; Yu, A. CFD-DEM modelling of hydraulic conveying of solid particles in a vertical pipe. Powder Technol. 2019, 354, 893–905. [Google Scholar] [CrossRef]

- Zeng, D.; Zhang, E.; Ding, Y.; Yi, Y.; Xian, Q.; Yao, G.; Zhu, H.; Shi, T. Investigation of erosion behaviors of sulfur-particle-laden gas flow in an elbow via a CFD-DEM coupling method. Powder Technol. 2018, 329, 115–128. [Google Scholar] [CrossRef]

- Petit, H.A.; Irassar, E.F.; Barbosa, M.R. Evaluation of the performance of the cross-flow air classifier in manufactured sand processing via CFD–DEM simulations. Comput. Part. Mech. 2017, 5, 87–102. [Google Scholar] [CrossRef]

- Li, L.; Qi, H.; Yin, Z.; Li, D.; Zhu, Z.; Tangwarodomnukun, V.; Tan, D. Investigation on the multiphase sink vortex Ekman pumping effects by CFD-DEM coupling method. Powder Technol. 2019, 360, 462–480. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Kuang, S.; Yan, H.; Diao, X.; Huang, Z.; Bo, H.; Dong, Y. Experimental and numerical study of coarse particle conveying in the small absorber sphere system: Overview and some recent CFD-DEM simulations. Nucl. Eng. Des. 2020, 357, 110420. [Google Scholar] [CrossRef]

- Naukkarinen, T.; Nikku, M.; Turunen-Saaresti, T. CFD-DEM simulations of hydrodynamics of combined ion exchange-membrane filtration. Chem. Eng. Sci. 2019, 208, 115151. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, Y. CFD-DEM simulation of pneumatic conveying in a horizontal pipe. Powder Technol. 2020, 373, 58–72. [Google Scholar] [CrossRef]

- Uzi, A.; Halevy, G.B.; Levy, A. CFD-DEM Modeling of soluble NaCl particles conveyed in brine. Powder Technol. 2020, 360, 1278–1294. [Google Scholar] [CrossRef]

- Vångö, M.; Pirker, S.; Lichtenegger, T. Unresolved CFD–DEM modeling of multiphase flow in densely packed particle beds. Appl. Math. Model. 2018, 56, 501–516. [Google Scholar] [CrossRef]

- Mindlin, R.D.; Deresiewicz, H. Elastic Spheres in Contact Under Varying Oblique Forces. J. Appl. Mech. 1953, 20, 327–344. [Google Scholar] [CrossRef]

- Wu, L.; Gong, M.; Wang, J. Development of a DEM–VOF Model for the Turbulent Free-Surface Flows with Particles and Its Application to Stirred Mixing System. Ind. Eng. Chem. Res. 2018, 57, 1714–1725. [Google Scholar] [CrossRef]

- Zhu H P, Yu A B. Discrete particle simulation of particulate systems[J]. Chem Eng Sci 2007; 62(13): 3378-3396.

- Sobieski, W. Switch Function and Sphericity Coefficient in the Gidaspow Drag Model for Modeling Solid-Fluid Systems. Dry. Technol. 2009, 27, 267–280. [Google Scholar] [CrossRef]

- Anderson TB, Jackson R. A fluid mechanical description of fluidized beds. Equations of motion. I & Ec Fund 1967; 6: 527-539.

- Saffman, P.G. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef]

- Rubinow, S.I.; Keller, J.B. The transverse force on a spinning sphere moving in a viscous fluid. J. Fluid Mech. 1961, 11, 447–459. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, Y.; Xiao, X.; Xu, H.; Chen, P.; Zeng, G. Ballast Flow Characteristics of Discharging Pipeline in Shield Slurry System. Appl. Sci. 2019, 9, 5402. [Google Scholar] [CrossRef]

| Experiment parameters | Value(s) |

|---|---|

| Ballast equivalent diameter (mm) | 10, 20, 30, 40, 50 |

| Ballast stacking quality (kg) | 0.001-10 |

| Ballast density (kg/m3) | 2140 |

| Water density (kg/m3) | 1000 |

| Water viscosity (Pa⋅s) | 0.001 |

| Ballast shape factor | 0.91 |

| Parameters | Values |

|---|---|

| Ballast diameter (mm) | 10, 20, 30, 40, 50 |

| Experiment value (m/s) | 0.52, 0.65, 0.77, 0.85, 0.91 |

| Simulation value (m/s) | 0.50, 0.70, 0.80, 0.90, 0.97 |

| Simulation Parameters | Value(s) | Simulation Parameters | Value(s) | |

|---|---|---|---|---|

| Ballast diameter (mm) | 15-75 | Sliding friction coefficient | ballast-ballast | 1 |

| Ballast stacking quality (kg) | 0.001-110 | ballast-wall | 0.5 | |

| Ballast density (kg/m3) | 2650 | rolling friction coefficient | ballast-ballast | 0.05 |

| Slurry density (kg/m3) | 1100 | ballast-wall | 0.15 | |

| Slurry viscosity (Pa⋅s) | 0.01 | restitution coefficient | ballast-ballast | 0.35 |

| Ballast shape factor | 0.91 | ballast-wall | 0.55 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).