2. Improvement Variant One

As shown in the introduction some types of KY converters have a linear voltage transformation ratio and a phase-minimum behavior. All of them have, however, a large current spike, when the intermediate capacitor (or capacitors) are recharged which stresses the components and can cause electromagnetic compatibility problems. This recharging also influences the efficiency of the converter.

In the converter types 2, 4 the capacitor is charged to the input voltage in mode M1, in type 3 the capacitor is charged to the output voltage, in type 4 both intermediate capacitors are charged to the input voltage. In the converters type 1, 5, 6 the recharging of the capacitor happens during mode M2. The intermediate capacitor is discharged by the value Δu during the respective other mode.

Now we study the current peak which occurs during the recharging of C1. All parasitic resistors (the series resistor of the capacitor, the differential resistor of the diode, the drain-source on-resistor of the switch, the resistor of the wiring) are summed up into R. The diode is modelled by a constant forward voltage VD and the differential resistor RD. At the end of mode M2 the capacitor is discharged to the value U1−ΔU

C1. With Kirchhoff’s voltage law (KVL) one can write with the stable input voltage U1

Solving the integral equation (e.g. with the help of the Laplace calculus) leads to

The current to recharge the capacitor C1 is a large spike The voltage across C1 decreases during the first mode M1 and is always lower than the input voltage. This is caused by the forward voltage of the diode D1. The current through L1 is nearly triangular and the ripple is influenced by the value of the inductor, the input and the output voltages, and the switching frequency. To reduce the ripple a larger inductor is necessary or/and the switching frequency must be increased.

The peak current depends on the loss of the voltage during M2 and on the parasitic resistor. The time constant is the product of the resistor and the value of the capacitor. The current peak leads to loss across the resistor. The energy which is transformed into heat is the integral of the product between the current and the voltage across the resistor. When the on-time of the switch is five times or more longer, one can integrate with practically no error until infinity. So one gets for the energy which is dissipated

Multiplying the energy with the switching frequency leads to the power loss caused by the recharge of the capacitor C1

The most interesting fact is that the value of the resistor R is not of importance. The best (or even ideal) components do not reduce this loss! On the other side it is possible to insert a resistor to reduce the peak current without increasing the losses.

2.1. KY Converter

Adding an additional resistor in the loop does not reduce the efficiency, the losses are not increased, but the peak recharging current is reduced. There are four possibilities to insert the resistor (

Table 1).

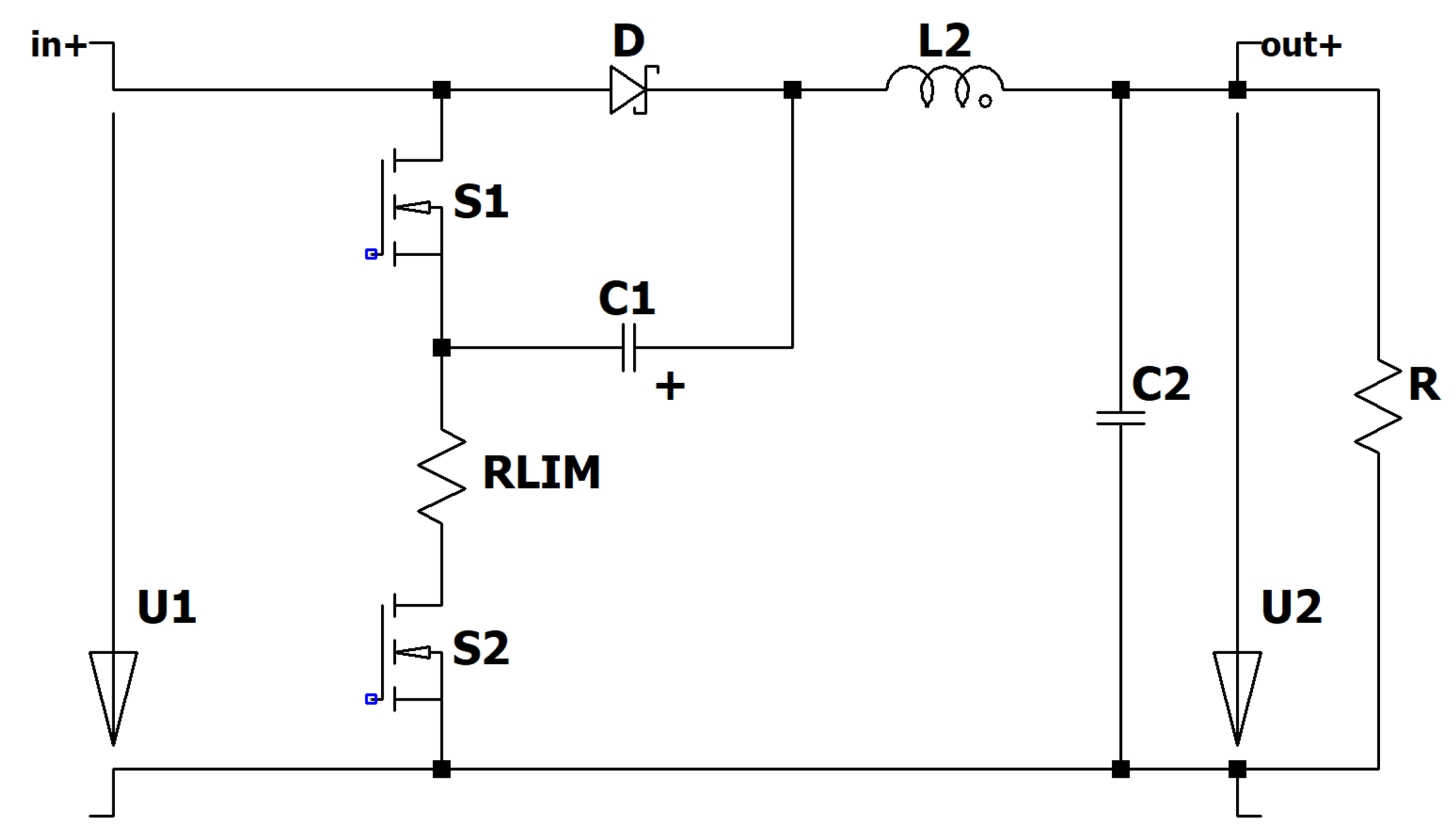

We insert the additional resistor in series to S2, because only the recharging current flows through it. Due to the load current no losses occur.

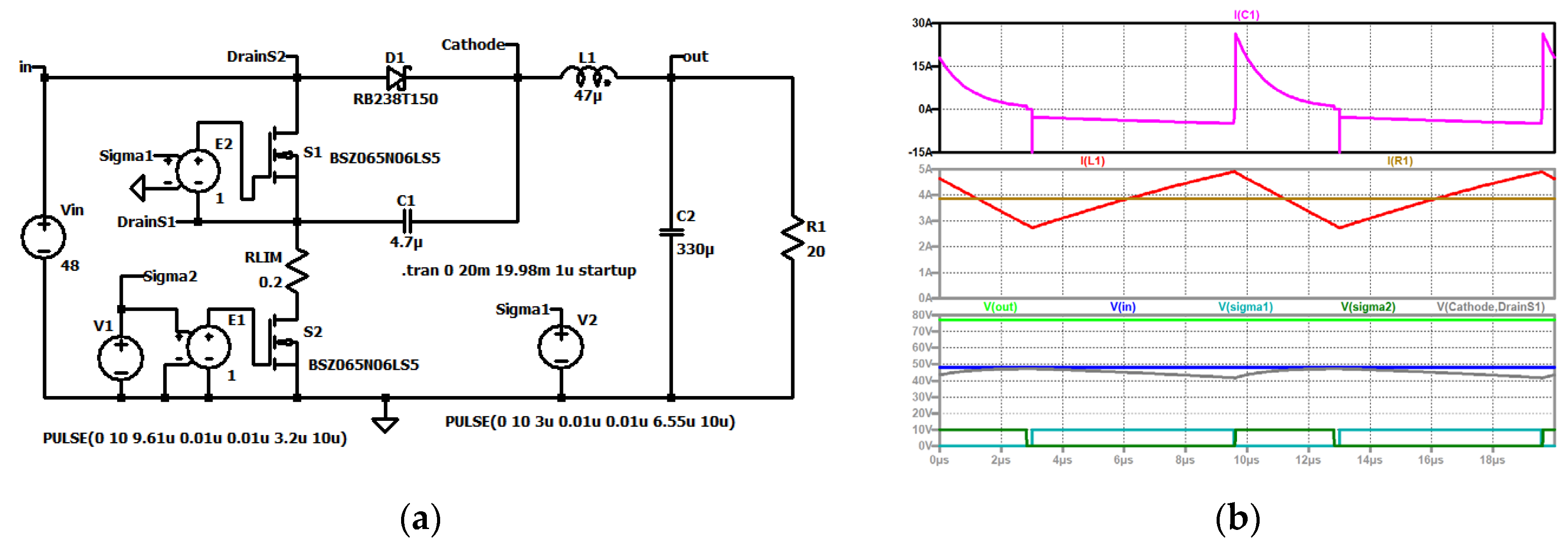

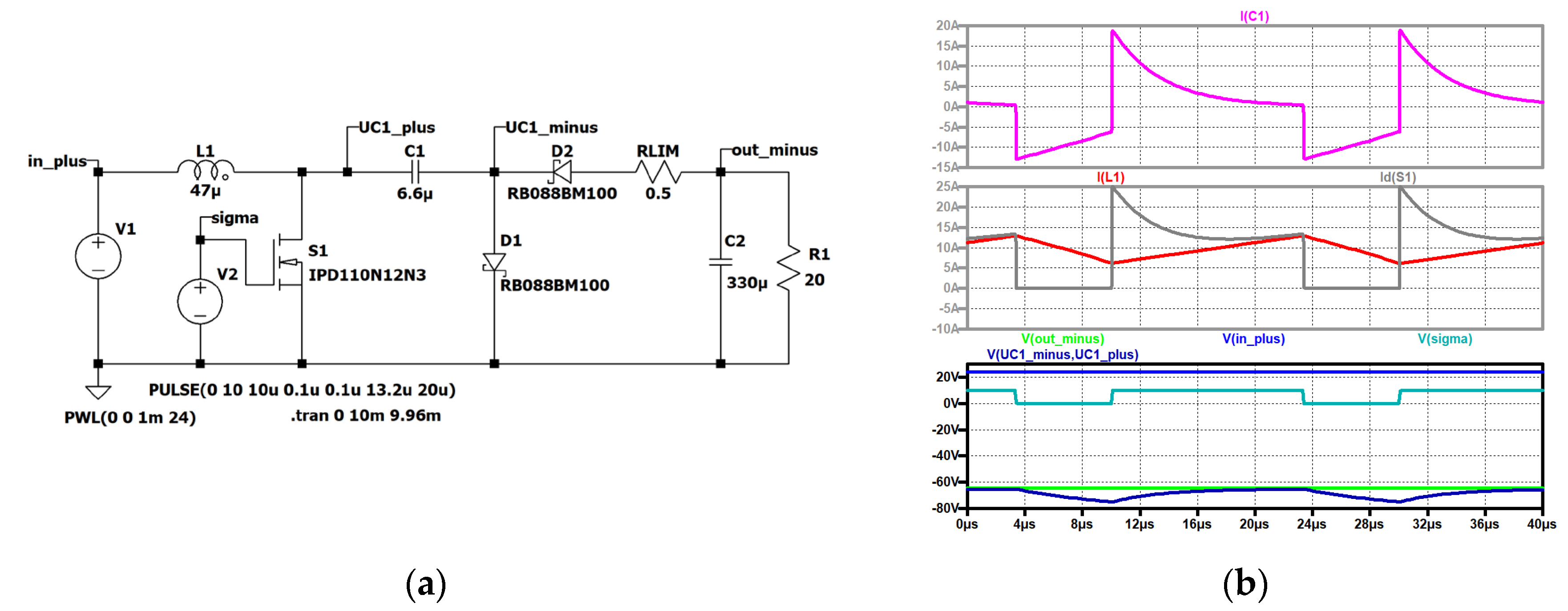

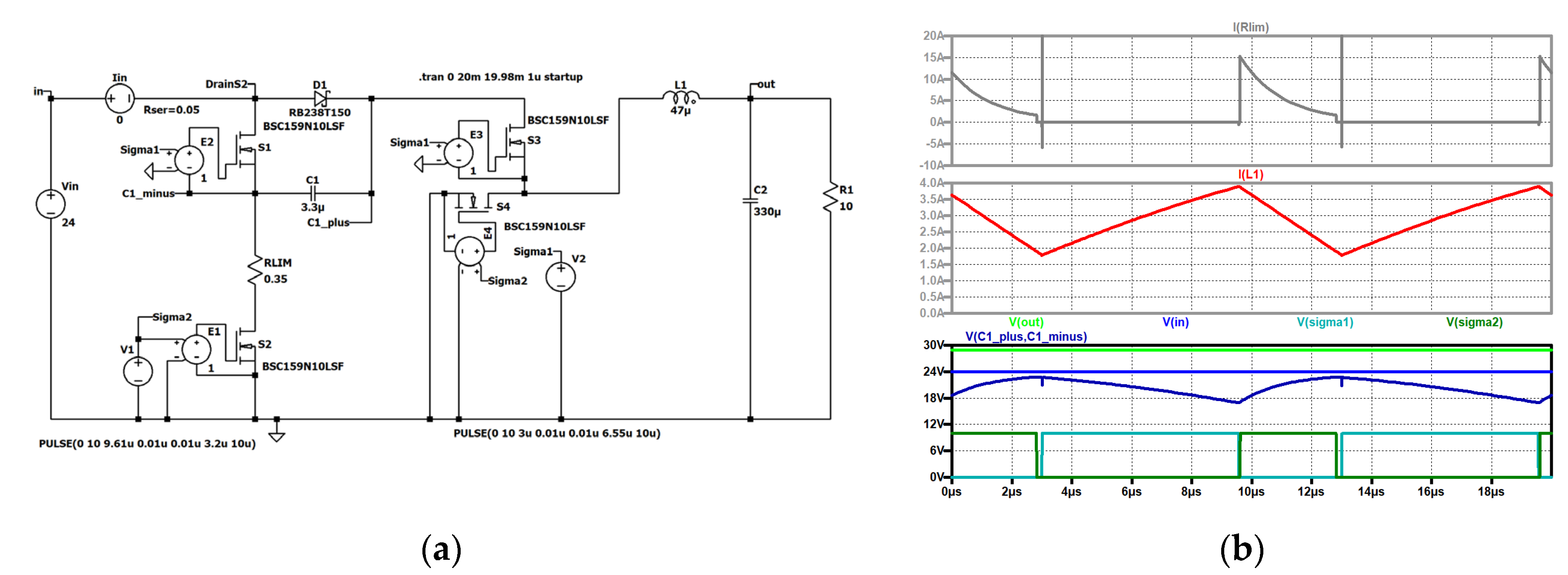

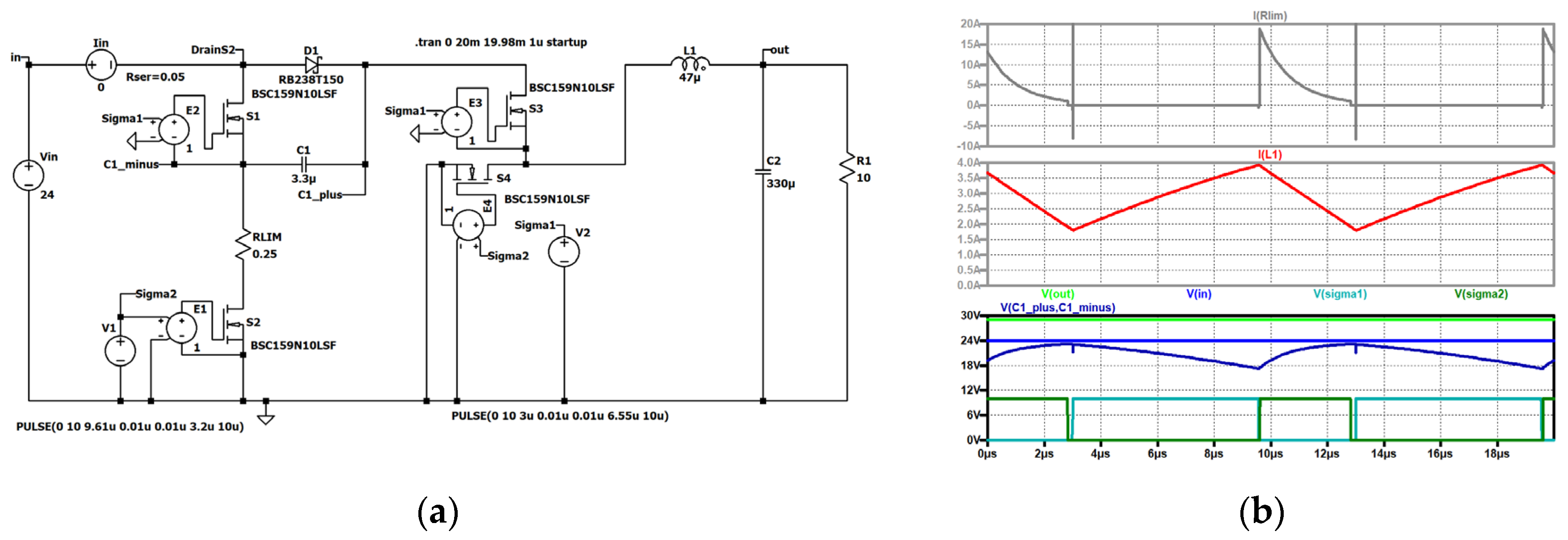

Figure 15 shows the circuit diagram with the additional limiting resistor RLIM.

In

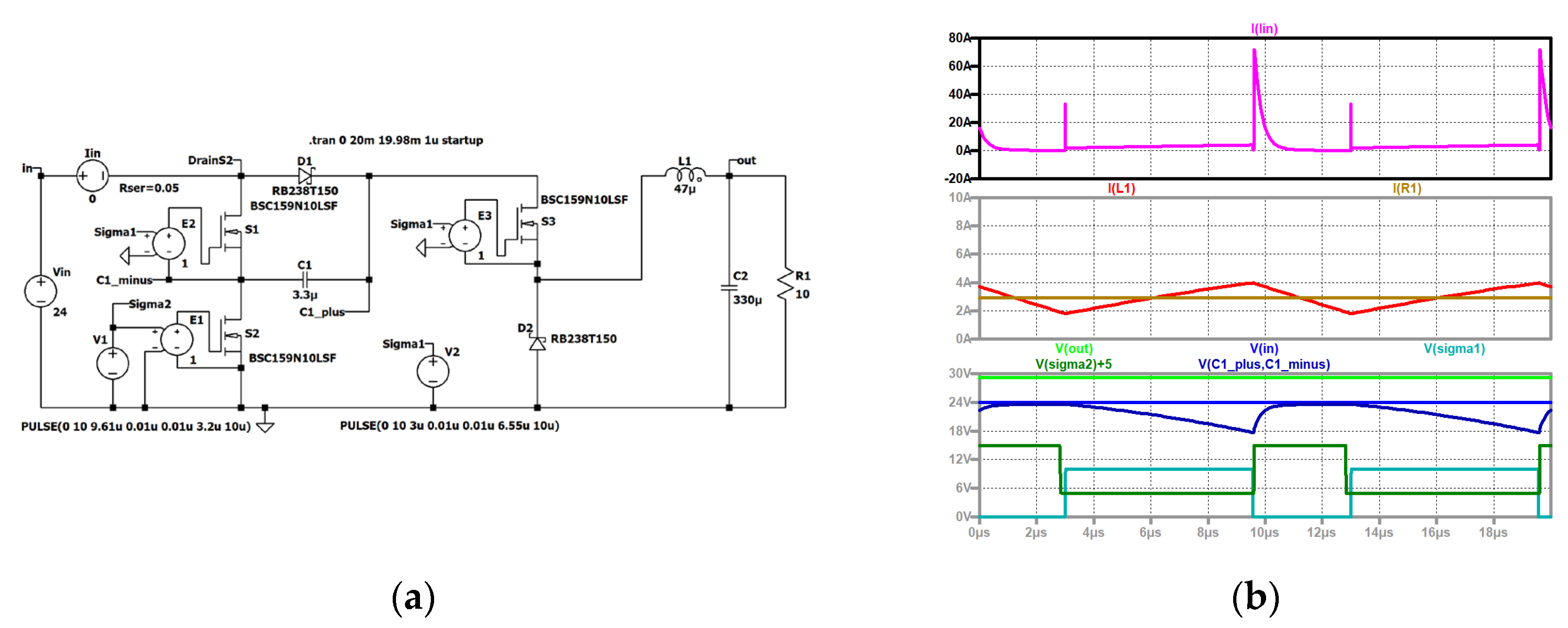

Figure 16 the current through the first capacitor, the current through the coil, the load current, the voltages at the output, the input voltage, the voltage across C1, and the control signals of the two electronic switches are shown.

The capacitor C1 is not completely recharged. There are two possibilities to improve it. Either the capacitor or the limiting resistor must be decreased.

The peak is reduced but it is longer. The on-time of S1 must be equal or five times longer than the time constant

The resistor R is now the sum of the parasitic capacitors plus the resistor RLIM to limit the current. One gets therefore

This is an easy method with no additional losses compared to the original circuit according to Figue 3.

The same considerations are valid for the other types.

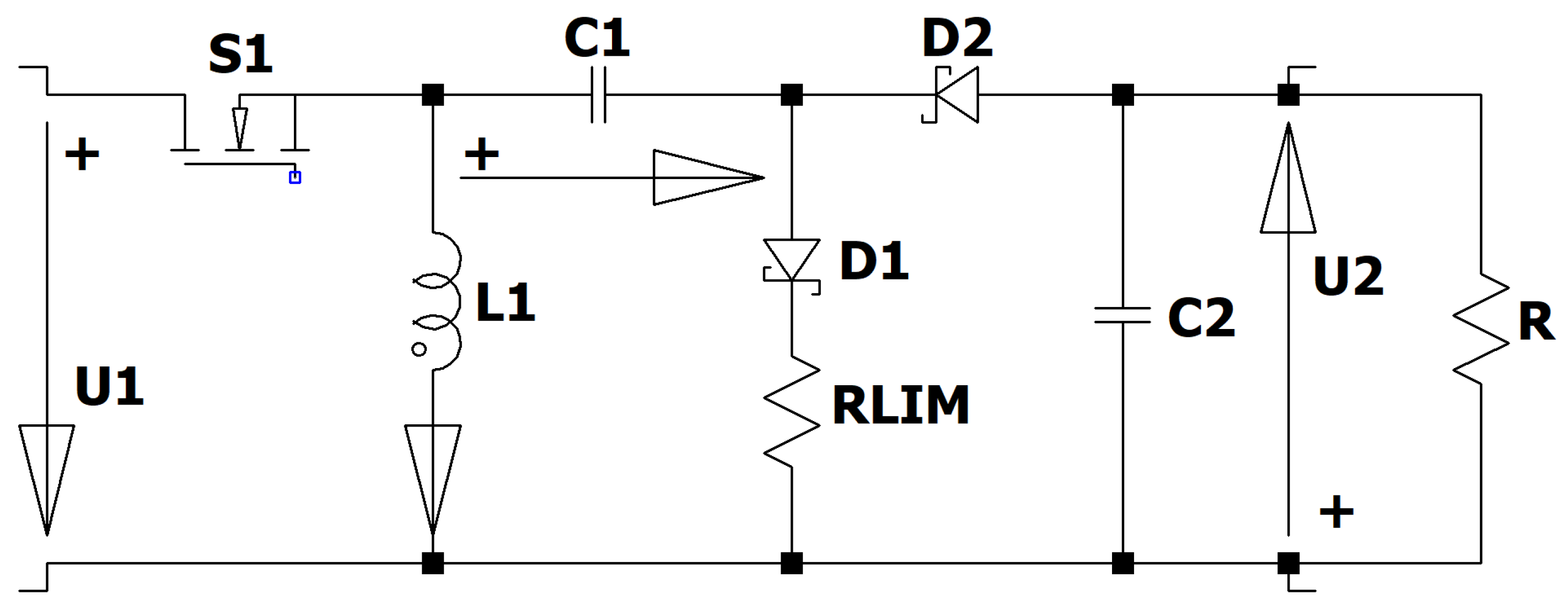

2.2. Negative Output KY Boost Converter Type I

The limiting resistor must be connected in series to the diode D1. Inserting it in series to other elements in the recharging loop would produce additional losses caused by the current through L1.

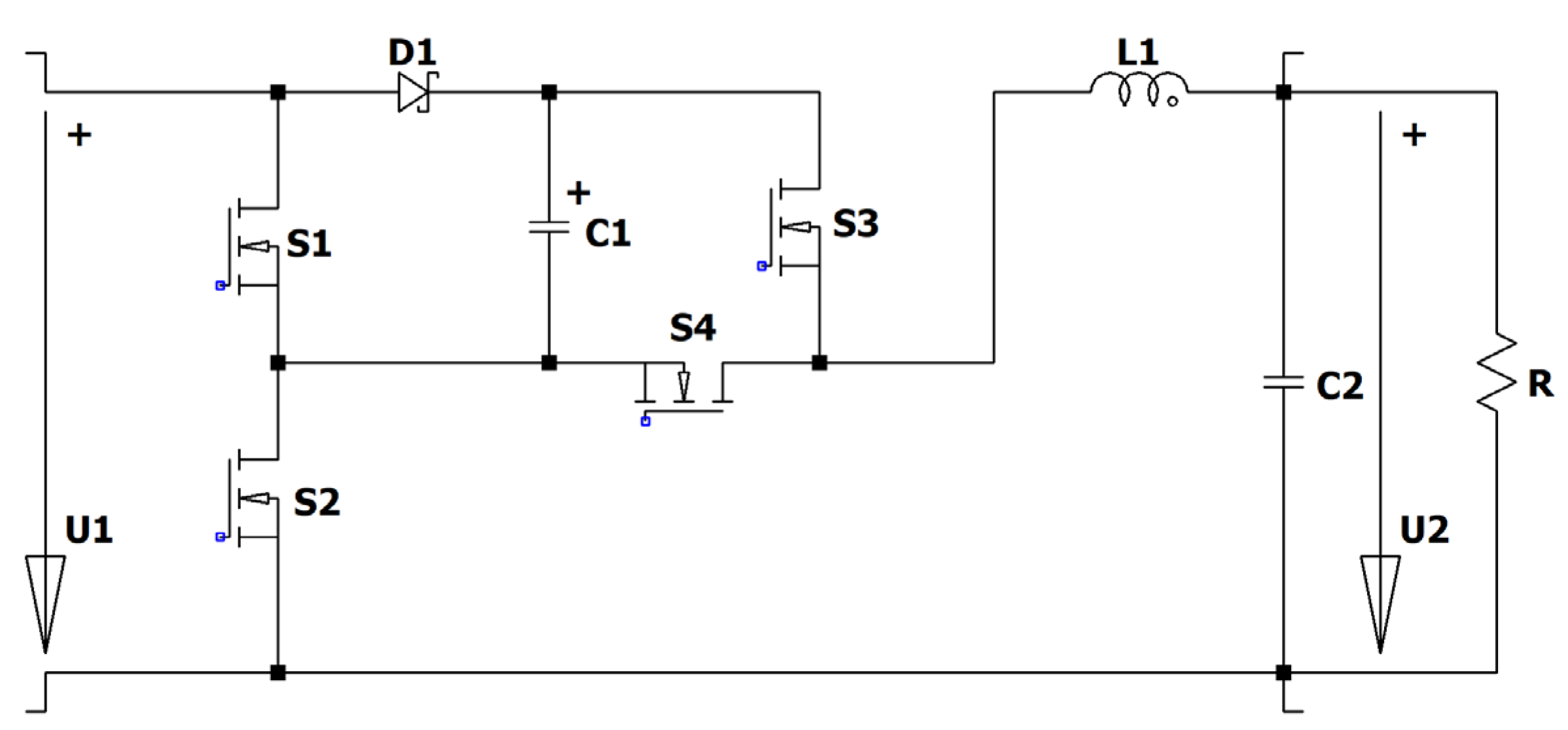

Figure 17 shows the circuit diagram of the converter with the resistor RLIM to limit the current which recharges the capacitor C1.

Figure 18 the signals.

Figure 18 shows the current through D1, the input voltage, the voltage across C1, the current through L1, the load current, the input voltage, the control signal, and the output voltage with current limiting resistor.

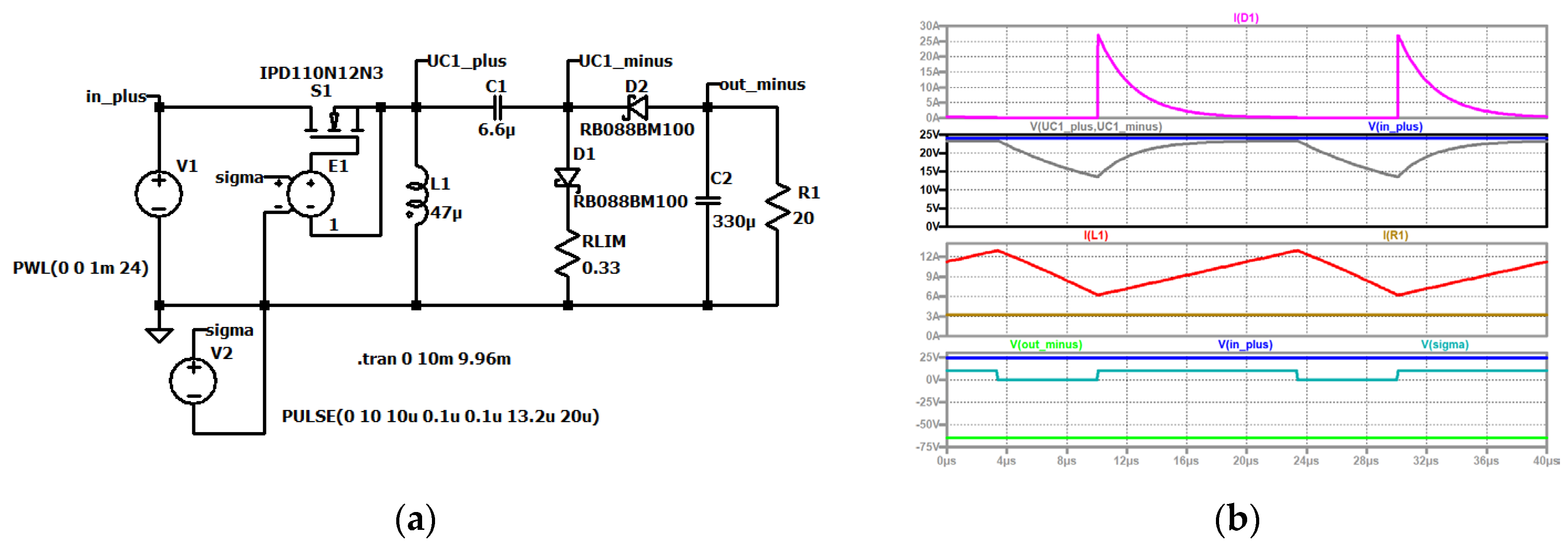

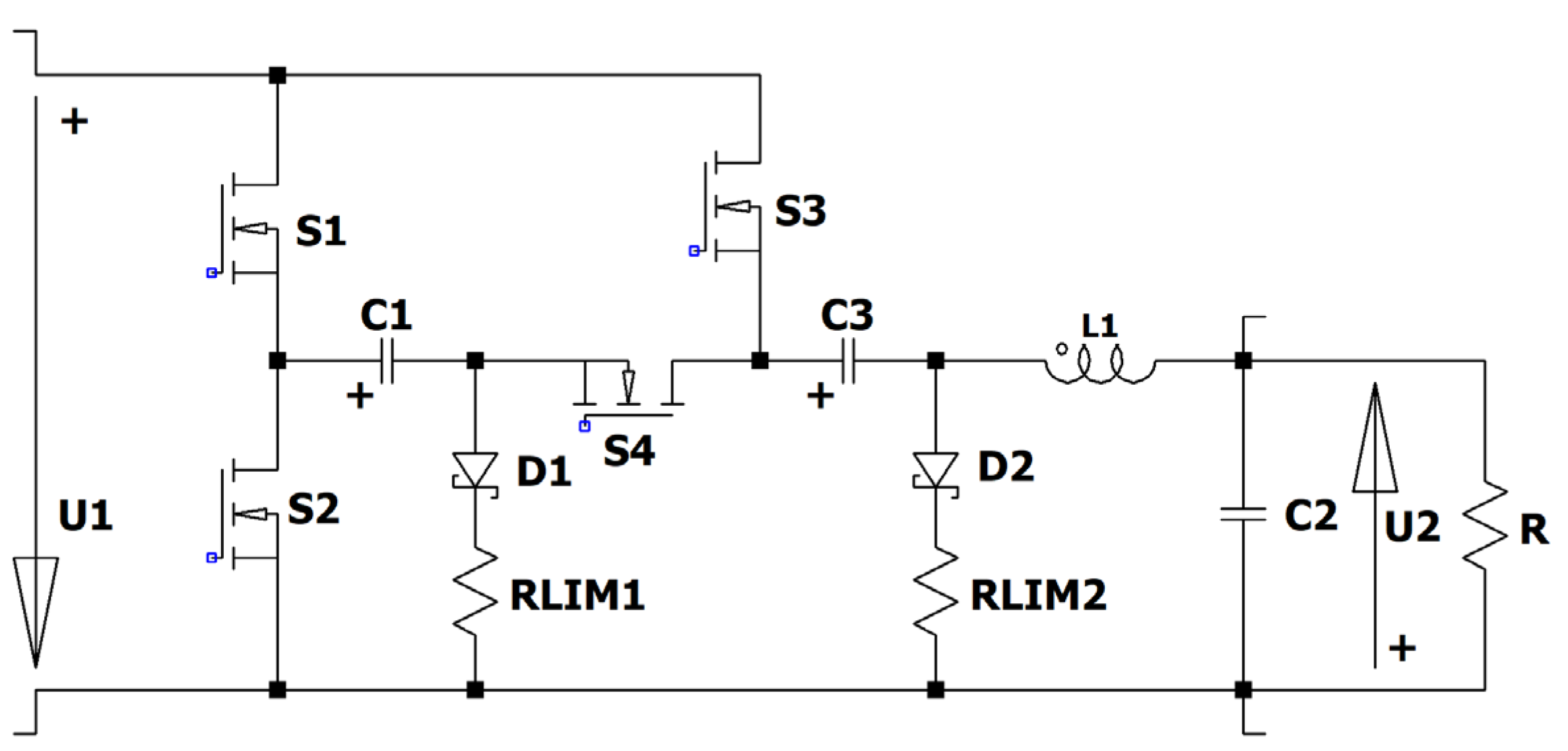

2.3. Negative Output KY Boost Converter Type II

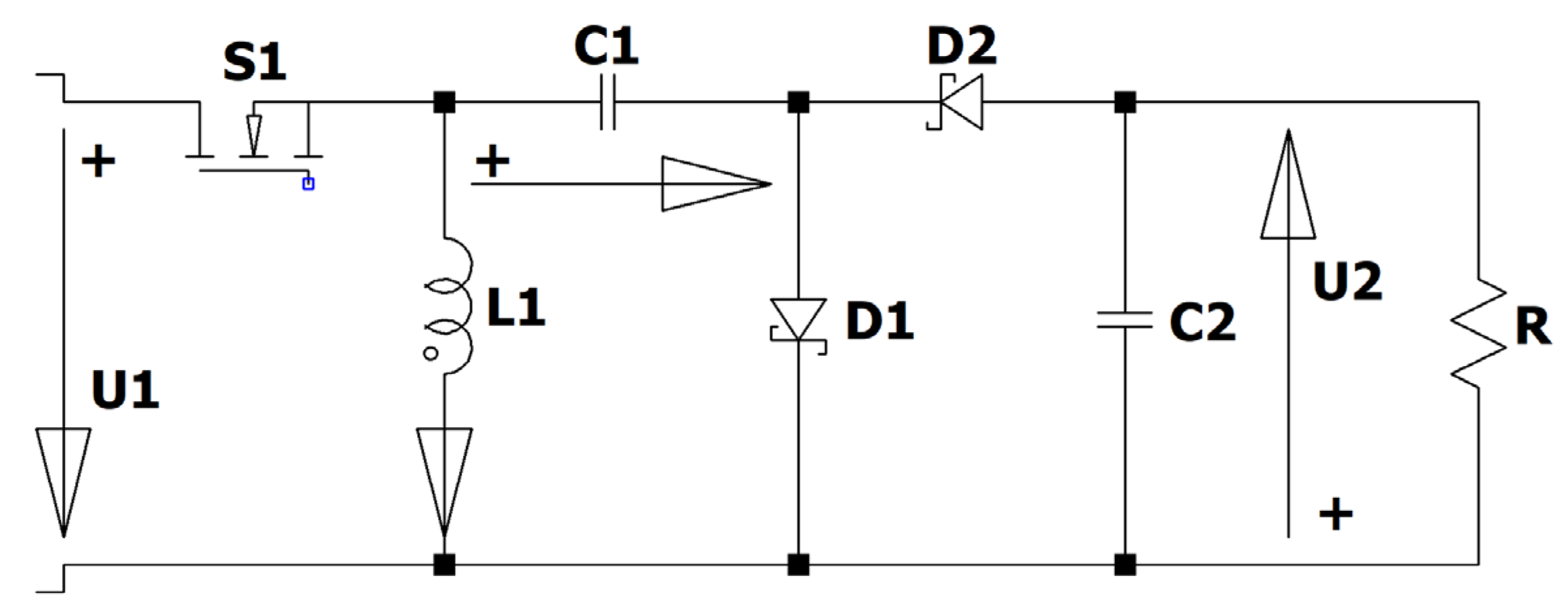

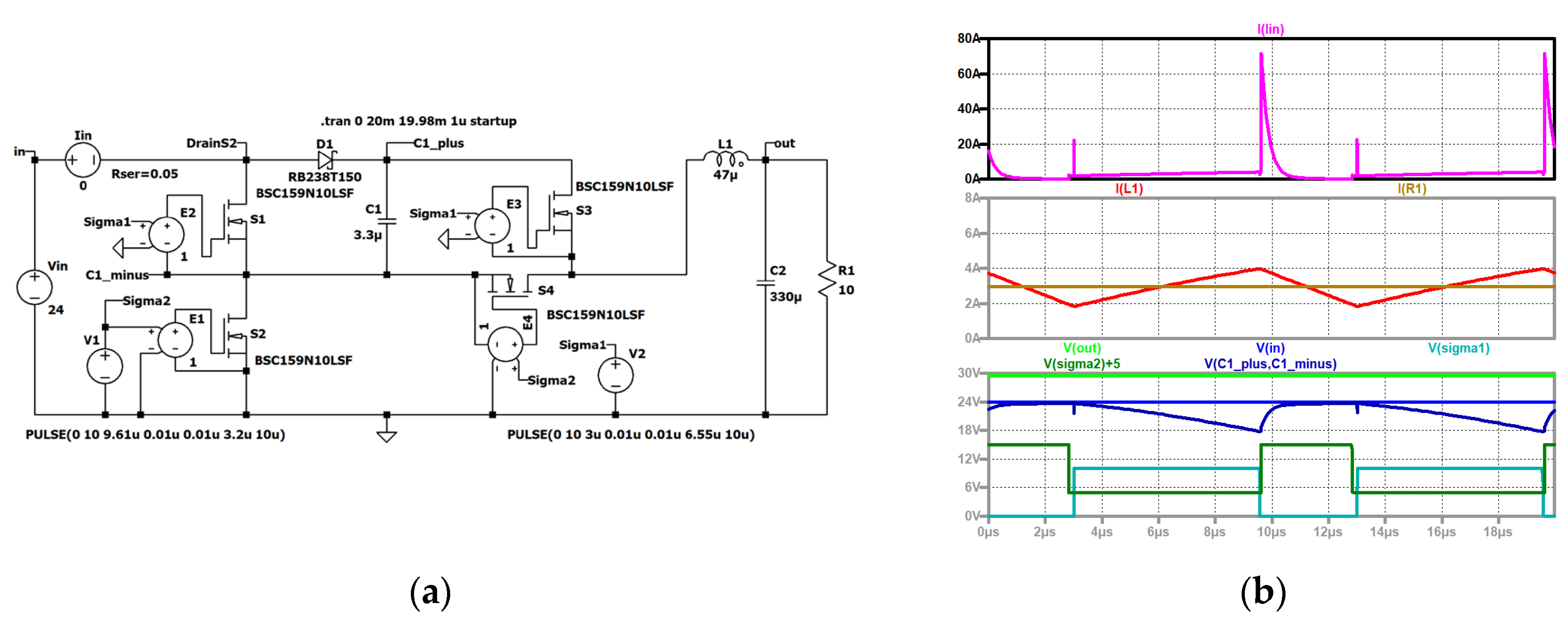

The recharging happens during the on-time of the electronic switch, during mode M1. The limiting resistor could be placed in series to the output capacitor, however increasing the output ripple, it could be placed in series to the switch, but the current through the coil would cause additional losses. It is also not sensible to place the resistor in series to the intermediate capacitor, because the current through the coil flows through it during mode M2 and produces additional losses. It is advisable to place the limiting resistor in series to D2. The circuit diagram is depicted in

Figure 19 and the current through intermediate capacitor C1, the current through the active switch, the current through L1, the input voltage, the control signal, the output voltage, and the voltage across C1 in

Figure 20.

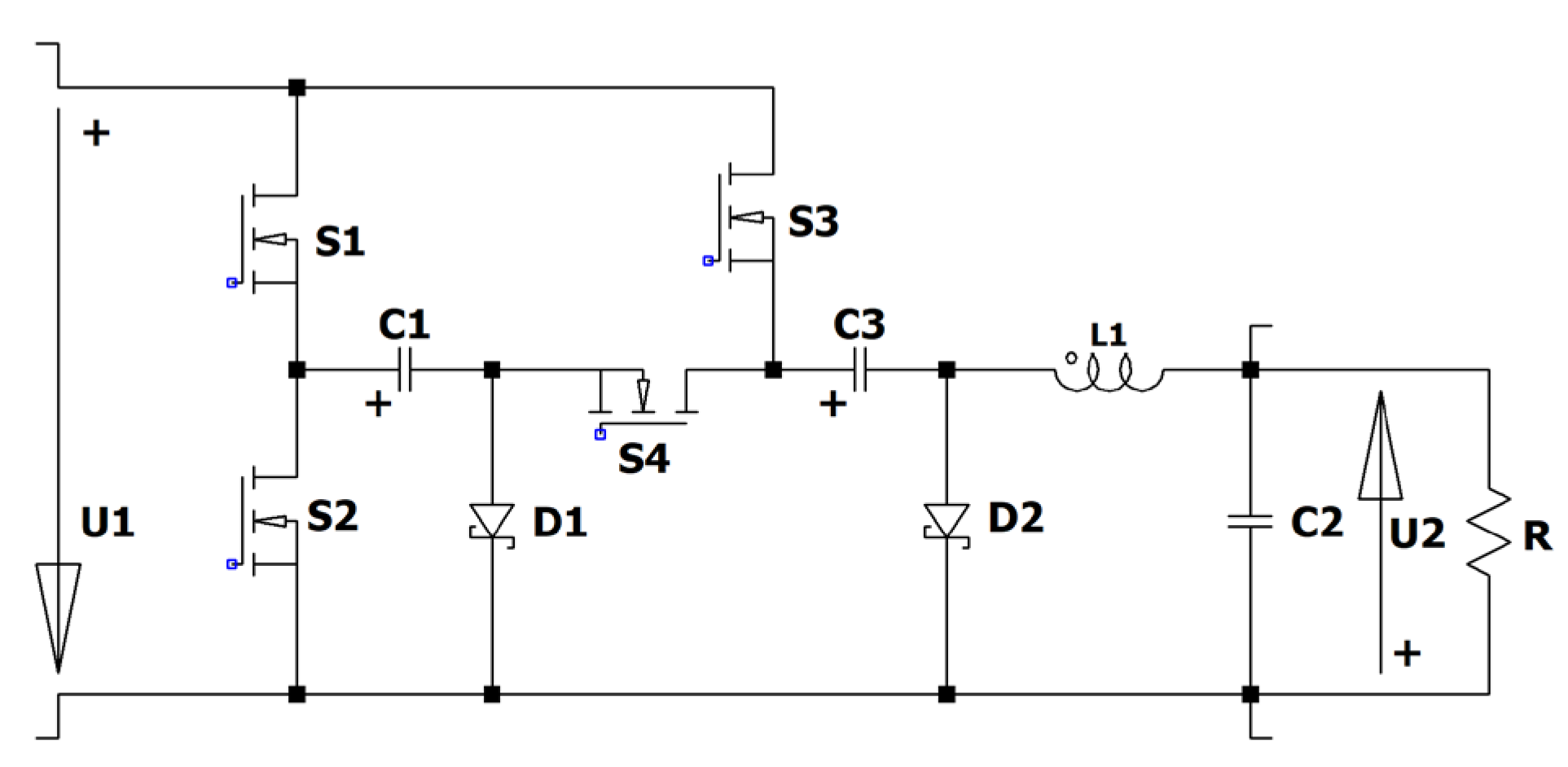

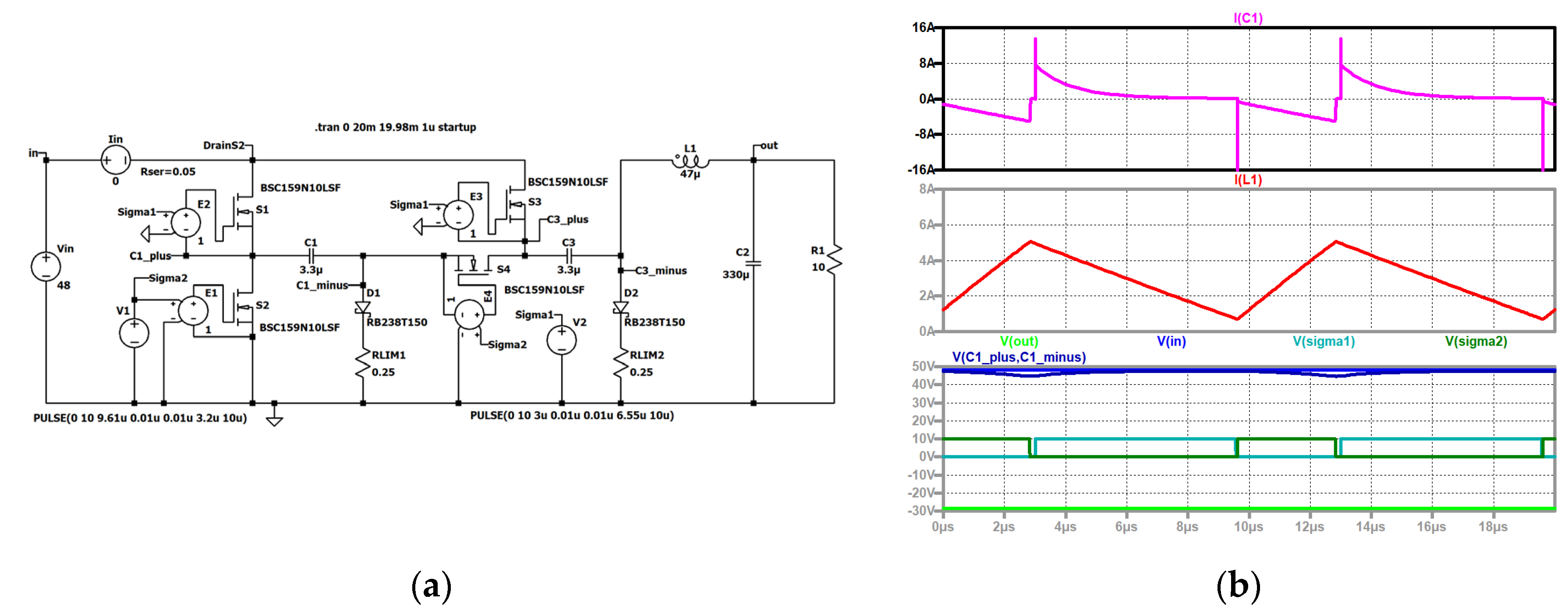

2.4. Inverting KY Buck-Boost Converter

When the upper switches S1 and S3 are on, the capacitors C1 and C3 are recharged up to the input voltage. To avoid additional losses, the limiting resistors are connected in series to the diodes D1 and D2 (

Figure21).

Figure 22 shows the current through the intermediate capacitor C1 (the shape through C3 is equal), the triangular current through L1, the input voltage, the voltage across C1 (the shape through C3 is equal), the control signal of the switches S1 and S3, the control signal of the switches S2 and S4, and the output voltage.

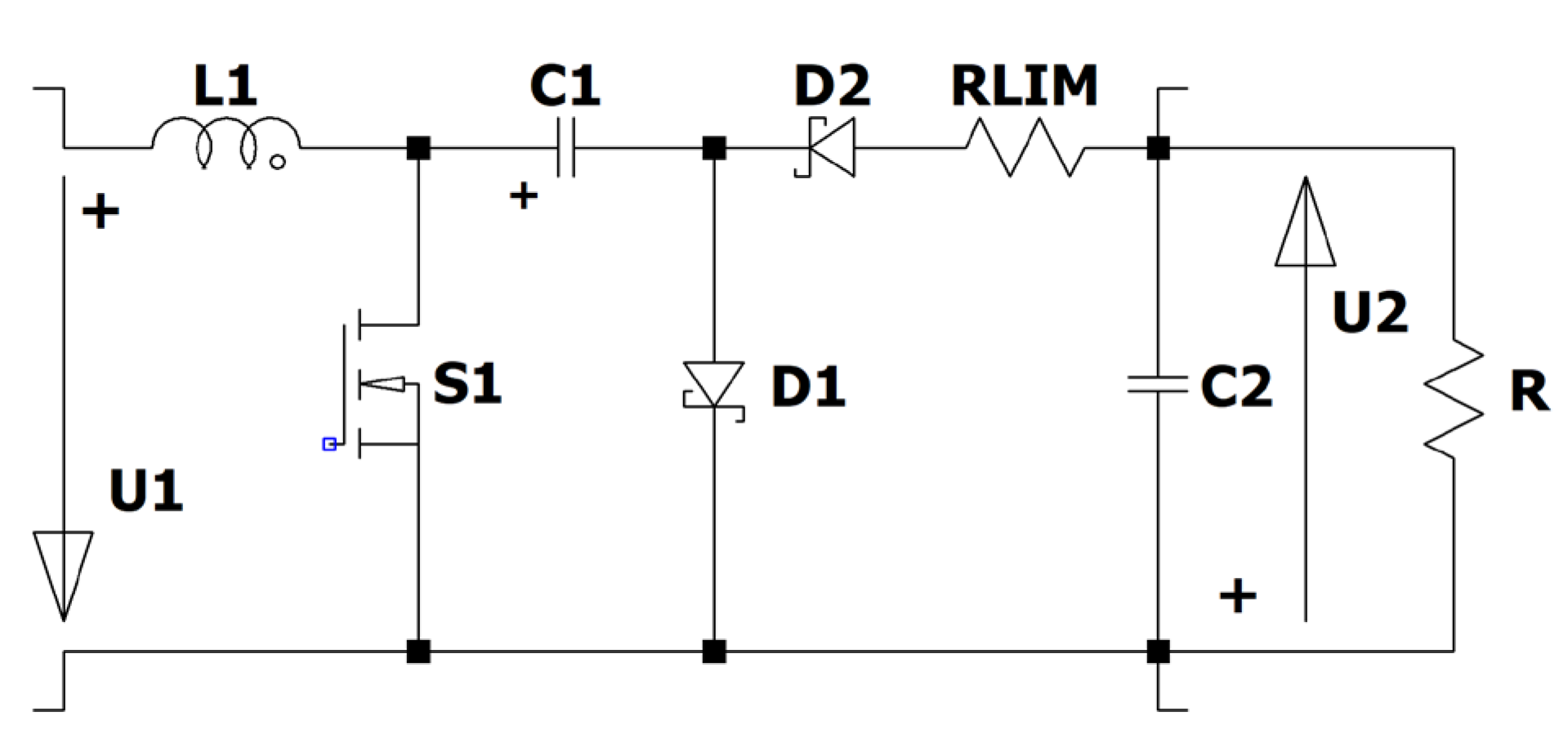

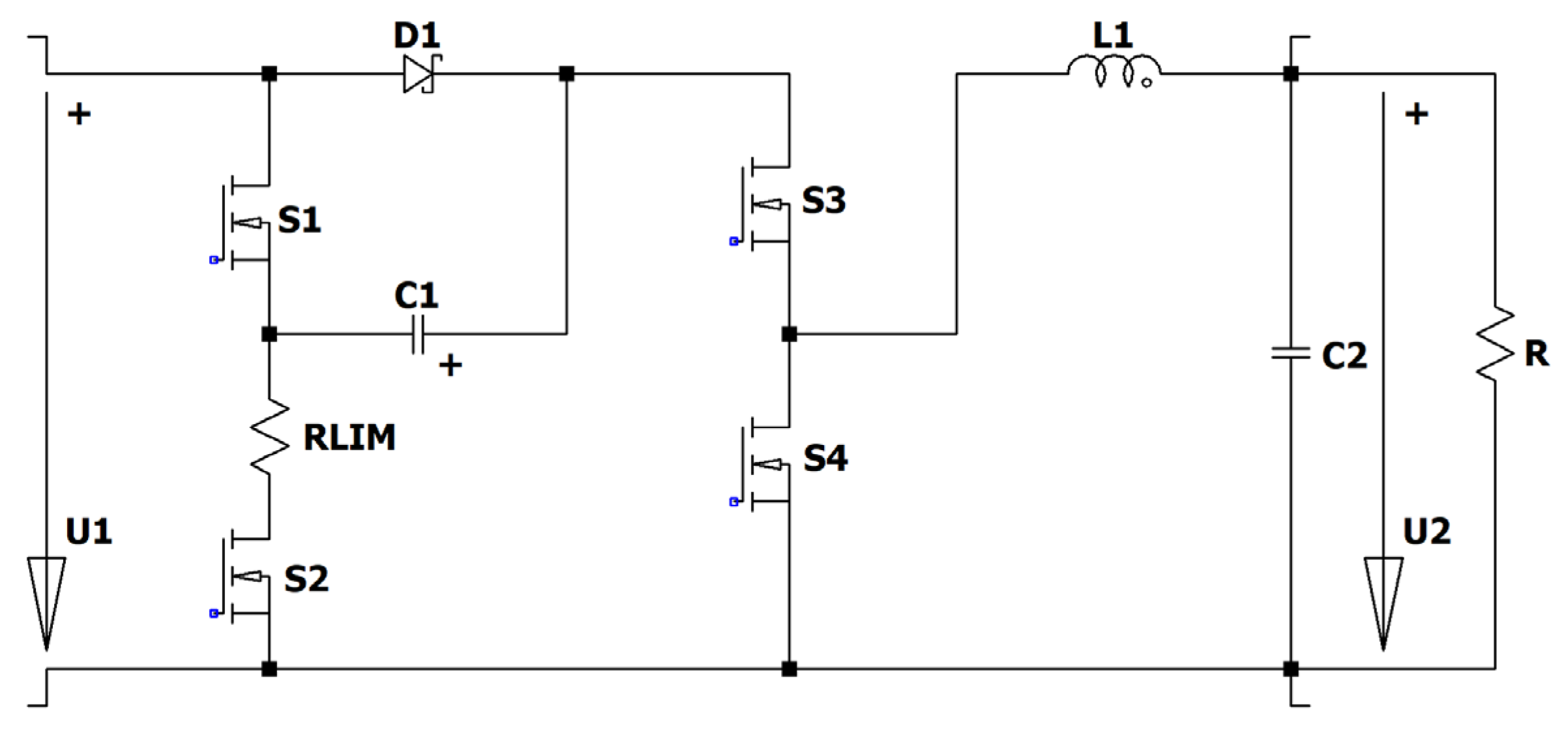

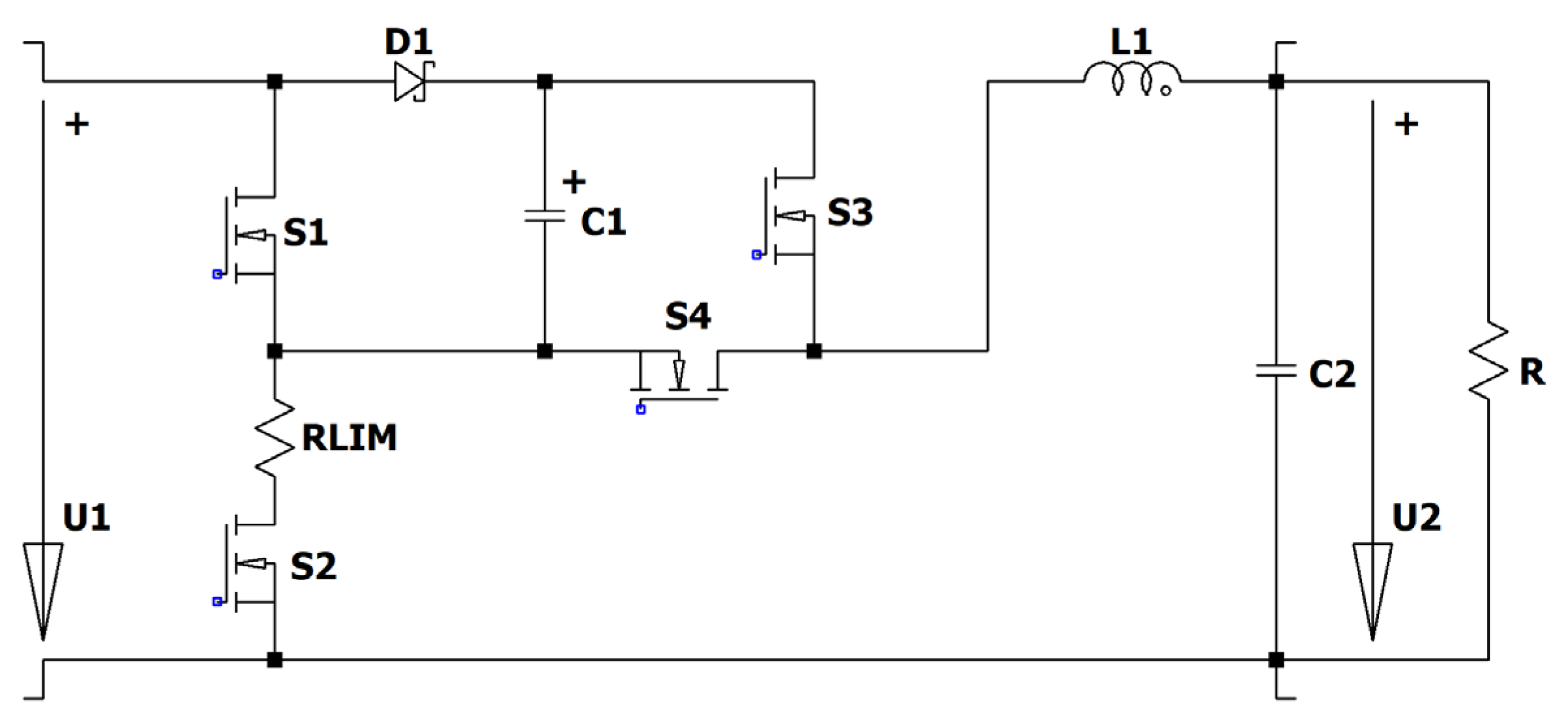

2.5. KY Buck-Boost Converter Type I

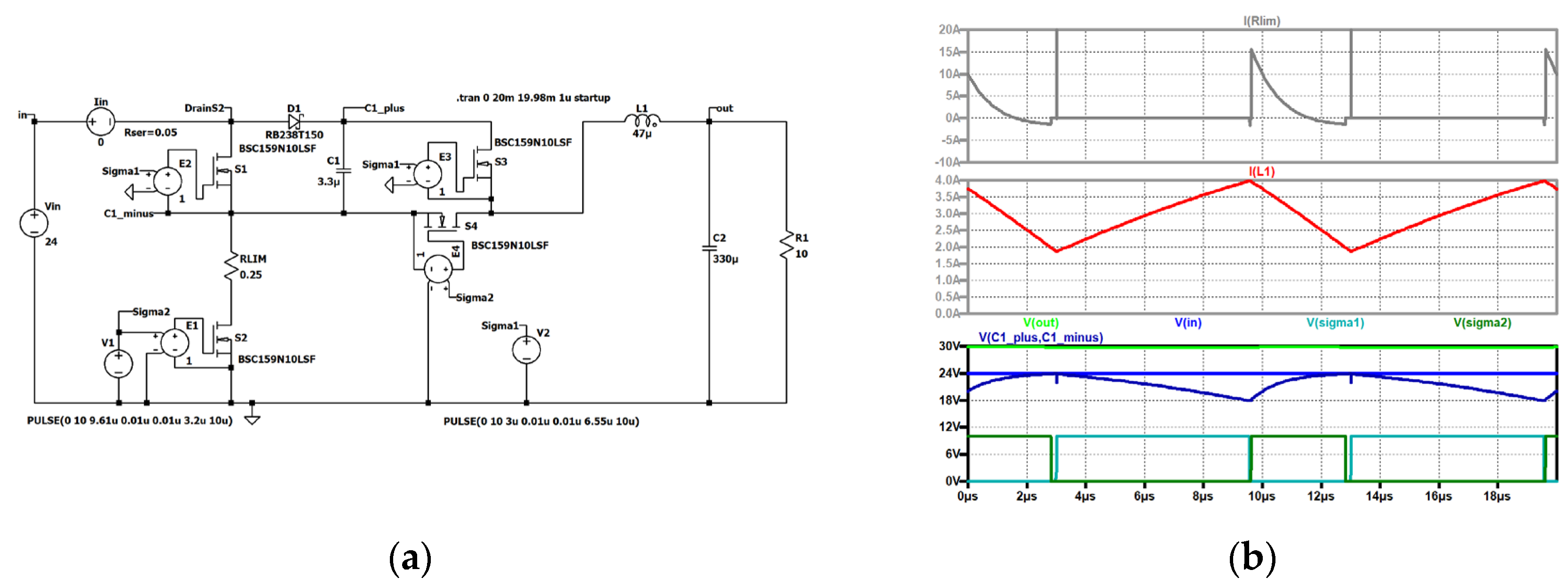

It is obvious where one has to place the limiting resistor to avoid additional losses: only in series to the second switch. The circuit diagram is depicted in

Figure 23.

Figure 24 shows the current through the limiting resistor RLIM, the triangular current through L1, the output voltage, the input voltage, the voltage across C1, the control signal of the switches S1 and S3, and the control signal of the switches S2 and S4. The intermediate capacitor or the limiting resistor should be reduced. An example with reduced resistor which leads to a higher peak but to a nearly complete recharge is shown in

Figure 25.

2.6. KY Buck-Boost Converter Type II

It stands to reason to insert the limiting resistor in series to the second switch S2 (

Figure 26). The signals shown in

Figure 27 are the current through limiting resistor RLIM, the current through L1, the output voltage, the input voltage, the voltage across C1, the control signal of S1, and the control signal of S2.

2.7. Summary

To reduce the peak current of the recharging pulse, a limiting resistor can be inserted into the recharging loop. The intermediate capacitor must be designed at such a low value that five times the time constant is shorter than the duration of the recharging, which happens in the cases described in 2.2, 2.3, 2.4 during mode M1 and in the topologies described in 2.1, 2.5, 2.6 during mode M2 and therefore lasts (1-d)⋅T.

4. Conclusion

Two methods to improve the KY converter are treated in this paper. Six converter topologies are presented:

1 the basic KY converter

2 the negative output KY Boost converter type I

3 the negative output KY Boost converter type II

4 the inverting KY Buck-Boost converter

5 the KY Buck-Boost converter type I

6 the KY Buck-Boost converter type II

The voltage transformation ratio is 1+d for type 1, 1/(1-d) for types 2 and 3, 2(1-d) for type 4, 2d for types 5 and 6. Type 2 has the same voltage transformation ratio as the classical Boost converter, however, the output voltage is inverse to the input voltage. All other types have a linear voltage transformation ratio depending on the duty cycle. It can be shown that this linearization is combined with a phase-minimum behavior. So, all these converters have no zeroes on the right side of the complex plane, and the phase shift is reduced compared to converters with zeroes on the right side.

The converters which have switches directly in series with the input source (2), and the converters with half-bridges (4, 5, 6) have no inrush current and the start-up can be done by increasing the duty cycle starting from zero. Only the classical KY converter (1) and the negative output KY Boost converter II (3) show an inrush current when connected to a stable input source. It is advisable to use converter 2 instead of converter 3. All these converters have the disadvantage of a large current pulse, when the intermediate capacitor (or capacitors) is (are) recharged. This happens in every switching period. It is shown that the losses caused by this recharging are independent of the resistor in the loop. Therefore, one can include an additional resistor in the recharging loop, which reduces the current peak without changing the losses. This is demonstrated in section 2. A better solution is demonstrated in section 3. Here the recharging happens in a resonant way. Now losses occur only by the parasitic resistors and depend on these. Ideal components would lead to no losses, because the energy transfer goes over the magnetic field.

The intermediate capacitor is charged to a fix voltage during each switching cycle, and the additional inductor reaches zero in each cycle. Therefore, the dynamics of the converter are determined only by the main inductor and the output capacitor. The small signal model is only of second order and is easier to control than a third or a fourth order system.

The circuits are useful for application with small step-up ratios.

Figure 1.

Basic KY converter.

Figure 1.

Basic KY converter.

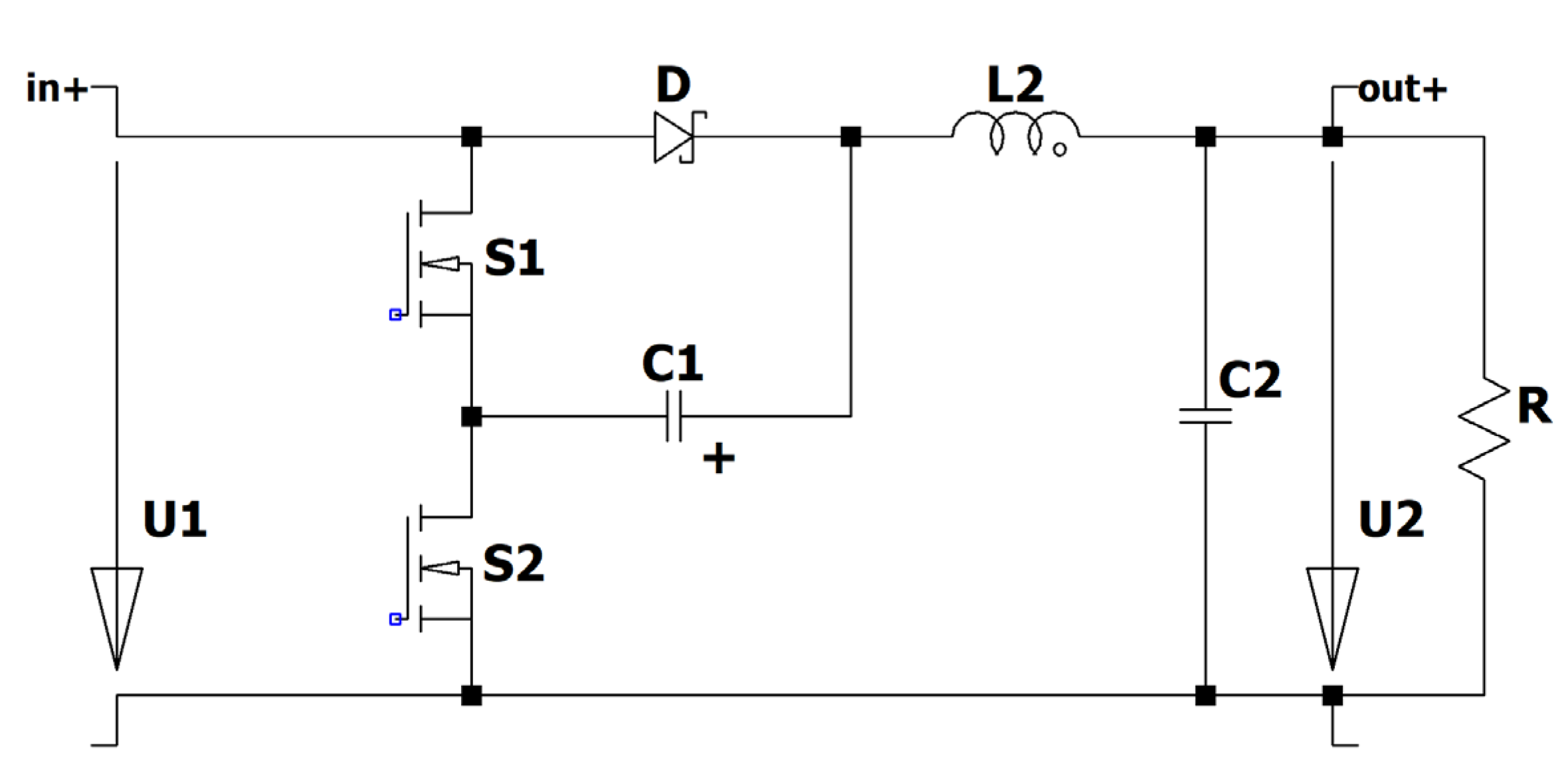

Figure 2.

KY converter (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil LH (red), load current (brown); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of switch S2 (dark green, shifted), control signal of switch S1 (turquoise).

Figure 2.

KY converter (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil LH (red), load current (brown); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of switch S2 (dark green, shifted), control signal of switch S1 (turquoise).

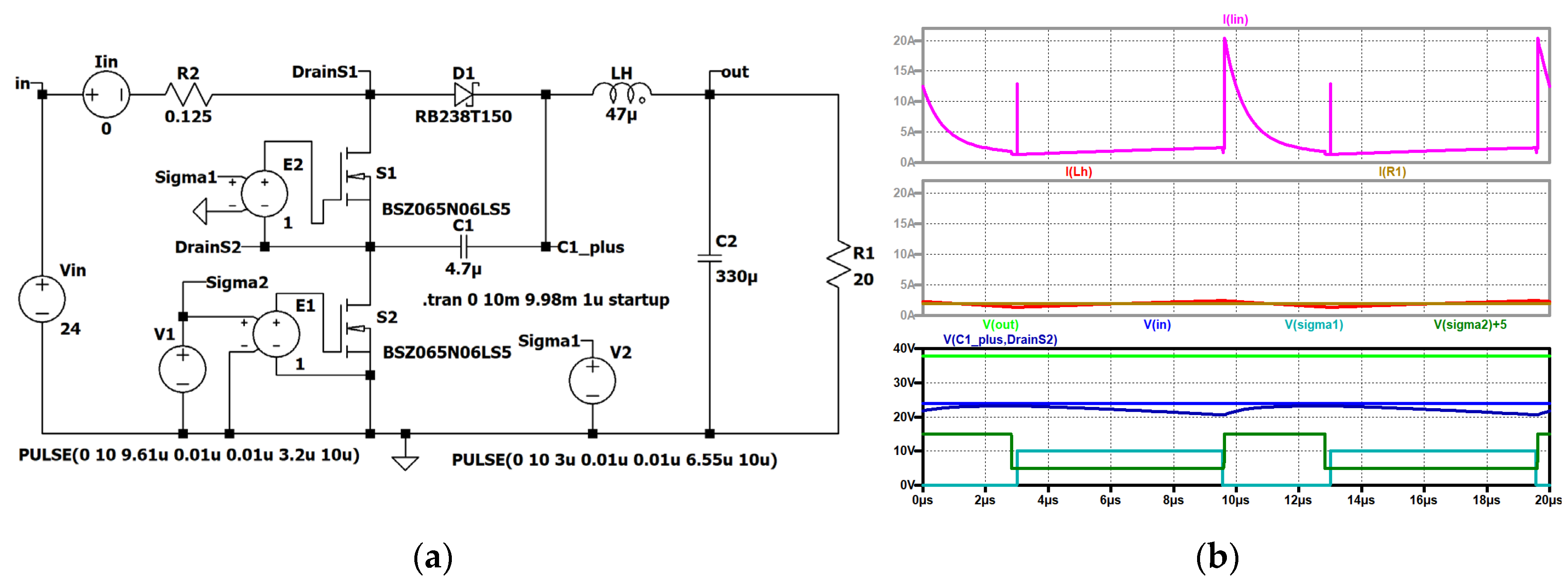

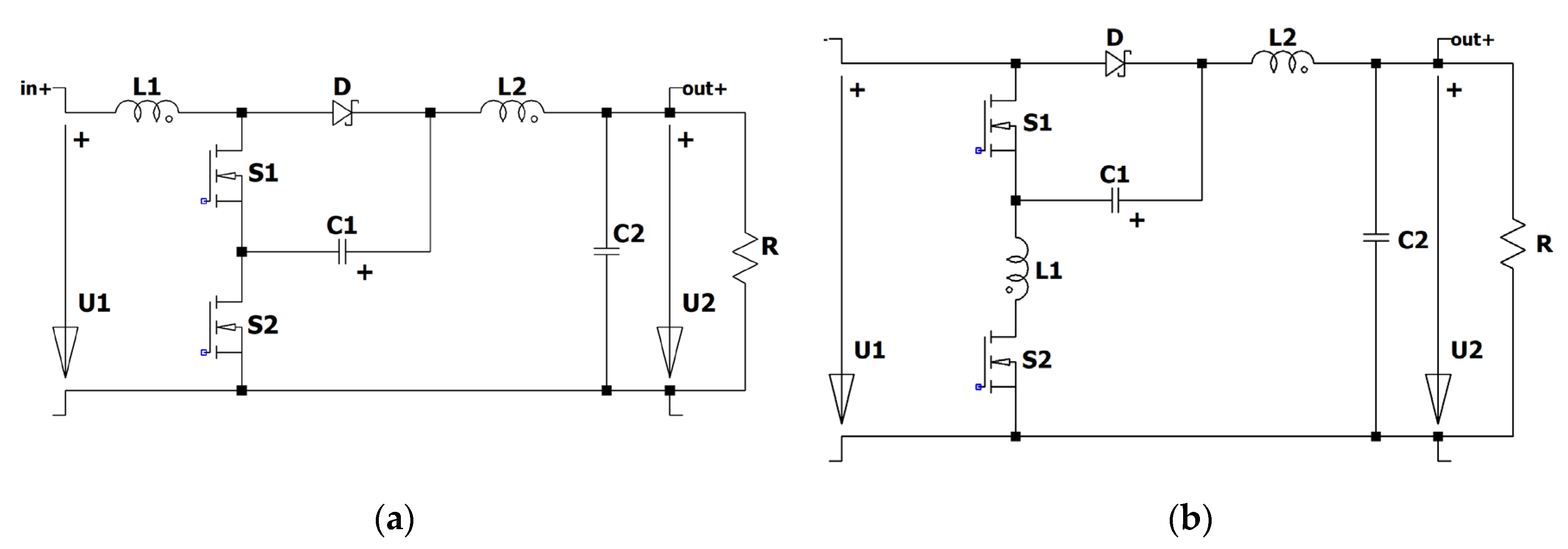

Figure 3.

Negative output KY boost converter type I.

Figure 3.

Negative output KY boost converter type I.

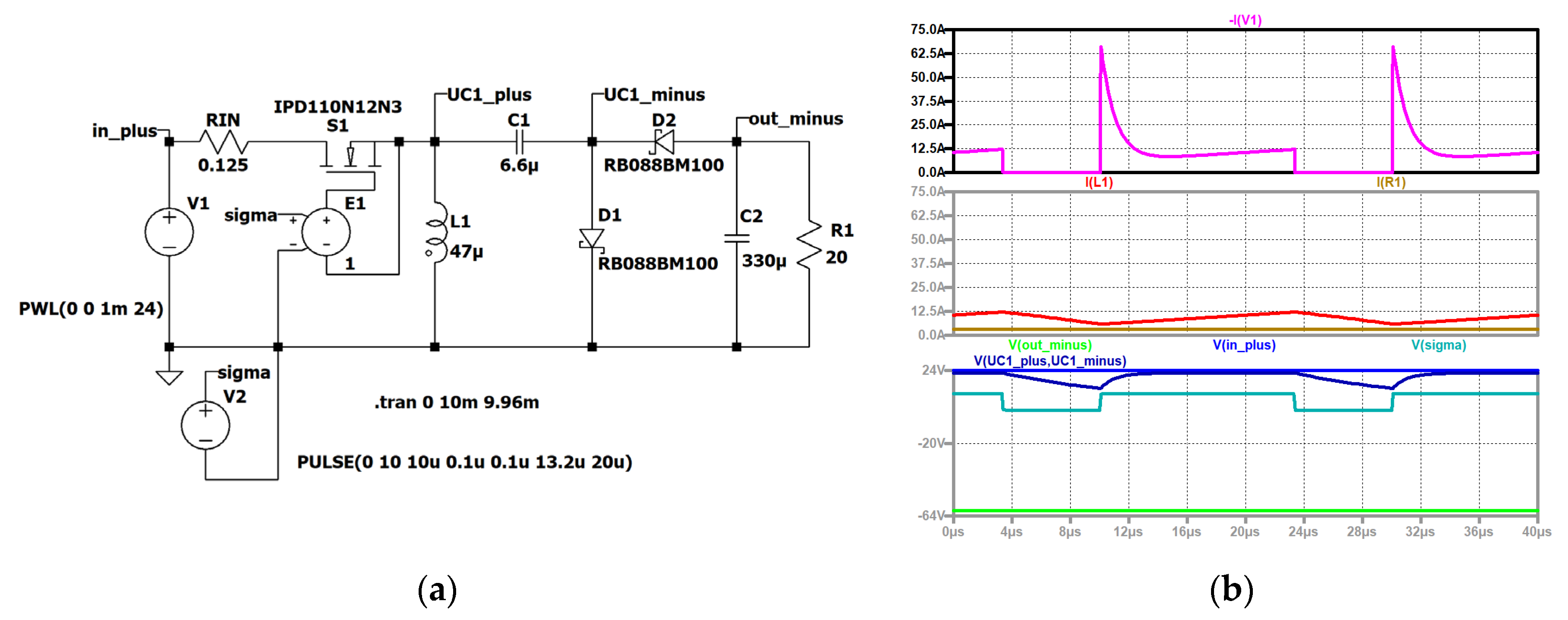

Figure 4.

Negative output KY Boost converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 4.

Negative output KY Boost converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

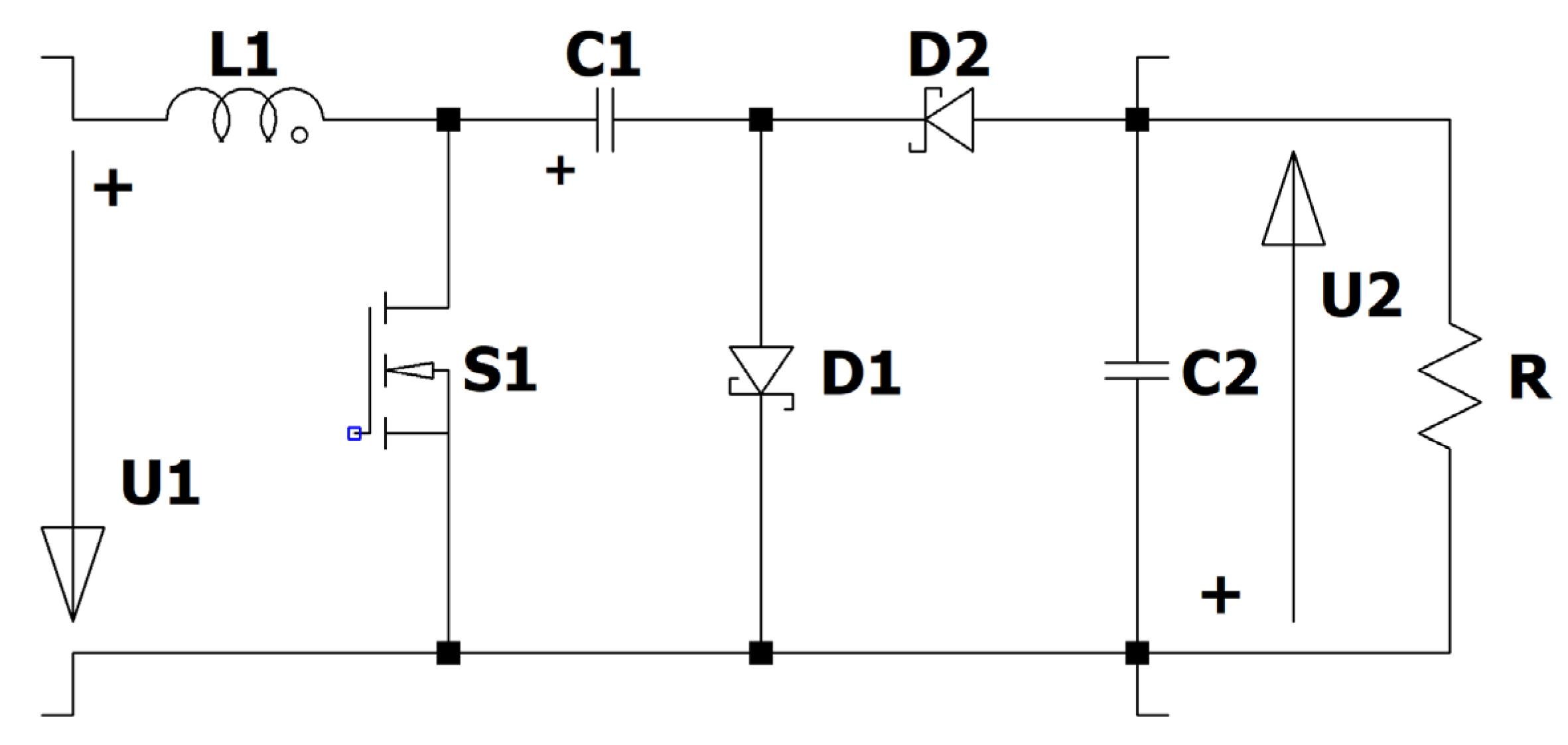

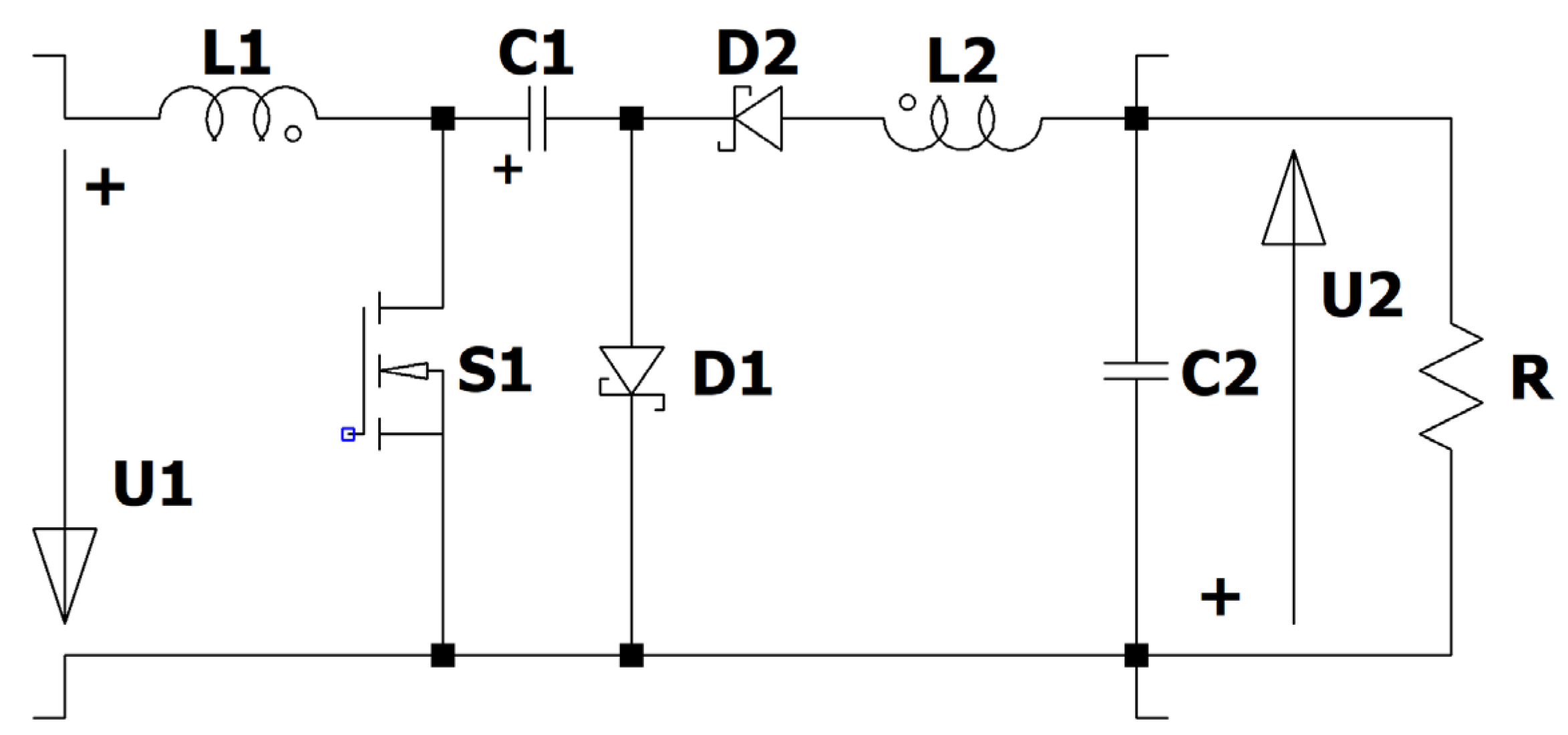

Figure 5.

Negative output KY Boost converter type II.

Figure 5.

Negative output KY Boost converter type II.

Figure 6.

Negative output KY Boost converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); voltage across C1 (dark blue), input voltage (blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 6.

Negative output KY Boost converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); voltage across C1 (dark blue), input voltage (blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 7.

Inverting KY Buck-Boost converter.

Figure 7.

Inverting KY Buck-Boost converter.

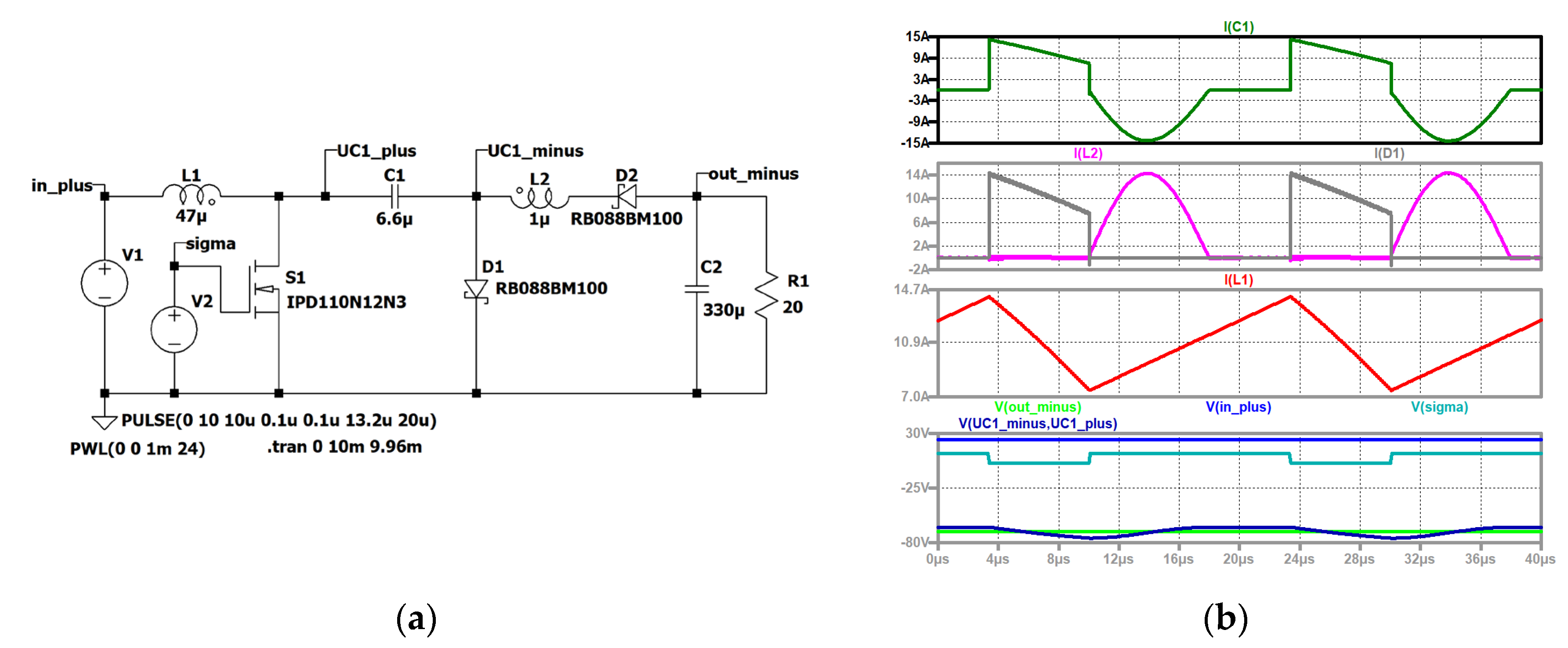

Figure 8.

Inverting KY Buck-Boost converter in step-down mode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 8.

Inverting KY Buck-Boost converter in step-down mode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 9.

Inverting KY Buck-Boost converter in step-up mode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 9.

Inverting KY Buck-Boost converter in step-up mode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 10.

KY Buck-Boost converter type I.

Figure 10.

KY Buck-Boost converter type I.

Figure 11.

KY Buck-Boost Converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 11.

KY Buck-Boost Converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 12.

KY Buck-Boost Converter type I, S4 replaced by a diode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 12.

KY Buck-Boost Converter type I, S4 replaced by a diode: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 13.

KY Buck-Boost converter type II.

Figure 13.

KY Buck-Boost converter type II.

Figure 14.

KY Buck-Boost Converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

Figure 14.

KY Buck-Boost Converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the coil L1 (red), load current (brown); input voltage (blue), voltage across C1 (dark blue), control signal of switch S1 (turquoise), output voltage (green).

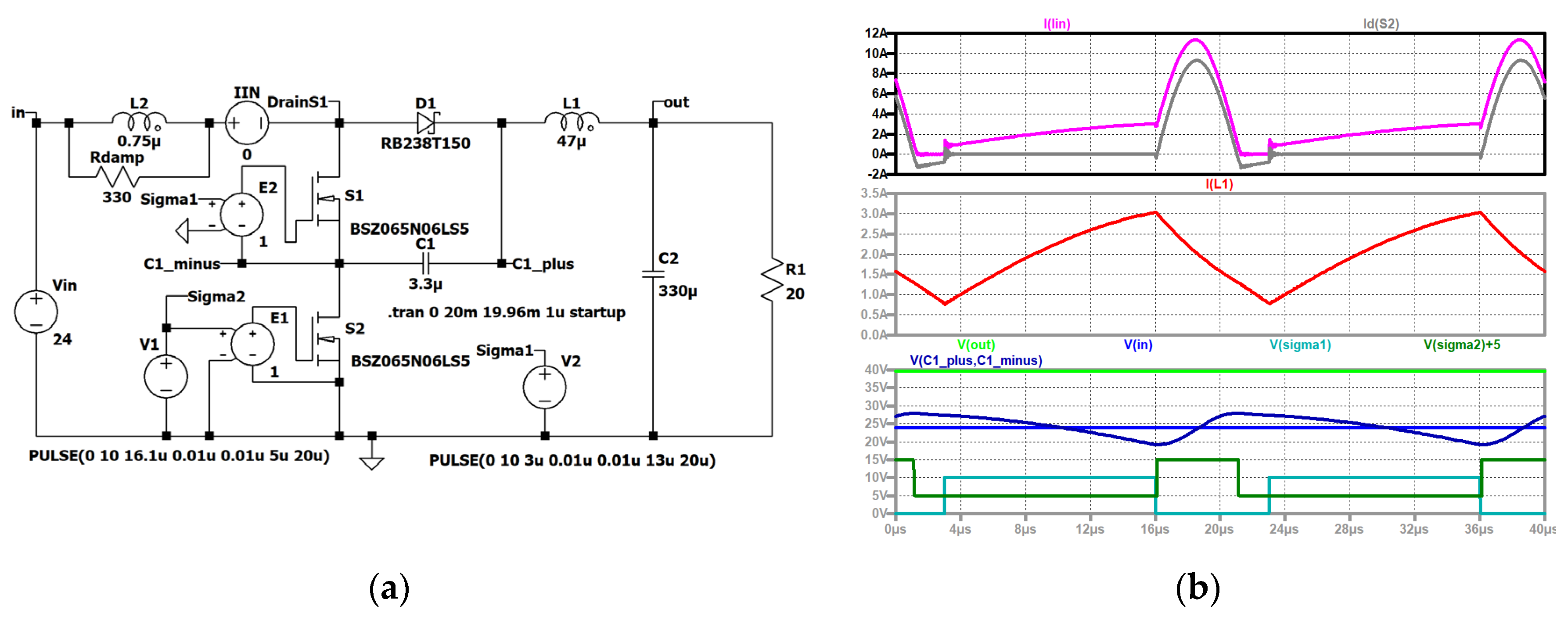

Figure 15.

KY converter with additional current limiting resistor.

Figure 15.

KY converter with additional current limiting resistor.

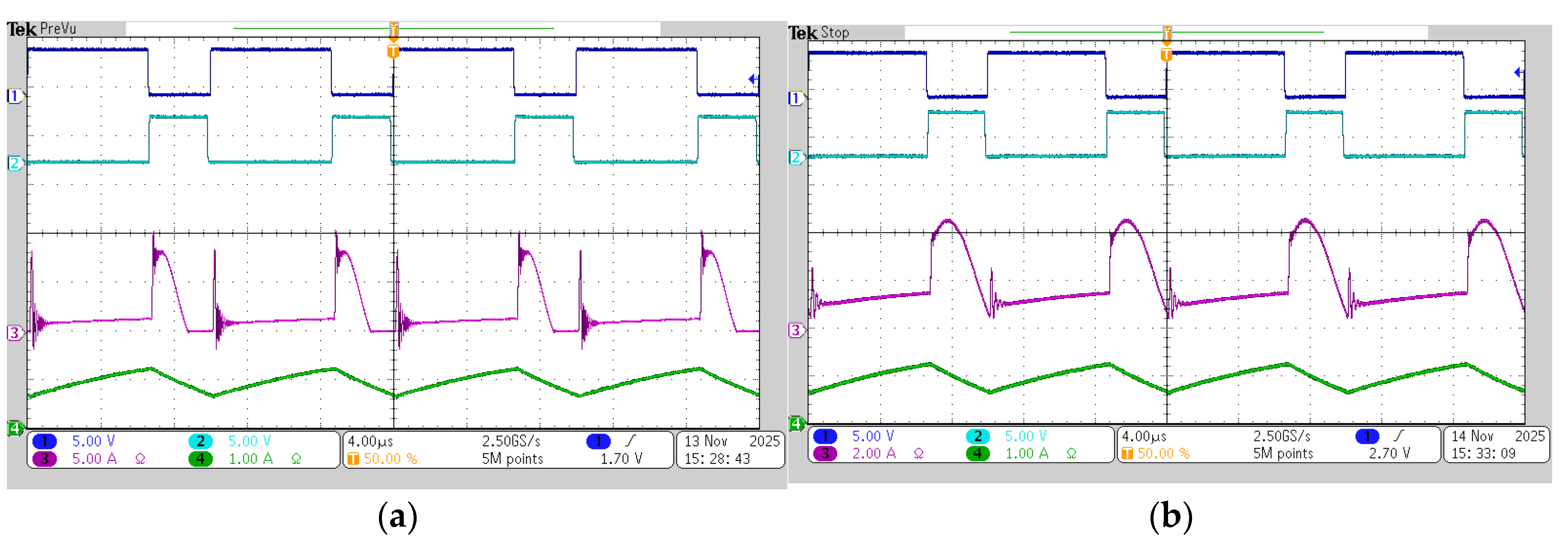

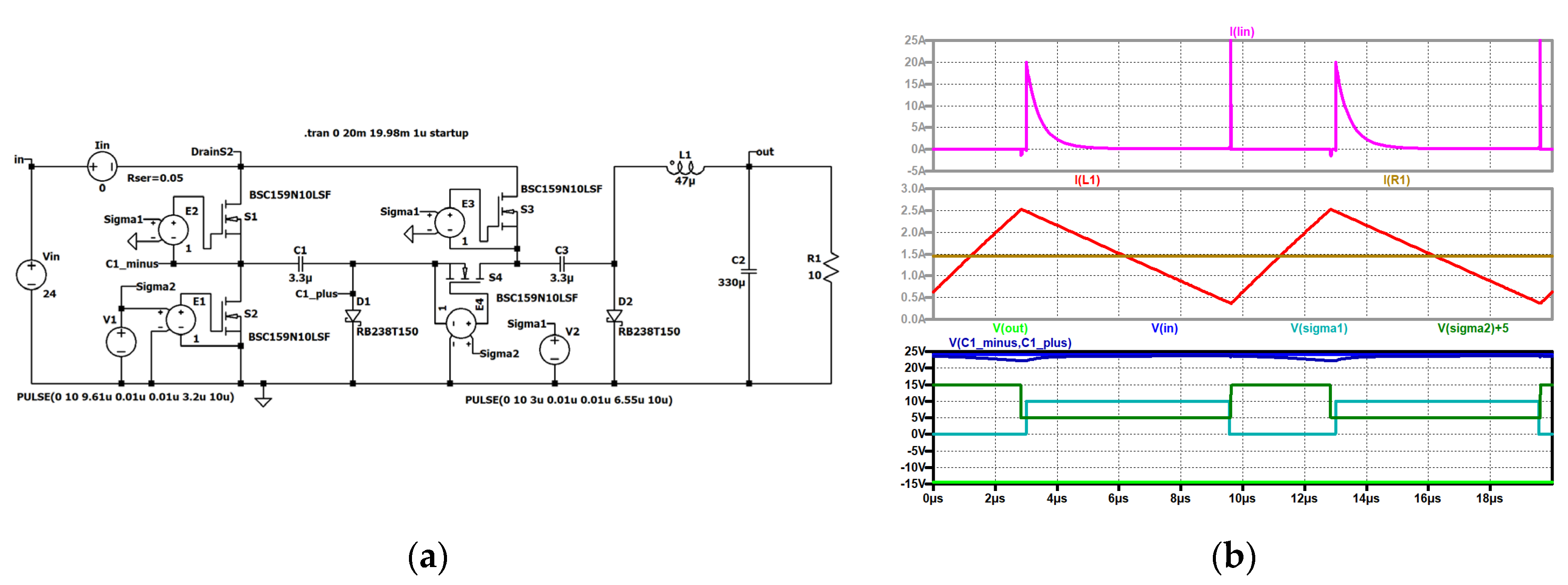

Figure 16.

KY converter with additional current limiting resistor: (a) simulation circuit; (b) up to down: current through the first capacitor (violet); current through the coil (red), load current (brown); output voltage (green), input voltage (blue), voltage across C1 (grey), control signal of the second electronic switch S2 (dark green), control signal of the first electronic switch S1 (turquoise).

Figure 16.

KY converter with additional current limiting resistor: (a) simulation circuit; (b) up to down: current through the first capacitor (violet); current through the coil (red), load current (brown); output voltage (green), input voltage (blue), voltage across C1 (grey), control signal of the second electronic switch S2 (dark green), control signal of the first electronic switch S1 (turquoise).

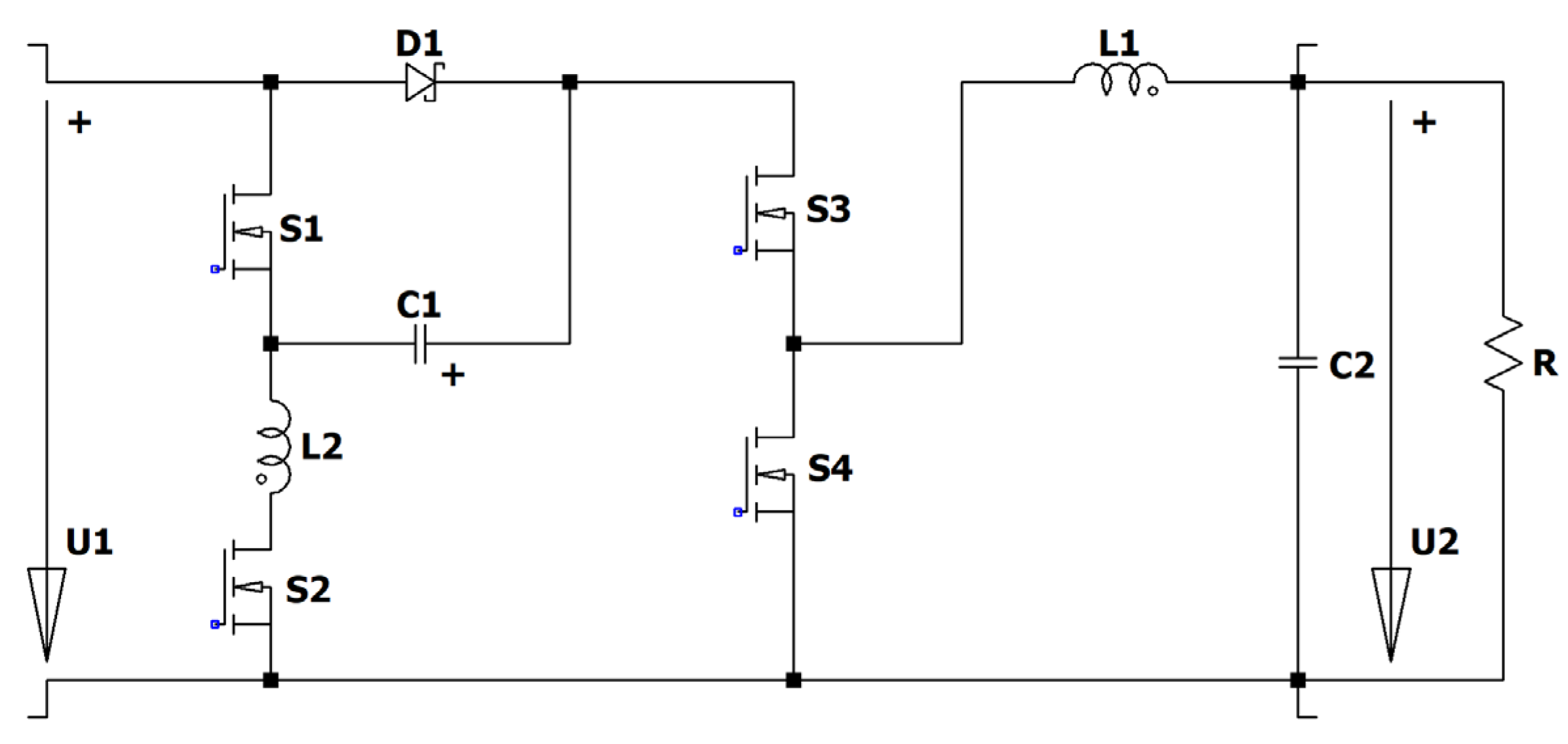

Figure 17.

Inverting KY Boost converter type 1 with limiting resistor.

Figure 17.

Inverting KY Boost converter type 1 with limiting resistor.

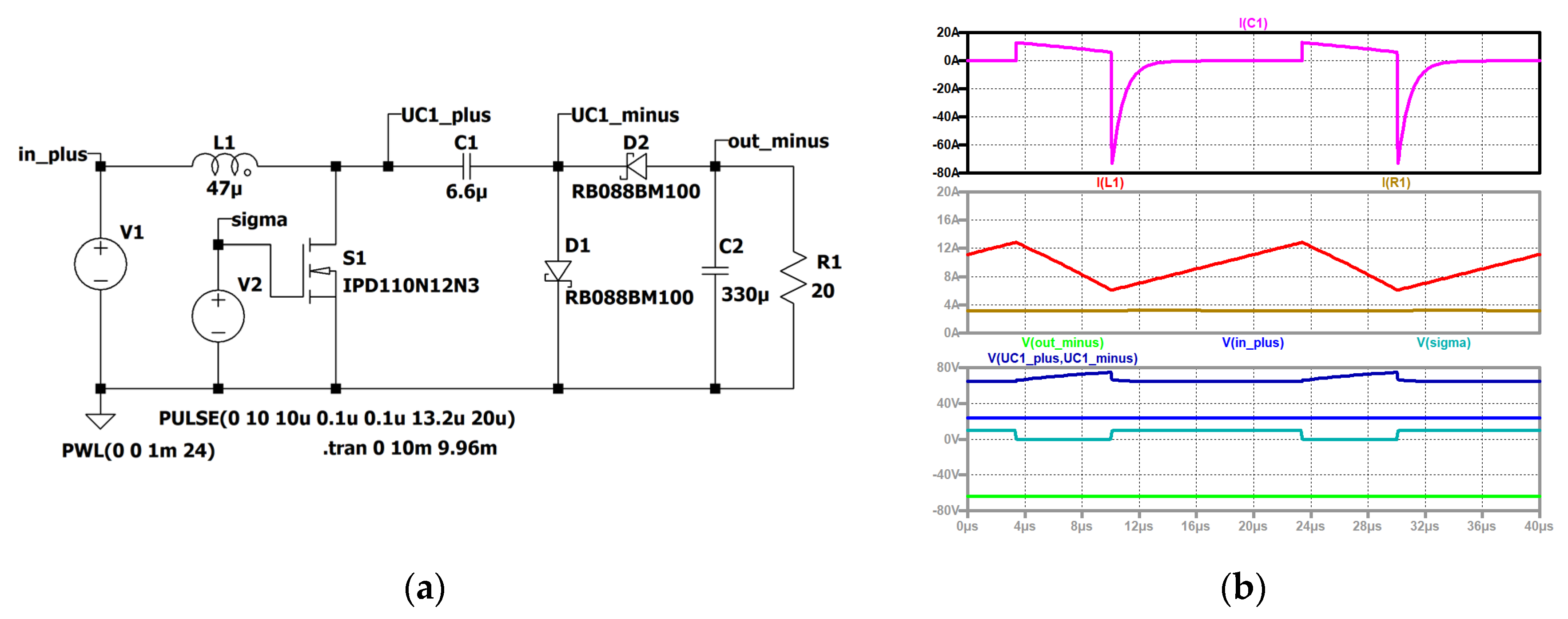

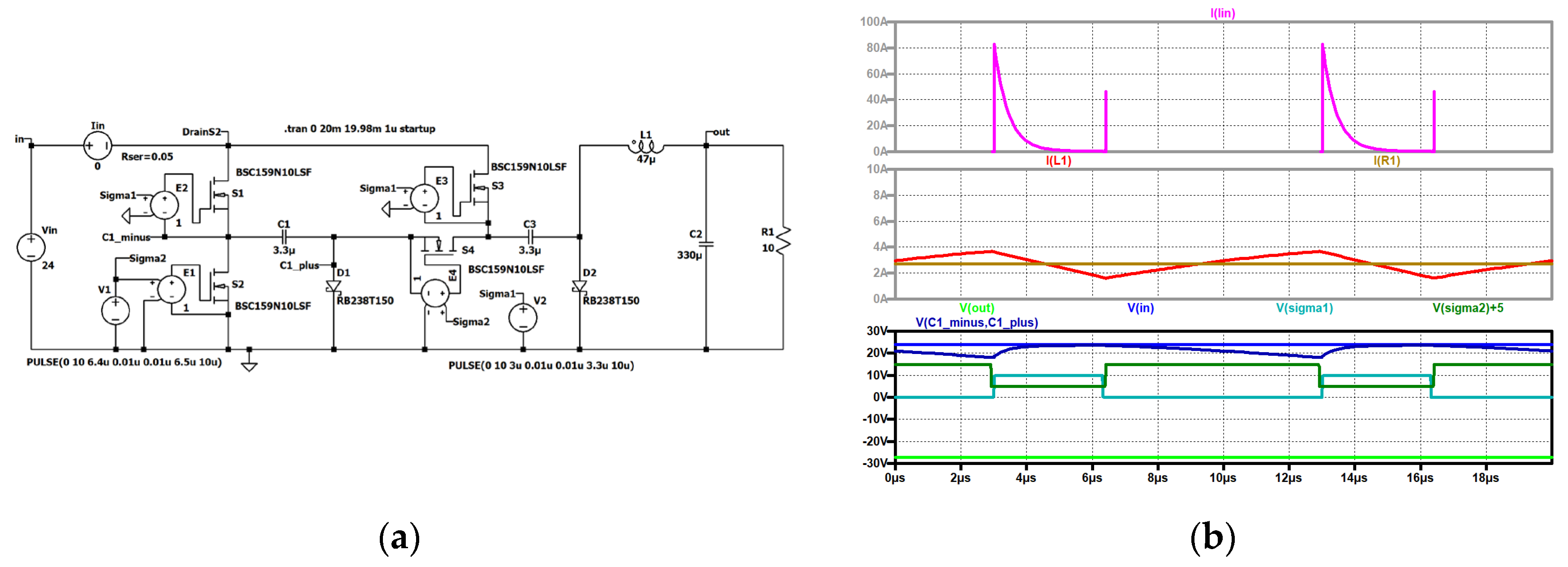

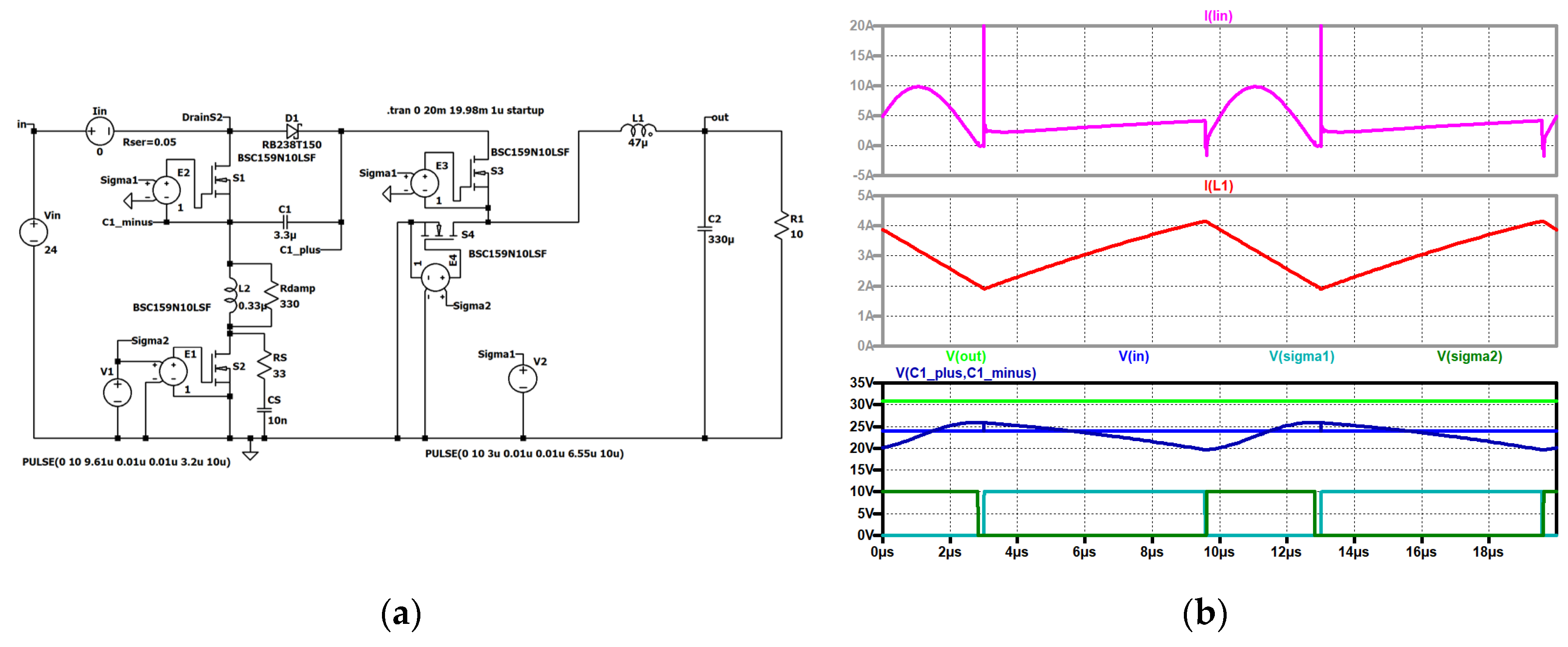

Figure 18.

Inverting KY Boost converter with limiting resistor type I: (a) simulation circuit; (b) top to bottom: current through D1 (violet); input voltage (blue), voltage across C1 (grey); current through L1 (red), load current (brown); input voltage (blue), control signal (turquoise), output voltage (green).

Figure 18.

Inverting KY Boost converter with limiting resistor type I: (a) simulation circuit; (b) top to bottom: current through D1 (violet); input voltage (blue), voltage across C1 (grey); current through L1 (red), load current (brown); input voltage (blue), control signal (turquoise), output voltage (green).

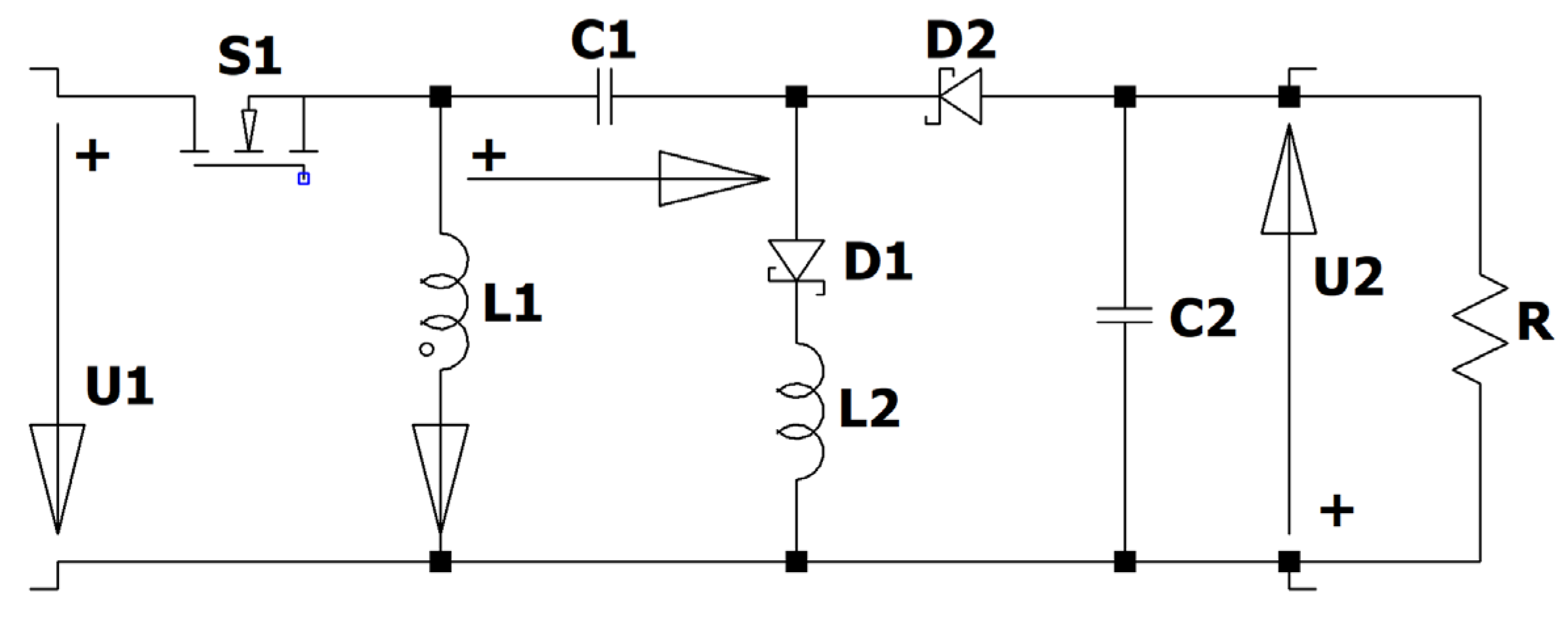

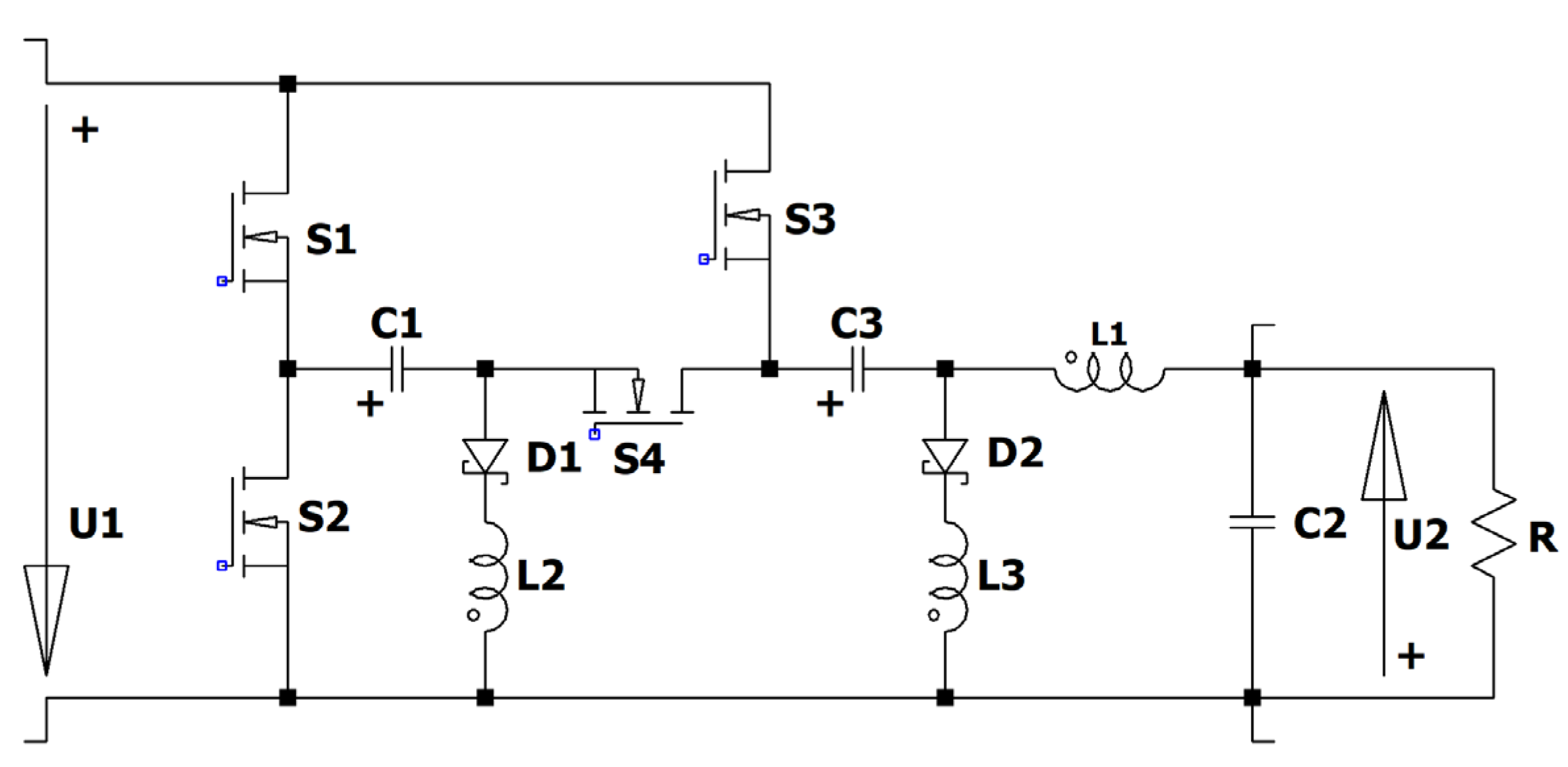

Figure 19.

Inverting KY Boost converter type II with limiting resistor.

Figure 19.

Inverting KY Boost converter type II with limiting resistor.

Figure 20.

Negative inverting KY Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through intermediate capacitor C1 (violet); current through the active switch (grey), current through L1 (red); input voltage (blue), control signal (turquoise), output voltage (green), voltage across C1 (dark blue).

Figure 20.

Negative inverting KY Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through intermediate capacitor C1 (violet); current through the active switch (grey), current through L1 (red); input voltage (blue), control signal (turquoise), output voltage (green), voltage across C1 (dark blue).

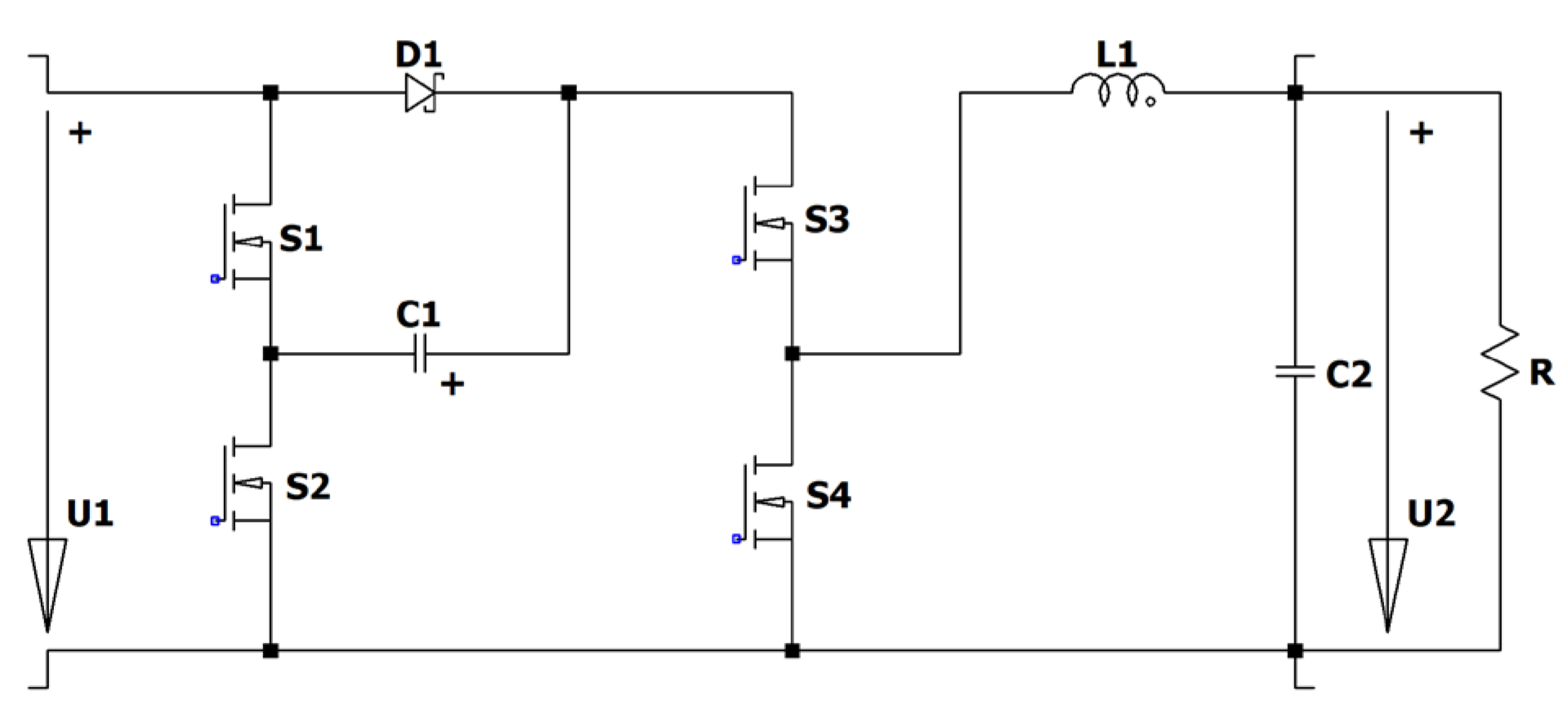

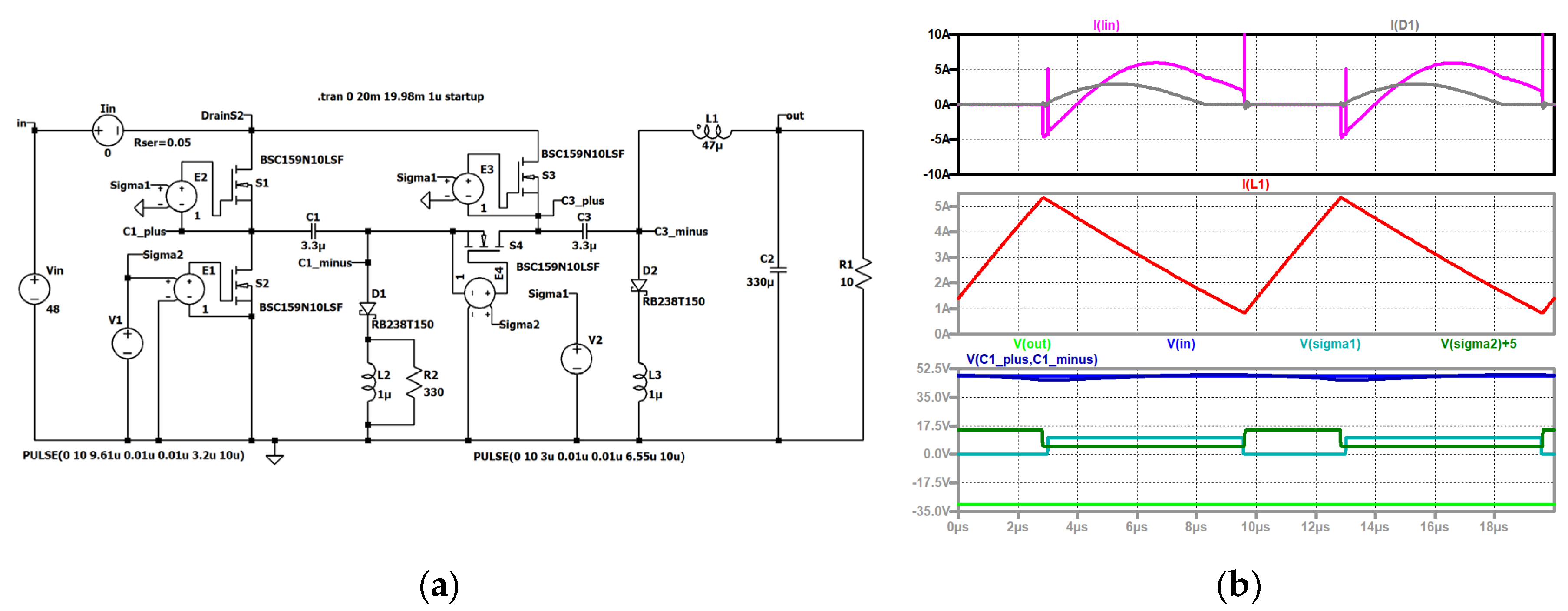

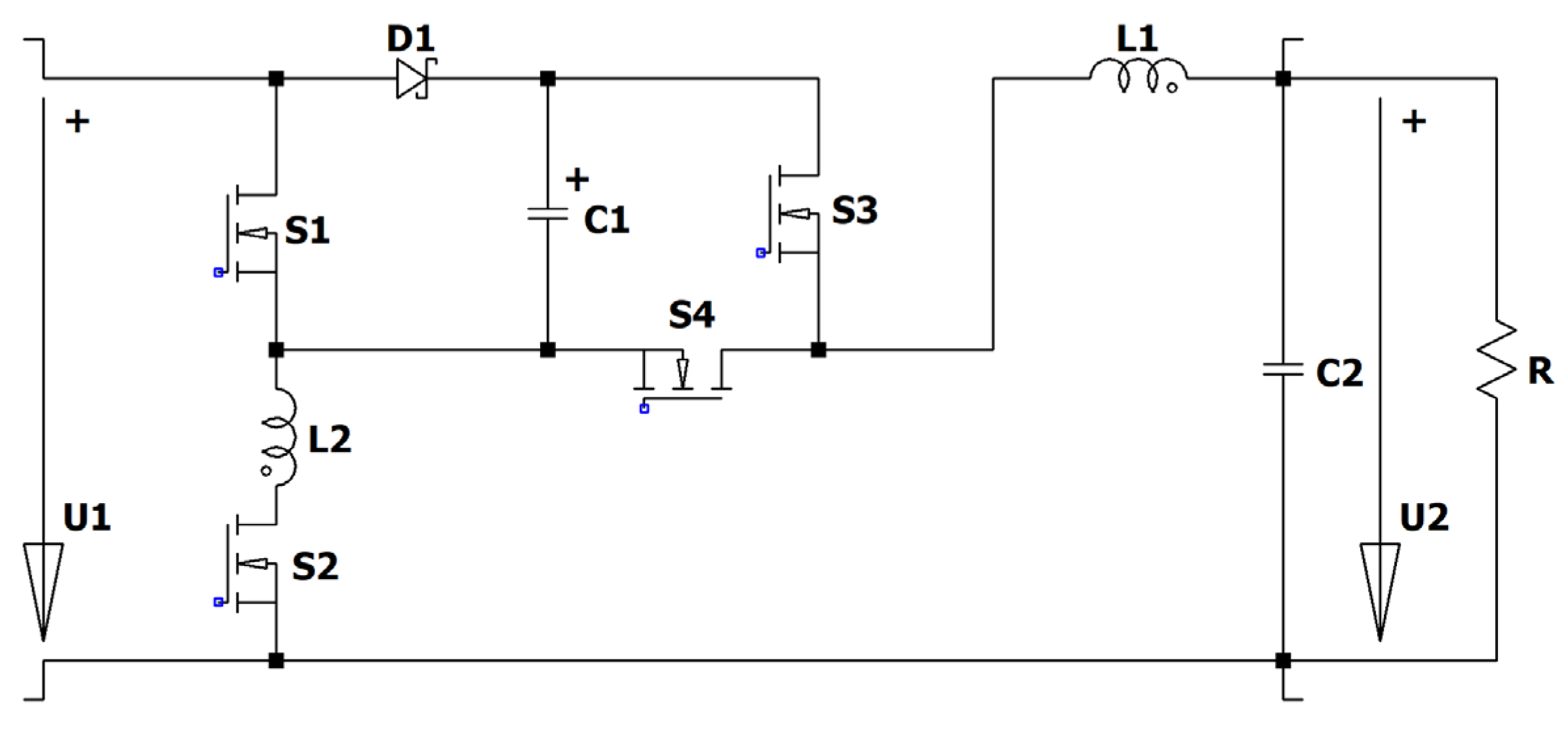

Figure 21.

Inverting KY Buck-Boost converter type II with limiting resistor.

Figure 21.

Inverting KY Buck-Boost converter type II with limiting resistor.

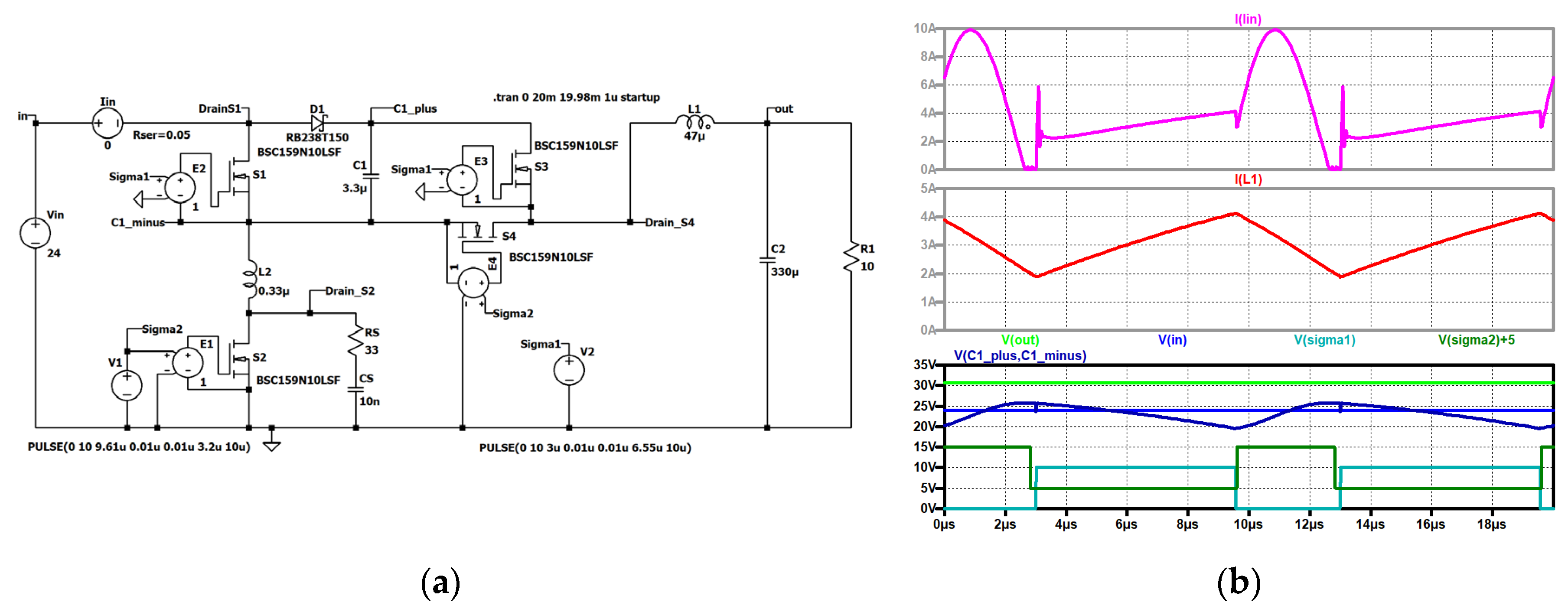

Figure 22.

Inverting KY Buck-Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through intermediate capacitor C1 (violet); current through L1 (red); input voltage (blue), voltage across C1 (dark blue), control signal of S1 and S3 (turquoise), control signal of S2 and S4 (dark green), output voltage (green).

Figure 22.

Inverting KY Buck-Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through intermediate capacitor C1 (violet); current through L1 (red); input voltage (blue), voltage across C1 (dark blue), control signal of S1 and S3 (turquoise), control signal of S2 and S4 (dark green), output voltage (green).

Figure 23.

KY Buck-Boost converter type I with limiting resistor.

Figure 23.

KY Buck-Boost converter type I with limiting resistor.

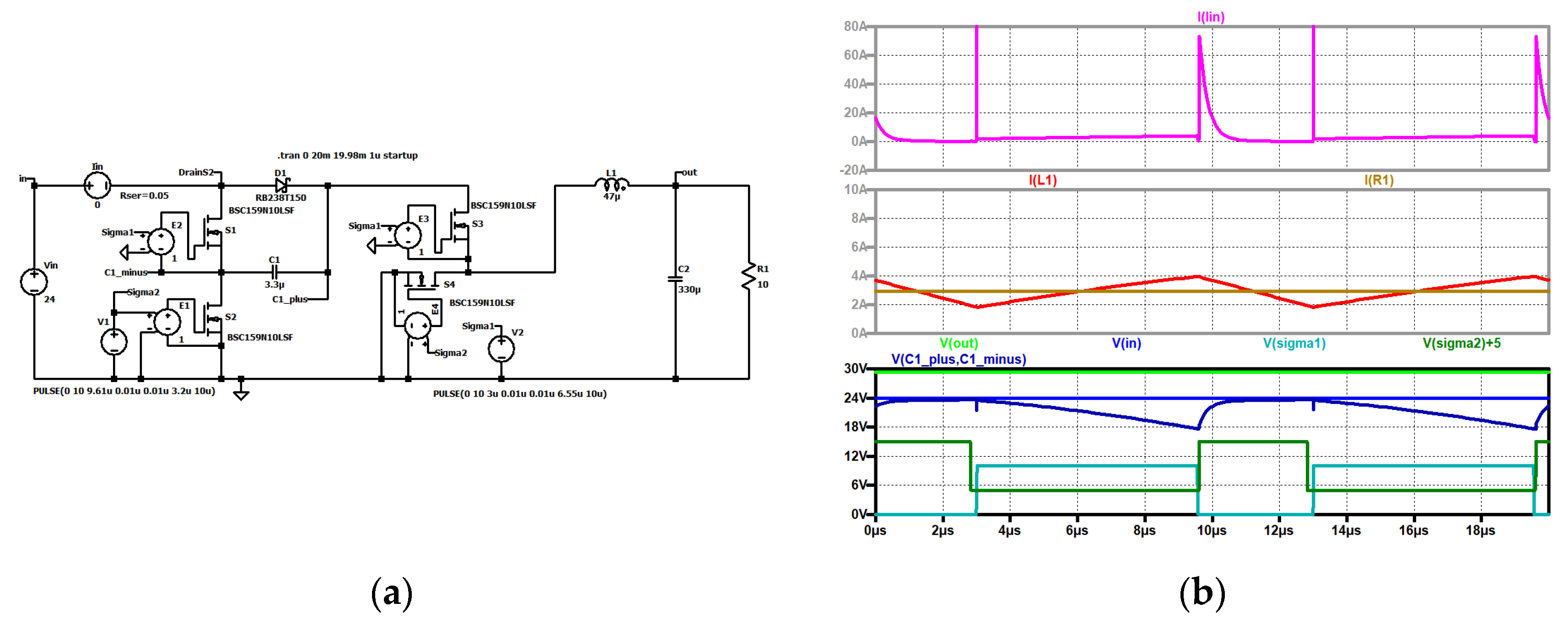

Figure 24.

KY Buck-Boost converter type I with limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 24.

KY Buck-Boost converter type I with limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 25.

KY Buck-Boost converter type I with reduced limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 25.

KY Buck-Boost converter type I with reduced limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 26.

KY Buck-Boost converter type II with limiting resistor.

Figure 26.

KY Buck-Boost converter type II with limiting resistor.

Figure 27.

KY Buck-Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 27.

KY Buck-Boost converter type II with limiting resistor: (a) simulation circuit; (b) up to down: current through the limiting resistor RLIM (grey); current through L1 (red); output voltage (green), input voltage (blue), voltage across C1 (dark blue), control signal of S1 (turquoise), control signal of S2 (dark green).

Figure 28.

Improved KY converter: (a) coil in series to the input; (b) coil in series to S2.

Figure 28.

Improved KY converter: (a) coil in series to the input; (b) coil in series to S2.

Figure 29.

Improved KY converter: (a) simulation circuit; (b) top to bottom: input current (violet), current through the second switch (grey); current through the coil (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of switch S2 (dark green, shifted), control signal of switch S1 (turquoise).

Figure 29.

Improved KY converter: (a) simulation circuit; (b) top to bottom: input current (violet), current through the second switch (grey); current through the coil (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of switch S2 (dark green, shifted), control signal of switch S1 (turquoise).

Figure 30.

Improved negative output KY Boost converter.

Figure 30.

Improved negative output KY Boost converter.

Figure 31.

Improved negative output KY Boost converter: (a) simulation circuit; (b) top to bottom: current through the active switch which is equal to the input current (grey); current through the coil (red); voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of switch S1 (turquoise), output voltage (green). A detailed explanation can be found in [

11].

Figure 31.

Improved negative output KY Boost converter: (a) simulation circuit; (b) top to bottom: current through the active switch which is equal to the input current (grey); current through the coil (red); voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of switch S1 (turquoise), output voltage (green). A detailed explanation can be found in [

11].

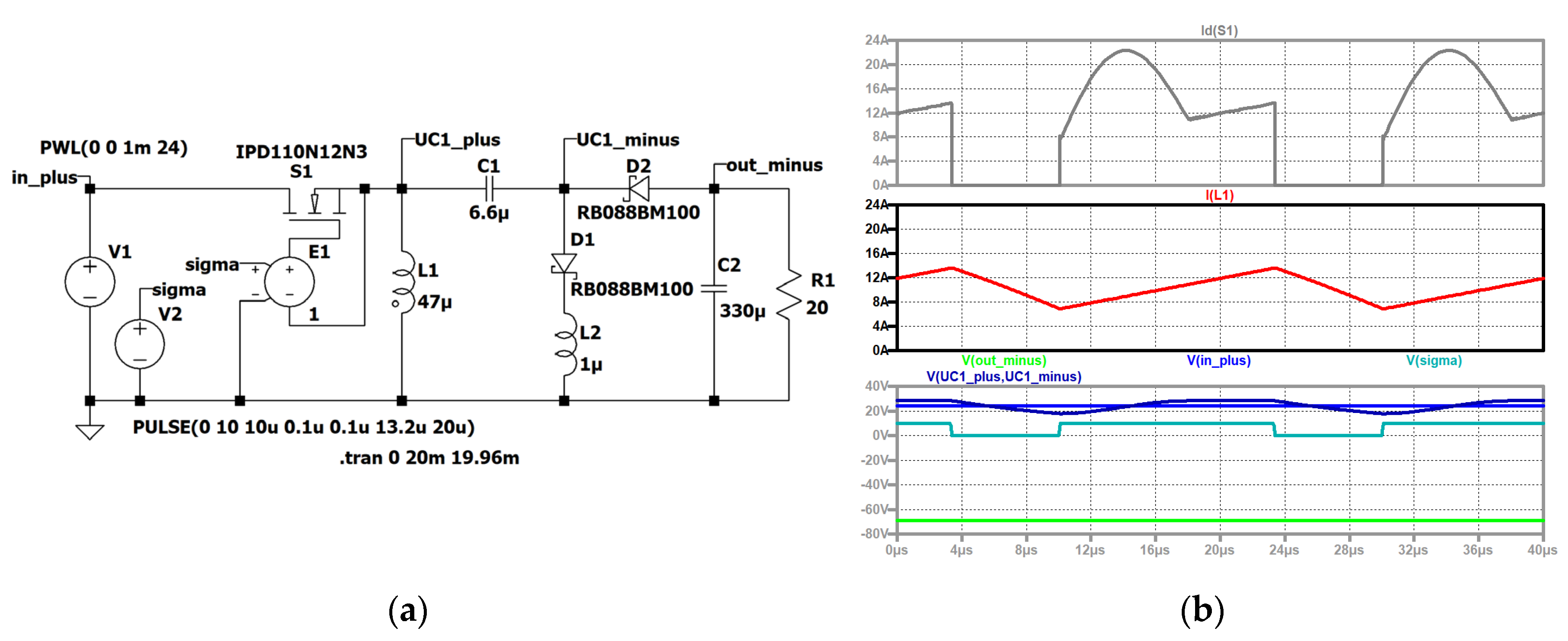

Figure 32.

Improved negative output KY Boost converter type II.

Figure 32.

Improved negative output KY Boost converter type II.

Figure 33.

Improved negative output KY Boost converter type II: (a) simulation circuit; (b) top to bottom: current through the intermediate capacitor C1 (dark green); current through the first diode (grey), current through the resonant coil L2 (violet); current through the main coil L1 (red); input voltage (blue), control signal of switch S1 (turquoise), voltage across the intermediate capacitor (dark blue), output voltage (green).

Figure 33.

Improved negative output KY Boost converter type II: (a) simulation circuit; (b) top to bottom: current through the intermediate capacitor C1 (dark green); current through the first diode (grey), current through the resonant coil L2 (violet); current through the main coil L1 (red); input voltage (blue), control signal of switch S1 (turquoise), voltage across the intermediate capacitor (dark blue), output voltage (green).

Figure 34.

Improved negative output KY Buck-Boost converter.

Figure 34.

Improved negative output KY Buck-Boost converter.

Figure 35.

Improved negative output KY Buck-Boost converter: (a) simulation circuit; (b) top to bottom: input current (violet), current through the diode D1 (grey); current through the main coil L1 (red); voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green, shifted), control signal of the switches S1 and S3 (turquoise), output voltage (green).

Figure 35.

Improved negative output KY Buck-Boost converter: (a) simulation circuit; (b) top to bottom: input current (violet), current through the diode D1 (grey); current through the main coil L1 (red); voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green, shifted), control signal of the switches S1 and S3 (turquoise), output voltage (green).

Figure 36.

Improved KY Buck-Boost converter type I.

Figure 36.

Improved KY Buck-Boost converter type I.

Figure 37.

Improved KY Buck-Boost converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the main coil L1 (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green), control signal of the switches S1 and S3 (turquoise).

Figure 37.

Improved KY Buck-Boost converter type I: (a) simulation circuit; (b) top to bottom: input current (violet); current through the main coil L1 (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green), control signal of the switches S1 and S3 (turquoise).

Figure 38.

Improved KY Buck-Boost converter type II.

Figure 38.

Improved KY Buck-Boost converter type II.

Figure 39.

Improved KY Buck-Boost converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the main coil L1 (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green, shifted), control signal of the switches S1 and S3 (turquoise).

Figure 39.

Improved KY Buck-Boost converter type II: (a) simulation circuit; (b) top to bottom: input current (violet); current through the main coil L1 (red); output voltage (green), voltage across the intermediate capacitor (dark blue), input voltage (blue), control signal of the switches S2 and S4 (dark green, shifted), control signal of the switches S1 and S3 (turquoise).

Table 1.

Possible positions of the limiting resistor.

Table 1.

Possible positions of the limiting resistor.

| In series to C1 |

Leads to additional losses during M1 |

| In series to S2 |

Losses only by the charging current |

| In series to D |

Additional losses during M2 |

| In front of the circuit |

Always additional losses |