1. Introduction

Pasteurization is a widely employed thermal technique in fruit juice processing, playing a crucial role in ensuring food safety, extending shelf life, and enhancing product stability. However, conventional pasteurization methods such as conduction and convection have notable drawbacks, including non-uniform heat distribution, extended processing times, and degradation of heat-sensitive nutrients. These limitations are particularly problematic in fruit juices, where excessive thermal exposure can lead to significant losses in vitamin C and adversely affect sensory attributes such as taste, color, and aroma, ultimately impacting consumer acceptance [

1,

2,

3]. Consequently, increasing attention has been directed toward alternative heating technologies that can achieve rapid and uniform heat transfer while better preserving product quality [

4].

Ohmic heating is an advanced thermal processing method that uses electric current to generate internal heat uniformly throughout the food matrix. It offers several advantages over conventional systems, including volumetric heating, minimal surface degradation, and improved retention of color, flavor, and antioxidant content [

5]. Extensively applied in liquid and semi-liquid food systems, ohmic heating shows considerable promise for high-quality fruit juice pasteurization [

6]. A key factor influencing the efficiency of ohmic heating is the electrical conductivity (EC) of the food, which is affected by temperature, ionic concentration, viscosity, and composition [

7]. Generally, EC increases with temperature due to enhanced ion mobility and lower viscosity. Its relationship with total soluble solids (TSS) is non-linear, as high TSS levels may reduce EC due to increased viscosity and limited free water.

The Box-Behnken Design (BBD) has emerged as a robust statistical tool for optimizing processing parameters in fruit juice production. By employing three levels for each factor, BBD minimizes the number of experimental runs required while enabling comprehensive analysis of response surfaces [

8]. Its effectiveness has been demonstrated in optimizing various food processes, such as pectin extraction from fruit peels [

9] and improving fermentation conditions in functional beverages [

10]. The interpretability and efficiency of BBD make it a valuable approach for identifying optimal processing conditions that enhance product quality and sustainability in the juice industry [

11].

In addition, recent advancements in electrode plate manufacturing, low-cost fiber optic temperature sensors, and IoT-based control systems have revitalized interest in ohmic heating as a viable pasteurization method for fruit juices and liquid foods [

12]. According to Phonchan et al. [

13] indicate that the efficiency of ohmic pasteurization in maintaining quality of passion fruit juice is mainly affected by pasteurization temperature, holding time, and voltage gradient. This agrees with the observation reported by Priyadarshini et al. [

11]. While different fruit juices, including madan Juice [

13], Carrot Juice [

14] and Mandarin Juice [

15] have been studied for ohmic heating application under some pathogen periods, there is scarcity of data on the passion fruit juice especially with respect to underlying enzymes inactivation mechanisms and shelf-life extension under optimized pasteurization conditions. These constitute the gaps to address in order to make ohmic heating a dependable and cost-effective pasteurization technology of tropical-based high-acid beverages.

Thus, the present study designed to explore the best conditions for pasteurization temperature (75, 85 and 95 °C), holding time (15, 30 and 45s) and voltage gradient (10, 20 and 30 V/cm). According to Phonchan et al. [

12] suggest that the effectiveness of ohmic pasteurization in preserving the quality of passion fruit juice is primarily influenced by pasteurization temperature, holding time, and voltage gradient. This corresponds to the findings presented in the research report by Priyadarshini et al. [

11].

Although ohmic heating has several advantages, limited information is available on its impact on the quality of fruit juice. Assawarachan and Tantikul [

16] studied the electrical conductivity of passion fruit juice and observed that which the highest thermal efficiency pasteurization was achieved under a voltage gradient of 10–30 V/cm. Therefore, the results of that study were taken as a reference to set up testing scope in this work. Thus, in the present study, these conditions optimize temperature (75, 85 and 95 °C), holding time (15, 30 and 45 s) and voltage gradient (10 V/cm, 20 V/cm and 30 V/cm) as obtained through Box–Behnken Design were assessed with their repercussions on total color difference (ΔE), vitamin C content, and system performance coefficient (SPC) being estimated. The best ohmic conditions will be compared with thermal pasteurization to evaluate product quality and stability.

2. Materials and Methods

2.1. Materials

The passion fruit used in this study was developed from the Royal Project Development Center in Mae Hae, Mae Hae District, Chiang Mai Province, Thailand. The juice was filtered and extracted using thoroughly washed fruits. A digital refractometer (Hanna Instruments, HI 96801, Woonsocket, RI, USA) was used to measure total soluble solids (TSS), which first registered at 11.5°Brix.

2.2. Batch Ohmic Heating Unit for Laboratory Pasteurization

2.2.1. System Description

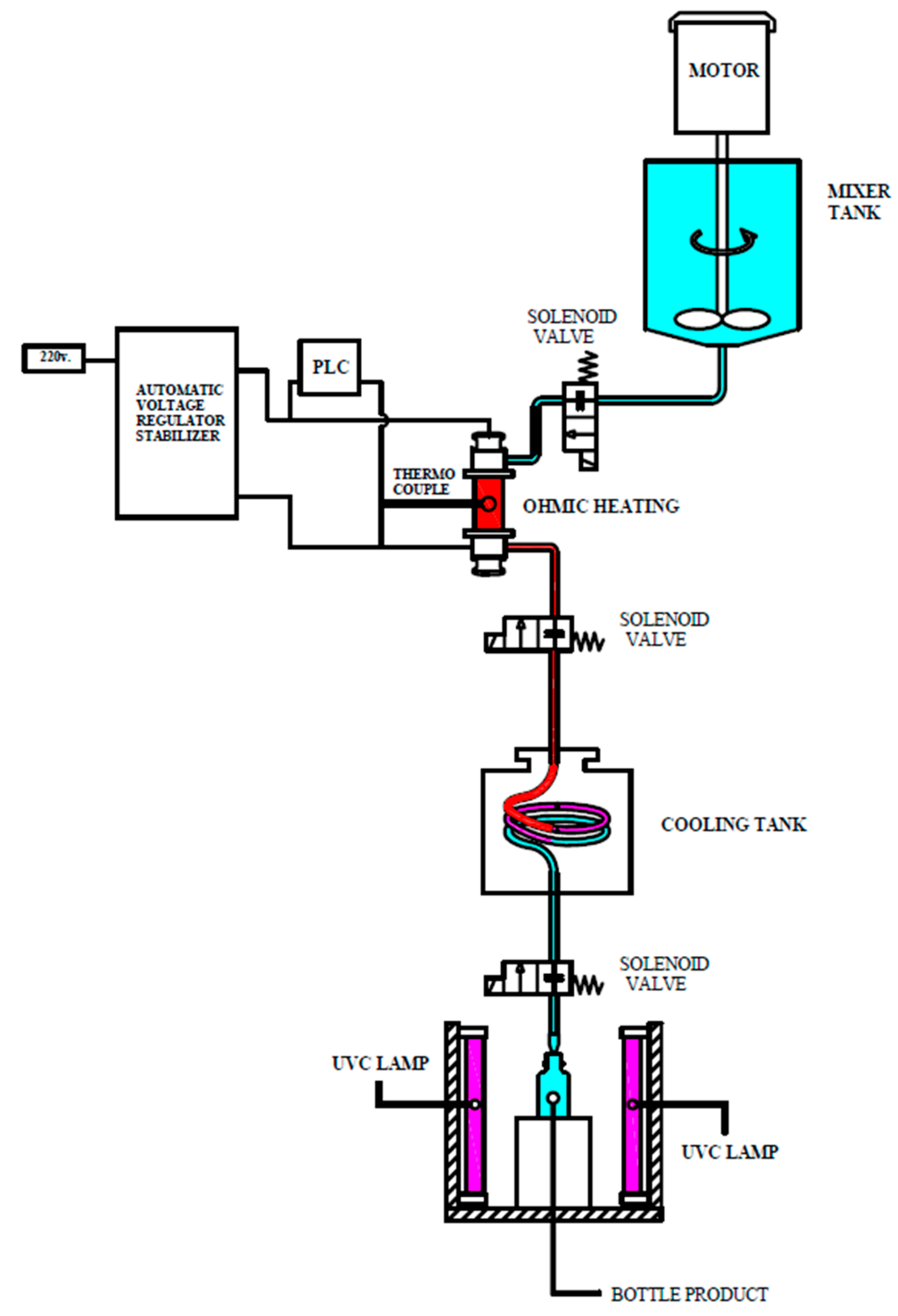

A laboratory-scale Ohmic Heating Pasteurization (OHP) system was developed under the Smart Farm Engineering and Agricultural Innovation Program at the School of Renewable Energy, Maejo University, Thailand, for batch pasteurization of passion fruit juice. The system comprises a 10-liter mixer tank equipped with a mechanical stirrer, a solenoid valve for flow control, and an acrylic OHP chamber (25 mm inner diameter, 10 mm length, 3 mm wall thickness). Three K-type thermocouples are strategically positioned within the chamber to monitor temperature distribution during the ohmic heating process. A programmable logic controller (Haiwell model D7-G, Xiamen, China) records real-time voltage, current, and temperature data at 5 second intervals. After pasteurization, the treated juice flows through a cooling coil, reducing the temperature to 10 °C before being directed into the filling chamber equipped with a UV-C sterilization system. The final product is then packed in glass bottles, which are further sterilized using a steam autoclave at 121 °C for 15 minutes to ensure microbiological safety. This integrated OHP system ensures precise thermal treatment and hygienic packaging, making it suitable for laboratory and pilot-scale applications in the food processing industry.

Figure 1.

The diagram of the Ohmic Heating Pasteurization (OHP) system for passion fruit juice in the laboratory.

Figure 1.

The diagram of the Ohmic Heating Pasteurization (OHP) system for passion fruit juice in the laboratory.

2.2.2. Experimental Operation Procedure

The experimental operation of laboratory-scale ohmic heating pasteurization (OHP) system was performed as follows. The passion fruit juice was added to the mixer tank and stirred mechanically to achieve a homogeneous mixture at an initial temperature of approximately 25 ◦C, valve 1 was opened thereafter, so that a 200 mL portion of the passion fruit juice could flow into the ohmic heating chamber (ohmic cell). The juice was then heated with the required volume up to, when the valve was closed, and the juice was heated under the specified ohmic heating conditions. After heating, the valve system switched automatically opening position and allowed treated juice to flow by gravity into cooling unit, where temperature was cooled down quickly to below 10 °C. Water-ice sludge was also formed inside the bottom part of this cooler. Then chilled juice exited from valve 3 and entered on glass bottles through filling unit. A UV-C sterilization lamp was installed in the filling part to reduce microbial contamination of airborne particles during the packaging. All OHP lines and the process chamber were steam sterilized prior to each run to achieve sterile operation while avoiding carry-over from experiment-to-experiment. Filled juice samples were then refrigerated at 10 °C until further physicochemical and microbiological analysis.

The Ohmic Heating Pasteurization (OHP) principle is based on the generation of internal heat from the conversion of electrical energy, which occurs as an alternating electric current flow through the electrically conductive food matrix. The heat is produced volumetrically by Joule’s law (Q = I²Rt where I is electric current, R the electrical resistance of the product and t heating time). OHP since heating is uniform over the entire volume leading to lower temperature gradients and a reduced thermal inertia compared with conventional surface heating techniques. This volume heating mode can efficiently heat the product and cook it through in both thermal efficiency and quality, without being overcooked around the surface to keep rich nutrients remaining in the bulk. In this study, to achieve uniform energy dissipation and suppress electrochemical corrosion, a low-frequency AC (50 Hz) with stainless steel electrodes was used [

11,

12,

16].

2.3. System Performance Coefficient

To assess the efficiency of the ohmic heating system, the system performance coefficient (SPC) was determined as the ratio of the sensible heat absorbed by the juice to the energy supplied to the system (1). Assuming a constant specific heat within the examined temperature range, SPC was calculated using juice mass (

m), specific heat (C

p), voltage

(V), current (

I), processing time (

t), and temperature difference (

T initial to

T final).

The specific heat capacity (

Cp) of high-moisture foods’ juice above the freezing point can be determined using the Seibel empirical formula, where

Xm denotes the moisture content of the juice [

14,

16].

where

m is the mass of juice (kg),

Cₚ is the specific heat capacity (J·kg⁻¹·°C⁻¹),

T₁ and

Tf are the initial and final temperatures (°C),

V is the applied voltage (V),

I is the electric current (A), and

t is the processing time (s). The SPC is dimensionless and represents the ratio between the sensible heat absorbed by the juice and the total electrical energy supplied to the system.

2.4. Optical Properties

The color of passion fruit juices was measured using a Chroma Meter (CR-400, Konica Minolta, Inc., Tokyo, Japan) in the CIE Lab color space, with calibration performed using a white standard (Y = 93.9, x = 0.3160, y = 0.3323). Measurements were taken under D65 illumination with an 8 mm aperture. The L*, a*, and b* values were recorded from three positions on each sample and averaged. L* indicates lightness, a* redness to greenness, and b* yellowness to blueness. Triplicate samples were analyzed. Color difference (ΔE) from the control was calculated as:

where

L₀*,

a₀*, and

b₀* refer to the values of the control or untreated sample.

2.5. Vitamin C

The ascorbic acid content was determined using a titrimetric method, employing 2,6-dichlorophenol-indophenol (DCPIP) as the oxidizing agent. The juice sample was titrated against a standardized DCPIP solution until a persistent pink endpoint was observed. The ascorbic acid concentration was quantified by comparing the titration results with a calibration curve constructed using L-ascorbic acid as the standard [

11,

13,

15].

2.6. Shelf-Life Estimation

Samples of passion fruit juice, pasteurized using either ohmic heating or conventional heating methods, were stored in ethylene vinyl alcohol (EVOH) bags at a regulated temperature of 8 ± 1 °C. The shelf life of the processed juices was evaluated by examining key microbiological and enzymatic quality indicators at consistent intervals of 7 days. The primary parameters analyzed were total aerobic bacteria (AMB), yeast and mold counts, proxidase (POD) and polyphenol oxidase (PPO) activity. The shelf life was established when the AMB count surpassed 10

3 CFU/mL or the yeast and mold count exceeded 1 CFU/mL, in accordance with the microbiological quality standards for fruit juices as stipulated by Thai safety regulations [

17].

2.7. Enzyme Activity

POD and PPO activities were determined spectrophotometrically or by titration in centrifuged juice supernatants to assess enzyme stability. Activity was expressed as U·min⁻¹·mg⁻¹ protein, with residual activity calculated relative to the untreated control [

18].

2.8. Statistical Evaluation

Design-Expert 13.0 (Stat-Ease Inc., Minneapolis, MN, USA) was used to improve the response surface by applying the Box-Behnken Design (BBD) with three factors: temperature (75, 85, 95 °C), holding time (15, 30, 45 sec), and voltage gradient (10, 20, 30 V/cm), leading to a total of 15 experiments. One-way ANOVA with Tukey’s test (p < 0.05) was used to compare ohmic and conventional pasteurization. Analyses were performed using SPSS 20.0 (IBM Corp., Armonk, NY, USA) under a Maejo University license. Results are presented as mean ± SD.

3. Results

3.1. Effect of Input Variables on the Response Surface

The Box-Behnken Design (BBD) represents an effective statistical approach for optimizing process variables in ohmic pasteurization (OHP), significantly enhancing both microbial safety and processing efficiency through systematic evaluation of interactive effects among critical factors [

17,

18]. Recent applications of similar design methodologies by Sittisart and Mahidsanan [

21] for quality control in juice processing have further validated BBD’s relevance in thermal processing investigations. Additionally, Alifaki and Barut Gök [

22] demonstrated BBD’s robust capability in optimizing combined thermal treatments utilizing ultrasound and ohmic heating technologies in sour cherry juice preservation. Several studies have identified temperature, holding time, and voltage gradient as the principal parameters that significantly influence OHP efficiency; notably, Priyadarshini et al. [

11] established that OHP achieves optimal performance within the temperature range of 75–95 °C, provided that voltage gradients remain below 30 V/cm to prevent electrode degradation and subsequent iron oxide contamination.

In this investigation, BBD methodology was implemented to determine optimal OHP processing conditions by systematically analyzing the effects of three critical parameters: processing temperature (75, 85, 95 °C), holding time (15, 30, 45 sec), and voltage gradient (10, 20, 30 V/cm) on SPC, ΔE, and vitamin C retention, as presented in

Table 1.

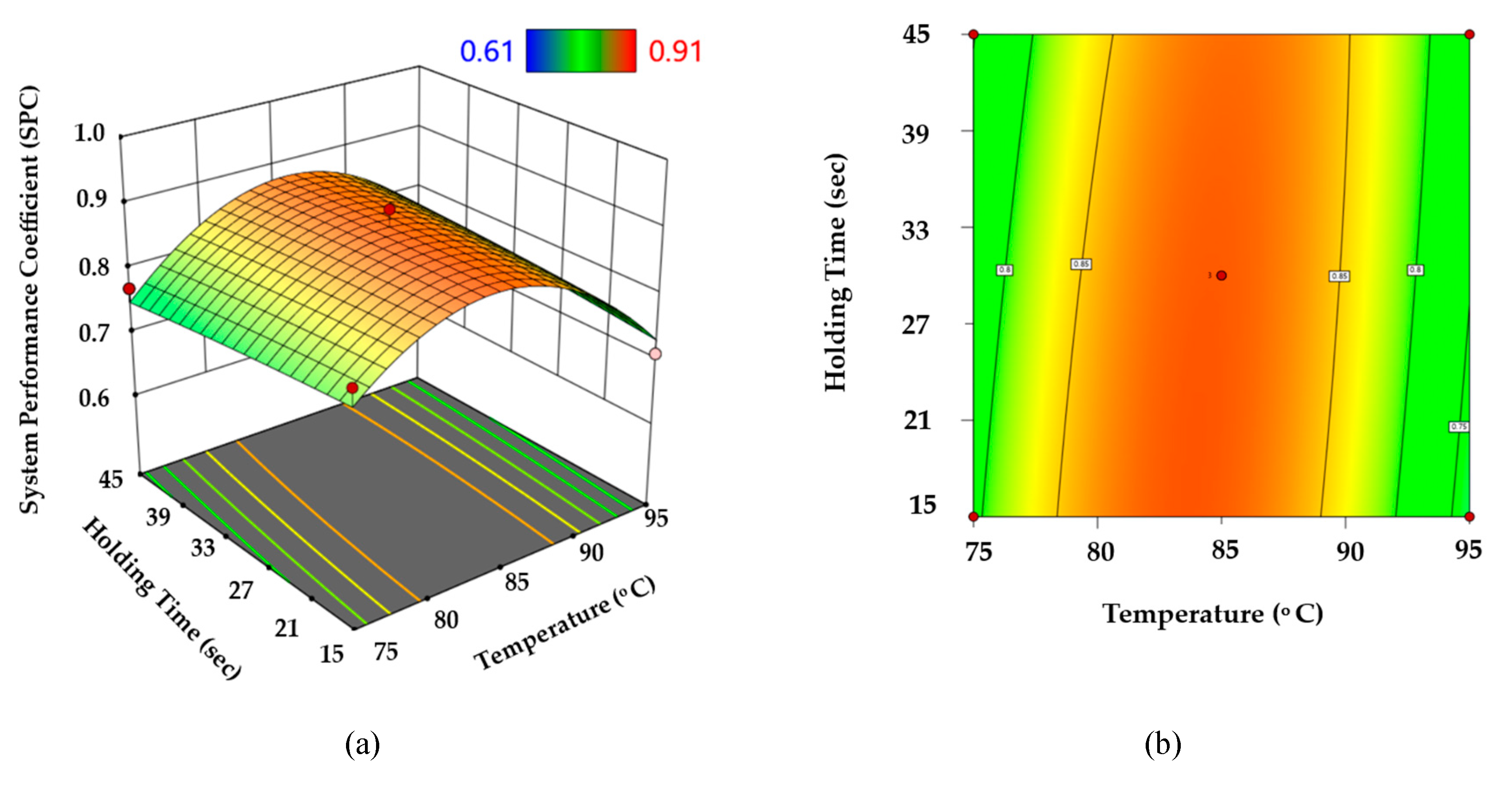

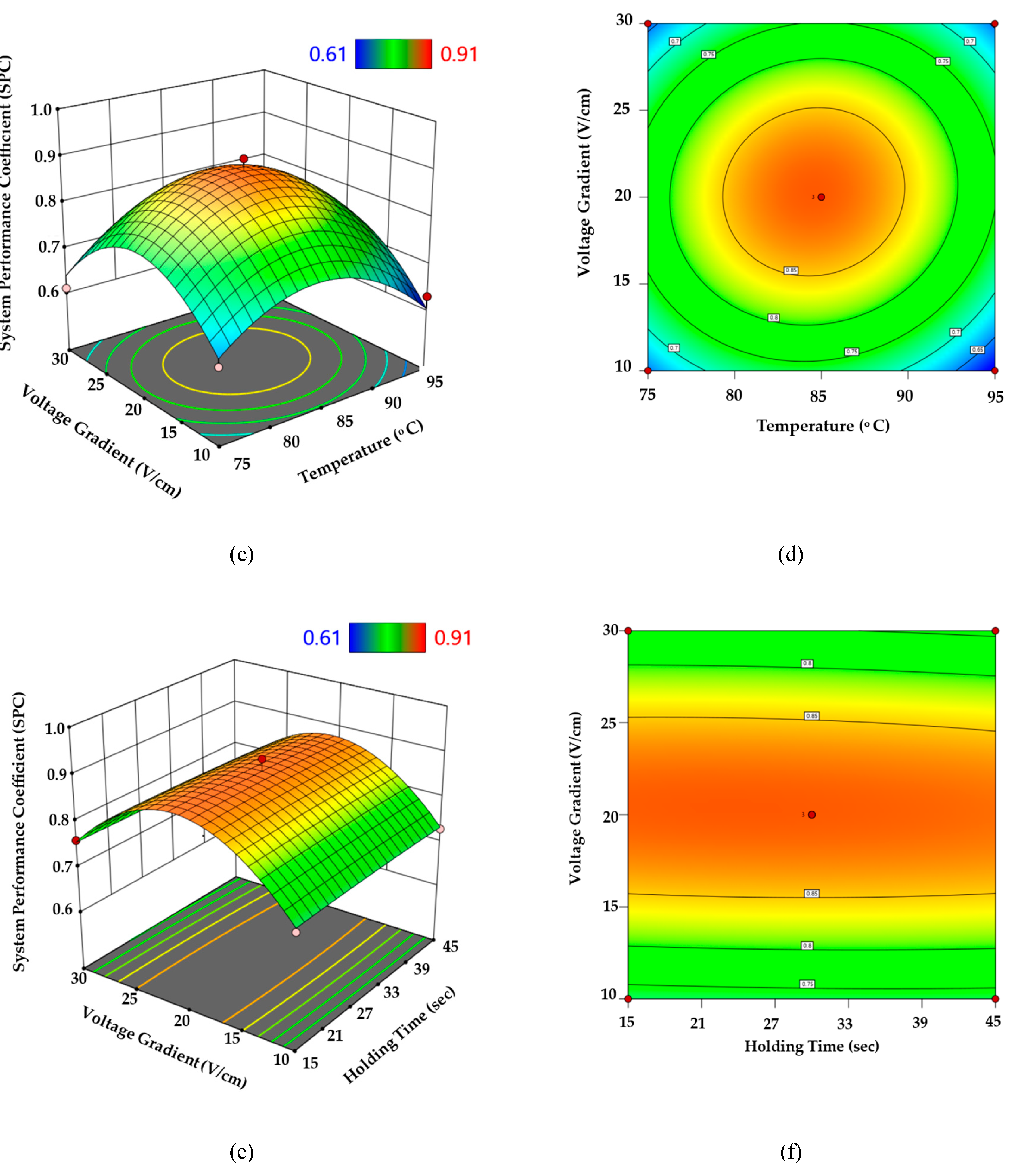

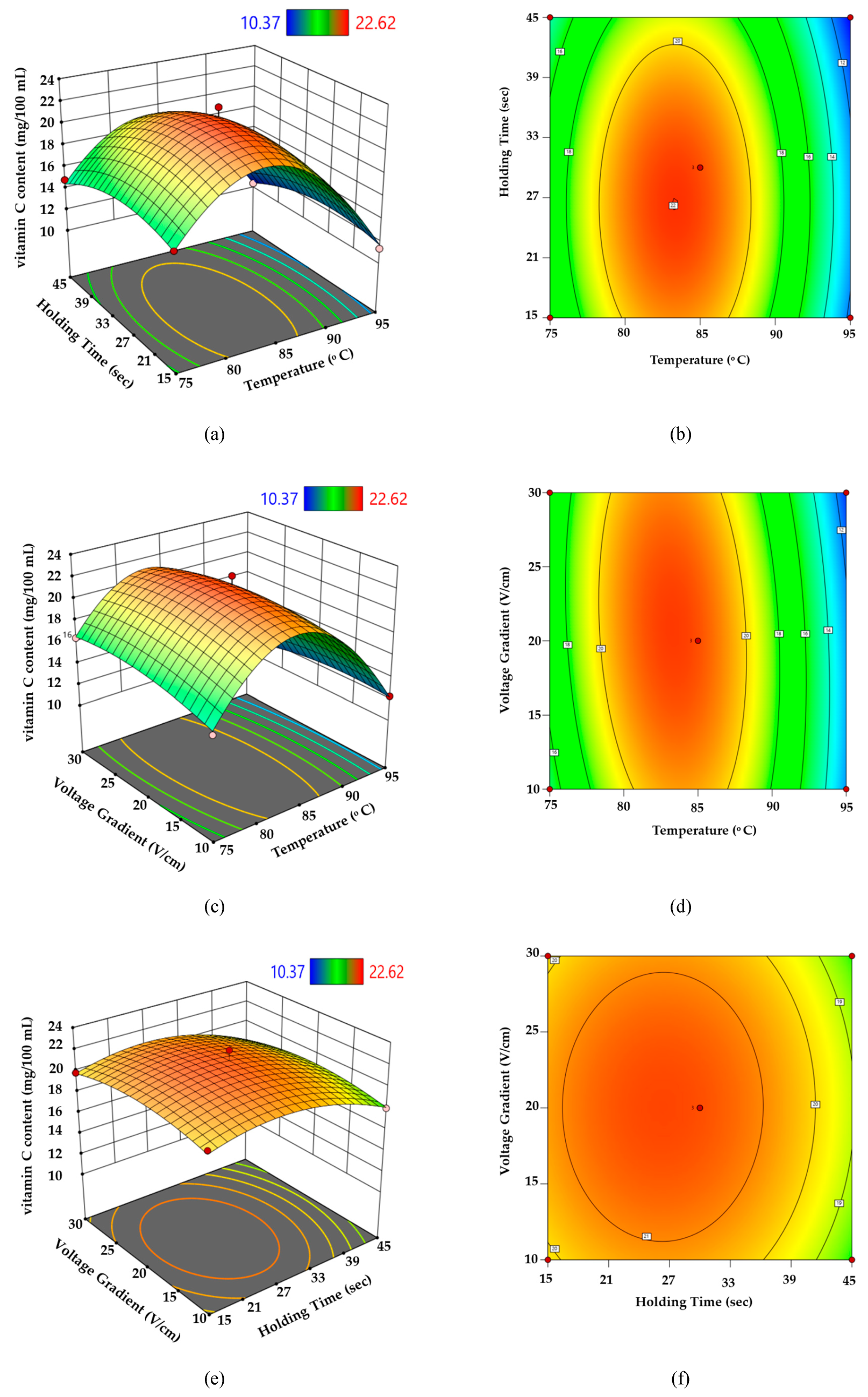

The research aimed primarily to maximize both SPC and vitamin C preservation while simultaneously minimizing ΔE values. Response surface methodology and corresponding contour plots (

Figure 2,

Figure 3 and

Figure 4) effectively illustrated the comprehensive influence of these parameters on quality indicators, revealing that SPC, ΔE, and vitamin C content ranged from 0.61 to 0.91, 6.21 to 14.65, and 10.37 to 22.62 mg/100 mL, respectively. The developed multi-response optimization model demonstrated statistically reliable results with high coefficient of determination values, confirming its suitability for quadratic regression analysis and subsequent process optimization.

Figure 2,

Figure 3 and

Figure 4 illustrate the relationships between responses and input variables by varying two variables while maintaining the third at optimized levels [

22,

23]. The System Performance Coefficient (SPC), defined as the ratio of heat absorbed to electrical energy input, serves as an indicator of thermal efficiency in ohmic pasteurization (OHP). Low voltage gradients lead to prolonged come-up times, resulting in energy losses and reduced SPC. Conversely, increasing voltage enhances heat transfer and SPC until the system reaches thermal equilibrium. However, excessive voltage gradient can diminish SPC due to electrochemical reactions, gas bubbles disrupting conductivity, and electrode corrosion. Achieving an optimal SPC requires careful balancing of these factors [

11,

16].

Prolonged heat loss to the environment extends the time required to reach thermal equilibrium within the system. As conductivity increases with rising temperature, heat transfer efficiency decreases, leading to energy loss through evaporation, structural changes, and the formation of oxygen bubbles. This phenomenon reduces the contact area between the liquid and electrodes, further exacerbating energy losses. The influence of holding time on the system is considered an ancillary factor, as depicted in

Figure 2.

The study investigated the effects of passion fruit juice input variables on vitamin C content and total color differences (ΔE).

Figure 3 and

Figure 4 illustrate the relationship between these responses and input variables using response surface analysis. The results indicated that temperature and holding time significantly influenced vitamin C content and ΔE, while the voltage gradient did not have a substantial impact on these parameters. These findings align with recent studies that have explored the effectiveness of Ohmic Heating Pasteurization (OHP) in preserving food nutrients, with a particular focus on ascorbic acid degradation and color changes. Basak et al. [

15] examined the impact of OHP on mandarin juice and observed significant nutrient retention at lower processing temperatures. Similarly, Kumar et al. [

19] emphasized the importance of maintenance times when treating pineapple juice, noting that shorter holding times resulted in better nutrient preservation. Furthermore, Giuliangeli et al. [

20] confirmed that optimized ohmic conditions minimize color degradation and ascorbic acid loss in various fruit juices.

The present study’s results, in conjunction with the existing literature, demonstrate that carefully controlled temperature and holding time are crucial factors in maintaining the nutritional quality and visual appeal of passion fruit juice during OHP. While voltage gradient played a less significant role in this context, it remains an essential parameter for optimizing the overall efficiency of the OHP process, as discussed in the previous section.

3.2. Analysis of Optimal Conditions for Ohmic Pasteurization

Identifying optimal processing conditions is essential for enhancing efficiency while maintaining the nutritional and sensory attributes of fruit juices. This section identifies the optimal parameters for ohmic pasteurization that concurrently improve vitamin C retention, reduce total color difference (ΔE), and maximize the system performance coefficient (SPC), following the assessment of input variable effects through response surface methodology (Section 3.1).

A multi-objective optimization utilizing the desirability function approach was performed to attain the optimal compromise among the three responses. Optimal conditions were obtained from predictive models created by quadratic regression analysis and confirmed through experimental trials. The optimized parameters seek to achieve efficient microbial inactivation while reducing energy losses and preserving quality. This section delineates the numerical optimization outcomes, encompassing the amalgamation of temperature, holding duration, and voltage gradient that produced the highest overall desirability index. The anticipated values of the three primary responses under these conditions are juxtaposed with actual experimental values to validate model adequacy and practical feasibility.

Selecting an appropriate experimental design is crucial for constructing a mathematical model to analyze responses during process optimization using Response Surface Methodology (RSM). For systems exhibiting non-linear behavior or curvature, a second-order model incorporating linear, quadratic, and interaction terms is necessary to accurately describe the system’s response.

The Box–Behnken design was chosen for this study due to its efficiency in reducing experimental runs while providing sufficient data to estimate the parameters of the second-order model effectively. This design facilitates the evaluation of main effects, quadratic effects, and two-factor interactions, as represented in Equation (4), enabling the identification of critical points and accurate prediction of outcomes under various experimental conditions [

22].

where β

0, is the constant term β

ii represents the coefficients of the quadratic parameter,

Xi ,Xj represents the variables, and ε is the residual associated to the experiments.

Identifying critical points in non-linear systems requires a second-order polynomial equation derived from experimental data. Setting the first derivative of the predictive model to zero yields the independent variable values that result in maximum or minimum response levels. The critical point’s nature (maximum, minimum, or saddle point) is evaluated using matrix techniques and eigenvalue analysis for accurate classification.

Second-order polynomial equations were developed to predict key response variables: system performance coefficient (SPC), vitamin C content, and total color difference (ΔE). Optimization goals were defined to maximize SPC and vitamin C while minimizing ΔE, reflecting optimal juice quality preservation. Equations

(5)–(7) present the resulting predictive models and optimal conditions.

X1 represents Temperature (°C), X2 denotes Holding Time (seconds), and X3 indicates Voltage Gradient (V/cm).

Numerical analysis was performed utilizing Design-Expert® version 13.0 to assess the impact of key ohmic heating process (OHP) parameters specifically, temperature, holding time, and voltage gradient on system performance and thermal treatment efficacy. The optimization objectives, as outlined in Table 2, sought to enhance thermal uniformity and microbial inactivation capacity while reducing quality deterioration. The analysis determined optimal process conditions within these ranges: temperature between 81.14 and 83.29 °C, holding time between 19.76 and 28.09 seconds, and voltage gradient between 14.82 and 21.09 V/cm. These ranges indicate the equilibrium between obtaining adequate ohmic heating energy input and maintaining product quality, especially regarding nutrient retention and color stability.

Table 2.

Optimized Ohmic Heating Conditions Based on Numerical Analysis of SPC, ΔE, and Vitamin C Retention.

Table 2.

Optimized Ohmic Heating Conditions Based on Numerical Analysis of SPC, ΔE, and Vitamin C Retention.

| |

Optimization |

Numerical Results |

| |

Goals |

Temperature ( oC) |

Holding Time (sec) |

Voltage Gradient (V/cm) |

| SPC |

maximize |

81.14 |

19.76 |

19.78 |

| ΔE |

minimize |

83.35 |

28.09 |

14.82 |

| vitamin C (mg/100 mL) |

maximize |

83.29 |

26.53 |

21.09 |

To ensure practical applicability under real-world processing conditions, the mean values of the optimal ranges were selected and slightly adjusted to account for expected thermal inertia and equipment limitations in pilot-scale operations. Consequently, the chosen parameters for the experimental validation of the Ohmic Heating Pasteurization (OHP) system were a temperature of 82.5 °C, a holding time of 25 seconds, and a voltage gradient of 18.5 V/cm. These settings were proposed to achieve effective pasteurization while minimizing thermal degradation, thus ensuring microbial safety and preserving product quality.

Table 3 compares the predicted values from the mathematical models with the actual experimental results for the OHP parameters. No statistically significant differences were observed (p > 0.05), verifying the predictive accuracy of the developed models. The validated mathematical model allowed for the precise determination of optimal conditions for the pasteurization process.

3.3. Comparison of Ohmic and Conventional Pasteurization on Quality and Shelf Life

After determining the optimal conditions for Ohmic Heating Pasteurization (OHP), researchers conducted a comparative study to evaluate the quality and shelf life of passion fruit juice processed using OHP and conventional thermal pasteurization. The purpose of this comparison was to validate the practical benefits of OHP in real processing scenarios. The study focused on key quality indicators such as vitamin C retention, color stability (measured by ΔE), and system performance coefficient (SPC). As summarized in

Table 4, the OHP-treated passion fruit juice exhibited superior physicochemical attributes and extended shelf life under refrigerated storage conditions compared to conventionally pasteurized juice. These findings support the potential of OHP as a more effective and energy-efficient alternative to traditional thermal pasteurization techniques for passion fruit juice processing.

As shown in

Table 4, the pH of passion fruit juice decreased across all processing methods, with values of 3.72 ± 0.12 for fresh juice, 3.54 ± 0.08 for conventional pasteurization, and 3.32 ± 0.12 for ohmic heating pasteurization (OHP). The reduction observed in the OHP-treated sample was statistically significant (

p < 0.05) compared to both fresh and conventionally pasteurized juices, suggesting that OHP induces a more pronounced acidification effect. This phenomenon may be attributed to electrochemical reactions, such as hydrolysis and ion release, occurring during exposure to high-temperature electric fields [

24,

25]. In contrast to the pH decrease, both pasteurization methods resulted in a slight increase in total soluble solids (%TSS) due to partial water evaporation during the heating process. The %TSS values were 14.2 ± 0.3 for fresh juice, 15.1 ± 0.2 for conventionally pasteurized juice, and 15.4 ± 0.4 for OHP-treated juice (

Table 4). The increase in %TSS was more pronounced in the OHP sample compared to the conventionally pasteurized one, although the difference was not statistically significant (

p > 0.05). This finding suggests that OHP may induce a higher degree of water loss, possibly due to the combined effects of heating and electroporation on cell membranes. Similar trends of %TSS increase after OHP treatment have been observed in other fruit juices, such as orange juice [

26].

Ohmic Heating Pasteurization (OHP) offers clear benefits over conventional methods in microbial control, nutrient retention, and sensory quality. It reduces microbial loads effectively while preserving heat-sensitive compounds [

24]. In contrast, traditional pasteurization often causes nutrient degradation and alters sensory attributes [

25]. Basak et al. [

15] reported a 42-day shelf life for OHP-treated mandarin juice, while this study achieved 63 days in passion fruit juice. The improved outcome may result from optimized parameters, fruit matrix differences, and rapid thermal shock cooling. Priyadarshini et al. [

11] found similar results in mango pulp. OHP at 75 °C, 19.5 V/cm, and 10 °Brix reduced microbial counts and preserved ascorbic acid at 129.39 mg/100 g dry matter.

The residual activities of POD and PPO were significantly reduced after OHP treatment, with only 8.4% and 12.6% remaining, respectively. In contrast, conventional pasteurization retained 32.5% and 48.7% of POD and PPO activity, respectively (

Table 4). These results confirm the superior enzyme inactivation capability of OHP, contributing to the extended shelf life and color stability of the juice. Alifakı and Barut Gök [

22] showed that combining ultrasound with ohmic heating improved microbial inactivation in sour cherry juice using lower temperatures. This hybrid approach shows potential for enhancing juice quality while minimizing thermal damage. Taken together, studies across passion fruit, mandarin, mango, and sour cherry confirm OHP’s versatility. It enables safer, longer-lasting, and higher-quality fruit juice products with greater energy efficiency.

4. Discussion

The current study has proven that OHP which involving Ohmic Heating Pasteurization (OHP) is applicable to improve the quality and shelf life of passion fruit juice. The optimized conditions for the product obtained by using Box–Behnken Design (82.5 °C, 25 sec and 18.5 V/cm) were found to improve performance of the product by retaining higher vitamin C contents, decreasing total color difference (ΔE), and increasing System Performance Coefficient (SPC). The juice was significantly better in color stability, nutrient retention and shelf life than the conventional pasteurized foods. These advances demonstrate OHP to be a technologically feasible alternative technology to conventional pasteurization systems in high-acid fruit beverages. The better retention of vitamin C and visual appearance by OHP-treated samples is due to volumetric heating nature of ohmic processing. Because of this, heat is evenly produced throughout the juice matrix by electrical current flow and there are no temperature gradients typically characteristic of surface-heating systems. This fast, even internal heating results in less time at high temperatures, which suppresses oxidative degradation and non-enzymatic browning. The profound inactivation of peroxidase (POD) and polyphenol oxidase (PPO) also shows that OHP could cause the enzyme denaturation via both thermal-denatured and electroporation effects, contributing to higher color retention as well as better storage stability.

The higher SPC revealed in this study indicates the energy used by OHP is highly efficient. Electrical energy is transformed directly into internal heat and this minimizes the loss of heat to the surround. The excellent agreement between theoretical and experimental SPC values suggests that the ohmic heating model proposed here is capable of successfully describing the energy dynamics of the system. Box–Behnken Design allowed optimization of the critical parameters (temperature, voltage gradient and holding time) for striking a balance between microbial inactivation and product quality. This optimization it is in agreement with previously reported results on mandarin, carrot and mango juices, where OHP resulted up to 5 fold better energy efficiency plus higher nutrient retention than traditional preservation methods [

11,

14,

15,

19,

20]. The decrease in pH and slight increase in total soluble solids of juice OHP-treated are typical from mild electrochemical reactions and controlled evaporation when processing is an at-hand behaviour. However, such modifications did not result in reduced product acceptability and may contribute to the enhancement of microbiological safety as a consequence of increased acidity. The considerable reduction of residual enzyme activity (POD and PPO less than 15%) compared with conventional pasteurization (approximatly 30–50%), indicates that OHP does not only allow for rapid heating, but may enhance protein structural change of enzymes by electric fields-protein molecule interation. From the viewpoint of process engineering, the optimized OHP system reveals that it is technically feasible and industrially applicable. The combined operation of real-time monitoring, automatic flow control and energy statistics into the system creates a sound platform for scaling up to continuous-flow operation. This study shows that microbial safety can be ensured in the OHP system to a level similar to that achieved by classic pasteurization but with reduced energy input and better product quality. OHP is a trustworthy and eco-sustainable processing technology for high-acid drinks, especially if color and vitamin C retention are the most important quality parameters. In the outlook perspective, Ohmic Heating Pasteurization might be considered a source platform between present and future high efficiency pasteurization technologies that will replace thermal ones. Classical pasteurization methods are limited in terms of slow heat transfer and non-uniform temperature distribution resulting to degradation fruit juice quality. In future on the contrary, ohmic-based systems coupled with sophisticated process control, in-line monitoring and adaptive data algorithms, would enable accurate thermal delivery, localized enzyme inactivation and efficient energy use. These advances will revolutionize juice pasteurization, transcending thermal constraints of current systems, all the while delivering better tasting/juicier products with higher nutritional quality.

5. Conclusions

This research demonstrates the efficacy of the Box–Behnken Design as a robust tool for optimizing Ohmic Heating Pasteurization (OHP) conditions. The identified optimal parameters (82.5 °C, 25 s, 18.5 V/cm) effectively preserve key quality attributes of passion fruit juice, such as vitamin C content and color, while ensuring sufficient microbial reduction. Compared to conventional thermal pasteurization, OHP-treated juice exhibits improved energy efficiency and significantly extended shelf life due to the absence of heat transfer limitations. These results highlight OHP as a promising and sustainable alternative to traditional methods, offering an innovative approach to thermal processing in the fruit juice industry. The outcomes provide a foundation for future advancements in pasteurization technologies aimed at enhancing product quality and energy efficiency.

Author Contributions

Conceptualization, Thitiphan Chimsook and Rittichai Assawarachan; methodology, Rittichai Assawarachan; software, Rittichai Assawarachan; validation, Rittichai Assawarachan; formal analysis, Thitiphan Chimsook and Rittichai Assawarachan; investigation, Rittichai Assawarachan; resources, Thitiphan Chimsook and Rittichai Assawarachan; data curation, Thitiphan Chimsook and Rittichai Assawarachan; writing—original draft preparation, Rittichai Assawarachan; writing review and editing, Rittichai Assawarachan; visualization, Rittichai Assawarachan; supervision, Rittichai Assawarachan; project administration, Rittichai Assawarachan; funding acquisition, Rittichai Assawarachan. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors express their gratitude to the Mae Hae Royal Project Development Center in Chiang Mai, Thailand, for supplying the organic passion fruit utilized in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mandha, J.; Shumoy, H.; Matemu, A.O.; Raes, K. Characterization of fruit juices and effect of pasteurization and storage conditions on their microbial, physicochemical, and nutritional quality. Food Bioscience 2023, 51, 102335, https://www.sciencedirect.com/science/article/pii/S2212429222007945. [Google Scholar] [CrossRef]

- Song, Q.; Rune, C.J.B.; Thybo, A.K.; Clausen, M.P.; Orlien, V.; Giacalone, D. Sensory quality and consumer perception of high pressure processed orange juice and apple juice. LWT 2023, 173, 114303, https://www.sciencedirect.com/science/article/pii/S0023643822012385. [Google Scholar] [CrossRef]

- Martins, I.B.A.; de Souza, C.R.; de Alcantara, M.; Rosenthal, A.; Ares, G.; Deliza, R. How are the sensory properties perceived by consumers? A case study with pressurized tropical mixed juice. Food Research International 2022, 152, 110940, https://www.sciencedirect.com/science/article/pii/S0963996921008401. [Google Scholar] [PubMed]

- Melios, S.; Stramarkou, M.; Grasso, S. Innovations in food processing: A review on the consumer perception of non-thermal technologies. LWT 2025, 117688. https://www.sciencedirect.com/science/article/pii/S002364382500372X. [Google Scholar] [CrossRef]

- Pereira, R.N.; Vicente, A.A. Environmental impact of novel thermal and non-thermal technologies in food processing. Food Research International 2010, 43, 1936–1943. [Google Scholar] [CrossRef]

- Darvishi, H.; Khostaghaza, M.H.; Najafi, G. Ohmic heating of pomegranate juice: Electrical conductivity and pH change. Journal of the Saudi Society of Agricultural Sciences 2013, 12, 101–108. [Google Scholar] [CrossRef]

- Icier, F.; Ilicali, C. Temperature dependent electrical conductivities of fruit purees during ohmic heating. Food Research International 2005, 38, 1135–1142. [Google Scholar] [CrossRef]

- Szpisják-Gulyás, N.; Al-Tayawi, A.N.; Horváth, Z.H.; László, Z.; Kertész, S.; Hodúr, C. Methods for experimental design, central composite design and the Box–Behnken design, to optimise operational parameters: A review. Acta Alimentaria 2023, 52, 521–537, https://akjournals.com/view/journals/066/aop/article-10.1556-066.2023.00235/article-10.1556-066.2023.00235.xml. [Google Scholar] [CrossRef]

- THUY, N. M. , TIEN, V. Q., GIAU, T. N., Van HAO, H., Van THANH, N., THANH, N. N.,... & MINH, V. Q. Box–Behnken design to determine optimal fermentation conditions for apple-fortified mulberry wine using Saccharomyces bayanus. Food Science and Technology 2023, 43. https://fst.emnuvens.com.br/revista/article/view/36. [Google Scholar]

- Haque, S.M. Application of combined Box–Behnken design with response surface methodology and desirability function in optimizing pectin extraction from fruit peels. Journal of the Science of Food and Agriculture 2024, 104, 149–173, https://scijournals.onlinelibrary.wiley.com/doi/abs/10.1002/jsfa.12925. [Google Scholar] [CrossRef]

- Priyadarshini, A.; Rayaguru, K.; Bal, L.M.; Jena, D.; Lenka, C.; Pradhan, S. Optimization of the Ohmic Heating Parameters for Pasteurization of Mango Pulp Using Response Surface Methodology. J. Sci. Ind. Res. 2022, 81, 1087–1097. [Google Scholar] [CrossRef]

- Phonchan, V.; Duangjai, N.; Thakhamsuk, K.; Jaisue, S. (2025). Effect of temperature on electrical conductivities of passionfruit (Passiflora laurifolia Linn.) purees during ohmic heating (Unpublished undergraduate thesis). Bachelor of Engineering Program in Smart Farm and Agricultural Innovation, School of Renewable Energy, Maejo University. 81 pages.

- Khuenpet, K.; Jittanit, W. The Effects of Pasteurization by Conventional and Ohmic Heating Methods and Concentration Processes on the Madan (Garcinia schomburgkiana Pierre) Juice Properties. Appl. Eng. Agric. 2020, 36, 205–219, Available online: https://elibrary.asabe.org/abstract.asp?aid=51187. [Google Scholar] [CrossRef]

- Rodríguez, L.M.N.; Arias, R.; Soteras, T.; Sancho, A.; Pesquero, N.; Rossetti, L.; Szerman, N. Comparison of the Quality Attributes of Carrot Juice Pasteurized by Ohmic Heating and Conventional Heat Treatment. LWT 2021, 145, 111255, Available online: https://www.sciencedirect.com/science/article/pii/S0023643821004084. [Google Scholar] [CrossRef]

- Basak, S.; Thakur, P.; Chakraborty, S. Pasteurization of Mandarin Juice by Ohmic Heating and Evaluation of Its Shelf-Life under Refrigerated and Ambient Conditions. Sustain. Food Technol. 2025, 3, 239–252. Available online: https://pubs.rsc.org/en/content/articlehtml/2025/fb/d4fb00267a (accessed on 4 November 2025). [CrossRef]

- Assawarachan, R.; Tantikul, S. Modeling the effects of temperature and total soluble solids on electrical conductivity of passion fruit juice during ohmic heating. Processes 2025, 13, 1324. [Google Scholar] [CrossRef]

- Ministry of Public Health (Thailand). Notification of the Ministry of Public Health No. 356 B.E. 2556 (2013): Beverages in Sealed Containers. Royal Thai Government Gazette, Special Volume 130, Section 87 Ngor, 24 July 2013. Available online: https://food.fda.moph.go.th/media.php?id=509377822071070720&name=P356_E.pdf (accessed on 4 May 2025).

- Kaur, M.; Kumar, S.; Samota, M.K.; Lalremmawii. Ohmic heating technology systems, factors governing efficiency and its application to inactivation of pathogenic microbial, enzyme inactivation, and extraction of juice, oil, and bioactive compounds in the food sector. . Food and Bioprocess Technology 2024, 17, 299–324, https://link.springer.com/article/10.1007/s11947-023-03126-w. [Google Scholar] [CrossRef]

- Kumar, A.; Mahboob, M.R.; Srivastava, B. Continuous Ohmic Heating Assisted Isothermal Treatment of Standardized Pineapple Juice: Its Effect on Bromelain Inactivation, Vitamin C Degradation, and Their Kinetic Modeling. Journal of Food Process Engineering 2025, 48, e70093, https://onlinelibrary.wiley.com/doi/abs/10.1111/jfpe.70093. [Google Scholar] [CrossRef]

- Giuliangeli, V.C.; Ströher, G.R.; Shirai, M.A. Comparison of energy consumption, color, ascorbic acid and carotenoid degradation in guava (Psidium guajava) pulp during conventional and ohmic heating. Journal of Food Science and Technology 2023, 60, 222–232, https://link.springer.com/article/10.1007/s13197-022-05607-w. [Google Scholar] [CrossRef]

- Sittisart, P.; Mahidsanan, T. Combined treatments of benzoic acid and pasteurization factors for controlling microbiological and physico-chemical quality in asparagus stalk juice using response surface methodology. Cogent Food & Agriculture 2024, 10, 2368262, https://www.tandfonline.com/doi/abs/10.1080/23311932.2024.2368262. [Google Scholar] [CrossRef]

- Alifakı, Y.Ö.; Barut Gök, S. Optimization of minimal thermal treatment conditions for sour cherry (Prunus cerasus L.) juice using ultrasound-ohmic combination treatment. Journal of Food Safety 2024, 44, e13111, https://onlinelibrary.wiley.com/doi/abs/10.1111/jfs.13111. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response Surface Methodology (RSM) as a Tool for Optimization in Analytical Chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Darvishi, H.; Khostaghaza, M.H.; Najafi, G. Ohmic heating of pomegranate juice: Electrical conductivity and pH change. Journal of the Saudi Society of Agricultural Sciences 2013, 12, 101–108. [Google Scholar] [CrossRef]

- Negri Rodríguez, L.M.; de Oliveira, R.C.; Funcia, E.S.; Gut, J.A.W.; Tadini, C.C. Ohmic heating assisted pasteurization of carrot juice: Effects on microbiological, physicochemical, and enzymatic properties. LWT 2021, 142, 111004. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. Optimization of ohmic heating applications for pectin methylesterase inactivation in orange juice. Journal of Food Science and Technology 2014, 51, 1817–1826. [Google Scholar] [CrossRef]

- Sain, M.; Minz, P.S.; John, H.; Singh, A. Effect of Ohmic Heating on Food Products: An In-Depth Review Approach Associated with Quality Attributes. Journal of Food Processing and Preservation 2024, 2024, 2025937, https://ifst.onlinelibrary.wiley.com/doi/abs/10.1155/2024/2025937. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).