With majority of the notable works done in SPUAVs quoted here, the primary focus is towards the aspects mentioned below:

1.1. Methodology of Integrating Solar Power with UAVs

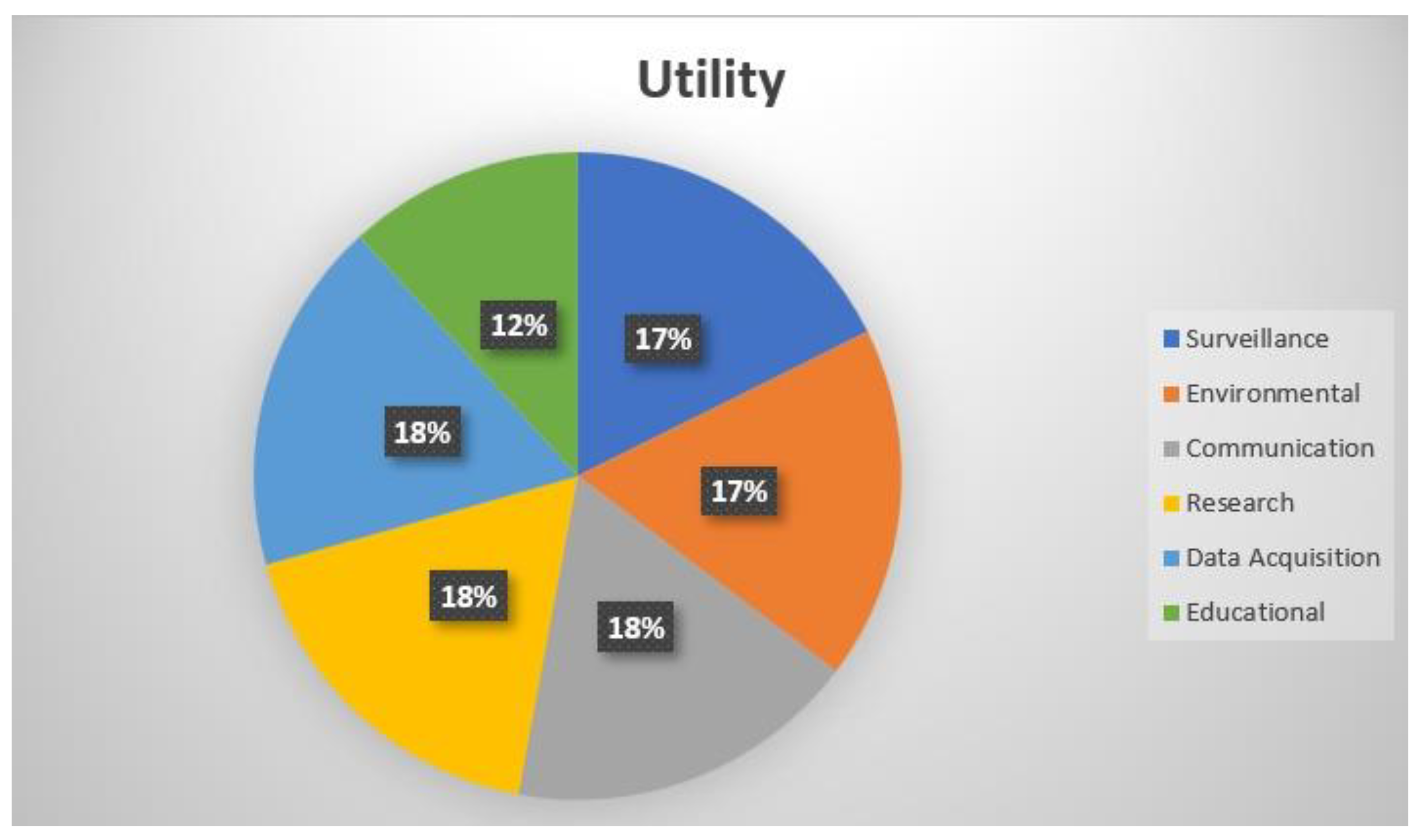

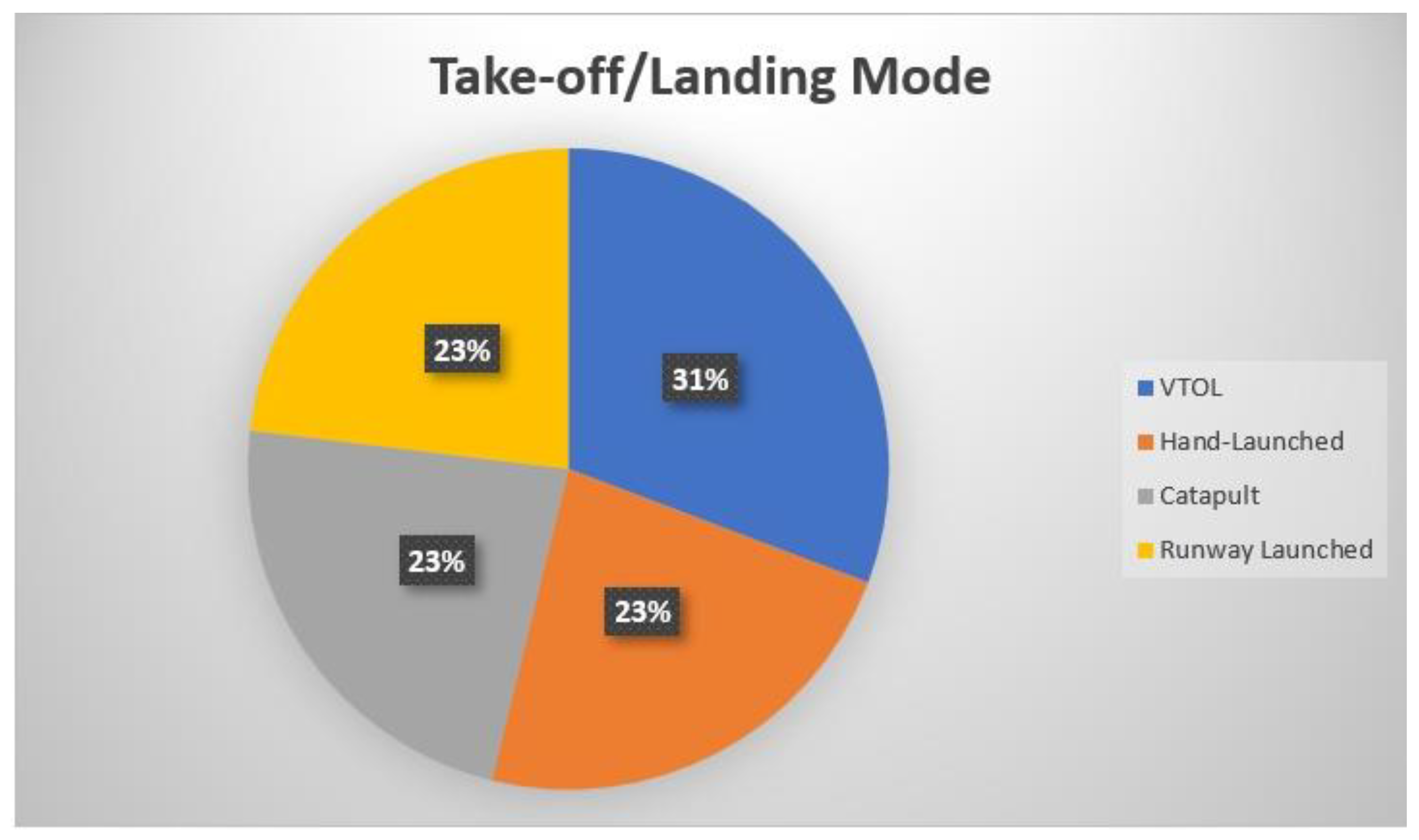

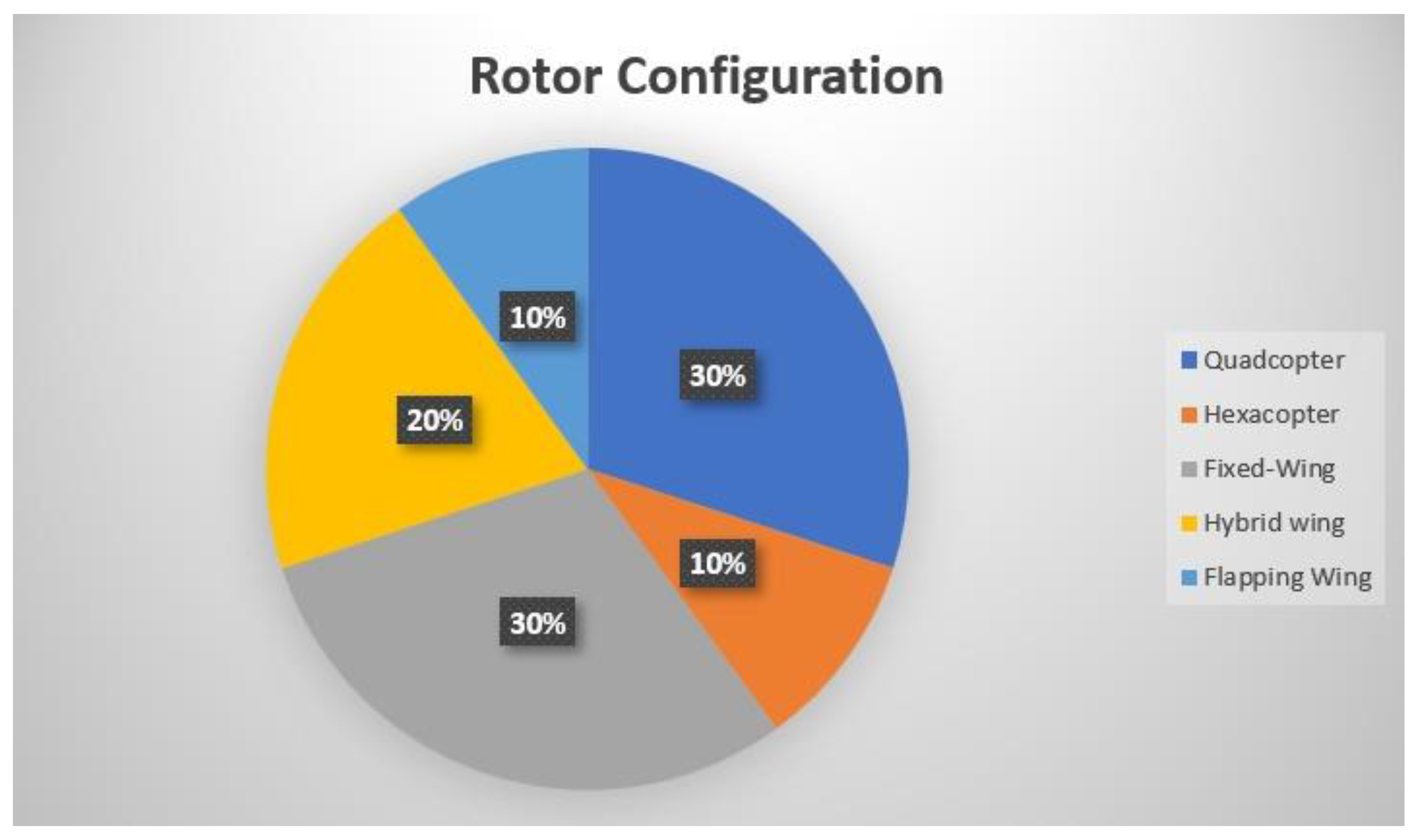

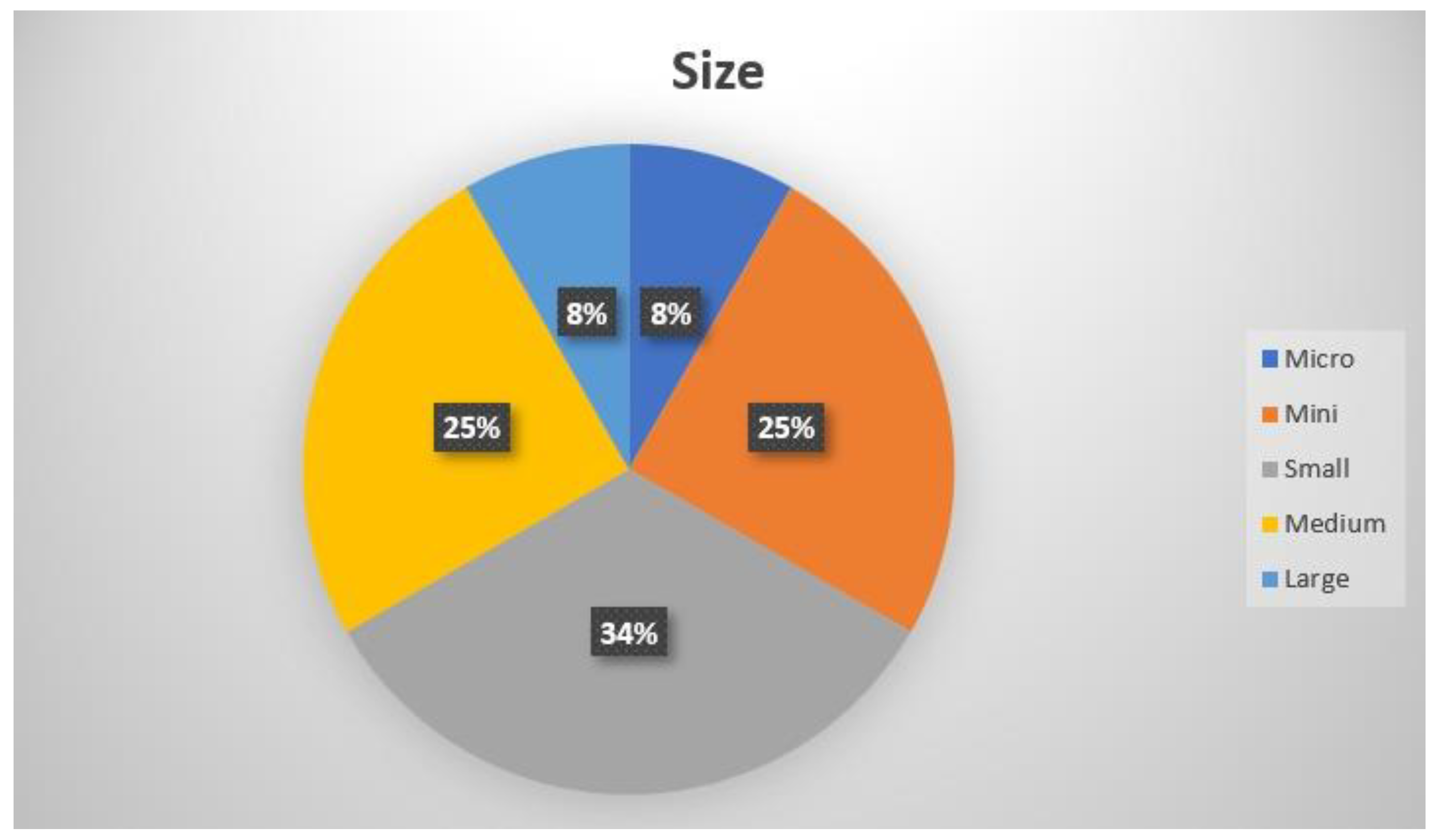

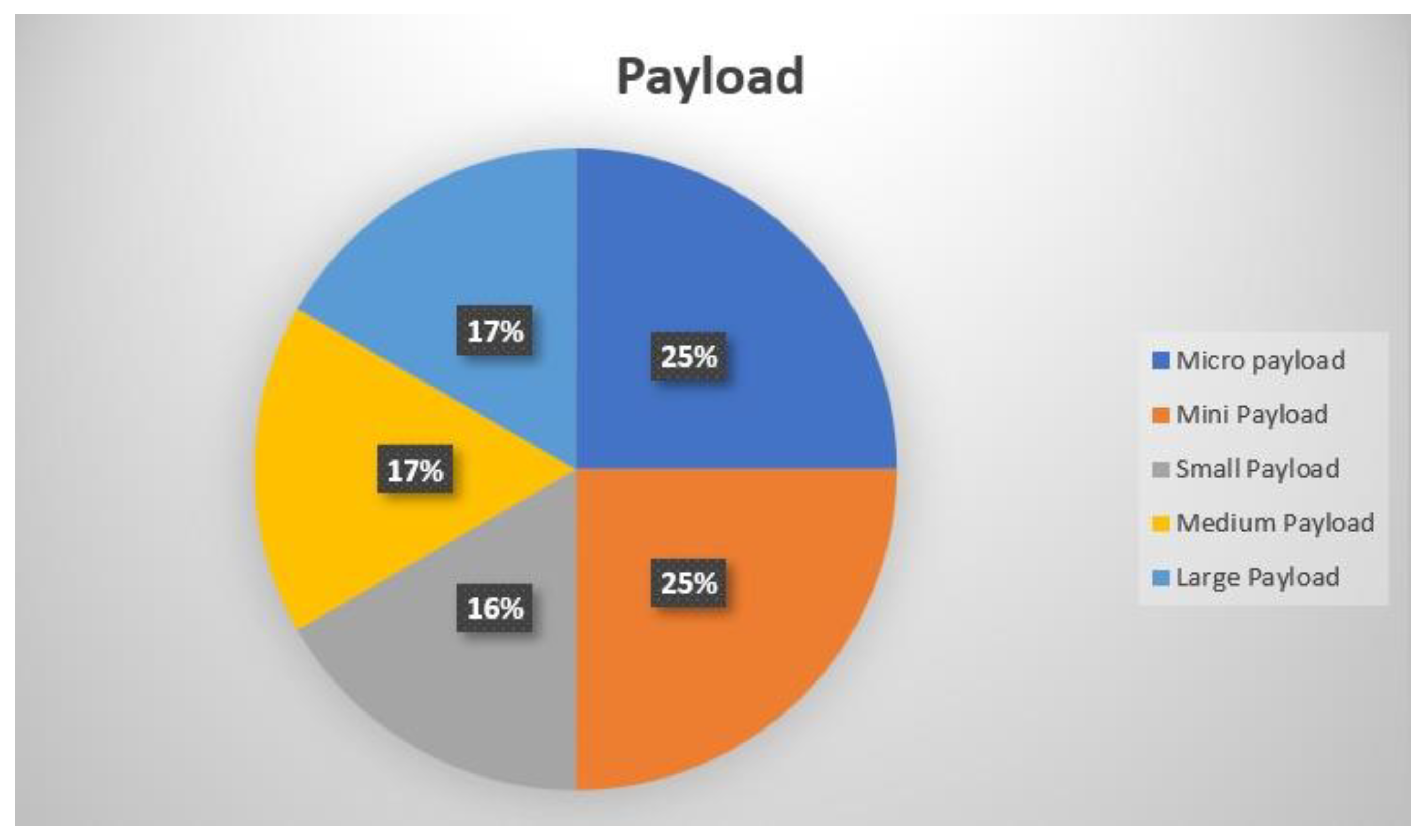

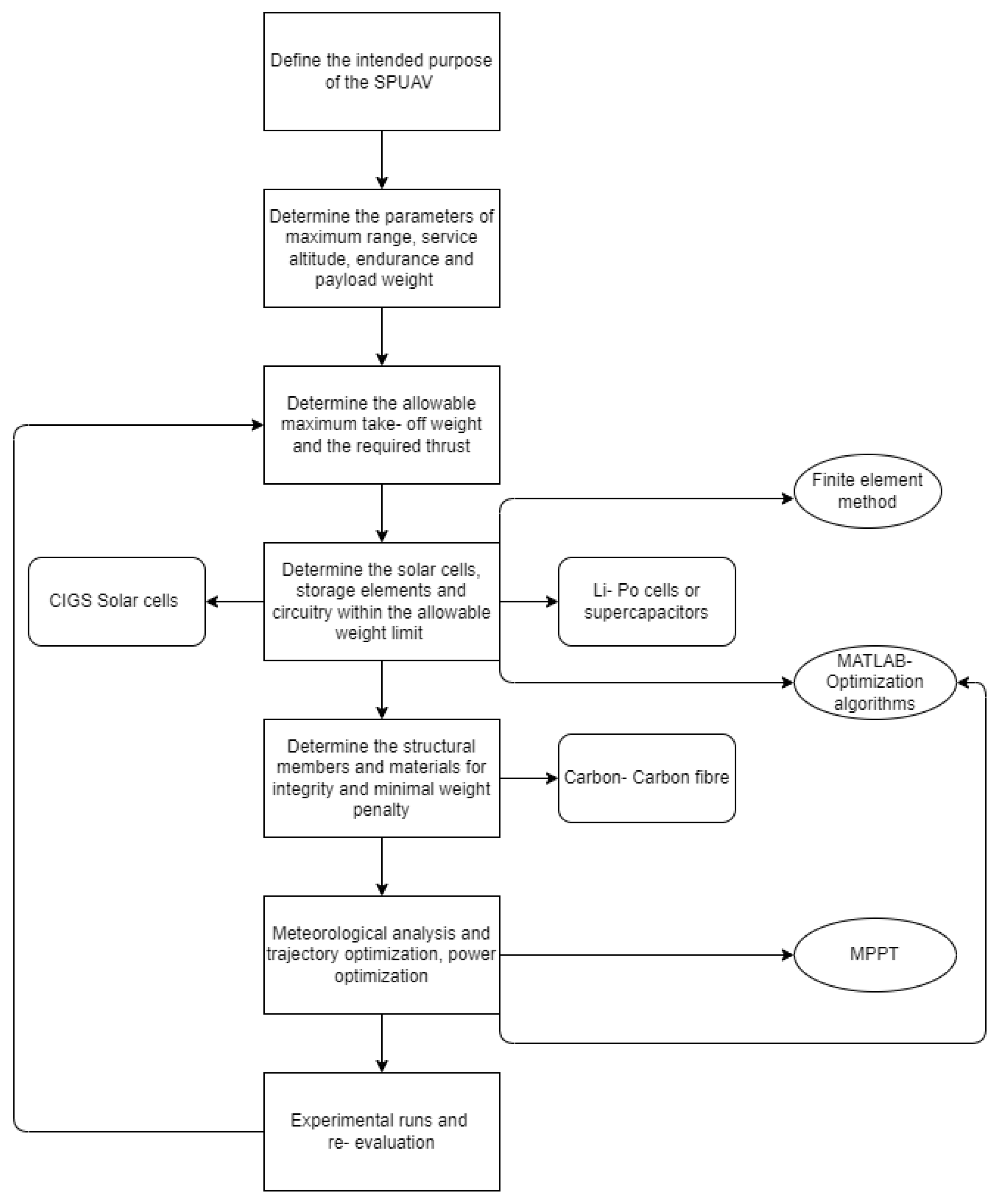

Unmanned aerial vehicles are diverse in their utility, build and cost. They are almost employed in every service sector such as mapping and geographical surveillance, goods delivery, photography and videography, aerial monitoring and surveillance, agricultural monitoring and pesticidal purposes and the budding concept of air taxis. With UAVs emerging at the forefront of aviation, integrating sustainability and experimenting with the same in impeccable. With the literature presented here, significant points of consideration with respect to the design of the UAV while integrating solar panels, are quoted here, eventually paving a way for a comprehensive framework for the design of SPUAVs.

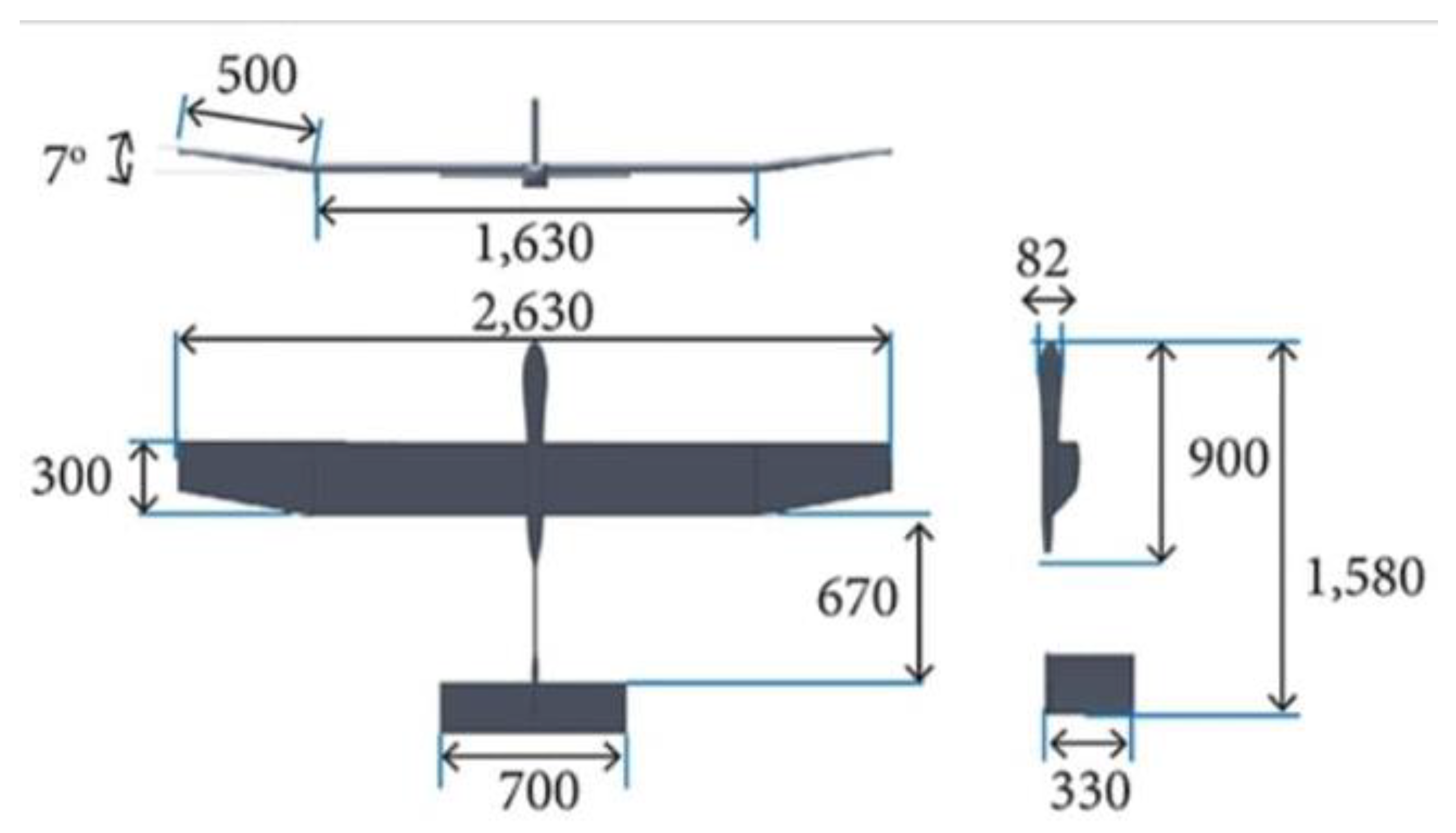

3.1.1. Engineering Design of the UAV with High Endurance

Any aerial vehicle is highly dependent on the interlinked concepts of aerodynamics, weight distribution and the center of gravity with the constraint of structural integrity. This determines the feasibility of the vehicle and eventually accounts for the performance parameters of range and endurance. A constraint analysis graph, generated using MATLAB code, was used to evaluate performance based on power-to-weight or thrust-to-weight ratios and wing loading by (Tomar). The fuselage design for solar aircraft is simplified by the absence of fuel tanks and fuel lines. A single fuselage and tail boom was deemed most suitable for a lightweight and efficient structure, minimizing surface friction drag and simplifying construction. The length of the fuselage was curtailed to decrease weight and drag. The designed UAV can demonstrate maneuvers at 5000 meters and demonstrates exceptional flight control and stability with a stalling angle of degrees. Upon the factor of weight addition due to the solar modules, most researchers had opted for a viable solution of Li- Po batteries as done by (Asutosh Pati) who had reported that the centre of gravity of the wing is maintained at the optimum quarter chord and a low dihedral is maintained, upon the right component placements including Li- Po batteries. For the structural integrity, lightweight carbon fibres are quoted by researchers. Carbon fibers are recommended for manufacturing components due to their lightweight and strong properties as mentioned by (Keerthana Reghunath). The design involves integrating the solar panels directly onto the wings. Moreover (S. Sathishkumar) quoted that this alternative supports for improved aerodynamics and better solar panel placement.

As mentioned before, the aid of CFD for a multi case analysis is undeniable. Using computational fluid dynamics based on the Navier–Stokes equations and a RANS (Reynolds - Averaged Navier – Strokes Equation) turbulence model, (Joana Engana Carmo) had simulated the aerodynamic flow and pressure distribution on the UAV structure to ensure that the thin-film crystalline silicon solar cells can withstand mechanical stresses during flight. The simulation results confirm that the aerodynamic pressures do not exceed the material yield limits, validating the structural feasibility of solar panel integration. Subsequent solar performance simulations, incorporating irradiance, wind cooling, and temperature effects through the Skoplaki 2 model, demonstrate that power generation and efficiency depend heavily on orientation, altitude, and time of year.

Finite element analysis verified minimal structural weakening (less than 3% strain reduction), while optical simulations predicted up to 28% increased power output due to enhanced photon capture. Experimental outdoor testing on small-scale UAV prototypes confirmed a 17% range extension compared to non-solar counterparts. (H Hrauda)

Focusing the core issue of limited battery life for surveillance drones, under desirable environmental conditions, the incorporation of solar power had drastically reduced the sue of the battery capacity stored by 22.5% as reported by (Vivek Sharma). Similarly, (Hareesha N G) reports a current production of 1.1 Amperes in optimal solar conditions, from the SPUAV they had developed. (Karthik Reddy Buchireddy Sri) had quoted that geographical area of operation, energy collection and storage mechanisms, payload requirements and overall design parameters are the significant aspects for the design of an SPUAV.

(O. A. Huseynov) had focused on Trajectory Optimization research to determine the optimal flight path (ascent and descent trajectories) for a solar-powered UAV to maximize the energy harvested by its solar panels and Atmospheric Impact Modeling is critical aspect of the study is the inclusion of atmospheric conditions in the energy calculation.

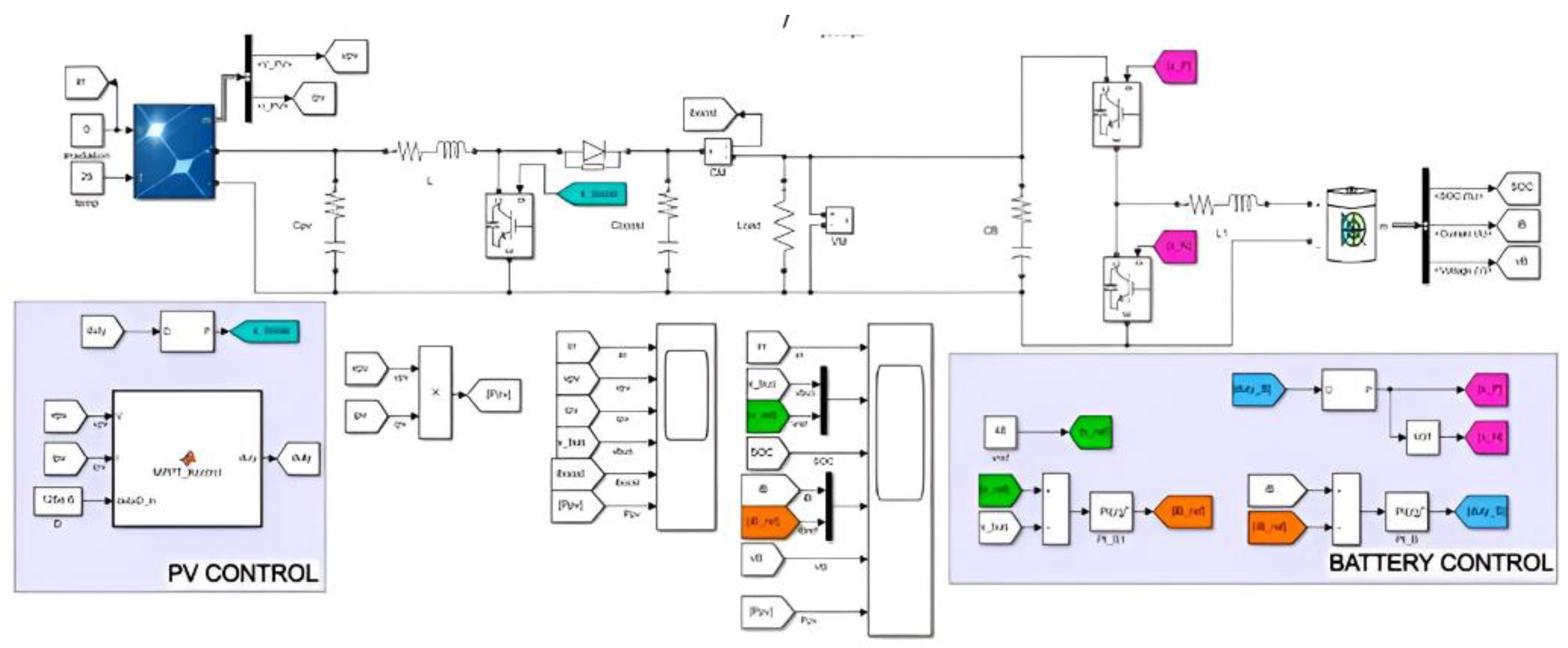

3.1.2. Energy Optimization

As opposed to any experiments or practical modelling of a design at its proposition, researchers choose to simulate and computationally analyze the parameters. Furthermore, a single engineering model in itself is seldom self- efficient nor advantageous unless there are kits and components installed to monitor the functioning, health and operability of various components, in major cases. (Dr. Raghvendra Tiwari) had employed a Maximum Power Point tracking (MPPT) kit to maintain the voltage level and ensure the power delivery to be maximum from the solar cells to the battery and eventually the circuits. (S. Sathishkumar) also employs MPPT for optimal energy utilization. In order to compute the effects of solar radiation under various meteorological conditions, (Zhonghua Hu) had developed multiple mathematical models along with the optimization algorithms to predict the performance of the solar cells, considering the factors of solar irradiation angle, mountain shadow occlusion, cloud shading. In addition to this, they had also developed a mountain shadow occlusion cost calculator based on the geometric relationship between the UAVs position, the mountain’s height and the sun’s altitude angle. From the work carried out by (Jessa) a total of 54 commercial UAVs and 25 solar cells were analyzed for a solar drone with the parameters of battery capacity of 6- 40 minutes, velocity of 18- 112 kmph and a maximum range of 52.7 km. The resulting power efficiency lies in between the range of 0.42- 1.64 Watts per 100 sq.cm. Upon calculating the total journey time (TJT), which is the time required to build a drone network chain of 100 km, factoring in both flight and solar recharging cycles. From this the most efficient solar cell was identified as Cell ID 25 with 1.64 Watts per 100 sq.cm efficiency, which also proved to be economical. (Farid Ibrahim) had developed a and lithium-polymer batteries. Experimental flight trials under full sunlight demonstrated that solar charging extended endurance by approximately 22–30%, depending on irradiance levels. The research also analyzes the trade-offs of additional structural mass and drag caused by solar integration. Computational analysis showed only minor aerodynamic penalties when the panels were flush-mounted. In the UAV developed by (Philipp Oettershagen) the UAV had demonstrated exceptional energy resilience, the minimum state-of-charge (SoC) of the battery never dropped below 40%, even during the longest night. On average, the system had 6.8 hours of excess endurance and 6.2 hours of daylight charge margin, indicating significant energy surplus for unforeseen weather conditions or additional payload power needs. Even under partial cloud cover and turbulent winds up to 17 m/s, the UAV maintained stable flight, validating both the robustness of the CDAF design approach and the system’s overall efficiency. (Franklin Salazar) had also developed a low flight UAV catering to the unique meteorological conditions of Ambato, Ecuador and had attained an appreciable increase in endurance as opposed to the weight addition of 690 grams due to the solar modules.

Moreover, a vast number of researchers had reported the use of Li- Po batteries for an efficient charging time as opposed to it weight penalty as mentioned by (Mrs. M. Uma Mythraye)

There are also novel approaches for energy conservation as introduced by (Jackson Liller Rishabh Goel) on employing a supercapacitor bank. a supercapacitor bank (six 2.7 V, 500 F capacitors in series), and a maximum power point tracking (MPPT) circuit for energy regulation. The supercapacitor system replaces lithium-based batteries, providing fast charge/discharge cycles and extended operational life. Constructed from laser-cut vinyl-reinforced polystyrene with 3D-printed reinforcements, the fixed-wing design optimizes surface area for solar collection while maintaining high lift-to-drag ratio through MH117 airfoil geometry. Power tests under simulated solar irradiance showed continuous thrust production up to 350 grams-force, Supercapacitors charged to 12 V in 150 seconds under peak irradiance (40 W), providing robust power buffering against solar intermittency. Proposed extensions include optimizing airframe aerodynamics to reduce parasitic drag and refining the power circuitry for continuous high-thrust operation. The combination of supercapacitor energy storage and adaptive control algorithms establishes a basis for future UAVs capable of indefinite flight under adequate solar conditions.

3.1.3. Note on the Global Trend Towards Sustainability

The main focus is to comprehend the contemporary techniques used for market rebalancing, pricing, and managing the supply demand balance in a power grid with increasing renewable penetration in the work by (J. Shri Saranyaa). The paper notes that power generation globally is rapidly transitioning to renewable energy technologies to address the energy crisis and promote clean energy. This transition is accelerating due to the signing of the Paris Agreement and the goal of achieving grid parity, where RES can compete economically with conventional energy generation. The overall global renewable energy capacity has seen incredible growth. Levelized Cost of Energy (LCOE) is presented as the primary global evaluator for energy pricing, ensuring a fair valuation of generation costs and tracking the achievement of grid parity for different technologies. The survey extensively reviews recent methodologies for LCOE estimation.

Upon considering all these nuances, we present a summarizing framework that serves as an overview for SPUAV design:

1.1. A Detailed Study on CIGS Solar Cells

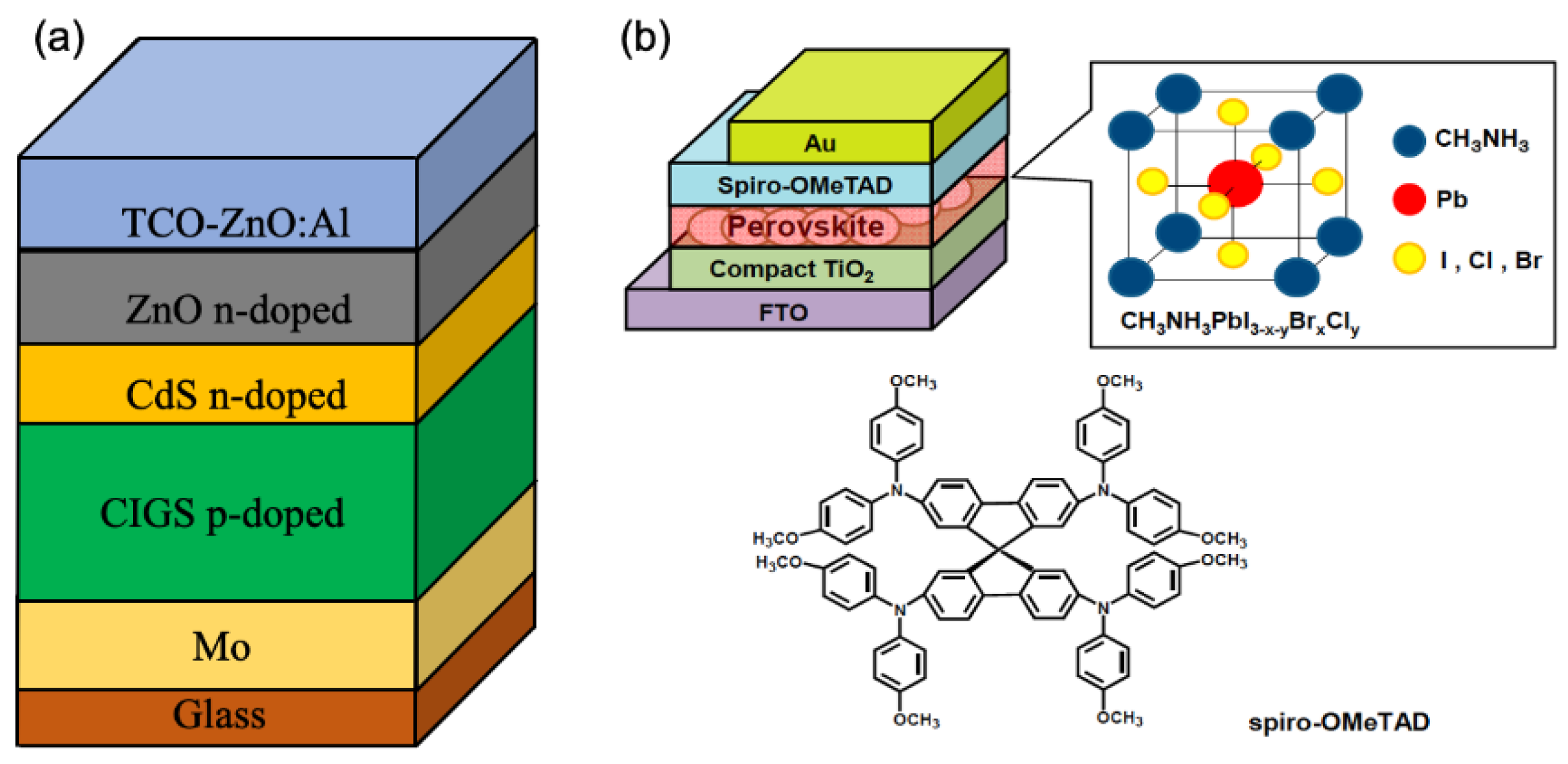

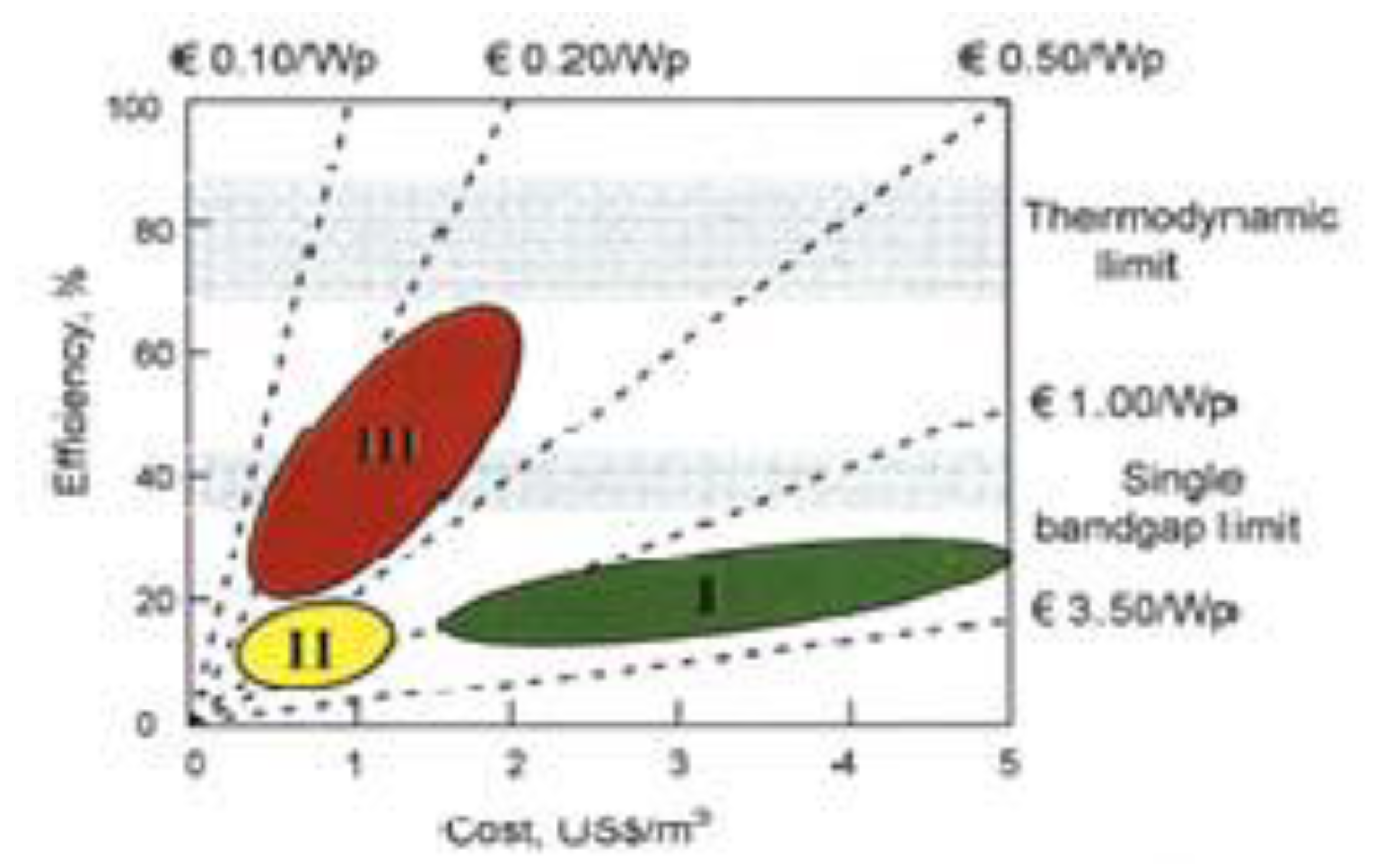

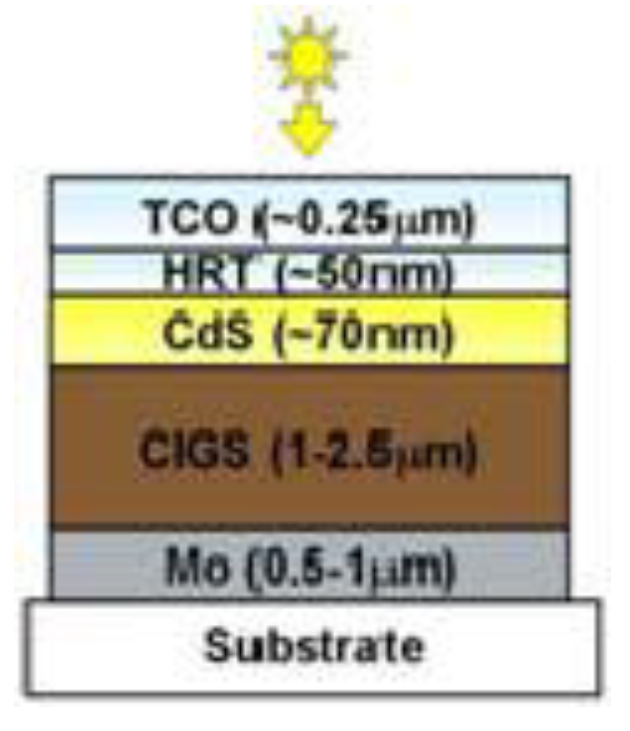

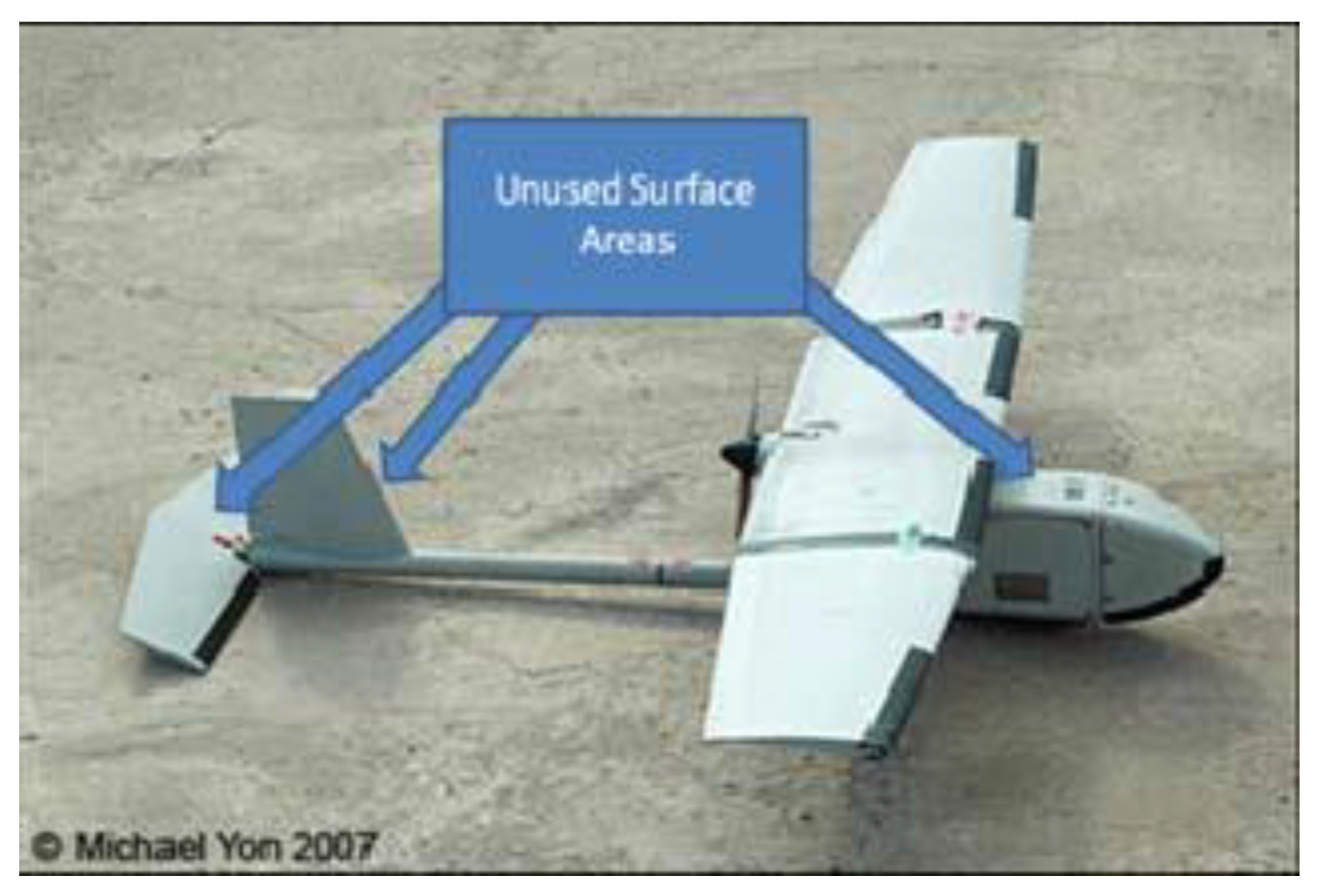

Copper Indium Gallium Selenide cells have revolutionized the thin film solar cells industry, paving way to new frontiers of interdisciplinary applications and enhancing sustainability to its practical peak. This thesis by (Hurd) investigates the practical application of commercially available thin-film photovoltaic (PV) cells, specifically Copper Indium Gallium Diselenide (CIGS) cells, to extend the endurance and capabilities of military Unmanned Aerial Vehicles (UAVs), with a focus on Small Unmanned Aerial Vehicles (SUAVs) like the RQ-11B Raven. The United States military operates over 11,000 battery-powered UAVs, which provide essential intelligence, surveillance, and reconnaissance capabilities. However, their limited battery life constrains mission duration and tactical flexibility. Increasing battery size to extend endurance is not a viable solution due to weight and volume penalties that compromise payload capacity and portability, especially critical for tactical units operating in austere environments. The thesis aims to explore how integrating flexible, thin-film CIGS solar cells into existing UAVs can enhance flight endurance and operational capabilities. Due to constraints in accessing actual military UAVs, a commercially available battery-powered plane with similar physical characteristics to the RQ-11B Raven was used as a proof-of-concept platform. The study examines solar cell selection, power integration including maximum power point tracking (MPPT), battery technology, and system assembly to demonstrate feasibility. The thesis delves into semiconductor physics and the photovoltaic effect, explaining how p-n junctions convert sunlight into electrical energy. It discusses factors affecting efficiency such as reflection, shading, and temperature effects. Thin-film CIGS cells offer high specific power per unit mass, flexibility to conform to aircraft surfaces, and better potential for integration with minimal aerodynamic penalties. The composition of a typical CIGS cell is shown in

Figure 8. Compared to other thin-film technologies like amorphous silicon and cadmium telluride, CIGS cells provide superior efficiency and specific energy density, making them the preferred choice for UAV applications. The study emphasizes minimizing energy losses through optimized power electronics. MPPT technology is critical to operate solar cells at their peak efficiency, incorporating voltage regulation and battery charge control to prevent damage. The variation of cost and efficiency of the photovoltaic cells across generations are shown in

Figure 7. Lithium polymer (Li-Po) batteries are standard in UAVs, but lithium-sulfur batteries offer higher energy density, promising longer endurance in future applications. Using off-the-shelf components, solar cells harvested from Global Solar’s portable chargers were adapted and installed on the wings of the proof-of-concept aircraft. The integration included MPPT controllers, voltage limiters, and blocking diodes to manage power flow and protect components. Initial tests characterized battery performance and solar cell output. Despite some MPPT malfunctions, solar charging significantly reduced battery recharge time to 2–3 hours under realistic conditions. The modified aircraft demonstrated endurance increases from 2.5 up to 3 times the baseline flight time under constant throttle conditions. This confirmed that even with less efficient (8%) and heavier solar cells, the net effect of solar integration was substantial. Calculations showed that solar cells contributed approximately 11 W of continuous power during flight, supplementing the battery's energy and validating the feasibility of solar-enhanced UAV endurance. The cost estimate for modifying an RQ-11 Raven with CIGS solar cells, MPPT, and integration materials is under

$1,000 per unit, which is economical considering the potential mission benefits and extended operational capability. The research demonstrates that flexible CIGS thin-film photovoltaic cells can effectively extend UAV endurance by a factor of 2.5 to 3, even with non-ideal components. The RQ-11 Raven is identified as a prime candidate for solar modification due to its widespread use and tactical importance. Advances in solar cell efficiency and lighter power electronics will further enhance these gains.

Figure 9 and

Figure 10 show the Raven- 11 with the desired solar cell assembly.

Among various photovoltaic materials, Copper Indium Gallium Selenide (CIGS) stands out due to its high conversion efficiency greater 20% and potential for cost-effective large-scale production, states the work by (A. Khamisa). The absorber layer in CIGS solar cells is critical as it directly absorbs sunlight and generates charge carriers that produce electricity. Enhancing this layer’s properties and thickness can significantly influence solar cell performance parameters such as open-circuit voltage (Voc), short-circuit current density (Jsc), fill factor (FF), and overall efficiency (η). The absorber layer acts as the "control center" in solar cells, capturing photons and stimulating electron-hole pairs essential for current generation. Optimizing its bandgap and thickness is crucial to maximize photon absorption and minimize recombination losses. Conventional absorber layers use materials like CdS and ZnO as buffer and front contact layers. Innovations focus on integrating materials like Graphene Nanoplatelets (GnP) and Copper Gallium Selenide (CGS) to enhance electrical and optical properties. Efficiency degradation occurs with temperature increases (288 K - 323 K) due to bandgap narrowing, necessitating optimization for temperature stability. Additionally, series resistance impacts fill factor and efficiency, emphasizing the need for low-resistance designs. The study proposes an ultra-thin CIGS solar cell design by modifying the absorber layer's thickness and composition, incorporating GnP and CGS materials. This aims to leverage the excellent electrical conductivity, flexibility, and broad absorption spectrum of graphene, combined with the tunable bandgap and high absorption coefficient of CGS. Graphene Nanoplatelets (GnP) is a two-dimensional material with high electrical conductivity and optical transparency. However, its limited absorption in the visible spectrum means it cannot serve as a standalone absorber and requires combination with other materials. Copper Gallium Selenide (CGS) is a p-type semiconductor with a bandgap around 1.68 eV, offering high absorption even in thin films. Its compositional tunability allows optimization for better sunlight absorption and stability. The study utilized the Solar Cell Capacitance Simulator (SCAPS), a one-dimensional simulation tool developed by the University of Gent, to model and predict electrical performance of solar cells based on capacitance characteristics. It is been found that the increasing thickness generally increased Jsc and efficiency due to enhanced photon absorption but decreased Voc and FF because of recombination losses, Optimal thickness for GnP absorber layer was identified as 0.1 μm with an efficiency of 17.14%, For the combined GnP and CGS absorber layer, thicknesses of 0.1 μm (GnP), 1 μm (CGS), and 1 μm (CIGS) yielded superior performance, enhancing carrier collection and reducing recombination, All electrical parameters (open-circuit voltage, short-circuit current density, fill factor, and overall efficienc) deteriorated as temperature increased due to bandgap narrowing and thermal expansion, The optimal operating temperature was around 300 K, where the ultra-thin CIGS solar cells maintained high efficiency, Increasing series resistance reduced FF and efficiency by causing voltage drops and limiting charge carrier flow, The optimum series resistance was found to be 0 Ω/cm² for maximum performance, Ultra-thin CIGS solar cells with GnP absorber layers showed a 30.02% efficiency improvement over conventional CIGS cells, with Voc increasing by 33.33%, though Jsc slightly decreased due to GnP’s limited light absorption. Incorporating CGS with GnP further improved performance, achieving efficiencies up to 25.33%, then a 28.06% increase over ultra-thin CIGS cells without the proposed absorber layers, Silicon (Si) absorber layers were also tested but showed lower efficiencies compared to CGS due to bandgap instability when paired with CIGS.

Table 1.

Performance Summary Table- From (Hurd).

Table 1.

Performance Summary Table- From (Hurd).

| Parameter |

Conventional CIGS |

Ultra-thin CIGS + GnP |

Ultra-thin CIGS + CGS |

Ultra-thin CIGS + GnP + CGS (Proposed) |

| Efficiency (%) |

15.39 |

20.01 (+30.02%) |

19.95 |

25.33 (+28.06%) |

| Fill Factor (%) |

79.53 |

80.35 (+1.03%) |

79.35 |

79.26 (-0.85%) |

| Jsc (mA/cm²) |

37.96 |

36.41 (-4.08%) |

36.42 |

36.34 (-0.18%) |

| Voc (V) |

0.51 |

0.68 (+33.33%) |

0.69 |

+29.26%) |

Thus, the proposed ultra-thin CIGS solar cell with GnP+CGS absorber layer demonstrates promising potential for more efficient, cost-effective photovoltaic devices.

The study by (Md. Ferdous Rahman) focuses on the numerical investigation and optimization of CIGS solar cells using SCAPS-1D simulation software. The key innovations include Replacement of toxic CdS buffer layer with non-toxic alternatives ZnSe and ZnS:In, Introduction of a novel tin sulfide (Sn₂S₃) back surface field (BSF) layer to enhance efficiency and reduce absorber thickness, Optimization of various physical parameters such as absorber and buffer thickness, doping concentration, defect densities, series and shunt resistances, and operating temperature. The proposed optimized structure is Al/FTO/ZnS:In/CIGS/Sn₂S₃/Ni (where ZnS:In is Indium doped Zinc selenide). SCAPS-1D solar simulator was employed to model the heterojunction solar cell, using experimentally verified material parameters at 300 K temperature and AM 1.5G solar spectrum of 100 mW/cm² illumination. CIGS absorber layer is p-type, band gap 1.1 eV, thickness optimized at 0.8 μm. Buffer layers are CdS (toxic), ZnSe, and ZnS:In (which is non-toxic, with band gaps 2.4 eV, 2.9 eV, and 3.1 eV respectively). Sn₂S₃ BSF layer: p⁺-type, band gap approximately 1.09 eV, thickness optimized at 0.05 μm. Front and back contacts are Aluminum (Al) and Nickel (Ni), selected for their work functions and compatibility Among the three buffer layers tested, ZnS:In exhibited the highest power conversion efficiency (PCE) of 21.83%, followed closely by CdS (21.72%) and ZnSe (20.77%). ZnS:In's superior performance is attributed to better lattice matching with CIGS (7.15% mismatch), reduced interface defects, and a wider band gap allowing more photon transmission. Incorporation of the Sn₂S₃ BSF layer significantly improved the solar cell efficiency from 16.09% (without BSF) to 21.83% (with BSF) at the same absorber thickness of 0.8 μm. The high doping concentration in the BSF layer creates an electric field that repels minority carriers from the back contact, reducing recombination losses and enhancing charge collection. Sn₂S₃ also contributes to additional photon absorption, increasing electron-hole pair generation. Without BSF, a thicker absorber greater than 3 μm is required to reach maximum efficiency with BSF, optimal performance is achieved at 0.8 μm thickness, reducing material usage and cost. Optimal acceptor concentration in the CIGS layer was found to be 1 × 10¹³ cm⁻³ to balance open-circuit voltage (V_OC), short-circuit current density (Jsc), and fill factor (FF). Bulk defect density should be minimized (optimized at 1 × 10¹⁴ cm⁻³) to reduce recombination losses and maintain high efficiency. Lower series resistance (Rs) and higher shunt resistance (Rsh) are critical for maintaining high FF and PCE. For example, an increase in Rs from 0 to 7 Ω·cm² reduced PCE from 21.83% to 11.54% Optimal interface defect density at CIGS/ETL and CIGS/BSF interfaces is around 10¹⁰ cm⁻², above which recombination increases and efficiency drops. Increase in operating temperature from 300 K to 475 K, decreases VOC, FF, and overall efficiency, while Jsc remains nearly constant. Quantum Efficiency (QE) improves with absorber thickness and shows high values below 500 nm wavelength, indicating effective photon absorption. The Mott-Schottky plot confirmed a built-in potential (Vbi) of about 0.75 V, consistent with efficient charge separation. ZnS:In shows the least lattice mismatch with CIGS compared to CdS and ZnSe, contributing to reduced interface defects and improved device performance.

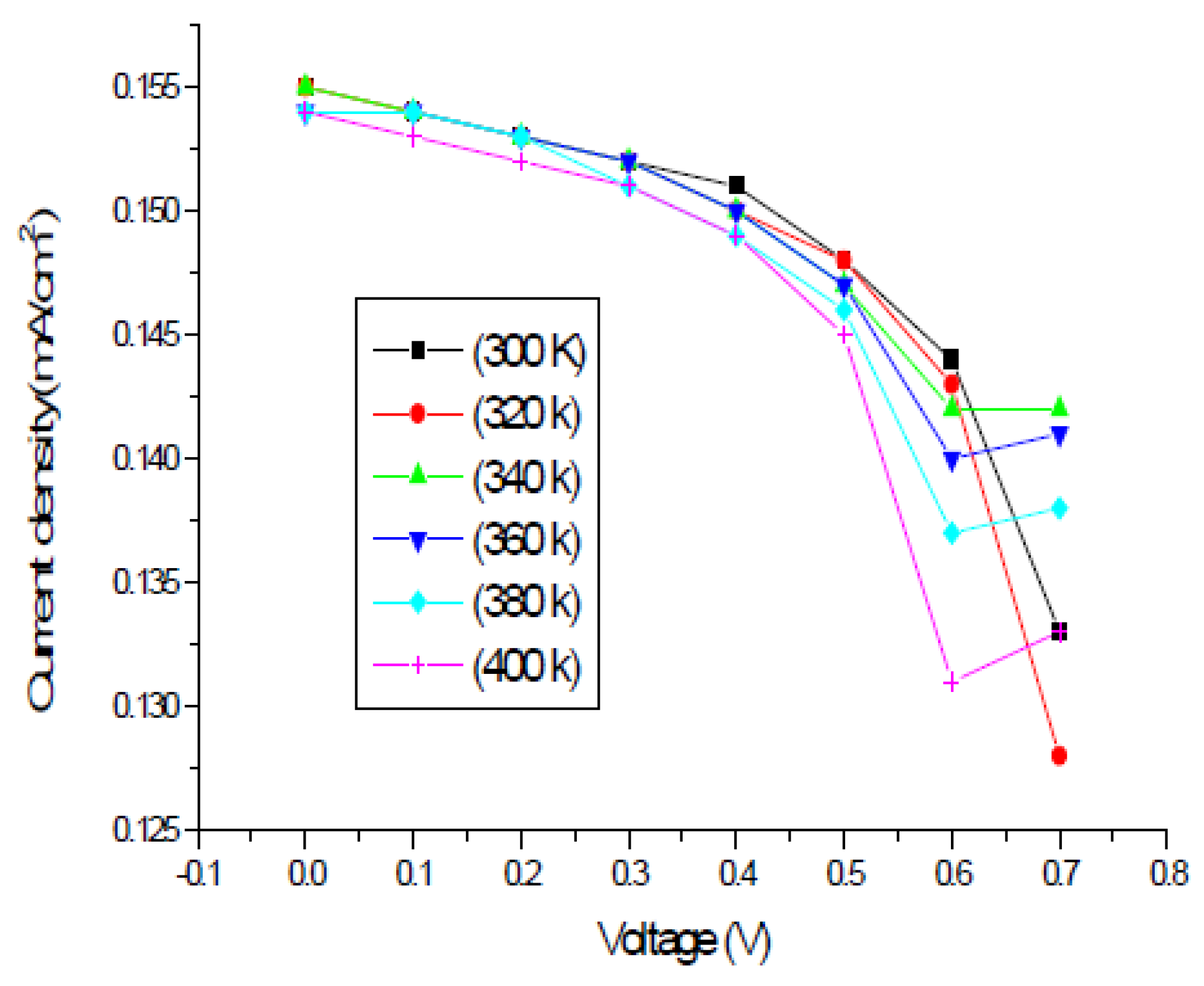

(A.M. Ferouani) explain how temperature influences the performance of Copper Indium Gallium Diselenide (CIGS) thin-film solar cells. Using the SCAPS simulation software, the authors analyzed the electrical behavior of a CIGS solar cell structure consisting of a molybdenum (Mo) back contact, a CIGS absorber layer (3000 nm), a cadmium sulfide (CdS) buffer layer (50 nm), and a zinc oxide (ZnO) window layer (80 nm). The study evaluates how parameters such as efficiency (η), open-circuit voltage (Voc), short-circuit current (Jsc), and fill factor (FF) change with temperature. The key principles used in the study are based on photovoltaic conversion and the one-diode equivalent circuit model, which includes series and shunt resistances. The main formulas applied are:

Fill Factor (FF) = Efficiency (η) = Short-Circuit Current Density (Jsc) = , where is the photon flux.

The simulation results revealed that the best performance occurs at a temperature of 300 K, where the cell achieved an efficiency of 20.61%, V

oc = 635.2 mV, J

sc = 44.08 mA/cm², and FF = 0.73. As temperature increases above 320 K, V

oc and FF decrease, causing a reduction in overall efficiency, while Jsc remains relatively stable between 300–400 K. The study also found that efficiency and power output are most stable at lower operating temperatures less than 320 K and decline rapidly beyond 340 K. In conclusion, the research demonstrates that temperature significantly affects the electrical characteristics of CIGS solar cells, primarily by reducing V

oc and efficiency at higher temperatures. The optimal design includes a 3 µm CIGS absorber layer and a 50 nm buffer layer, operating best at ambient temperature (300 K). J–V characteristics of solar cell with variable the temperature of CIGS is presented in

Figure 11 which shows that maintaining low operating temperatures is essential for achieving high efficiency in CIGS thin-film solar cells.

The master’s thesis by (Joar Johansson) presents the development and optimization of a numerical model for Cu(In,Ga)Se₂ (CIGS) thin-film solar cell modules. The research combines electrical, optical, and geometrical modeling to enhance the efficiency of CIGS solar modules under both standard and concentrated light conditions. Conducted at Lund University and Uppsala University, the study integrates modeling, simulation, and experimental verification. The objective was to determine the optimal relationship between the cell width and the sheet resistance of the transparent front contact layer (ZnO:Al) to maximize overall module efficiency. CIGS technology offers notable advantages such as low material consumption and high conversion efficiency, making it a strong candidate for thin-film photovoltaics. In addition, low-concentration systems, which use reflectors to focus sunlight onto smaller solar areas, were investigated as a complementary approach. A numerical model based on the one-diode equivalent circuit was implemented in COMSOL Multiphysics, utilizing the finite element method (FEM) to solve the coupled electrical and optical equations. Optimization and parameter sweeps were performed in MATLAB, varying key design factors such as cell width, contact resistance, conductivity, and irradiance. The model incorporated distributed resistances in the front and back contacts, optical transmission losses, and active-area effects from interconnect structures. Experimental data from CIGS mini-modules fabricated at Uppsala University having cell widths of 3, 5, 7, and 9 mm were used for model calibration and validation. The model achieved agreement within ±3% for key performance parameters: open-circuit voltage (Voc), short-circuit current (Isc), fill factor (FF), and efficiency (η). A top efficiency of 15.1% was experimentally measured for a 3 mm cell width module under standard test conditions (STC). Simulation results revealed that for 1 kW/m² (STC), the optimal design had a 3 mm cell width and ZnO:Al sheet resistance of 20 Ω/□ (Ω/□ is read as ohm per square), yielding about 14.5–15% efficiency. Under low concentration (8 kW/m²), the optimal configuration shifted to 2 mm cell width and 10 Ω/□ sheet resistance, achieving 14.6% efficiency. Narrower cells were found to be less sensitive to variations in ZnO:Al sheet resistance (tolerating 6–60 Ω/□) compared to wider cells, which had narrower operational windows. Although narrower cells lose more active area due to interconnect width, this is outweighed by improved optical transmission and lower electrical losses. Further simulations indicated that as irradiance increases, modules optimized for higher illumination (8X and 20modules) maintain efficiency more effectively than standard modules. The 1X module achieved peak efficiency near 1 kW/m², while 8X and 20X modules sustained higher relative efficiencies under intensified light, making them suitable for low-concentrating photovoltaic systems such as MaReCo and Solar8 developed in Sweden. In conclusion, Johansson successfully demonstrated a validated numerical model for CIGS solar cell modules capable of predicting and optimizing performance across different irradiance levels. The study established design guidelines: 3 mm cell width and 20 Ω/□ ZnO:Al for standard applications, and 2 mm cell width and 10 Ω/□ ZnO:Al for low-concentration systems. The model provides a valuable tool for future design and scaling of efficient thin-film solar modules.

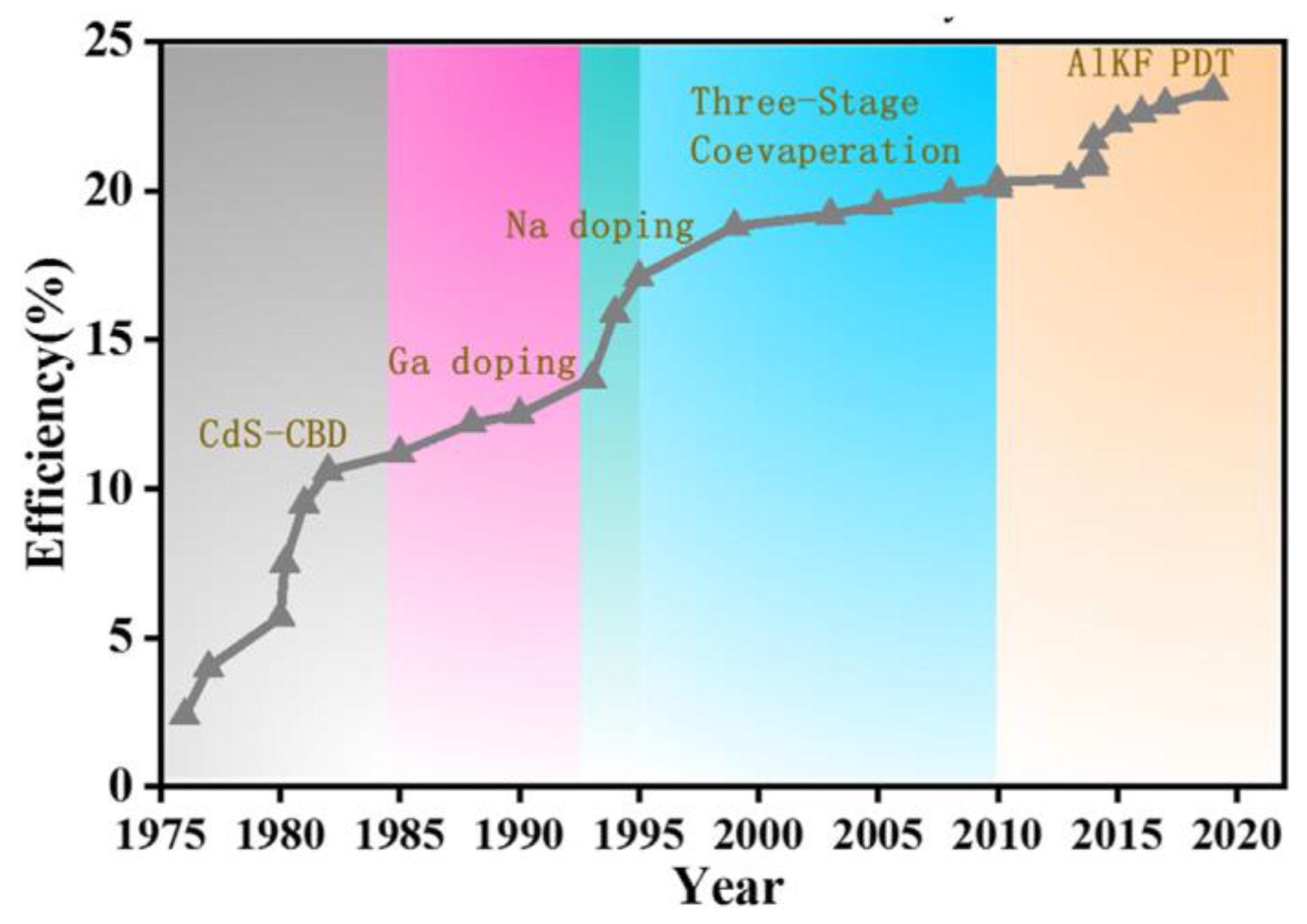

(Chencehn Zhao) review major advancements in Cu(In,Ga)Se₂ (CIGS) thin-film solar cells, emphasizing the critical role of alkali element post-deposition treatment (PDT) in improving device performance. Over the past decade, CIGS solar cell efficiency has increased from 20.4% to 23.35%, mainly due to optimized incorporation of alkali metals such as Na, K, Rb, and Cs. The review consolidates recent findings on the mechanisms, processes, and effects of alkali doping in enhancing electrical, structural, and morphological properties of CIGS absorbers. CIGS technology has evolved since 1975, demonstrating advantages like high efficiency, tunable bandgap, and excellent stability. Early breakthroughs, such as the CdS buffer layer and the three-stage co-evaporation

process paved the way for efficiencies above 19%. Subsequent discoveries of alkali effects, beginning with Na diffusion from soda-lime glass substrates, revealed improvements in open-circuit voltage (Voc) and fill factor (FF), marking the start of intentional alkali metal incorporation via PDT. Alkali elements affect grain boundary passivation, defect reduction, and carrier concentration. Light alkali metals (Li, Na) penetrate grain interiors, enhancing p-type conductivity by suppressing compensating donor defects, while heavier alkalis (K, Rb, Cs) primarily modify surface chemistry and form secondary AInSe₂ (A = alkali metal) phases, influencing band structure and surface recombination. NaF-PDT: Improves hole concentration, passivates defects, and forms a Na-rich alloy layer that enhances the valence-band alignment. KF-PDT: Introduced by EMPA (2013), achieving 20.4% efficiency on flexible substrates. Potassium modifies the surface, enhances CdS buffer growth, passivates grain boundaries, and suppresses recombination. RbF-PDT: Further improves V

oc and FF, achieving efficiencies up to 22.6%, with RbInSe₂ phases at grain boundaries providing superior passivation and carrier transport. CsF-PDT: Used in Solar Frontier’s record 23.35% cell (2019), forming CsInSe₂ compounds that reduce defects, improve carrier lifetime, and modify band bending. Cs remains mainly at grain boundaries due to its large ionic radius, creating Cu-poor regions and enhanced p-type conductivity. Key PDT parameters include substrate temperature (300–400 °C), source temperature, and duration, which determine alkali incorporation and secondary phase formation. The CGI (Cu/Ga/In ratio), GGI grading, and annealing atmosphere also affect the uniformity and electrical characteristics of the treated absorber. Over-treatment or excessive alkali concentration can cause defect states or degraded performance. Alkali element PDTs are now recognized as the most influential technological advancement in CIGS research in the past decade. Each alkali exhibits distinct diffusion behaviour and effects on microstructure and interface chemistry. The synergistic combination of light and heavy alkali metals offers optimized doping profiles, enhancing V

oc, J

sc, FF, and overall efficiency. The

Figure 12 clearly depicts the progress in the laboratory efficiency of CIGS solar cells. Future work focuses on understanding atomic-scale mechanisms, defect dynamics, and scaling of alkali-treated CIGS modules for industrial applications.

The paper by (N.M. Ravindra) provides a comprehensive overview of Copper Indium Gallium Selenide (CIGS) and Perovskite solar cells (PSCs), two of the most promising thin-film photovoltaic technologies. The chemical structures of CIGS and perovskite solar cells are shown in

Figure 13. It highlights their rapid progress, structural characteristics, fabrication methods, and performance trends. CIGS solar cells are known for their high absorption coefficient, tunable bandgap of 1.0–1.7 eV, flexibility, and compatibility with both rigid and flexible substrates. The authors review advances in CIGS fabrication through co-evaporation, precursor annealing, and alkali post-deposition treatments using NaF and KF, which have improved efficiencies beyond 23%. Despite these advantages, challenges remain due to toxic elements (Cd), the reliance on rare materials (In, Ga), and high-temperature processing. Flexible substrates such as polyimide (PI) are discussed as alternatives to soda-lime glass to enable lightweight and bendable devices. In contrast, perovskite solar cells, with the formula ABX₃, have emerged as high-efficiency, low-cost devices capable of exceeding 24% power conversion efficiency (PCE) due to excellent charge transport and tunable bandgaps. The paper reviews progress in halide-based perovskites (e.g., MAPbI₃, FAPbI₃), highlighting their rapid development, structural variations (n-i-p and p-i-n architectures), and improvements through interface engineering, dopant-free hole transport materials (HTMs), and non-fullerene electron transport materials (ETMs). However, perovskites still face major issues of instability, moisture sensitivity, and degradation under light and temperature stress. The authors discuss the roles of series and shunt resistances on performance, emphasizing the need to optimize interfacial layers and minimize recombination losses for scalability. The paper concludes that CIGS and perovskites are complementary technologies poised to compete with traditional silicon solar cells, especially in flexible, lightweight, and tandem configurations. Future improvements depend on enhancing stability, lowering toxicity, and integrating environmentally friendly materials, with tandem CIGS-perovskite systems already demonstrating efficiencies above 24%.

The paper by (Jixiang Zhou) provides a detailed review of the structure, fabrication, and development of Copper Indium Gallium Selenide (CIGS) thin-film solar cells, highlighting their advantages, evolution, and current challenges. CIGS solar cells, first developed in the late 1980s, are known for their high light absorption coefficient, stability, and tunable bandgap, allowing theoretical efficiencies above 20%. The authors explain the fundamental working principle of CIGS cells, focusing on p–n heterojunctions that enhance carrier separation and reduce recombination. The paper discusses the typical device configuration, which includes a molybdenum back electrode, p-type CIGS absorber, CdS buffer, i-ZnO, and Al-doped ZnO (AZO) transparent electrode. It also notes the shift from traditional rigid soda-lime glass substrates to flexible substrates such as polyimide and metal foils to enable lightweight and bendable devices. Various deposition techniques like thermal co-evaporation, selenization, and chemical bath deposition are reviewed, along with efforts to replace toxic CdS buffers with cadmium-free alternatives such as ZnS, ZnSe, In₂S₃, and SnS₂. The paper traces the technological progress from early CuInSe₂ devices with 4.5% efficiency in 1976 to the record 23.4% efficiency achieved by Solar Frontier in 2019, showing major milestones by institutions like NREL, AIST, and EMPA. While rigid glass remains the most efficient substrate type, recent advances have made flexible CIGS devices exceed 20% efficiency, expanding their applicability. The authors also describe the commercialization of CIGS technology, where modules are now mass-produced for both rooftop and flexible photovoltaic applications, though the industrial-scale efficiencies (around 17.4%) still lag behind laboratory results. Key challenges identified include complex manufacturing processes, low industrial yield, toxicity of Cd and Se compounds, and the scarcity and cost of indium and gallium. The paper concludes that future research should focus on low-temperature deposition techniques, eco-friendly materials, and optimization of interface and material performance to enhance both efficiency and sustainability of CIGS thin-film solar cells.

Figure 14.

The fundamental structure of (a) CIGS and (b) Perovskite solar cell with its detailed chemical structure. [From (N.M. Ravindra)].

Figure 14.

The fundamental structure of (a) CIGS and (b) Perovskite solar cell with its detailed chemical structure. [From (N.M. Ravindra)].