Submitted:

02 February 2023

Posted:

06 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

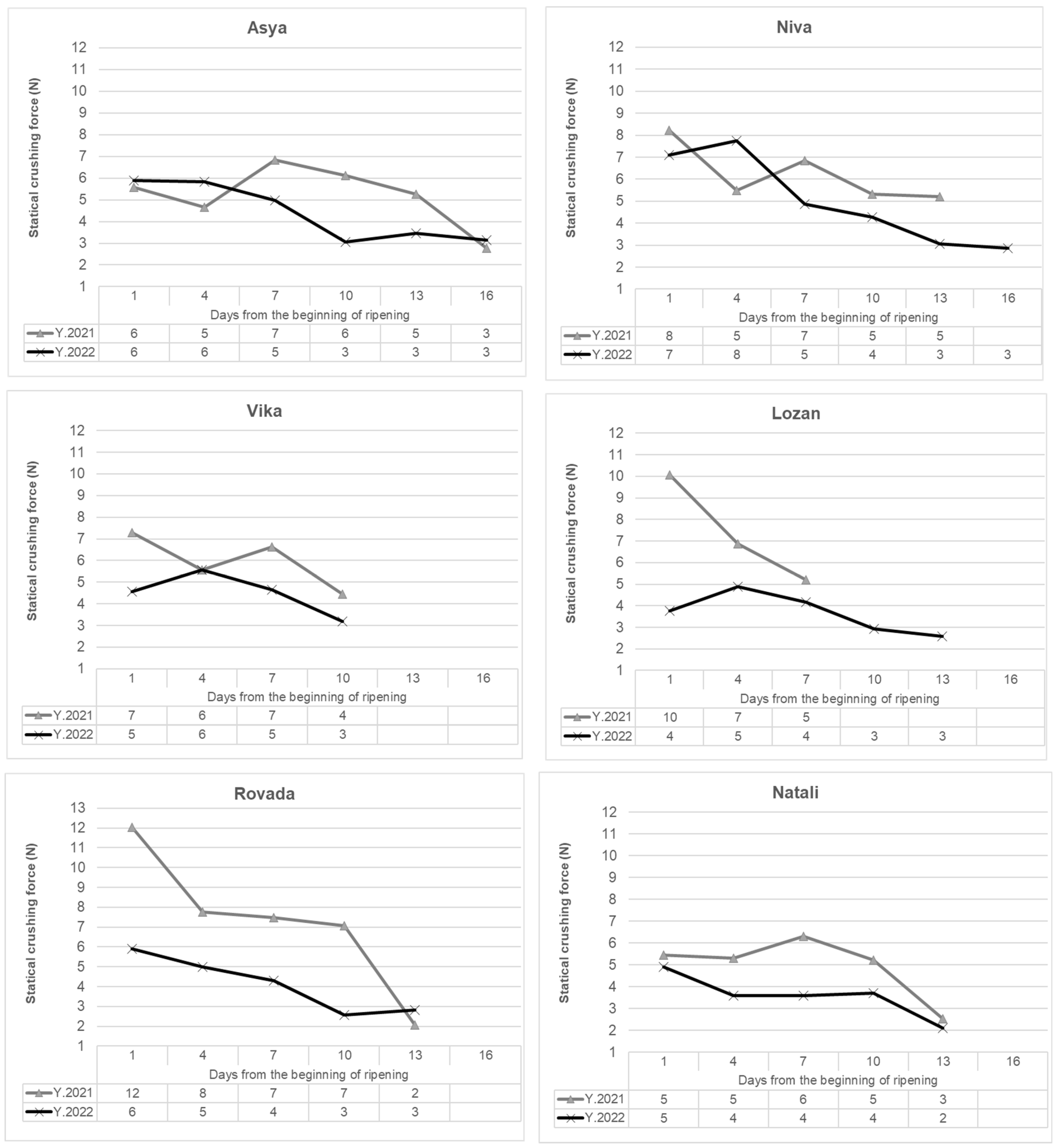

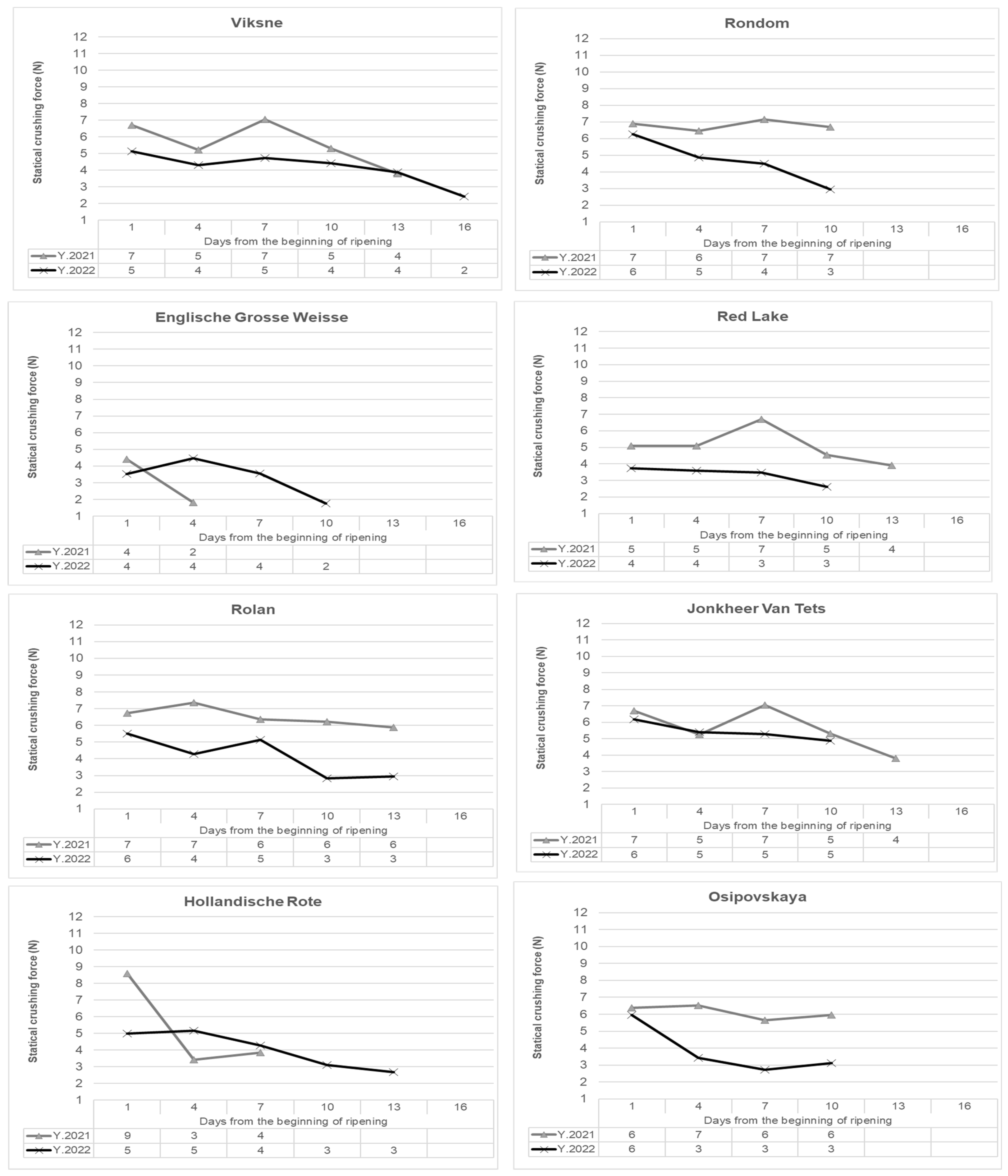

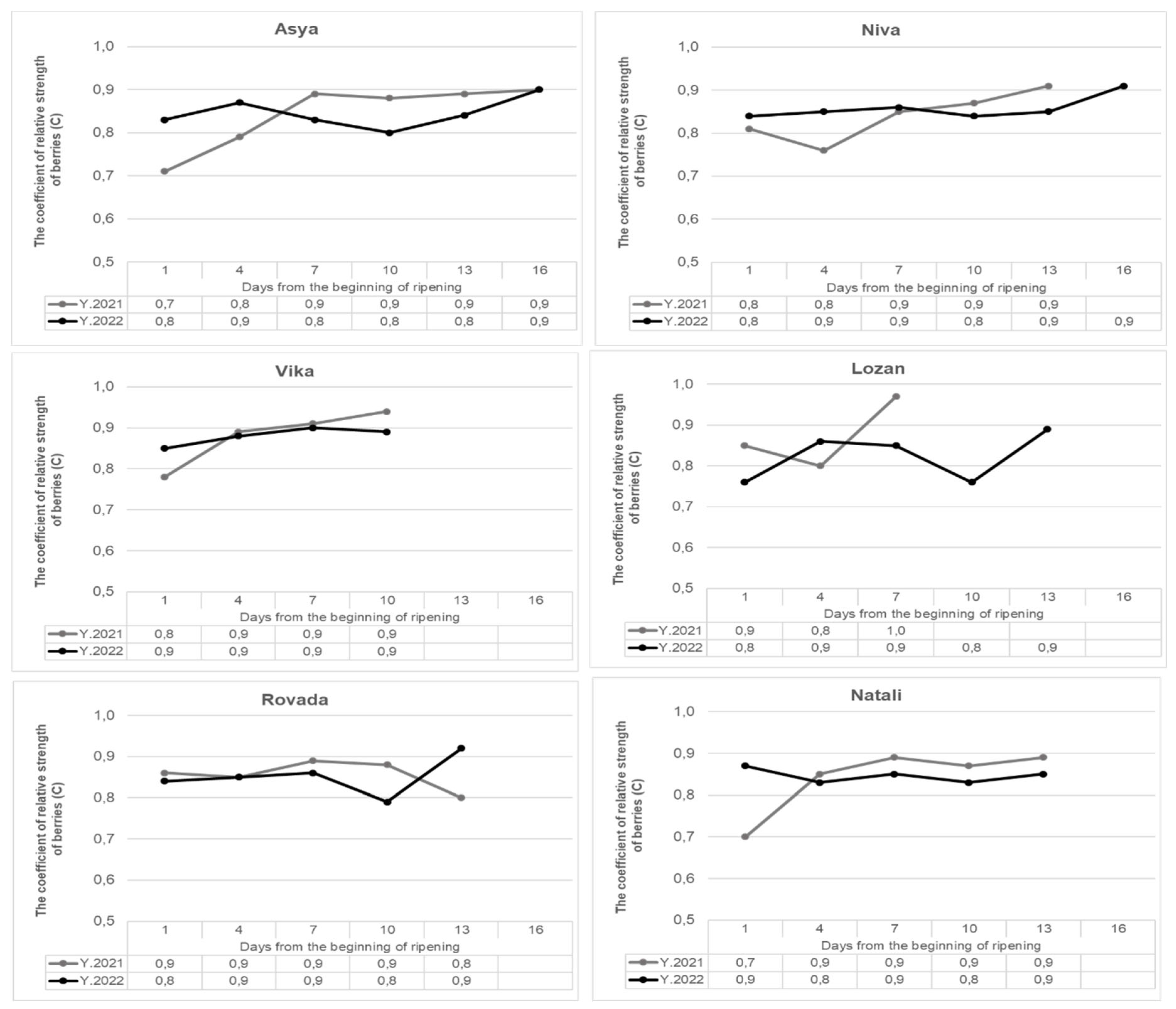

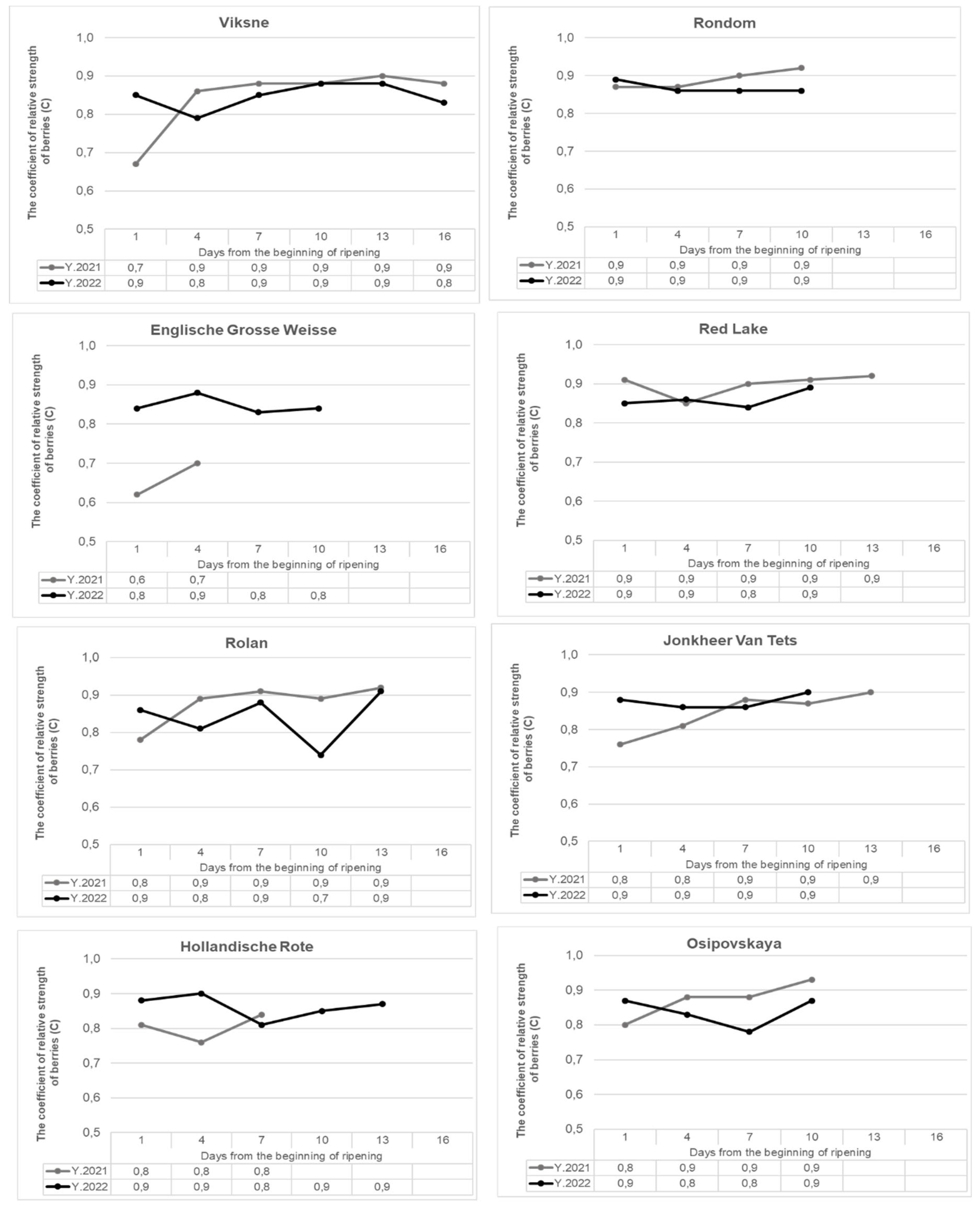

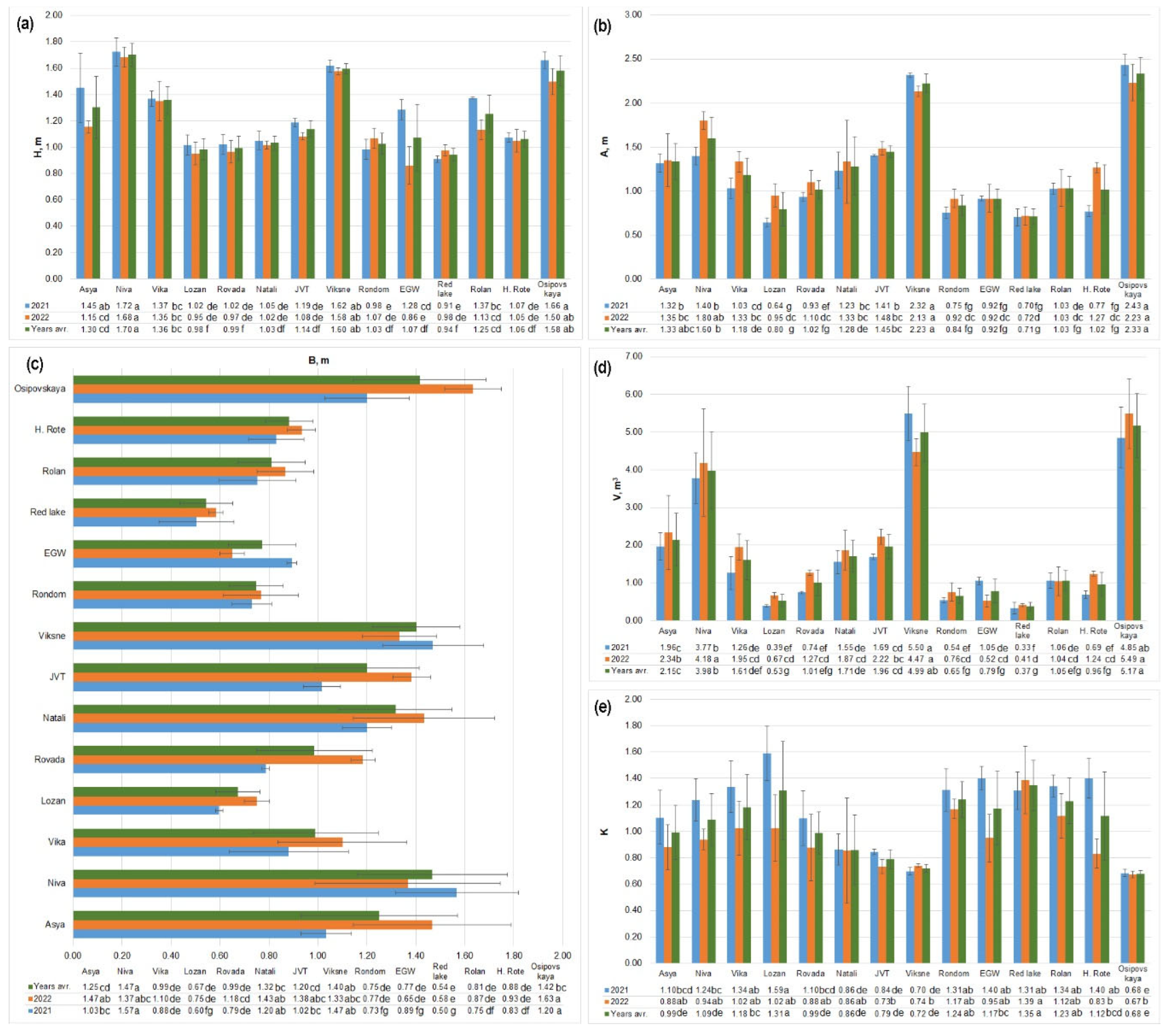

2.1. Non-limiting features for assessing the adaptability of the cultivar

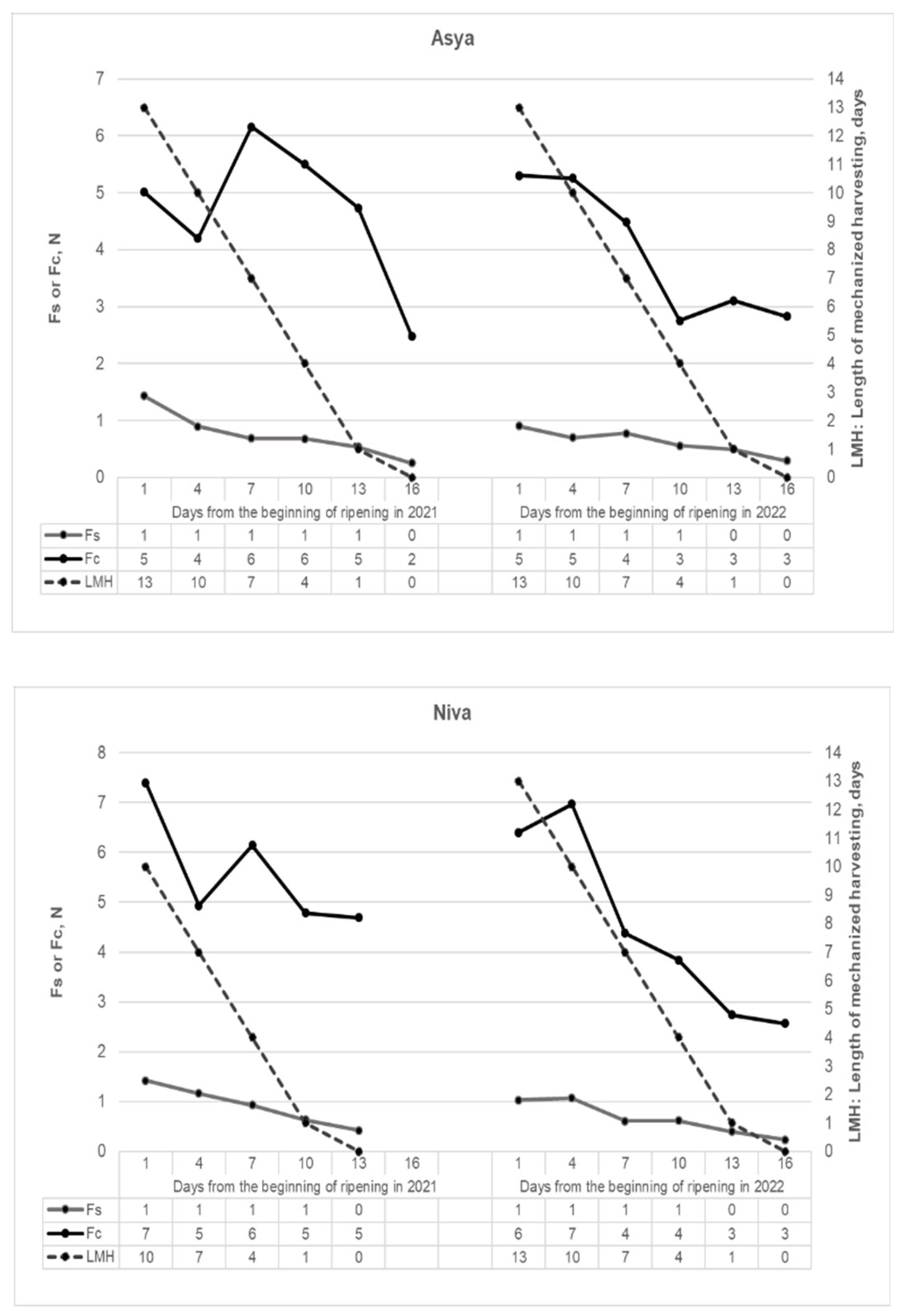

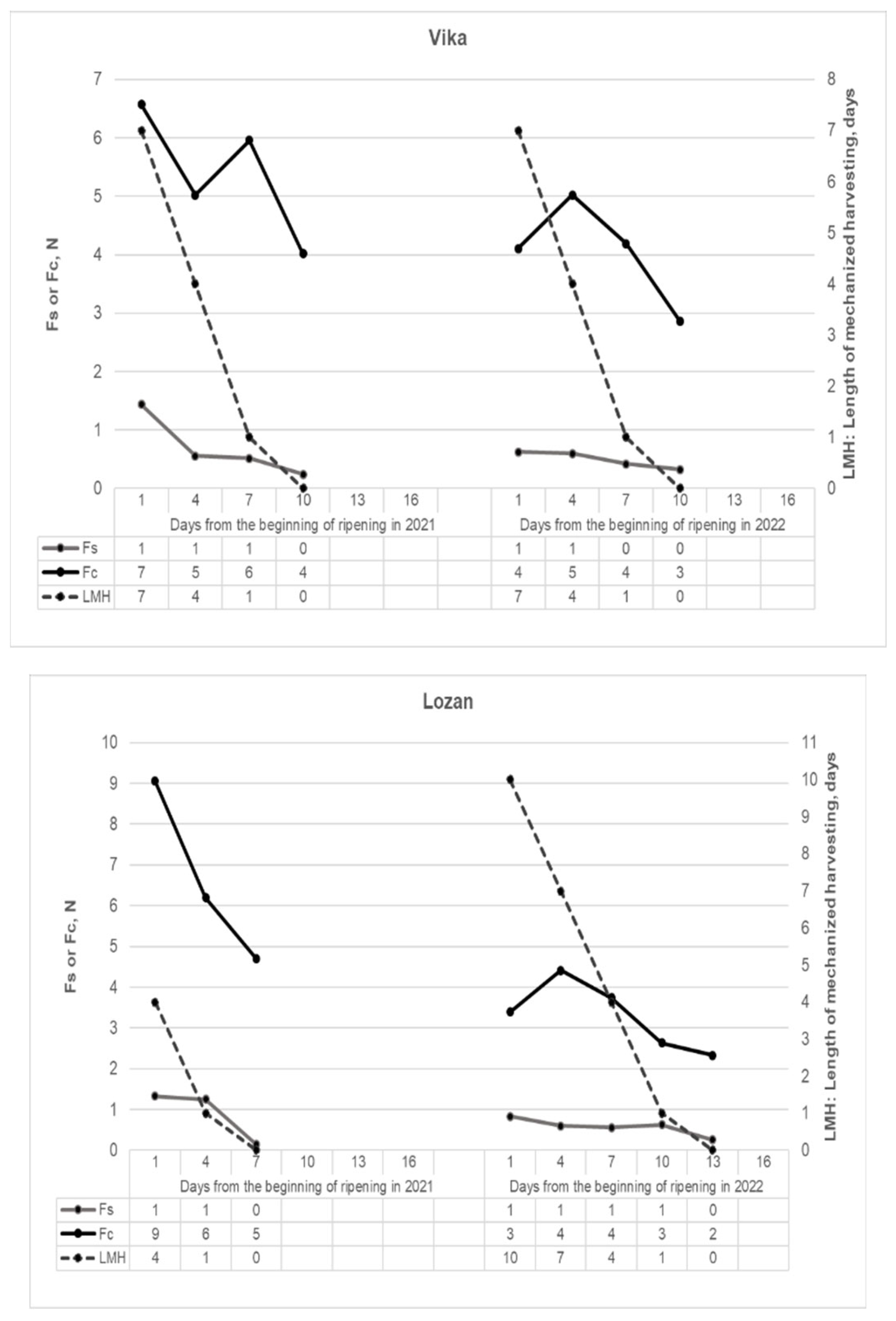

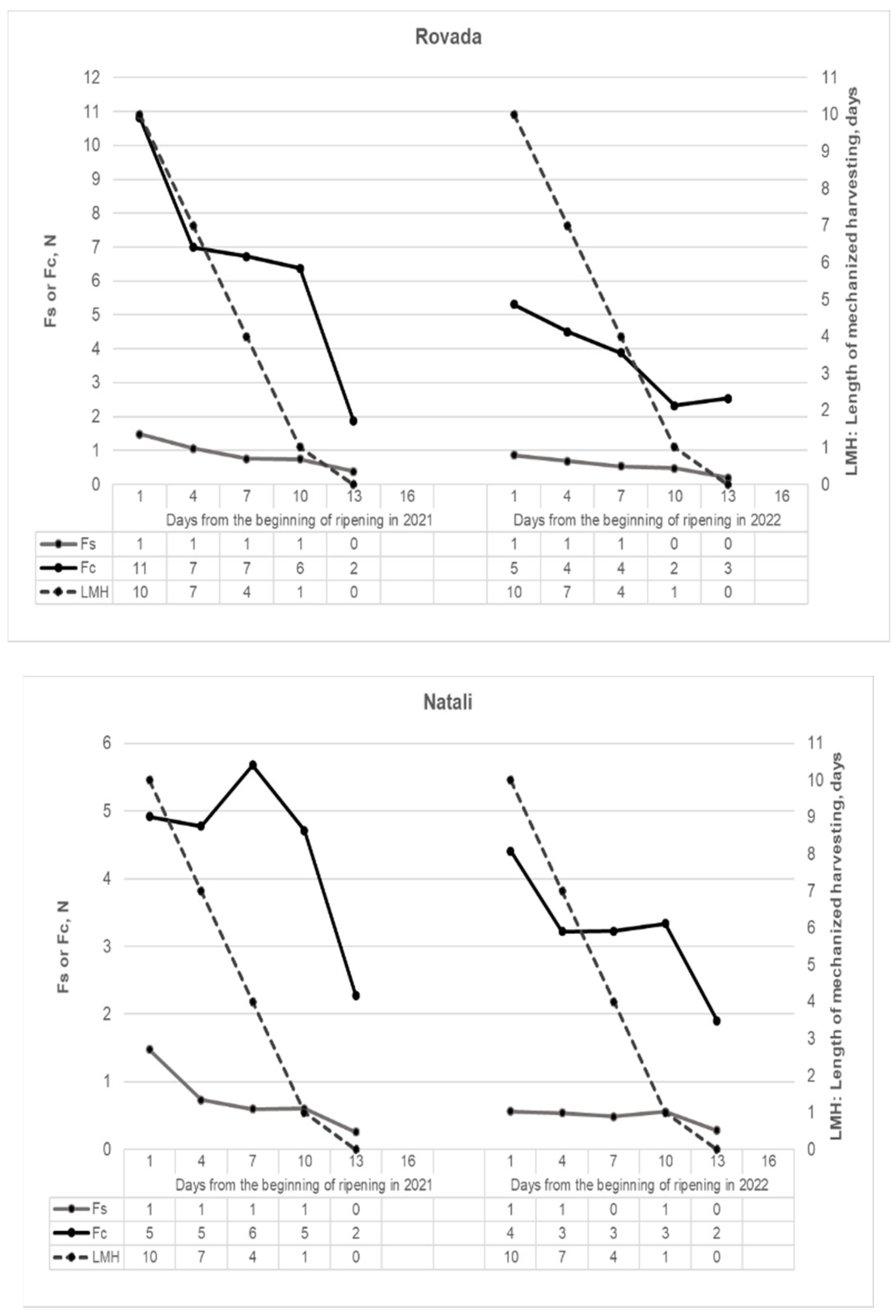

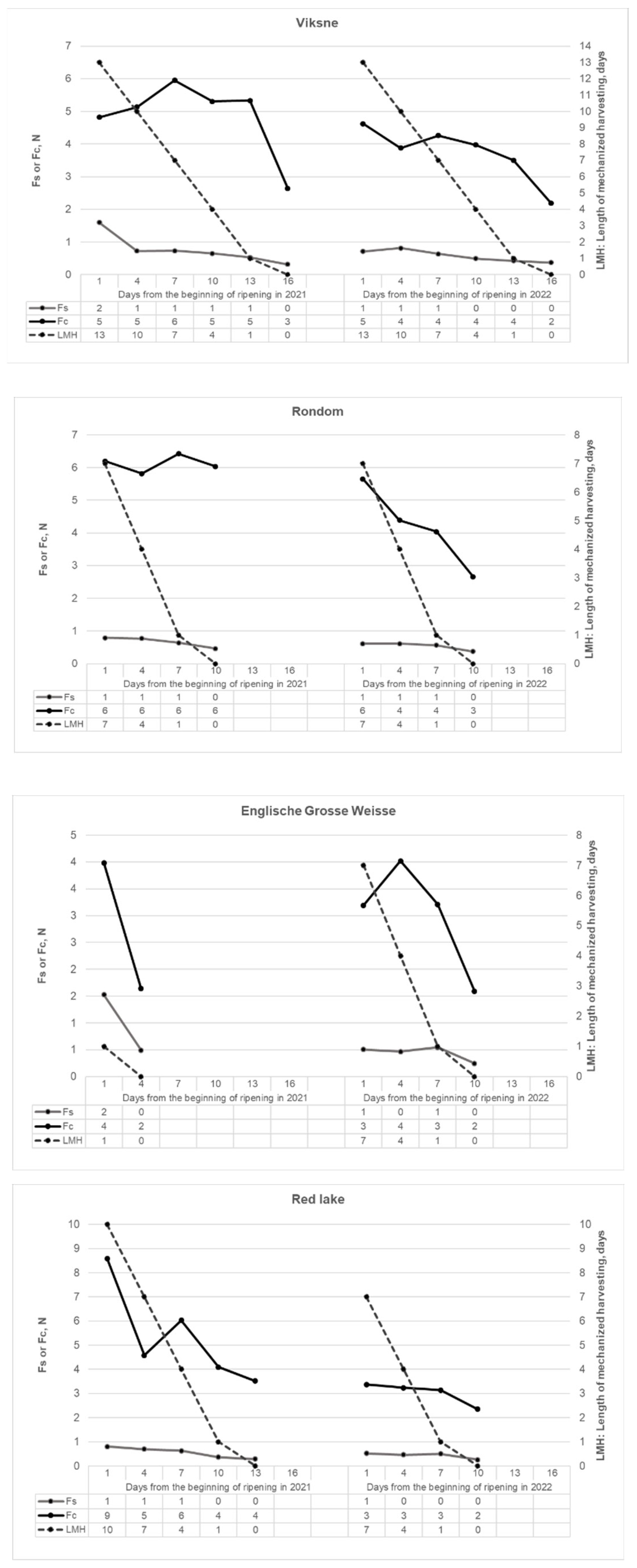

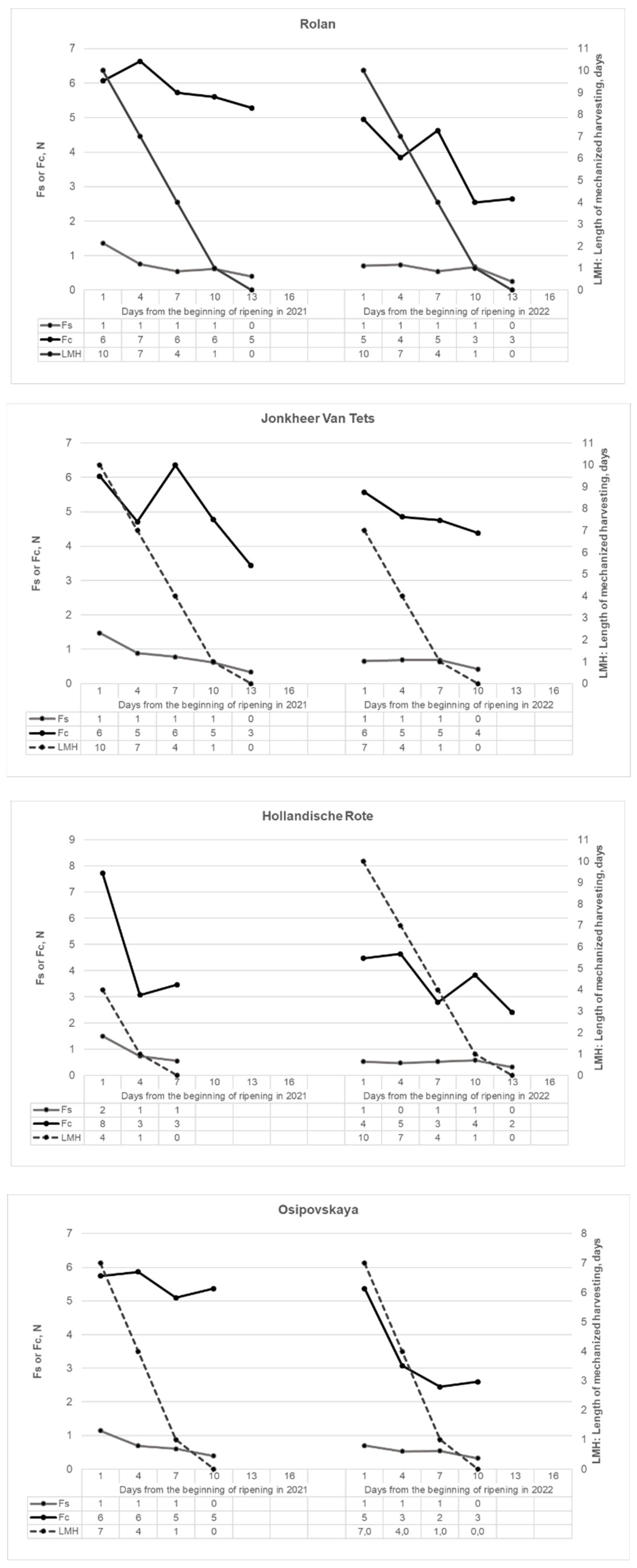

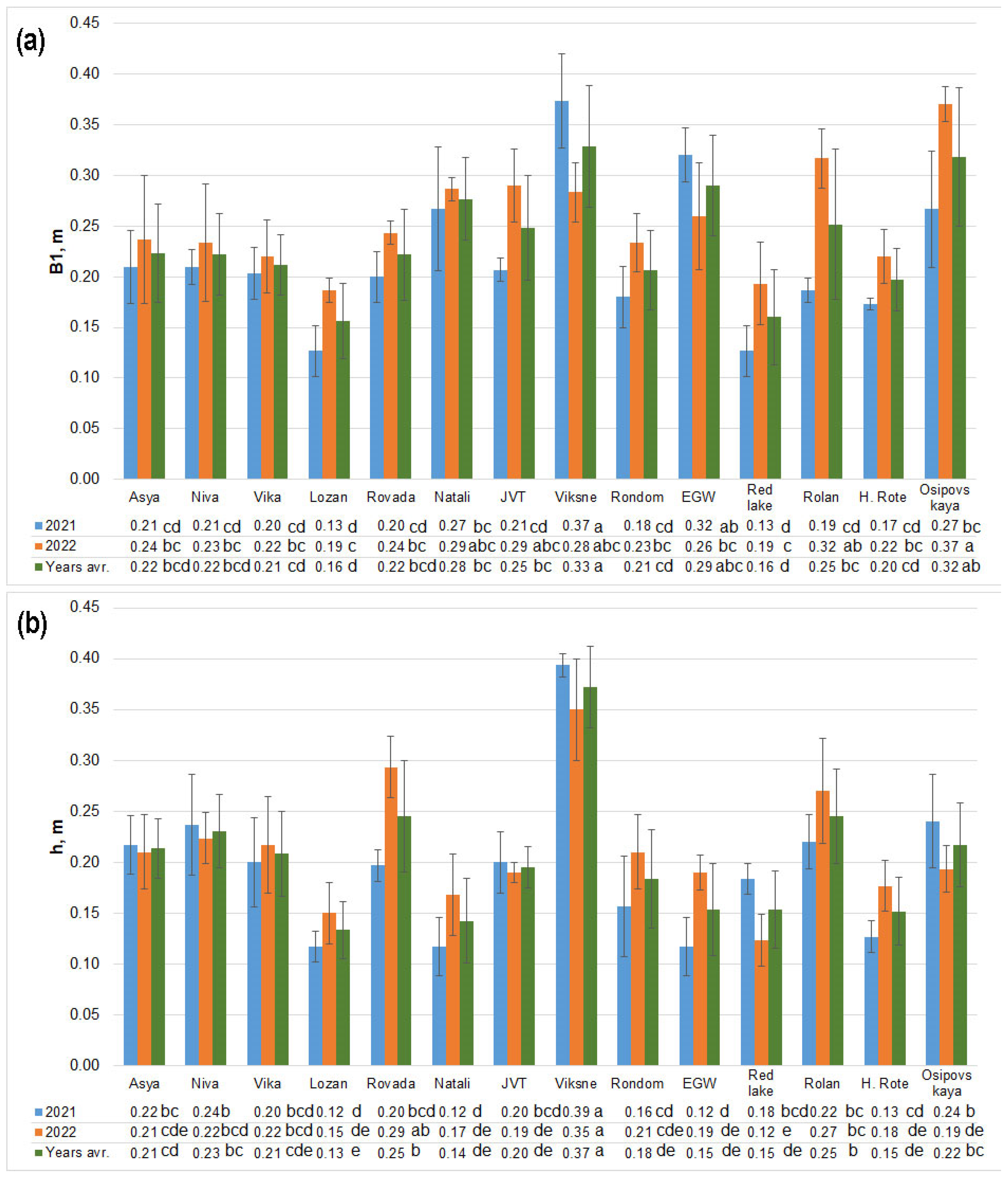

2.2. Limiting features for assessing the technological quality of the cultivar

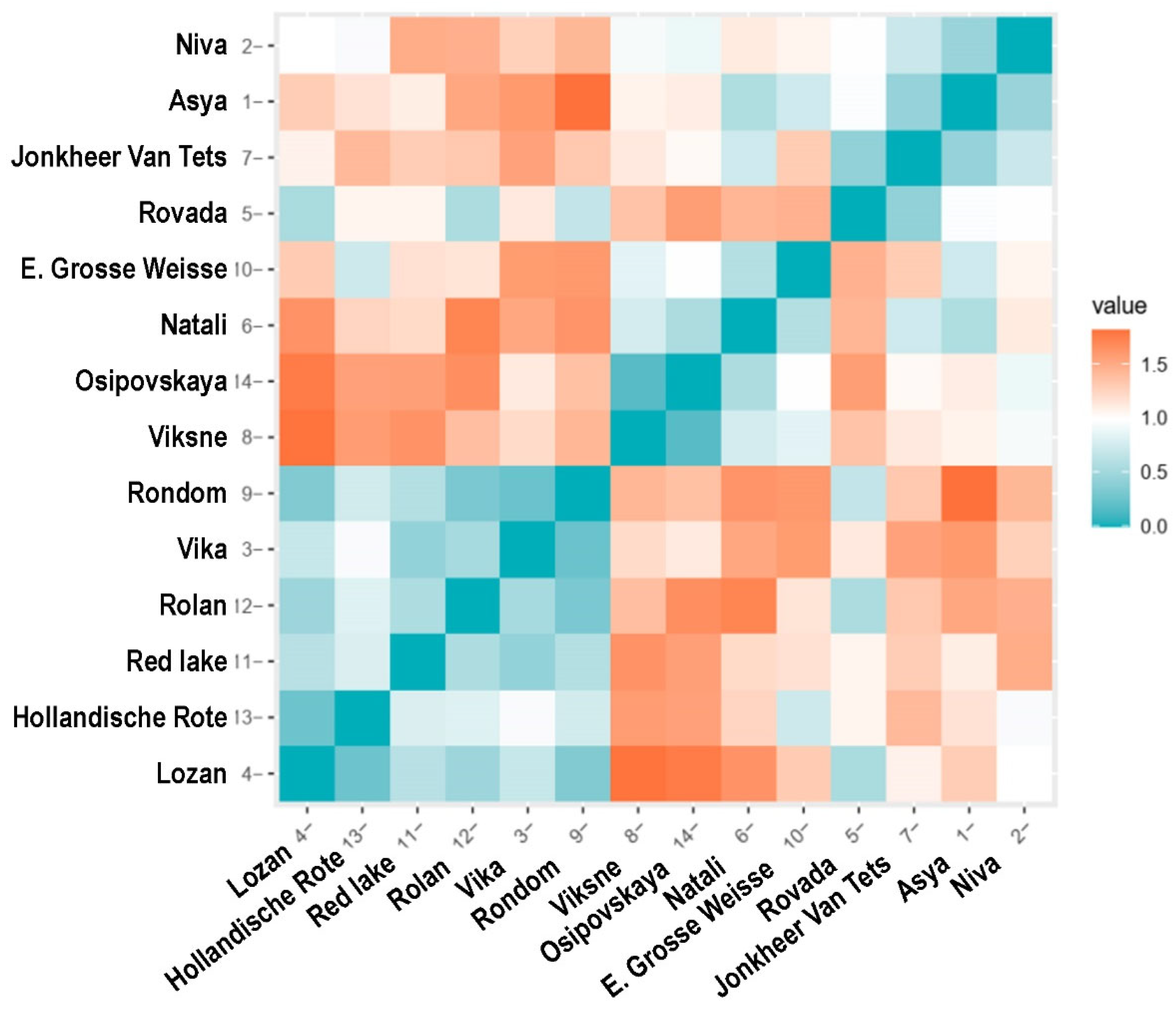

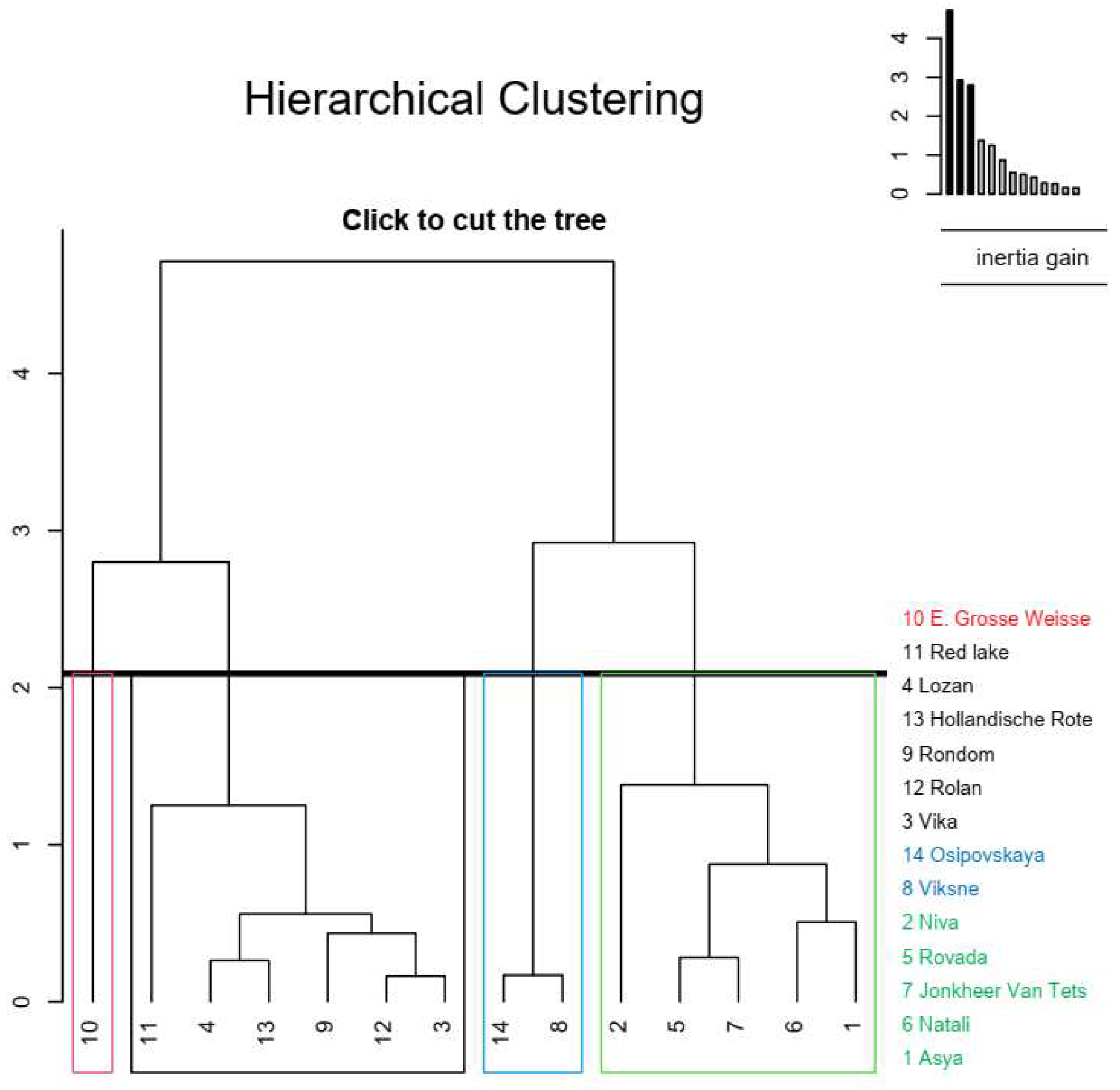

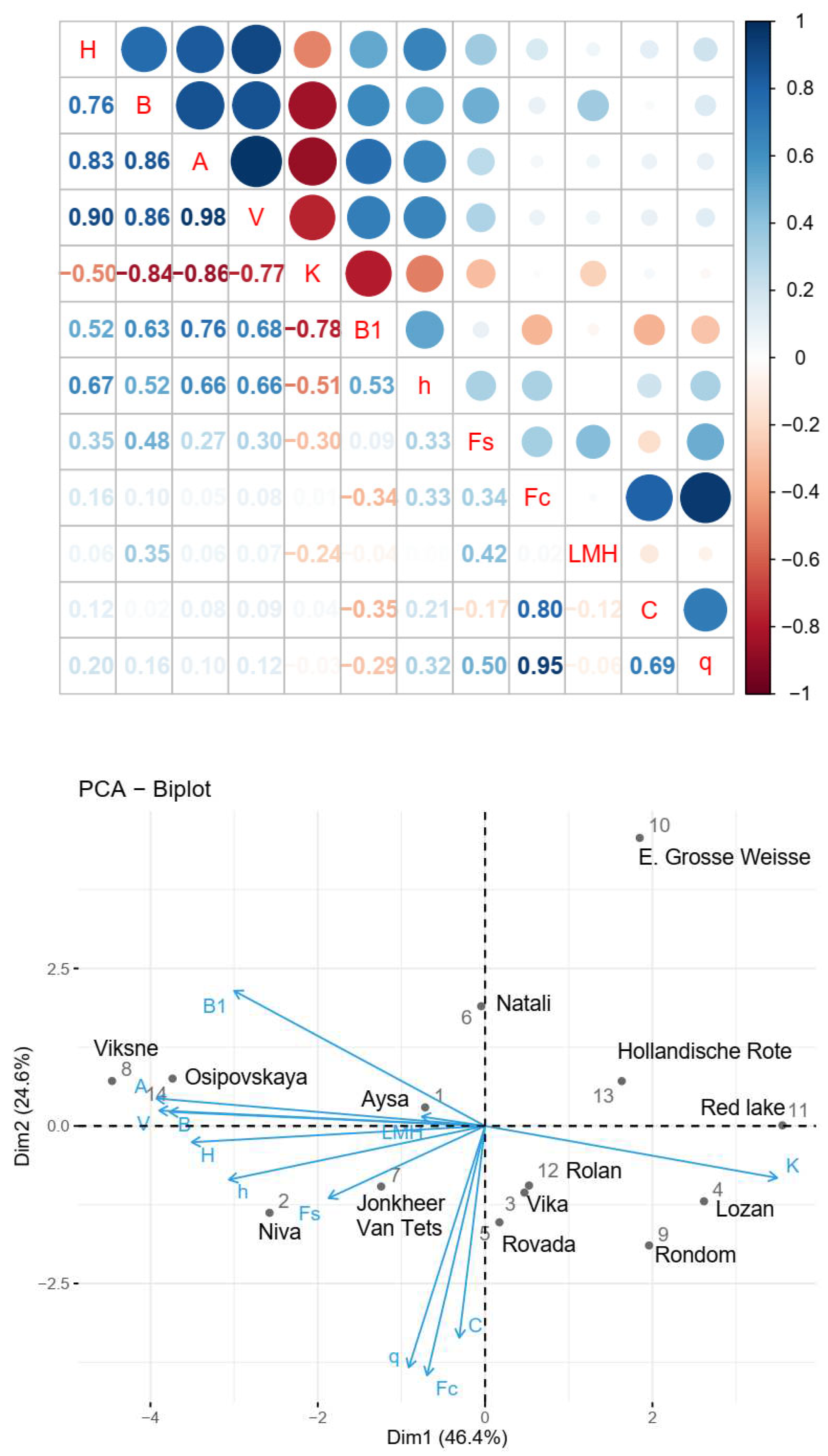

2.3. Relationships among study cultivars

3. Discussion

4. Materials and Methods

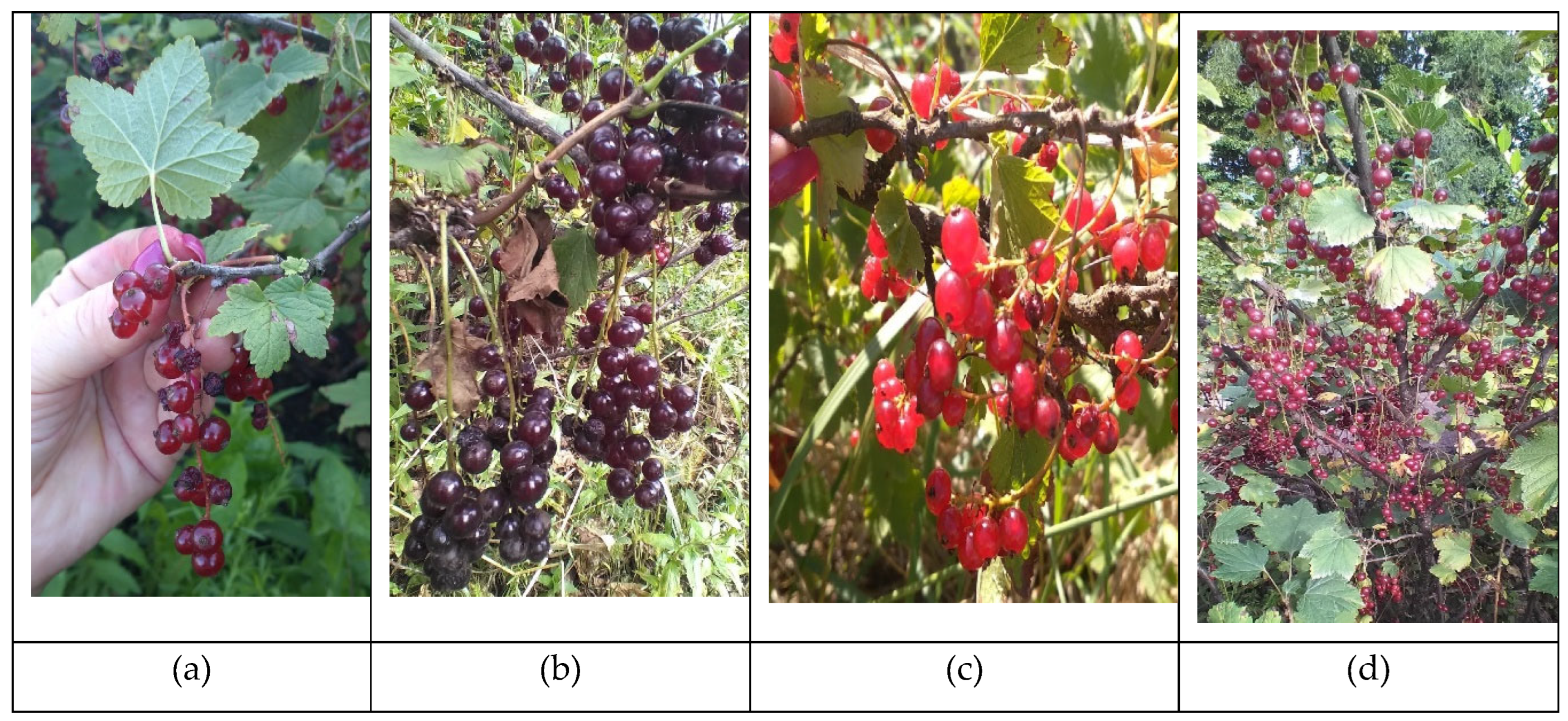

4.1. Place objects of research

4.2. Accounting elements

4.2.1. Non-limiting features for assessing the technological qualities of the cultivar:

- the shape of the bush is erect, and the angle between the direction of the main fruiting branches and the soil surface is more than 75° (coefficient >0.9);

- the shape of the bush is slightly spreading – the angle between the direction of the main fruiting branches and the soil surface is 60-75 ° (coefficient 0.7-0.9);

- the shape of the bush is spreading – the angle between the direction of the main fruiting branches and the soil surface is 45-60° (coefficient 0.6-0.7);

- the shape of the bush is very spreading – the angle between the direction of the main fruiting branches and the soil surface is 30-45° (coefficient 0.4-0.6);

- the shape of the bush is trailing – the angle between the direction of the main fruiting branches and the soil surface is less than 30° (coefficient ˂0.4).

4.2.2. Limiting features for technological qualities of the cultivar

4.3. Statistical Analysis of Data

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Debnath, S. Bioreactors and molecular analysis in berry crop micropropagation – A review. Canadian Journal of Plant Science 2011, 91, 147–157. [Google Scholar] [CrossRef]

- Seeram, N.P. Recent trends and advances in berry health benefits research. Journal of Agricultural and Food Chemistry 2010, 58, 3869–3870. [Google Scholar] [CrossRef] [PubMed]

- Kirina, I.B.; Belosokhov, F.G.; Titova, L.V.; Suraykina, I.A.; Pulpitow, V.F. Biochemical assessment of berry crops as a source of production of functional food products. IOP Conf. Ser.: Earth Environ. Sci 2020, 548, 082068. [Google Scholar] [CrossRef]

- Kahramanoğlu, İ.; Panfilova, O.; Kesimci, T.G.; Bozhüyük, A.U.; Gürbüz, R.; Alptekin, H. Control of Postharvest Gray Mold at Strawberry Fruits Caused by Botrytis cinerea and Improving Fruit Storability through Origanum onites L. and Ziziphora clinopodioides L. Volatile Essential Oils. Agronomy 2022, 12, 389. [Google Scholar] [CrossRef]

- Asănică, A. Growing berries in containers - a new perspective for urban horticulture. Scientific Papers-Series B, Horticulture 2019, 63, 97–102. [Google Scholar]

- Food and Agriculture Organization of the Unated Nations. Available online: https://www.fao.org/sustainable-development-goals/background/ru/ (accessed on 14 December 2022).

- Bilici, M. The Effect of Currant (Ribes) on Human Health and Determination Certain Antioxidant Activities. East. J. Med. 2021, 26, 470–474. [Google Scholar] [CrossRef]

- Ropelewska, E. Assessment of the Influence of Storage Conditions and Time on Red Currants (Ribes rubrum L.) Using Image Processing and Traditional Machine Learning. Agriculture 2022, 12, 1730. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#compare (accessed on 14 December 2022).

- Helgi Library. Available online: https://www.helgilibrary.com/indicators/redcurrants-area-cultivation-harvested-production/ (accessed on 14 December 2022).

- Kowalczyk, Z.; Grotkiewicz, K. Labour consumption of production of selected fruit. Agricultural Engineering 2018, 22, 29–36. [Google Scholar] [CrossRef]

- Wróblewska, W.; Pawlak, J.; Paszko, D. Economic aspects in the raspberry production on the example of farms from Poland, Serbia and Ukraine. Journal of Horticultural Research 2019, 27, 71–80. [Google Scholar] [CrossRef]

- Brondino, L.; Borra, D.; Giuggioli, N.R.; Massaglia, S. Mechanized Blueberry Harvesting: Preliminary Results in the Italian Context. Agriculture 2021, 11, 1197. [Google Scholar] [CrossRef]

- Sazonov, F.F.; Danshina, O.V. Breeding possibilities of creation varieties and forms of blackcurrant for machine harvesting. Horticulture and viticulture 2016, 2, 22–27. [Google Scholar] [CrossRef]

- Perekopskiy, A.N.; Zykov, A.V.; Egorova, K.I. Evaluation of black currant varieties suitability for combine harvesting. The Agrarian Scientific Journal 2021, 7, 35–39. [Google Scholar] [CrossRef]

- Kikas, A.; Laurson, P.; Libek, A.V. Evaluation of the biological-economic and biochemical traits of promising Ribes nigrum hybrids in Estonia. Zemdirbyste-Agriculture 2021, 108, 57–62. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Liang, D.; Xu, W.; Chen, Y. Design of a Buffered Longitudinal Vibratory Picking Mechanism for Berry Shrub Fruits. Transactions of the ASABE 2021, 64, 1165–1171. [Google Scholar] [CrossRef]

- Sava, P.; Bodiu, G. Growing technology implementation of black currant varieties for berries production in District Soroca, Republic of Moldova. Scientific Papers - Series B Horticulture 2012, 56, 167–170. [Google Scholar]

- Djordjević, B.; Rakonjac, V.; Akšić, M.F.; Šavikin, K.; Vulić, T. Pomological and biochemical characterization of European currant berry (Ribes sp.) cultivars. Scientia Horticulturae 2014, 165, 156–162. [Google Scholar] [CrossRef]

- Rakonjac, V.; Djordjević, B.; Fotirić-Akšić, M.; Vulić, T.; Djurović, D. Estimation of variation and correlation analysis for yield components in black currant cultivars. Genetika 2015, 47, 785–794. [Google Scholar] [CrossRef]

- Panfilova, O.; Kahramanoğlu, I.; Ondrasek, G.; Okatan, V.; Ryago, N.; Tsoy, M.; Golyaeva, O.; Knyazev, S. Creation and Use of Highly Adaptive Productive and Technological Red Currant Genotypes to Improve the Assortment and Introduction into Different Ecological and Geographical Zones. Plants 2022, 11, 802. [Google Scholar] [CrossRef] [PubMed]

- Gurin, A.G. Prediction of the duration of mechanized harvesting of blackcurrant. Horticulture and viticulture 2000, 3, 13–15. [Google Scholar]

- Barbaroș, M.; Cimpoieș G. Berry species varieties classification on growth and productivity indicators. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca 2007, 373-376.

- Wang, Y.; Chen, H.; Lin, Q. Optimization of parameters of blackcurrant harvesting mechanism. Transactions of the Chinese Society of Agricultural Engineering 2009, 25, 79–83. [Google Scholar]

- Olander, S. A review of berry harvest machine development in Sweden. Acta Hortic 2012, 965, 171–178. [Google Scholar] [CrossRef]

- Sarig, Y. Mechanical harvesting of fruit - past achievements. current status and future prospects. Acta Hortic 2012, 965, 163–169. [Google Scholar] [CrossRef]

- Čejka, B.; Matějíček, A.; Matějičková, J.; Paprštein, F. Red currant cultivar ‘Rubigo’. Vědecké Práce Ovocnářské 2013, 23, 79–86. [Google Scholar]

- Sazonov, F.F. Genetic resources of black currant in breeding for suitability for mechanized harvesting. Pomiculture and small fruits culture in Russia 2018, 54, 63–66. [Google Scholar] [CrossRef]

- Krayushkina, N.S.; Perekopskiy, A.N.; Egorova, K.I.; Evseev, S.P. Creation of black currant varieties range for regionally adaptive machine-based technology of berry production. AgroEcoEngineering 2020, 2, 64–72. [Google Scholar]

- Danshina, O.V. Selection evaluation of black currant forms for suitability for machine harvesting. Ph.D. Thesis, Bryansk State Agrarian University, Russia, 2017. [Google Scholar]

- Panfilova, O.; Kalinina, O.; Golyaeva, O.; Knyazev, S.; Tsoy, M. Physical and mechanical properties of berries and biological features of red currant growth for mechanized harvesting. Res. Agr. Eng. 2020, 66, 156–163. [Google Scholar] [CrossRef]

- Masny, A.; Pluta, S.; Seliga, Ł. Breeding value of selected blackcurrant (Ribes nigrum L.) genotypes for early-age fruit yield and its quality. Euphytica 2018, 214, 1–21. [Google Scholar] [CrossRef]

- Rakonjac, V.; Djordjević, B.; Fotirić-Akšić, M.; Vulić, T.; Djurović, D. Estimation of variation and correlation analysis for yield components in black currant cultivars. Genetika 2015, 47, 785–794. [Google Scholar] [CrossRef]

- Sasnauskas, A.; Rugienius, R.; Mazeikiene, I.; Bendokas, V.; Stanys, V. Small fruit breeding tendencies in Lithuania: a review. Acta Hortic. 2019, 1265, 225–231. [Google Scholar] [CrossRef]

- Utkov, Yu. A. Ways to enhance the quality and efficiency of combine harvesting on the industrial plantations of currant. Horticulture and viticulture 2015, 4, 40–44. [Google Scholar]

- Korovin, K.L. Evaluation of black currant varieties and hybrids on some parameters of suitability to mechanized fruit harvesting. Fruit Growing: scientific papers 2011, 23, 198–202. [Google Scholar]

- Toushik, S.H.; Lee, K.T.; Lee, J.S.; Kim, K.S. Functional applications of lignocellulolytic enzymes in the fruit and vegetable processing industries. Journal of food science 2017, 82, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Spinei, M.; Oroian, M. The potential of grape pomace varieties as a dietary source of pectic substances. Foods 2021, 10, 867. [Google Scholar] [CrossRef] [PubMed]

- Kazakhmedov, R.; Mamedova, S.; Magomedova, M. The growth regulators as a factor of increasing in transport ability and long storage of grapes. Fruit growing and viticulture of South Russia 2017, 46, 94–107. [Google Scholar]

- Aleynikov, A.F.; Mineyev, V.V. Measurement of mechanical properties of sea buckthorn and black currant berries. Siberian Herald of Agricultural Science 2016, 4, 105–111. [Google Scholar]

- Bac, C.W.; Hemming, J.; Van Henten, E.J. Stem localization of sweet-pepper plants using the support wire as a visual cue. Computers and electronics in agriculture 2014, 105, 111–120. [Google Scholar] [CrossRef]

- Yarborough, D.E.; Hergeri, G.B. Mechanical harvesting of berry crops. Hortic. Rev 2010, 16, 255–282. [Google Scholar]

- Milošević, T.; Milošević, N.; Mladenović, J. Soluble solids, acidity, phenolic content and antioxidant capacity of fruits and berries cultivated in Serbia. Fruits 2016, 71, 239–248. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, X.; Au, W.; Kang, H.; Chen, C. Intelligent robots for fruit harvesting: recent developments and future challenges. Precision Agric. 2022, 23, 1856–1907. [Google Scholar] [CrossRef]

- Mehta, S.; MacKunis, W.; Burks, T. Robust visual servo control in the presence of fruit motion for robotic citrus harvesting. Computers and Electronics in Agriculture. 2016, 123, 362–375. [Google Scholar] [CrossRef]

- Sola-Guirado, R.; Castro-Garcia, S.; Blanco-Roldán, G.; Gil-Ribes, J.; González-Sánchez, E. Performance evaluation of lateral canopy shakers with catch frame for continuous harvesting of oranges for juice industry. International Journal of Agricultural and Biological Engineering. 2020, 13, 88–93. [Google Scholar] [CrossRef]

- Sanders, K.F. Orange harvesting systems review. Biosystems Engineering 2005, 90, 115–125. [Google Scholar] [CrossRef]

- Tulipani, S.; Marzban, G.; Herndl, A.; Laimer, M.; Mezzetti, B.; Battino, M. Influence of environmental and genetic factors on health-related compounds in strawberry. Food Chem. 2011, 124, 906–913. [Google Scholar] [CrossRef]

- Paprstein, F.; Sedlak, J.; Kaplan, J. Rescue of red and white currant germplasm in the Czech Republic. Acta Hortic. 2016, 1133, 49–52. [Google Scholar] [CrossRef]

- Di Vittori, L.; Mazzoni, L.; Battino, M.; Mezzetti, B. Pre-harvest factors influencing the quality of berries. Scientia Horticulturae 2018, 233, 310–322. [Google Scholar] [CrossRef]

- Rivera, S.; Kerckhoffs, H.; Sofkova-Bobcheva, S.; Hutchins, D.; East, A. Influence of harvest maturity and storage technology on mechanical properties of blueberries. Postharvest Biology and Technology 2022, 191, 111961. [Google Scholar] [CrossRef]

- Giacosa, S.; Torchio, F.; Segade, S.R.; Gaiotti, F.; Tomasi, D.; Lovat, L.; Vincenzi, S.; Rolle, L. Physico-mechanical evaluation of the aptitude of berries of red wine grape varieties to resist the compression in carbonic maceration vinification. International journal of food science & technology 2013, 48, 817–825. [Google Scholar] [CrossRef]

- Rolle, L.; Torchio, F.; Ferrandino, A.; Guidoni, S. Influence of wine-grape skin hardness on the kinetics of anthocyanin extraction. International Journal of Food Properties 2012, 15, 249–261. [Google Scholar] [CrossRef]

- Kalmykova, O.V. Features of the influence of growth regulators on yield and quality of apple fruit in the conditions of the lower Volga region. Ph.D of Thesis, Michurinsk State Agrarian University, Russia, 2015.

- Podvigin, O.; Sylaieva, A.; Sherengovyi, P. The influence of exogenous plant growth regulators there upon the black currant (Ribes nigrum L.) productivity and its berry quality. Bioresources and nature management 2015, 7(1-2), 65-69.

- Paltrinieri, G. Agricultural marketing improvement—Handling of fresh fruits, vegetables and root crops. Food and Agriculture Organization of United Nations 2002, 89. Retrieved November 28, 2020 https://www.fao.org/3/a-au186e.pdf.

- Baeten, J.; Donné, K.; Boedrij, S.; Beckers, W.; Claesen, E. Autonomous fruit picking machine: A robotic apple harvester. Springer Tracts in Advanced Robotics 2008, 42, 531–539. [Google Scholar]

- Pluta, S.; Zurawicz, E.; Krawiec, A.; Salamon, Z. Evaluation of the suitability of polish blackcurrant cultivars for commercial cultivation. Journal of Fruit and Ornamental Plant Research 2008, 16, 153–166. [Google Scholar]

- Gardiner, B.; Berry, P.; Moulia, B. Wind impacts on plant growth, mechanics and damage. Plant science 2016, 245, 94–118. [Google Scholar] [CrossRef] [PubMed]

- Patrick, A.; Li, C. High throughput phenotyping of blueberry bush morphological traits using unmanned aerial systems. Remote Sens. 2017, 9, 1250. [Google Scholar] [CrossRef]

- Mikhailova, N.V. Methods for Evaluating Sea Buckthorn Varieties for Machine Harvesting by Vibration Method: Method. Recom; RIO AGAU: Barnaul, Russia, 2014; p. 15. [Google Scholar]

- Draper, N.R.; Smith, H. Selecting the “best” regression equation, in: chap. 15 in Applied Regression Analysis, 3rd Edn., John Wiley & Sons, Inc., 1998, 327–368. [CrossRef]

| Cultivar | Total yield (t/ha) | Сrop loss (t/ha) | Average crop loss | |||

|---|---|---|---|---|---|---|

| 2021 | 2022 | 2021 | 2022 | t/ha | % | |

| Asya | 19.43 | 15.40 | 1.20 | 1.27 | 1.24 | 7.09 |

| Niva | 10.86 | 7.74 | 1.29 | 1.40 | 1.35 | 14.46 |

| Vika | 19.40 | 15.20 | 1.11 | 1.02 | 1.07 | 6.16 |

| Osipovskaya | 12.00 | 12.80 | 1.71 | 1.70 | 1.71 | 13.75 |

| Parameter | 0-20 сm | 20-40 сm | Notes: |

|---|---|---|---|

| pH | 4.82 | 4.89 | The soil is medium acidic |

| Potassium | 41.75 mg/kg | 12.00 mg/kg | Low content |

| Phosphorus | 65-85 mg/kg | 34-98 mg/kg | Low total content for berry bushes |

| Temperature (° C) | Rain (mm) | ||||

|---|---|---|---|---|---|

| Month/Year | Decade | 2021 | 2022 | 2021 | 2022 |

| May | I D | 10.5 | 9.8 | 29.0 | 8.3 |

| II D | 16.0 | 11.1 | 12.2 | 11.5 | |

| III D | 15.4 | 11.7 | 22.1 | 18.5 | |

| June | I D | 14.2 | 17.9 | 24.1 | 0.0 |

| II D | 19.9 | 19.0 | 28.2 | 17.6 | |

| III D | 24.9 | 20.4 | 47.3 | 25.0 | |

| July | I D | 21.3 | 21.2 | 12.5 | 12.9 |

| II D | 24.5 | 17.5 | 9.4 | 53.9 | |

| III D | 19.6 | 19.2 | 15.9 | 5.1 | |

| August | I D | 21.0 | 20.1 | 2.0 | 17.5 |

| II D | 21.2 | 20.7 | 9.7 | 3.2 | |

| III D | 18.4 | 20.4 | 17.3 | 8.5 | |

| Year | Dates of the experiment | |||||

|---|---|---|---|---|---|---|

| 2021 | July 06 | July 09 | July 12 | July 15 | July 18 | July 21 |

| 2022 | July 13 | July 16 | July 19 | July 22 | July 25 | July 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).